High-efficiency energy-saving hydrochloric acid pickling waste liquor triple-effect negative-pressure graphite evaporation crystallizer

A technology of pickling waste liquid and graphite evaporation, applied in the direction of solution crystallization, multi-effect evaporation, etc., can solve the problems of short service life, low degree of automation, poor corrosion resistance of equipment, etc., to solve noise and pollution problems and avoid steam loss. , the effect of improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

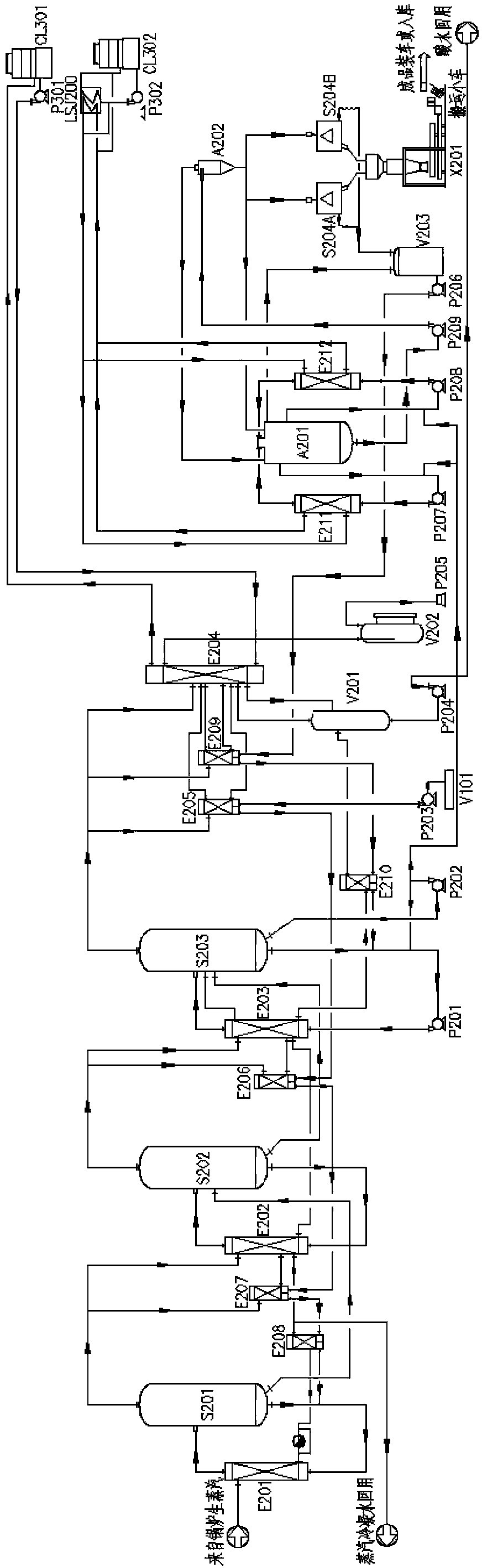

[0052] combine figure 1 , a high-efficiency and energy-saving hydrochloric acid pickling waste liquid three-effect negative pressure graphite evaporation and crystallization device in this embodiment includes an evaporation concentration unit, a feeding unit, a gas condensation unit, a cooling crystallization unit, a solid-liquid separation unit, a mother liquor circulation unit, Vacuum unit, cooling water circulation unit and packaging unit, of which:

[0053]Evaporation and concentration unit includes primary preheater E205, secondary preheater E206, third stage preheater E207, fourth stage preheater E208, first effect evaporator E201, second effect evaporator E202, third effect evaporator E203, One-effect separator S201, second-effect separator S202, three-effect separator S203, steam trap and three-effect forced circulation pump P201, first-stage preheater E205, second-stage preheater E206, third-stage preheater E207 and four-stage preheater The first-stage preheater E208...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com