Boiler main steam temperature control system

A technology of main steam temperature and main steam system, which is applied in the control of superheated temperature, steam superheating, steam generation, etc. It can solve the problems of outlet main steam temperature deviation, flow interference of desuperheating water valve, main pipe water pressure fluctuation, etc., to achieve The effects of eliminating main steam temperature fluctuations, fast stabilization of the system, and reduction of deviation accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The specific implementation manner and working principle of the present invention will be further described in detail below in conjunction with the accompanying drawings.

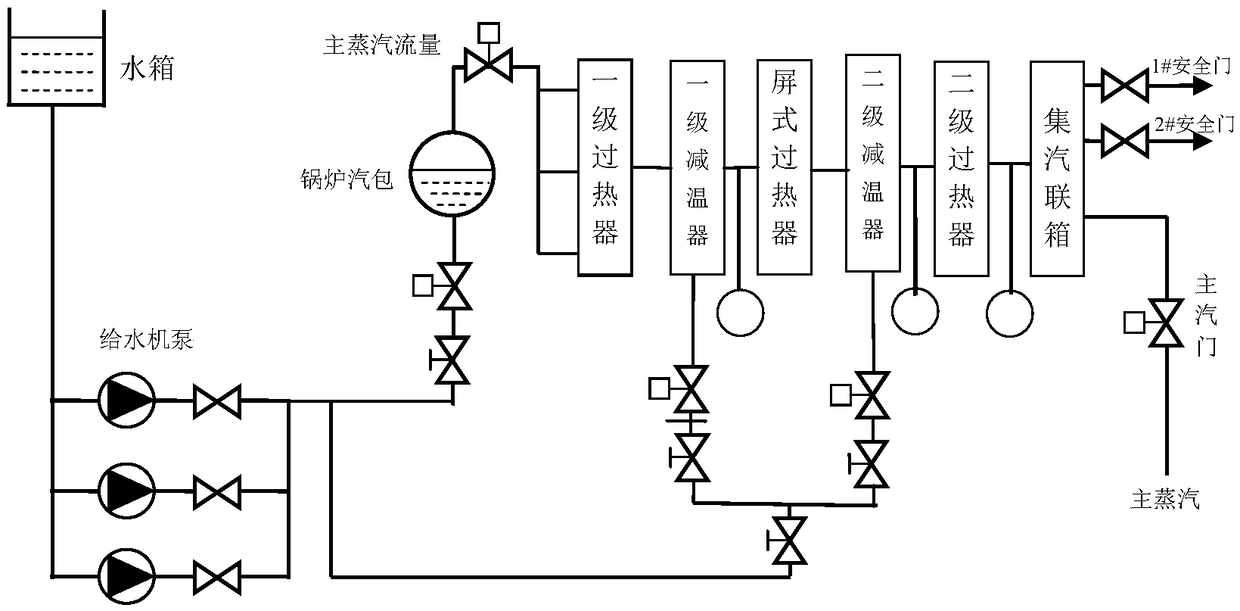

[0037] From figure 1 It can be seen that a boiler main steam temperature control system includes a main steam system and a water supply system.

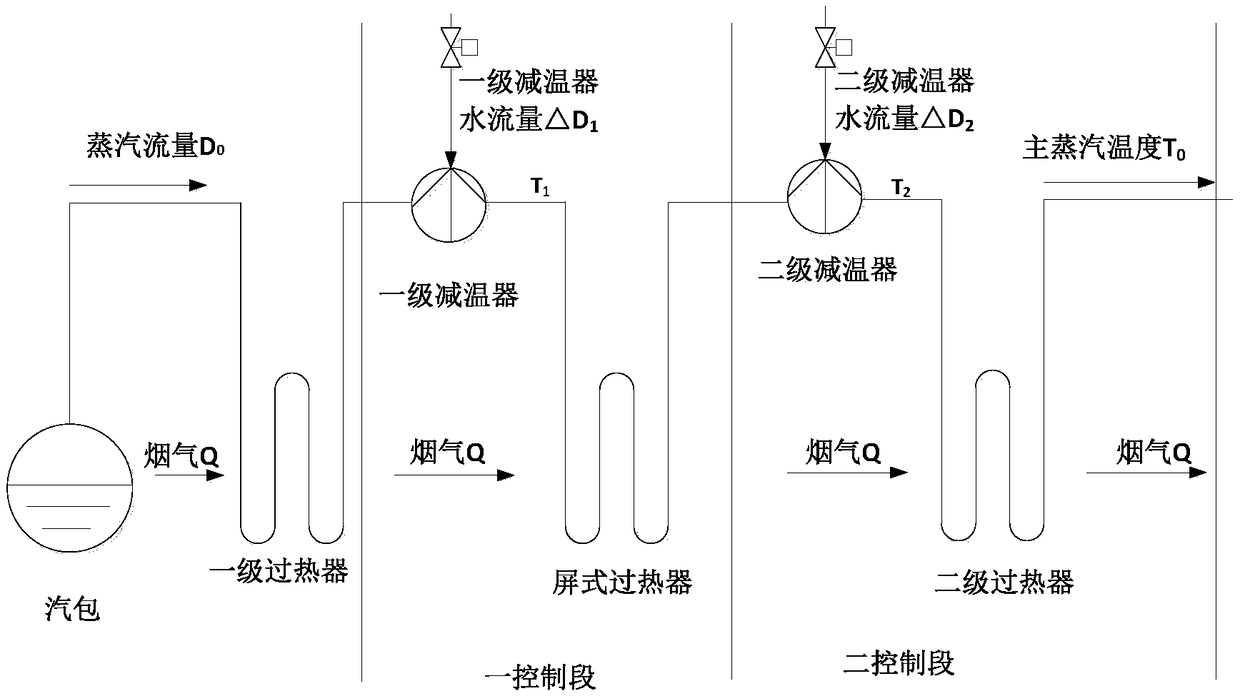

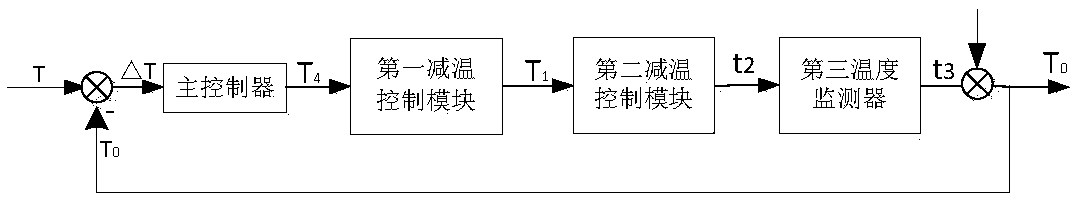

[0038] From figure 1 and figure 2 It can be seen that the main steam system is provided with a boiler drum, and a primary superheater, a primary desuperheater, a panel superheater, a secondary desuperheater, and a secondary The superheater and the steam header are provided with a first temperature monitor at the steam outlet of the first-stage desuperheater, and a second temperature monitor is arranged at the steam outlet of the second-stage desuperheater, The steam output port of the secondary superheater is provided with a third temperature monitor, and a steam flow sensor is installed at the steam drum output port of the boiler.

[0039] From figur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com