Hydrogen bromide purifying device and method

A purification method, hydrogen bromide technology, applied in directions such as hydrogen bromide, bromine/hydrogen bromide, etc., can solve problems such as difficulty in realizing industrialized continuous production, adsorbent desorption, difficulty in recovery, and no more than 2 ppm, etc. Small investment, reduced corrosion resistance requirements, and the effect of reducing dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

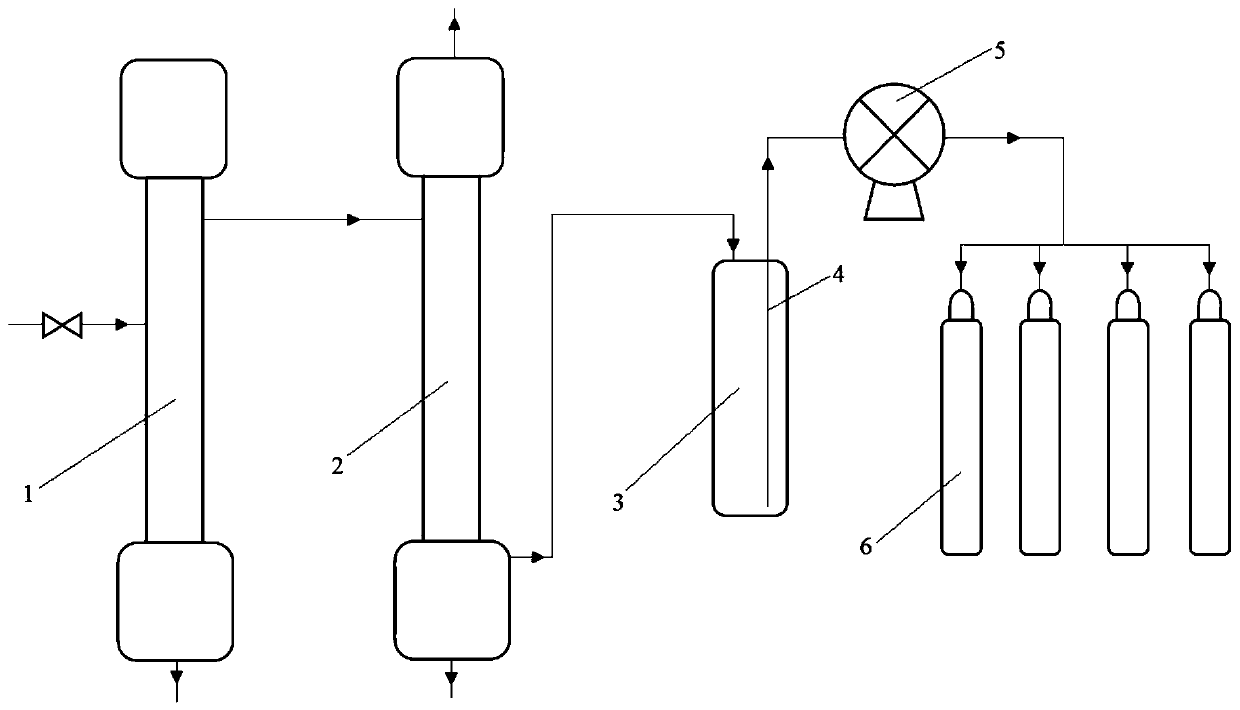

[0043] In this embodiment, the weight removal tower 1 and the light removal tower 2 are packed towers, the weight removal tower 1 is 8m high, 0.5mm in diameter, 40 theoretical plates, and has a built-in diameter of 5mm θ ring packing. Among them, the light removal tower 2 is 8m high, 0.5mm in diameter, 30 theoretical plates, and has a built-in 5mm diameter θ ring packing. The feed pipeline and de-weight tower 1 are made of Hastelloy, and the de-light tower 2, product collector 3 and filling bottle 6 are made of stainless steel. Filling pump 5 adopts diaphragm pump.

[0044] The hydrogen bromide crude product flow rate is 30L / min.

[0045] The parameters of weight removal column 1 are set as follows: column temperature -15°C, pressure 0.9MPa, reflux ratio 20. In this state, the hydrogen bromide vaporizes and rises, and the heavy components such as water condense and collect in the bottom of the de-weighting tower in liquid or solid form to realize the removal of heavy compone...

Embodiment 2

[0049] In this embodiment, the weight removal tower 1 is 14 mm high, 1 m in diameter, 60 theoretical plates, and has a built-in Pall ring packing with a diameter of 25 mm. Light removal tower 2 is 14m high, 1m in diameter, 60 theoretical plates, and has a built-in Raschig ring packing with a diameter of 25mm. The feed pipeline and weight removal tower 1 are made of Hastelloy. Bottling 6 is in stainless steel. Filling pump 5 adopts diaphragm pump.

[0050] The hydrogen bromide crude product flow rate is 30L / min.

[0051] The parameters of weight removal tower 1 are set as follows: column temperature -64°C, pressure 0 MPa, reflux ratio 80.

[0052] The parameters of light removal tower 2 are set as follows: column temperature -70°C, pressure 0 MPa, reflux ratio 200.

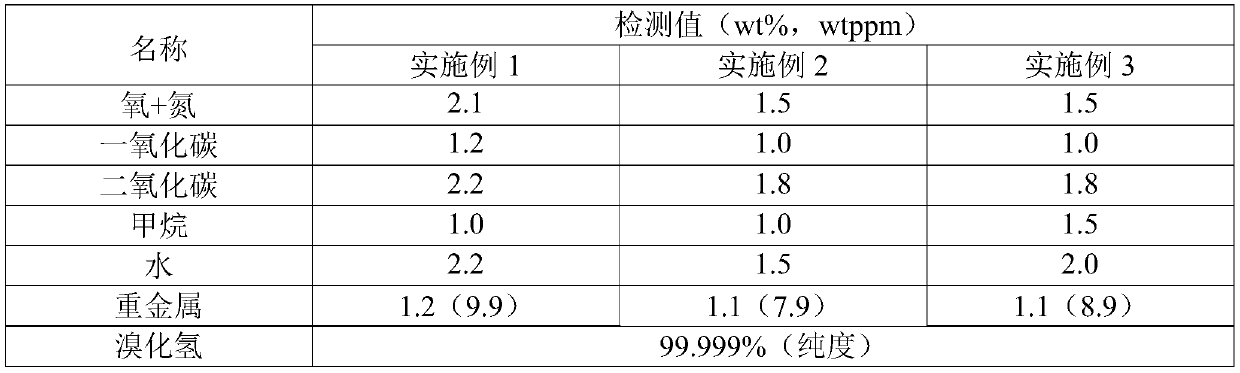

[0053] After testing, the main components and contents of hydrogen bromide after purification are shown in Table 2.

Embodiment 3

[0055] In this embodiment, the weight removal tower 1 is 6 mm high, 0.1 m in diameter, 40 theoretical plates, and has a built-in Pall ring packing with a diameter of 3 mm. Light removal tower 2 is 6m high, 0.1m in diameter, 30 theoretical plates, and has a built-in Raschig ring packing with a diameter of 3mm. The filling bottle 6 is made of stainless steel. Filling pump 5 adopts diaphragm pump.

[0056] The hydrogen bromide crude product flow rate is 30L / min.

[0057] The parameters of weight removal tower 1 are set as follows: column temperature 30°C, pressure 2.3MPa, reflux ratio 80.

[0058] The parameters of light removal tower 2 are set as follows: column temperature 20°C, pressure 2.3MPa, reflux ratio 280.

[0059] After testing, the main components and contents of hydrogen bromide after purification are shown in Table 2.

[0060] Table 2

[0061]

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com