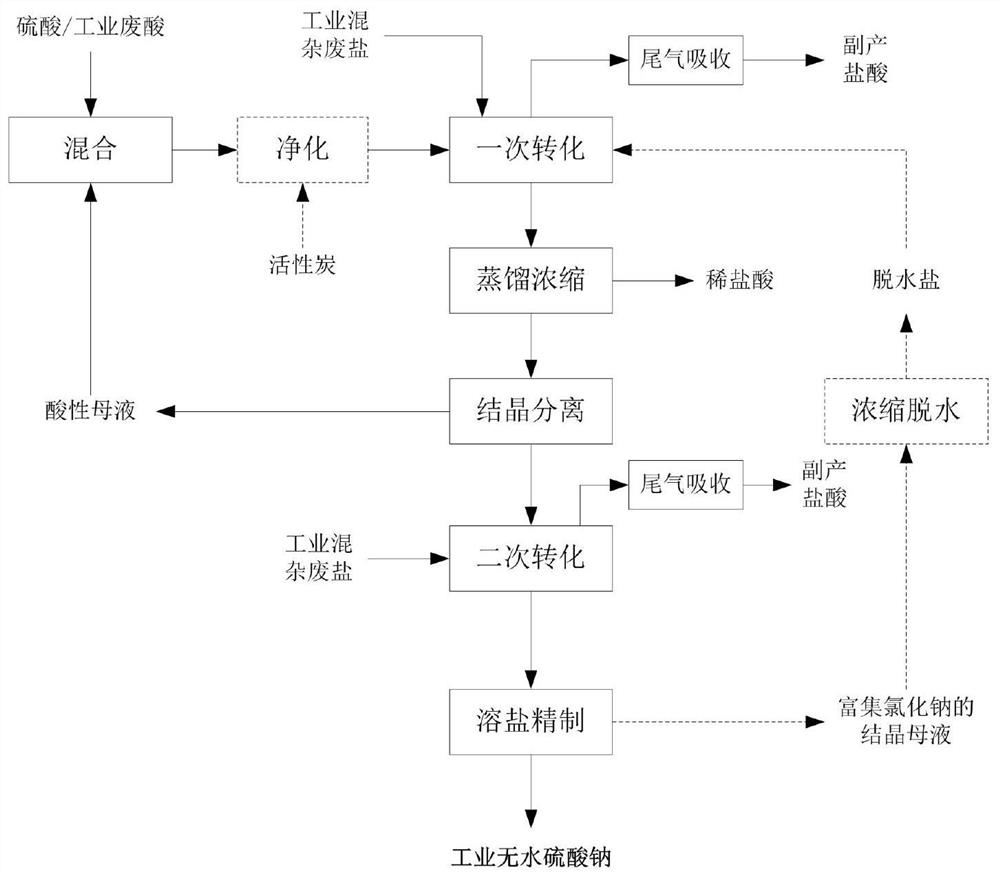

Method for treating industrial mixed waste salt by using sulfuric acid

A sulfuric acid treatment and industrial technology, which is applied in the field of industrial mixed waste salt treatment, can solve the problems of difficult removal of organic and inorganic impurities, restrictions on the comprehensive utilization of waste acid, secondary pollution of the environment, etc., and meet the requirements of reducing the corrosion resistance of equipment , Solve the difficulty of waste acid treatment and realize the effect of comprehensive utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Mix the industrial mixed waste salt with a sodium chloride content of 65.15% (mass fraction, the same below), a sodium sulfate content of 29.18%, a water content of 2.3%, and an organic impurity content of 3.37% in a mixing tank, and use high temperature After drying the residual heat of the treatment system, use the feeder to put the mixed waste salt into the rotary kiln incinerator. Under aerobic conditions, high-temperature incineration is carried out at 500-600°C to remove organic matter, and the waste salt stays in the incinerator for 1 hour, and the removal rate of organic impurities in industrial mixed waste salt is 98.9%.

[0038] Put the mixed waste salt after high-temperature incineration to remove organic matter into the reactor, and add waste sulfuric acid with a content of 65% (TOC=0.12%), and control the dosage of waste acid as sulfuric acid: sodium chloride and sodium sulfate Sum = 1.8:1 (molar ratio), react at 110°C for 1h. The tail gas produced by the ...

Embodiment 2

[0042] Mix industrial mixed waste salt with a sodium chloride content of 35.64%, a sodium sulfate content of 53.47%, a moisture content of 5.09%, and an organic impurity content of 5.8% in a mixing tank. The feeding machine puts the mixed waste salt into the rotary kiln incinerator. Under aerobic conditions, high-temperature incineration is carried out at 500-600°C to remove organic matter, and the residence time of waste salt in the incinerator is 1.5 hours. The removal rate of organic impurities in industrial mixed waste salt is 99.2%.

[0043] Put the mixed waste salt after high-temperature incineration to remove organic matter into the reactor. The acidic mother liquor in embodiment one is reused, mixed with 45% industrial waste acid (TOC=0.08%), then added to the reactor and mixed evenly with mixed waste salt, and the dosage of controlled waste acid is sulfuric acid in waste acid: The sum of sodium chloride and sodium sulfate = 1.5:1 (molar ratio), react at 80°C for 1 h...

Embodiment 3

[0047] Mix the miscellaneous salt obtained after the concentration and crystallization of the centrifuged mother liquor in Example 2 and the industrial miscellaneous waste salt in the mixing tank to obtain a sodium chloride content of 72.33% (mass fraction), a sodium sulfate content of 19.01%, and a moisture content of 5.61%. %, industrial mixed waste salt with an organic impurity content of 3.05%, after being dried by the waste heat of the high-temperature treatment system, the mixed waste salt is put into the rotary kiln incinerator using a feeder. Under aerobic conditions, high-temperature incineration is carried out at 500-600°C to remove organic matter, and the residence time is 1 hour. The removal rate of organic impurities in industrial mixed waste salt is 98.6%.

[0048] Put the mixed waste salt after high-temperature incineration to remove organic matter into the reactor. The industrial waste sulfuric acid (TOC=0.43%) containing 2.2% of hydrochloric acid and 25% of s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com