Method for recycling dusty waste gas

A technology for recovery and treatment of waste gas, applied in separation methods, chemical instruments and methods, separation of dispersed particles, etc., can solve the problem of low dust absorption rate, achieve the effects of reducing corrosion resistance requirements, reducing corrosion, and saving production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention is described in detail below in conjunction with accompanying drawing:

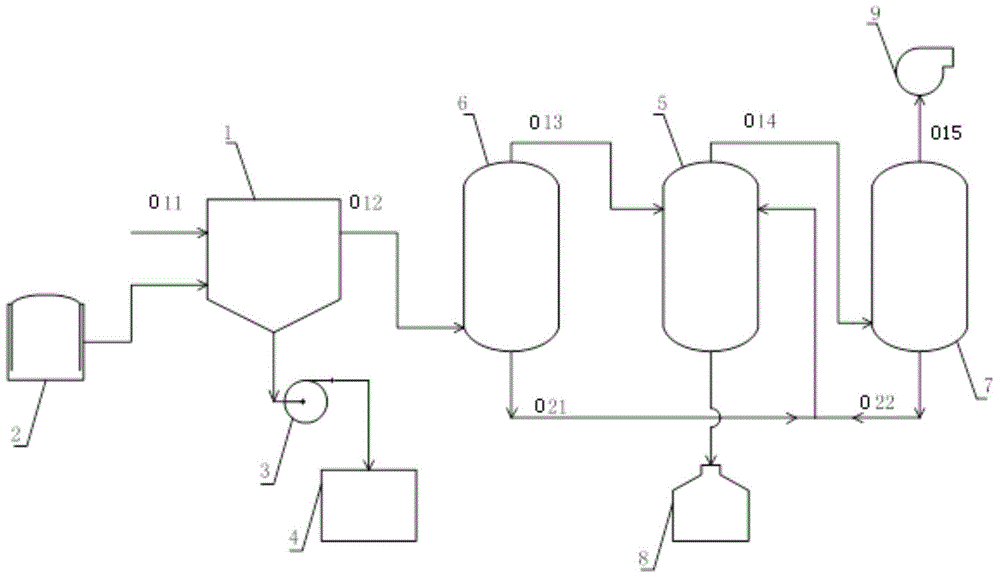

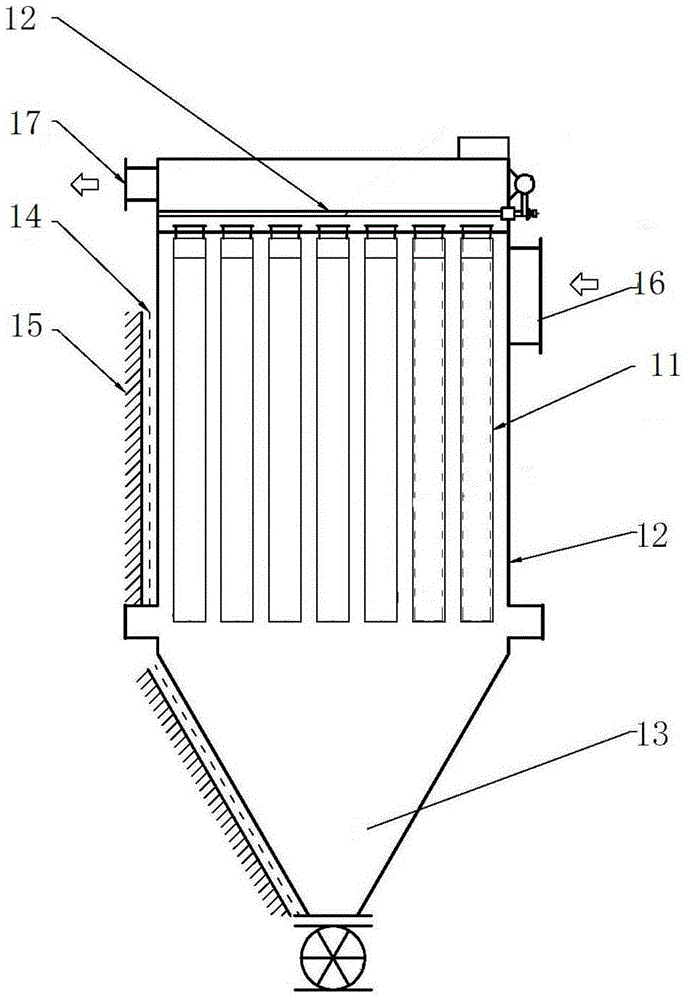

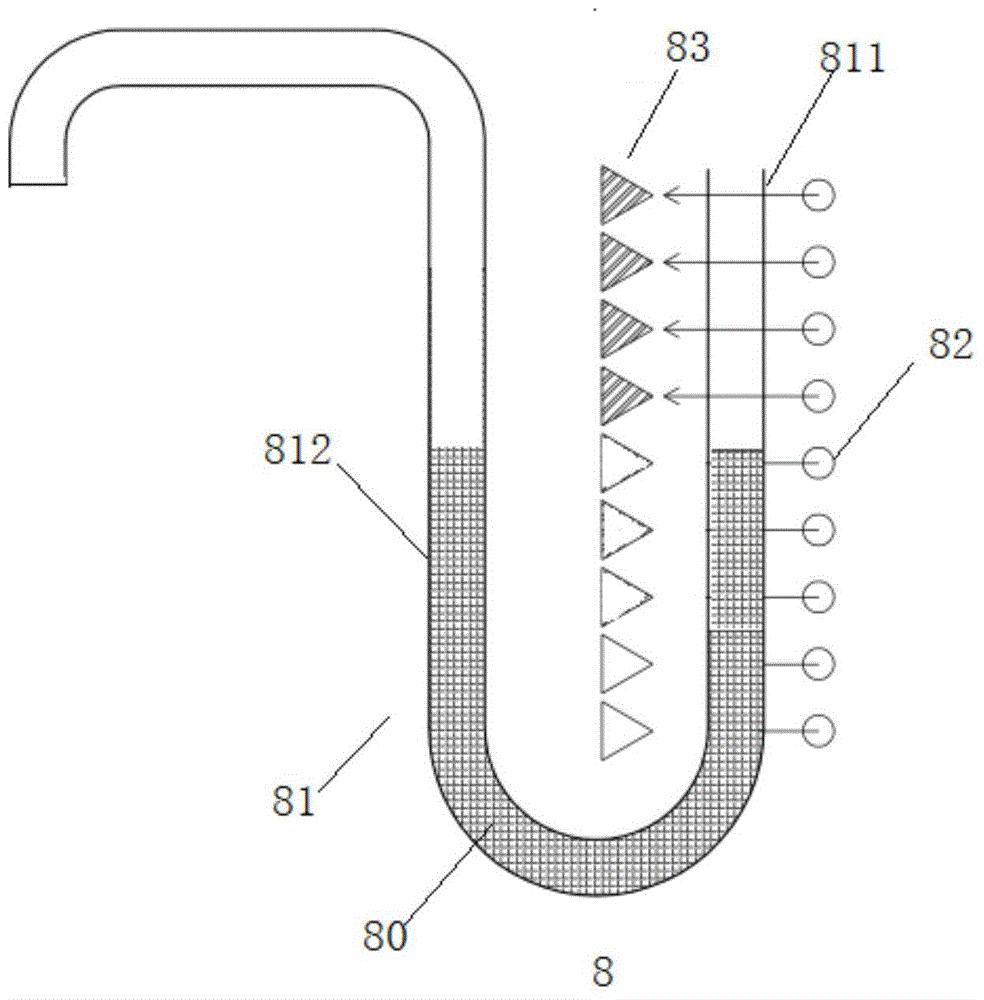

[0044] Such as figure 1 with 2 As shown, the recovery and treatment device for dusty waste gas includes a gas-solid separation device 1 . The gas-solid separation device 1 is used for separating dust and gas in the dust-laden waste gas, and collecting the dust. The separation efficiency of the gas-solid separation device 1 (the SiO collected by the gas-solid separation device 1 per unit time 2 The dust weight accounts for the SiO2 entering the gas-solid separation device 1 per unit time 2 Dust weight percentage) ≥ 99.5%. The gas-solid separation device 1 of the present invention is preferably a bag-type gas-solid separator. The dust in the dusty exhaust gas is intercepted by the filter bag 11 in the bag-type gas-solid separator, and only the gas is allowed to pass through. When the dust on the filter bag 11 is deposited to a certain amount, the compressed air is sprayed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| separation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com