Novel circulating fluidized bed combined cycle

A circulating fluidized bed and combined cycle technology, which is applied in the direction of fluidized bed combustion equipment, combustion type, and fuel burned in a molten state, can solve the problems of fuel consumption, stable combustion, large fuel consumption, and large heat capacity, and achieve improved net Efficiency, reduction of power consumption, and improvement of thermal radiation heat transfer capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the technical means, creative features, objectives and effects achieved by the present invention easy to understand, the present invention will be further elaborated below in conjunction with specific embodiments.

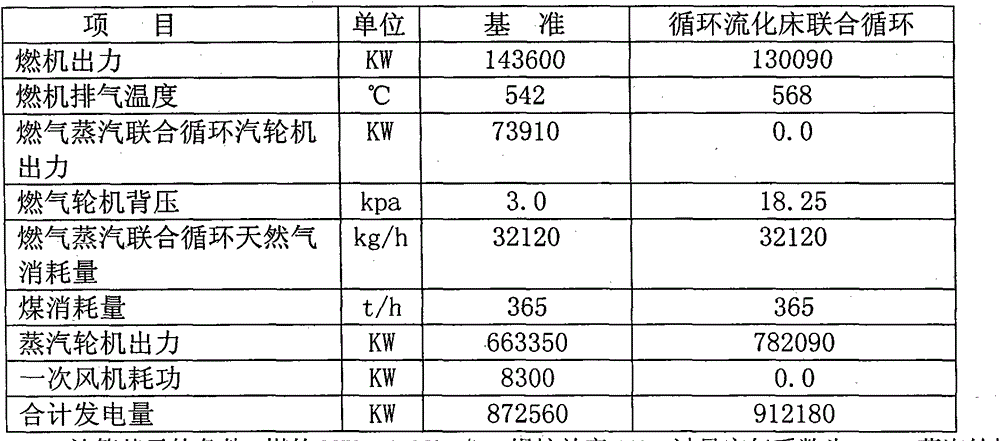

[0025] This example is based on an existing typical gas turbine. The exhaust gas temperature of the gas turbine under the ISO working condition is 542°C, the exhaust gas flow rate is 1700t / h, and the exhaust gas component is O 2 : 15.57%, N 2 : 73.65%, CO 2 : 4.91%, H 2 O: 4.55%, Others: 1.32%.

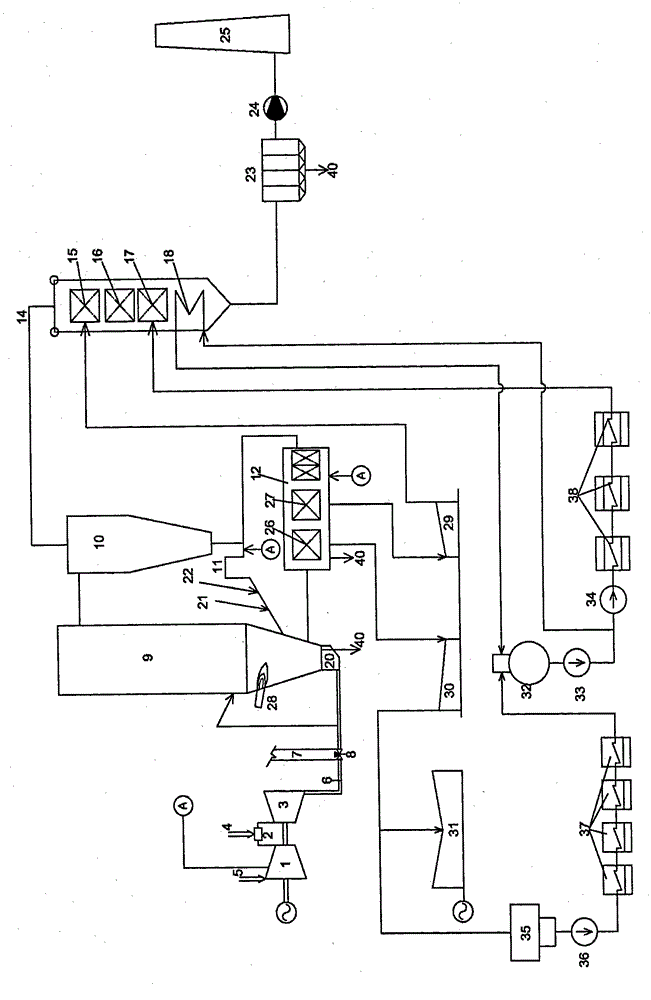

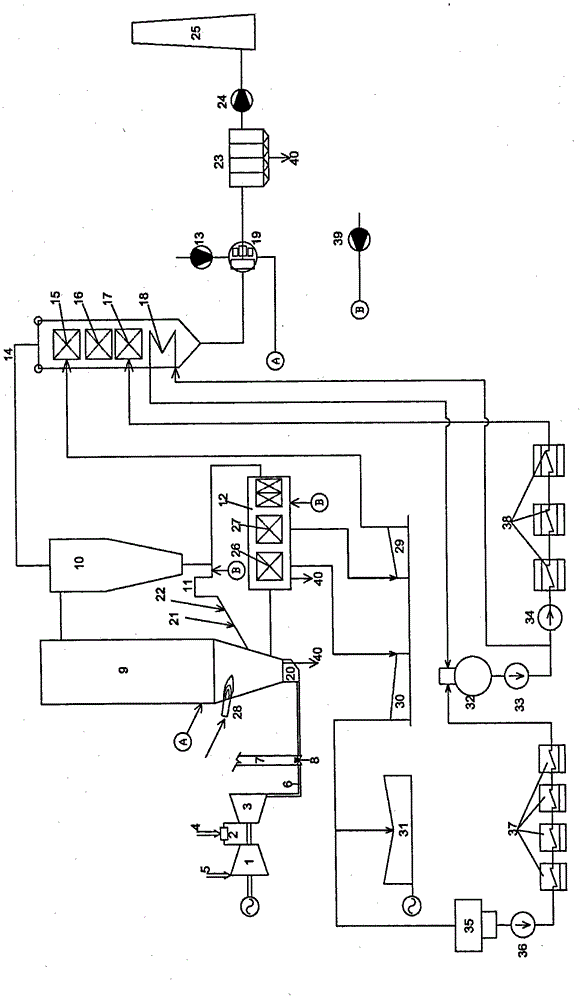

[0026] According to the principle of "furnace random", reduce mutual influence, improve operation flexibility and reliability, determine the integration range of the system: the primary air comes from the exhaust of the gas turbine; the boiler secondary air system and high-pressure air system are configured separately. The schematic diagram of embodiment circulating fluidized bed combined cycle system is shown in figure 2 .

[0027] As shown i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com