Internal-combustion engine with waste heat reclamation and utilization function and control method

A waste heat recovery, internal combustion engine technology, applied in engine control, fuel injection control, internal combustion piston engine, etc., can solve the problems of large intake flow loss, high exhaust temperature, low thermal efficiency, etc., to improve performance and expand the range of lean combustion , The effect of reducing exhaust temperature and exhaust noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

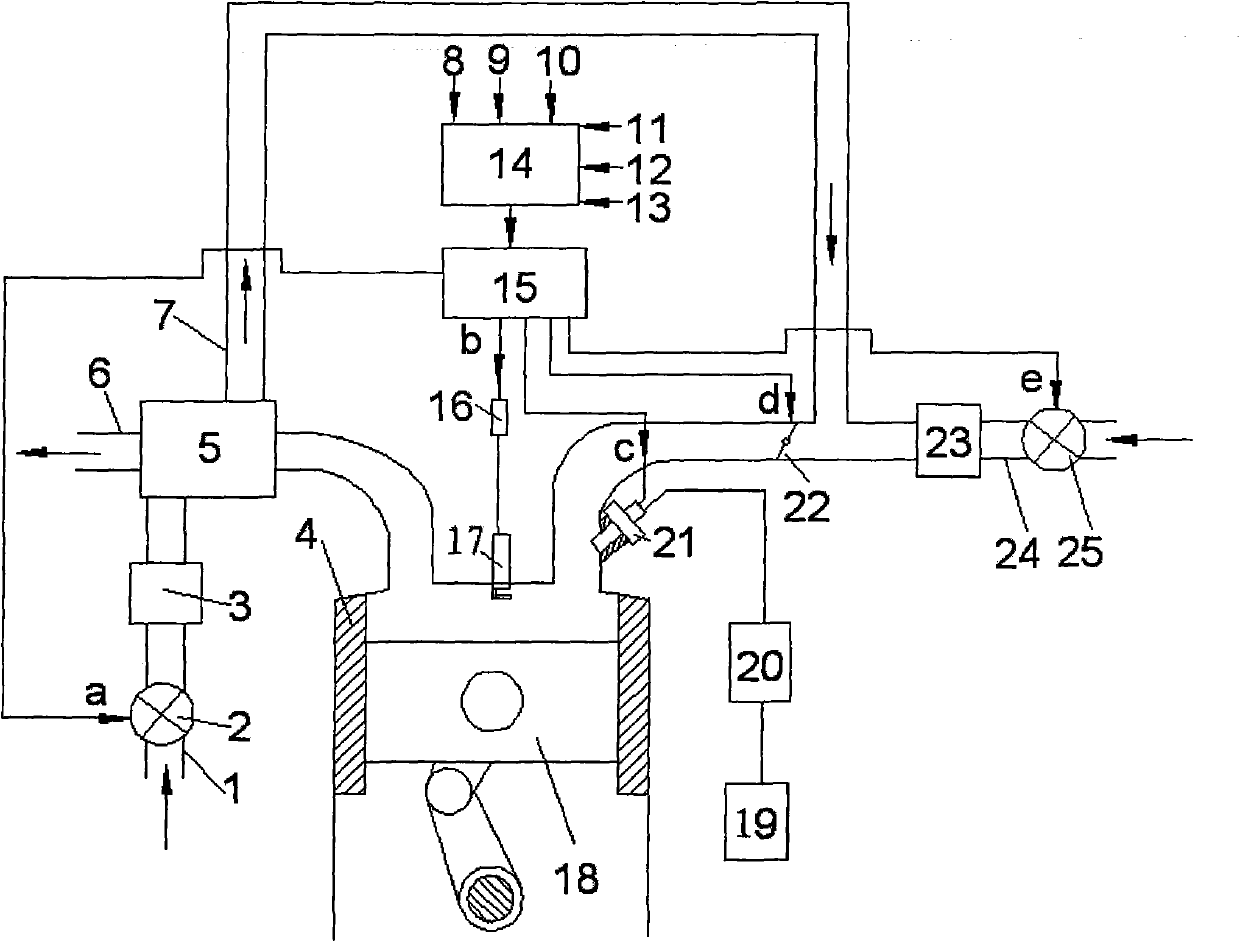

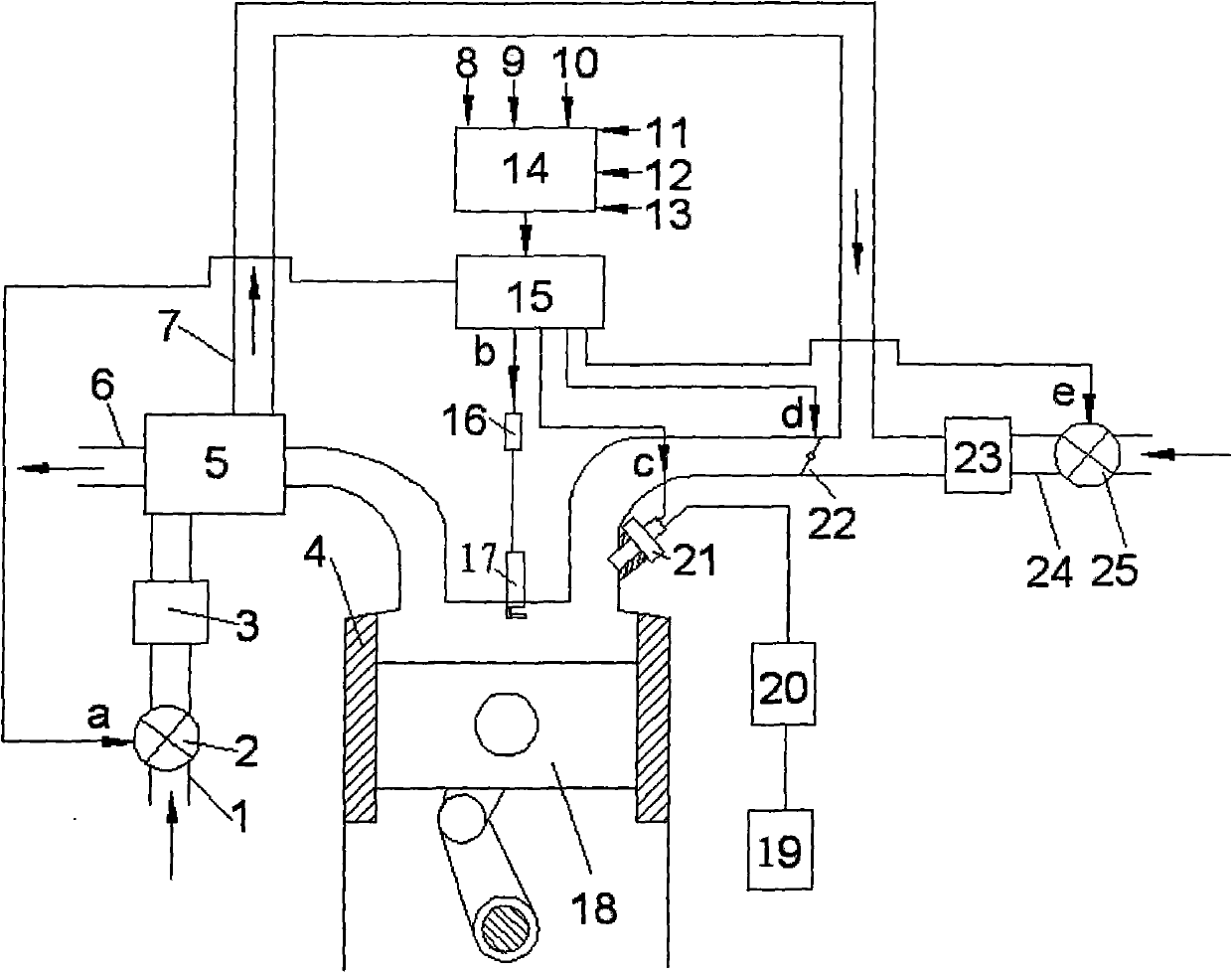

[0013] Since waste heat recovery and utilization are not carried out at startup, idle speed and heavy load, the original machine is completely used for control. Therefore, this embodiment has only carried out experiments on gasoline engines under partial load conditions. The following describes this embodiment in detail with reference to the accompanying drawings. Such as figure 1As shown, this embodiment includes: heat exchanger low-temperature intake pipe (1), heat exchanger intake switch valve (2), heat exchanger intake air filter (3), internal combustion engine cylinder (4), heat exchanger ( 5), internal combustion engine exhaust pipe (6), heat exchanger high temperature outlet pipe (7), crank angle position sensor (8), cooling water temperature sensor (9), intake air temperature and pressure sensor (10), throttle position sensor (11), knock sensor (12), linear oxygen sensor (13), original machine electric control unit (14), waste heat management control unit (15), ignitio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com