Polyurethane oil/polyacrylate latex interpenetrating network polymer emulsion material and synthesizing process thereof

A polyacrylate, polymer emulsion technology, applied in the direction of coating, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Add 110 grams of alkali-bleached cannabis oil and 23.5 grams of glycerin into a 500-milliliter four-neck bottle with heating equipment and a vacuum system, start stirring, heat up, and start vacuuming when it is close to 100 ° C. The vacuum degree is kept at 750-760mmHg, heat at 120°C for 2 hours for dehydration. Then remove the vacuum, put in nitrogen protection, install a reflux condenser, add 0.2 grams of lithium hydroxide, raise the temperature to 200-240 ° C for 2-3 hours, until the tolerance of methanol is 1:2-3, add 0.2 gram of phosphoric acid, stir evenly, quickly cool down to 40-50°C, discharge, filter, and pack to obtain the alcoholyzate, which is ready for use.

[0047] Add 26.7 grams of the above-mentioned alcoholyzate and 30.6 grams of polyether 1000 into a 1000 ml four-necked bottle with a heating and vacuum system, start stirring and heating to 100 ° C to start vacuuming, the temperature is kept at 120 ° C and the vacuum degree is 750 Dehydration at -760...

Embodiment 2

[0050] Heat 20.0 grams of alkali-bleached cannabis oil, 4.7 grams of glycerin and 0.052 grams of lithium hydroxide to 120°C under stirring, then dehydrate under vacuum at 750-760mmHg for 1 hour, then remove the vacuum and heat up to 220-250°C After alcoholysis for 2-3 hours until the tolerance of methanol is 1:2-3, add an appropriate amount of phosphoric acid to decompose the residual catalyst, quickly cool down to 150°C, add 30.6 grams of polyether 1000 to the reactor and keep the temperature at 120°C, The vacuum degree is 750-760mmHg dehydration for 1.5 hours. Remove the vacuum, lower the temperature to 60°C, install a reflux condenser, add 50.5 grams of isophorone diisocyanate (IPDI), keep the temperature at 70-80°C, react for 3-4 hours and then cool down to 60°C, add 6.7 grams of dimethylol Butyric acid (DMBA) and 15 ml butanone were reacted at 75-85° C. for 6 hours under reflux. Cool down to 40°C, add 3.1 g of triethylamine and stir thoroughly for 5 minutes, increase the...

Embodiment 3

[0053] Heat 20.1 grams of alkali-bleached tung oil, 12 grams of trimethylolpropane and 0.03 grams of calcium oxide to 120°C under stirring, then dehydrate under vacuum at 760mmHg for 2 hours, then remove the vacuum and raise the temperature to 240-250°C. After alcoholysis for 3 hours until the tolerance of methanol is 1:2-3, add an appropriate amount of phosphoric acid to decompose the residual catalyst and quickly cool down to 150°C, then add 51.6 grams of polyether 2000 to the reactor, keep the temperature at 110°C, and The vacuum degree is 750-760mmHg, dehydrate for 1 hour, remove the vacuum, cool down to 60°C, install a reflux condenser, add 54.86 grams of isophorone diisocyanate (IPDI), keep the temperature at 70-80°C, and cool down to 50°C after 4 hours of reaction. 10.54 grams of dihydroxypropionic acid (DMBA) and 20 milliliters of methyl ethyl ketone were added at ℃, and reacted at 75-85 ℃ for 5 hours under reflux. Cool down to 40°C, add 6.9 grams of triethylamine and ...

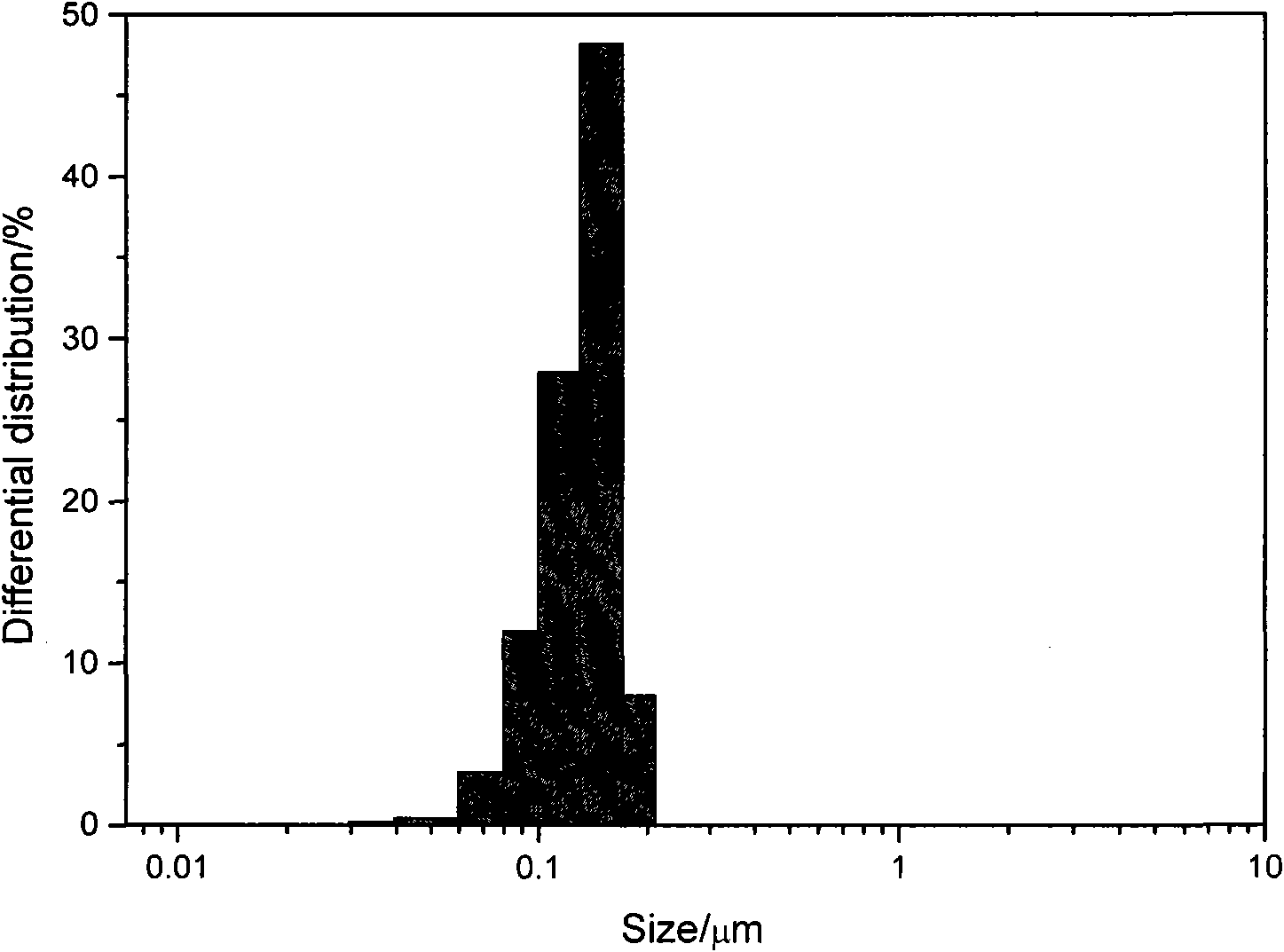

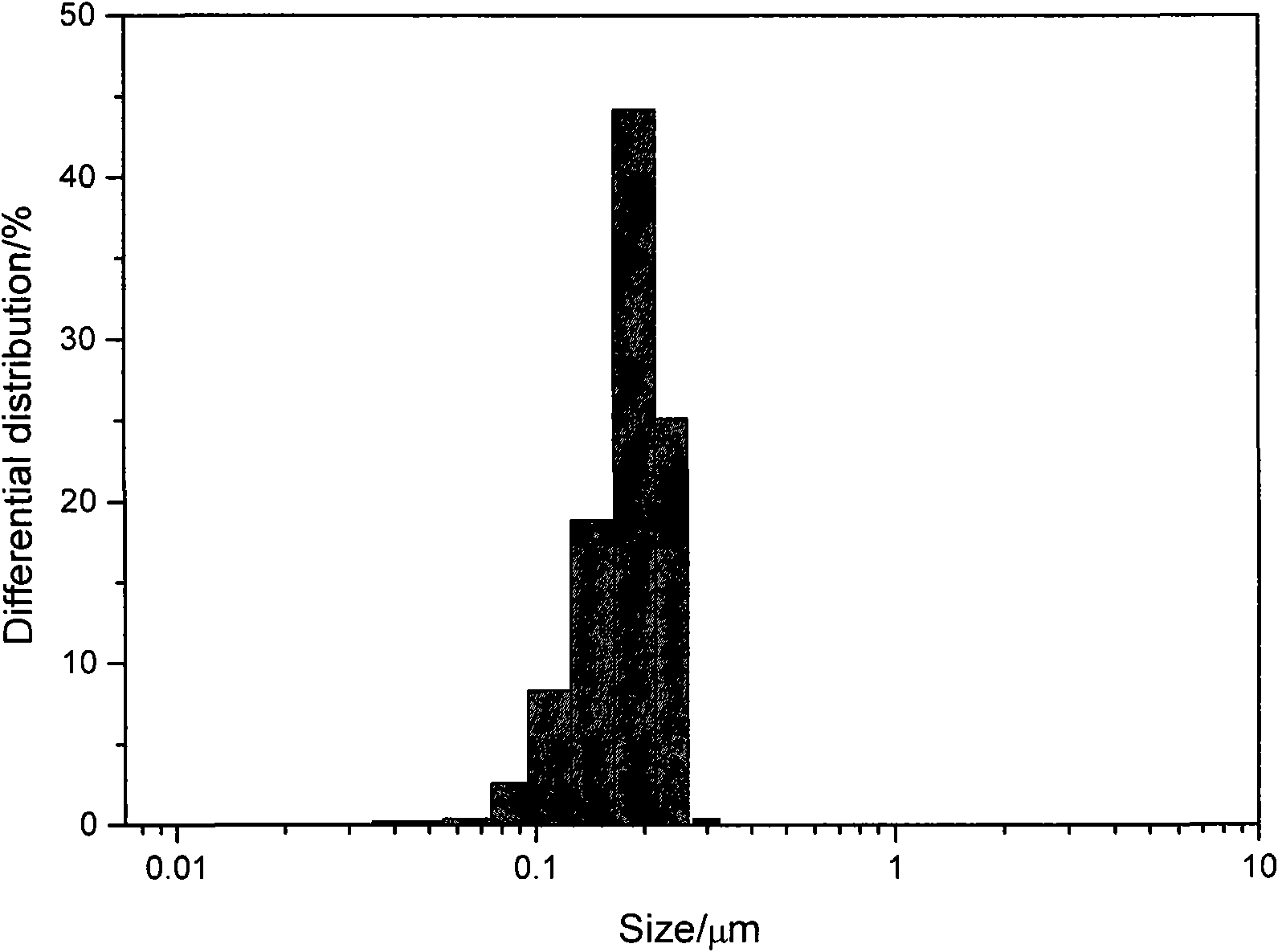

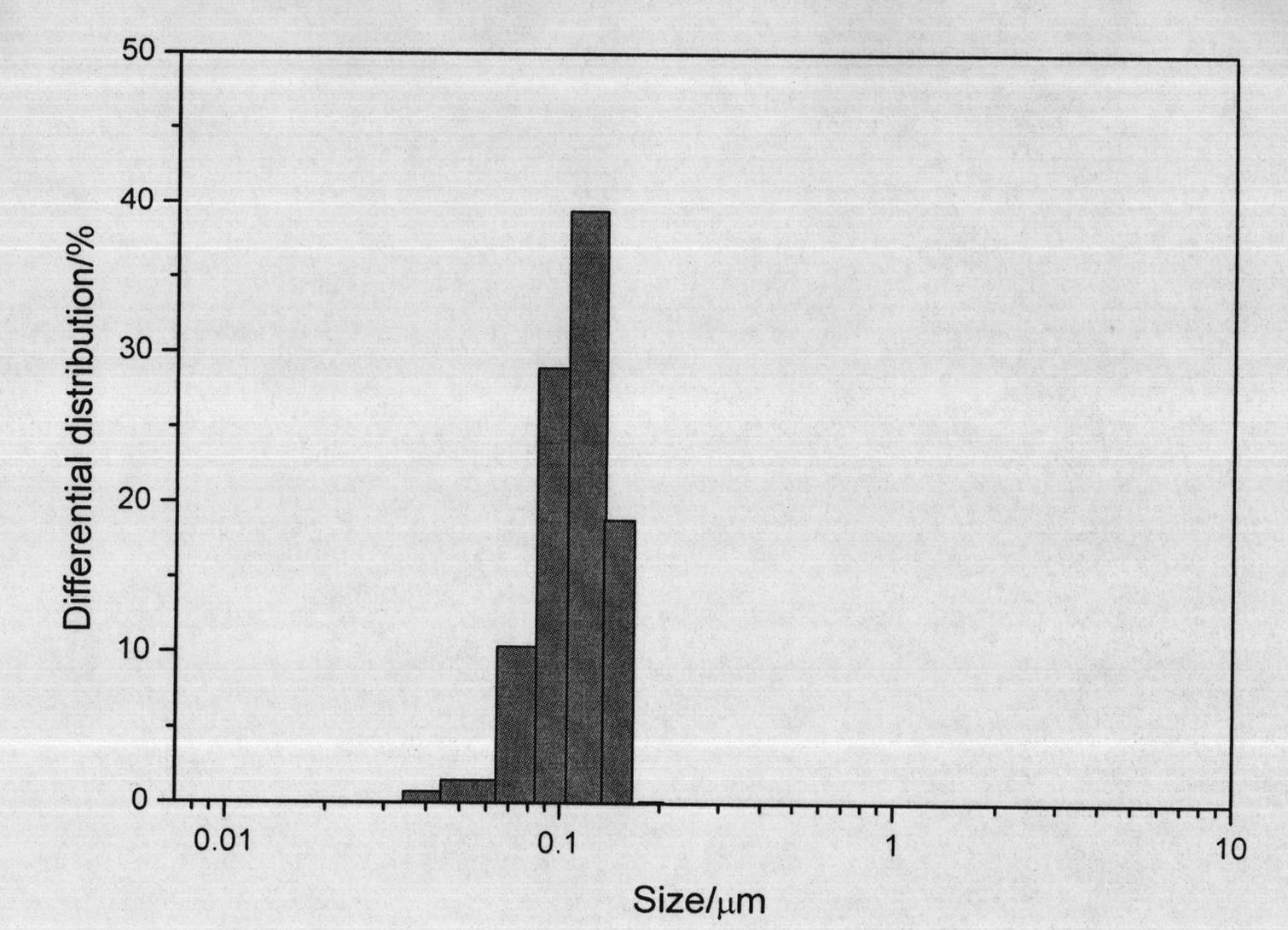

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com