Film-coated slow-released fertilizer and preparation process thereof

A technology of coated slow-release fertilizers, applied in fertilizer mixtures, fertilization devices, applications, etc., can solve problems such as high prices, environmental stress, and complicated manufacturing processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

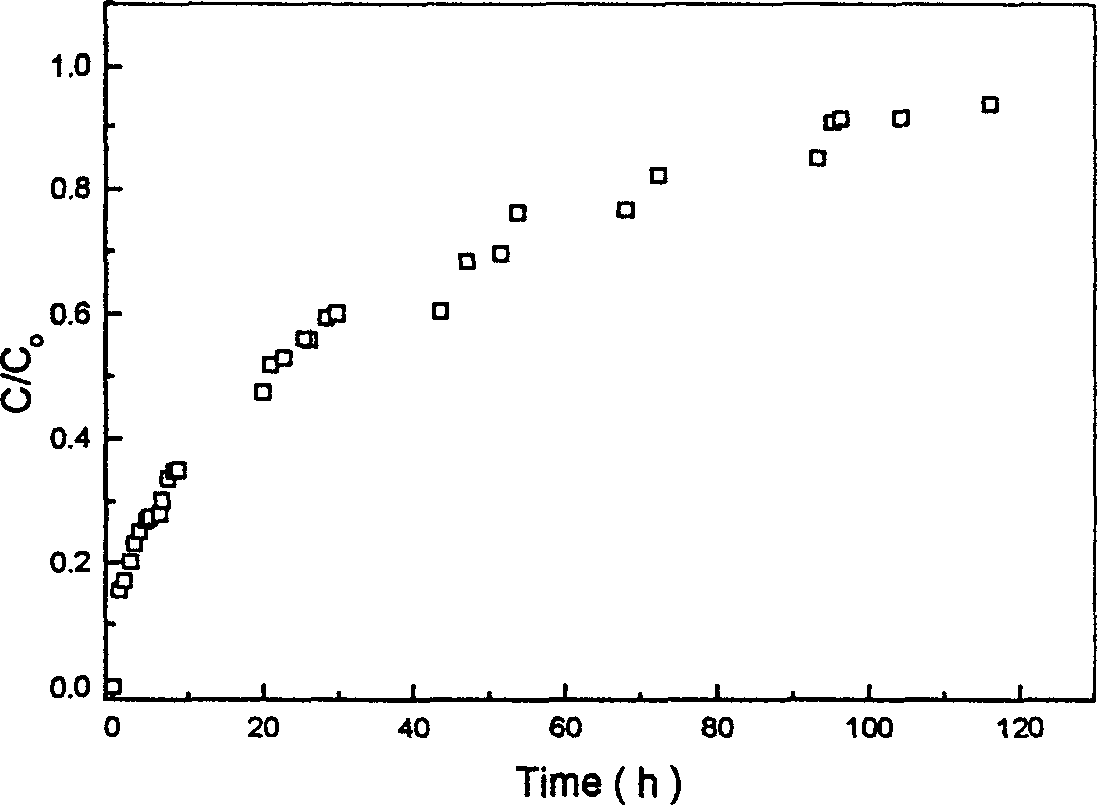

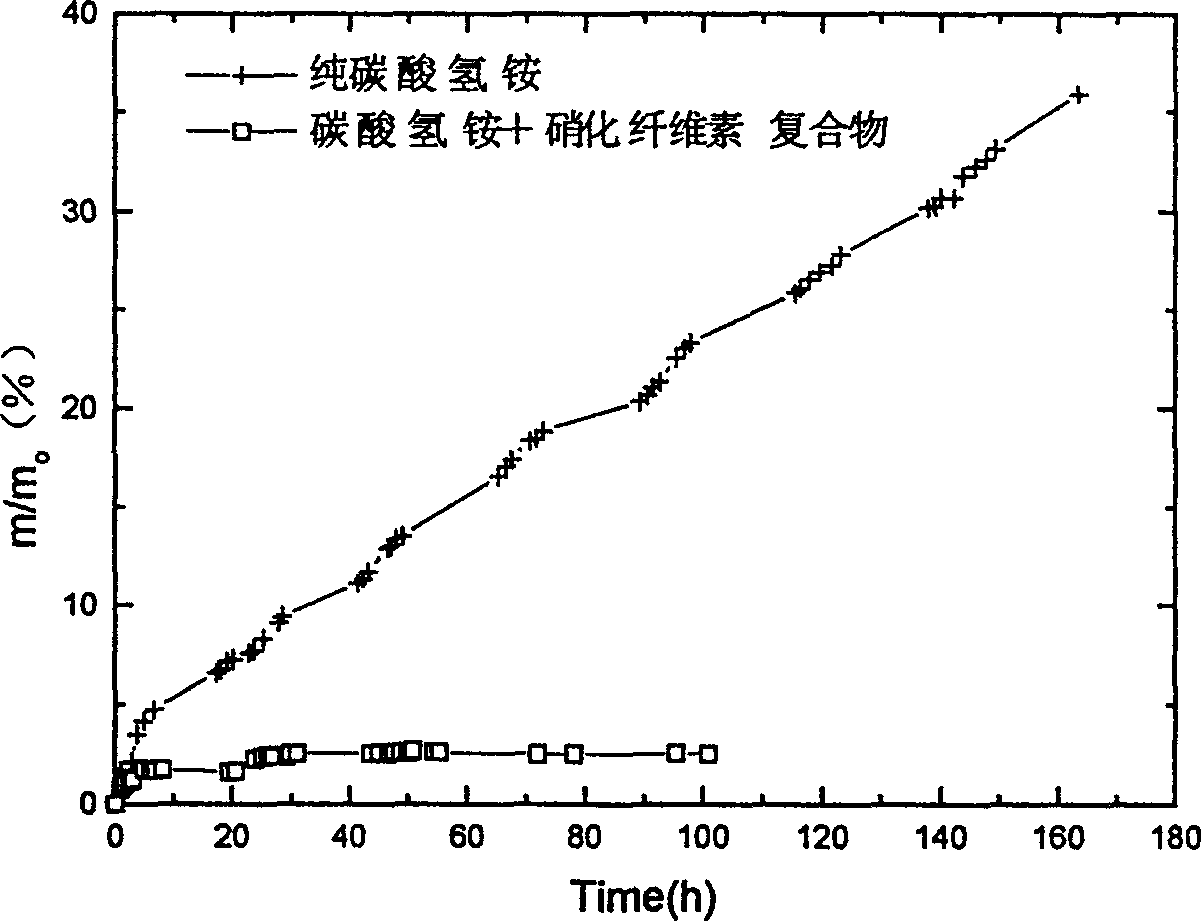

[0037] Dissolve nitrocellulose in ethanol / ether (ethanol: ether = 1: 1) mixed solvent, and prepare a 5% (weight) solution as a coating solution; repeatedly smear on the surface of urea granule fertilizer, and add The tung oil is used as an additive; the solvent is recovered, and the nitrocellulose and tung oil form a film on the surface of the fertilizer granule to obtain a coated slow-release fertilizer. Wherein the coating accounts for 25% of the total weight, and tung oil accounts for 15% of the coating weight. The release in water was determined by high performance liquid chromatography. Such as figure 1 Shown, which is the release curve of nitrocellulose complex coated urea in pure water at 20°C, where c / c 0 urea concentration at time t / urea concentration at complete release. It was found that the release of coated urea in pure water took about 120 hours at 20°C.

Embodiment 2

[0039] Dissolve nitrocellulose in ethanol / ether (ethanol: ether = 1: 4) mixed solvent, and prepare a 2% (weight) solution as a coating solution; repeatedly smear on the surface of urea granule fertilizer, and add Chinese fir oil is used as an additive; the solvent is recovered, and the nitrocellulose and fir oil form a film on the surface of the fertilizer granules to obtain a coated slow-release fertilizer. Wherein the envelope accounts for 10% of the total weight, and fir oil accounts for 20% of the envelope weight.

Embodiment 3

[0041] Dissolve nitrocellulose in ethanol / ether (ethanol: ether=4: 1) mixed solvent, be mixed with 10% solution, as wrapping liquid; Repeatedly smear on the surface of urea granular fertilizer; Recover solvent, nitrocellulose is in fertilizer A film is formed on the surface of the granules, and the film-coated slow-release fertilizer is obtained. Wherein the envelope accounts for 30% of the total weight.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com