Method for recycling glyphosate solvent and byproducts

A glyphosate and by-product technology, applied in the field of glyphosate solvent and by-product recovery, can solve the problems of weakening the effect of vapor phase feed to reduce process energy consumption, inability to use cooling water, and lower condensation temperature, so as to achieve saving Equipment investment, strong separation ability, and the effect of increasing the condensation temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

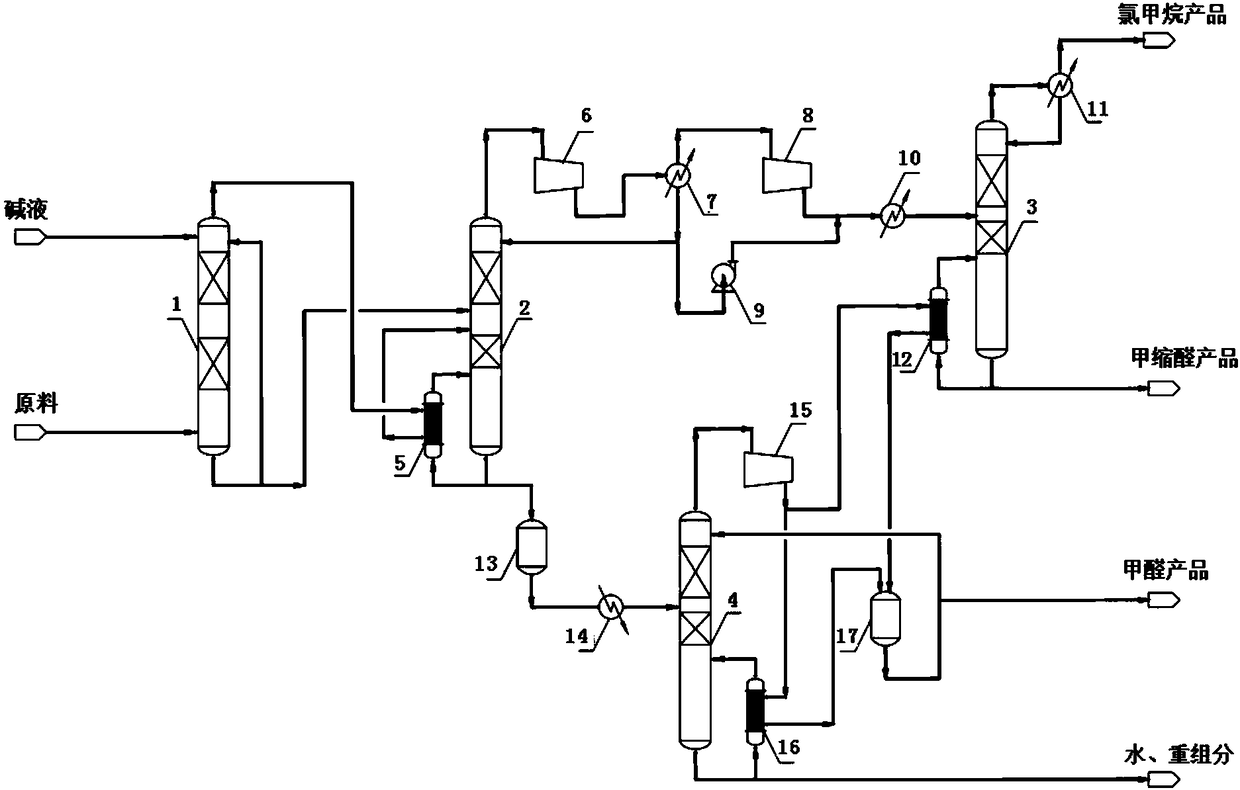

[0031] The invention provides a method for recovering glyphosate solvent and by-products, which has good energy-saving and consumption-reducing effects, high recovery rate of glyphosate solvent and by-products, high product quality, wide application prospects, and specific process route Such as figure 1 As shown, the specific method is as follows:

[0032] The steam produced by hydrolysis in the glyphosate production process is passed into the vapor phase neutralization tower 1, neutralized with lye, and the vapor phase obtained by neutralization is heated for the pre-rectification tower reboiler 5 and then passed into the pre-rectification tower In the tower 2, a part of the liquid phase obtained by neutralization is circulated back to the vapor phase neutralization tower 1, and a part is passed into the pre-rectification tower 2;

[0033] The vapor phase and the liquid phase that are passed in are obtained at the top of the pre-rectification tower 2 to contain methylal and ...

Embodiment 2

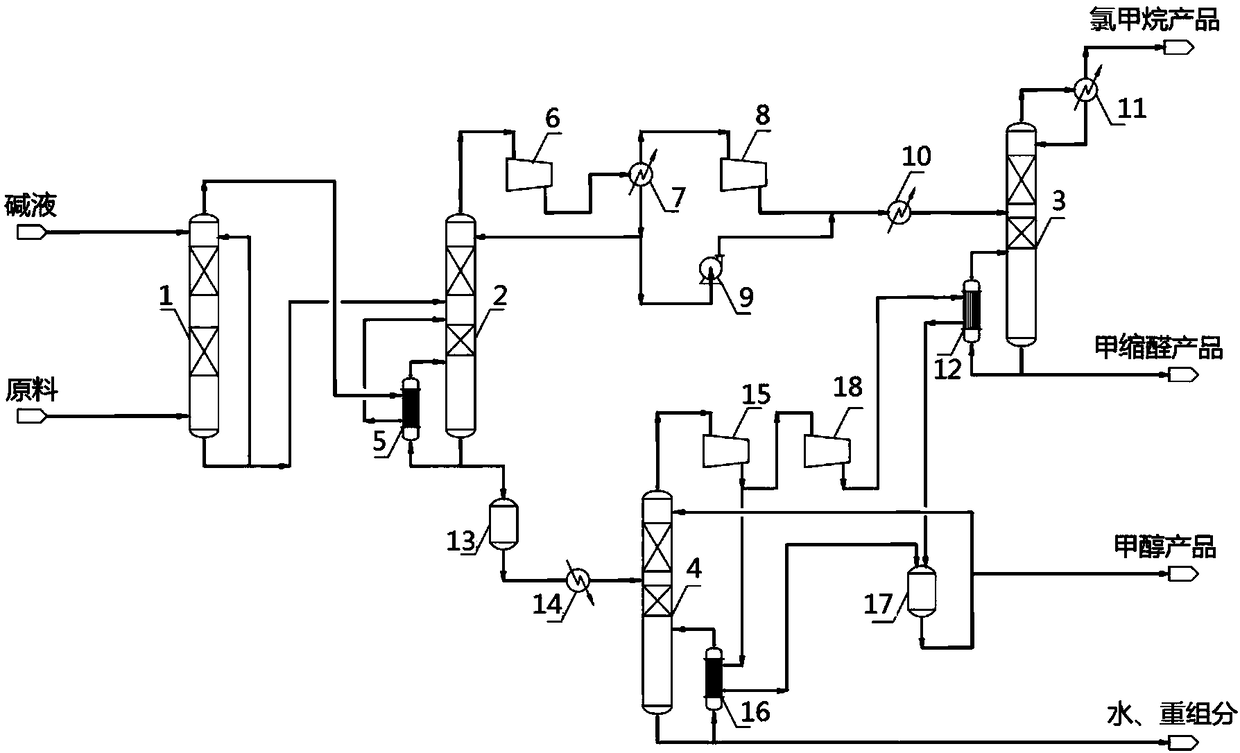

[0043] Embodiment 2 is the preferred scheme of embodiment 1, and the methanol compressor adopts the two-stage compression scheme, which can further reduce the energy consumption of the process. The specific process is as follows figure 2 As shown, the process is the same as in Example 1, the difference being that the overhead steam of the methanol refining tower 4 is compressed by a methanol compressor 15 to improve the energy grade, and a part is used as a heat source for the methanol refining tower reboiler 16, and the other part is passed through two stages. The stage methanol compressor 18 is used as a heat source for the reboiler 12 of the light ends refining column after being compressed. Because the tower bottom temperature of the light-end refining tower 3 is higher than the tower bottom temperature of the methanol refining tower 4, so in the one-stage compression scheme of embodiment 1, it is necessary to increase the grade of methanol vapor pressurization at the top ...

Embodiment 3

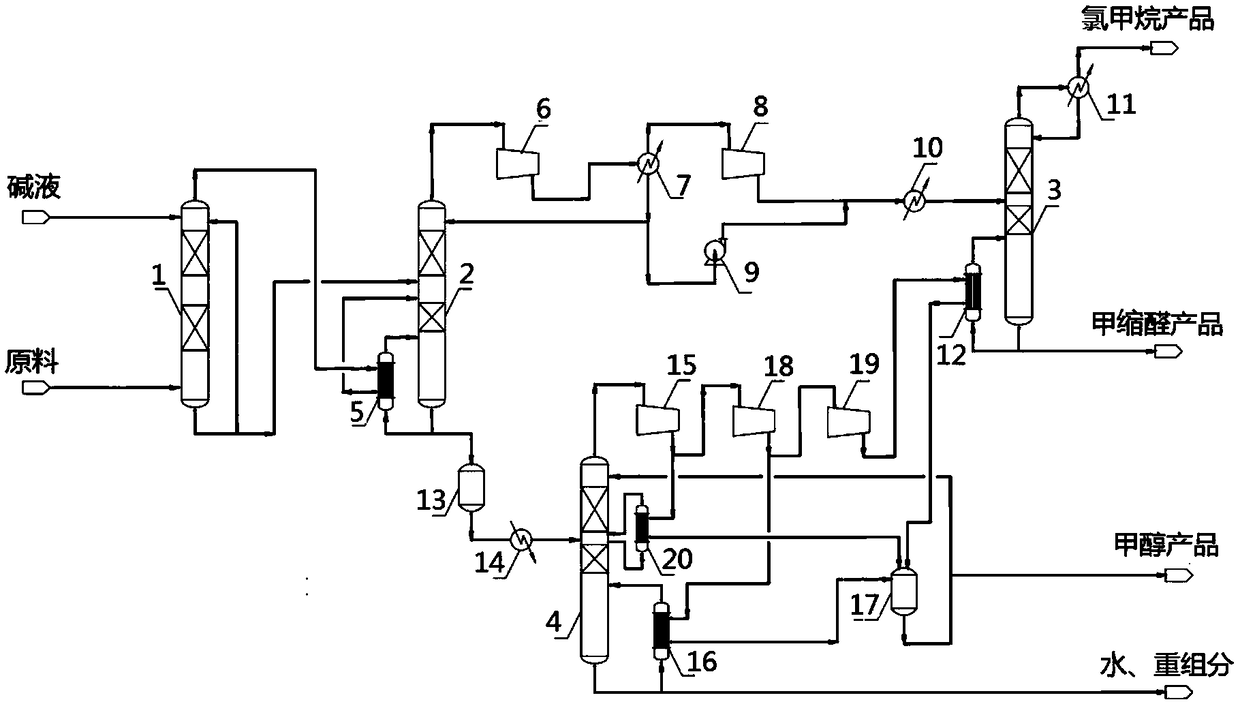

[0061] Embodiment 3 is the preferred scheme of embodiment 1, can further reduce process energy consumption, and concrete process is as image 3 As shown, the process is the same as in Example 1, except that an intermediate reboiler 20 is added to the methanol refining tower 4, and the methanol compressor adopts a three-stage compression scheme, specifically: the overhead steam of the methanol refining tower 4 passes through the methanol compressor 15 After one-stage compression improves the energy grade, a part is used as the heat source of the intermediate reboiler 20, and the other part enters the secondary methanol compressor 18. After compression and the grade is improved, a part is used as the heat source of the methanol refining tower reboiler 16, and the other part is passed through The three-stage methanol compressor 19 is used as a heat source for the reboiler 12 of the light components refining column after being compressed. Since the temperature distribution of meth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com