Double-alkali flue gas desulfurization oxidation tank

A technology of oxidation pond and double-alkali method, which is applied in separation methods, chemical instruments and methods, and separation of dispersed particles, etc. It can solve the difficulties in the oxidation process of double-alkali desulfurization process, uneven distribution of oxidizing air, and insufficient oxidation efficiency of gypsum, etc. problems, to achieve the effect of ensuring long-term stable operation, improving oxidation efficiency, and increasing the gas-liquid contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

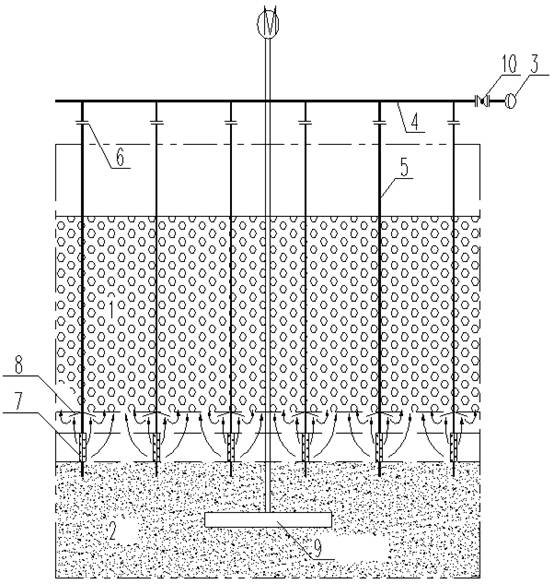

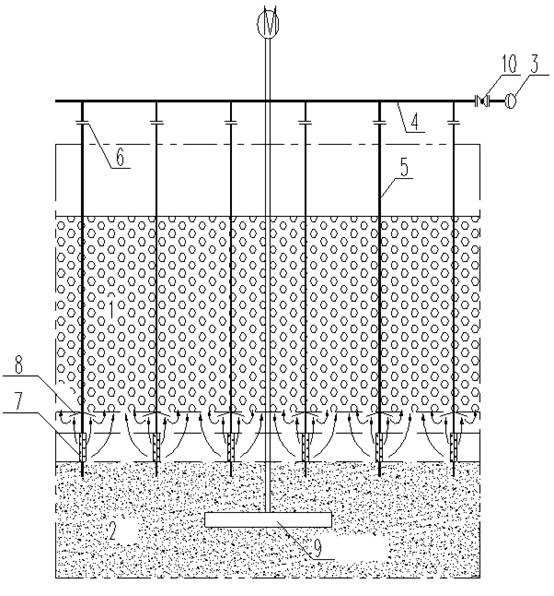

[0016] Accompanying drawing is a kind of specific embodiment of the present invention. This embodiment includes an aeration zone 1 and a settling zone 2 arranged up and down. An oxidation air main pipe 3 and several evenly distributed primary branch pipes 4 connected thereto are arranged above the liquid level of the oxidation tank. The primary branch pipe 4 is connected with The secondary branch pipes 5 evenly distributed in the aeration area 1, the secondary branch pipes 5 are connected by flanges 6, the end of the secondary branch pipes 5 is equipped with an aerator 7, the aerator 7 is a porous pipe with cross openings, and the upper part A reflector 8 is installed, and a straight blade agitator 9 is installed in the sedimentation area 2; a valve 10 is arranged between the oxidation air main pipe 3 and the first-level branch pipe 4; the front pipe of the second-level branch pipe 5 flange 6 It is a carbon steel pipe, and the pipeline behind the flange 6 is a stainless steel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com