Patents

Literature

481 results about "Drying oil" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A drying oil is an oil that hardens to a tough, solid film after a period of exposure to air. The oil hardens through a chemical reaction in which the components crosslink (and hence, polymerize) by the action of oxygen (not through the evaporation of water or other solvents). Drying oils are a key component of oil paint and some varnishes. Some commonly used drying oils include linseed oil, tung oil, poppy seed oil, perilla oil, and walnut oil. Their use has declined over the past several decades, as they have been replaced by alkyd resins and other binders.

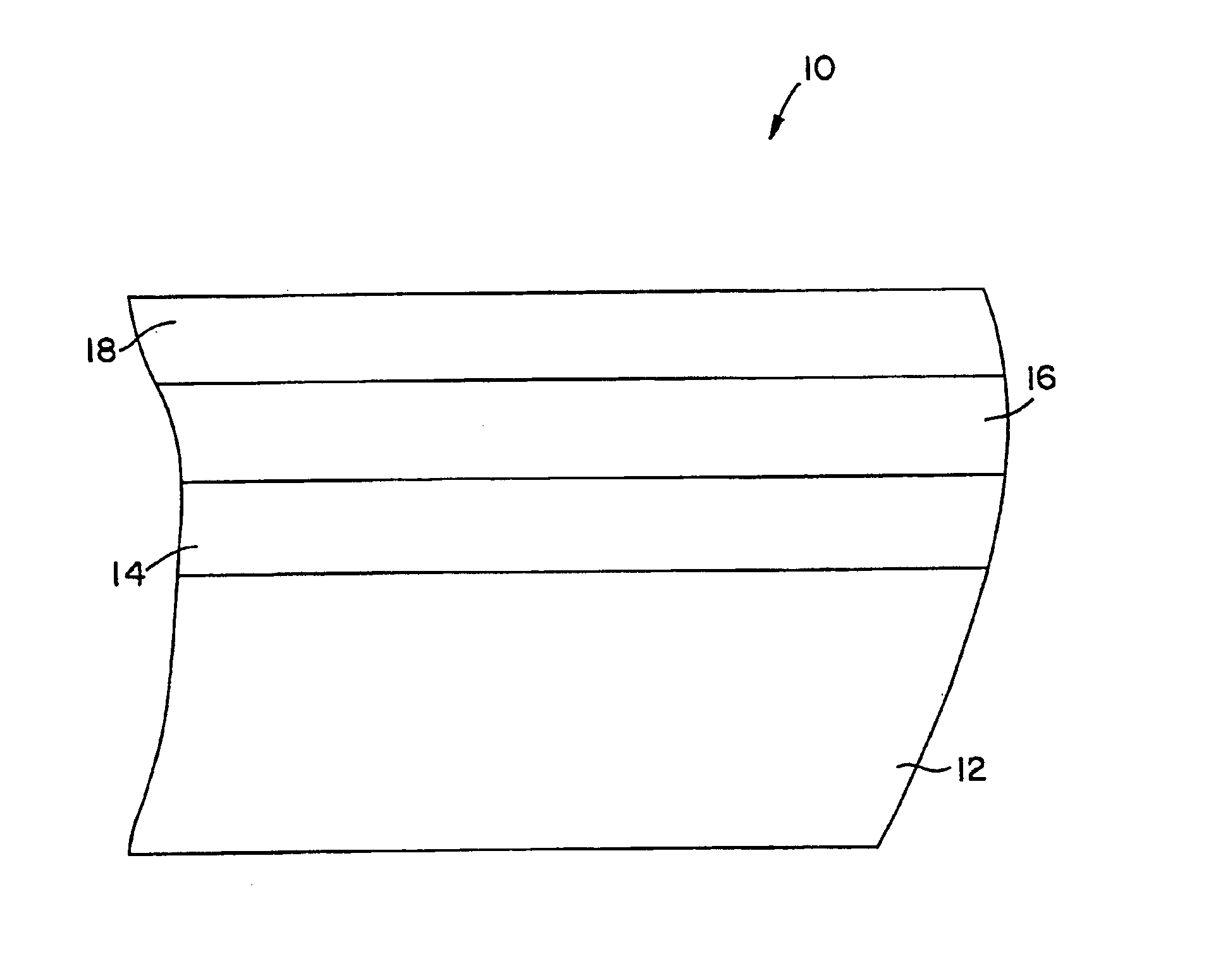

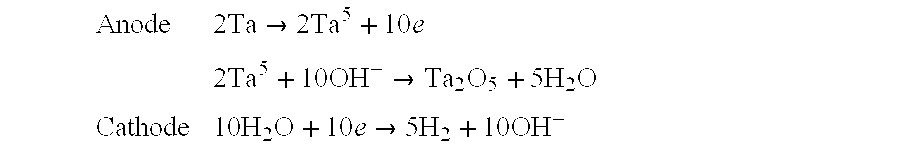

Protective coating for electrolytic capacitors

InactiveUS6864147B1Low dissipation factorLow leakage currentSolid electrolytic capacitorsSemiconductor/solid-state device manufacturingShellacElectrolysis

A solid electrolytic capacitor that comprises an anode that contains a valve-action metal (e.g., tantalum, niobium, and the like) and a dielectric film overlying the anode is provided. The capacitor also comprises a protective coating overlying the dielectric film, wherein the protective coating contains a relatively insulative, resinous material. For example, in one embodiment, the resinous material can be a drying oil, such as olive oil, linseed oil, tung oil, castor oil, soybean oil, shellac, and derivatives thereof. The capacitor also comprises a conductive polymer coating overlying the protective coating. As a result of the present invention, it has been discovered that a capacitor can be formed that can have a relatively low leakage current, dissipation factor, and equivalents series resistance.

Owner:KYOCERA AVX COMPONENTS CORP

Carbonising and/or Activating Carbonaceous Material

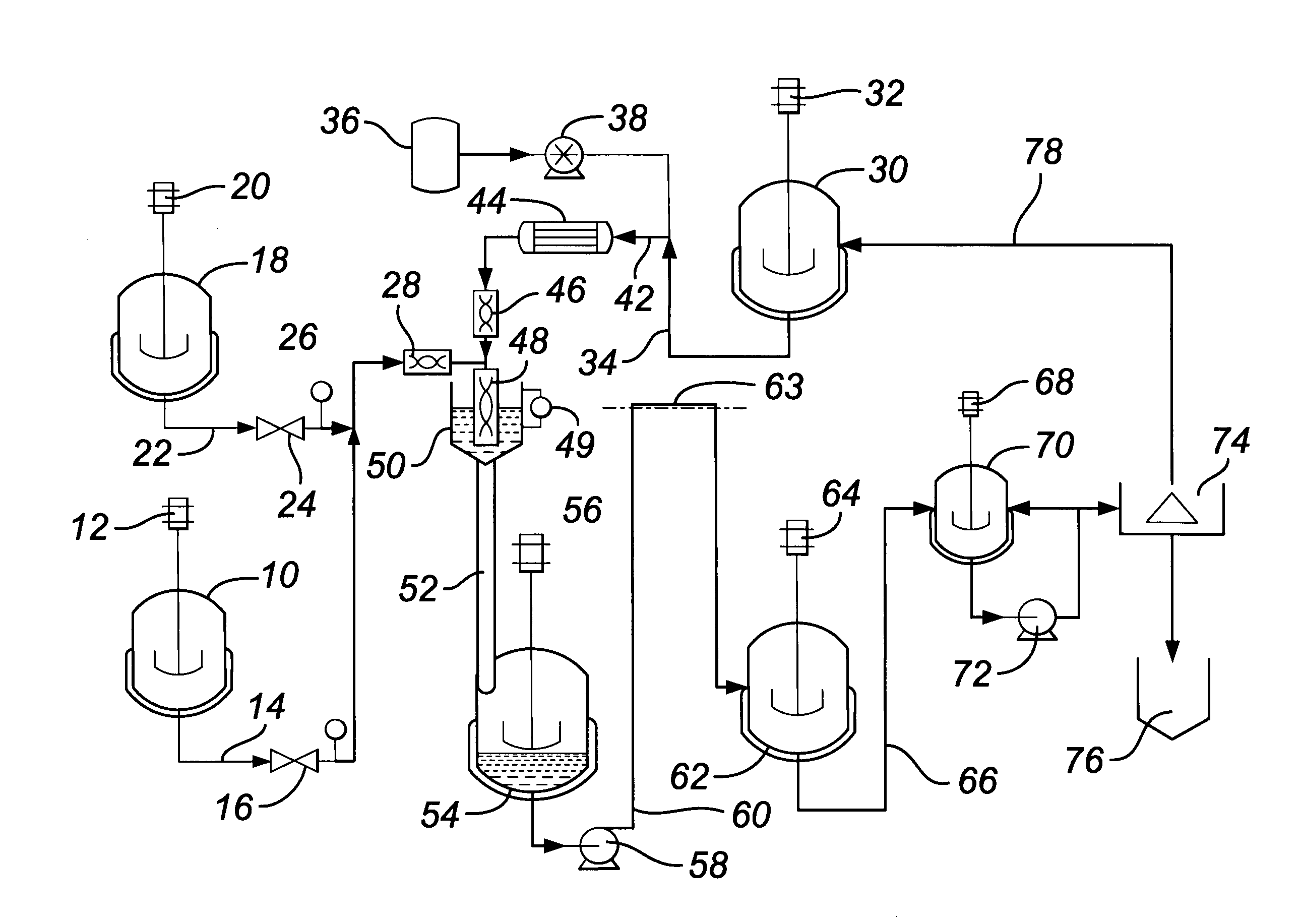

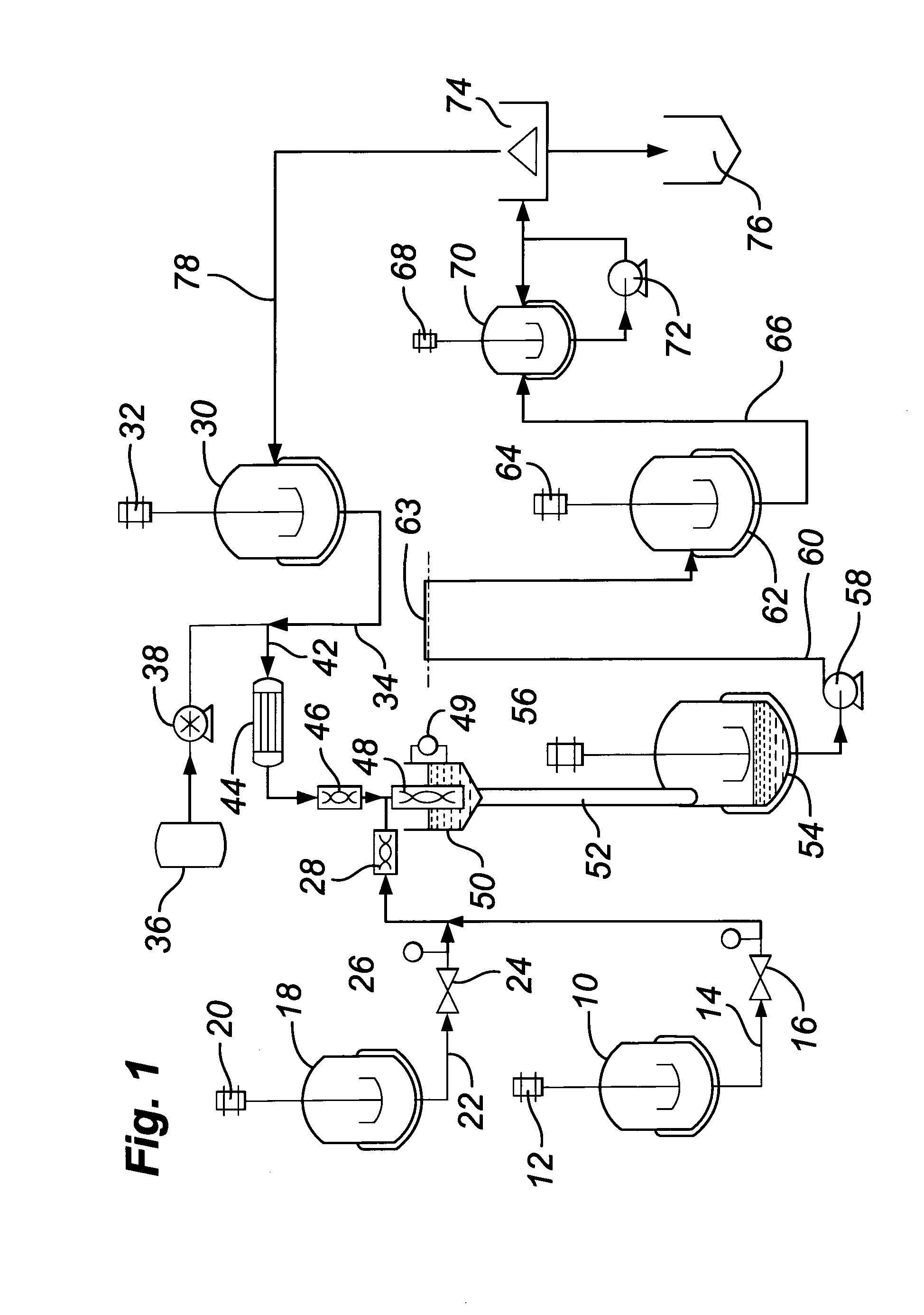

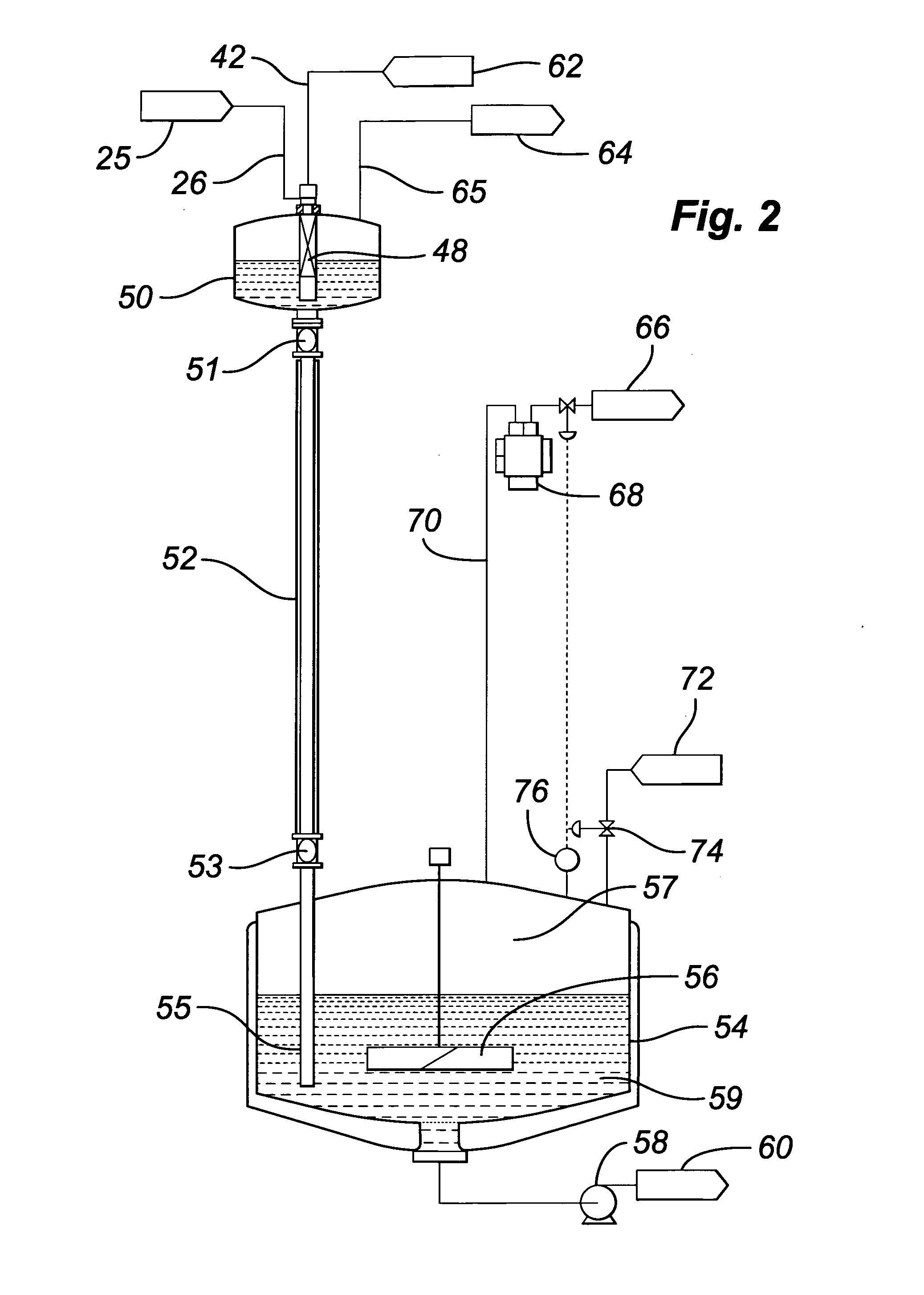

A method is provided for carbonizing and activating carbonaceous material, which comprises supplying the material to an externally fired rotary kiln maintained at carbonizing and activating temperatures, the kiln having a downward slope to progress the material as it rotates, the kiln having an atmosphere substantially free of oxygen provided by a counter-current of steam or carbon dioxide, and annular weirs being provided at intervals along the kiln to control progress of the material. There may further be provided an externally fired rotary kiln for carbonizing and activating carbonaceous material having a hollow rotary body that has a downward slope towards a discharge end thereof, and which is provided at intervals along its length with annular weirs for controlling progress of the carbonaceous material. In embodiments, there is also provided a process is for producing discrete solid beads of polymeric material e.g. phenolic resin beads having a mesoporous structure, which may be useful as feedstock for the above mentioned carbonization / activation process or which may have other utility e.g. as ion exchange resins. The process may produce resin beads on an industrial scale without aggregates of resin building up speedily and interrupting production. The process comprises the steps of: (a) combining a stream of a polymerizable liquid precursor e.g. a novolac and hexamine as cross-linking agent dissolved in a first polar organic liquid e.g. ethylene glycol with a stream of a liquid suspension medium which is a second non-polar organic liquid with which the liquid precursor is substantially or completely immiscible e.g. transformer oil containing a drying oil; (b) mixing the combined stream to disperse the polymerizable liquid precursor as droplets in the suspension medium e.g. using an in-line static mixer; (c) allowing the droplets to polymerise in a laminar flow of the suspension medium so as to form discrete solid beads that cannot agglomerate; and (d) recovering the beads from the suspension medium. There is also provided apparatus for forming discrete solid beads of polymeric material, said apparatus comprising: a first line for conveying s stream of a polymerizable liquid precursor; a second line for conveying a stream of a dispersion medium with which the polymerizable liquid precursor is substantially or completely immiscible; an in-line mixer configured to receive a combined flow from the first and second lines and to disperse the polymerizable liquid precursor as droplets in the dispersion medium; a vertical polymerization column configured to receive the dispersion medium with the droplets dispersed therein and to permit the polymerizable liquid precursor polymerize while descending the column in a descending flow of polymerization medium; and a vessel at the base of the column for receiving the descending flow of dispersion medium and collecting polymerized solid beads.

Owner:BRITISH AMERICAN TOBACCO (INVESTMENTS) LTD

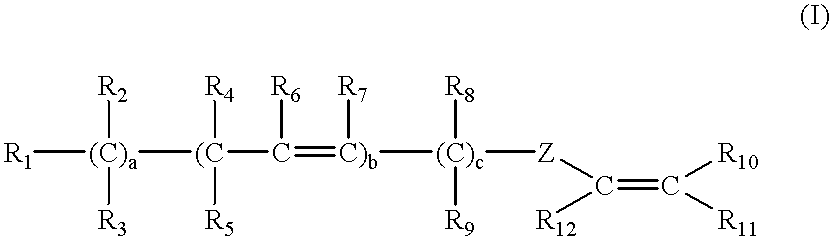

Latex compositions containing ethylenically unsaturated esters of fatty compounds and applications thereof

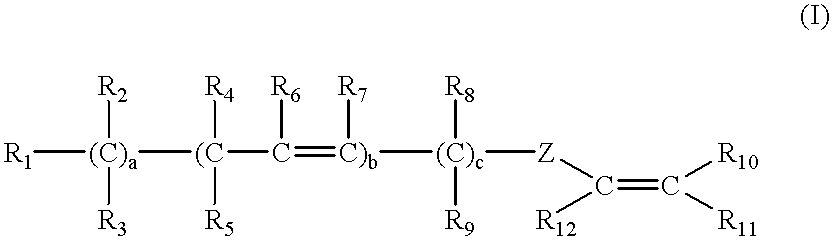

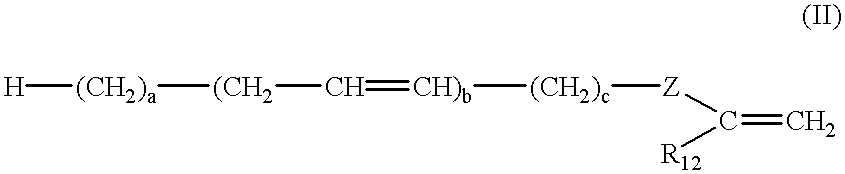

Novel latex or emulsion compositions containing internally plasticizing and crosslinkable monomers derived from traditional semi-drying or non-drying oils are disclosed and claimed. The monomers are ethylenically unsaturated derivatives of long-chain olefinic compounds. Preferred embodiments include latex formed from acrylate or methacrylate esters of fatty alcohols. A process for the synthesis of the latex composition is also disclosed, which involves (a) polymerization of the ethylenically unsaturated derivatives of a long-chain olefinic compound in an aqueous phase with at least one other copolymerizable monomer; and (b) blending of so formed polymer with at least one drier and a surfactant to form the novel latex or emulsion compositions. These compositions form films at low minimum film forming temperatures (MFT) ranging from -5 to 10° C. and cure to above ambient glass transition (Tg) polymers without the use of traditional organic cosolvents which contribute to environmental pollution via volatile organic compounds (VOCs) emissions. These compositions are therefore useful in waterborne coatings, contact and pressure sensitive adhesives, and inks.

Owner:UNIVERSITY OF SOUTHERN MISSISSIPPI +1

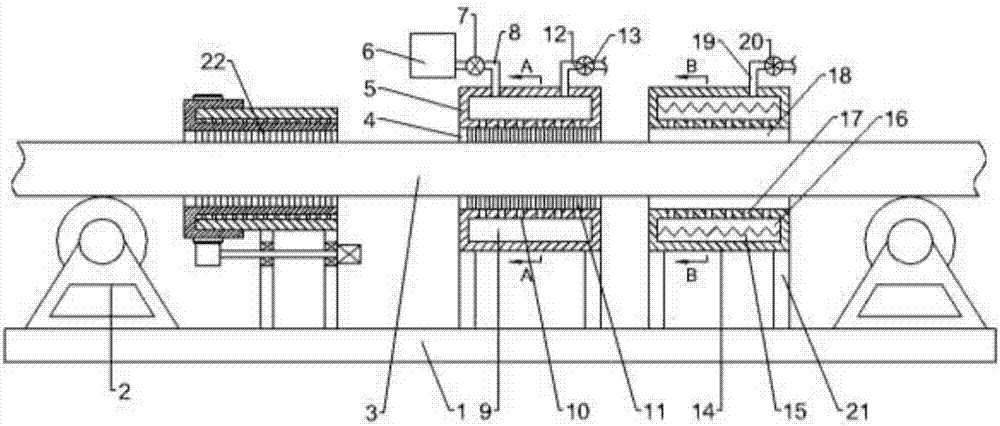

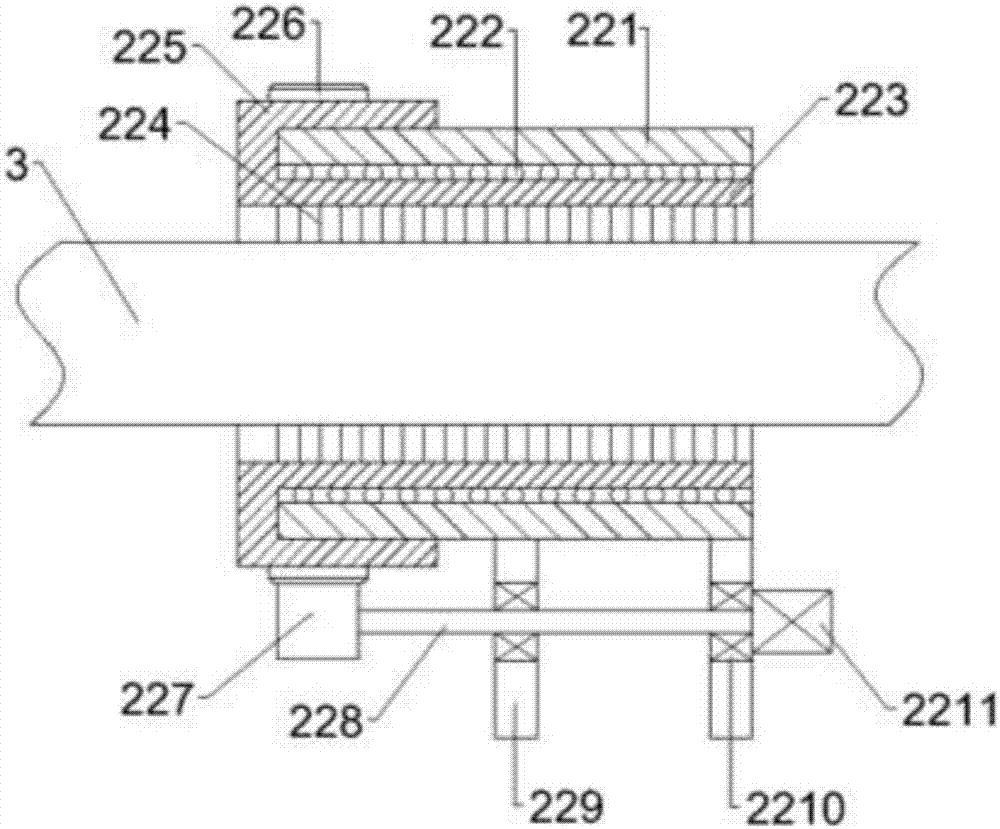

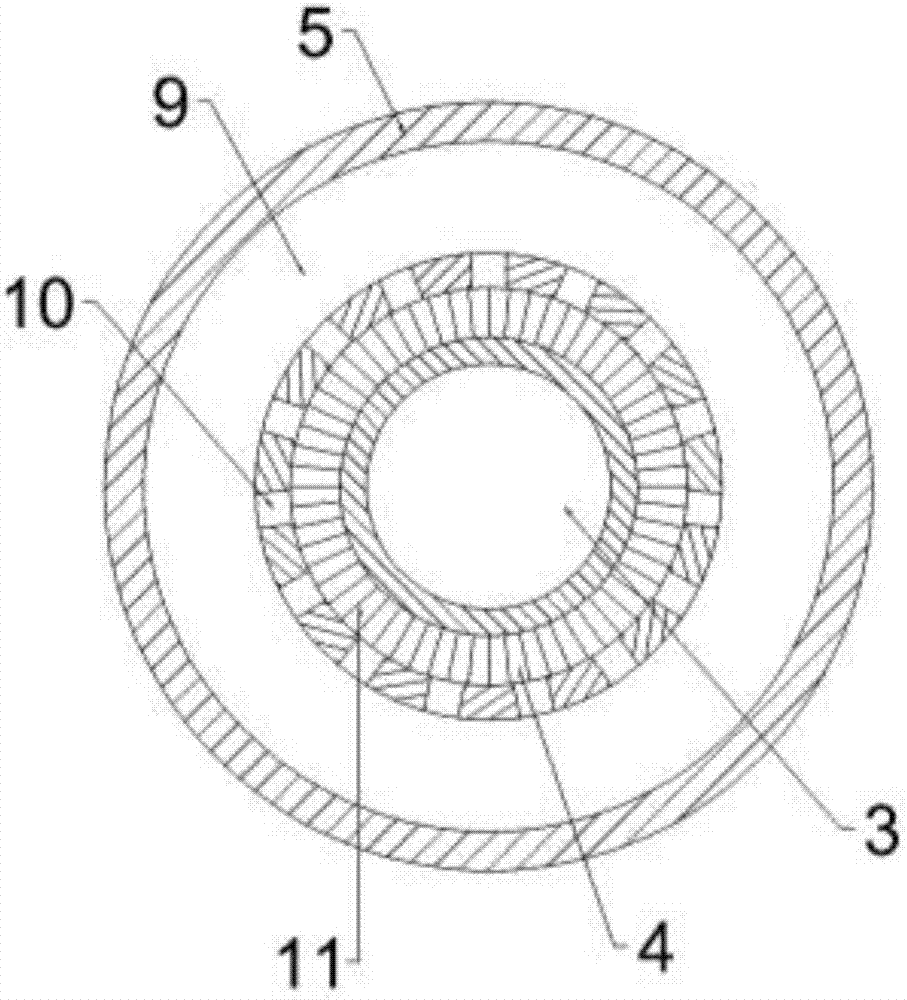

Rust removing, oil coating and drying integrated equipment used for production and manufacturing of steel pipes

InactiveCN107127093AGood removal effectGuaranteed uniformityLiquid surface applicatorsGrinding drivesBristleFuel tank

An integrated equipment for derusting, oiling, drying and manufacturing of steel pipes, including a workbench, on which two support rollers are symmetrically arranged, steel pipes are arranged on the support rollers, and a descaling roller is arranged between the two support rollers. A rusting device, an oiling device and a drying device, the oiling device includes an oiling shell, the oiling shell is in the shape of a horizontal column, a first through hole is arranged in the oiling shell, and a steel pipe is set through the first through hole , bristles are arranged on the inner side wall of the first through hole; the inside of the oil-coated housing is provided with a first cavity, the first cavity is annular, and there are several first outlets between the first cavity and the first through hole connected. The beneficial effect of the present invention is that the oil pump pumps the antirust oil in the oil storage tank into the first cavity, and then sprays it out from the first outlet to oil the surface of the steel pipe. The oil is evenly brushed to effectively ensure the uniformity of oil application.

Owner:HANGZHOU XIAOCHENG IND DESIGN CO LTD

Thermal ink jet ink composition

A thermal ink jet ink composition include a volatile organic solvent, a binder resin, a dye, a humectant in an amount less than 40% by weight of the thermal ink jet ink composition, and an additive for extending the decap time. The additive is present in an amount greater than 0.1% by weight of the thermal ink jet ink composition. The additive is selected from plasticizers, surfactants, aliphatic hydrocarbons, drying oils and mixtures thereof. The additive does not phase separate from the ink jet composition during application of the ink to a substrate in thermal ink jet printing.

Owner:VIDEOJET TECH INC

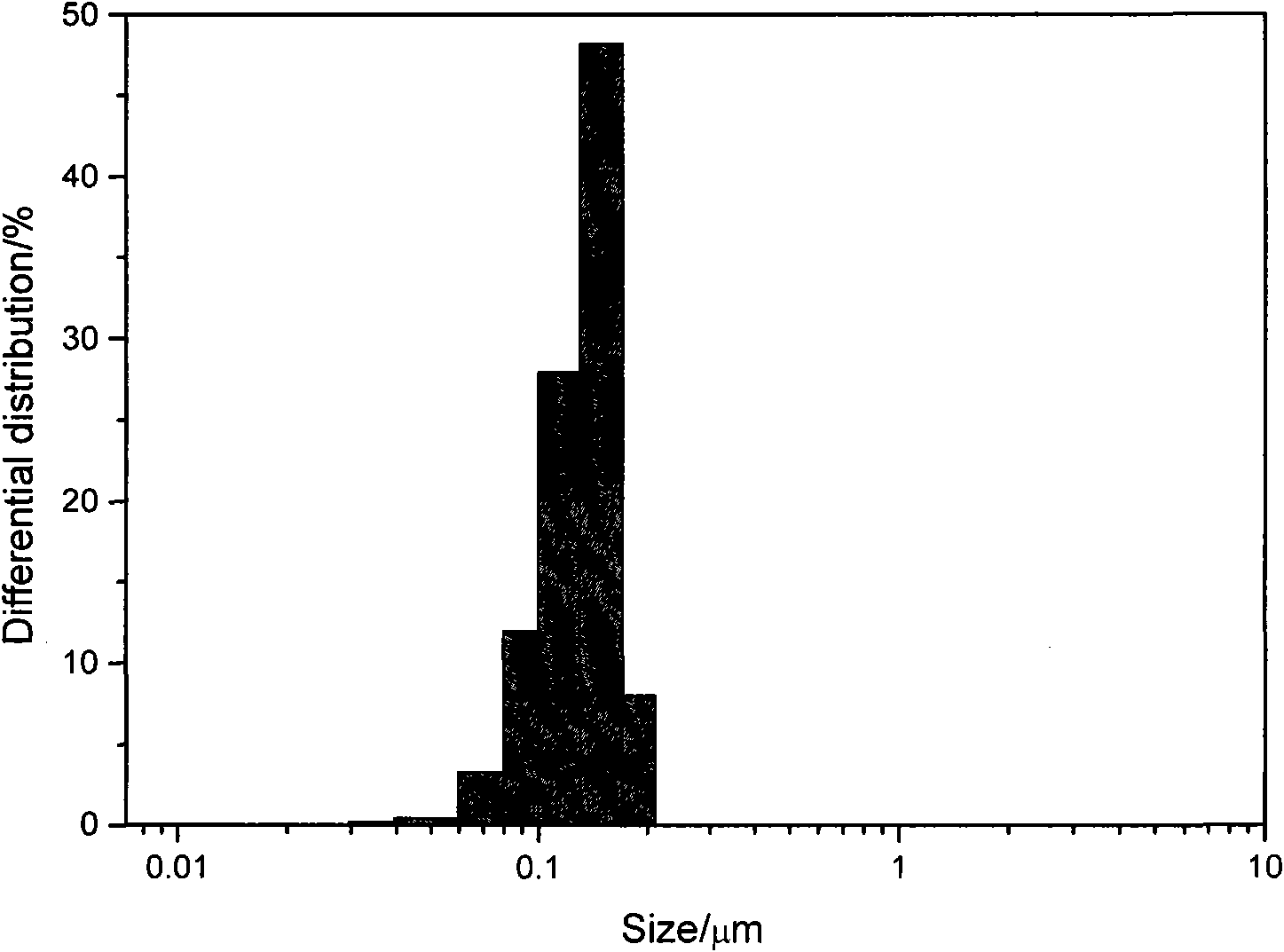

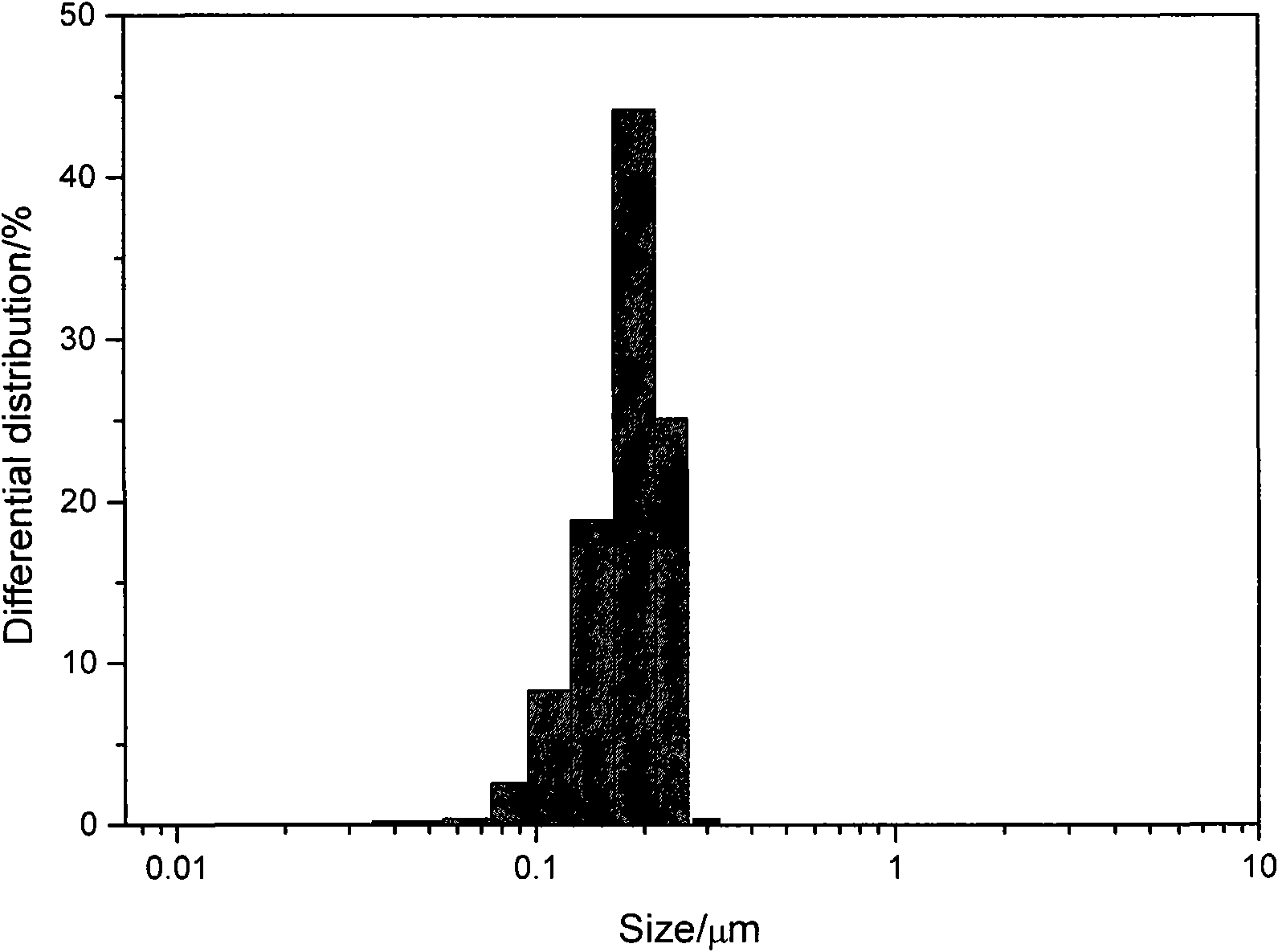

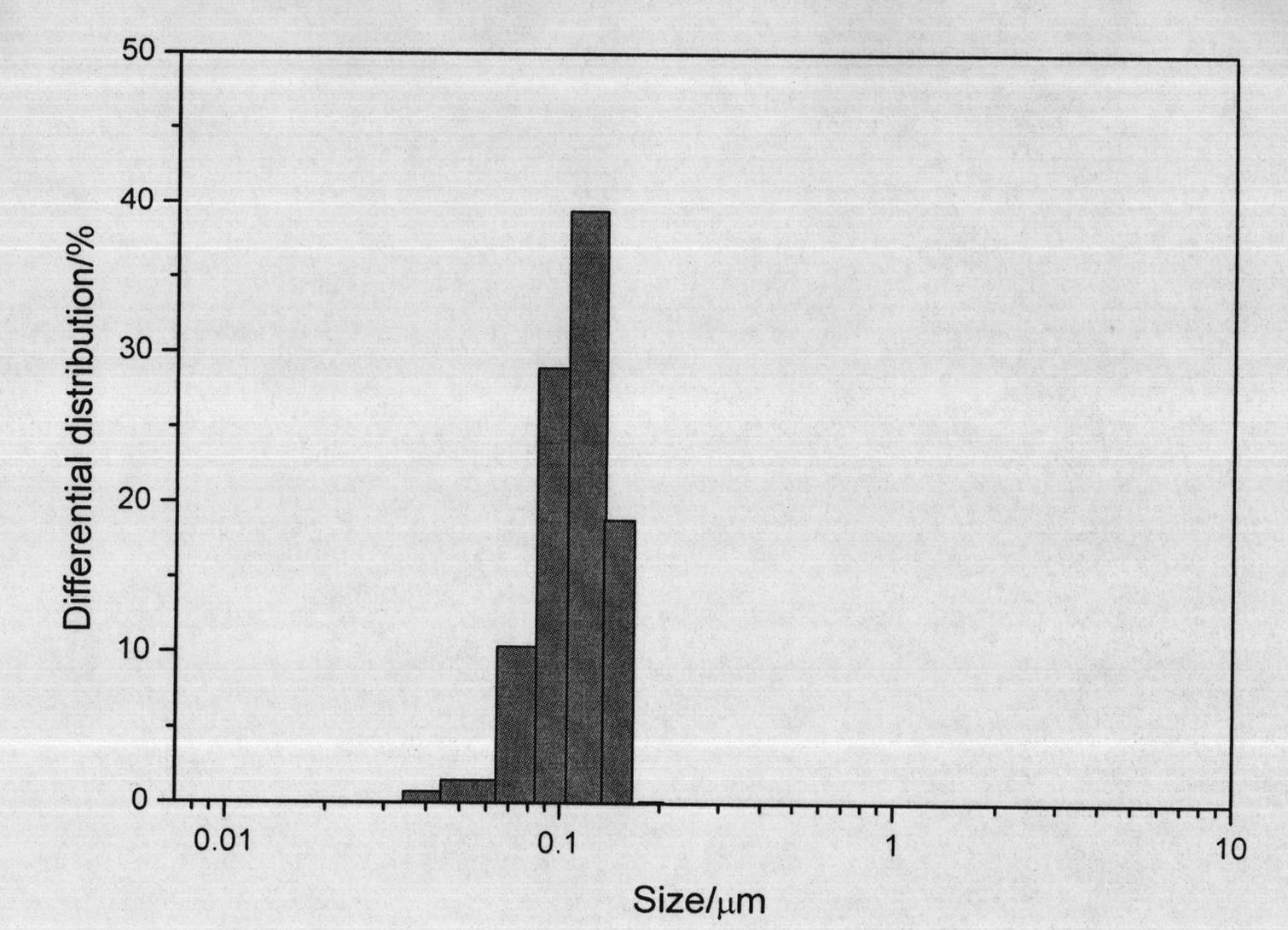

Polyurethane oil/polyacrylate latex interpenetrating network polymer emulsion material and synthesizing process thereof

The invention discloses a new polyurethane oil / polyacrylate latex interpenetrating network polymer emulsion material and a synthesizing process thereof. The average particle diameter of the emulsion colloidal particles is less than 200nm, the topography characteristic of the particles is a multi-layer colloidal particle structure, the core is a polyurethane oil polyacrylate graft copolymer, and the outer layer is a hydrophilic polymer of the polyurethane oil. The synthesizing process comprises the following steps: preparing an alcoholysate from drying oil or semi-drying oil and low-molecular-weight polyalcohol; synthesizing a polyurethane oil solution and ionizing; preparing polyurethane oil-water dispersion; and preparing the polyurethane oil / polyacrylate latex interpenetrating network polymer emulsion material LIPN PUO / PA. Compared with the general water dispersion, the emulsion of the invention has higher luster and can effectively solve the problem of surface finish of a general water-base metal coating, a wooden ware coating, a leather coating and a paper coating, thus further improving the over-all properties of the material.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

Use of oils with high concentrations of polyunsaturated fatty acids in plastics and surface coatings

Oil compositions having a high concentration of polyunsaturated fatty acids are described for use in various applications including use as drying oils, in ink compositions and coating compositions. Oil compositions wherein the double bonds of the fatty acids are substantially epoxidized are described and used as plasticizers and thermal stabilizers for various halogenated polymer compositions.

Owner:MONSANTO TECH LLC

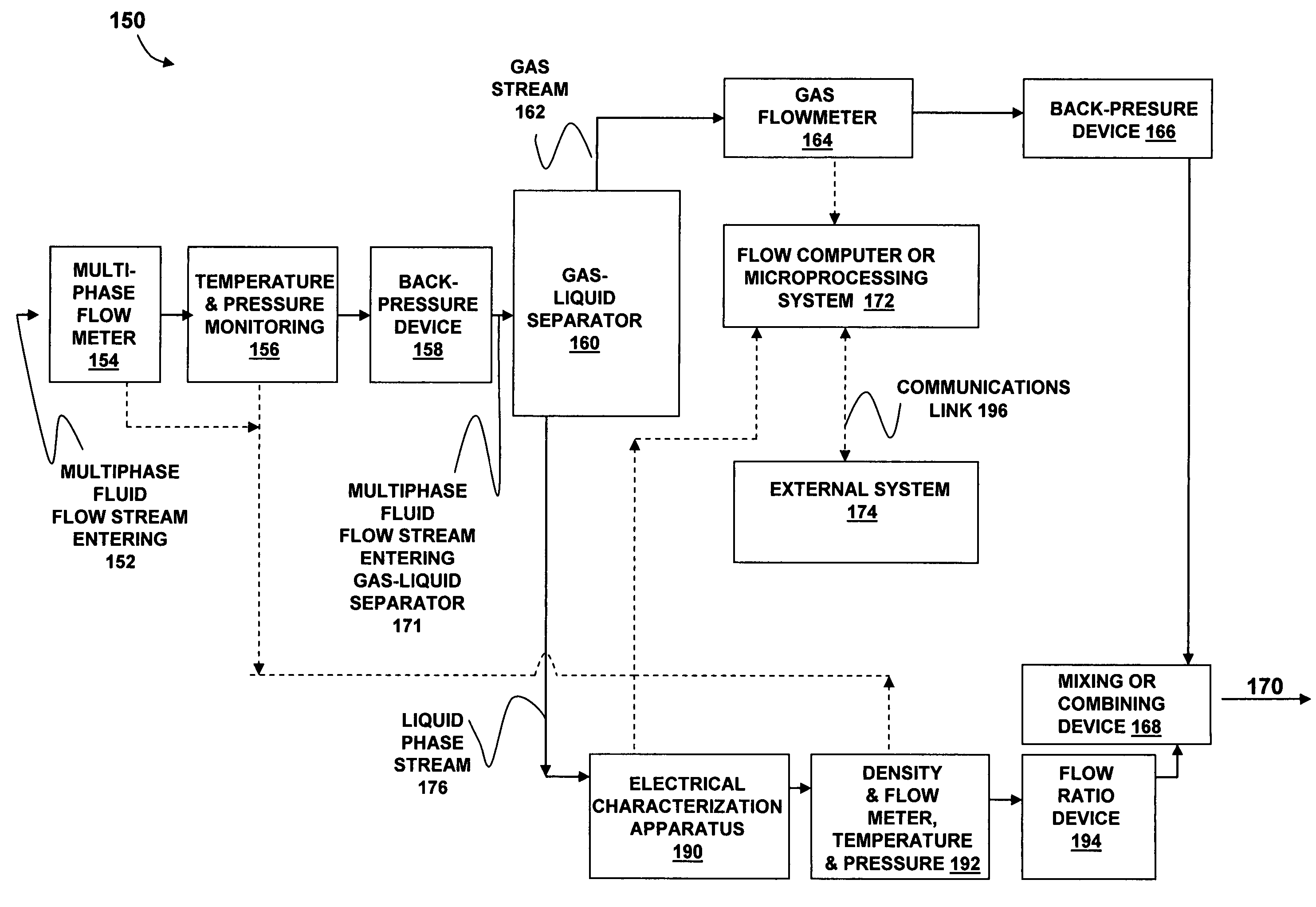

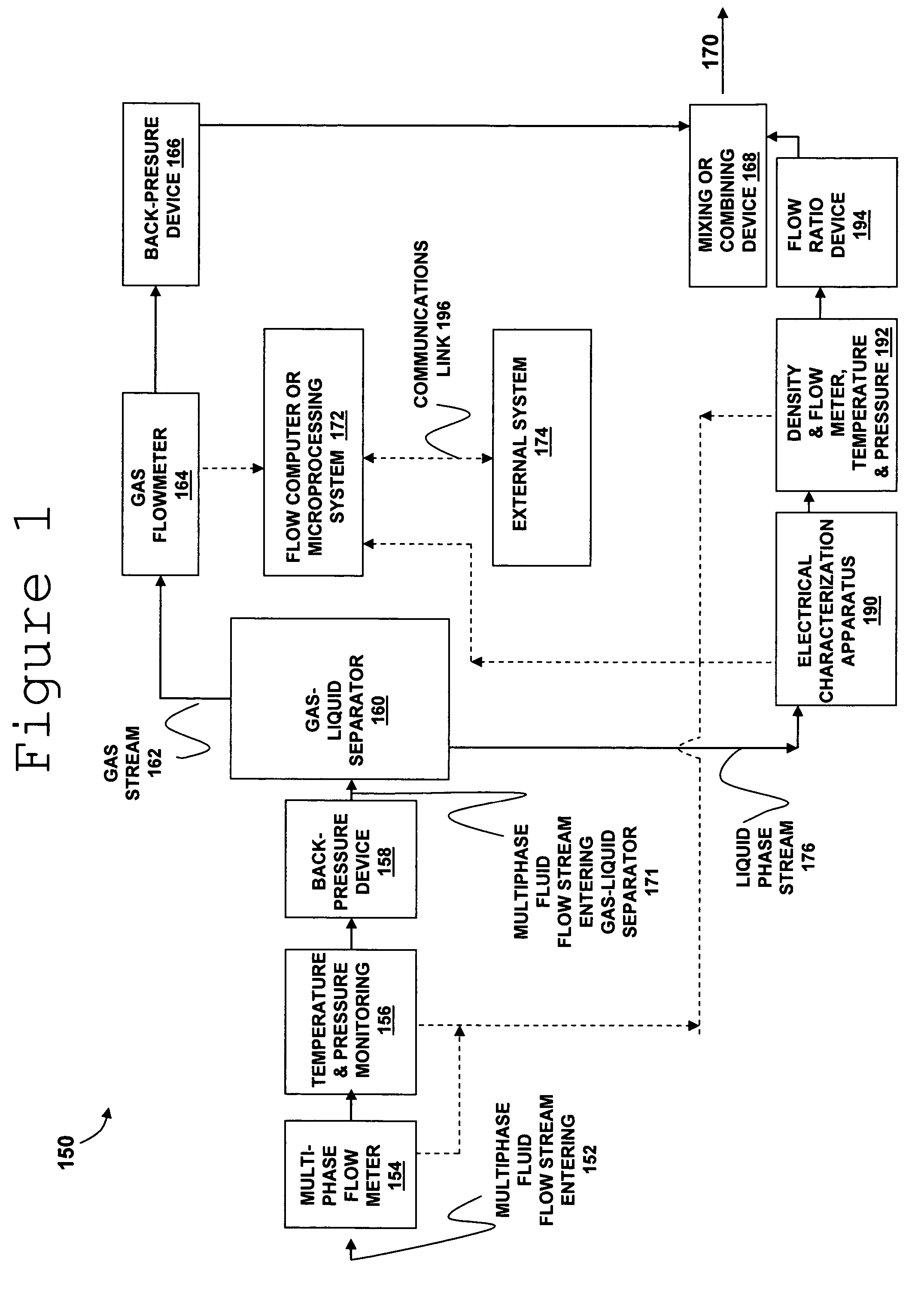

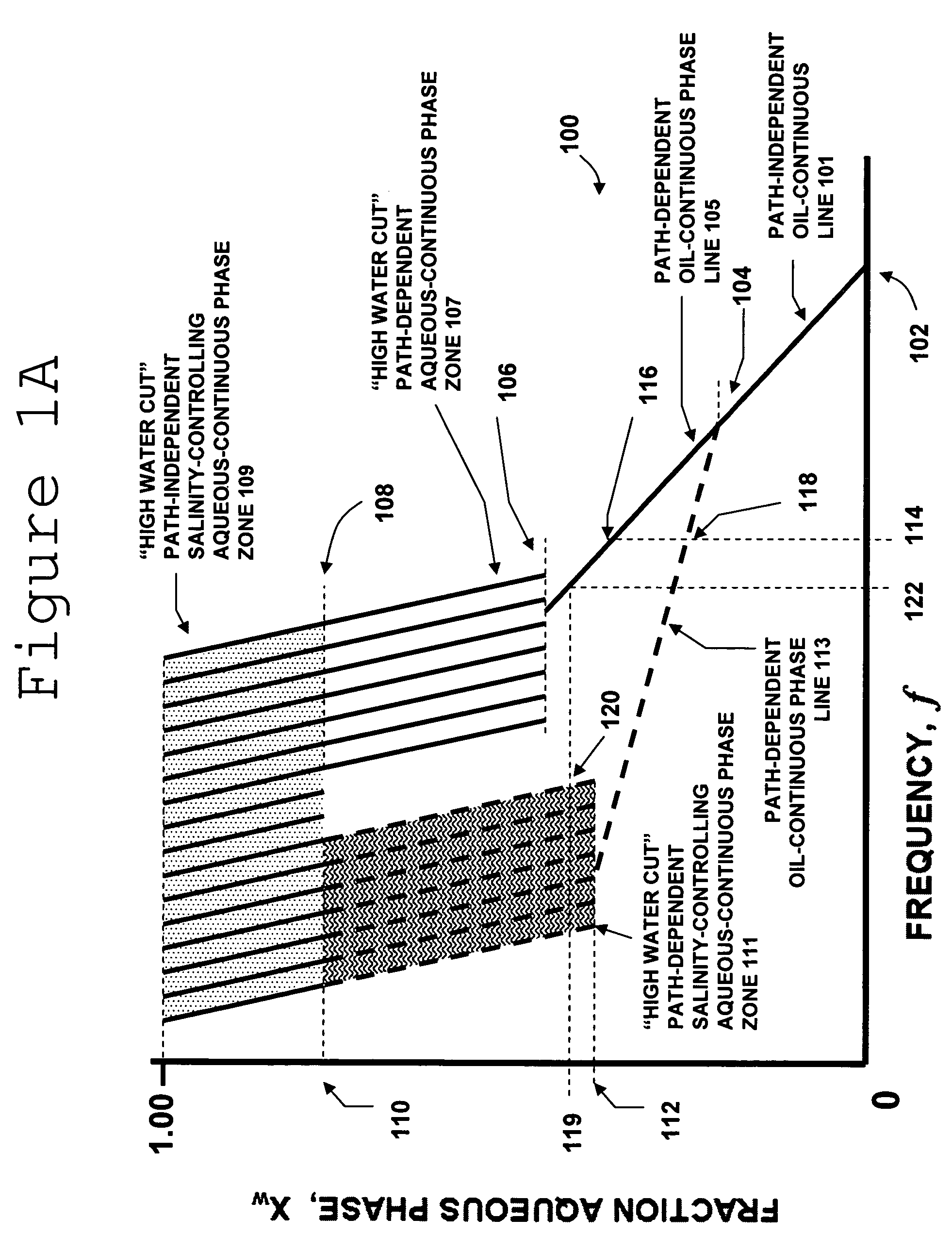

Multiphase fluid characterization

ActiveUS7523647B2Accurate measurementGreat advantageMaterial analysis by electric/magnetic meansSpecific gravity using flow propertiesPermittivityPetroleum oil

Methods for determining and validating a first phase fraction of a gravitationally-separated multiphase fluid by conducting physical and electrical property measurements on samples of the fluid. The water content of crude petroleum oil is determined after the oil and water have begun to separate into phase layers such as occurs during un-agitated holding of the crude petroleum oil. A series of measurements of electrical properties such as permittivity and physical properties such as density is collected. The density minima can be used to generate hindsight determinations of average properties, such as the dry oil phase density, which in turn can be used to increase the accuracy of the water percentage in the oil determined by the permittivity and density methods. Flow weighted averages of water percentages by each method can be used to determine and validate the water content of the crude petroleum oil.

Owner:PHASE DYNAMICS

Modified dry oil alkyd resin for protective paint for metal coating on the back of the mirror and the curtain coating paint

InactiveCN1621430AImprove drynessImprove water resistancePolyester coatingsOptical elementsEpoxySolvent

The modified drying alkyd resin for curtain coated paint protecting metal coating in the back of mirror includes medium oil content drying alkyd resin in 55-70 wt%, acrylate monomer in 20-30 wt% and epoxy resin as modifier in 10-15 wt%. The medium oil content drying alkyd resin and the acrylate monomer form copolymer resin, and the copolymer resin is reacted with epoxy resin to form the modified drying alkyd resin with final viscosity of 150-300 s, acid value lower than 5 mg KOH / g and solid powder content over 50 wt%. The modified drying alkyd resin, selected cross-linking resin, pigment and solvent constitute curtain coated paint capable of well attaching to the surface of smooth metal coating.

Owner:徐金龙

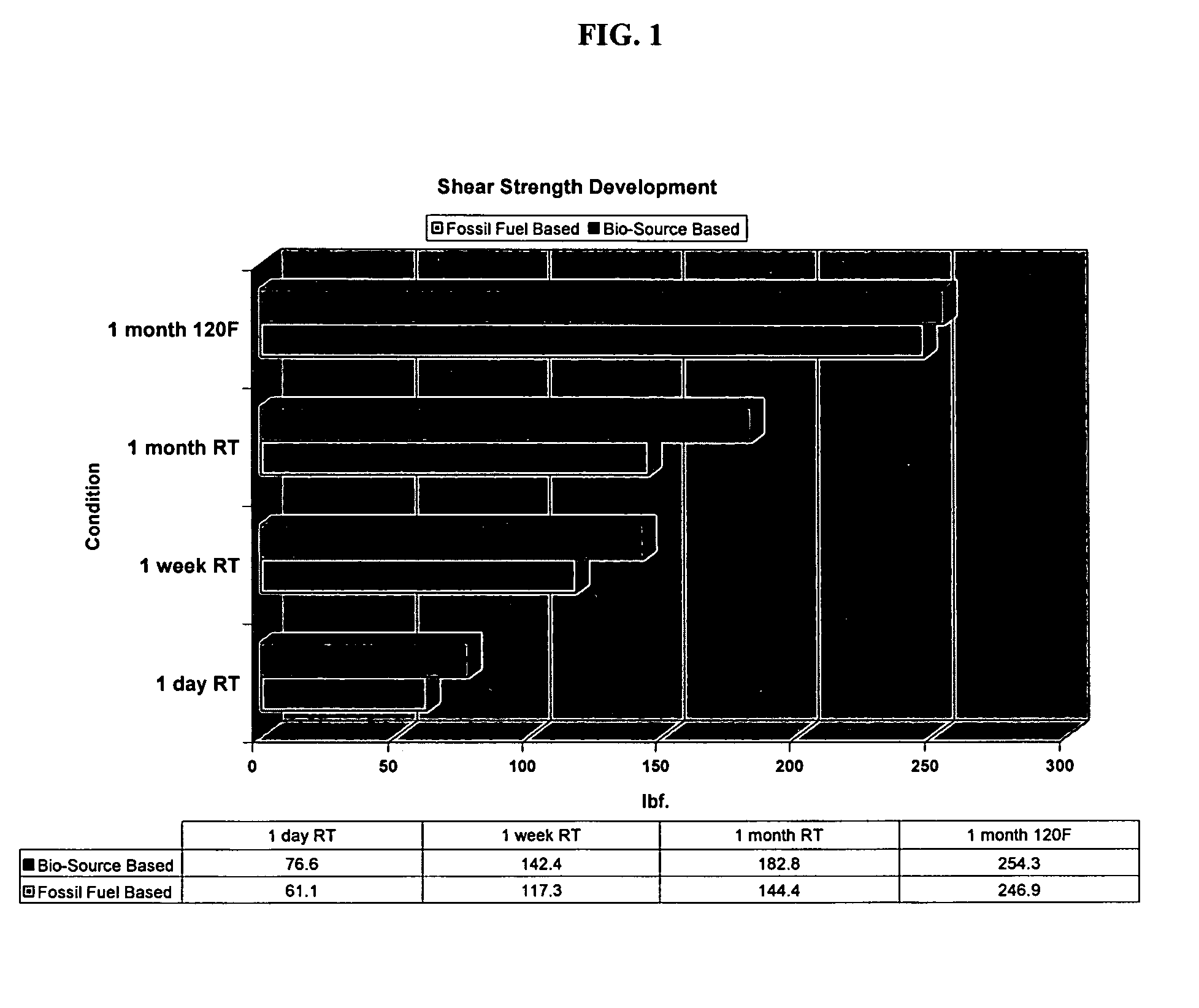

Low VOC bio-source adhesive

ActiveUS20080064852A1High strengthLow and substantially no VOC emissionDrying oil adhesivesProtein adhesivesAdhesiveFatty acid

A one component adhesive composition is provided, which can be formulated from substantially or totally bio-based, renewable raw materials. Such adhesives can be formulated to have high strength and / or low or substantially no VOC emissions. This can be achieved by utilizing polymers that are derived or extracted from renewable plant materials such as soybeans, corn, sunflowers, wheat, etc. Adhesive compositions in accordance with the invention can include oils. The composition preferably contains bio-based oils only, but need not be completely free of fossil fuel or synthetic based oils. It should also include drying oils and / or similarly acting polymers, co-polymers, and fatty acids. Plasticizers, such as hydrogen oxide, derived from renewable sources are utilized to impart performance properties to the formulated adhesive. Metal napthanates can be used to catalyze the drying and / or curing speed when the adhesive composition is applied to a substrate.

Owner:W F TAYLOR

Methods for removal of oil and other contaminants from water

The invention relates to compositions and methods for separating oil and other contaminants (particularly oleophilic compounds) from water and other carriers. The invention is particularly useful for separating oil and other oleophilic compounds from bilgewater and other wastewater. The compositions typically comprise a hydrocarbon resin and a drying oil. The compounds in the composition are typically combined in an organic solvent. For example, hydrocarbon resin and tung oil are optionally combined into a naphtha solvent. The invention is particularly useful for separating emulsified oil from water, whether oil in water emulsions or water in oil emulsions.

Owner:ROBERTS DAVID

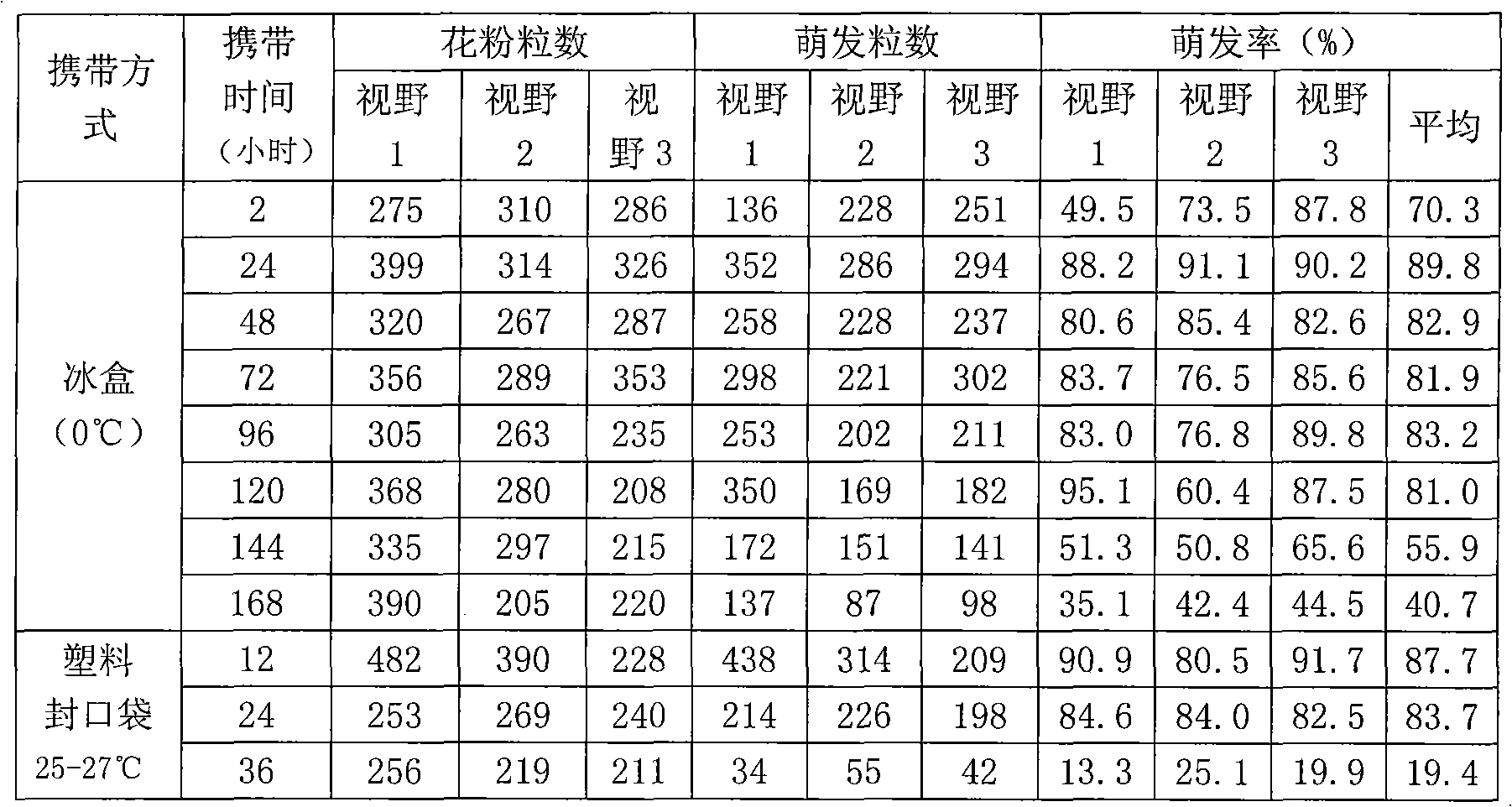

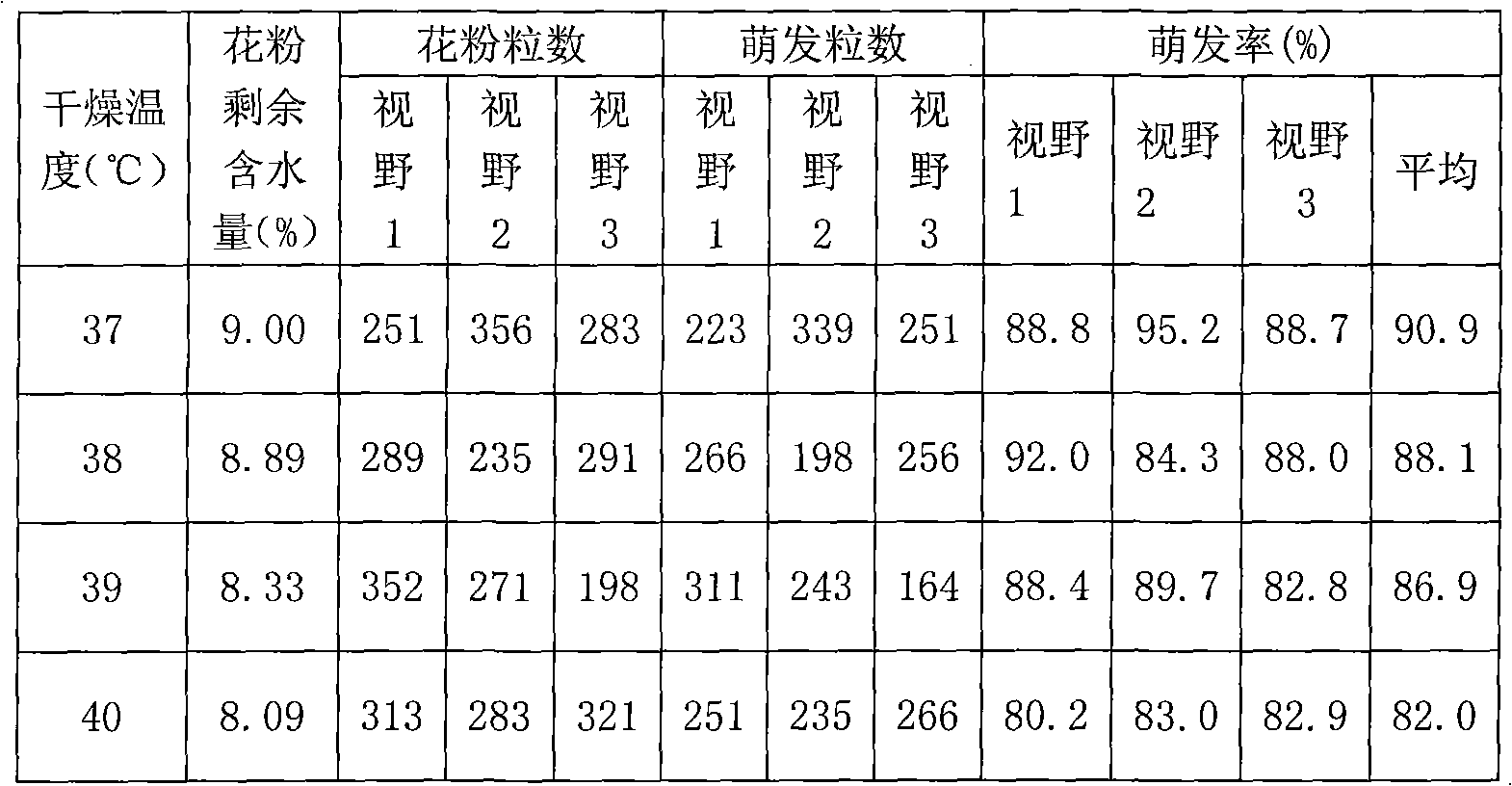

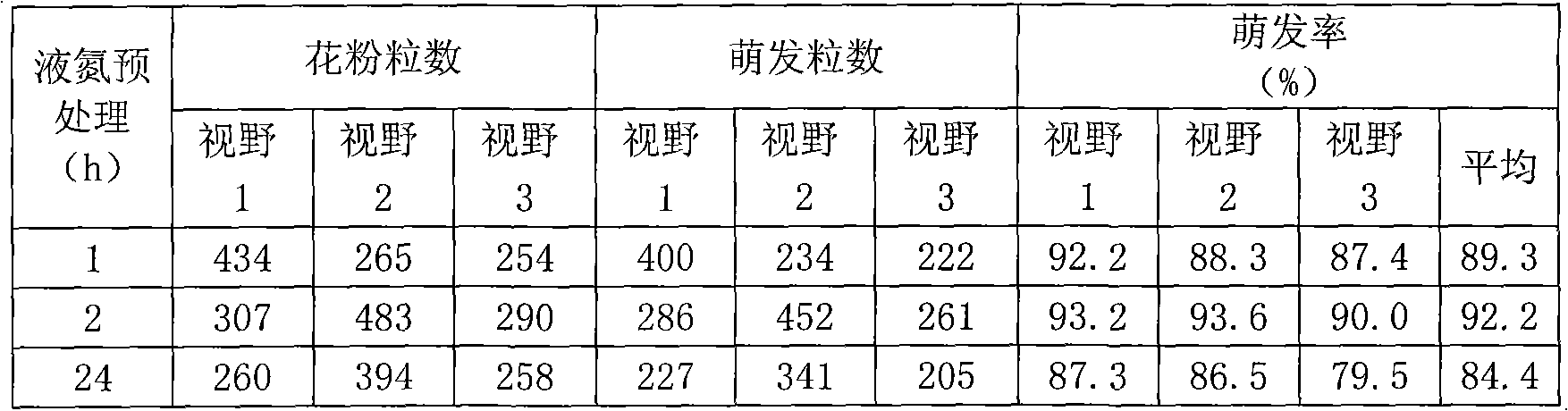

Ultra-low temperature preservation method for oil palm pollen

InactiveCN101926323AImprove germination rateAchieve long-term preservationDead plant preservationUltra Low Temperature FreezerPollen

The invention relates to an ultra-low temperature preservation method for oil palm pollen, which comprises the following steps of: drying the collected fresh oil palm pollen after impurity removal to control the residual moisture content of the oil palm pollen to between 8 and 9 percent; filling the dried oil palm pollen into a freezing pipe, directly putting the freezing pipe into liquid nitrogen to perform pre-freezing treatment, then transferring the freezing pipe to an ultra-low temperature refrigerator for preservation, and flushing the ultra-low temperature preserved oil palm pollen by using normal-temperature tap water during de-freezing. The method has simple process and low cost, effectively realizes long-term preservation of the oil palm pollen by preserving the oil palm pollen at the ultra-low temperature on the premise of controlling the residual moisture content of the pollen, and has the advantages of low preservation cost, long storage time, high pollen germination rateand the like.

Owner:RUBBER RES INST CHINESE ACADEMY OF TROPICAL AGRI SCI +1

Petroleum resin modified alcohol acid antirust primer with high solid content

InactiveCN1840594AReduce pollutionDry fastAnti-corrosive paintsPolyester coatingsOrganic solventAlcohol

Disclosed is a rust-inhibiting priming paint, wherein the proportion of the raw material comprises (by weight percent) medium oil-degree dry oil alkide resin 25-35%, petroleum resin 5.5-7.5%, color filling material 45-55%, organic solvent 6-10% and auxiliary agent 2-3.5%.

Owner:东莞市黑马化工有限公司

Kapok fiber-based three-dimensional network oil absorption material

The invention discloses a kapok fiber-based three-dimensional network oil absorption material. According to the invention, activation-treated kapok fibers are used as base materials, and the three-dimensional network oil absorption material is prepared by grafting copolymerization, crosslinking, washing, drying, and crushing in the presence of an initiator. The dry oil absorption material can absorb diesel oil with a mass being 40-50 times of the mass of the material, can absorb gasoline with a mass being 40-47 times of the mass of the material, and can absorb chloroform with a mass being 60-67 times of the mass of the material. The oil absorption material of the invention is simple in preparation operation, is characterized by high oil absorption rate and high oil absorption speed, and is applicable to fields such as sea, river, lake surface oil pollution, kitchens, and the like.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Method for comprehensively extracting tea oil, flavonoids compounds, tea saponin and tea polysaccharide

InactiveCN102925292ALow toxicityFew stepsFatty oils/acids recovery from wasteSugar derivativesCamellia oleiferaSolvent

The invention provides a method for comprehensively extracting tea oil, flavonoids compounds, tea saponin and tea polysaccharide. The method comprises the following steps of: extracting the tea oil in a dry oil-tea cake by using a low-polarity solvent, and extracting the oil-tea cake by using ethyl acetate, an ethanol-water solution and water in turn to obtain flavonoid glycosides compounds, the tea saponin and the tea polysaccharide respectively. According to the method for comprehensively extracting the tea oil, the flavonoids compounds, the tea saponin and the tea polysaccharide, provided by the invention, five effective components in the oil-tea cake can be comprehensively extracted in the same process, and the method has the advantages of fewer steps, low toxicity of the solvent and good extracting effect.

Owner:伊国群

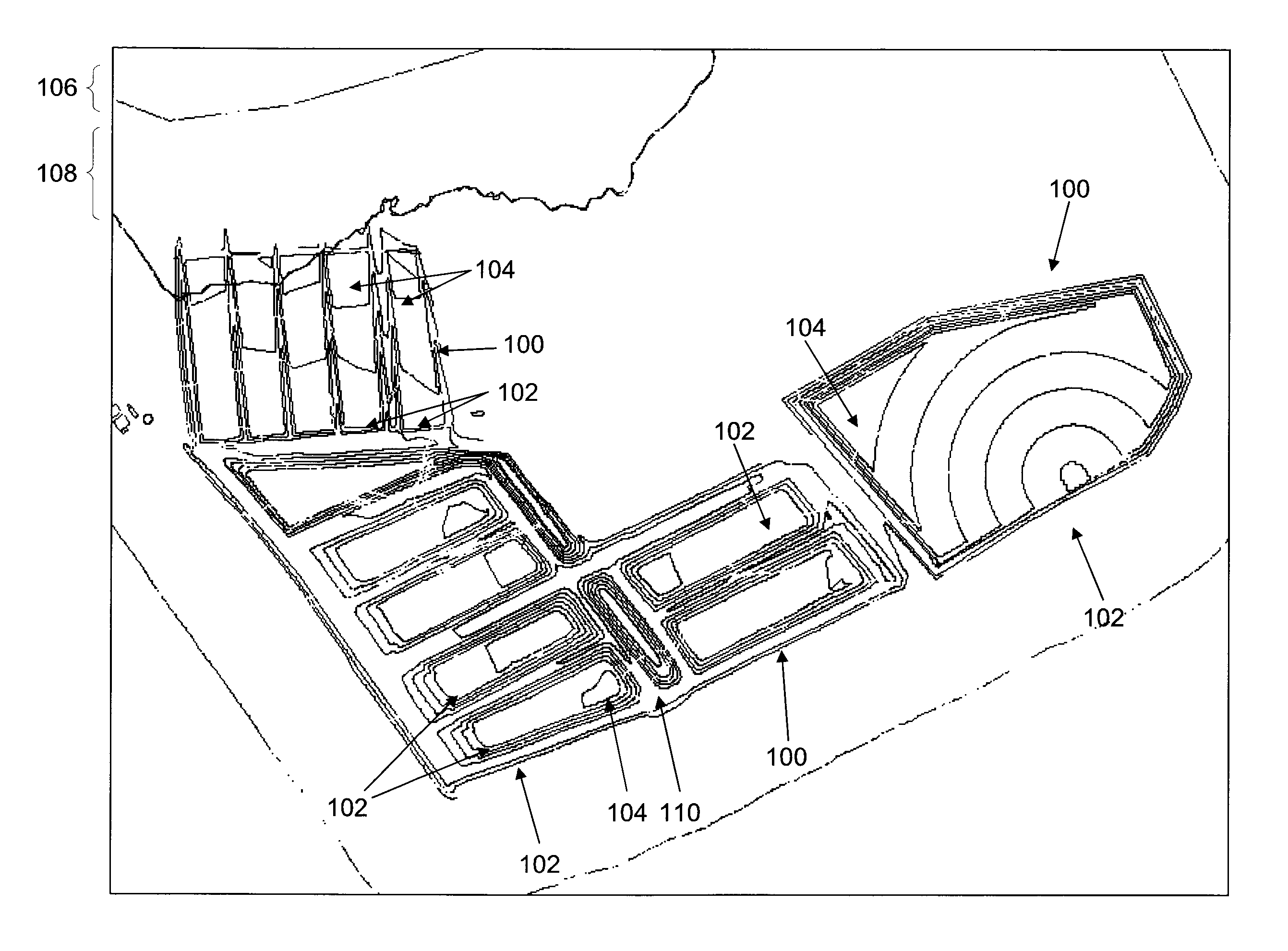

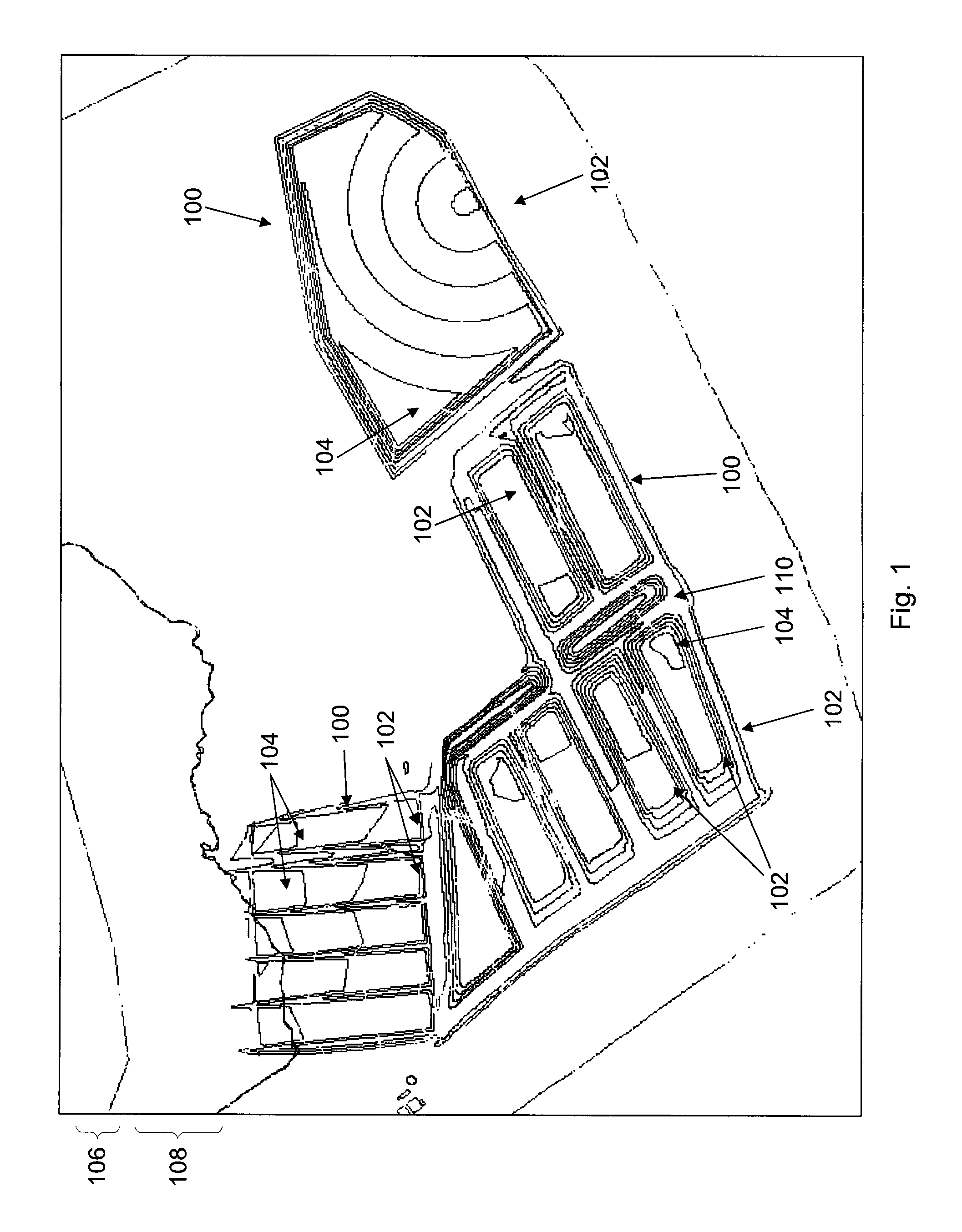

Depositing and Farming Methods for Drying Oil Sand Mature Fine Tailings

InactiveUS20130081298A1Improve initial dewateringAccelerated dryingDrying using combination processesSand dryingUpper crustEngineering

Methods for drying oil sand fine tailings treated to comprise flocculated fine tailings, by deposition and farming techniques, are provided. A deposition cell is provided with a sloped bottom surface and the flocculated fine tailings are deposited to undergo channelless advancement in the cell while allowing drainage of release water. When the deposit is uneven, the deposit may be plowed while wet for spreading and ensuring water release conditioning is imparted thereto, while avoiding over-shearing, and maintaining sufficient shear strength to allow standing. Once a dried upper crust forms, the deposit may be harrowed to break up the crust, expose wet regions there-beneath and create furrows in the standing deposit. The methods improve the dewatering and drying of mature fine tailings in oil sands.

Owner:SUNCOR ENERGY INC

Anticorrosion paint for chimney of electric plant and its uses

InactiveCN101007921AExtended service lifeGood corrosion resistanceAnti-corrosive paintsEpoxy resin coatingsBrickDiethylenetriamine

The invention belongs to anticorrosion paint field, which in detail relates to anticorrosion paint for power plant chimney and its application to protecting inner wall of chimney. It comprises: component A: drying-oil modified epoxy resin and flake glass-filled coating; component B composite curing agent: triethanolamine, calcium trisodium diethylenetriamine pentoacetate and polyethylene polyamine.Mixing component A and B according to ratio by weight of 100: 15- 30, coating it on inner wall of chimney, curing at normal temperature for 48 hours and forming hard paing film, which can protect armored concrete or brick construction from corrosion caused by temperature and smoke gas and perlong chimney life length. The product is characterized by strong adhesion force and excellent corrosion- resistance and as long as 30 years' life length.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

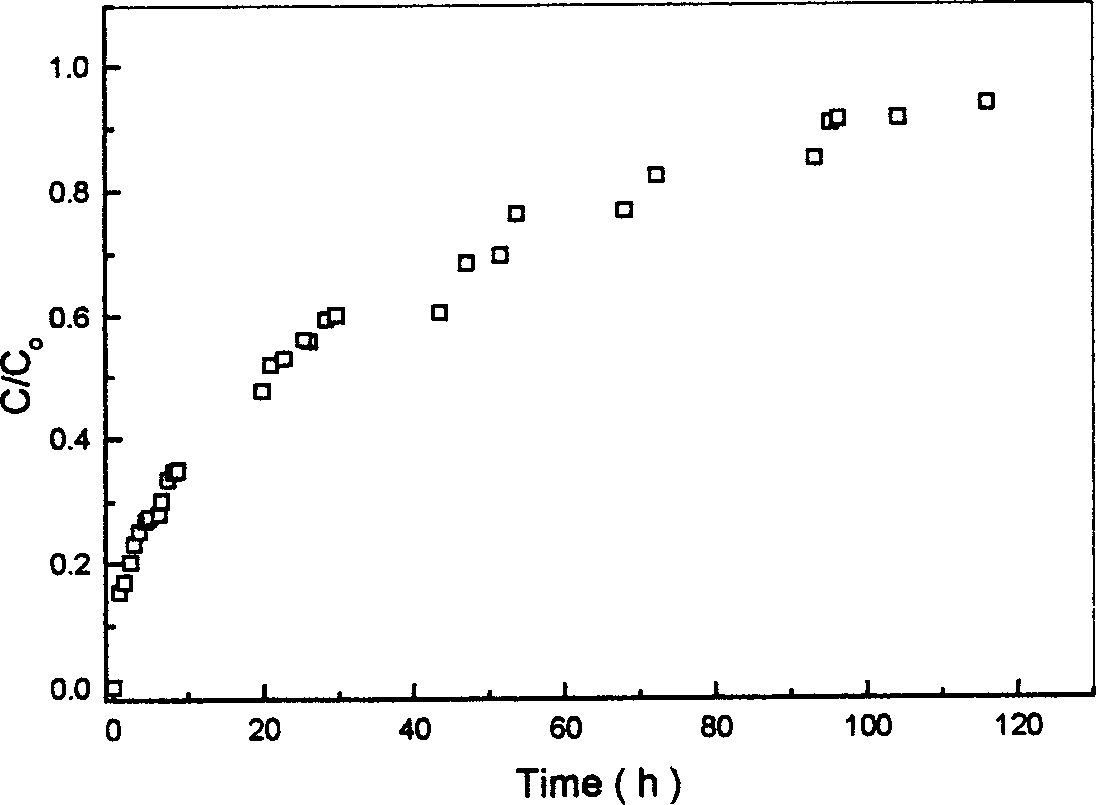

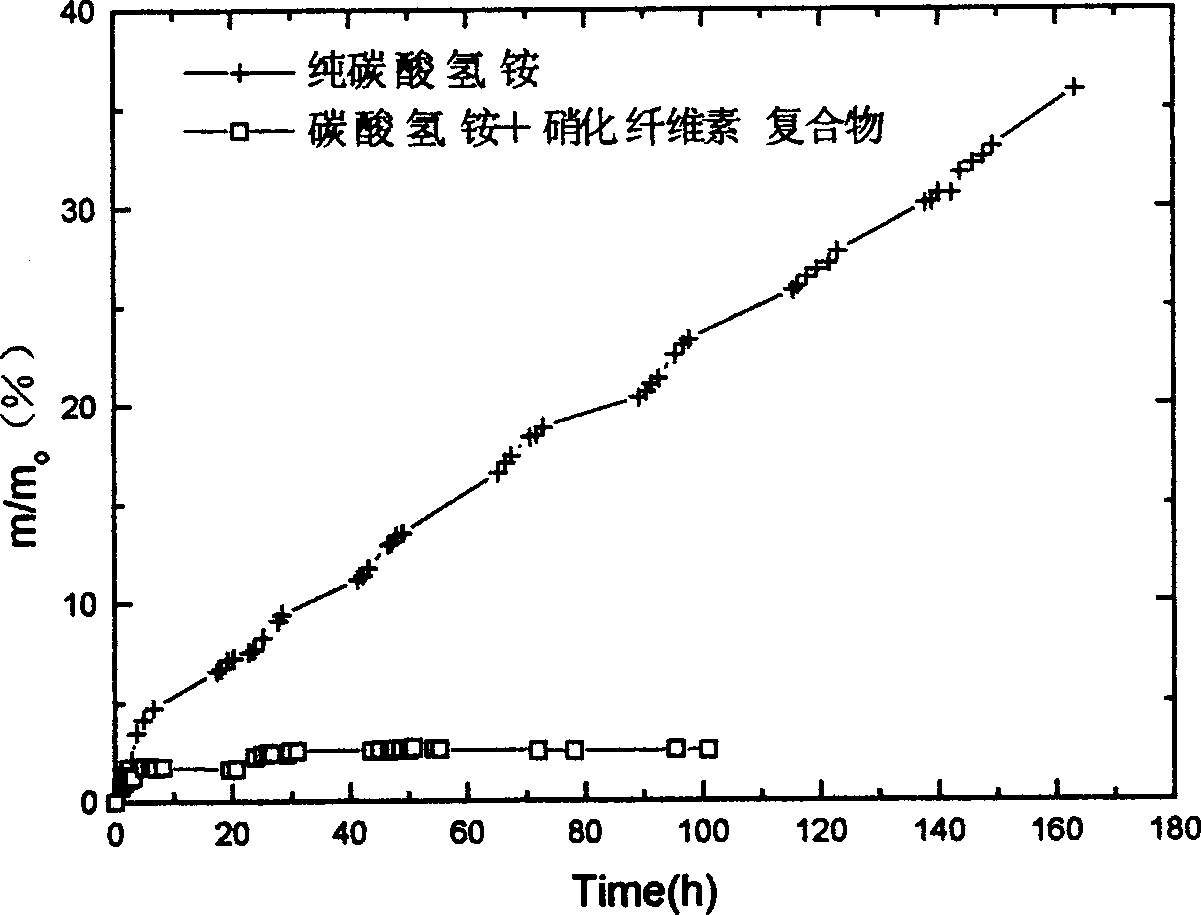

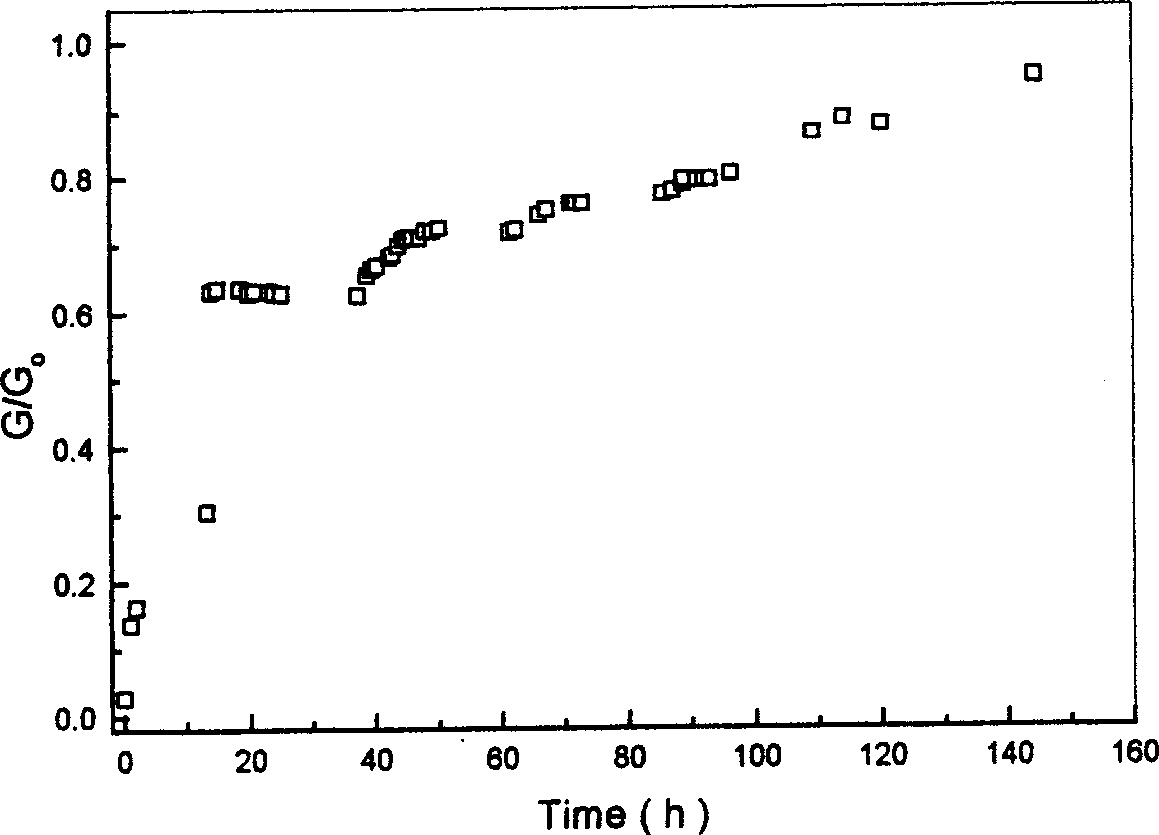

Film-coated slow-released fertilizer and preparation process thereof

InactiveCN1465552ABiodegrades quicklyMeet the needs of sustainable developmentFertilizer mixturesAlcoholNitrocellulose

The present invention relates to a coated granular slowly-releasing fertilizer and its preparation method. It is characterized by that the surface of the nitrogen granular fertilizer is covered witha layer of coated film, and said coated film is formed from nitro-cotton and tung oil as dry oil additive, and the coated film is 5%-30% of total weight and added quantity of tung oil is 0-20% of coated film weight. Its preparation method includes the following steps: dissolving the cellulose compound and its derivative for example nitro-cotton in solvent to obtain covering solution, said solventis ethyl alcohol and ethyl ether mixed solution, then coating surface of granular fertilizer with said covering solution, finally recovering solvent so as to obtain the invented coated granjlar slowly-releasing fertilizer.

Owner:NANJING UNIV +1

A kind of sludge secondary vapor compression drying method

InactiveCN102276131AReduce energy consumptionGuaranteed cleanlinessSludge treatment by de-watering/drying/thickeningHigh energyOil sludge

The invention relates to a secondary steam compressed drying method of sludge. Present drying methods have the disadvantages of high energy consumption and low efficiency. The method of the invention comprises the following steps: uniformly mixing dewatered sludge generated in the process of sewage treatment with oil according to a weight ratio of 1-20:1 to form oil sludge, drying the oil sludge with secondary steam, carrying out oil and dry sludge separation on the dried oil sludge; reusing separated oil as a raw material of mixed oil sludge, and treating separated dry sludge as a dry finished product of sludge; and separating saturated secondary steam from the secondary steam generated in the process, compressing to superheated steam superheated steam, and sending the superheated steam which is treated as a heat source to a heating chamber of a drier. The method of the invention fully utilizes the heat energy of the secondary steam, so the energy consumption of a drying system is greatly reduced; and no dust is entrained in the drying process, so the cleaning of heat exchange surfaces of a drying device is kept, and the drying efficiency is high.

Owner:HANGZHOU DIANZI UNIV +1

Mirror back lacquer resin and mirror back lacquer

The invention relates to mirror back paint resin and mirror back paint thereof. The mirror back paint resin comprises the following components with the following weight percentage: dry oil or dry oleic acid is 20.0 to 50.0 percent, polyatomic acid is 20.0 to 50.0 percent, polyatomic alcohol is 10.0 to 40.0 percent and other component is organic solvent. The mirror back paint resin is dry alkyd resin with the acid value less than 20mgKOH / g and the solid content more than 50.0wt percent; the mirror back paint, which consists of the resin as well as the pigments, the extender pigment, the auxiliary agent, the amino resin and the organic solvent selected by the invention, has quick solidifying, high paint film rigidity, strong adhesive force and excellent chemical corrosion resistance; therefore, the mirror back paint is suitable to be used in the production line of the prior glass silver mirror.

Owner:SHANGHAI JIAO TONG UNIV

Oil resistant rubber material and preparation method thereof

The invention provides an oil resistant rubber material. The oil resistant rubber material comprises the following components in parts by weight: 60-70 parts of butadiene-acrylonitrile rubber, 25-35 parts of fluororubber, 5-10 parts of dioctyl tin maleate, 2-3 parts of glass fibers, 1-2 parts of stearic acid, 0.5-0.8 part of light calcium carbonate, 3-5 parts of magnesium dimethacrylate, 2-3 parts of drying oil alkyd resin, 1-2 parts of paraffin, 3-5 parts of dilauryl thiodipropionate, 1-2 parts of diacetyl peroxide, 0.8-1.2 parts of zinc oxide, 8-10 parts of aluminium oxide, 6-8 parts of white carbon black, 0.8-1.5 parts of anti-aging agent and 1-3 parts of sulfur. The invention also provides a preparation method of the oil resistant rubber material. The oil resistant rubber material has good sealability, high temperature resistance and oil resistance and is suitable for sealing automobile gearboxes.

Owner:LIUZHOU YINGHANG AUTO PARTS

Removal of Contaminants from Water and Gas by Filtration

ActiveUS20100096342A1Water treatment parameter controlGas treatmentFiltrationInternal combustion engine

The invention relates to compositions and methods for separating oil and other contaminants (particularly oleophilic compounds) from water, gas and other carriers. The invention is useful for separating oil, including emulsified oil, from water and other oleophilic compounds from bilgewater and other wastewater. The compositions comprise a hydrocarbon resin and a drying oil, which may be combined in an organic solvent. For example, hydrocarbon resin and tung oil are optionally combined into a naphtha solvent. The invention is also useful for removing a variety of contaminants from an air stream, such as exhaust from internal combustion engines, burners, and other sources.

Owner:ROBERTS AB

Process for Drying Oil Sand Mature Fine Tailings

ActiveUS20130043165A1Efficient actionSufficient energyDewatering/demulsification with chemical meansSludge treatment by de-watering/drying/thickeningFlocculationReactor system

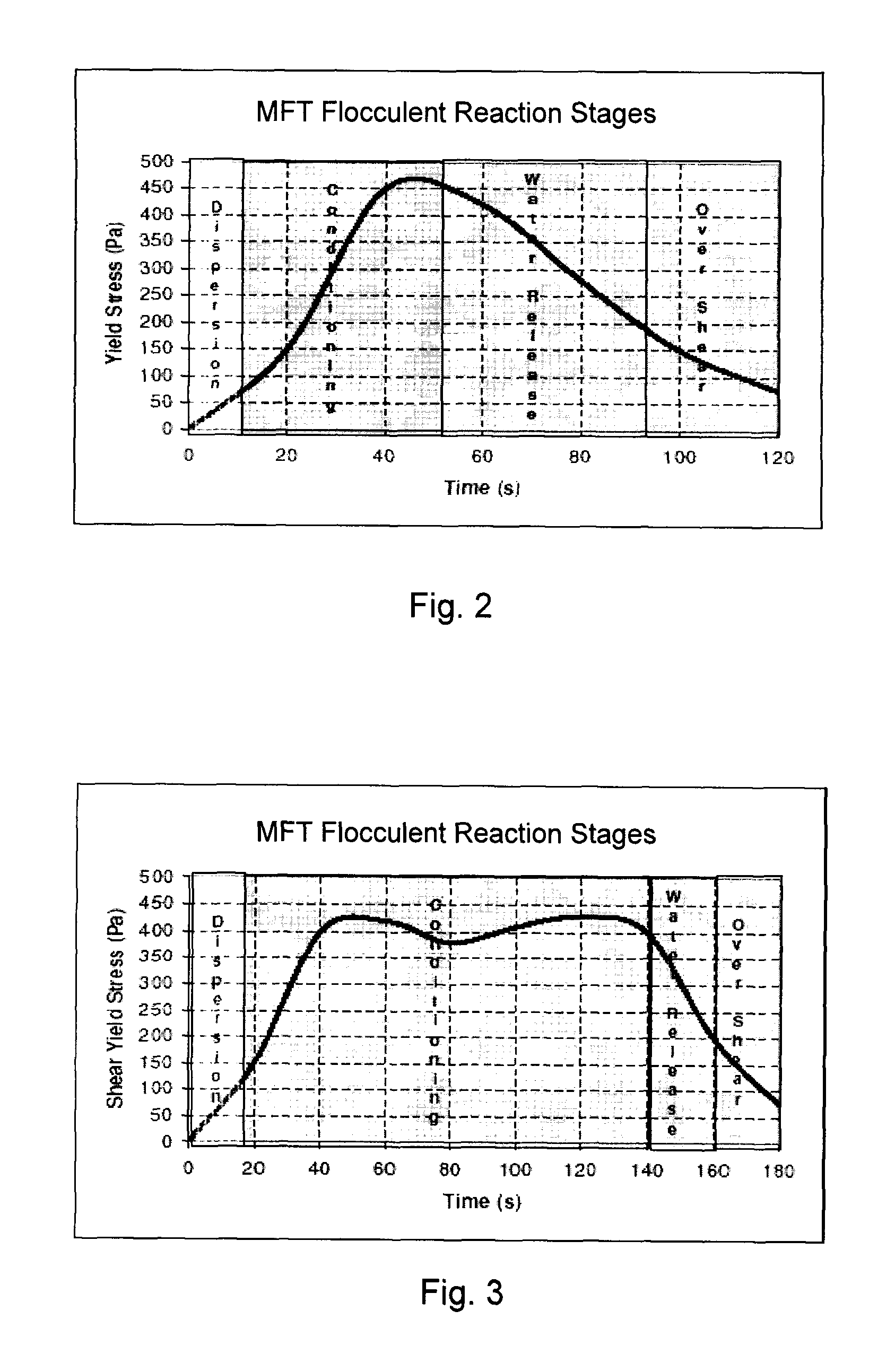

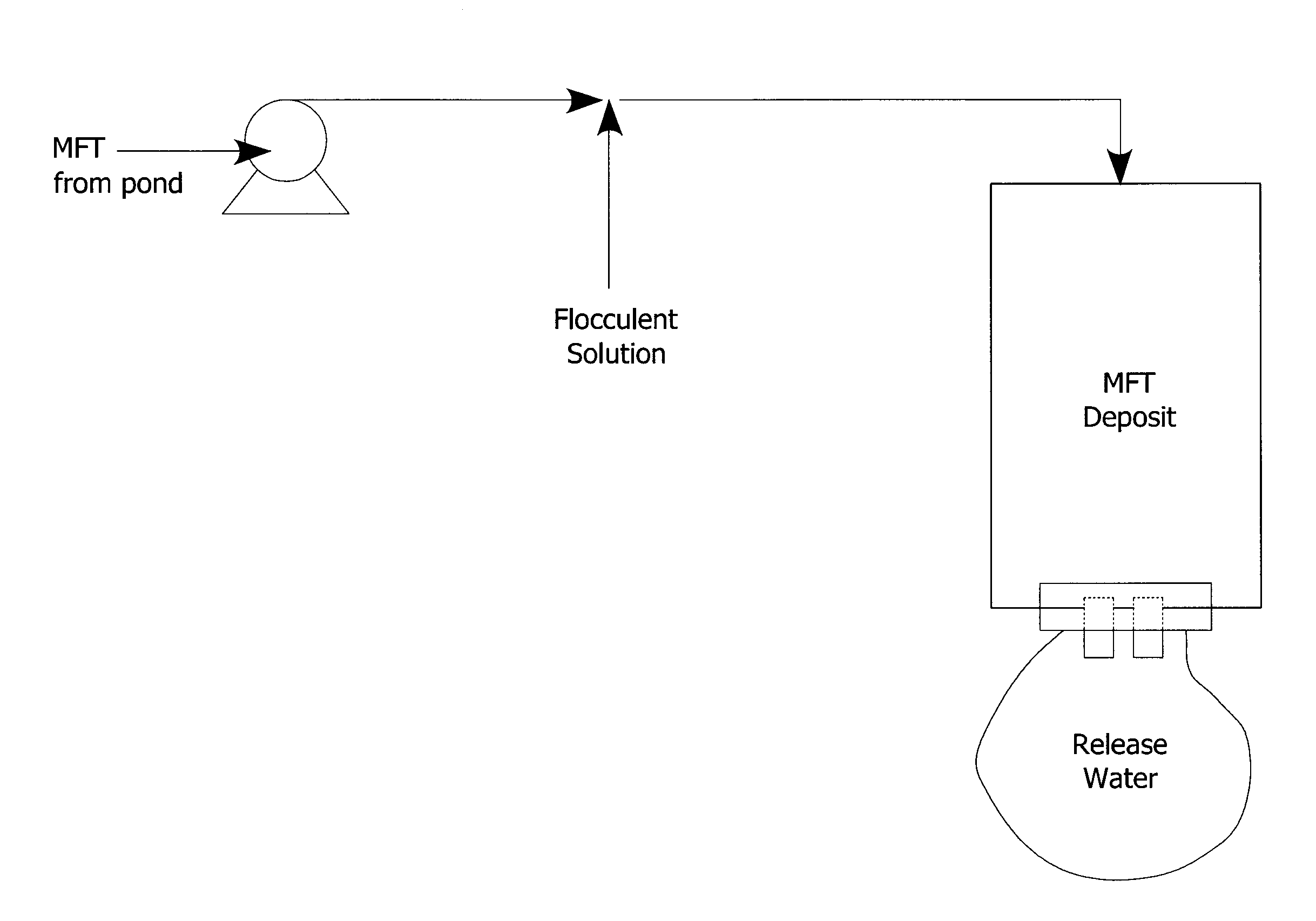

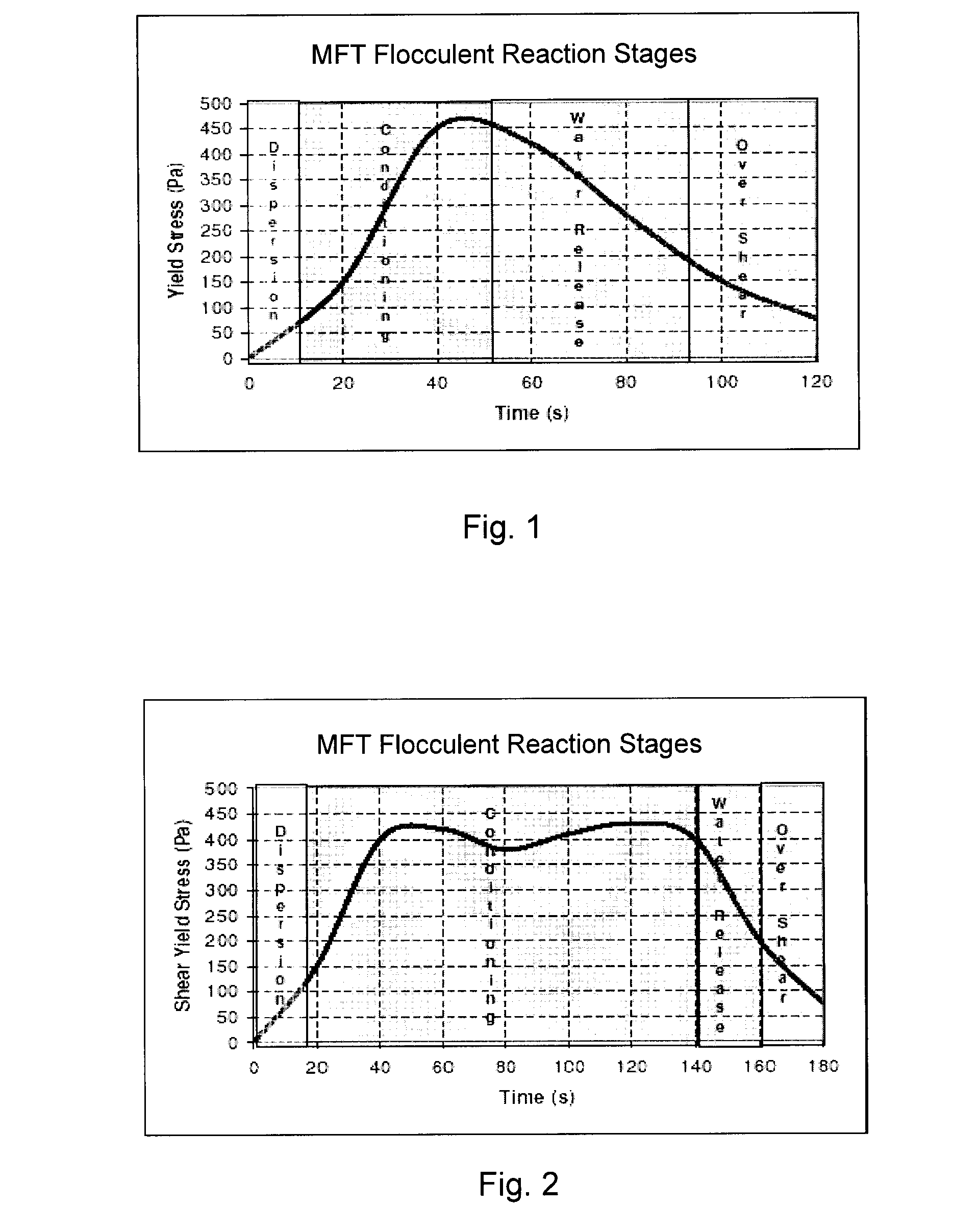

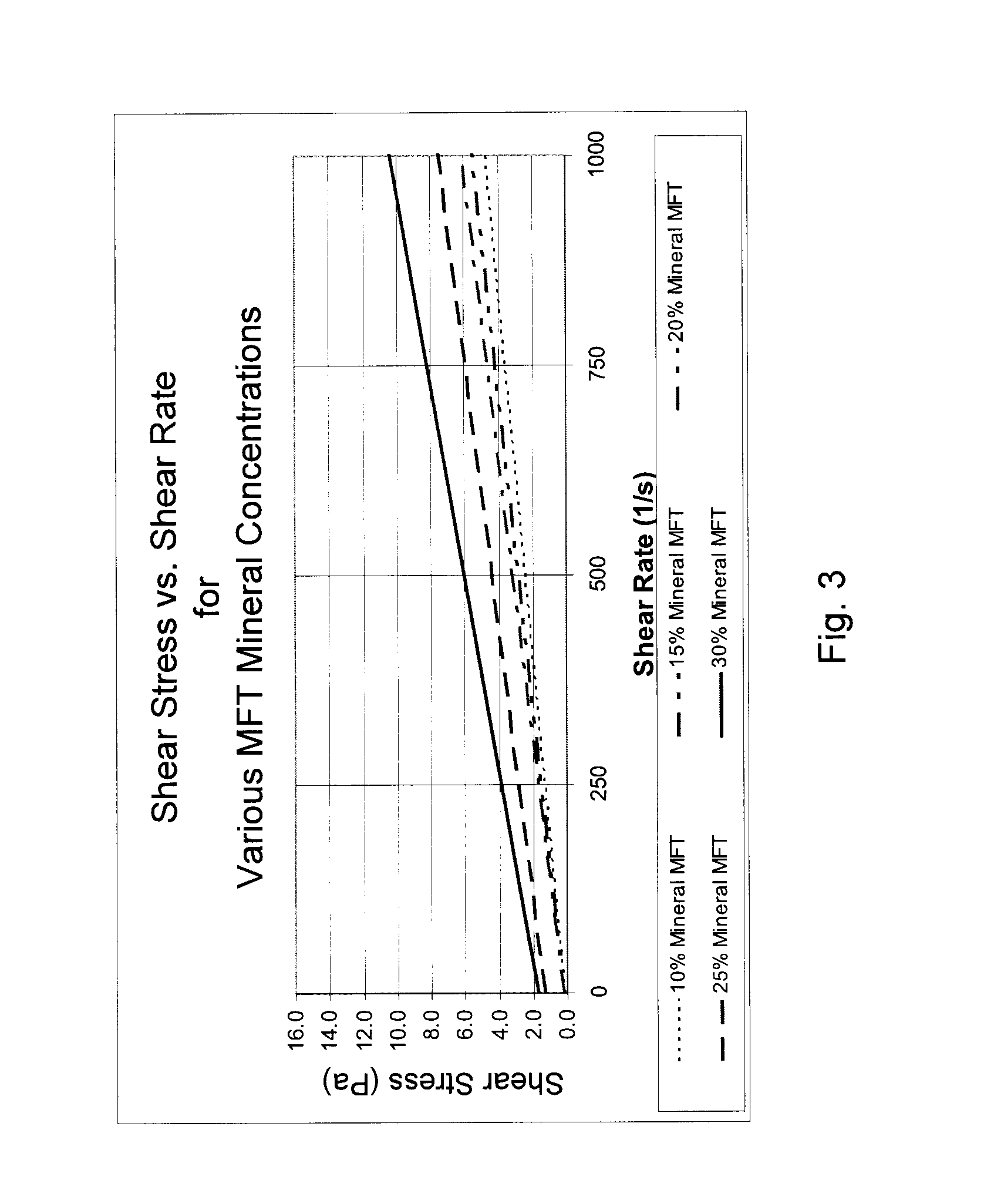

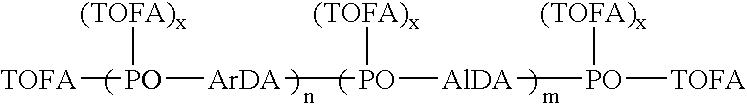

A process for drying fine tailings is provided. The process, which may use a pipeline reactor system, comprises providing an in-line flow of the fine tailings; continuously introducing a flocculent solution to cause dispersion and commence flocculation of the fine tailings and may comprise rapid turbulent mixing; subjecting the fine tailings to flocculation and water release conditioning in-line to cause formation and rearrangement of floes and increasing the yield shear stress to form flocculated fine tailings while avoiding over-shearing of the flocs; and depositing the fine tailings to allow the release of water, formation of a non-flowing fine tailings deposit and drying of the non-flowing fine tailings deposit. The process enables effective in-line dispersion, flocculation and water release, resulting in reliable deposition and drying of the fine tailings deposit.

Owner:SUNCOR ENERGY INC

Modified dry alkyd resin and mirror back curtain drenching paint

The invention relates to modified drying alkyd resin and the mirror back curtain paint thereof. The modified drying alkyd resin comprises the following components with the contents by weight percentages: 30.0 percent to 51.0 percent dry oil or dry oleic acid, 30.0 percent to 51.0 percent polybasic acid, 20.0 percent to 41.0 percent polybasic alcohol, 5.0 percent to 20.0 percent phenol-formaldehyde resin and the rest of organic solvent. The modified drying alkyd resin is the phenol-formaldehyde modified drying alkyd resin, the acid value of the resin is lower than 35mgKOH / g, the solid content is larger than 50.0 percent by weight, the mirror back paint which is composed of the resin and pigment, body pigment, additive, amino resin and organic solvent that are selected by the invention has fast curing, high hardness of paint film, good adhesion and great chemical resistance, thus being applicable to the prior production assembly line of glass silver mirrors.

Owner:SHANGHAI JIAO TONG UNIV

Puffing expression method for producing oil with low oil-containing oil-bearing material

InactiveCN101245284AImprove product qualityAvoid excessive denaturationFatty-oils/fats productionPress cakeImpurity

The invention relates to a method for extracting oil by swelling and pressing low oil content oil seeds and is characterized by comprising the following steps: 1) clearing: impurities are removed from the oil seeds; 2) quality-adjusting: the temperatures and water contents are adjusted for the oil seeds; 3) the oil seeds are pressed and swelled; 4) enzyme killing and drying are carried out for the pressed and swelled oil seeds; 5) most of the oil is pressed from the dried oil seeds; the oil seeds can be crushed and then the quality adjusting can be done after the clearing of the step 1); after the step 2) of quality-adjusting, the bloom rolling can be done to the oil seeds and then the pressing and swelling can be done. The method adds the procedures of pressing and swelling before the traditional one time pressing and obtains pure physical pressed oil with high quality and pressed cakes which can be directly used for feed processing, which increases the processing amount of a press and reduces the power consumption and wearing. The method is mainly used for producing small-scale pressed oil and pressed cakes with good qualities and raw materials of low oil content oil seeds such as soybeans and rice bran.

Owner:中机康元粮油装备(北京)有限公司

Single-sheet non-skinning oil ink

The invention relates to a single-sheet non-skinning oil ink which aims at realizing slow drying on a machine and fast drying on paper. The oil ink comprises the following components by weight percent: 10-25% of pigments, 0.1-5% of extender pigment, 20-30% of vegetable oil, 15-30% of mineral oil, 25-35% of resin, 0.5-3% of assistants, 0.5-2% of wax powder and 0.3-1% of gelatinizing agent, whereinthe pigments are the pigments with various colors which are red, yellow, blue and black generally; the extender pigment is any one of bentonite and calcium carbonate or the mixture of the two with anyproportion; the vegetable oil is bleaching sesame oil; the mineral oil is high-boiling point kerosene; the resin is the mixture of rosin modified phenolic resin and alkyd resin; the assistants are antioxidant and drying oil; the wax powder is polyethylene micro-powder wax; and the gelatinizing agent is liquid aluminum AO-3. The oil ink is prepared by adopting the production technology of the conventional offset printing oil ink.

Owner:TAIYUAN PRINTING INK

Non-aqueous coating formulation of low volatility

A non-aqueous coating composition of very low volatility (i.e., low-VOC) that can be cured in a short period of time under an ambient temperature condition without the use of solvents consisting essentially of a mixture or blend of three components: (1) a complex ester made by reacting a monomeric monobasic fatty acid, a mixture of diacids and a polyol;(2) a drying oil (i.e., primarily an unsaturated fatty acid triglyceride); and (3) an unsaturated monomer of low volatility and its use for producing a coated substrate and especially a wood composite material substrate having a cured seal coat.

Owner:GEORGIA PACIFIC CHEM LLC

Emulsion type waterproof corrosion-resistant acrylate exterior wall coating

ActiveCN104109430AIncrease densityImprove compactnessAnti-corrosive paintsPolyester coatingsKetonePolyvinylpyrrolidone

The invention discloses an emulsion type waterproof corrosion-resistant acrylate exterior wall coating, comprising the following raw materials by weight: 50 to 60 parts of a base material, 5 to 15 parts of an alcohol-ester 12 film-forming additive and 30 to 40 parts of an accessory material. The base material comprises the following raw materials by weight: 5 to 10 parts of a drying oil alkyd resin, 50 to 60 parts of acrylic emulsion, 30 to 40 parts of silica sol, 2 to 6 parts of a coupling agent and 1 to 4 parts of sodium butylnaphthalenesulfonate. The accessory material comprises the following raw materials by weight: 20 to 25 parts of borax, 15 to 20 parts of light calcium carbonate, 15 to 20 parts of titanium dioxide, 18 to 23 parts of wollastonite powder, 5 to 10 parts of nanometer zinc oxide, 0.5 to 1 part of polyvinylpyrrolidone, 0.5 to 1.5 parts of an antifoaming agent, 0.8 to 1.3 parts of carboxymethylcellulose sodium, 1 to 2 parts of 1,2-benzoisothiazole-3-one, 1 to 1.3 parts of ammonia water, 10 to 15 parts of water and 2 to 5 parts of methyl nylon acid ester. The emulsion type waterproof corrosion-resistant acrylate exterior wall coating has excellent waterproof performance, good corrosion resistance and long service life.

Owner:湖南爱因新材料有限公司

Self-crosslinked oxidation and high-efficient dispersion with water polyurethane and production thereof

A high-efficient and oxide self-cross-linking disperser of water-based polyurethane and its production are disclosed. The disperser consists of polyester polybasic alcohol (A) containing at least two hydroxyl groups, drying oil long oil alkyd resin (B) containing at least one hydroxyl group, vulcabond containing at least one aromatic or fatty group and water-based functional monomer. It has better coating comprehensive performance and costs low. It can be used for plastic, wood and metal.

Owner:广东天银实业有限公司

Low emissions one part adhesive

An adhesive composition which can be formulated to have low or substantially no VOC emissions is provided. Adhesives in accordance with the invention can be formulated as high solids, one-part, reactive, cross-linked adhesives. This can be achieved by utilizing amide-ester-acrylate reactions or reactions with any other carboxylated polymers. Adhesive compositions in accordance with the invention can include oils, such as various drying oils and similarly acting polymers, co-polymers, and fatty acids. Adhesives in accordance with the invention can also include various hydrocarbon resins, particularly crosslinkable hydrocarbons having a melting point in the range 70° C. to 140° C. Cross-linking agents, such as materials with pendant oxazoline groups are also advantageously included. Various other mixing, flow and other handling ingredients can also be included.

Owner:W F TAYLOR

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com