A kind of preparation device and method of aluminum alloy composite tube billet

A technology for preparing a device and a composite tube is applied in the field of preparing devices for an aluminum alloy composite tube blank, which can solve the problems of large friction between an ingot and a core mold, and achieve the effects of stable melt flow, good metallurgical bonding, and clean interface.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The present invention will be described in further detail below through embodiments by way of examples and with reference to the accompanying drawings. It should be understood that the embodiments of the present invention are used to illustrate the present invention rather than limit the present invention. The simple improvements made to the present invention according to the essence of the present invention all belong to the protection scope of the present invention.

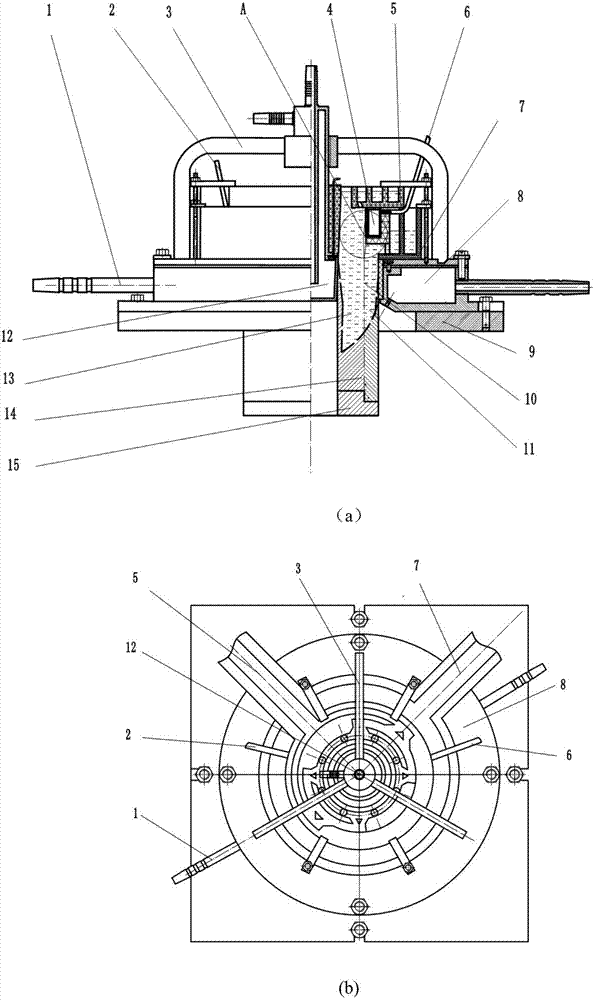

[0055] The preparation device of aluminum alloy composite tube billet, such as figure 1 As shown, it includes an outer crystallizer 8, an inner mold 4, a mandrel 12, a support 3, a dummy ingot 15 and a casting machine; wherein the inner mold 4 is located inside the outer mold 8, is directly above the outer mold 8 and is concentric; the core The mold 12 is concentric with the inner mold 4, and passes through the center of the inner mold 4 and the outer mold 8; the bracket 3 is fixed on the water chamber ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com