Method for producing guaiacol with methanol method

A technology of guaiacol and methanol method, which is applied in the direction of ether preparation, chemical instruments and methods, dehydration of hydroxyl-containing compounds to prepare ether, etc., which can solve the problem of low catalyst recycling efficiency, unable to meet the growing demand, and methyl chloride gas Environmental pollution and other problems, to achieve the effect of low equipment investment and operating costs, short response time, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] 1) Add catechol 2.5g, solid acid catalyst (phosphomolybdic acid supported on aluminum phosphorus molecular sieve) and methanol into the autoclave respectively, tighten the autoclave, and heat, stir and reflux at 200°C for 1 hour, stop the reaction, and naturally cool down.

[0025] Wherein, the mol ratio of pyrocatechol and methyl alcohol is 1: 10, and the addition of solid acid catalyst is 1% of total system mass;

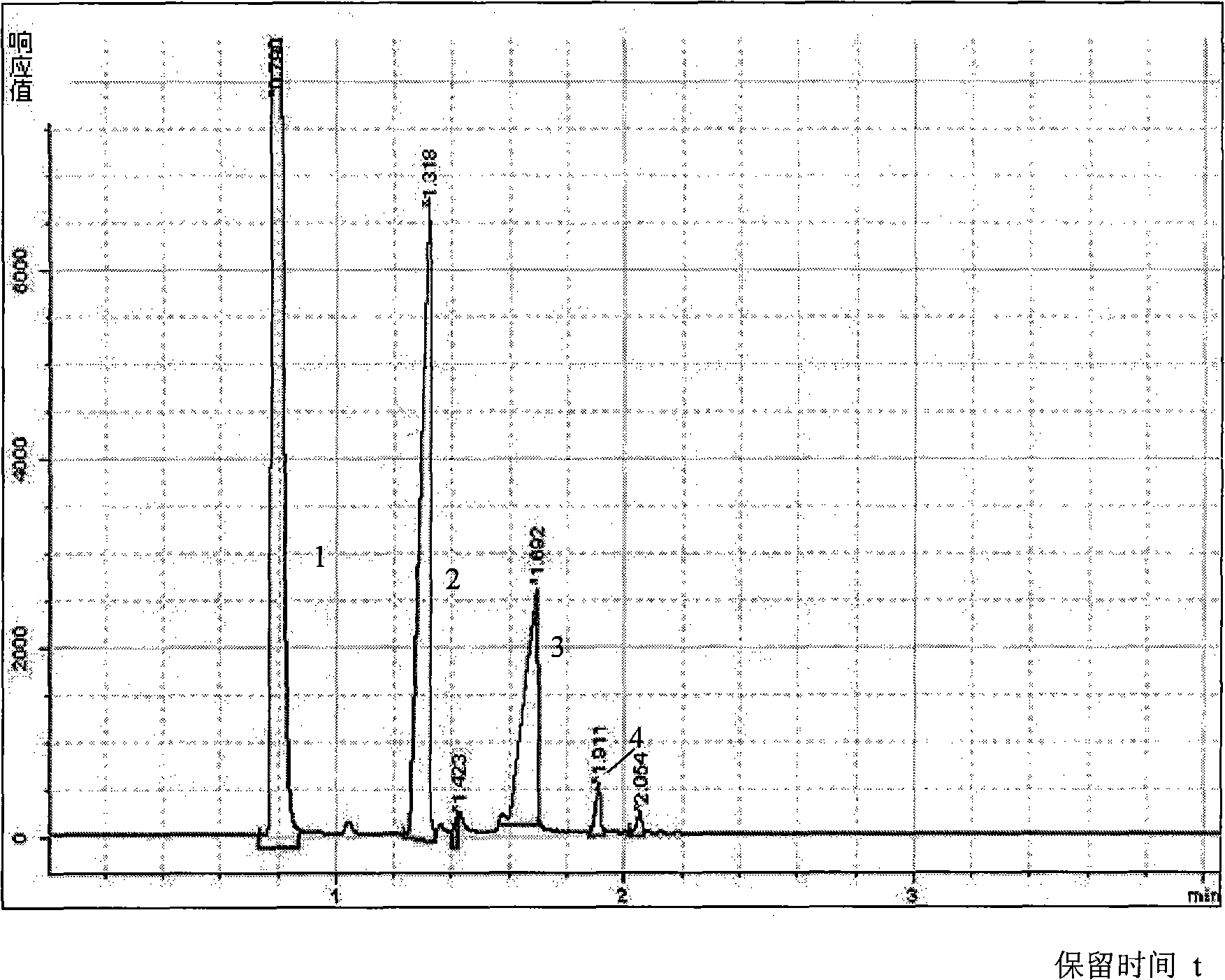

[0026] 2) The catalyst in the reaction solution is filtered out and recovered, and the filtrate is simply distilled to distill methanol and water to obtain a mixture of catechol, guaiacol and by-products. The mixture was added to toluene to make it liquid and analyzed by gas chromatography to obtain a mixture of catechol, guaiacol and by-products. The mixture was added to toluene to make it liquid, and analyzed by gas chromatography, the yield of guaiacol was 35.12%, the selectivity was 87.22%, and the conversion rate was 40.26%. The mixture of distilled ...

Embodiment 2

[0028] 1) Add 2.5g of catechol, solid acid catalyst (phosphotungstic acid supported on silica) and methanol into the autoclave respectively, tighten the autoclave, and heat, stir and reflux at 220°C for 4h. The mol ratio of diphenol and methyl alcohol is 1: 16, and the add-on of solid acid catalyst is 6% of total system quality;

[0029] 2) The catalyst in the reaction solution is filtered out and recovered, and the filtrate is simply distilled to distill methanol and water to obtain a mixture of catechol, guaiacol and by-products. The mixture was added to toluene to make it liquid, and analyzed by gas chromatography, the yield of guaiacol was 28.80%, the selectivity was 89.02%, and the conversion rate was 32.35%. The mixture of distilled methanol and water is then separated and extracted with toluene and water, the upper layer is the toluene layer containing guaiacol, and the toluene is distilled off to obtain guaiacol with a product purity greater than 95%.

Embodiment 3

[0031] 1) Add 2.5g of catechol, solid acid catalyst (zirconium sulfate tetrahydrate supported on activated carbon, hereinafter represented by ZS / AC) and methanol into the autoclave, tighten the autoclave, and heat, stir and reflux at 240°C 4h, wherein, the mol ratio of catechol and methanol is 1: 16, and the addition amount of solid acid catalyst is 6% of total system quality;

[0032] 2) The catalyst in the reaction solution is filtered out and recovered, and the filtrate is simply distilled to distill methanol and water to obtain a mixture of catechol, guaiacol and by-products. The mixture was added to toluene to make it liquid, and analyzed by gas chromatography, the yield of guaiacol was 80.91%, the selectivity was 90.29%, and the conversion rate was 89.61%. The mixture of distilled methanol and water is then separated and extracted with toluene and water, the upper layer is the toluene layer containing guaiacol, and the toluene is distilled off to obtain guaiacol with a p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com