Ship engine waste heat power generation comprehensive utilization method

A waste heat power generation and power engine technology, applied to engine components, combustion engines, machines/engines, etc., can solve problems such as environmental pollution and energy waste, achieve the effects of saving cooling water circulation systems, improving net efficiency, and eliminating environmental temperature fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

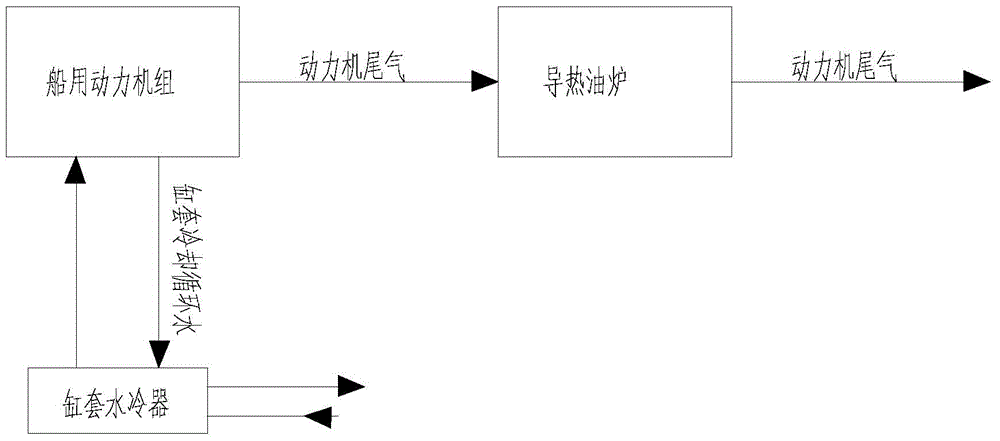

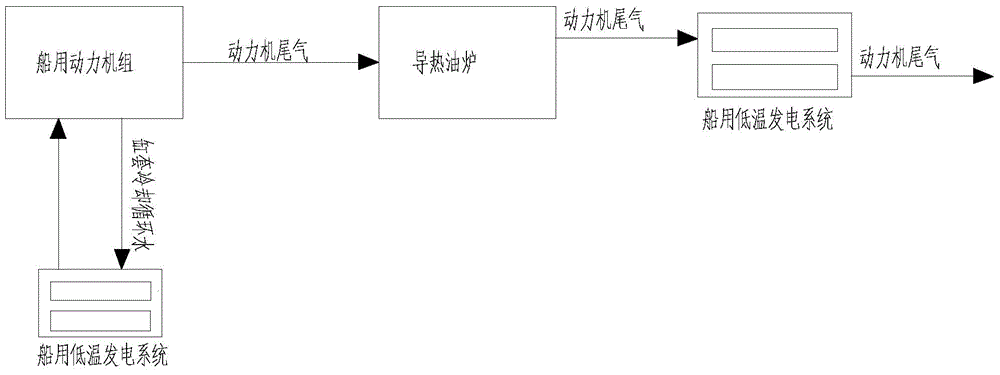

Method used

Image

Examples

Embodiment 1

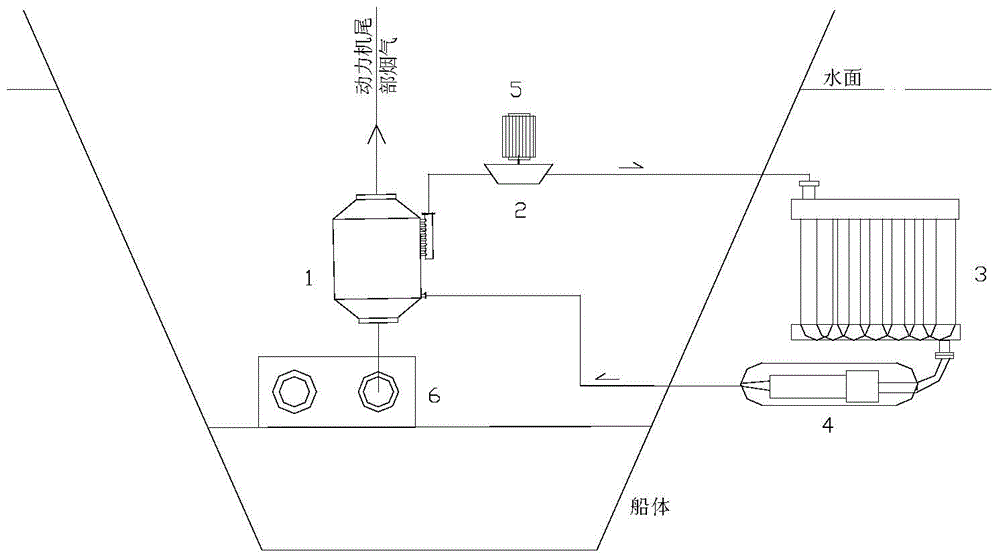

[0030] (1) A flue gas evaporator 1 is installed on the exhaust channel of the marine heat-conducting oil furnace 6. The flue gas evaporator adopts finned tubes. The shell side of the flue gas evaporator passes high-temperature flue gas, and the tube side of the flue gas evaporator generates electricity through waste heat. The power generation medium of the system, the power generation medium and the high-temperature flue gas perform heat exchange and absorb heat; at the same time, the cylinder liner cooling circulating water of the marine power unit enters the tube side of the shell-and-tube evaporator 7, and enters the shell-and-tube evaporator 7 shell of the waste heat power generation system The power generation medium of the process is used for heat exchange; the power generation medium is 1,1,1,2-tetrafluoroethane, that is, R134a.

[0031] (2) The power generation medium after absorbing the waste heat of the high-temperature flue gas and the power generation medium after t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com