Film-coated slow-released fertilizer and preparation process thereof

A coated slow-release, fertilizer technology, applied in fertilizer mixtures, fertilization devices, applications, etc., can solve problems such as high price, difficulty in meeting the needs of sustainable environmental development, and environmental stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

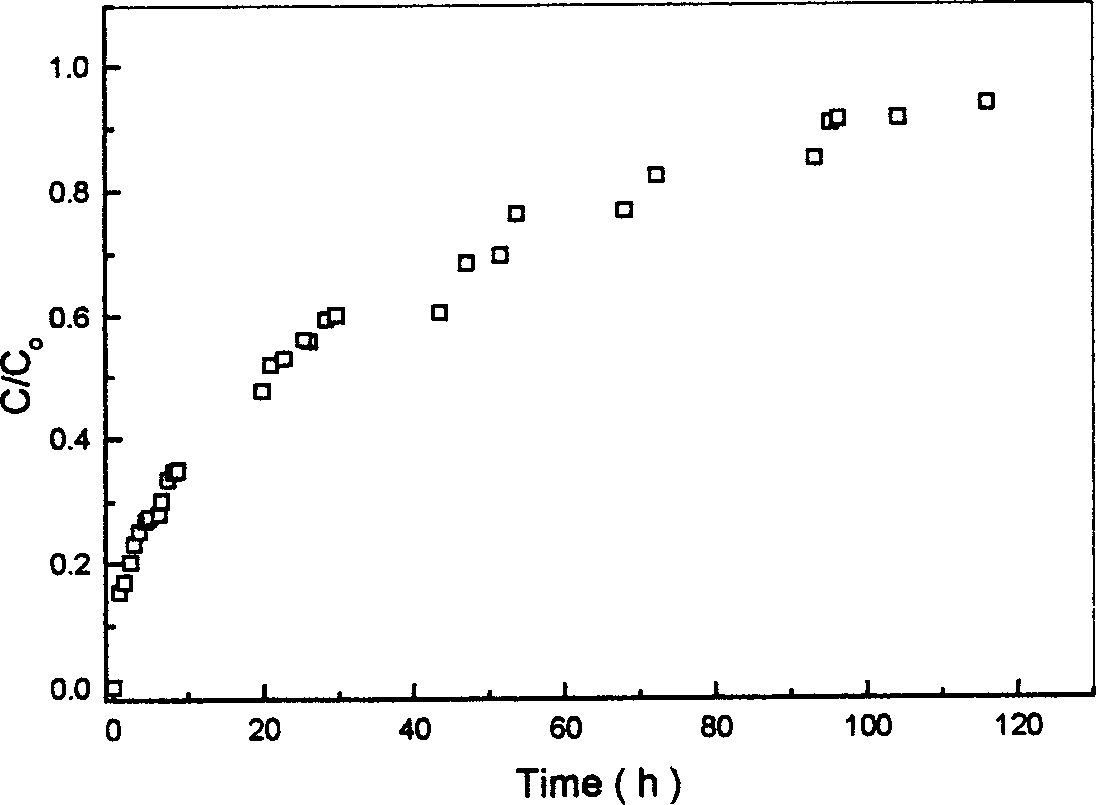

[0037] Dissolve nitrocellulose in a mixed solvent of ethanol / ether (ethanol:ether=1:1) and prepare a 5% (weight) solution as a coating solution; apply repeatedly on the surface of the urea granular fertilizer and add it during the application process Tung oil is used as an additive; the solvent is recovered, and the nitrocellulose and tung oil form a film on the surface of the fertilizer particles to obtain a coated slow-release fertilizer. The coating accounts for 25% of the total weight, and tung oil accounts for 15% of the coating weight. Measure its release in water by high performance liquid chromatography. Such as figure 1 As shown, it is the release curve of nitrocellulose composite coated urea in pure water at 20°C, where c / c 0 It is the urea concentration at time t / the urea concentration at the time of complete release. It is found that it takes about 120 hours to release the coated urea in pure water at 20°C.

Embodiment 2

[0039] Dissolve nitrocellulose in a mixed solvent of ethanol / ether (ethanol:ether=1:4) to prepare a 2% (weight) solution as a coating solution; apply repeated coating on the surface of the urea granular fertilizer and add it during the coating process Fir oil is used as an additive; the solvent is recovered, and the nitrocellulose and cedar oil form a film on the surface of the fertilizer particles to obtain a coated slow-release fertilizer. The coating accounted for 10% of the total weight, and the cedar oil accounted for 20% of the coating weight.

Embodiment 3

[0041] Dissolve nitrocellulose in a mixed solvent of ethanol / ether (ethanol:ether=4:1) and prepare a 10% solution as a coating solution; apply repeated coating on the surface of the urea granular fertilizer; recover the solvent, and the nitrocellulose is used in the fertilizer A film is formed on the surface of the particles to obtain a coated slow-release fertilizer. The envelope accounts for 30% of the total weight.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com