Ocean thermal energy conversion pipe connection

A technology connected to the pipe, applied in the direction of ocean energy power generation, pipes/pipe joints/fittings, pipes, etc., can solve problems such as fish school and coral reef system impact, marine environmental impact, etc., to improve operational performance and improve overall efficiency , the effect of good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

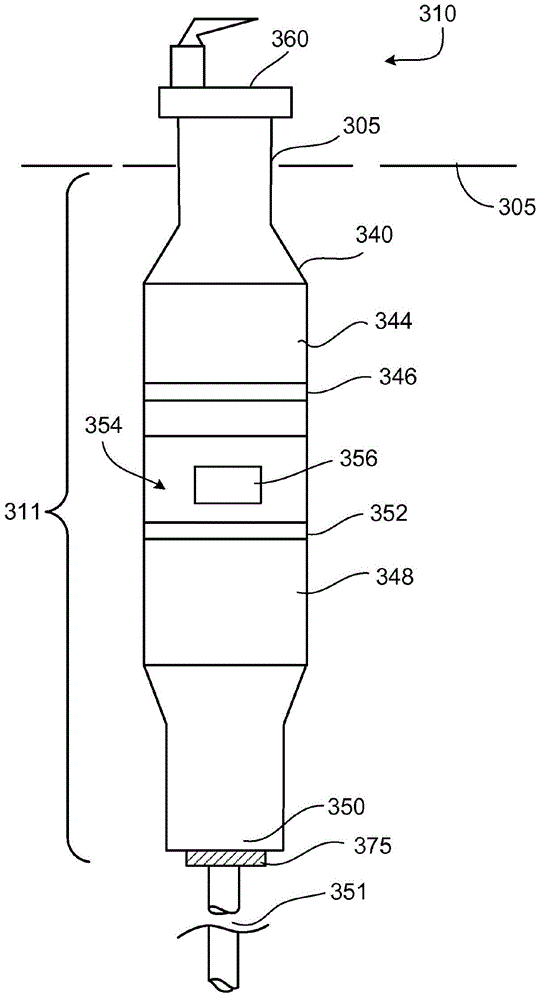

[0111] Example 1: Cold water pipe assembly

[0112] Fabrication of components and assembly devices

[0113] The various component parts are obtained and / or fabricated prior to assembly and connection of the cold water piping to the spar platform.

[0114] A floating vessel such as a barge (eg, tank barge) 900 is obtained for use as an assembly platform for the cold water pipe 217 . like Figure 9 As shown, a barge 900 is typically used with an open central bay (moon pool) 902, enabling material to be loaded into the water below the barge from a crane or lowering device located in the center of the barge, providing protection from other elements damage and minimize relative motion between the barge and the lowered cold water pipe. In some cases, tank barges are retrofitted with moon pools 902 . By utilizing the moon pool 902, the barge 900 is more balanced during cold water pipe assembly than a barge with devices loaded into the water on one side of the barge. The barg...

Embodiment 2

[0143] Example 2: Cold water pipe assembly

[0144] Platform assembly

[0145] In some embodiments, devices located along the floating platform 210 can be used to assemble the cold water pipe 217 . In this embodiment, once the cold water piping components (e.g., tube staves 936, bellmouths 932, and counterweights 934) and assembly devices (e.g., drop winch 926B) are on board barge 900 and ready for assembly, barge 900 Can be driven to platform 210 for cold water pipe assembly. Once in place near platform 210, staging may begin, with pieces of the various devices tested and / or prepared for assembly. For example, drop cable winch 926B on barge 900 undergoes a burnout test to check that drop cable 926A has sufficient travel length to support the length of cold water pipe 217 during assembly.

[0146] A burnout test was also performed on the platform crane 946 located on the floating platform 210 . The exhaustion test confirms that the platform crane 946 will be fit to per...

example 3

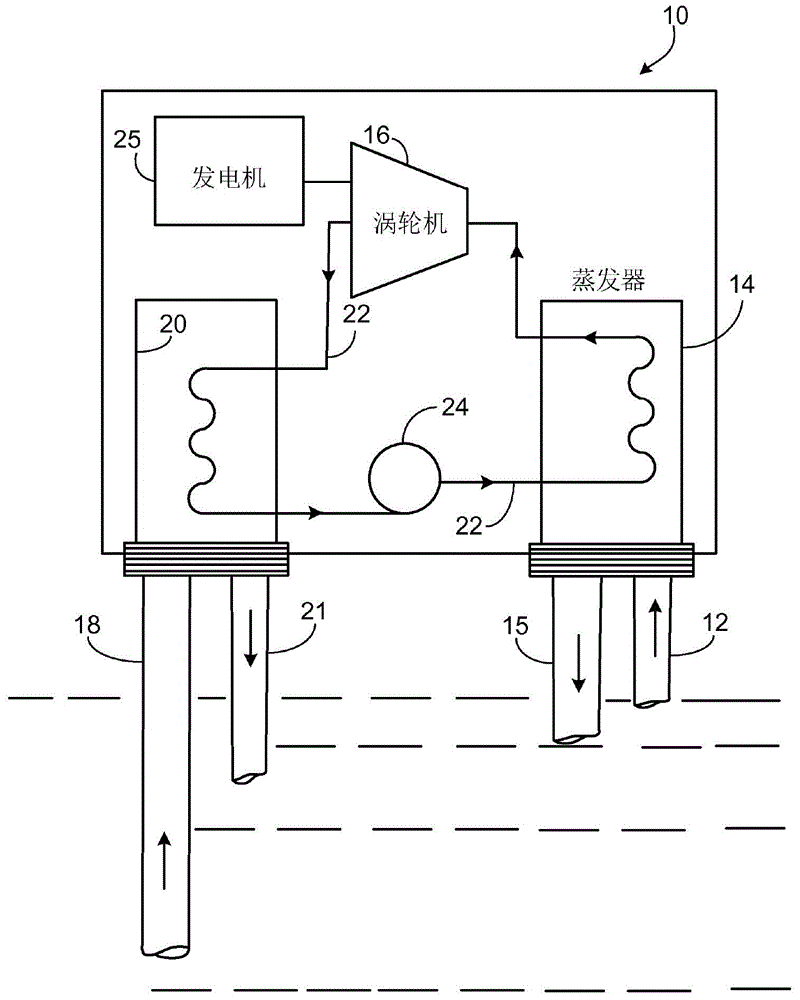

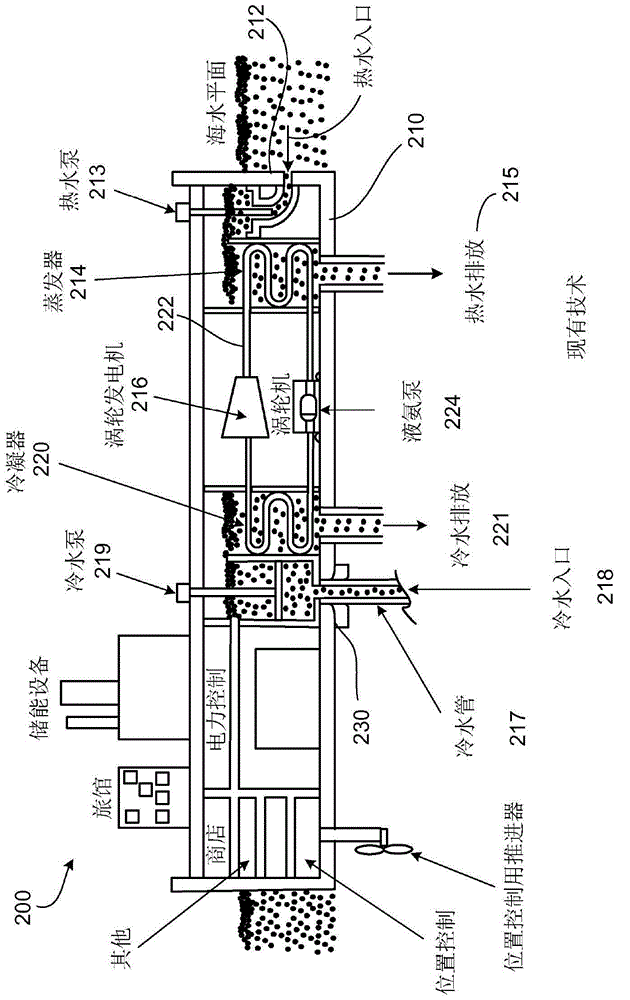

[0183] Example 3: Method used

[0184] An integrated multi-stage OTEC plant is able to generate electricity by utilizing the temperature difference between surface water and deep seawater in tropical and subtropical regions. These aspects eliminate traditional piping routes for seawater by using the structure of the offshore vessel or platform as the conduit or flow channel. Alternatively, the hot and cold seawater pipeline routes may use pipes or tubes of sufficient size and strength to provide vertical or other structural support for the vessel or platform. These integrated seawater pipe sections or channels serve as structural members of the vessel, reducing the need for additional steel. As part of the integrated seawater channel, the multi-stage cabinet heat exchanger provides multi-stage evaporation of the working fluid without external water nozzles or piping connections. The integrated multi-stage OTEC plant allows hot and cold seawater to flow in their natural dir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com