Device and method for achieving low-grade cogeneration by means of IGCC

A waste heat power generation, low-grade technology, used in steam generation methods, steam engine devices, steam superheating and other directions using pressure combustion, can solve the problems of low-grade heat being difficult to use up, energy waste, etc., to reduce coal consumption, reduce water consumption, The effect of improving power generation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

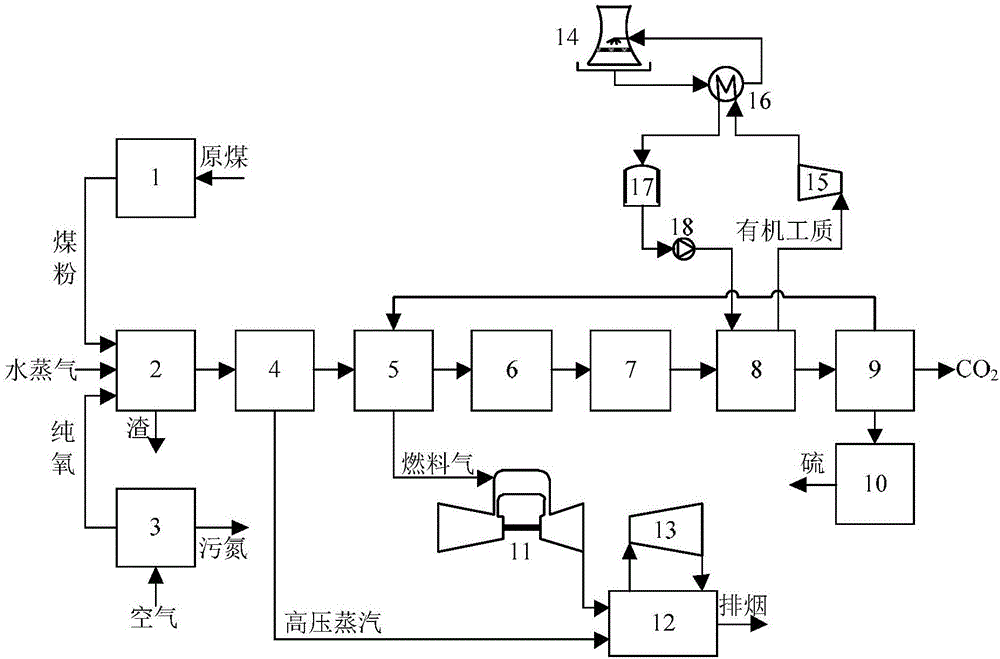

[0017] Such as figure 1 As shown, the present invention utilizes the method for generating electricity with low-grade waste heat of IGCC. After the raw coal is processed into pulverized coal in the coal processing equipment 1, it is transported to the gasifier 2; the pure oxygen produced by the air separation system 3 and another steam are used as The oxidant and reaction medium of the gasification furnace 2 enter the gasification furnace 2; the synthesis gas produced by the gasification furnace 2 enters the waste heat boiler 4, and the slag produced by the gasification furnace 2 is discharged; after the synthesis gas releases high-temperature sensible heat in the waste heat boiler 4, Enter the gas-gas heat exchanger 5, and the high-pressure steam generated by the waste heat boiler 4 enters the waste heat boiler 12 for superheating; the syngas cools down in the gas-gas heat exchanger 5 and releases heat to the fuel gas, and then enters the washing and dust removal equipment 6; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com