Method and device for refining methanol through dividing wall column combined with heat pump

A dividing wall rectification tower and refined methanol technology, applied in the chemical industry, can solve the problems of low product quality, high energy consumption in the methanol refining process, and large equipment footprint, achieving high purity, remarkable energy-saving effect, and reduced land occupation area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

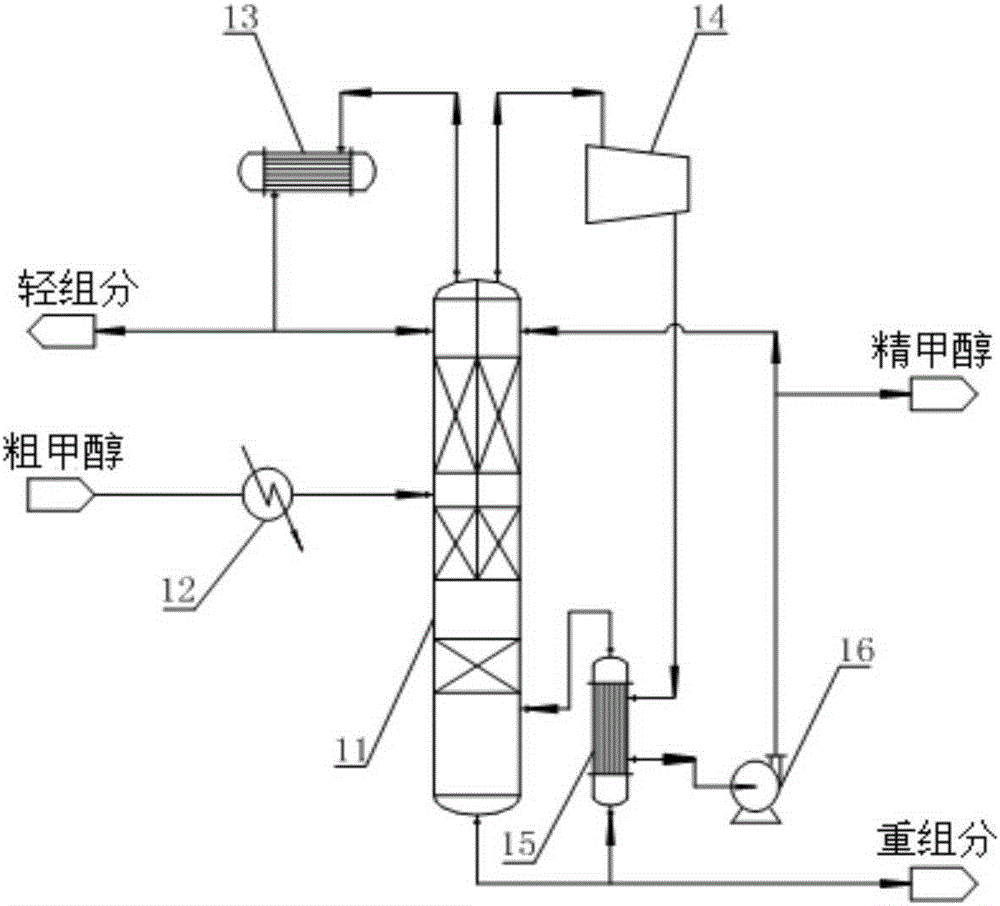

[0045] Such as figure 1 As shown, a device for refining methanol using a dividing wall distillation column combined with heat pump technology, including a crude methanol preheater 12, a dividing wall distillation column 11, a dividing wall distillation column condenser 13, a compressor 14, a dividing wall refiner Distillation column reboiler 15 and refined methanol delivery pump 16. A vertical dividing wall is provided in the dividing wall rectifying column 11, and the height of the dividing wall is 2 / 3 of the total height of the dividing wall rectifying column 11, and the top of the dividing wall extends upwards and is fixed with the top of the dividing wall rectifying column 11. The upper rectification section of the dividing wall rectification column 11 is divided into two parts, the feed side and the non-feed side, wherein the middle part of the tower wall on the feed side is provided with a feed port, and the top of the side tower is provided with a light component discha...

Embodiment 2

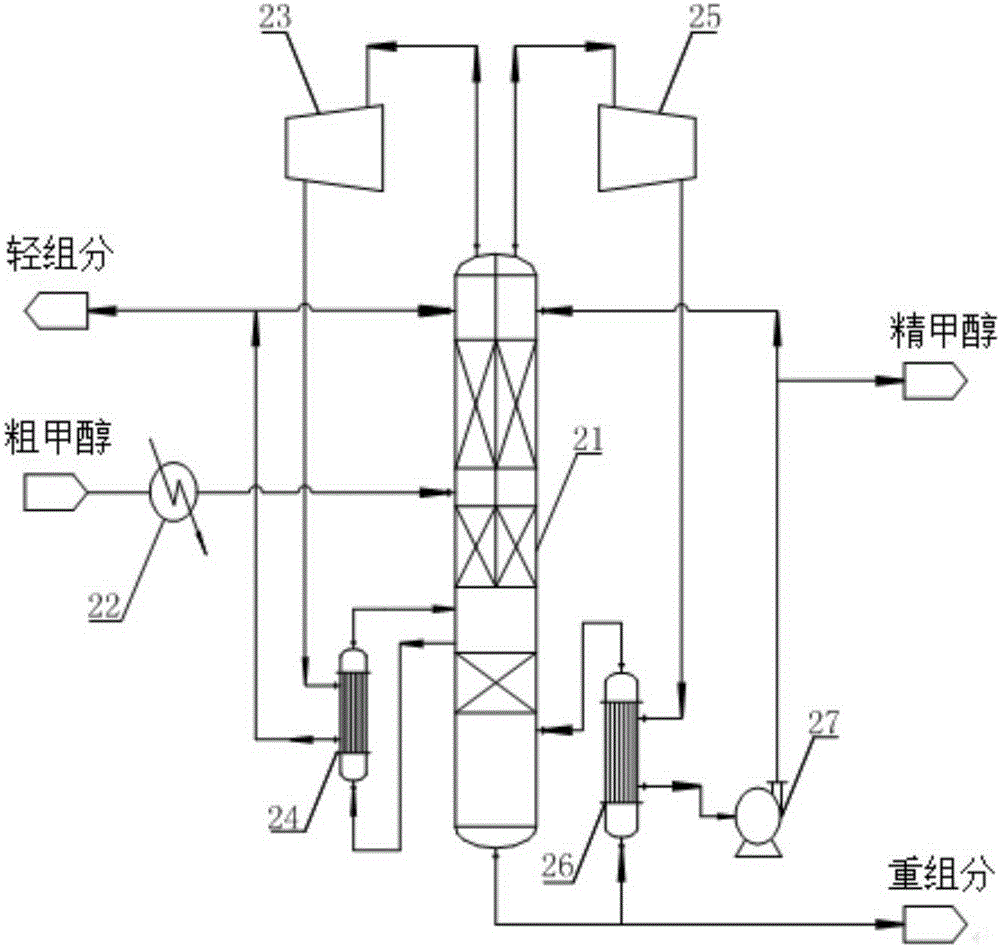

[0057] Such as figure 2 As shown, a device for refining methanol using a dividing wall distillation column combined with heat pump technology, including a crude methanol preheater 22, a dividing wall distillation column 21, a light component compressor 23, an intermediate reboiler 24, and a refined methanol compressor Machine 25, dividing wall rectification column reboiler 26 and refined methanol delivery pump 27. A vertical dividing wall is provided in the dividing wall rectifying tower 21, and the height of the dividing wall is 2 / 3 of the total height of the dividing wall rectifying tower 21, and the top of the dividing wall extends upwards and is fixed with the top of the dividing wall rectifying tower 21. The upper rectification section of the dividing wall rectification column 21 is divided into two parts, the feed side and the non-feed side, wherein the middle part of the tower wall on the feed side is provided with a feed port, and the top of the side tower is provided...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com