Patents

Literature

39results about How to "Slow down the electrode reaction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Clean-type metal surface treatment agent

InactiveCN104818491APrevent metal corrosionSlow down the electrode reactionMetallic material coating processesIonYttrium

The invention discloses a clean-type metal surface treatment agent which is composed of the following raw materials, by weight, 0.1-0.2 part of propanamide, 2-3 parts of glycerin, 4-6 parts of sericin, 0.05-0.1 part of yttrium nitrate hexahydrate, 0.4-1 part of a silane coupling agent KH-550, 150-200 parts of water, 0.1-0.2 part of 2,6-Di-tert-butyl-4-methylphenol, 0.01-0.02 part of potassium hydroxide, 4-6 parts of triisopropanolamine, 0.7-1 part of didecyldimethyl ammonium bromide, 0.1-0.13 part of p-toluenesulfonhydrazide and 2-3 parts of disodium hydrogen phosphate. After hydrolysis of the added silane, an adsorption type film can be formed on metal surface so as to isolate water molecules and oxygen molecules in the environment, thus having a protective effect. The rare earth metal ions and OH- generated by oxygen absorption corrosion of the metal substrate surface undergo complexing to generate insoluble complexes which can help enhance stability of the formed film and improve effects of rust protection and corrosion inhibition.

Owner:BENGBU TIMES ELECTRONICS

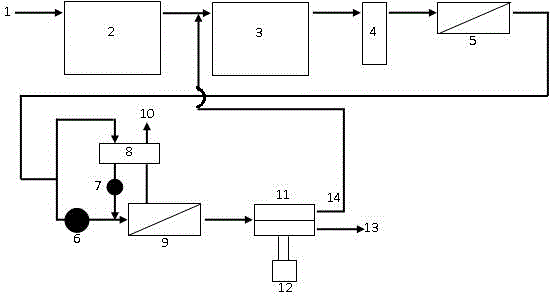

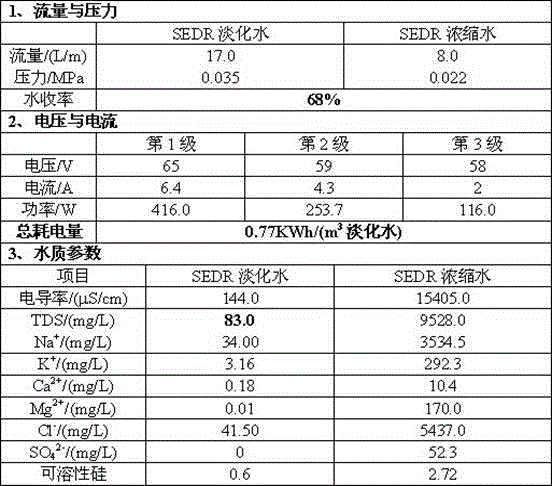

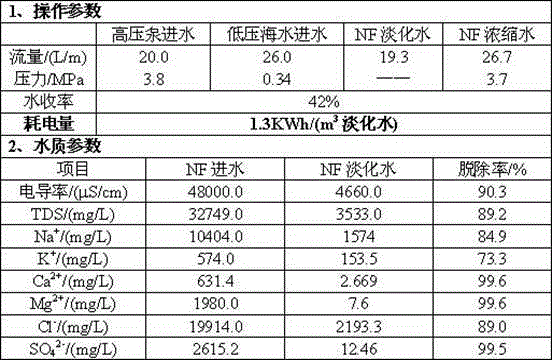

Seawater desalination method for integrated membrane process

ActiveCN104909503AImprove conductivitySlow down the electrode reactionSeawater treatmentMultistage water/sewage treatmentUltrafiltrationHigh energy

The invention provides a seawater desalination method for an integrated membrane process and belongs to a water desalination technology. Aiming at the defects of high investment, high pressure, high energy consumption and the like in an existing membrane-method seawater desalination process, 'nanofiltration / electrodialysis reversal' is taken as a core desalination process, wherein during nanofiltration, a high-desalination nanofiltration membrane with desalination ratio of 90% is adopted; during electrodialysis reversal, a thin-type electrode chamber is filled with a multistage multi-section energy-saving electroosmosis device provided with mixed-bed ion exchange resin. Seawater raw water is sequentially pretreated by virtue of a coagulative precipitation tank, a settling tank, a sand filter and an ultrafiltration membrane, and then is subjected to graded desaltination sequentially by virtue of a nanofiltration desalination device with an energy recovery device, and an energy-saving frequent electrodialysis reversal device; nanofiltration and energy-saving electrodialysis are respectively performed at low operation pressures which do not exceed 3.8MPa and 0.4MPa; the salt content of water produced by the system is 80-250mg / L, the total desalinization ratio can be mechanically regulated within a range of 99-99.75%, the body power consumption of per ton of water does not exceed 2.15KWh / m<3>, the investment and energy consumption of the whole seawater desalination process are obviously reduced, and the process operation is relatively safe and stable.

Owner:天津中领水系统技术有限公司

Gas-phase slow-release antirust oil

Disclosed gas-phase slow-release antirust oil is composed of the following raw materials in parts by weight: 2-4 parts of dicyclohexylammonium nitrite, 0.1-0.2 part of hydroxy oximido acid, 3-5 parts of lanolin, 3-5 parts of hydrogenated castor oil, 1-3 parts of urotropine, 1-2 parts of coconut diethanolamide, 1-2 parts of calcium ricinolate, 1-2 parts of dibutyl phthalate, 0.2-0.5 part of allylthiourea, 0.4-1 part of zinc dialkyl dithiophosphate, 60-70 parts of 250sn base oil, 1-2 parts of mannitol, 4-6 parts of antirust agent T706, and 3-5 parts of film-forming machine oil. The added film-forming machine oil pentaerythrityl oleate possesses excellent lubricity and good surface film-forming property, and is capable of obviously improving the film-forming effect of a finished product and reducing film-forming temperature after being blended with 2,2,4-trimethyl-1,3-pentanediolmono(2-methylpropanoate) for modification; and the added rare earth lanthanum ion is capable of reacting with OH<-> generated in an oxygen-absorption corrosion process on a metal base material surface so as to generate an indissoluble complex, helps to alleviate corrosion electrode reaction and gives play to extremely good slow release effect.

Owner:ANHUI RONGDA VALVE

Antirust oil for metal pipelines

The invention discloses an antirust oil for metal pipelines, which is prepared from the following raw materials in parts by weight: 16-20 parts of rare-earth antirust hydraulic oil, 60-80 parts of 20# machine oil, 1-3 parts of dimethyl chlorophthalate, 3-7 parts of asphalt, 1-2 parts of N,N-bis(2-cyanoethyl)formamide, 2-3 parts of polyoxyethylene stearate, 1-2 parts of sorbitan fatty acid ester, 1-3 parts of methyl benzotriazole, 0.5-1 part of zinc naphthenate, 0.1-3 parts of santobrite, 0.3-1 part of stannous sulfate and 0.4-1 part of thiosinamine. The rare-earth antirust hydraulic oil is added into the antirust oil. The alkyl ketone dispersion solution can improve the flowability and enhance the reaction activity. The added rare-earth ions can generate an insoluble complex with OH- generated in the oxygen-absorption corrosion process on the metal substrate surface, thereby decelerating the corrosive electrode reaction and having favorable slow-release effect.

Owner:HEFEI ZHENGTUO DECORATION MATERIALS CO LTD

Copper and copper alloy dedicated metal surface treatment agent

InactiveCN104818479APlay a protective effectHigh tensile strengthMetallic material coating processesPotassium perfluorobutanesulfonateSodium bicarbonate

The invention discloses a copper and copper alloy dedicated metal surface treatment agent which is composed of the following raw materials, by weight, 2-3 parts of mercaptobenzothiazole, 0.8-1.2 parts of ferrous sulphate, 0.1-0.2 part of dimethyl acetamide, 10-15 parts of polyvinyl alcohol, 0.01-0.02 part of p-hydroxybenzoic acid, 4-6 parts of sericin, 0.07-0.1 part of boric acid, 0.05-0.1 part of yttrium nitrate hexahydrate, 0.4-1 part of a silane coupling agent KH-550, 2-3 parts of barium petroleum sulfonate, 0.3-0.4 part of phytosterol, 160-200 parts of water, 0.5-1 part of potassium perfluorobutanesulfonate and 0.6-1 part of sodium bicarbonate. According to the invention, water-soluble polymer polyvinyl alcohol and sericin are mixed, and then silanization treatment is carried out. After hydrolysis of silane, an adsorption type film can be formed on metal surface so as to isolate water molecules and oxygen molecules in the environment, thus having a protective effect. Through boric acid modification, tensile strength and heat stability of blend films can be enhanced.

Owner:BENGBU TIMES ELECTRONICS

Rust-proof oil for metal processing molding

InactiveCN104450023AGood compatibilityImprove film formationLubricant compositionDiacetone alcoholSodium acetate

The invention discloses rust-proof oil for metal processing molding. The rust-proof oil comprises the following raw materials in parts by weight: 2-3 parts of sulfurized olefin cottonseed oil T405, 2-3 parts of calcium stearyl lactylate, 1-2 parts of diacetone alcohol, 70-80 parts of 400sn base oil, 2-3 parts of polyglycerol fatty acid ester, 2-4 parts of ethylene carbonate, 2-6 parts of lanolin, 2-3 parts of magnesium ethoxylate, 1-2 parts of fatty alcohol polyoxyethylene ether, 1-2 parts of sodium diacetate, 1-2 parts of 6-tert-butyl-o-cresol, 1-2 parts of phenethanolamine, 2-3 parts of trihexyl trimellitate and 10-20 parts of rare earth corrosion-inhibiting hydraulic oil. The rare earth corrosion-inhibiting hydraulic oil is added to the rust-proof oil; by mixing polyepoxysuccinic acid and phosphate, good synergistic effect can be played and stable corrosion-inhibiting function is achieved; by the aluminosilicate sol, the compatibility among various materials can be promoted and the film-forming effect of a finished product is improved; the added rare earth ions can be reacted with OH<-> generated during the oxygen absorption corrosion process on the surface of a metal substrate to produce an insoluble complex and the electrode reaction of the corrosion is slowed so as to achieve very good slow-release effect.

Owner:HEFEI ZHENGTUO DECORATION MATERIALS CO LTD

Rotproof and rustproof metal oil

The invention discloses rotproof and rustproof metal oil. The rotproof and rustproof metal oil is composed of the following raw materials in parts by weight: 1-2 parts of nitrilotriacetic acid, 50-60 parts of 500 sn base oil, 10-15 parts of kerosene, 2-3 parts of ethylenediamine tetraacetic acid copper disodium salt, 1-2 parts of fatty alcohol polyoxyethylene ether ammonium sulfate, 2-3 parts of dimethyl glutarate, 1-3 parts of tebelon, 2-4 parts of lanum, 0.8-2 parts of potassium citrate, 0.1-2 parts of isotridecyl alcohol ethoxylate, 0.4-1 part of dialkyl diphenol, 1-2 parts of diammonium hydrogen phosphate and 12-20 parts of rear earth corrosion inhibition hydraulic oil. The rear earth corrosion inhibition hydraulic oil is added in the rustproof oil disclosed by the invention; cis-epoxysuccinic acid is mixed with phosphate to play a good synergistic effect and ensure a stable corrosion inhibition function; the silicon aluminum sol can promote the compatibility of the materials and perfect the film forming effect of the finished product; the added rear earth ions can generate an insoluble complex with OH<-> generated in an oxygen uptake corrosion process with the surface of a metal base material, in order to alleviate the corrosion electrode reaction to play a good slow release effect.

Owner:HEFEI ZHENGTUO DECORATION MATERIALS CO LTD

Antibacterial anticorrosive metal surface treatment agent

InactiveCN104818477APlay a protective effectHigh tensile strengthMetallic material coating processesSodium PyrithioneSilanes

The invention discloses an antibacterial anticorrosive metal surface treatment agent which is composed of the following raw materials, by weight, 0.4-0.6 part of hydrolytic polymaleic anhydride, 0.02-0.04 part of triglyceride, 10-15 parts of polyvinyl alcohol, 4-6 parts of sericin, 0.07-0.1 part of boric acid, 0.05-0.1 part of yttrium nitrate hexahydrate, 0.4-1 part of a silane coupling agent KH-550, 160-200 parts of water, 0.1-0.2 part of calcium ascorbate, 1-2 parts of coco fatty acid diethanolamide, 0.2-1 part of zinc pyrithione, 0.1-0.3 part of Casson and 0.08-0.1 part of dimethicone. According to the invention, water-soluble polymer polyvinyl alcohol and sericin are mixed, and then silanization treatment is carried out. After hydrolysis of silane, an adsorption type film can be formed on metal surface so as to isolate water molecules and oxygen molecules in the environment, thus having a protective effect. Through boric acid modification, tensile strength and heat stability of blend films can be enhanced.

Owner:BENGBU TIMES ELECTRONICS

Hard film anti-rusting oil for railway wheel hub

The invention discloses hard film anti-rusting oil for a railway wheel hub. The hard film anti-rusting oil is prepared from the following raw materials in parts by weight: 0.5-1 part of geranyl butyrate, 2-3 parts of propylene glycol monomethyl ether, 3-5 parts of wood creosote oil, 4-6 parts of dodecencylsuccinic acid, 2-3 parts of sucrose acetate isobutyrate, 1-2 parts of isopropyl palmitate, 70-80 parts of 120# solvent oil, 0.6-1 part of dialkyl p-diphenol, 1-2 parts of sodium carboxymethyl cellulose, 0.4-1 part of ammonium trimolybdate, 0.6-1 part of an antioxidant DLTP, 3-5 parts of sodium myrastate, 3-4 parts of rosin, and 5-6 parts of anti-stripping mechanical oil. The added film-forming mechanical oil and pentaerythritol oleate have excellent lubricating property and good surface film-forming property, and are mixed and modified with 2,2,4-trimethyl-1,3-pentanediol monoisobutyrate, so that the film-forming effect of a finished product can be obviously improved and the film-forming temperature is lowered; the added rear-earth lanthanum ion can react with OH<-> produced in an oxygen absorption corrosion process on a metal base material surface to produce an insoluble complex, so that the corrosion electrode reaction is retarded to achieve a good slow release effect.

Owner:WUHU HONGKUN AUTO PARTS

Metal rust-removing and rust-preventing mixed oil

InactiveCN104611099AImprove adhesionImprove thermal stabilityLubricant compositionPolyesterPhosphate

The invention discloses metal rust-removing and rust-preventing mixed oil. The metal rust-removing and rust-preventing mixed oil is composed of the following raw materials in parts by weight: 1-2 parts of trithiocyanuric acid, 0.1-0.2 parts of epoxy propane, 30-40 parts of 150sn basic oil, 30-40 parts of kerosene, 4-6 parts of acetylated lanolin, 3-4 parts of polypropylene adipate, 2-7 parts of natural latex, 2-4 parts of capric triglyceride, 1-2 parts of disodium hydrogen phosphate, 1-2 parts of sorbitan mono-oleic acid ester, 1-2 parts of zinc naphthenate, 0.4-1 part of 8-hydroxyquinoline, 0.1-0.3 part of dodecyl dimethylamine and 3-5 parts of anti-wear machine oil. The anti-wear machine oil added in the rust-preventing oil disclosed by the invention is capable of forming a molecular directional adsorption film on the surface of a metal to reduce friction, and the obtained modified terpene resin is good in caking property, high in heat stability, capable of promoting compatibility among the materials, and capable of enhancing the adhesive force of a coating film; zinc dihydrogen phosphate is used as a common metal surface treatment agent, and has great rust-removing and rust-preventing effects; the added rare-earth lanthanum ions are capable of generating insoluble complexes with the OH- generated during an oxygen absorption corrosion process carried out on the surface of a metal base material, thus slowing down the electrode reaction of corrosion and playing a great controlled-release effect.

Owner:ANHUI KING AUTO ELECTRONICS TECH CO LTD

Antirust oil for storage of engine

InactiveCN104450027AGood compatibilityImprove film formationLubricant compositionBenzoic acidPhosphorous acid

The invention discloses antirust oil for storage of an engine. The antirust oil consists of the following raw materials in parts by weight: 2-3 parts of polyisobutene, 60-70 parts of aviation lubricating oil, 0.6-2 parts of ephedrine, 2-3 parts of di-n-butyl phosphite, 3-5 parts of polyphthalate, 1-3 parts of acrylic acid, 1-2 parts of beta-naphthylamine, 1-2 parts of cyclohexylamine benzoate, 2-4 parts of polyglycerol fatty acid ester, 2-5 parts of barium petroleum sulfonate, 0.5-1 part of trioctyl phosphate, 0.3-0.6 part of zinc acetylacetone, 0.2-0.5 part of methyl silicone oil and 12-20 parts of rare-earth anticorrosive hydraulic oil. The rare-earth anticorrosive hydraulic oil is added to the antirust oil disclosed by the invention; by mixing polyepoxysuccinic acid and phosphate, the antirust oil is excellent in synergistic effect an stable in anticorrosive function; by virtue of silicon-aluminum sol, the compatibility among various materials is promoted and the film forming effect of a finished product is improved; the added rare-earth ions can react with OH<-> generated from oxygen absorption corrosion on the surface of a metal base material so as to generate an insoluble complex; therefore, the electrode reaction of corrosion is relieved and a better slow-release effect is achieved.

Owner:HEFEI ZHENGTUO DECORATION MATERIALS CO LTD

Environment-friendly non-toxic metal surface treatment agent

InactiveCN104928662APrevent metal corrosionSlow down the electrode reactionMetallic material coating processesYttriumChemistry

The invention discloses an environment-friendly non-toxic metal surface treatment agent which is prepared from the following raw materials in parts by weight: 4-6 parts of alkenyl succinate, 0.1-0.2 part of tetramethyl glutaric acid, 0.8-2 parts of alpha-olefin sulfonate, 1-2 parts of sodium polycarboxylic acid, 0.6-1 part of N,N-diethylaniline, 0.2-0.3 part of tetraethylammonium tetrafluoroborate, 0.1-0.2 part of sodium diacetate, 0.7-1 part of pyrrolidone hydroxy acid sodium, 2-3 parts of diethanol amine, 4-5 parts of triethanolamine borate, 0.05-0.1 part of yttrium nitrate hexahydrate, 0.4-1 part of a silane coupling agent KH-550 and 150-200 parts of water. The metal surface treatment agent has the advantages of being non-toxic and pollution-free, good in environment-friendly property, good in anticorrosive and antibacterial properties, good in storage stability and long in service life.

Owner:BENGBU TIMES ELECTRONICS

Sericin rare-earth metal surface treatment agent

InactiveCN104818471APlay a protective effectHigh tensile strengthMetallic material coating processesHexamethylphosphoramidePolyvinyl alcohol

The invention discloses a sericin rare-earth metal surface treatment agent which is composed of the following raw materials, by weight, 0.1-0.2 part of polyglutamic acid, 10-15 parts of polyvinyl alcohol, 4-6 parts of sericin, 0.07-0.1 part of boric acid, 0.05-0.1 part of yttrium nitrate hexahydrate, 0.4-1 part of a silane coupling agent KH-550, 150-200 parts of water, 0.1-0.3 part of diazolidinyl urea, 1-2 parts of sodium acid pyrophosphate, 2-4 parts of triethanolamine borate, 0.2-0.3 part of hexamethylphosphoramide and 1-2 parts of octoxinol. After hydrolysis of silane, an adsorption type film can be formed on metal surface so as to isolate water molecules and oxygen molecules in the environment, thus having a protective effect. Through boric acid modification, tensile strength and heat stability of blend films can be enhanced. The added rare earth metal ions and OH- generated by oxygen absorption corrosion of the metal substrate surface undergo complexing to generate insoluble complexes. The complexes can alleviate the electrode reaction of corrosion.

Owner:BENGBU TIMES ELECTRONICS

Special rustproof oil for iron powder stamped parts

InactiveCN104450050AImprove coalescence performanceImprove stabilityLubricant compositionParaffin waxPhenyl Ethers

The invention discloses special rustproof oil for iron powder stamped parts. The rustproof oil is prepared from the following raw materials in parts by weight: 70-80 parts of No. 30 mechanical oil, 2-3 parts of dimethyl tetrachloroterephthalate, 0.4-1 part of dioctylmethyl tertiary amine, 4-6 parts of a rustproof agent t746, 0.5-1 part of xylene, 0.5-2 parts of polytetrafluoroethylene, 2-3 parts of dimethyl fumarate, 1-2 parts of benzotriazole, 1-2 parts of calcium ricinoleate, 6-10 parts of liquid paraffin, 2-3 parts of ethylene glycol, 0.6-1 part of phytic acid, 1-2 parts of triethanolamine and 14-20 parts of rare earth film-forming hydraulic oil. Rare earth film-forming hydraulic oil is added into the rustproof oil; propylene glycol phenyl ether is added into a modified gelatin system disclosed by the invention, propylene glycol phenyl ether is completely absorbed by the gelatin system particles and thus the coalescence property and stability of the system are increased and the film-forming property of the rare earth film-forming hydraulic oil is enhanced; and added rare earth ions can react with OH- generated in oxygen absorption corrosion process happening on the surface of a metal substrate to produce an insoluble complex and thus the corrosive electrode reaction is alleviated and good corrosion-inhibition effect is achieved.

Owner:合肥宏图彩印有限公司

Black bright antirust oil

The invention discloses a black bright antirust oil which is prepared from the following raw materials in parts by weight: 4-6 parts of coal tar, 1-2 parts of methyl perfluoro-nonyl ketone, 0.5-1 part of copper chrome black, 0.5-1 part of lauryl nitro tropone, 60-70 parts of N68 machine oil, 1-2 parts of formamide, 0.5-1 part of fluorinated ethylene propylene copolymer, 1-2 parts of chitin, 2-4 parts of castor oil, 2-4 parts of tributyl citrate, 2-6 parts of chlorinated paraffin wax, 0.5-2 parts of lauroyl diethanolamide, 0.6-1 part of N-hydroxymethyl acrylamide, 0.5-1 part of ammonium molybdate, 3-5 parts of antifriction machine oil and 0.4-1 part of calcium lactate. The antifriction machine oil added into the antirust oil can form a molecular orientation adsorption film on the metal surface to reduce the friction; the obtained modified terpene resin has favorable binding property and high heat stability, and can enhance the compatibility among the materials and increase the adhesion of the coated film; the zinc dihydrogen phosphate used as a common metal surface treating agent has favorable derusting and antiseptic effects; and the added rare-earth lanthanum ions can be combined with -OH, which is generated in the oxygen-absorption corrosion process on the metal substrate surface, to generate an insoluble complex, thereby decelerating the corrosive electrode reaction and having favorable slow release effect.

Owner:ANHUI KING AUTO ELECTRONICS TECH CO LTD

Antirust oil for steel plate of automobile

The invention discloses antirust oil for a steel plate of an automobile. The antirust oil is prepared from the following raw materials in parts by weight: 0.6 to 1 part of alkenyl succinic anhydride, 50 to 70 parts of 100sn base oil, 1 to 2 parts of tea saponin, 1 to 2 parts of a titanate coupling agent 201, 2 to 4 parts of triethyl acetyl citrate, 3 to 4 parts of natural latex, 1 to 2 parts of calcium stearate, 2 to 3 parts of diisocyanate, 2 to 5 parts of an antirust agent t705, 1 to 3 parts of dipropylene glycol methyl ether acetate, 0.6 to 1 part of 1, 4-cyclohexanedimethanol, 0.5 to 1 part of benzalkonium bromide, and 4 to 5 parts of anti-wear mechanical oil. According to the antirust oil, the added anti-wear mechanical oil can form a molecular oriented adsorbing film on the metal surface, so that the friction is reduced, and the obtained modified terpene resin is high in adhering performance and high in thermal stability, promotes the compatibility of materials, and improves the adhesion of a coating film; zinc dihydrogen phosphate is used as a commonly-used metal surface treating agent and has good antirust and anticorrosion effects; added lanthanum ions and OH<-> generated by performing oxygen absorption corrosion for the surface of a metal base material can generate an insoluble complex to delay the corroded electrode reaction, and thus, a good controlled release effect is achieved.

Owner:ANHUI KING AUTO ELECTRONICS TECH CO LTD

Quick-drying metal thin film antirust oil

InactiveCN104450053AImprove coalescence performanceImprove stabilityAdditives1-PropanolPolyvinyl chloride

The invention discloses quick-drying metal thin film antirust oil, which is prepared from the following raw materials in parts by weight: 0.4-1 part of zinc cyanurate, 60-70 parts of 30# machine oil, 0.2-0.4 part of phosphotungstic acid, 0.7-1 part of perfluorooctyl acrylate, 3-4 parts of polyvinyl chloride, 1-2 parts of dilauryl thiodipropionate, 1-2 parts of methyl parahydroxybenzoate, 1-2 parts of sodium pyrophosphate, 1-2 parts of polyoxyethylene oleate, 0.2-1 part of sodium lauryl sulfate, 3-6 parts of an antirust agent T705, 2-3 parts of methyl pentachlorostearate and 13-20 parts of rare-earth film-forming hydraulic oil. The rare-earth film-forming hydraulic oil is added to the antirust oil disclosed by the invention; phenoxy-1-propanol is added to a modified gelatin system disclosed by the invention, so that phenoxy-1-propanol I is completely absorbed by particles, thus the coalescence performance and the stability of the system are improved, and the film-forming property in the system is also enhanced; an insoluble complex can be generated by added rare-earth ions and OH<-> generated in the oxygen absorption corrosion process on the surface of a metal base material, so that the electrode reaction of corrosion is retarded, and a good slow-release effect is achieved.

Owner:合肥宏图彩印有限公司

Electrostatic spraying slushing oil

The invention discloses electrostatic spraying slushing oil. The electrostatic spraying slushing oil is composed of the following raw materials in parts by weight: 0.4-1 part of p-nitrophenyl phosphate sodium, 60-70 parts of #25 transformer oil, 1-2 parts of polyisobutene, 3-5 parts of microcrystalline wax, 2-3 parts of hosho oil, 2-4 parts of phthalate polyester, 4-6 parts of petroleum sodium sulfonate, 2-3 parts of fumed silica, 1-3 parts of triethanolamine oleic soap, 1-2 parts of diphenyl silandiol, 0.5-1 part of monopotassium phosphate, 0.4-1 part of inositol hexaphosphoric acid, 0.3-0.5 part of zinc acetylacetonate, 2-3 parts of oleic acid and 3-5 parts of wear resistant machine oil. A molecular directional adsorption film can be formed on the surface of the metal by adding the wear resistant machine oil into the slushing oil, so that the friction can be reduced; the modified terpene resin has a good cohesive property and strong thermal stability so that the compatibility between the materials can be promoted and the adhesive force of the film can be enhanced; the zinc dihydrogen phosphate is used as a common metal surfactant which has a good rust removal preservative effect; the rare earth lanthanum ion and the OH<-> generated on the surface of the metal material during the oxygen absorption corrosion process can generate an insoluble complex which can slow down the corrosion of the electrode reaction and has a good slow-release effect.

Owner:ANHUI KING AUTO ELECTRONICS TECH CO LTD

Extreme pressure antiwear and antirust oil

InactiveCN104513701AImprove thermal stabilityGuaranteed stabilityLubricant compositionRare earthSulfide

The invention discloses an extreme pressure antiwear and antirust oil, which is composed of the following raw materials by weight part: 1-2 of nitrilotriacetic acid trisodium salt, 1-2 of star anise oil, 0.6-1 of sodium nitrite, 2-3 of phthalic acid ester, 1-2 of linalool, 1-2 of polyglycerol fatty acid ester, 0.4-1 of potassium citrate, 0.4-1 of phthalic anhydride, 0.6-1 of lithium naphthenate, 0.4-1 of castor oil polyoxyethylene ether, 4-6 of petroleum sodium sulfonate, 60-70 of n68# machine oil, 2-4 of T321 isobutenyl sulfide, and 4-6 of anti-stripping machine oil. The film-forming machine oil pentaerythritol oleate added in the invention has excellent lubricity and good surface film-forming property, and blending modification with alcohol ester-12 can obviously improve the film-forming effect of the finished product and lower the film-forming temperature. The added rare earth lanthanum ion and the OH- generated in an oxygen absorption corrosion process on a metal substrate surface can generate an insoluble complex to slow down corrosive electrode reaction so as to play a good slow-release role.

Owner:ANHUI RONGDA VALVE

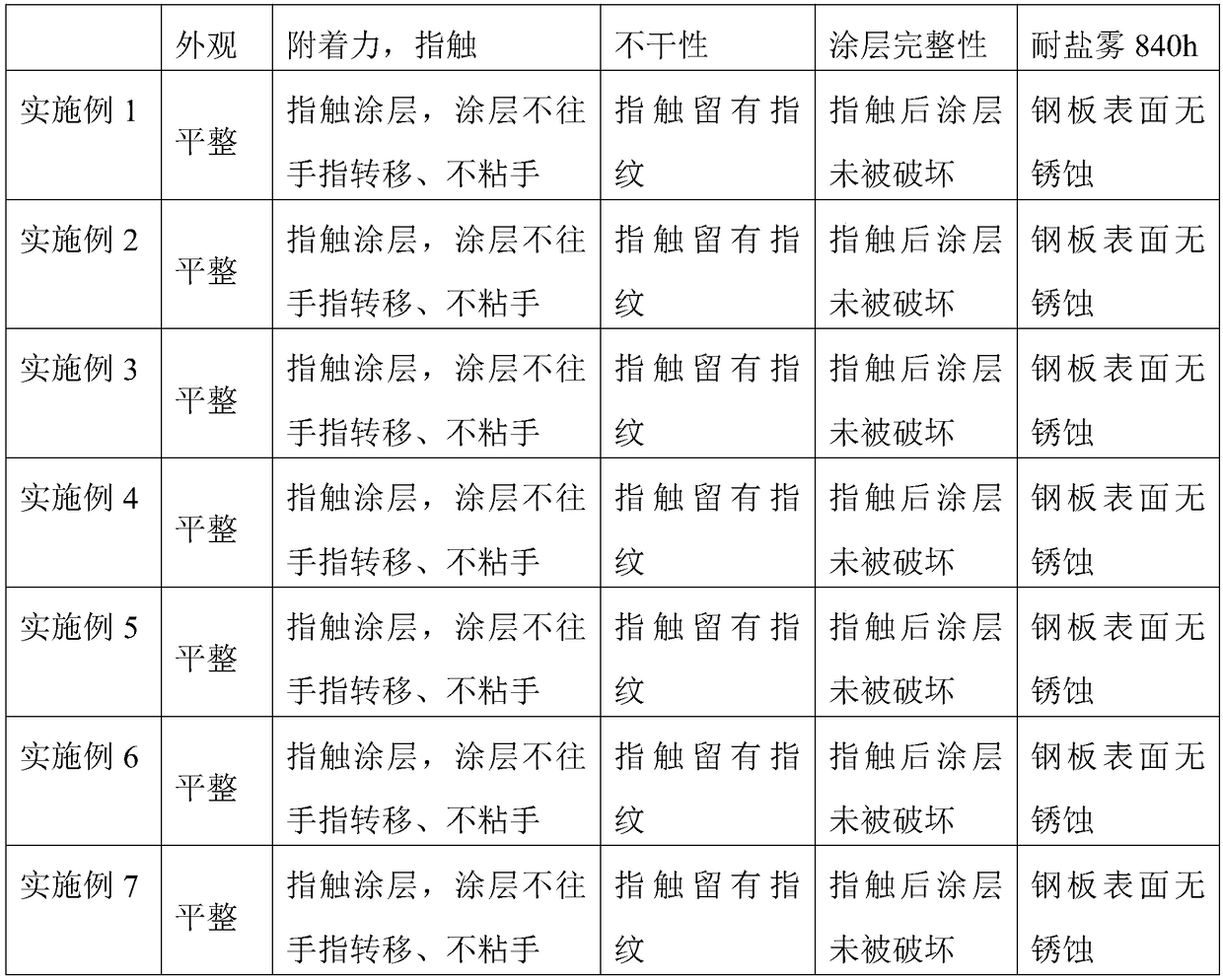

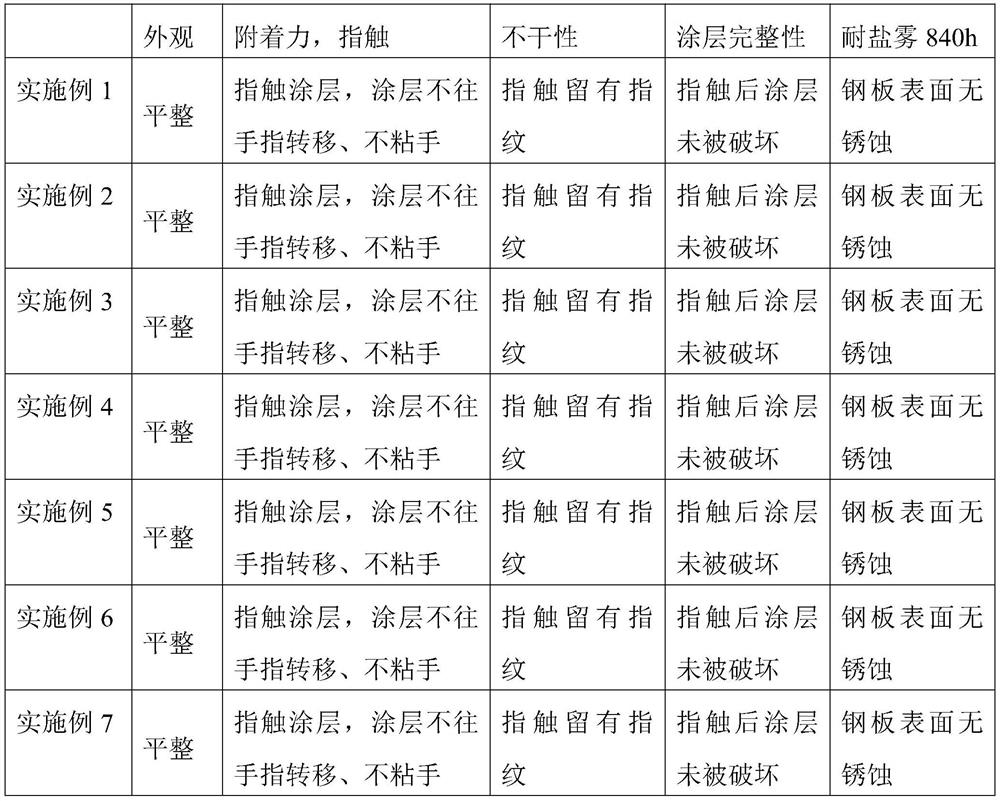

Phenolic resin modified metal protection anti-rust non-drying oil and preparation method thereof

ActiveCN109401521AImprove film formationImprove the lubrication effectAnti-corrosive paintsTurpentineSuccinic acid

The invention discloses phenolic resin modified metal protection anti-rust non-drying oil and a preparation method thereof. The phenolic resin modified metal protection anti-rust non-drying oil is prepared from the following raw materials: a solvent, polyisobutene, base oil, ethylene-propylene copolymer, wool grease, calcium petroleum sulfonate, dodecyl phenyl succinic acid, calcium carbonate andthe like. The solvent is at least one of 200# solvent oil or methylbenzene or turpentine. According to the phenolic resin modified metal protection anti-rust non-drying oil, the compatibility of all materials is good, the film-forming property is high, the bonding strength between an oil film and metal parts is high, the peel strength is high, the adhesive force is high, the metal part is not prone to damage in the packaging and transportation process, the salt mist performance can reach 840h, and the requirements of the metal parts for the adhesive force and salt mist resistance of the non-drying oil are met. The phenolic resin modified metal protection anti-rust non-drying oil can not be transferred after finger tough and collision, is not prone to dripping after being sprayed, and greatly improves the protection capacity to the metal parts.

Owner:SHANDONG NORTH MODERN CHEM IND

Overlong weather resistant and salt-fog resistant antirust oil

InactiveCN104450022ASlow down the electrode reactionImprove liquidityLubricant compositionKetonePotassium oleate

The invention discloses overlong weather resistant and salt-fog resistant antirust oil prepared from the following raw materials in parts by weight: 14-20 parts of rare-earth antirust hydraulic oil, 0.7-1 part of hydroximic acid, 60-70 parts of 30# machine oil, 10-20 parts of gear oil, 0.6-2 parts of kieselguhr, 0.3-1 part of an anti-ageing agent mb, 1-3 parts of sodium salicylate, 4-10 parts of potassium oleate soap, 0.5-3 parts of polyoxyethylene oleate, 3-6 parts of epoxidized soybean oil, 3-5 parts of neutral barium dinonyl naphthalene sulfonate, 0.2-1 part of chitosan and 0.2-2 parts of diallylamine. The rare-earth antirust hydraulic oil is added to the antirust oil disclosed by the invention; the mobility can be improved by an alkyl ketone dispersion liquid; the reaction activity is improved; an insoluble complex can be generated by added rare-earth ions and OH<-> generated in the oxygen absorption corrosion process on the surface of a metal base material; the corrosive electrode reaction is retarded; and a good slow-release effect can be achieved.

Owner:HEFEI ZHENGTUO DECORATION MATERIALS CO LTD

Lubricating metal surface treatment agent

InactiveCN104818475AGood anti-rust lubricityGood compatibilityMetallic material coating processesPolyethylene oxidePolyvinyl alcohol

The invention discloses a lubricating metal surface treatment agent which is composed of the following raw materials, by weight, 0.2-0.3 part of linseed oil, 1-2 parts of palmitic acid, 0.01-0.02 part of polyethylene oxide, 10-15 parts of polyvinyl alcohol, 4-6 parts of sericin, 0.07-0.1 part of boric acid, 0.05-0.1 part of yttrium nitrate hexahydrate, 0.4-1 part of a silane coupling agent KH-550, 0.4-1 part of sodium molybdate, 160-200 parts of water, 0.9-1 part of tea saponin and 0.1-0.14 part of sodium hyposulfite. According to the invention, water-soluble polymer polyvinyl alcohol and sericin are mixed, and then silanization treatment is carried out. After hydrolysis of silane, an adsorption type film can be formed on metal surface so as to isolate water molecules and oxygen molecules in the environment, thus having a protective effect. Through boric acid modification, tensile strength and heat stability of blend films can be enhanced. The added rare earth metal ions and OH- generated by oxygen absorption corrosion of the metal substrate surface undergo complexing to generate insoluble complexes.

Owner:BENGBU TIMES ELECTRONICS

Saline-resistant rust-preventative oil for ships

InactiveCN104450032ASlow down the electrode reactionImprove liquidityLubricant compositionNitrilotriacetic acidPhthalate

The invention discloses saline-resistant rust-preventative oil for ships. The saline-resistant rust-preventative oil for ships is composed of the following raw materials in parts by weight: 60-80 parts of kerosene, 0.6-1 part of nitrilotriacetic acid trisodium salt, 1-2 parts of calcium palmitate, 8-10 parts of calcium petroleum sulfonate, 1-2 parts of hydroxyethylidene diphosphonic acid, 1-3 parts of alkylated diphenylamine, 2-3 parts of bitertanol, 2-3 parts of acrylic acid, 0.8-1 part of antioxidant 168, 1-2 parts of 1-hydroxybenzotriazole, 0.3-1 part of potassium dichromate, 2-4 parts of phthalate, 1-3 parts of polyisocyanate and 14-20 parts of rare-earth rust-preventative hydraulic oil. The rare-earth rust-preventative hydraulic oil is added to the rust-preventative oil disclosed by the invention; menthanone dispersing liquid is capable of improving flowability and improving reactivity, and the added rare-earth ions are capable of generating insoluble complexes with the OH<-> generated during an oxygen absorption corrosion process on the surface of a metal base material, slowing down the electrode reaction of the corrosion and acting a great slow-release effect.

Owner:HEFEI ZHENGTUO DECORATION MATERIALS CO LTD

High humid and heat resistant anti-rust oil

InactiveCN104450030ASlow down the electrode reactionImprove liquidityLubricant compositionKetoneAcetylated Lanolin

The invention discloses high humid and heat resistant anti-rust oil. The high humid and heat resistant anti-rust oil consists of the following raw materials in parts by weight: 60-70 parts of No.0 light diesel oil, 20-30 parts of rare earth anti-rust hydraulic oil, 0.2-0.3 part of vegetable fat powder, 0.8-1 part of methyl perfluorobutyl ketone, 1-2 parts of sodium bisphosphate, 2-3 parts of urea, 1-2 parts of benzotriazole, 1-2 parts of zinc dialkyl dithiophosphate, 2-5 parts of hydrogenated castor oil, 2-3 parts of ethylene glycol, 3-4 parts of phthalic acid ester, 2-3 parts of 1,2-dially phthalate, 1-2 parts of hexamethylene tetramine and 4-10 parts of acetylated lanolin. According to the anti-rust oil disclosed by the invention, the rare earth anti-rust hydraulic oil is added; by virtue of an alkyl ketone dispersion liquid, the flowability can be improved, and the reaction activity can be increased; and added rare earth ions can react with OH<-> which is produced in a process of performing oxygen absorption corrosion on the surface of a metal base material to produce insoluble complexes, so that the corrosion electrode reaction can be slowed down, and a very good slow-release effect can be achieved.

Owner:HEFEI ZHENGTUO DECORATION MATERIALS CO LTD

Low-temperature antirust oil for bearing storage

InactiveCN104629877AImprove adhesionImprove thermal stabilityLubricant compositionWear resistantPhosphate

The invention discloses a low-temperature antirust oil for bearing storage. The low-temperature antirust oil consists of the following raw materials in parts by weight: 60-70 parts of 150sn base oil, 1-2 parts of ephedrine, 0.2-1 part of ammonium tungstate, 1-2 parts of tetradecanol oleate, 1-2 parts of tertiary butyl para-diphenol, 0.1-0.3 part of butyl hydroxy anisd, 3-5 parts of petroleum calcium sulfonate, 0.5-1 part of dicumyl peroxide, 1-2 parts of diisopropylethanolamine, 2-4 parts of tricresyl phosphate, 0.3-1 part of diazolidinyl urea and 3-5 parts of wear-resistant mechanical oil. The wear-resistant mechanical oil added into the antirust oil disclosed by the invention can form a molecular orientation adsorption film on a metal surface to reduce friction; the obtained modified terpene resin is good in caking property, strong in thermal stability, capable of promoting compatibility of materials and strengthening the adhesive force of a coating film; zinc dihydrogen phosphate which is used as a normal metal surface treating agent has a good antirust anticorrosion effect; the added rear-earth lanthanum ion can generate in-soluble complex with OH<-> generated in an oxygen absorption corrosion process on a metal base surface, and electrode reaction causing corrosion is relieved, so that a good controlled-release effect is achieved.

Owner:ANHUI KING AUTO ELECTRONICS TECH CO LTD

Anti-peeling anti-rust oil

InactiveCN104531318AImprove the lubrication effectGood surface film formationLubricant compositionRare earthPotassium

The present invention discloses an anti-peeling anti-rust oil, which comprises the following raw materials by weight: 0.4-1 part of potassium hexafluorotitanate, 2-3 parts of methylparaben, 4-6 parts of dodecencylsuccinic acid, 0.4-1 part of zinc cyanurate, 1-2 parts of phytosterin, 0.4-1 part of 5-hydroxy-2-adamantanone, 0.5-1 part of alkylated diphenylamine, 0.5-1 part of sodium hypophosphite, 2-3 parts of isobutyl oleate, 60-70 parts of 300sn base oil, 0.2-1 part of 3-pyrroline, and 4-6 parts of film forming machine oil. According to the present invention, the added film forming machine oil pentaerythrite oleate with characteristics of excellent lubricity and good surface film forming property and the dodecyl alcohol ester are subjected to co-mixing modification so as to significantly improve the film forming effect of the finished product and reduce the film forming temperature, and the added rare earth lanthanum ions and the OH<-1> produced during the oxygen uptake etching process occurring on the metal substrate surface can produce the insoluble complex so as to slow down the etching electrode reaction and provide the good slow-release effect.

Owner:ANHUI RONGDA VALVE

Long-acting rust-preventing oil

InactiveCN104312668ASlow down the electrode reactionImprove liquidityAdditivesTetramethylammonium nitrateButanedioic acid

The invention discloses long-acting rust-preventing oil. The long-acting rust-preventing oil consists of the following raw materials in parts by weight: 0.2-0.5 part of gaseous-phase silicon dioxide, 50-70 parts of 100sn base oil, 2-4 parts of polymethyl methacrylate, 3-7 parts of dodecyl phenyl succinic acid, 1-2 parts of 1,2,3- benzotriazole, 2-4 parts of polyvinyl alcohol, 2-3 parts of alkenyl succinate, 1-2 parts of tetramethylammonium nitrate, 2-3 parts of 4-oxobutanoic acid methyl ester, 3-6 parts of ethyl acetate, 0.2-0.5 part of isophorone diisocyanate, 0.6-2 parts of ammonium tungstate and 14-20 parts of rear-earth rust-preventing hydraulic oil. The long-acting rust-preventing oil disclosed by the invention is added with the rear-earth rust-preventing hydraulic oil; an alkyl ketone dispersion fluid can be used for improving the mobility and improving the reaction activity; the added rear earth ions and OH<-> produced in an oxygen-up corrosion process can produce insoluble complex on a metal substrate surface to slow down corroded electrode reaction, so that very good controlled-release effects are achieved.

Owner:HEFEI ZHENGTUO DECORATION MATERIALS CO LTD

Resin-based dustproof anti-pollution rust-proof oil

InactiveCN104450056AImprove coalescence performanceImprove stabilityLubricant composition1-PropanolMicroparticle

The invention discloses resin-based dustproof anti-pollution rust-proof oil. The resin-based dustproof anti-pollution rust-proof oil comprises the following raw materials in parts by weight: 0.5-1 part of alkyl ketene dimer, 0.8-1 part of polyepoxysuccinic acid, 1-2 parts of barium stearate, 2-4 parts of oleic acid, 65-80 parts of No.20 machine oil, 1-2 parts of isopropyl palmitate, 0.6-2 parts of nylon 66, 2-3 parts of polyoxyethylene rosin ester, 1-2 parts of hydroxyethyl ethylene bistatic amide, 3-5 parts of barium petroleum sulfonate, 14-20 parts of rare earth film-forming hydraulic oil, 1-2 parts of tetradecyl alcohol oleic acid ester and 2-4 parts of petroleum ether. The rare earth film-forming hydraulic oil is added into the rust-proof oil; the phenoxy-1-propanol is added into a modified gelatin system to be fully absorbed by microparticles of the gelatin system, so that the coalescence performance and the stability of the system are improved; the self film-forming property is also improved in the system; insoluble complexes can be generated by the added rear earth ions and OH- generated in the oxygen absorption corrosion process on the surface of the metal substrate; the corrosion electrode reaction is alleviated; a good slow-release effect is achieved.

Owner:合肥宏图彩印有限公司

A kind of phenolic resin modified metal protection anti-rust non-drying oil and preparation method thereof

ActiveCN109401521BImprove film formationImprove the lubrication effectAnti-corrosive paintsButanedioic acidSuccinic acid

The invention discloses a phenolic resin modified metal protection antirust non-drying oil and a preparation method thereof, which is composed of the following raw materials: solvent, polyisobutylene, base oil, ethylene-propylene copolymer, lanolin, calcium petroleum sulfonate, ten Dienyl succinic acid, calcium carbonate, etc.; the solvent is at least one of No. 200 solvent naphtha, toluene or turpentine; the phenolic resin modified metal protection anti-rust non-drying oil of the present invention is compatible between each material Good performance, strong film-forming property, high bonding strength between oil film and metal parts, high anti-peeling strength, high adhesion, the metal layer of metal parts is not easy to be damaged during packaging and shipping, and the salt spray performance can reach 840h, Satisfy the adhesion and salt spray resistance requirements of metal parts to anti-rust non-drying oil; the phenolic resin modified metal protection anti-rust non-drying oil of the present invention will not transfer after finger touch and collision, and it is not easy to drip after spraying. Greatly improved the protection ability of metal parts.

Owner:SHANDONG NORTH MODERN CHEM IND

High-speed rail turnout anti-rusting oil

InactiveCN104450055AImprove coalescence performanceImprove stabilityLubricant compositionPhenyl EthersMicroparticle

The invention discloses high-speed rail turnout anti-rusting oil which is prepared from the following raw materials in parts by weight: 60-70 parts of #20 mechanical oil, 0.5-1 part of sodium pentachlorophenate, 2-3 parts of stearoyl calcium lactate, 0.3-0.6 part of hexamethyl cyclotrisiloxane, 1-3 parts of triethanolamine oleic soap, 3-4 parts of dodecenylsuccinic acid, 2-4 parts of barium petroleum sulfonate, 2-4 parts of maleic acid dibutyl ester, 2-3 parts of Vaseline, 0.1-0.3 part of molybdenum disulfide, 0.5-2 parts of an antioxidant 2246 and 13-20 parts of rare earth filming hydraulic oil. As the rare earth filming hydraulic oil is added into the anti-rusting oil disclosed by the invention, i.e., propylene glycol phenyl ether is added into a modified gelatin system of the high-speed rail turnout anti-rusting oil and is completely absorbed by grains of the gelatin system, the coalescence property and stability of the system are improved, and the filming property of the anti-rusting oil self is also improved in the system; due to added rare earth ions, insoluble complexes can be generated from OH<-1> generated in the oxygen absorption corrosion process on the surface of a metal substrate, the reaction of a corroded electrode is inhibited, and a very good slow-release effect is achieved.

Owner:合肥宏图彩印有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com