Phenolic resin modified metal protection anti-rust non-drying oil and preparation method thereof

A technology of phenolic resin and tert-butylphenol formaldehyde resin, which is applied in the field of phenolic resin-modified metal protection anti-rust non-drying oil and its preparation field, can solve the problems of reduced protective ability, easy dripping, low metal adhesion, etc. The effect of slowing down the electrode reaction, not easy to drip, and high peeling strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

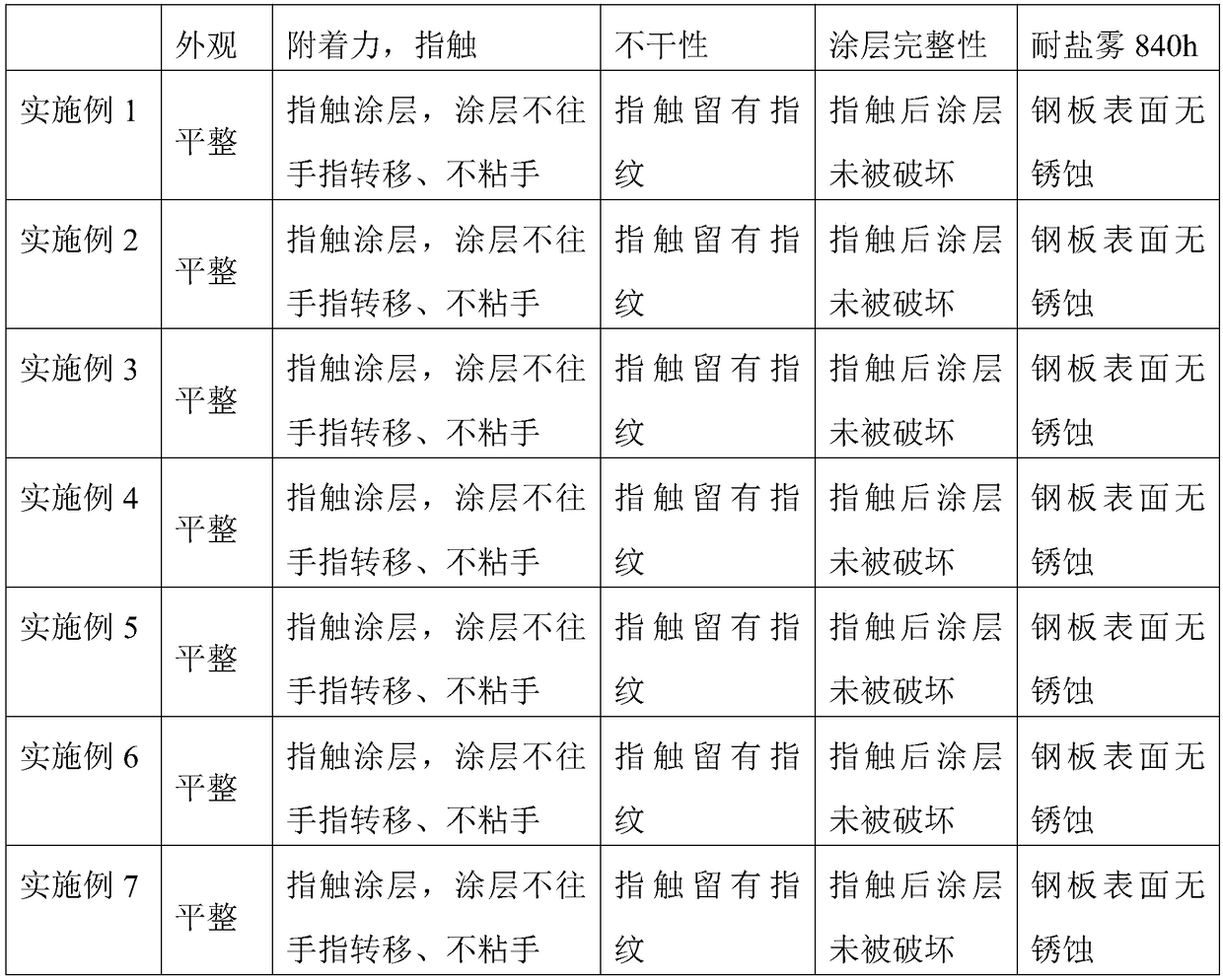

Examples

Embodiment 1

[0026] A phenolic resin modified metal protection anti-rust non-drying oil, composed of the following raw materials: No. 200 solvent oil 15kg, polyisobutylene 8kg, ethylene-propylene copolymer 5kg, lanolin 5kg, petroleum calcium sulfonate 5kg, dodecenyl Succinic acid 0.1kg, calcium carbonate 22kg, carbon black 1kg, magnesium carbonate 1kg, potassium aluminum silicate 8kg, manganese dioxide 0.01kg, nickel oxide 0.01kg, barium chromate 0.01kg, p-tert-butylphenol formaldehyde resin 8kg and bentonite 1kg.

Embodiment 2

[0028] A phenolic resin modified metal protection anti-rust non-drying oil, composed of the following raw materials: toluene 22kg, polyisobutylene 12kg, base oil 2.5kg, ethylene-propylene copolymer 10kg, lanolin 10kg, petroleum calcium sulfonate 10kg, twelve Alkenyl succinic acid 0.8kg, calcium carbonate 30kg, carbon black 2kg, magnesium carbonate 4kg, potassium aluminum silicate 15kg, manganese dioxide 0.08kg, nickel oxide 0.05kg, barium chromate 0.05kg, p-tert-butylphenol formaldehyde resin 18kg and bentonite 2kg.

Embodiment 3

[0030] A phenolic resin modified metal protection anti-rust non-drying oil, composed of the following raw materials: turpentine 18kg, polyisobutylene 9kg, base oil 1kg, ethylene-propylene copolymer 6kg, lanolin 9kg, petroleum calcium sulfonate 6kg, dodecene Succinic acid 0.7kg, calcium carbonate 24kg, carbon black 1.2kg, magnesium carbonate 2kg, potassium aluminum silicate 10kg, manganese dioxide 0.03kg, nickel oxide 0.04kg, barium chromate 0.02kg, p-tert-butylphenol formaldehyde resin 10kg and bentonite 1.8kg.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com