Patents

Literature

90results about How to "Reduced corrosion resistance requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lithium ion flow redox battery

InactiveCN102315473AScale upSolution to short lifeCell electrodesRegenerative fuel cellsHigh energyRedox

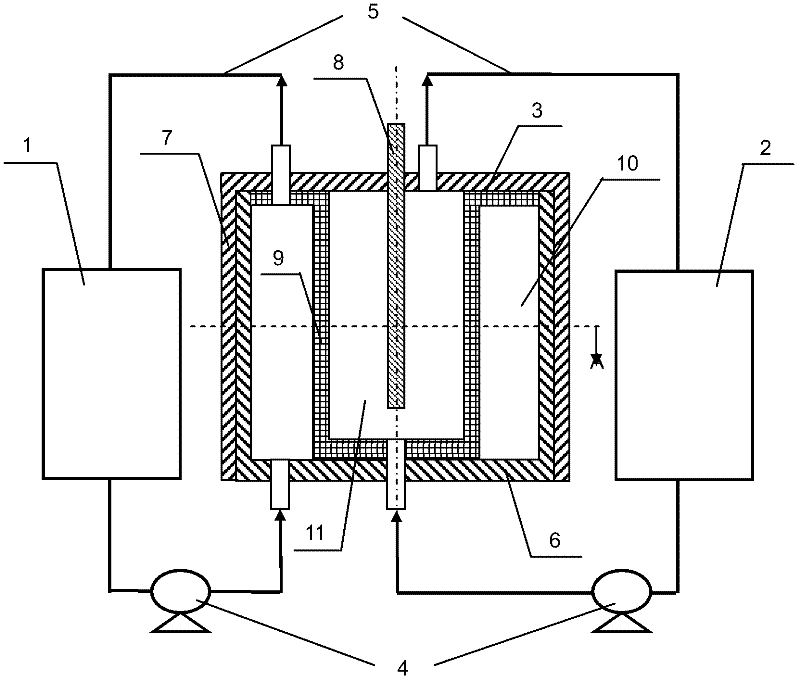

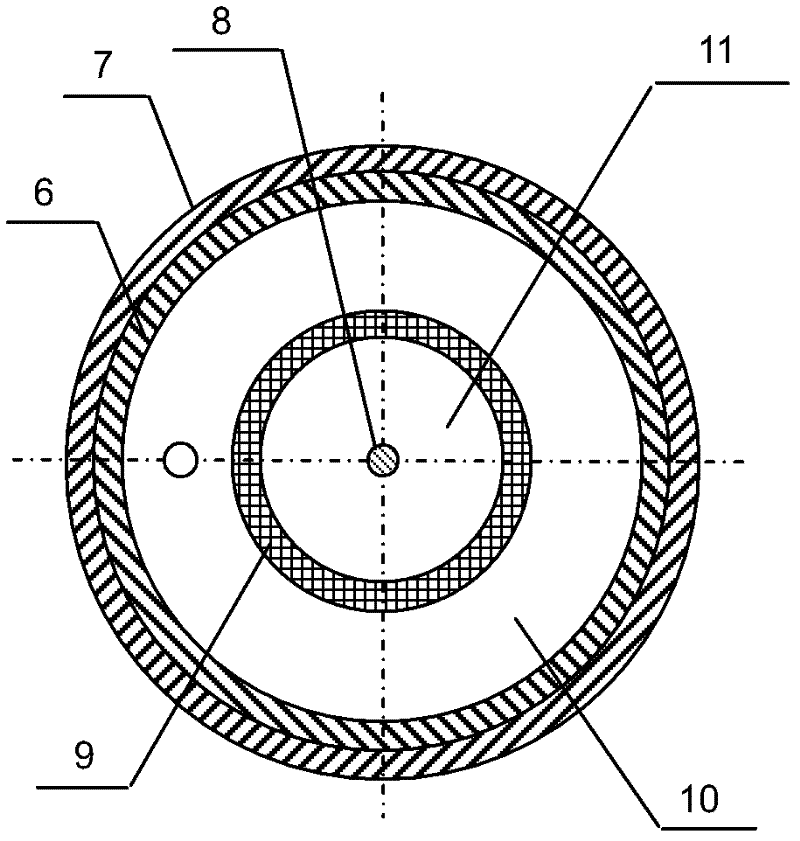

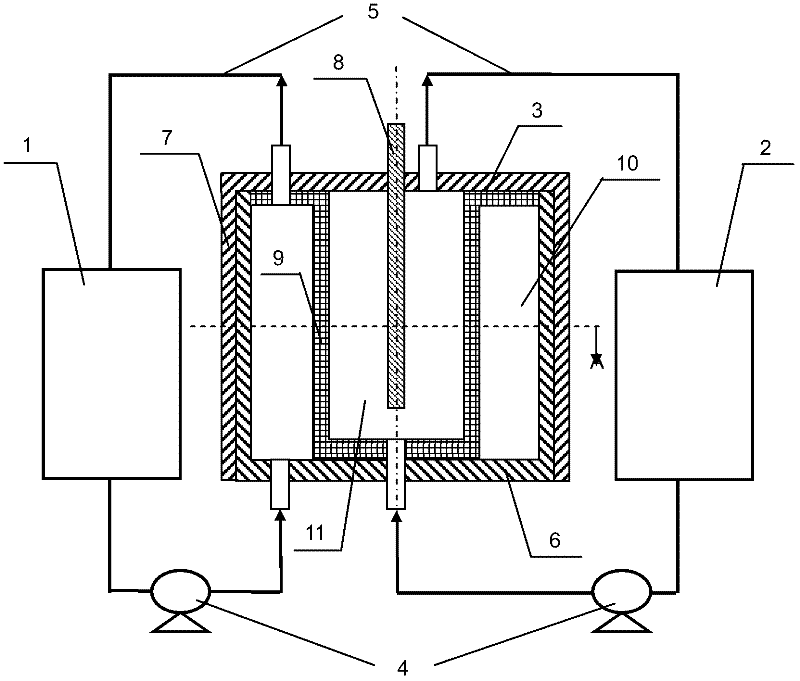

The invention provides a lithium ion flow redox battery, belonging to the technical field of lithium ion batteries. The lithium ion flow redox battery comprises a positive electrode suspension tank, a negative electrode suspension tank and a battery reactor, wherein the positive electrode suspension tank contains the mixture of positive electrode composite material particles and an electrolyte; the negative electrode suspension tank contains negative electrode composite material particles and an electrolyte; the battery reactor comprises a positive electrode current collector, a negative electrode current collector and one layer or a plurality of layers of microporous separators; the microporous separators separate the positive electrode current collector from the negative electrode current collector in an insulation mode so as to respectively form a positive electrode chamber and a negative electrode chamber; the positive electrode chamber is communicated with the positive electrode suspension tank through a seal pipeline; and the negative electrode chamber is communicated with the negative electrode suspension tank through a seal pipeline. Compared with a full vanadium flow redox battery, the lithium ion flow redox battery has the advantage of high energy density, the adoption of the environmentally-friendly and non-toxic electrolyte and low cost, and is applicable to large-scale energy storage of power grids.

Owner:BEIJING HAWAGA POWER STORAGE TECH +1

Carbon preparation material based on coke modification and sulphur-applying activated char, and production process thereof

InactiveCN101428795AHigh activation reactivityReduced corrosion resistance requirementsSulfurRoom temperature

The invention relates to carbon preparation material and sulfuric active carbon based on the modification of coke and a preparation method thereof. The invention adopts the scheme that the preparation method comprises the following steps: dipping the coke in KOG solution for 1 to 24 hours at the temperature of 20 to 100 DEG C, wherein the mass ratio of KOH and the coke is 0.05 to 0.5:1; carrying out heat treatment to the coke after being dipped for 1 to 5 hours under the condition of inert atmosphere and 300 to 700 DEG C; then cooling the coke to the room temperature; and finally preparing the carbon preparation material after the coke is washed and dried. The carbon preparation material prepared can react for 1 to 5 hours under the conditions that the mass ratio of active gas flow rate and the carbon preparation material is 5 to 30:1 L / min / kg and the temperature is 350 to 850 DEG C, so as to prepare the sulfuric active carbon. The invention has the advantages of saved alkali consumption and energy consumption, shortened activating treatment time, high yield, and reduced corrosion resistant requirements of the material; the prepared carbon preparation material has high reaction activation; and the sulfuric active carbon prepared by the carbon preparation material has larger specific surface area and high sulphur content, and exits in a straight chain sulfuric shape as the subject of S2 and S6.

Owner:WUHAN UNIV OF SCI & TECH

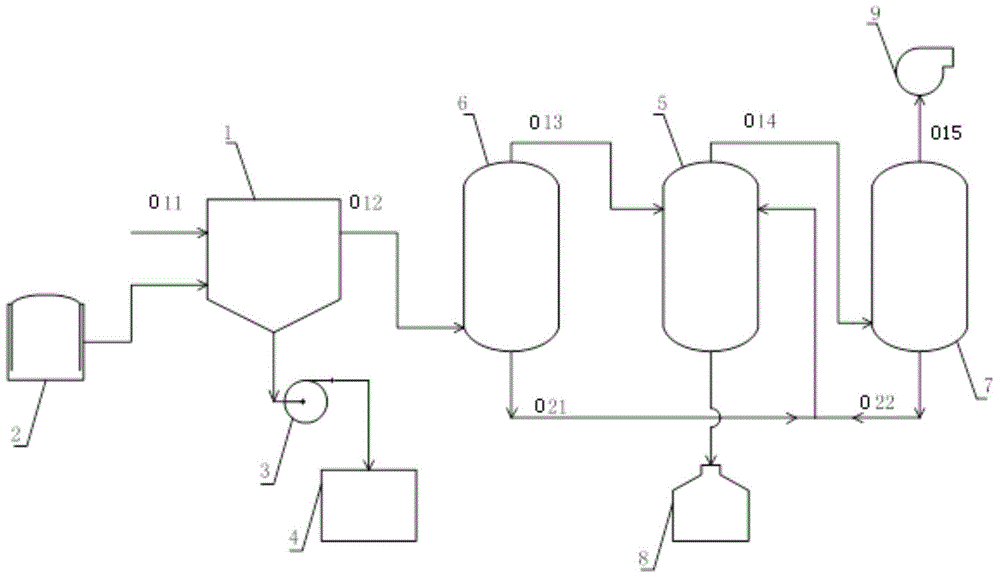

Continuous wet oxidation process for degrading high concentration organic waste water and equipment thereof

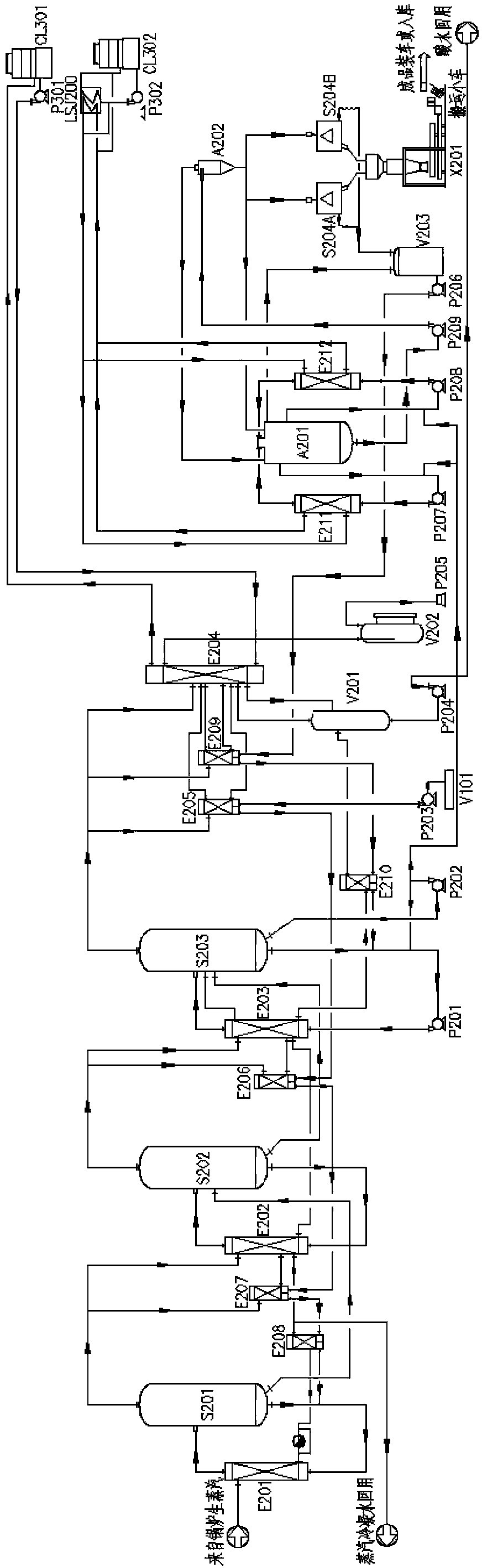

PendingCN106348421AEasy to handleSave spaceSpecific water treatment objectivesWater contaminantsHigh concentrationEnergy consumption

The invention discloses a continuous wet oxidation process for degrading high concentration organic waste water, belonging to the field of water treatment. The continuous wet oxidation process for degrading high concentration organic waste water comprises the procedures: a waste water pressurizing procedure: pressurizing waste water to be treated; a waste water heat exchange procedure: carrying out direct and / or indirect heat exchange on the pressurized waste water and treated waste water so the temperature of the pressurized waste water rises; an oxidizer pressurizing procedure: pressurizing an oxidizer; a mixing procedure: thoroughly mixing the pressurized and heated waste water with the pressurized oxidizer; a reaction procedure: causing the mixed waste water and the oxidizer to generate oxidation reaction, obtaining the treated waste water and generating gas; and a separation procedure: continuously separating the treated waste water from gas. The continuous wet oxidation process for degrading high concentration organic waste water has the advantages of high efficiency, less energy consumption, stability of operation and the like.

Owner:羿太环保科技(上海)有限公司

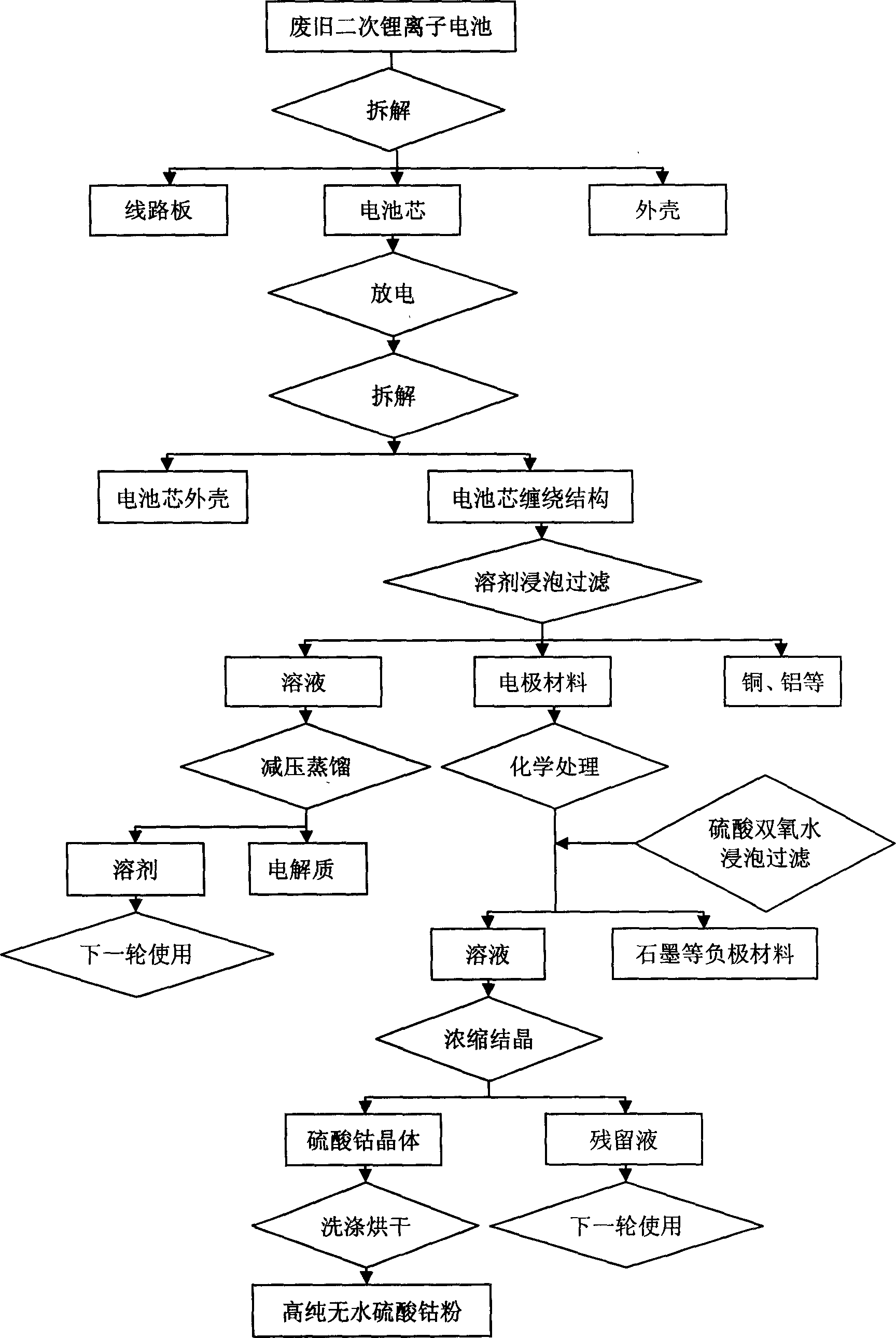

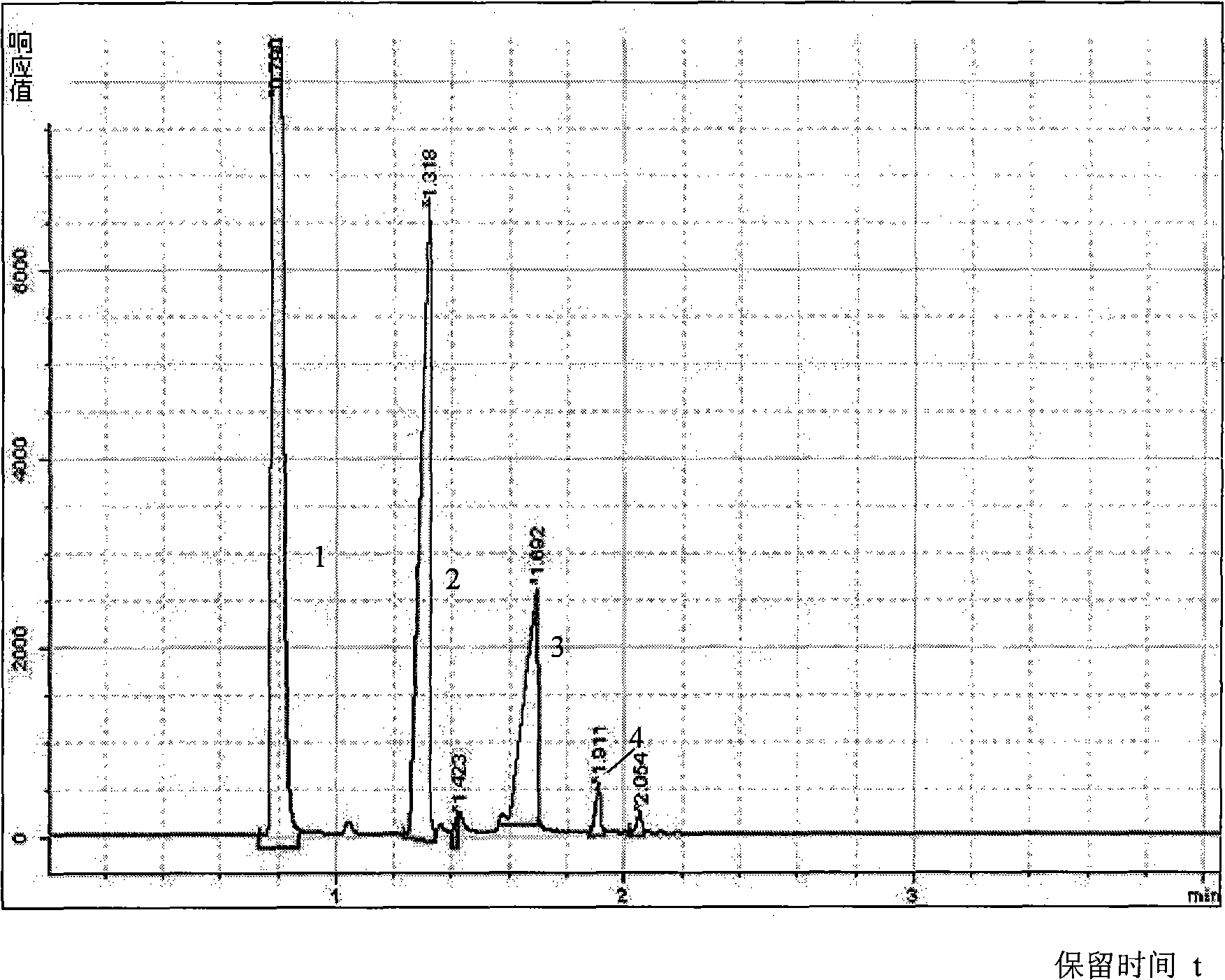

A method to reclaim and dispose waste secondary lithium ion battery

InactiveCN1964129AReduce cross contaminationReduce usageSolid waste disposalWaste accumulators reclaimingOrganic solventElectrical polarity

The related recovery and process method for waste secondary Li-ion cell comprises: separating cell shell, circuit board and cell core by mechanical means; discharging the core; then separating to obtain the shell and coiling material of cell core; putting the last one into some organic solvent to separate the cell polar material from collector foil, filtering to obtain the foil and active material for recovery by chemical way. With small investment, this invention is simple and safe and high yield.

Owner:BEIJING UNIV OF TECH

Method for producing guaiacol with methanol method

InactiveCN101492353AImprove product qualityHigh yieldMolecular sieve catalystsChemical recyclingMethylating AgentGuaiacol

The invention provides a method for preparing guaiacol by a methanol method. Methanol used as a methylating agent and pyrocatechol are used for synthesizing the guaiacol under the action of a solid acid catalyst in a high pressure vessel. The solid acid catalyst used for synthesizing the guaiacol has low price, is friendly to environment and can be recycled. The invention is characterized in that the invention has simple preparation technology, mild reaction condition and short reaction time; the obtained guaiacol is light yellow clear transparent liquid and has good product quality, high yield, high selectivity and few side products; and all side products in reaction liquid can be recycled.

Owner:BEIJING UNIV OF CHEM TECH

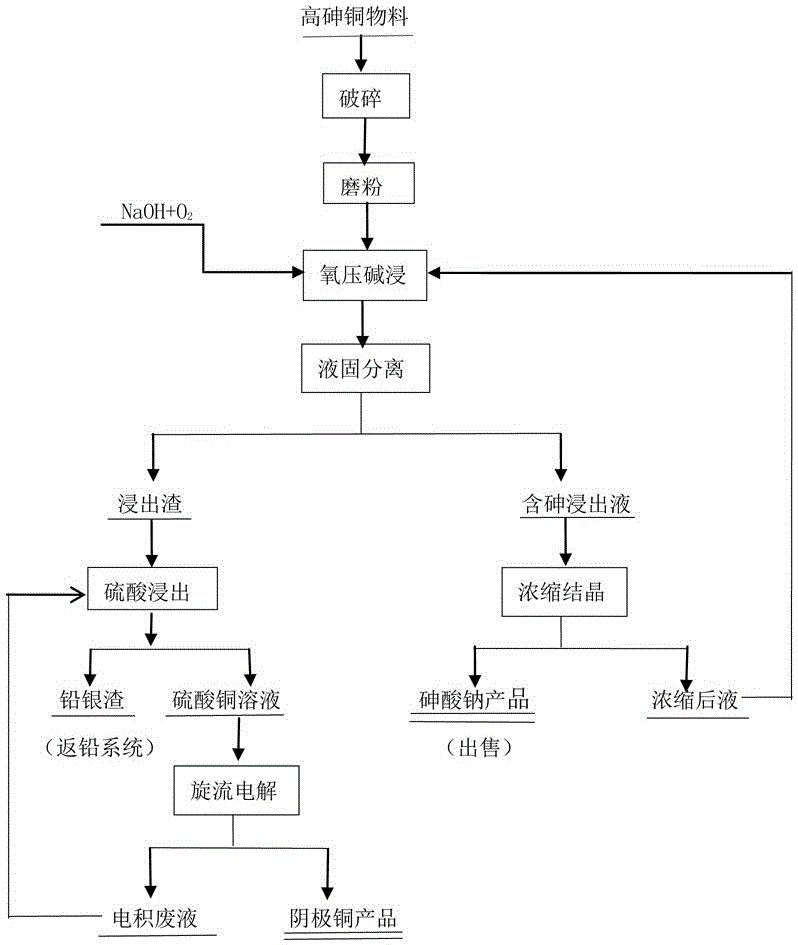

Technology for treating high-arsenic copper material

ActiveCN106555058AEnvironmental pollutionNo pollution to the environmentPhotography auxillary processesProcess efficiency improvementElectrolysisCopper sulfate

The invention discloses a technology for treating a high-arsenic copper material. The technology comprises the steps that the high-arsenic copper material is subjected to crushing, grinding, sodium hydroxide mixing and oxidizing leaching, copper in the high-arsenic copper material is oxidized and left in residues in a residual mode along with lead and noble metal of gold, silver and platinum, arsenic enters a solution in a sodium arsenate mode, leachate is subjected to concentration and crystallization, a sodium arsenate product is obtained, and a concentrated solution returns to be subject to oxygen-pressure alkali leaching; leached residues are subjected to sulfuric-acid atmospheric pressure leaching, copper enters the solution in a copper sulfate mode, acid adjustment is conducted, and vortex electrolysis is directly conducted for extracting copper; electrodeposited waste liquid is recycled; and lead and the noble metal enter lead and silver residues, and valuable elements of Pb, Ag and Au are comprehensively recycled. The technology belongs to a clean metallurgy process, is low in equipment corrosion-resistant requirement, free of pollution to environment, easy to operate and high in comprehensive recycling degree of metal and has the advantages of being higher in practicability and adaptability to raw materials and the like.

Owner:CHENZHOU CITY JINGUI SILVER IND CO LTD

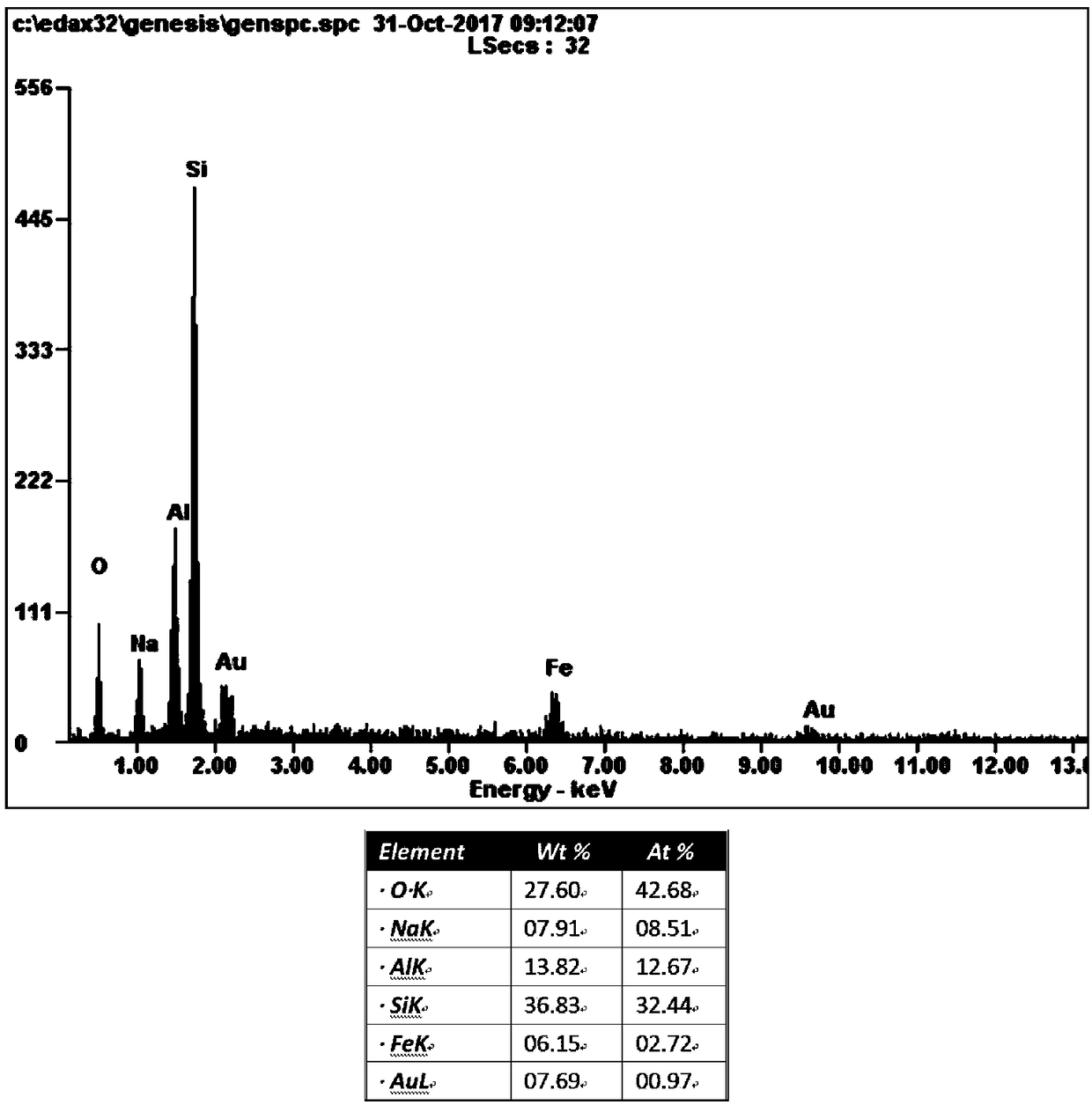

Preparation method of gold-based catalyst for preparing vinyl chloride by acetylene hydrochlorination method

ActiveCN109622036AImprove performanceHigh activityPreparation by halogen halide additionOrganic-compounds/hydrides/coordination-complexes catalystsFixed bedSolvent

The invention provides a preparation method of a gold-based catalyst for preparing vinyl chloride by an acetylene hydrochlorination method and the catalyst prepared by the method. According to the catalyst, an activated carbon is used as a carrier, a complex formed by gold and a nitrogen-containing ligand is a main active component, compared with other gold-based catalysts, green solvents such aswater, ethanol and the like are utilized to replace acidic solvents such as hydrochloric acid, aqua regia and the like in the catalyst preparation process, and the gold in a high valence state is stabilized by the complexation of the nitrogen-containing ligand with the gold, thereby improving the effectiveness of the catalyst. The catalyst has high activity and vinyl chloride selectivity in the reaction of fixed bed acetylene hydrochlorination to prepare the vinyl chloride, the preparation method is green and environmentally friendly, and the method has a great industrial application value.

Owner:NANKAI UNIV

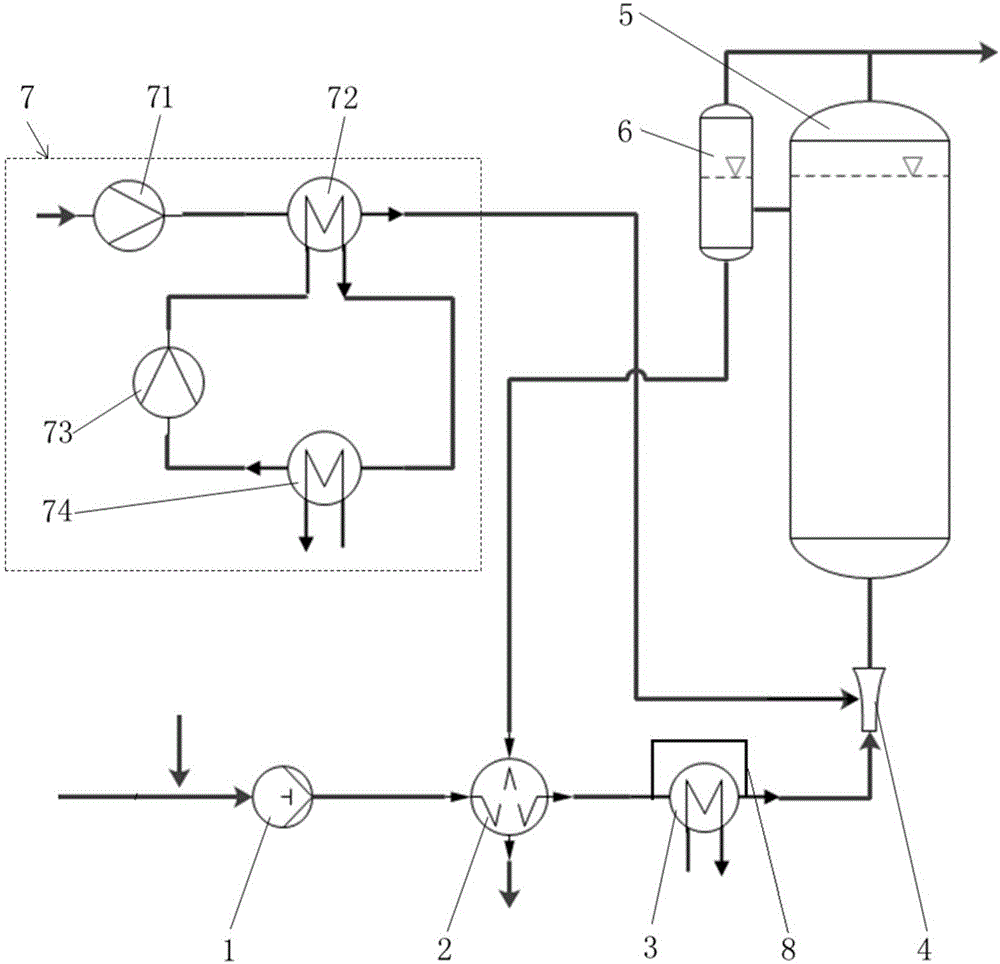

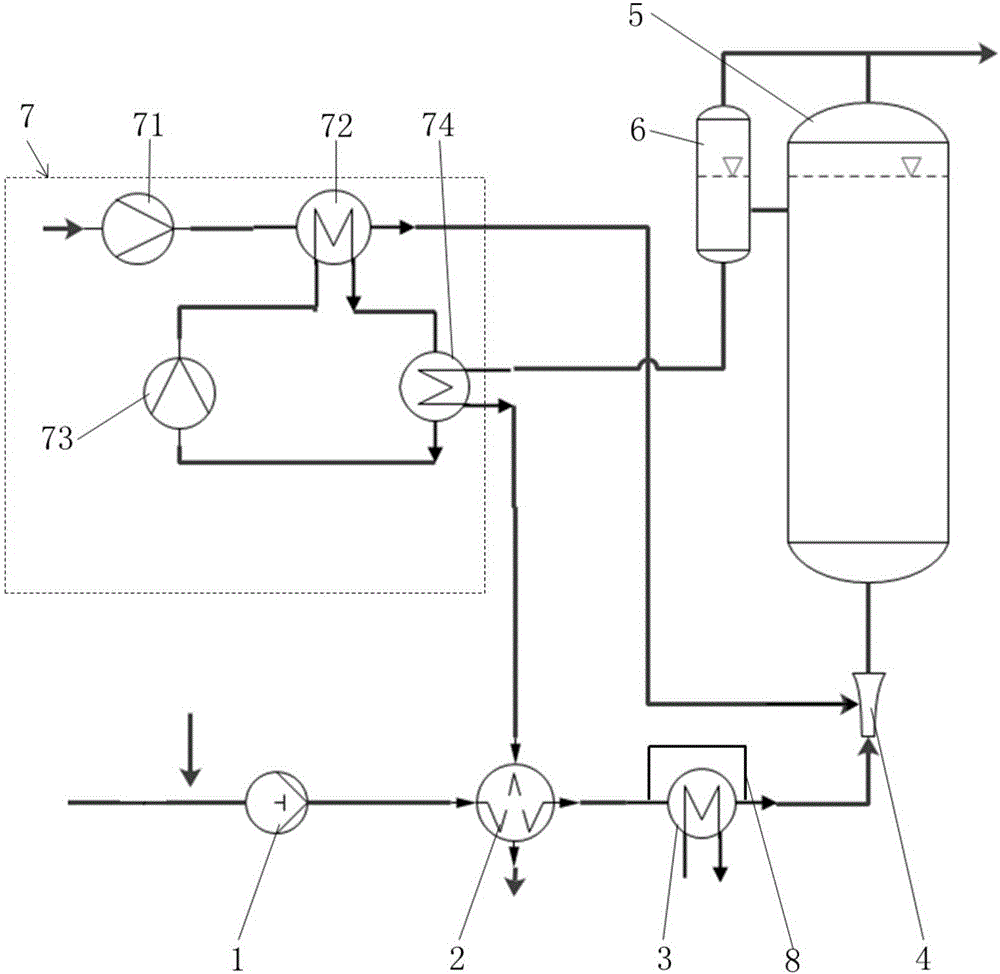

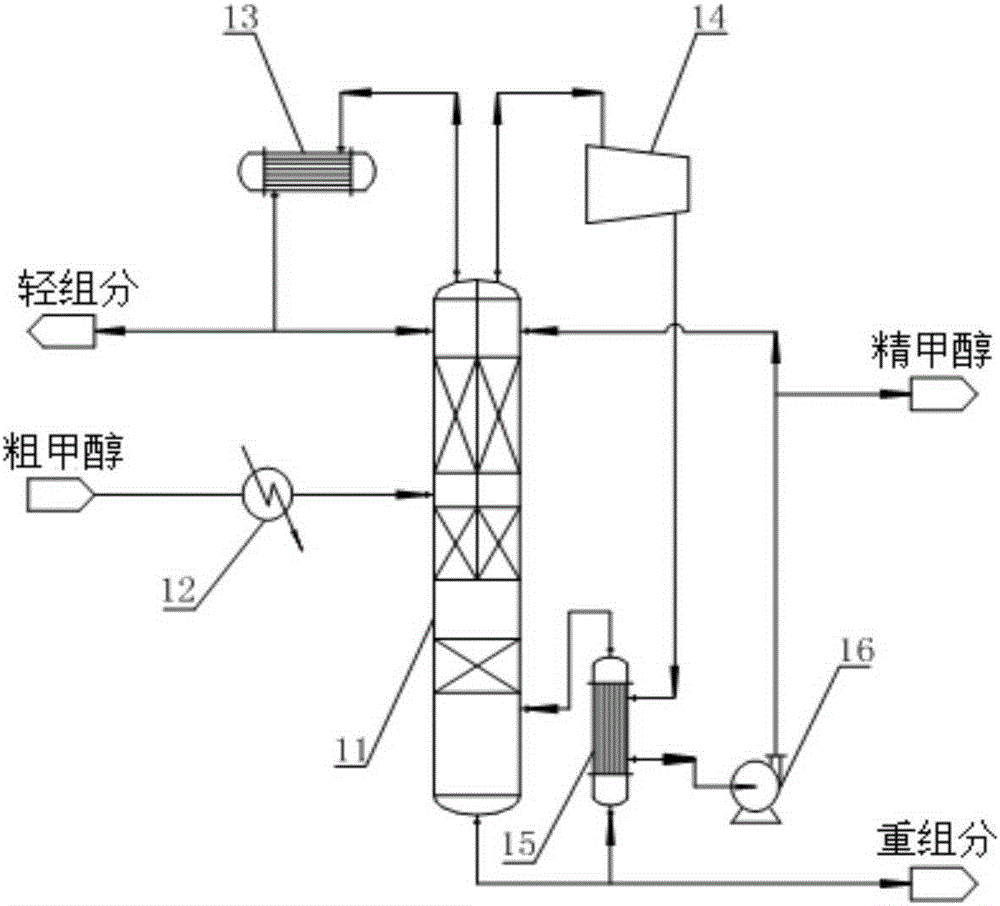

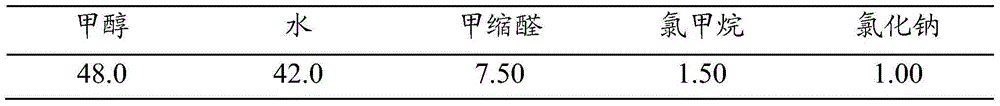

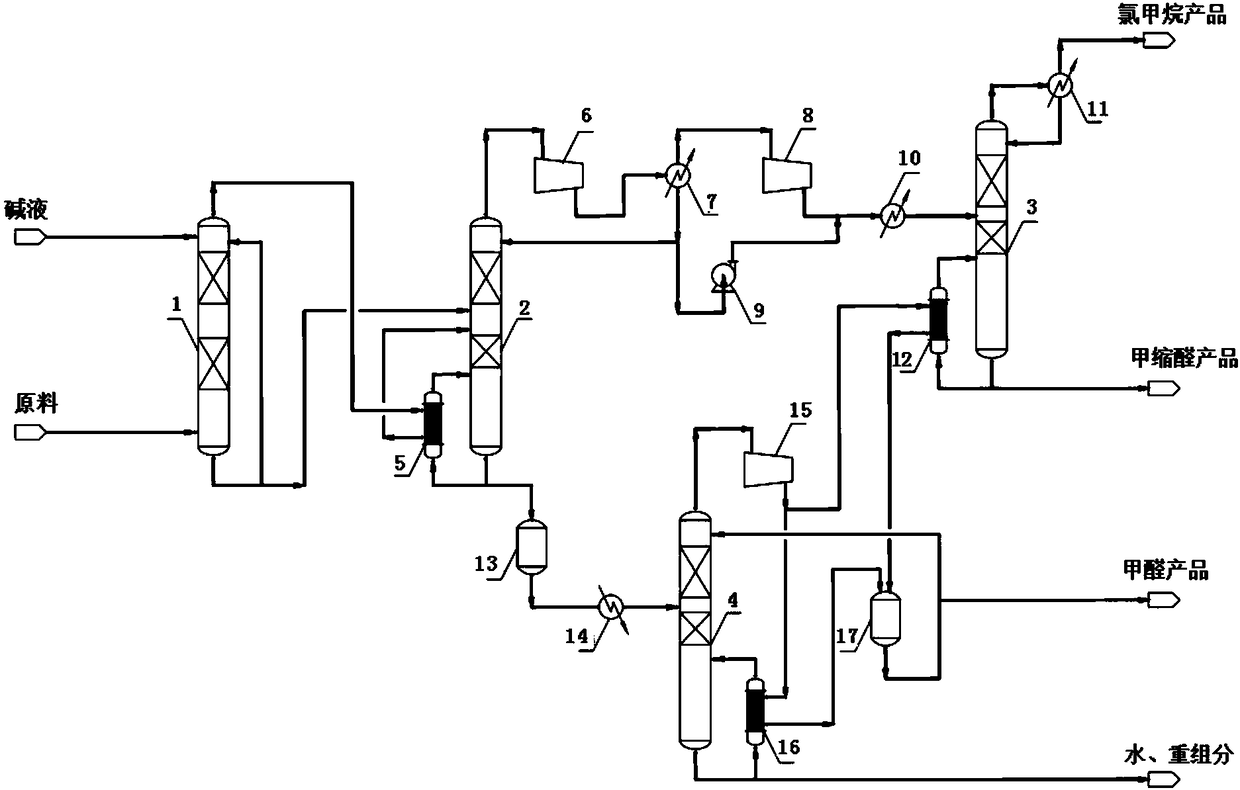

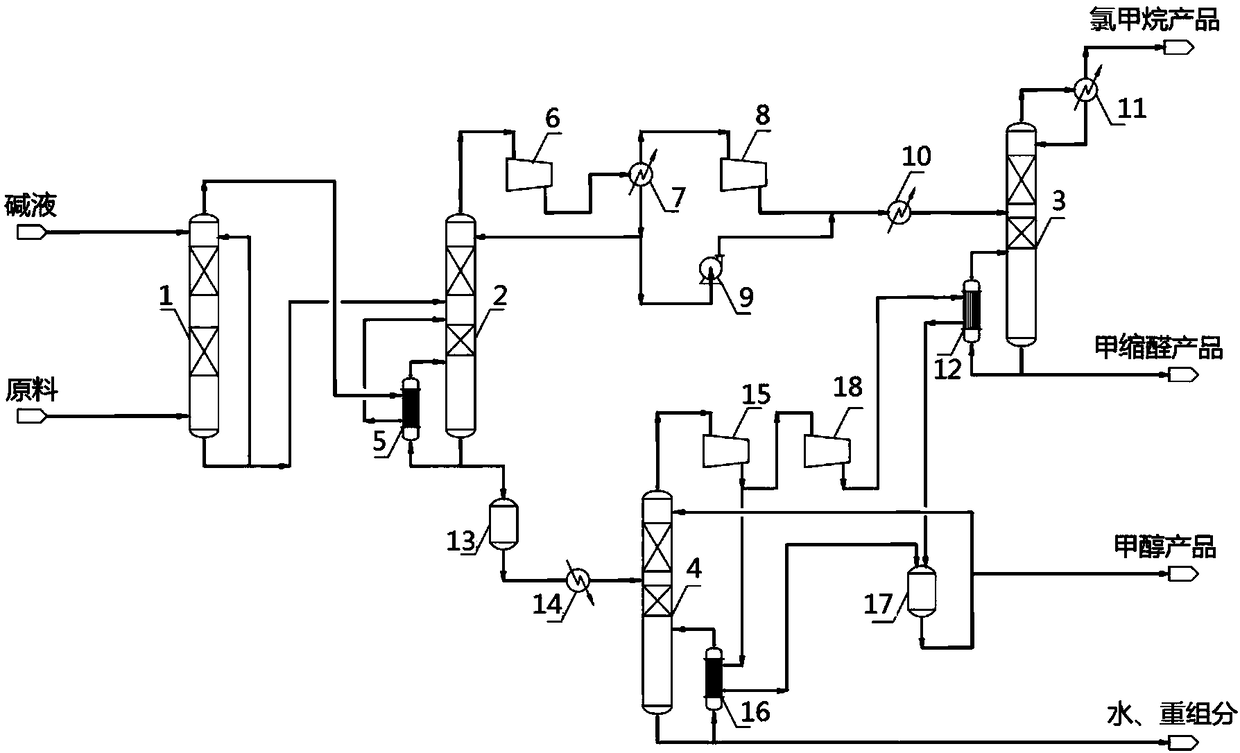

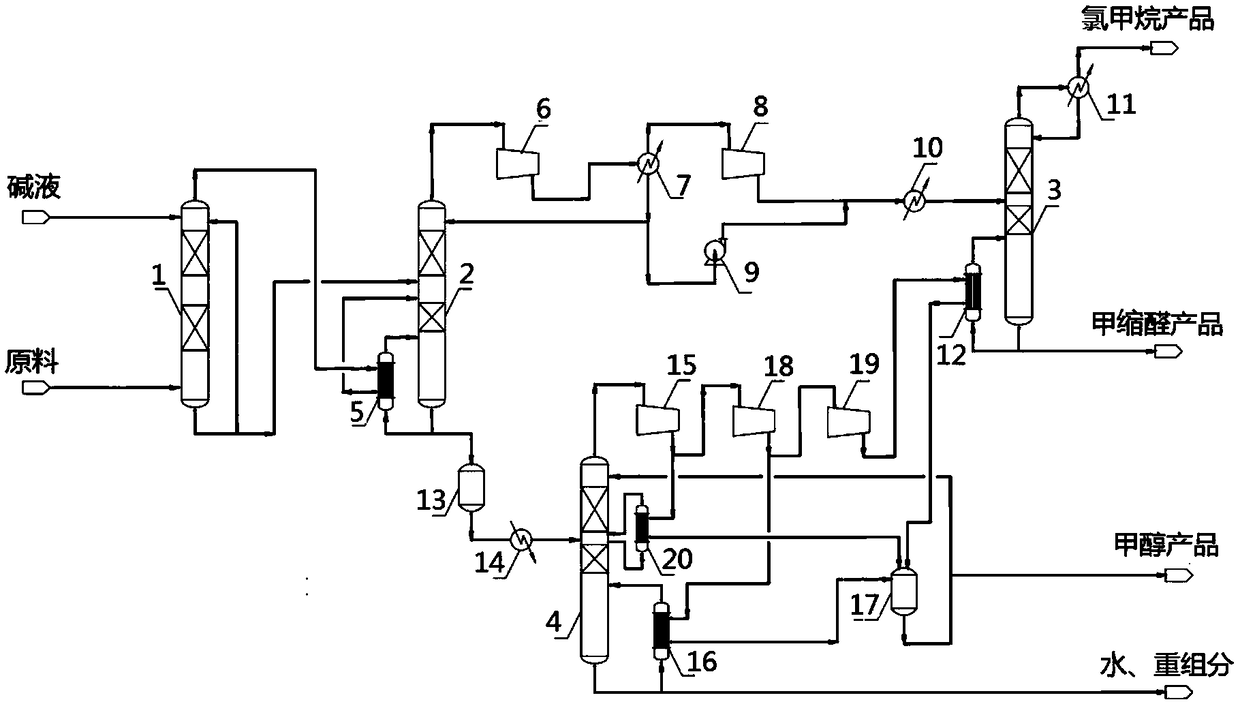

Method and device for refining methanol through dividing wall column combined with heat pump

ActiveCN105218315AReduced corrosion resistance requirementsEasy to separateOrganic compound preparationHydroxy compound preparationReboilerMaterial requirements

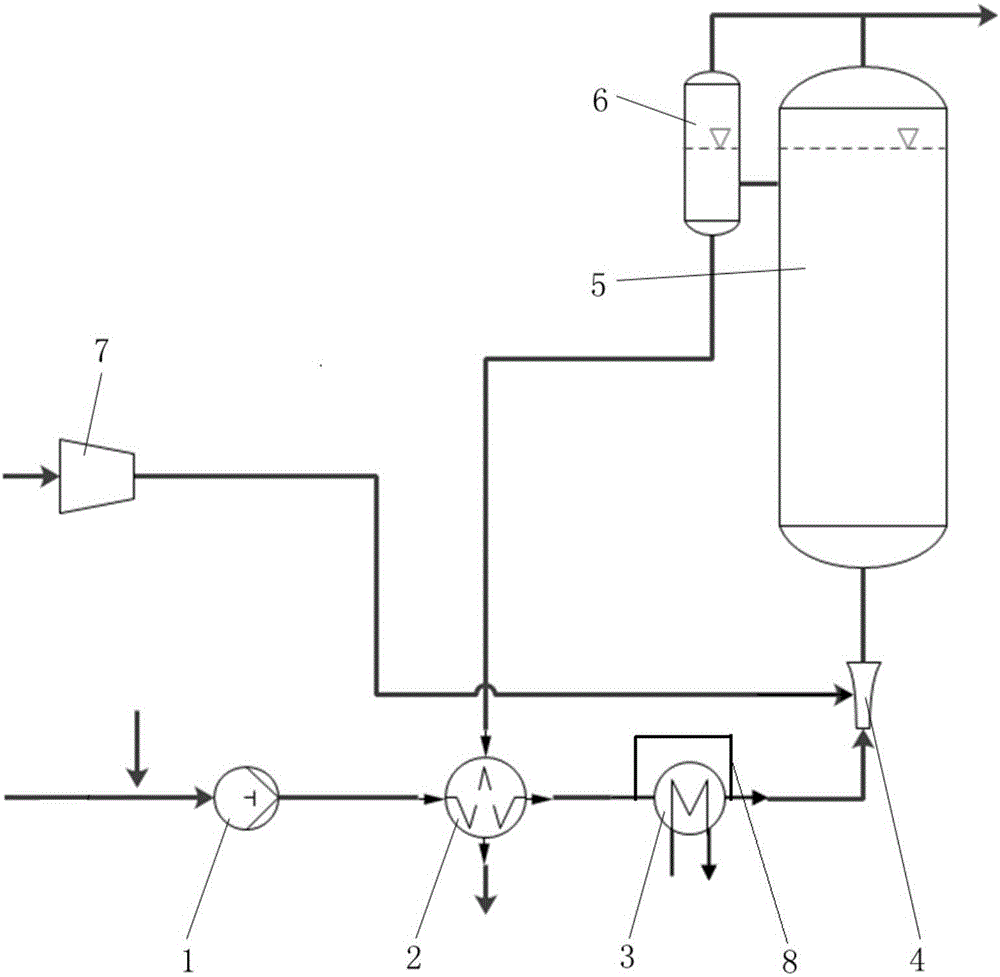

The invention discloses a method for refining methanol through a dividing wall column combined with a heat pump. The method comprises the steps of preheating coarse methanol, then introducing the coarse methanol into the dividing wall column with a stripping section shared, and conducting rectification treatment; obtaining light component impurities from the part, located at the feed side, of the top of the dividing wall column, and extracting the light component impurities after condensation is conducted; obtaining heavy component impurities containing non-volatile impurities at the column bottom; obtaining refined methanol vapor from the part, located at the non-feed side, of the top of the dividing wall column wherein after the energy grade of the refined methanol vapor is raised through pressurization of a compressor, the refined methanol vapor is used as a heat source of a dividing wall column reboiler, and obtaining refined methanol after heat exchange and condensation are completed. The invention further discloses a device for refining methanol through the dividing wall column combined with the heat pump. By means of the method and device for refining methanol through the dividing wall column combined with the heat pump, heat is utilized reasonably, and process energy consumption is greatly lowered; the operation capacity is large, and the energy conservation effect is remarkable; the equipment size is small, and the occupied area is reduced; operation is conducted under a normal pressure condition, corrosion to equipment caused by the impurities is avoided, material requirements of the equipment are lowered, and equipment investment is saved; the impurity separation capability is great, and an obtained product is high in purity and good in quality.

Owner:HANGZHOU ZJU HOLLEY TECH

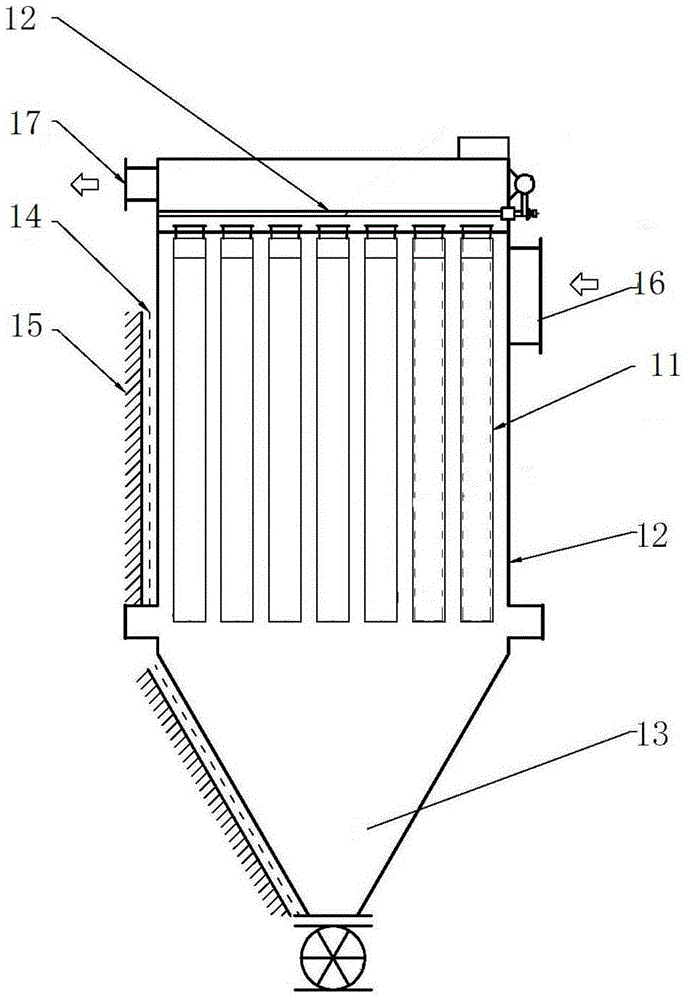

High-efficiency energy-saving hydrochloric acid pickling waste liquor triple-effect negative-pressure graphite evaporation crystallizer

ActiveCN103394206AIncrease profitImprove economySolution crystallizationMultiple-effect evaporationLiquid wasteSolvent

The invention discloses a high-efficiency energy-saving hydrochloric acid pickling waste liquor triple-effect negative-pressure graphite evaporation crystallizer, belonging to the field of pickling waste liquoir treatment. The evaporation crystallizer disclosed by the invention comprises an evaporation concentration unit, a feed unit, a gas condensation unit, a cooling crystallization unit, a solid-liquid separation unit, a mother liquor circulating unit and a vacuum unit. The hydrochloric acid pickling waste liquor is heated in a vacuum state, so that volatile chlorine hydride and water in the solution are evaporated together, and are condensed through the gas condensation unit to form reusable clean hydrochloric acid; and the concentration of the nonvolatile metal salt in the solution is continuously increased to form a metal salt supersaturated solution, and the metal salt supersaturated solution is cooled by the cooling crystallization unit, so that part of metal salts are precipitated in the crystalline-state hydrous crystal, thereby achieving the goal of separating the solute and solvent in the solution. The invention mainly aims to provide a high-efficiency energy-saving hydrochloric acid pickling waste liquor triple-effect negative-pressure graphite evaporation crystallizer which has the advantages of favorable antiseptic property, high recovery ratio and low treatment cost.

Owner:常州泰特环境设备工程有限公司

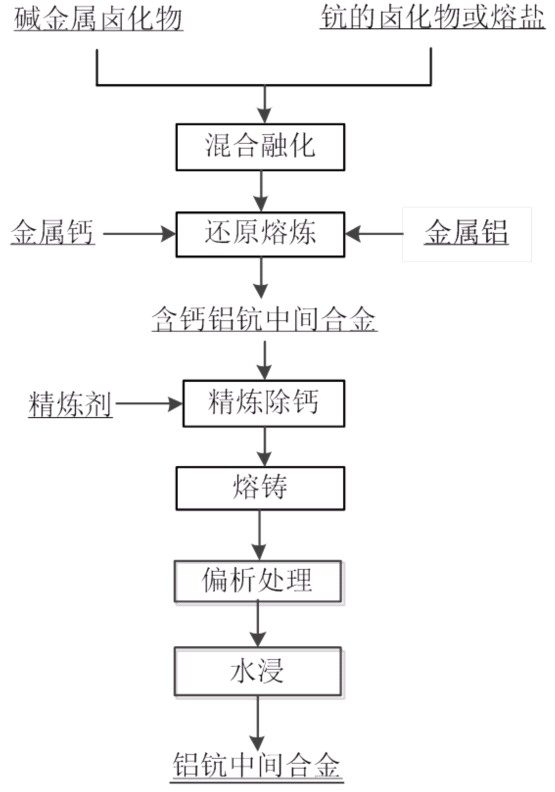

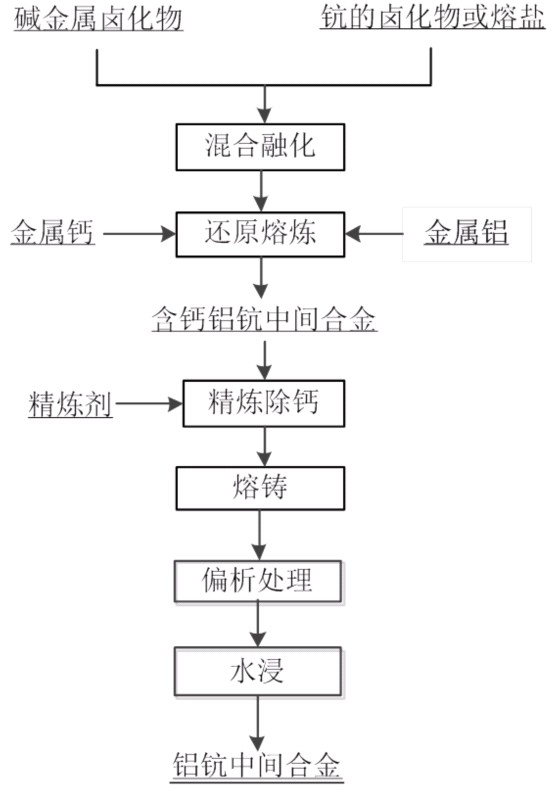

Method for preparing aluminum-scandium intermediate alloy by using calciothermy

The invention discloses a method for preparing an aluminum-scandium intermediate alloy by using calciothermy. The method comprises the following steps of: (1) calculating the weights of halides of aluminum, metal calcium and scandium serving as raw materials, or scandium-containing fused salt, anhydrous calcium chloride and alkali chloride required for smelting in each furnace according to the component content of the aluminum-scandium intermediate alloy; (2) after uniformly mixing a flux, adding the flux into a crucible to smelt; (3) when the flux is completely smelted, adding scandium halide and preserving the heat in a closed protective atmosphere; (4) adding aluminum and metal calcium into the smelted scandium-containing fused salt, preserving the heat and thermally reducing for 20 to 200 minutes; (5) after finishing the thermal reduction reaction, slagging off, and adding an excessive amount of refining agent to remove the calcium, when the calcium content in the alloy is less than 50ppm, casting an ingot and cooling, and performing water leaching to remove slag so as to obtain the aluminum-scandium intermediate alloy. The method disclosed by the invention has the advantages of low fluorine, micro discharge, easiness in operation, steady aluminum-scandium alloy product, novelty and economy.

Owner:INST OF MULTIPURPOSE UTILIZATION OF MINERAL RESOURCES CHINESE ACAD OF GEOLOGICAL SCI +1

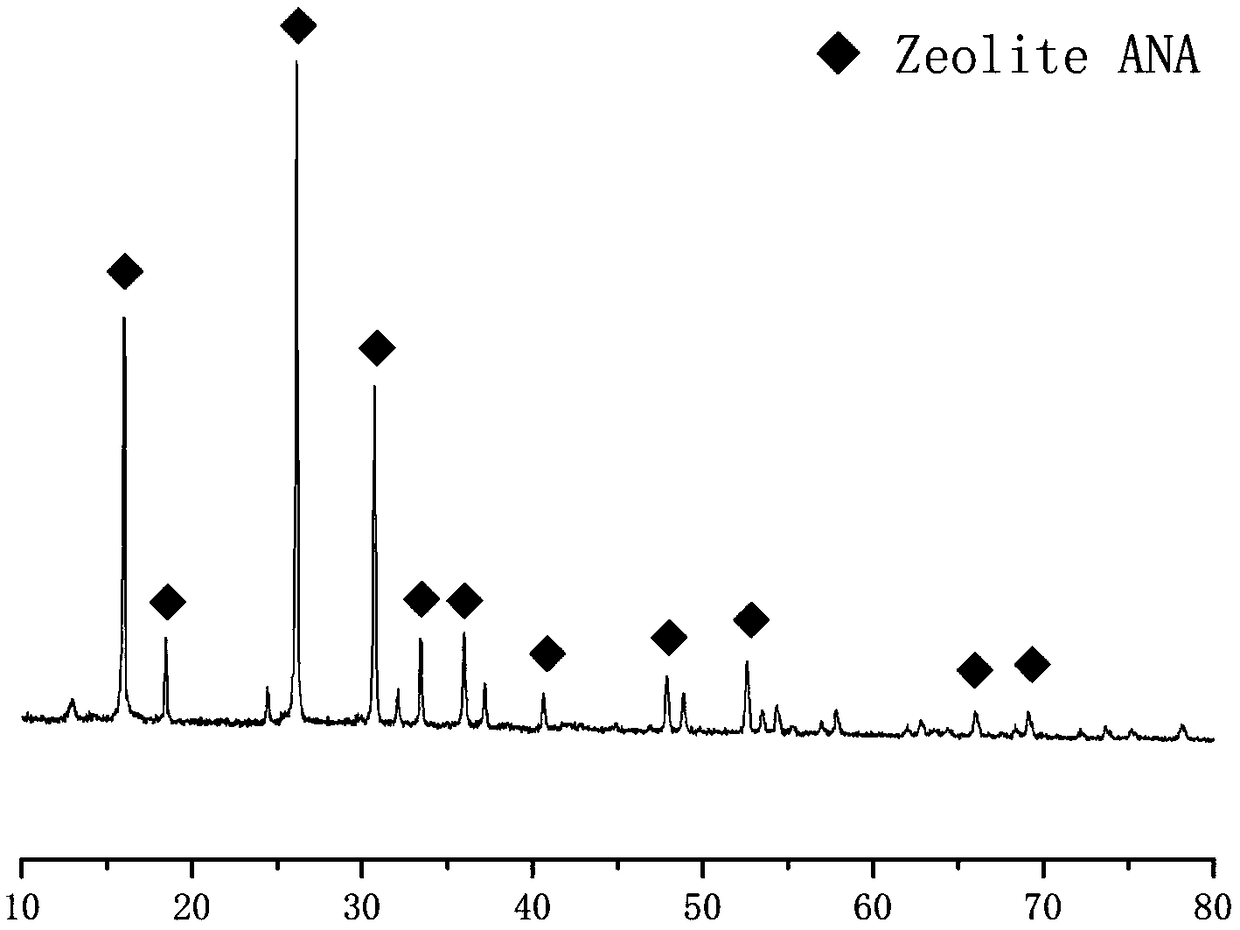

Method for preparing analcite from electrolytic manganese residues

ActiveCN109205638ARealize resource utilizationSolve pollutionCrystalline aluminosilicate zeolitesElectrolysisResource utilization

The invention discloses a method for preparing analcite from electrolytic manganese residues. The method is characterized in that electrolytic manganese residue powder is oxidized and complexed to effectively remove iron; the iron recovery is realized; the manganese residue subjected to iron removal is subjected to calcination activation and then reacts with aluminum oxide, sodium hydroxide and water; crystallization is performed to obtain high-pure-phase analcite. The method has the advantages that the steps are simple; the conditions are mild; the cost is low; when the electrolytic manganeseresidue is used for preparing the high-pure-phase analcite, the iron can also be recovered; the resource utilization of the electrolytic manganese residue is really realized; the problem of environment protection caused by the electrolytic manganese residue is solved.

Owner:肇庆市珈旺环境技术研究院

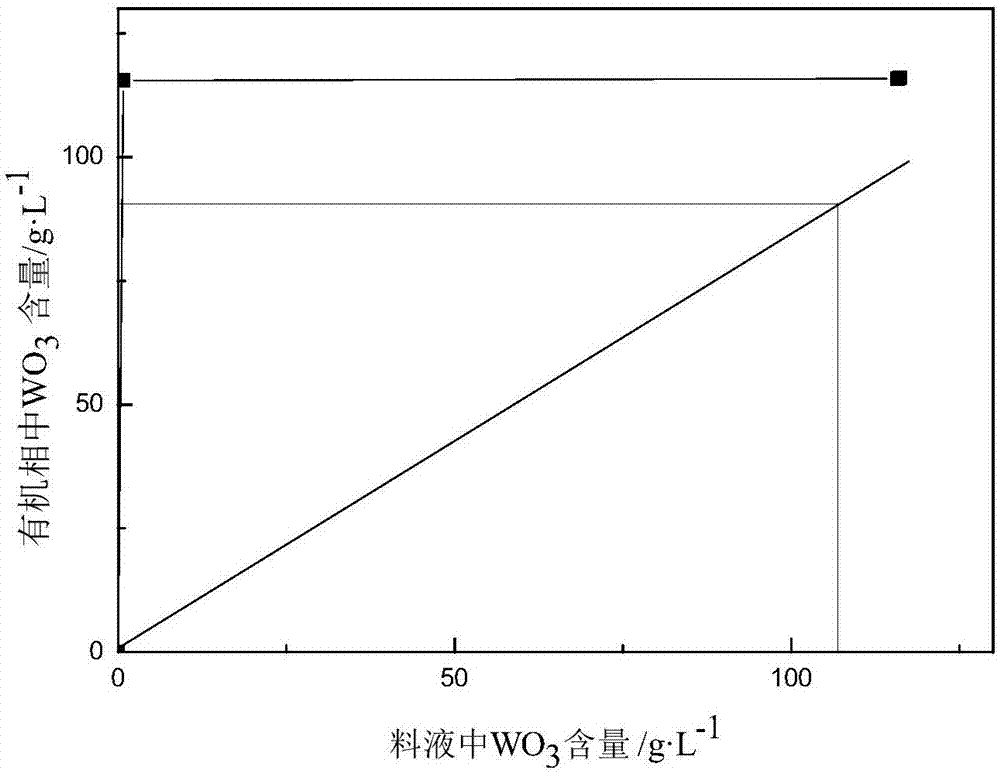

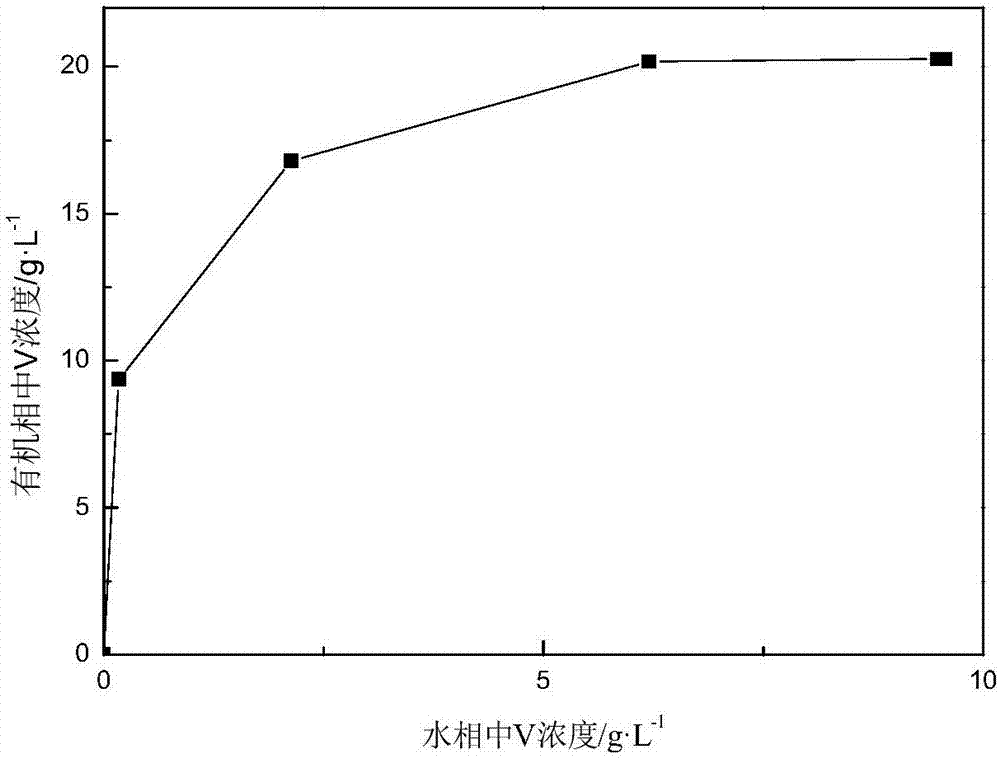

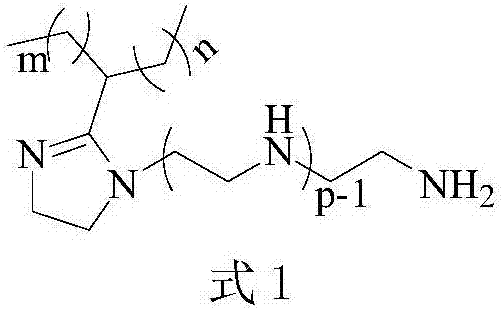

Branched-chain long-chain fatty acid base imidazoline extraction agent and preparing method and application thereof

ActiveCN107385211AImprove extraction abilityLarge saturated capacityOrganic chemistryChemical recyclingLong chain fatty acidPhase splitting

The invention discloses a branched-chain long-chain fatty acid base imidazoline extraction agent and a preparing method and application thereof. The imidazoline extraction agent comprises multiple N atoms and long-branch-chain alkyl groups. The preparing method of the imidazoline extraction agent comprises the steps that in the normal pressure, carboxylic acid and polyethylene polyamine are subjected to the reaction under the action of a solid catalyst, after the reaction is finished, the solid catalyst is recycled through solid-liquid separation, the liquid mixture is distilled, the raw material incompletely reacted is recycled, and then the branched-chain long-chain fatty acid base imidazoline extraction agent is obtained. The preparing method has the beneficial effects that reaction conditions are moderate, the catalyst can be repeatedly used, and equipment investment and operation cost are low; the imidazoline extraction agent is used for extraction negative ions including tungsten, molybdenum and vanadium, the beneficial effects that the extraction volume is high, the phase splitting time is short, and the extraction and reverse extraction performance is excellent; and good industrial application prospects are achieved.

Owner:CENT SOUTH UNIV

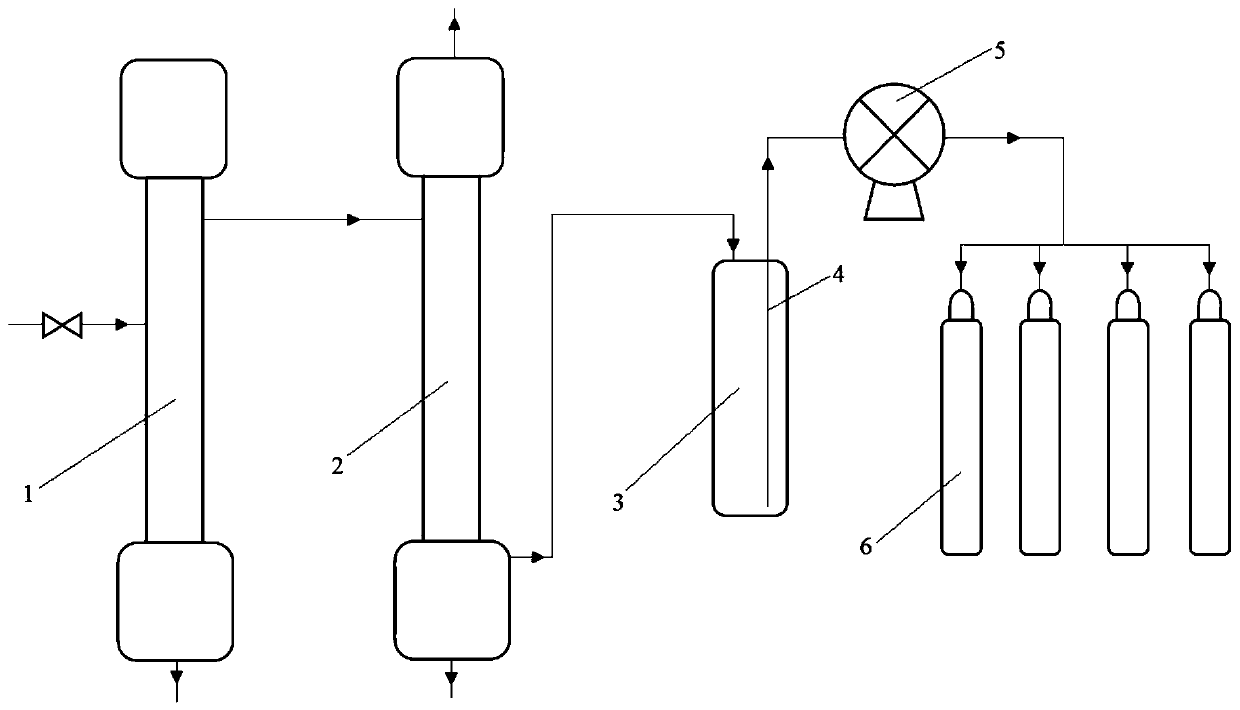

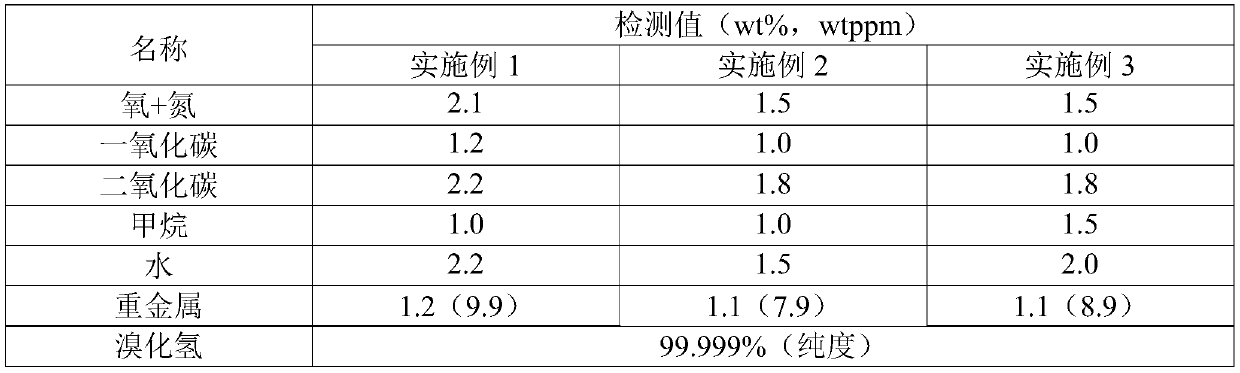

Hydrogen bromide purifying device and method

PendingCN110980648ASimple purification processLess investmentHydrogen bromideFluid phaseProcess engineering

The intention relates to a hydrogen bromide purifying device and method, and belongs to the technical field of fine chemical engineering. A hydrogen bromide crude product enters a heavy component removal tower from a heavy component removal tower feeding hole through a feeding pipeline to be rectified, heavy component impurities are removed from the tower bottom of the heavy component removal tower, hydrogen bromide in which the heavy component impurities are removed is discharged from a heavy component removal tower discharging hole and then enters a light component removal tower to be rectified through a light component removal tower feeding hole, light component impurities are removed from the tower top of the light component removal tower, hydrogen bromide in which the light componentimpurities are removed is discharged from a light component removal tower discharging hole and then enters a product collector through a feed port of the product collector, and liquid-phase hydrogen bromide is detected; the hydrogen bromide collected by the feeding port of the product collector is collected; the hydrogen bromide in the product collector is heated after the detection is qualified,and the liquid-phase hydrogen bromide passes through a filling pump along a filling pipeline led out from bottom to top in the product collector and then enters a filling bottle. The hydrogen bromidepurifying device is simple in process, small in equipment investment, low in energy consumption, small in environmental pollution, good in economical efficiency and easy to realize industrial production.

Owner:PERIC SPECIAL GASES CO LTD

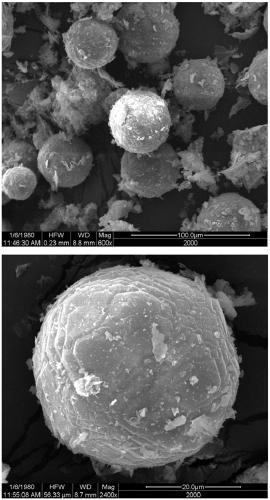

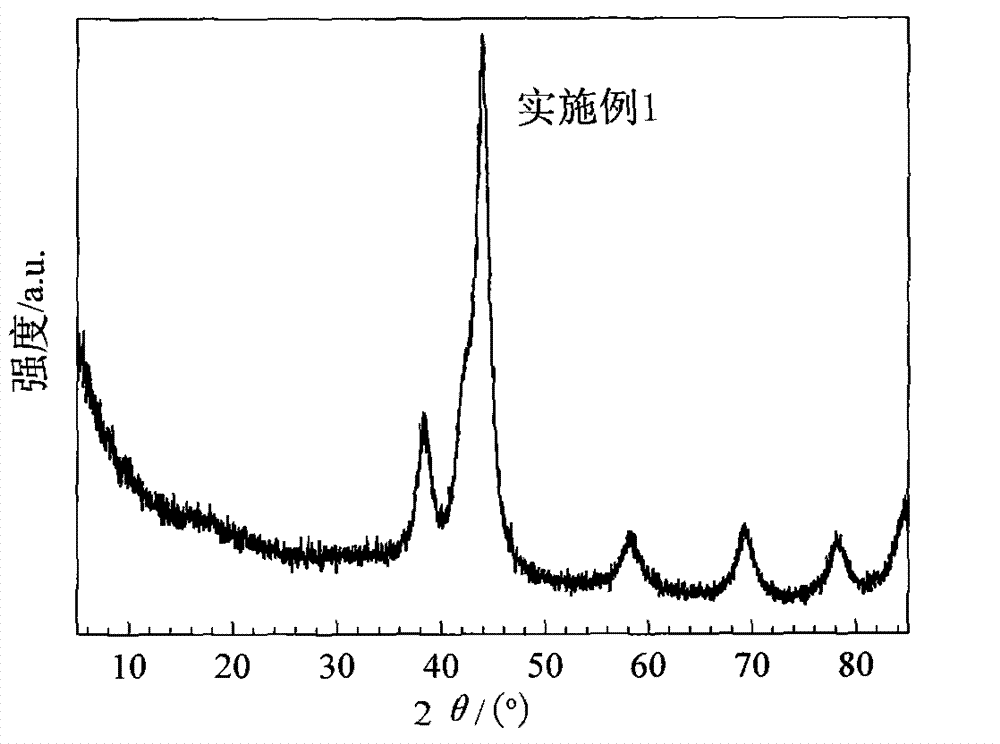

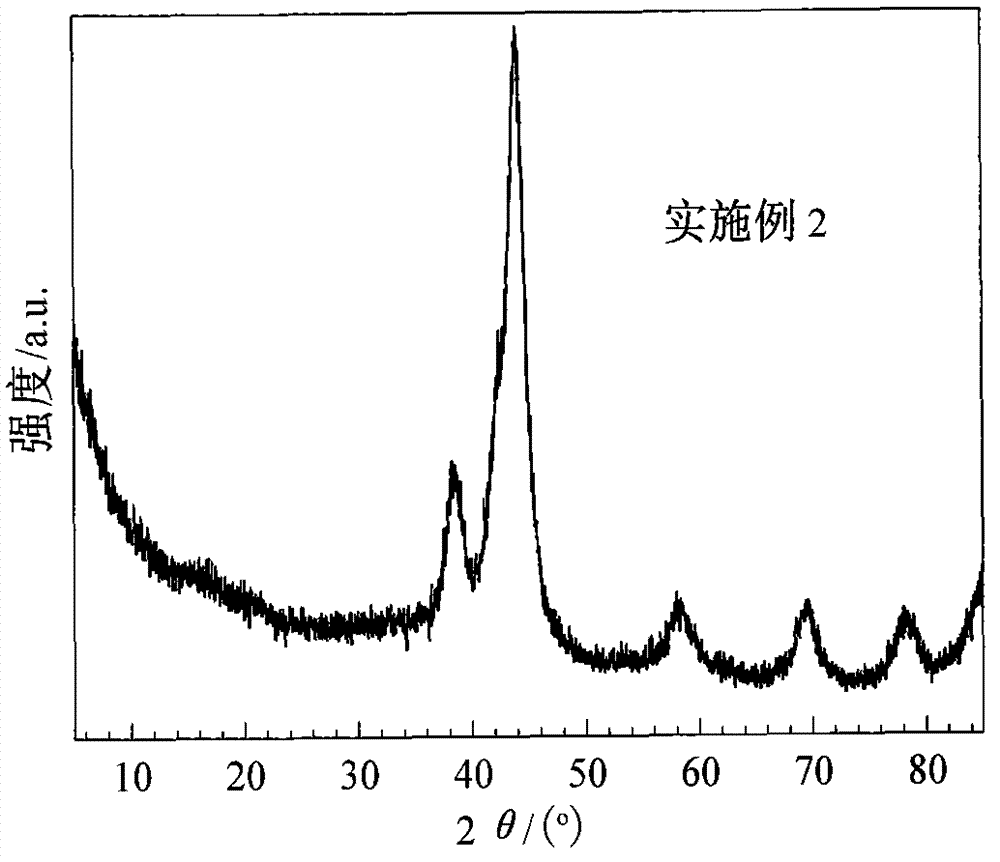

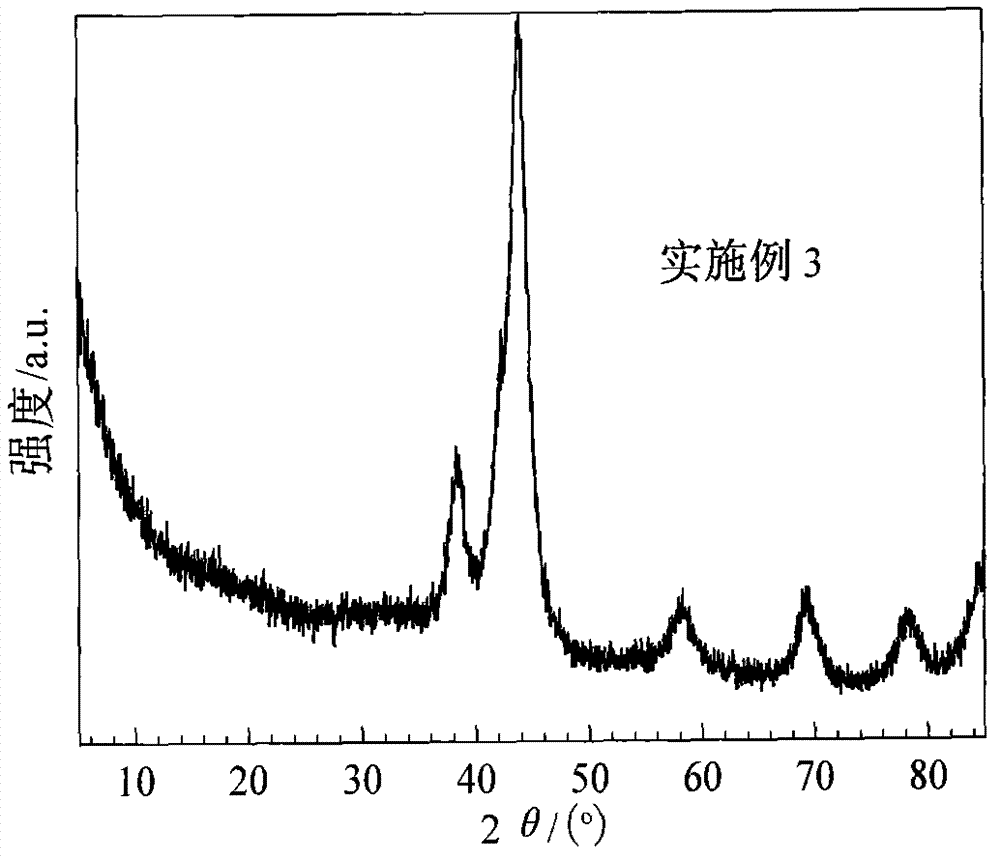

B-containing nano crystalline Ru-based catalyst, preparation method and applications thereof

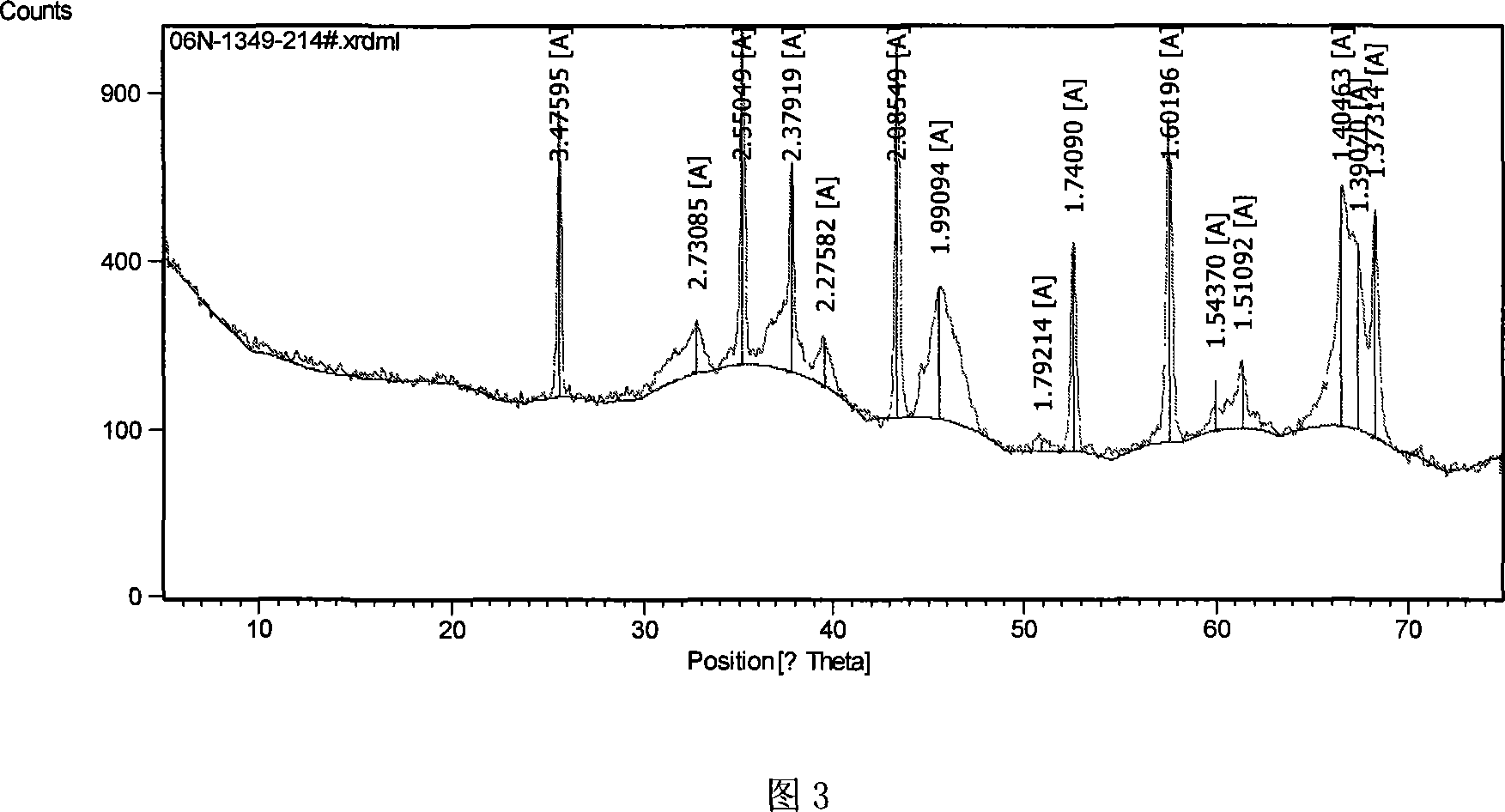

ActiveCN103752309AHigh activityHigh selectivityHydrocarbon by hydrogenationMetal/metal-oxides/metal-hydroxide catalystsSulfateInstability

The invention discloses a B-containing nano crystalline Ru-based catalyst and the application thereof in preparation of cyclohexene by selective hydrogenation. The catalyst contains B, Ru and Zn, and the catalyst is characterized in that the crystallite size of Ru is 3-7nm, and a 2-theta angle of an XRD spectrum diagram is 38.2-38.4 DEG, 43.7-43.9 DEG, 58.1-58.3 DEG, 69.3-69.5 DEG, and / or 78.0-78.2 DEG, and has a characteristic peak. The catalyst disclosed by the invention makes up for a thermodynamic instability characteristic of an amorphous Ru-B catalyst, and has good thermal stability, and in the presence of zinc sulfate, the activity, selectivity and stability of the catalyst are higher than those of a traditional industrial catalyst; and in the absence of zinc sulfate, the catalyst also has high cyclohexene selectivity. The catalyst disclosed by the invention has a good industrial application prospect.

Owner:ZHENGZHOU NORMAL UNIV +1

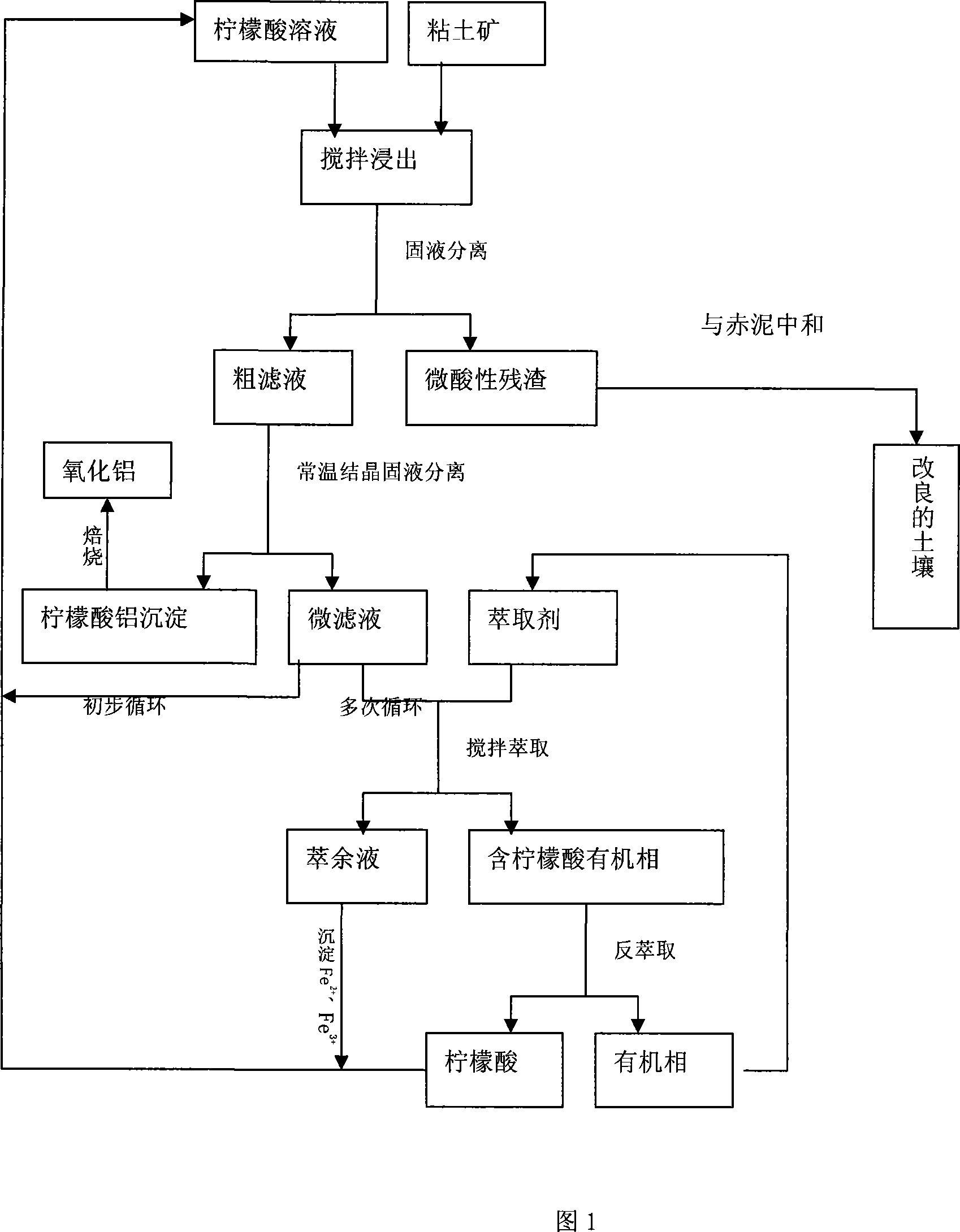

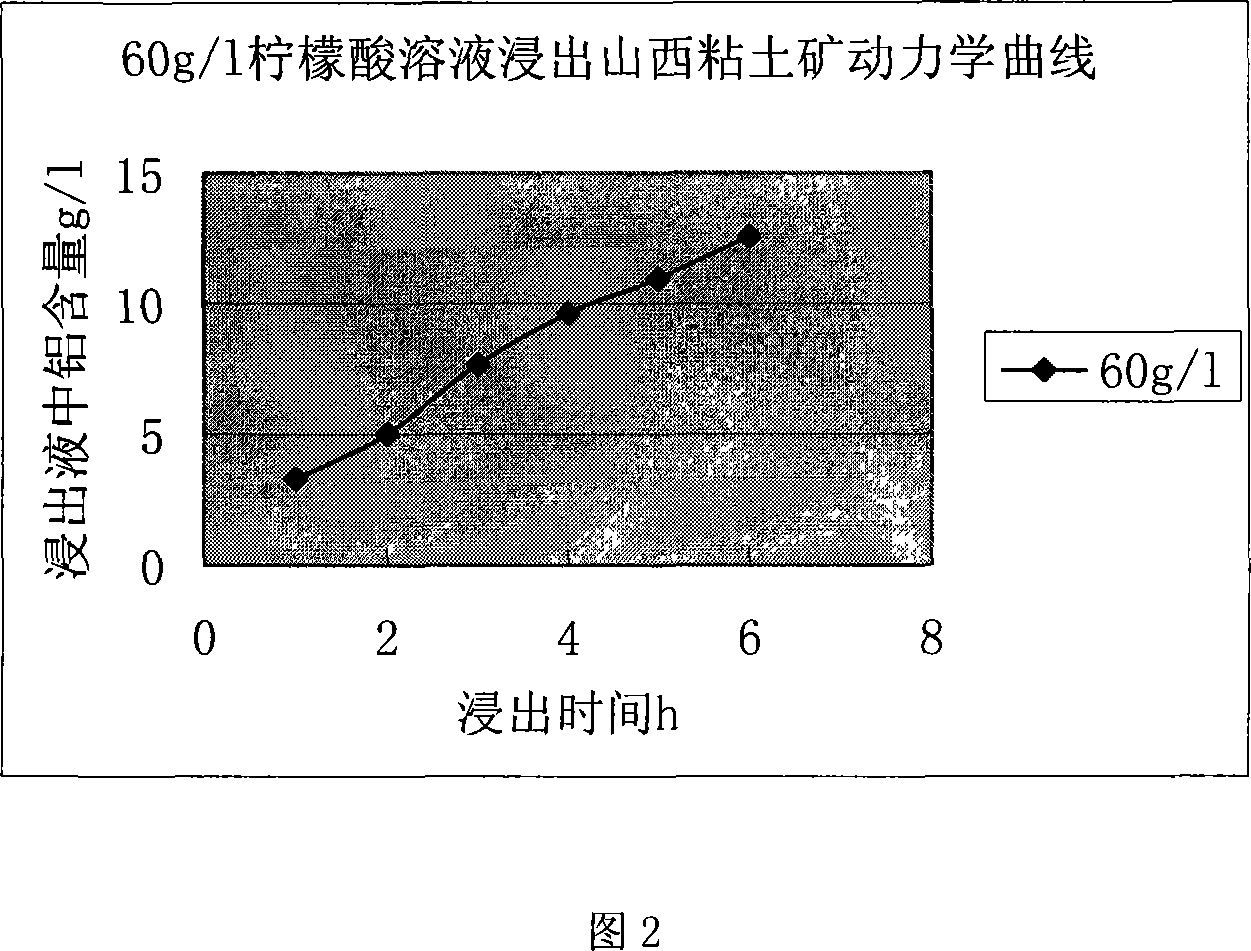

Method of preparing aluminum oxide from clay mine by citric acid extraction

InactiveCN101058432AOvercome the higher requirements of tasteExpand the scope of resources for productionAluminium oxide/hydroxide preparationCITRATE ESTERSlag

The invention discloses an alumina manufacturing method through leaching clay by citrate, which is characterized by the following: adopting organic citrate as leaching agent to leach the sintered aluminium in the clay; filtering to remove the leached slag; cooling and stewing the leached liquid; sedimenting the aluminium citrate; sintering the aluminium citrate through high temperature to produce the alumina product; circulating the leaching liquid with little polluting discharge.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

Method for preparing dimer acid and dimer acid methyl ester

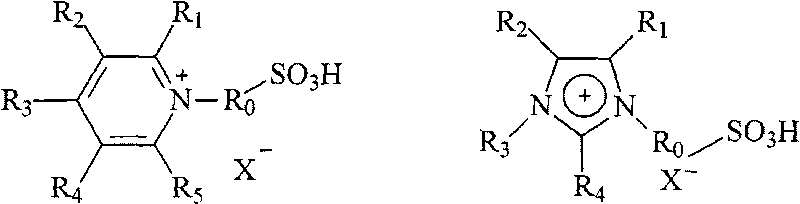

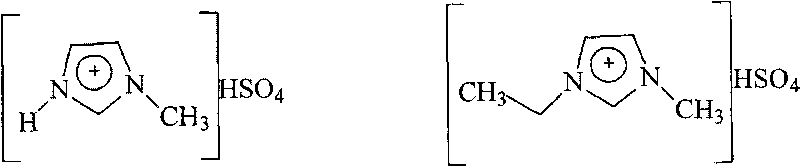

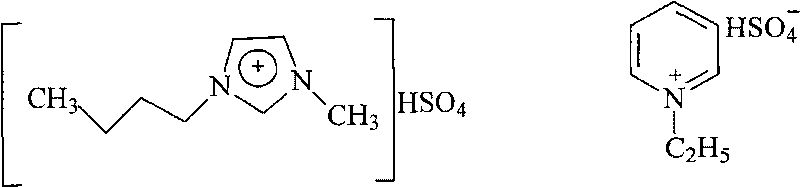

InactiveCN101735035ANot corrosiveImprove stabilityFatty acid chemical modificationOrganic compound preparationCentrifugationDimer acid

The invention relates to an improvement of a method for preparing dimer acid and dimer acid methyl ester by using unsaturated fatty acid and corresponding fatty acid methyl ester thereof, which is characterized in that a catalyst for reaction is sulfonate ionic liquid which contains SO3H functional groups and accounts for not less than 0.5% in parts by weight, the reaction is carried out at the temperature of 150-300 DEG C, the iodine value of products are controlled to be 65-80%, and the products and the catalyst are stratified by standing after the reaction is complete. The method has the advantages of high polymerization reaction activity, fast reaction speed and relatively mild reaction conditions, and the reaction can be carried out at atmospheric pressure and relatively low temperature, thereby not only reducing the reaction energy consumption and having low requirements on equipment, but also greatly reducing the preparation cost. The catalyst has good stability and small usingquantity, only 0.5% by weight of the catalyst can carry out full reaction, the catalyst is difficult to hydrolyze and easy to realize the phase separation with the products, the catalyst can be separated from the products only through ordinary standing or centrifugation without entrainment of the products, the catalyst can be repeatedly recycled, and the production process is environment-friendly.

Owner:JIANGSU ZHONGSHENG GAOKE ENVIRONMENTAL CO LTD +1

Preparation method for producing hydrolysis crystal seeds in titanium white technique, and titanium white for matting agents prepared by method

ActiveCN106186055ANot easy to sinter and reuniteSmall particle sizeTitanium dioxideWater basedSulfate

The invention relates to a method for preparing hydrolysis crystal seeds by reaction between a titanyl sulfate solution and a Na3PO4 solution. The method comprises the following steps: adding the titanyl sulfate solution at certain temperature into the Na3PO4 solution according to a certain mass ratio, and curing by stirring until the stability of the crystal seeds drops to the specified requirement; and producing the titanium white product for matting agents by the process. The titanium white obtained by hydrolysis has the advantages of excellent whiteness, high water-based dispersing power, favorable matting capacity, low impurity content, moderate particle size, narrow particle size distribution and the like, and is suitable to be used as a matting agent.

Owner:GUANGXI JINMAO TITANIUM

Seawater desalination method for integrated membrane process

ActiveCN104909503AImprove conductivitySlow down the electrode reactionSeawater treatmentMultistage water/sewage treatmentUltrafiltrationHigh energy

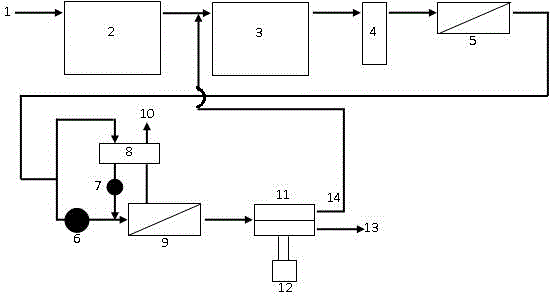

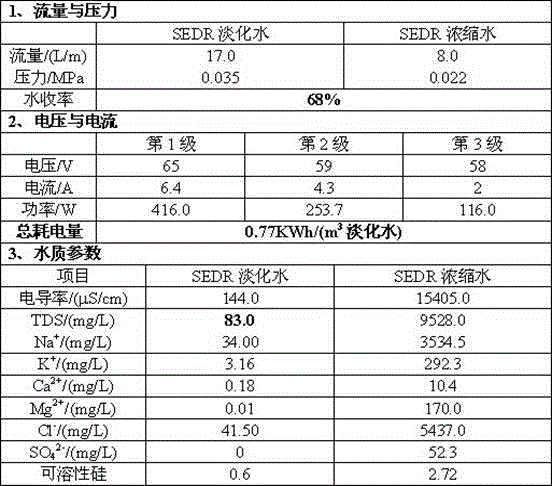

The invention provides a seawater desalination method for an integrated membrane process and belongs to a water desalination technology. Aiming at the defects of high investment, high pressure, high energy consumption and the like in an existing membrane-method seawater desalination process, 'nanofiltration / electrodialysis reversal' is taken as a core desalination process, wherein during nanofiltration, a high-desalination nanofiltration membrane with desalination ratio of 90% is adopted; during electrodialysis reversal, a thin-type electrode chamber is filled with a multistage multi-section energy-saving electroosmosis device provided with mixed-bed ion exchange resin. Seawater raw water is sequentially pretreated by virtue of a coagulative precipitation tank, a settling tank, a sand filter and an ultrafiltration membrane, and then is subjected to graded desaltination sequentially by virtue of a nanofiltration desalination device with an energy recovery device, and an energy-saving frequent electrodialysis reversal device; nanofiltration and energy-saving electrodialysis are respectively performed at low operation pressures which do not exceed 3.8MPa and 0.4MPa; the salt content of water produced by the system is 80-250mg / L, the total desalinization ratio can be mechanically regulated within a range of 99-99.75%, the body power consumption of per ton of water does not exceed 2.15KWh / m<3>, the investment and energy consumption of the whole seawater desalination process are obviously reduced, and the process operation is relatively safe and stable.

Owner:天津中领水系统技术有限公司

Immobilized lipase catalyst for preparing biodiesel and application of immobilized lipase catalyst

The invention discloses a lipase catalyst immobilized on sepiolite, a preparation method of the lipase catalyst and a method for preparing biodiesel from the catalyst, and belongs to the field of preparation of biodiesel. Dosage of the immobilized lipase catalyst is low, and the immobilized lipase catalyst can be reused by 10 times. In addition, the biodiesel prepared from the catalyst is high in reaction activity and high in reaction speed, reaction conditions are mild relatively, reaction can be carried out under atmospheric pressure at low temperature, and reaction energy consumption and cost can be reduced. Besides, a production process is environment-friendly, an operation process is simple, and erosion to equipment is low.

Owner:连云港力润粮油贸易有限公司 +1

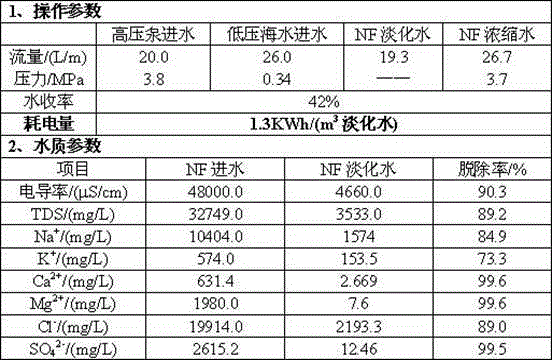

Method for treating industrial mixed waste salt by using sulfuric acid

PendingCN113896208AHigh yieldGood qualitySulfate/bisulfate preparationAlkali metal sulfite/sulfate purificationIndustrial wasteSodium bisulfate

The invention relates to a method for treating industrial mixed waste salt by using sulfuric acid, the industrial mixed waste salt refers to industrial waste salt containing sodium chloride and sodium sulfate, and the method comprises the following steps: (1) adding a sulfuric acid aqueous solution with the concentration of more than 20% and the industrial mixed waste salt into a reactor, controlling the temperature to be 65-120 DEG C, reacting for 0.5-1.5 hours, and collecting volatile gas to obtain a byproduct hydrochloric acid; controlling the acidity of the obtained reaction liquid to be 55-85%, then cooling and crystallizing the reaction liquid, and separating to obtain sodium hydrogen sulfate crystals and acidic mother liquor; (2) mixing the sodium hydrogen sulfate crystal with industrial mixed waste salt, reacting at 450-600 DEG C for 3.0-6.0 hours to obtain crude sodium sulfate and hydrogen chloride-containing tail gas, and using the hydrogen chloride-containing tail gas for preparing byproduct hydrochloric acid; and (3) carrying out salt dissolving refining on the crude sodium sulfate, concentrating and crystallizing the refined solution, and separating to obtain the sodium sulfate product. The practical problem that industrial mixed waste salt is difficult to treat is solved, and the industrial anhydrous sodium sulfate and the byproduct hydrochloric acid which meet the quality requirements of national standard I-class first-grade products are prepared.

Owner:ZHEJIANG LONGSHENG GROUP +2

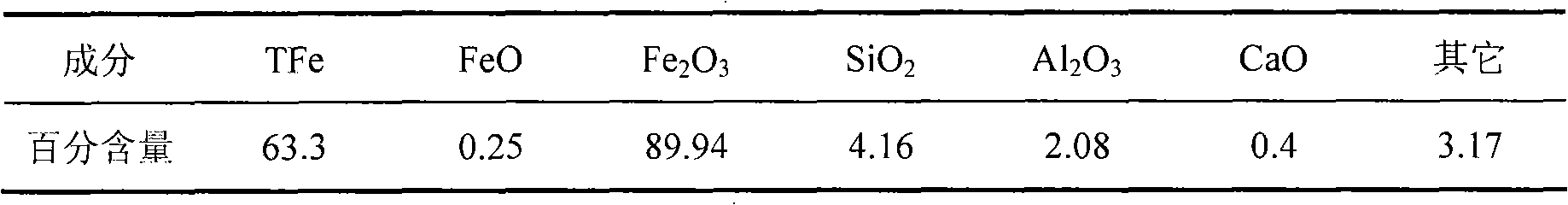

Method for preparing iron sulfate with iron ore

InactiveCN101269847AImprove leaching rateEasy to control production process conditionsIron sulfatesIron sulfateIron powder

The invention provides a method of preparing ferric sulfate, which has the procedures that: iron ore is ground into iron powdered ore which is calcined for 2-3 h under the condition of 750-900 DEG C for the spare after being cooled; industrial sulphuric acid solution with 36-40 percent of mass percent concentration is added into a container provided with a mixing device; the iron ore is weighted and added into the industrial sulphuric acid solution for mixing; wherein, the mass percent of the iron ore and the industrial sulphuric acid solution satisfies the need of 1:6; the mixed solution of the iron ore and the industrial sulphuric acid solution is reacted for 2-3 h under the constant temperature of 100 DEG C, and then the ferric sulfate solution can be obtained after being cooled and filtered. The method adopts the iron ore with low cost to be used as the raw material, the iron ore is mixed and reacted with the industrial sulphuric acid solution after being calcined, not only the production process and the operation condition are easily controlled, but also the leaching rate of iron is higher. A feasible path can be provided for the multipurpose use of the iron ore, and a process route with low-cost raw material is provided for producing flocculating agent.

Owner:CHONGQING UNIV

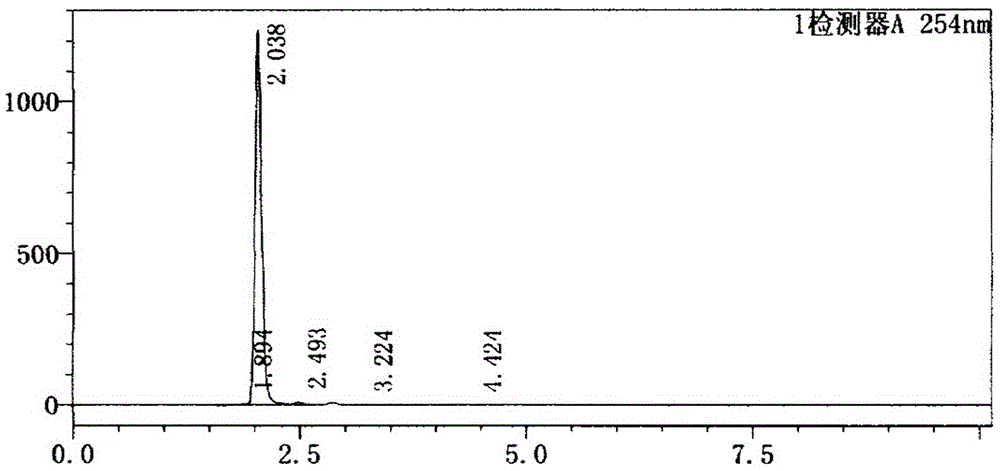

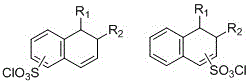

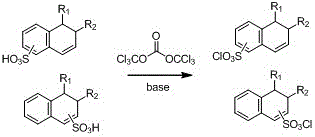

Method for synthesizing naphthoquinone sulfonyl chloride

InactiveCN105753743AEase of industrial productionHigh yieldSulfonic acid preparationSulfonyl chlorideOrganic base

The invention discloses a method for synthesizing naphthoquinone sulfonyl chloride and belongs to the technical field of organic synthesis.The method includes the step that naphthoquinone sulfonyl chloride is synthesized by naphthoquinone sulfonic acid and di(trichloromethyl) carbonic ester in an inert solvent under the condition that organic base serves as a catalyst.Naphthoquinone sulfonic acid serves as a raw material, safe and environment-friendly di(trichloromethyl) carbonic ester serves as an acylating chlorination reagent, the organic base is used, naphthoquinone sulfonyl chloride is prepared at moderate temperature under simple and convenient operating conditions, industrial production of the compound is promoted, and the whole reaction process meets the requirements on safety and environment friendliness.The yield of the prepared naphthoquinone sulfonyl chloride product is larger than 80%, and the purity of the prepared naphthoquinone sulfonyl chloride product is larger than 95%.

Owner:DENBISHI FINE CHEM DALIAN CO LTD

Method for preparing methyl p-tert-butylbenzoate

ActiveCN107311868AImprove stabilityHigh catalytic activityOrganic compound preparationCarboxylic acid esters preparationBenzoic acidEsterification reaction

The invention relates to a method for preparing methyl p-tert-butylbenzoate. The method comprises the following steps: with methanol and p-tert-butyl benzoic acid as raw materials, under the action of sulfonic acid resin as a catalyst, performing an esterification reaction, and separating to obtain the methyl p-tert-butylbenzoate, wherein the sulfonic acid resin as the catalyst is environment-friendly, can be easily separated from a product and can be recycled. The method has the advantages as follows: the catalyst is good in stability, high in reactivity and environment-friendly, equipment corrosion is avoided, the product is easy to separate, and the catalyst can be recycled.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY +1

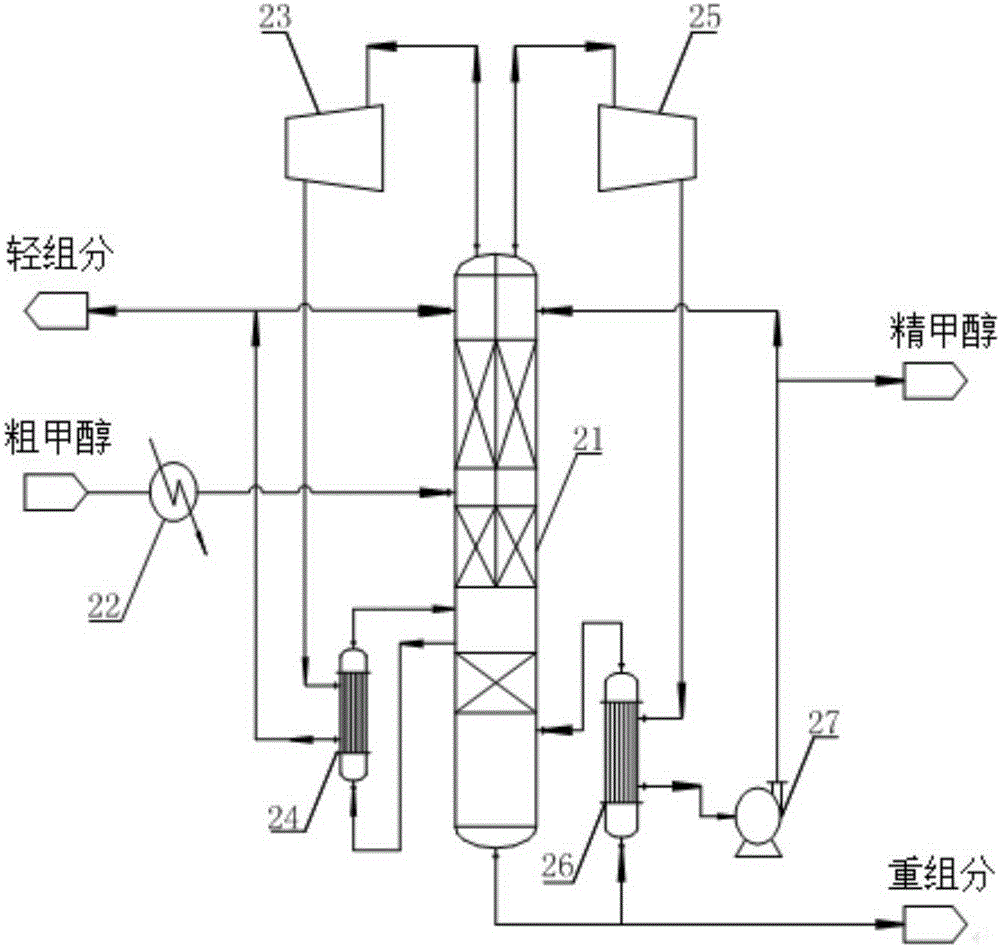

Method for recycling glyphosate solvent and byproducts

ActiveCN108083984AReduce processing energy consumptionTo achieve the purpose of saving energy and reducing consumptionOrganic compound preparationEnergy inputReboilerGlyphosate

The invention relates to a method for recycling glyphosate solvent and byproducts. By the method, methanol steam is used as a heat source for a light component refining tower reboiler and a methanol refining tower reboiler after being pressurized to increase the energy grade, and heat is reasonably used for replacing use of low-pressure or medium-pressure steam, so that when a device works normally, consumption of raw steam is not needed completely, and thus the technological energy consumption is greatly lowered and the purposes of saving energy and reducing consumption are achieved; a compressor is used for pressurizing light components, so that the light component condensing temperature is raised, thus discharged materials on the tops of a pre-rectifying tower and a light component refining tower can be cooled by cooling water and use of frozen salt water with higher cost is avoided, and thus the production cost is reduced and the technological economy is increased; in addition, bythe method, the capability of separation each component is relatively strong, and methanol and the byproduct methylal and methyl chloride are high in recycling rate, high in purity and good in quality; the method can be industrially applied.

Owner:吴嘉

Method for catalytically decomposing wood fiber raw material

PendingCN109942835AHigh extraction rateImprove stabilityPulping with organic solventsRaw material divisionCelluloseFiber

The invention relates to a method for catalytically decomposing a wood fiber raw material. The method comprises the following steps: preprocessing the wood fiber raw material by virtue of an organic solvent, after the preprocessing is finished, adding a solid acid catalyst, cooking, and carrying out solid-liquid separation; washing a separated solid-phase mixture, and sieving, so as to obtain cellulose and the solid acid catalyst; and concentrating separated cooking liquid, and recycling the organic solvent, so as to obtain a mixture of sugar and lignin. According to the method, the organic solvent is taken as a solution for separating the wood fiber raw material and is combined with the solid acid catalyst for catalytic reaction, and three products including sugar liquid, lignin and cellulose are obtained through controlling the process conditions, so that the efficient extraction of valuable components in the wood fiber raw material is realized, and the recycling rate of the valuablecomponents can reach over 92%. Meanwhile, the corrosion resistance requirement of the separation equipment is reduced, and the solid acid catalyst and the organic solvent can be repeatedly used, so that the production cost is lowered, the environmental pollution is reduced, and the method has good application prospects.

Owner:GUANGZHOU YINNOVATOR BIOTECH CO LTD

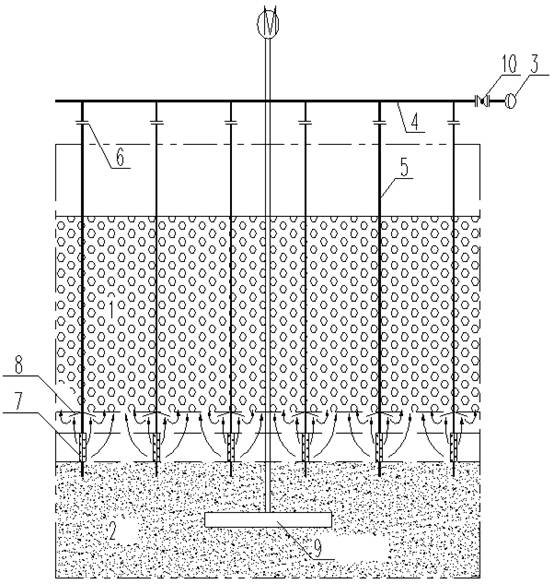

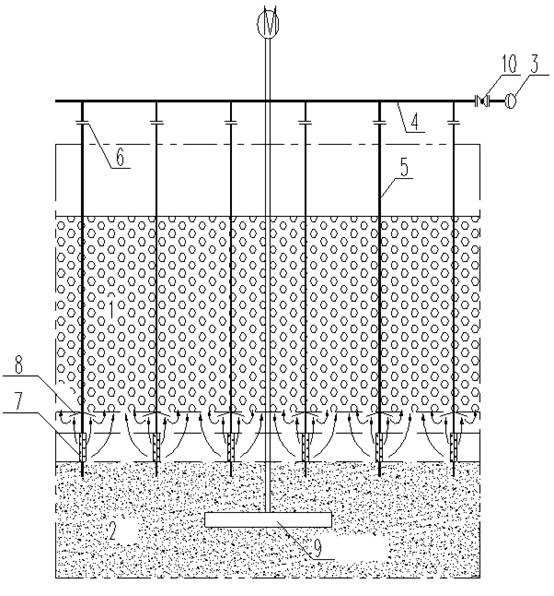

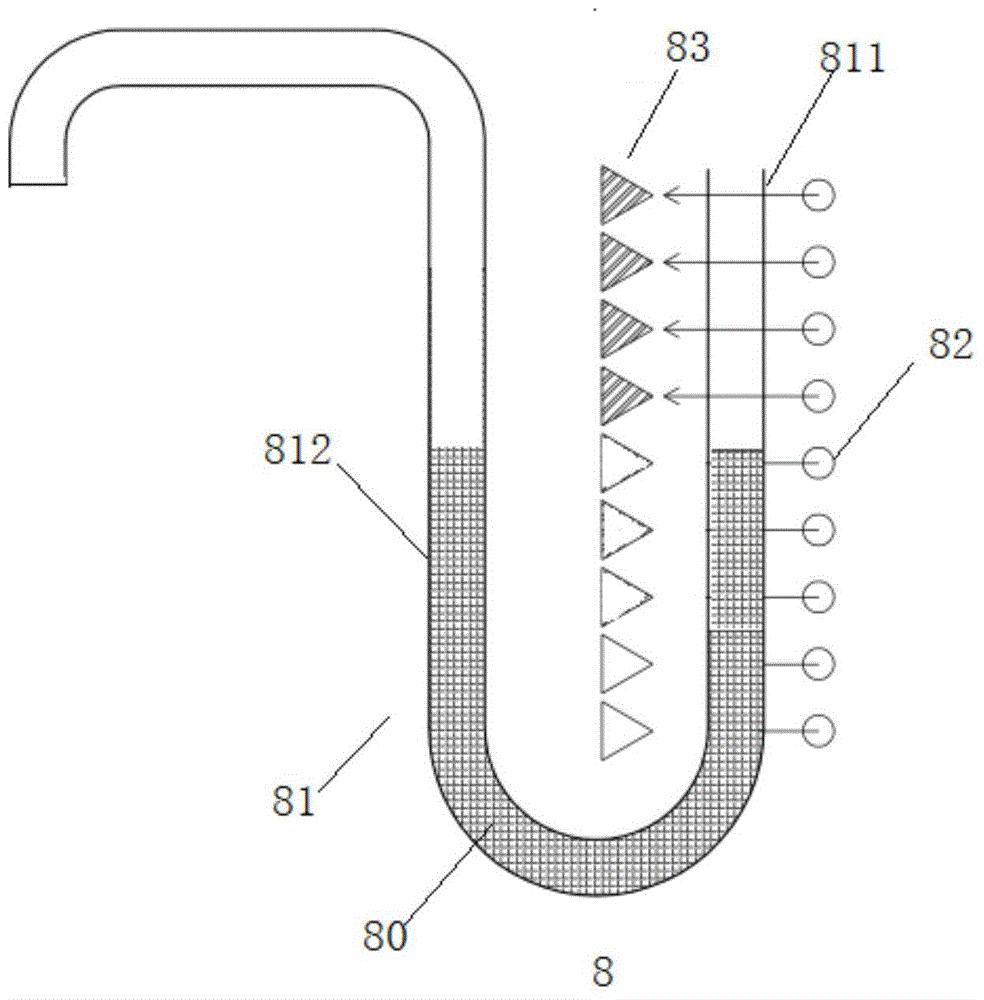

Double-alkali flue gas desulfurization oxidation tank

InactiveCN102580487AReduced corrosion resistance requirementsUniform air volumeDispersed particle separationPorous pipeEngineering

The invention relates to the field of flue gas desulfurization equipment for medium and small coal-fired boilers, and in particular discloses a double-alkali flue gas desulfurization oxidation tank. The double-alkali flue gas desulfurization oxidation tank comprises an aeration region and a settling region which are arranged vertically. The oxidation tank is characterized in that: an oxidation air main pipe and a plurality of primary branched pipes which are uniformly distributed and communicated with the oxidation air main pipe are arranged above the liquid level of the oxidation tank, the primary branched pipes are connected with secondary branched pipes which are uniformly distributed in the aeration region, the secondary branched pipes are connected through flanges, an aerator is arranged at the tail end of each secondary branched pipe, each aerator is a cross porous pipe, a reflecting plate is arranged on the upper part of each aerator, and a flat straight oar type stirrer is arranged in the settling region. The oxidation tank is unique in structure; and through the oxidation tank, air is distributed uniformly, the gas-liquid contact area is enlarged, and the oxidation efficiency is remarkably improved.

Owner:COAL IND JINAN DESIGN & RES

Inorganic salt catalytic synthesis method for 5-hydroxy methyl furfural

InactiveCN105330623ANo emissionsReduce generationOrganic chemistryRotary evaporatorSynthesis methods

The invention discloses an inorganic salt catalytic synthesis method for 5-hydroxy methyl furfural. The method comprises the steps that sugar used as a raw material and inorganic salt used as a catalyst react under the effect of an organic solvent, the mole ratio of the sugar to the inorganic salt is 2:1, the heating temperature in the reaction process is controlled to 100-120 DEG C, the redundant organic solvent is removed through a rotary evaporator after the reaction is performed for 0.5-24 h, a sodium chloride saturated solution is added in, extraction is performed through ethyl acetate, organic phases are collected, and therefore the 5-hydroxy methyl furfural is obtained. Due to the fact that the inorganic salt is used as the catalyst, compared with traditional strong acid and other catalysts, produced by-products are reduced, the requirement for equipment corrosion resistance is greatly lowered, energy is saved, no waste liquid harmful to the environment is drained, and large-scale production produces no influence and damage to the environment.

Owner:CHINA PETROLEUM & CHEM CORP +1

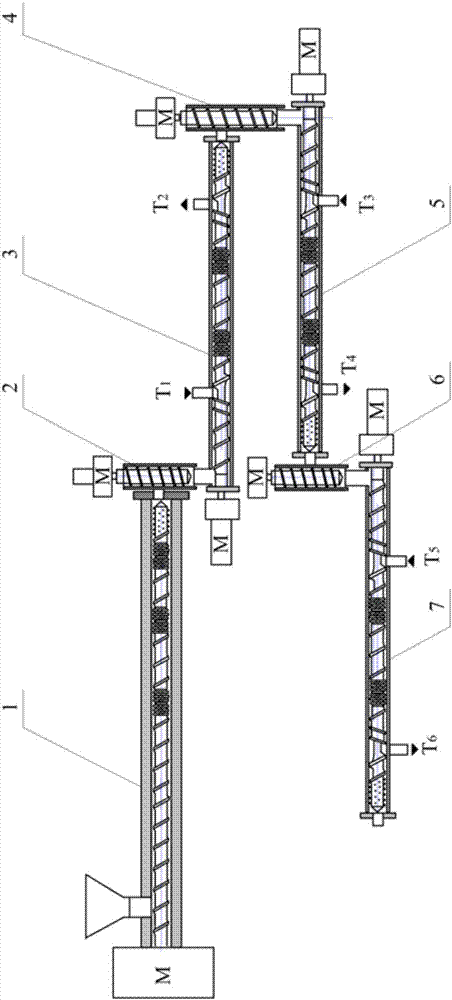

Multi-order screw extrusion type polyolefin halogenation equipment and polyolefin halogenation method

ActiveCN107457935AHalogen atoms are evenly distributedEquipment corrosion resistance requirements are reducedPolyolefinCompound (substance)

The invention provides a multi-order screw extrusion type polyolefin halogenation equipment and a polyolefin halogenation method, and belongs to the field of chemical equipment. The multi-order screw extrusion type polyolefin halogenation equipment comprises N-order extruders connected in series, every two adjacent extruders are connected through a single screw or a screw pump in a closed mode; the inlet end of a machine barrel of each single screw or each screw pump is connected to the extruder head of a last-order extruder, and the outlet end of the machine barrel of each single screw or each screw pump is connected to the extruder tail of a next-order extruder; the screws of the N-order extruders are formed by connecting building block type composite structures in series; a feed port is formed in a first-order extruder; and air inlets and air outlets are formed in the other-order extruders.

Owner:BEIJING UNIV OF CHEM TECH +1

Method for recycling dusty waste gas

InactiveCN104083957AHigh puritySolve the problem of enriching a large amount of dustDispersed particle filtrationEnvironmental engineeringAnti-corrosion

The invention discloses a method for recycling dusty waste gas. The method for recycling the dusty waste gas is characterized by comprising the following steps: firstly introducing the dusty waste gas into a gas-solid separation device, separating dust from gas in the dusty waste gas by using the gas-solid separation device, and collecting the dust; and subsequently introducing the waste gas discharged by the gas-solid separation device into a gas absorbing device, and absorbing the gas in the dusty waste gas through the gas absorbing device. The method for recycling the dusty waste gas is simple and reliable in process; by separating the dust and the gas in the dusty waste gas and then independently recycling the dust and the gas, the corrosion of the device can be reduced, so that the anti-corrosion requirement on the device and the maintenance times of the device can be reduced, and the production cost can be saved.

Owner:HAWK SHANGHAI ENVIRONMENTAL TECH

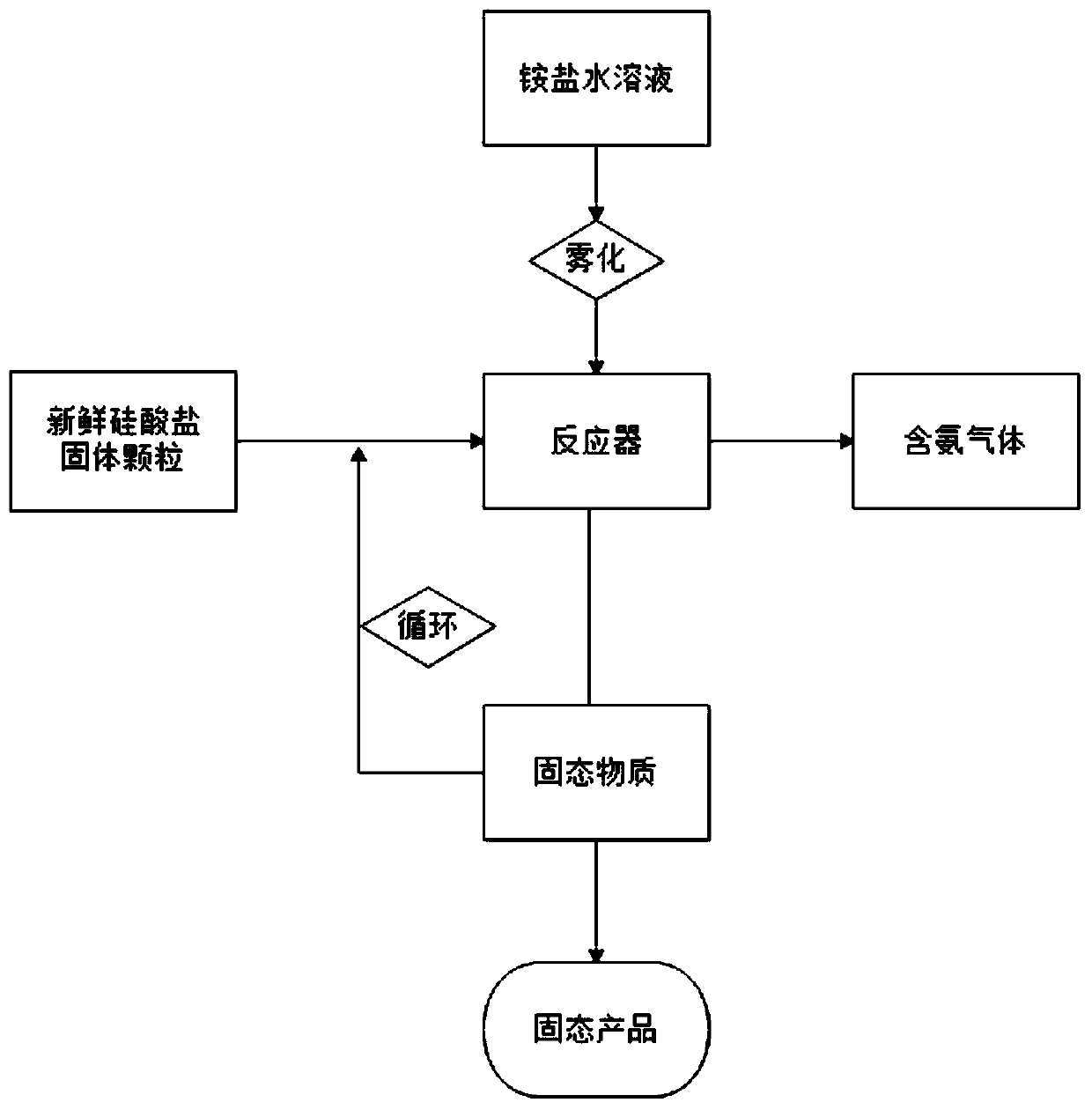

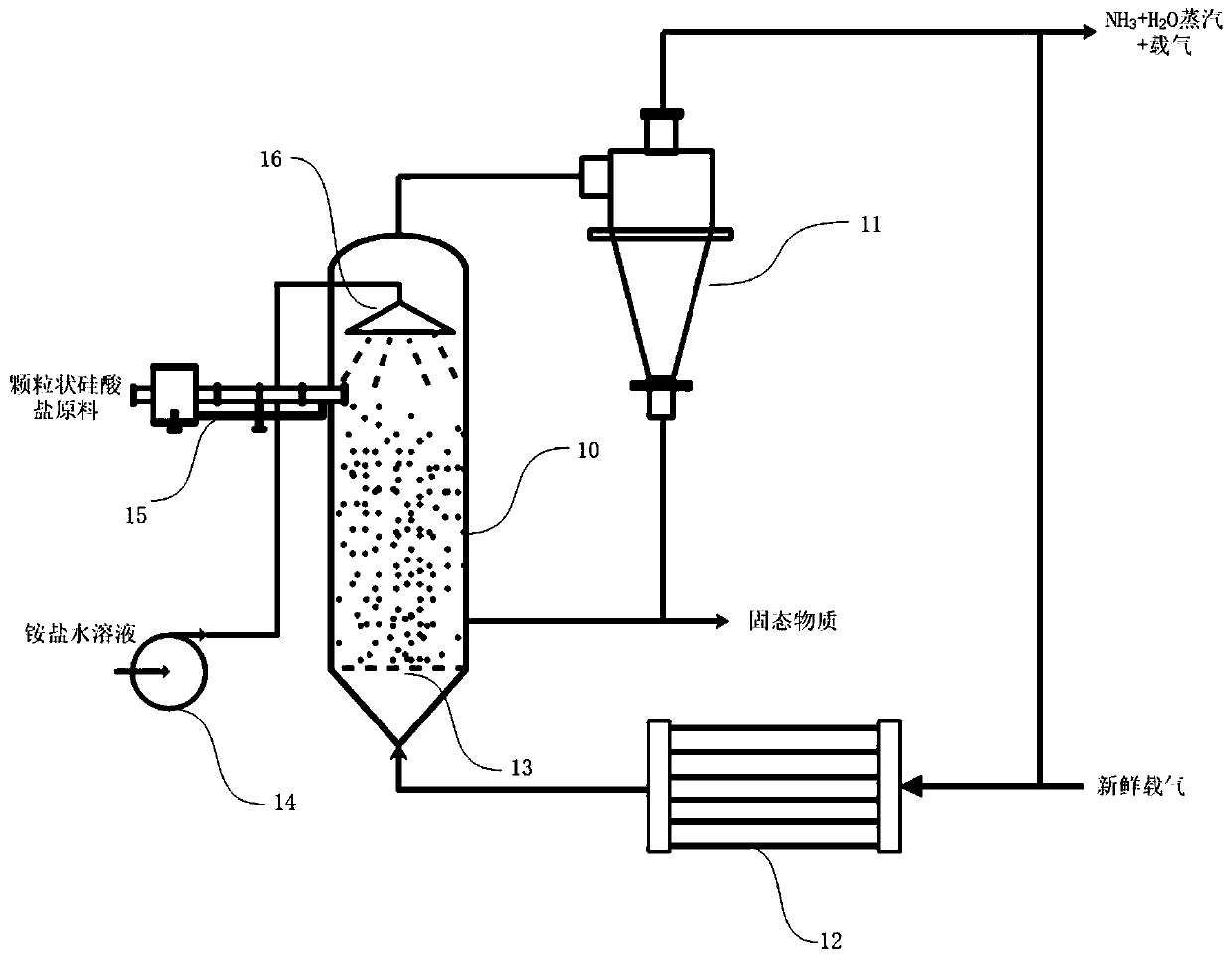

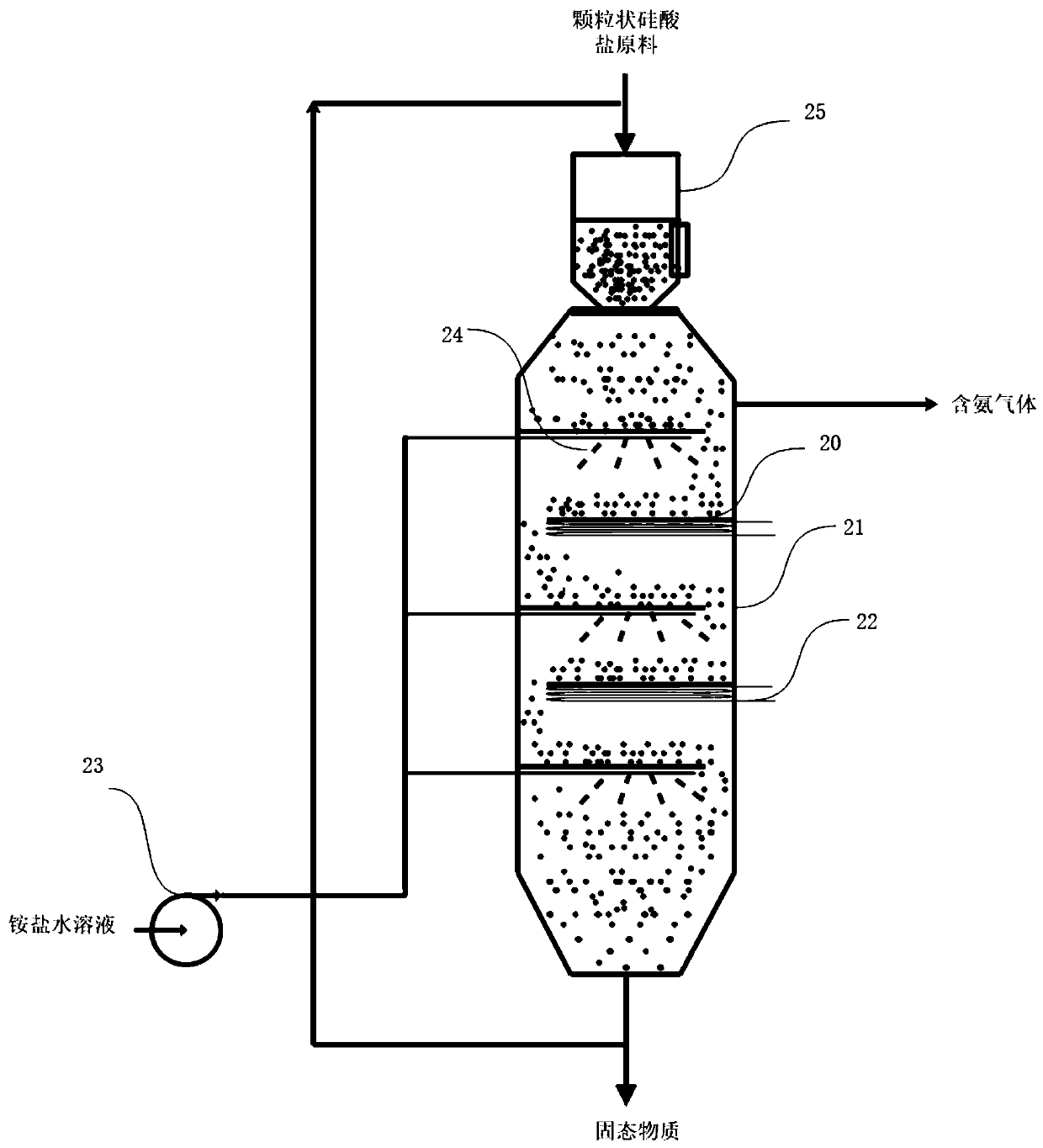

Method used for preparing ammonia gas from ammonium salt and silicate

ActiveCN109956481AReduced corrosion resistance requirementsSolve corrosiveGas generation devicesFeed devicesSolid substrateAqueous solution

The invention discloses a method used for preparing ammonia gas from an ammonium salt and a silicate. The preparation method comprises following steps: an ammonium salt aqueous solution is contacted with a high temperature silicate solid granule bed layer in the form of droplets, reaction is carried out on the surfaces of silicate solid granules to generate ammonia gas and a solid substance, the generated ammonia gas is collected, the solid substance is discharged, a part of the solid substrate is mixed with fresh silicate solid granules, and is subjected to reaction with the droplets of the ammonium salt solution. According to the method used for preparing ammonia gas from an ammonium salt and a silicate, ammonia gas can be produced only through one-step reaction in a preparation device,reaction steps are simplified, operation difficulty is reduced, and it is convenient for industrialized amplify production.

Owner:YUANCHU TECH (BEIJING) CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com