Multi-order screw extrusion type polyolefin halogenation equipment and polyolefin halogenation method

A technology of screw extrusion and polyolefin, which is applied in bromination, fluorination of polyolefin, chlorination, and chemical equipment fields, can solve the problems of unfulfilled chlorine content requirements, etc., and achieve the reduction of equipment corrosion resistance requirements, halogen atom evenly distributed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

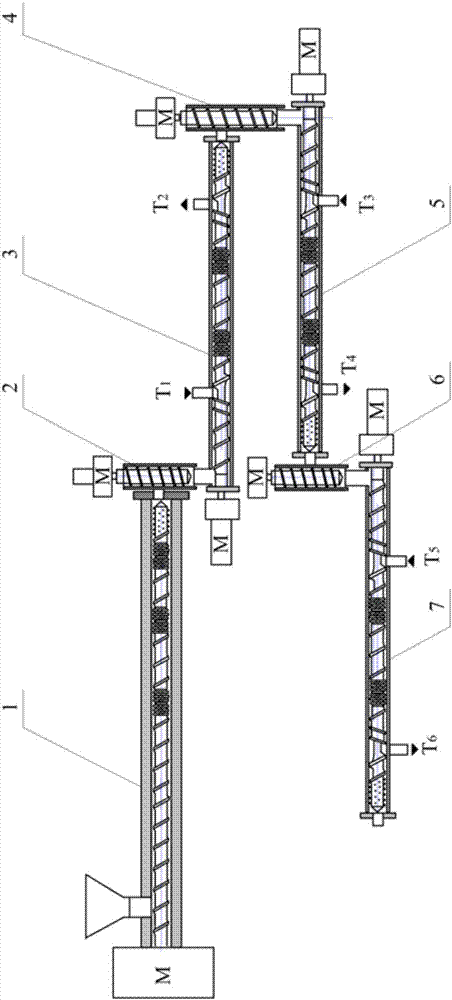

[0073] Such as figure 1 As shown, a schematic diagram of a three-stage screw extrusion halogenation equipment containing structure II.

[0074] The granular or powdery polyolefin to be halogenated is physically blended with other additives (initiator, catalyst, etc.) and then melted, plasticized and uniformly mixed in the twin-screw extruder 1; the diameter of the screw is D, and the ratio of length to diameter is L / D is about 25-35D, preferably 30; the screw and barrel are made of conventional screw extrusion alloy (such as 38CrMoAl), and the surface is nitriding treatment. The mixing section of the screw adopts the combined structure of thread and meshing block. The length of the mixing section is about 5-10D. The front end of the machine head is directly connected to the feeding section of the next-stage halogenation reaction extruder. Pumped to the next stage halogenation extruder 3. Extruder 3 is a parallel twin-screw or triple-screw extruder. The twin-screw extruder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com