High-performance water-based anticorrosion paint and preparation method thereof

An anti-corrosion coating, high-performance technology, applied in anti-corrosion coatings, alkali metal silicate coatings, coatings, etc., to achieve the effects of low heavy metal content, improved mechanical properties, and good heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

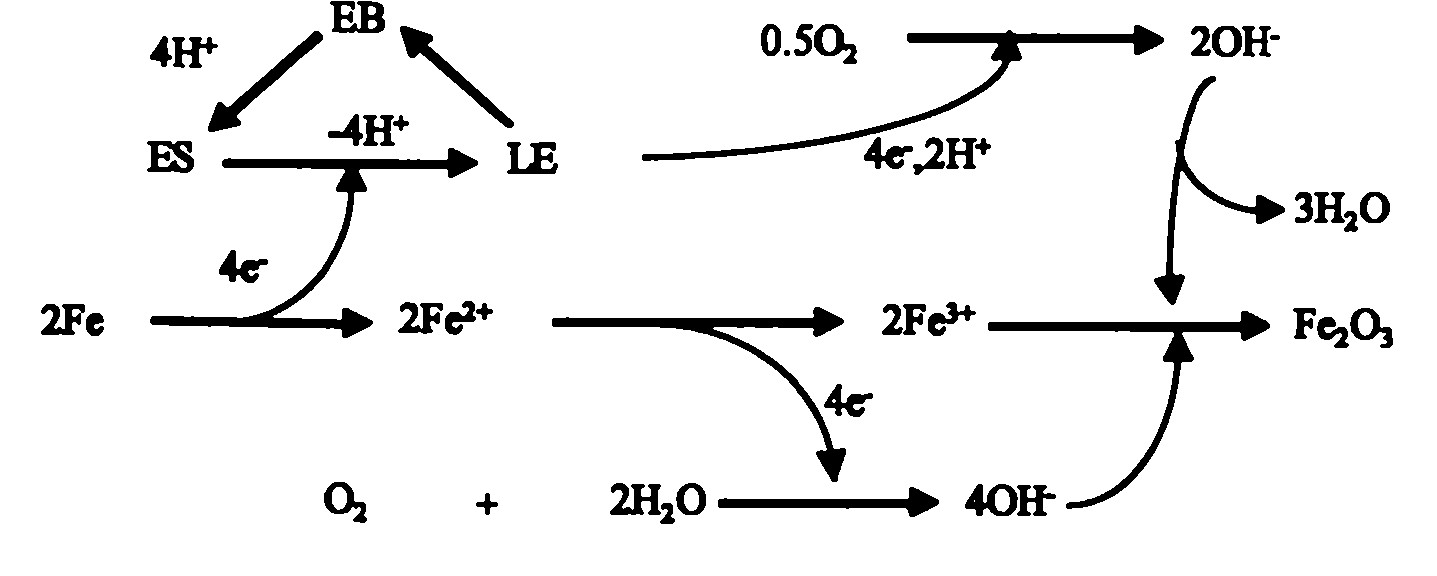

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Disperse 10.00g of nano-titanium oxide into 100.00g of deionized water to form a nano-titanium oxide dispersion, then add 3.00g (0.03226mol) of aniline and 95.80ml of 4.0mol / L hydrochloric acid aqueous solution to the nano-titanium oxide dispersion, and stir evenly. Add 32.30ml of 1.2mol / L ammonium persulfate aqueous solution at a reaction temperature of 0°C, stir continuously, and after 24 hours of reaction, filter with suction and wash until the filtrate is colorless to obtain a titanium oxide / polyaniline nanocomposite filter cake.

[0027] Take 70.00g of phosphoric acid with a mass percentage concentration of 85%, 30.00g of aluminum hydroxide, and 20.00g of water at 100°C and mix and stir for 1 hour. After cooling, use water to adjust the solution density to 1.10g / cm 3 , That is, aluminum dihydrogen phosphate resin.

[0028] Mix 60.00g of aluminum dihydrogen phosphate resin, 30.00g of titanium oxide / polyaniline nanocomposite filter cake, and 1.00g of sodium hexametap...

Embodiment 2

[0032] Disperse 10.00g of nano-zirconia into 33.30g of deionized water to form a nano-zirconia dispersion, then add 10.00g (0.10753mol) of aniline and 16.13ml of 1.0mol / L sulfosalicylic acid aqueous solution to the nano-zirconia dispersion , stir evenly, add 107.53ml of 0.8mol / L ammonium persulfate aqueous solution at a reaction temperature of 50°C, and keep stirring. After reacting for 1 hour, filter with suction and wash until the filtrate is colorless to obtain a zirconia / polyaniline nanocomposite Material filter cake.

[0033] Dissolve 40.00g of sodium silicate and 10.00g of sodium hydroxide in 100g of water to form a solution, then add 80g of metakaolin into the solution and stir until a jelly-like substance is formed to obtain a geopolymer.

[0034] Mix 30.00g of geopolymer, 0.50g of zirconia / polyaniline nanocomposite filter cake, and 0.10g of hydroxymethylcellulose under a sand mill for 0.5h, then add 10.00g of potassium fluorosilicide, 0.10g of silicone oil, 0.10g of ...

Embodiment 3

[0038] Disperse 10.00 g of titanium phosphate into 80.00 g of deionized water to form a titanium phosphate dispersion, then add 3.00 g (0.03226 mol) of aniline and 83.40 ml of 1.5 mol / L p-toluenesulfonic acid aqueous solution to the titanium phosphate dispersion, and stir evenly. At a reaction temperature of 20°C, add 32.30ml of 1.0mol / L ammonium persulfate aqueous solution and stir continuously. After reacting for 4 hours, filter with suction and wash until the filtrate is colorless to obtain a titanium phosphate / polyaniline nanocomposite filter cake.

[0039] Take 40.00g of phosphoric acid with a mass percentage concentration of 85%, 10.00g of aluminum hydroxide, and 30.00g of water at 80°C and mix and stir for 4 hours. After cooling, use water to adjust the solution density to 1.6g / cm 3 , That is, aluminum dihydrogen phosphate resin.

[0040] Mix 50.00g of aluminum dihydrogen phosphate resin, 1.00g of titanium phosphate / polyaniline nanocomposite filter cake, and 0.50g of so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com