Engine exhaust gas and waste heat utilization system based on single-screw expansion engine

An expander and engine technology, applied in the direction of machines/engines, mechanical equipment, steam engine devices, etc., can solve problems such as potential safety hazards, polluting the air in the car, and increasing the back pressure of the exhaust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

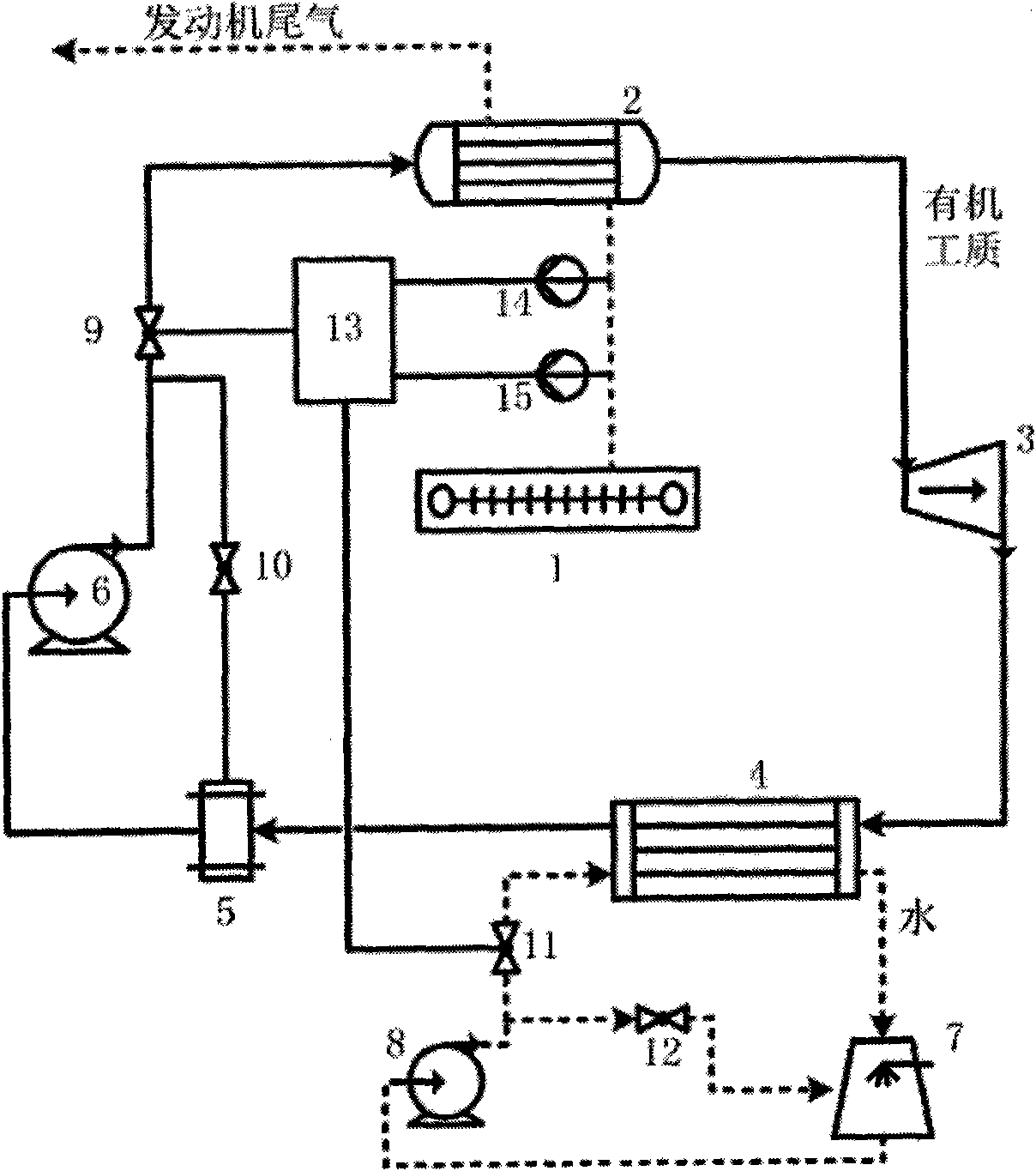

[0025] Based on the characteristics of low engine exhaust energy, the present invention mainly adopts single-screw expander organic Rankine cycle system to recover the energy in engine exhaust; The measured engine exhaust temperature and flow data control the change of the organic working medium flow and the change of the cooling water flow to recover the engine exhaust energy.

[0026] The engine exhaust waste heat utilization system based on the single-screw expander of the present invention mainly includes an engine 1, a tube-bundle evaporator 2, a single-screw expander 3, a plate condenser 4, a liquid storage tank 5, a plunger pump 6, and a cooling tower 7. Water pump 8, voltage proportional control valve I 9, safety valve I 10, voltage proportional control valve II 11, safety valve II 12, single chip microcomputer 13, flow sensor 14, temperature sensor 15 and various connecting pipelines and connecting circuits. The connection relationship of the internal components of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com