Continuous wet oxidation process for degrading high concentration organic waste water and equipment thereof

An organic waste water and wet oxidation technology, applied in the field of water treatment, can solve the problems of inconvenient disassembly, high cost, and reduced oxidation reaction rate, and achieve the effects of reducing heating energy consumption, saving equipment space, and reducing cooling load.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

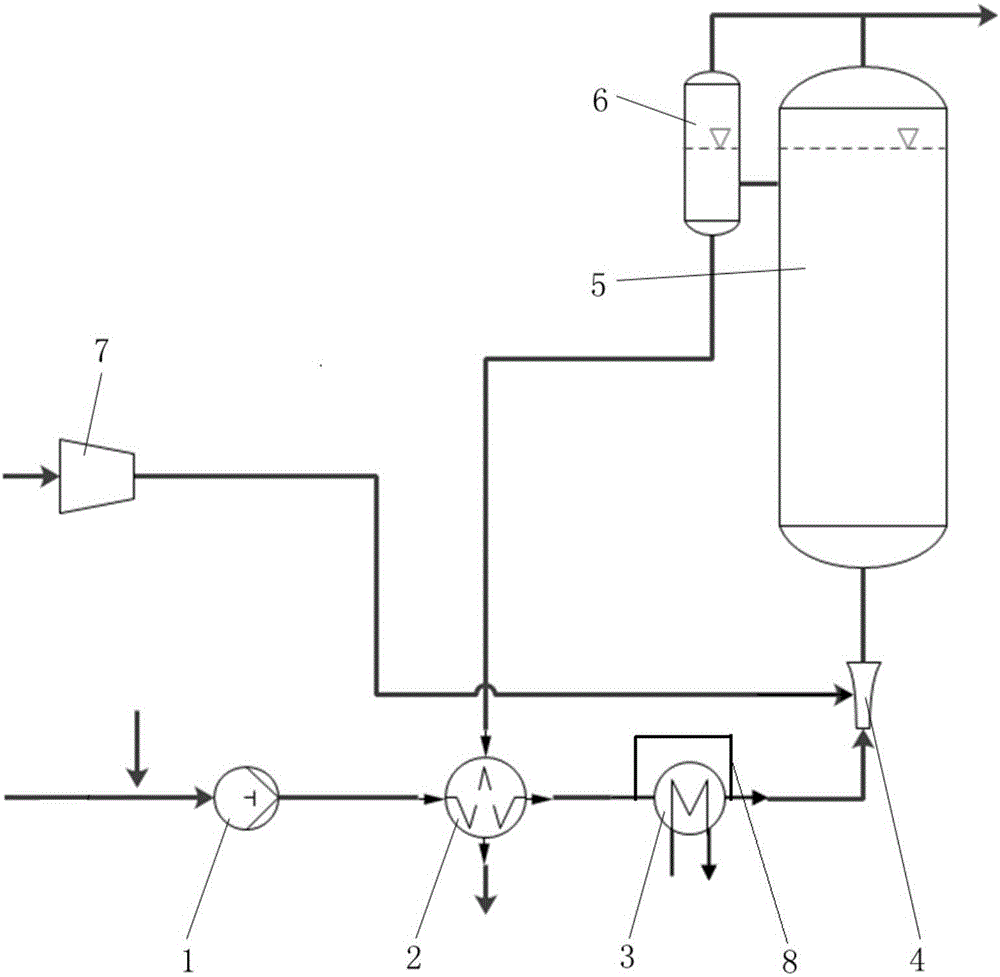

[0030] This embodiment provides a continuous wet oxidation process for degrading high-concentration organic wastewater, which is used to treat industrial wastewater containing organic matter, including sequentially performing a catalyst introduction process, a wastewater pressurization process, and a wastewater heat exchange process along the flow direction of the wastewater to be treated , a mixing process, a reaction process and a separation process; it also includes an oxidizing agent pressurizing process, which communicates with the mixing process.

[0031] Step 1: Carrying out a catalyst introduction process, a waste water pressurization process, and a waste water heat exchange process sequentially along the flow direction of the waste water to be treated. Specifically: adding a homogeneous catalyst Cu(NO 3 ) 2 , the added quality is 0.5% of the waste water quality. The mixed catalyst wastewater was pressurized to 11 bar. The pressurized wastewater is heat-exchanged wi...

Embodiment 2

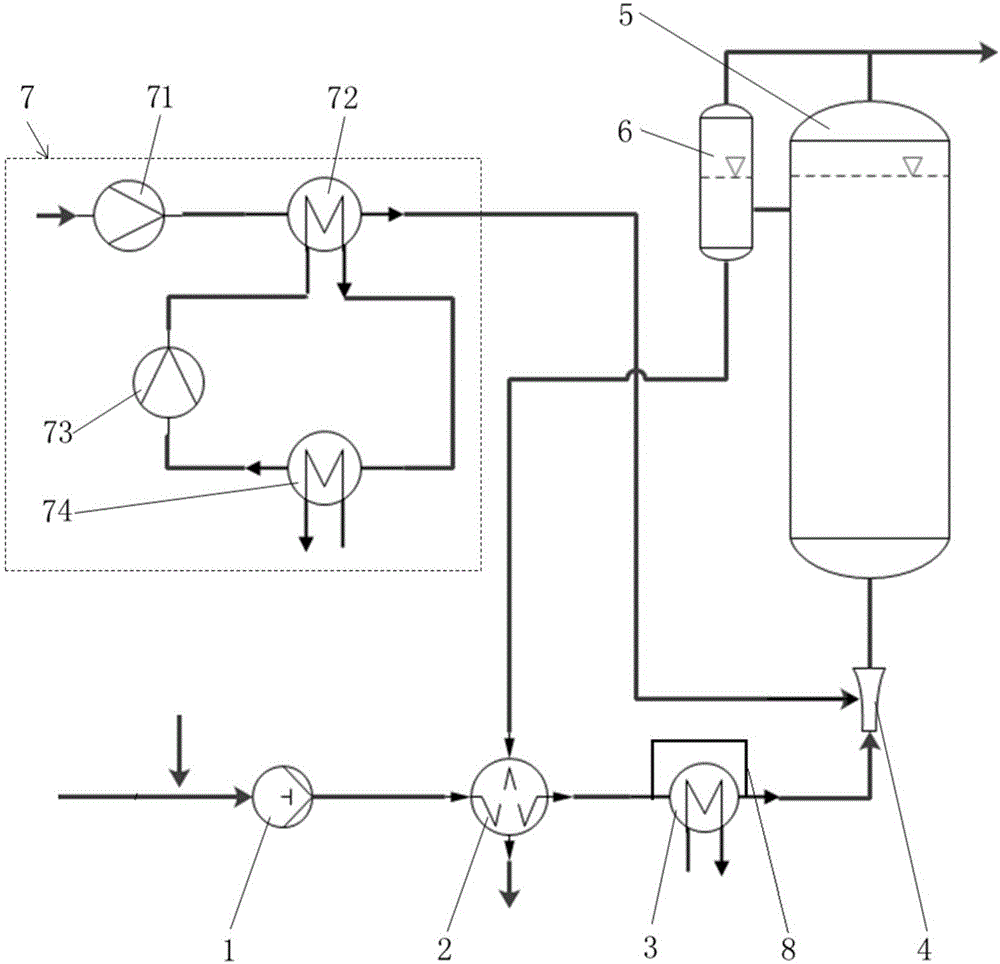

[0050] This embodiment provides a continuous wet oxidation process for degrading high-concentration organic wastewater, which is used to treat industrial wastewater containing formaldehyde-containing organic matter. The chemical components of the wastewater are mainly formaldehyde and methanol. The waste water pressurization process, the waste water heat exchange process, the mixing process, the reaction process and the separation process; also includes the oxidant pressurization process, which is connected with the mixing process.

[0051] Step 1: Carrying out a catalyst introduction process, a waste water pressurization process, and a waste water heat exchange process sequentially along the flow direction of the waste water to be treated. Specifically: adding Cu(NO 3 ) 2 and Fe 2 (SO 4 ) 3 Composite homogeneous catalyst, Cu(NO 3 ) 2 with Fe 2 (SO 4 ) 3 The mass ratio is 1:2, and the added mass is 3% of the waste water mass. The catalyst mixed wastewater was pressur...

Embodiment 3

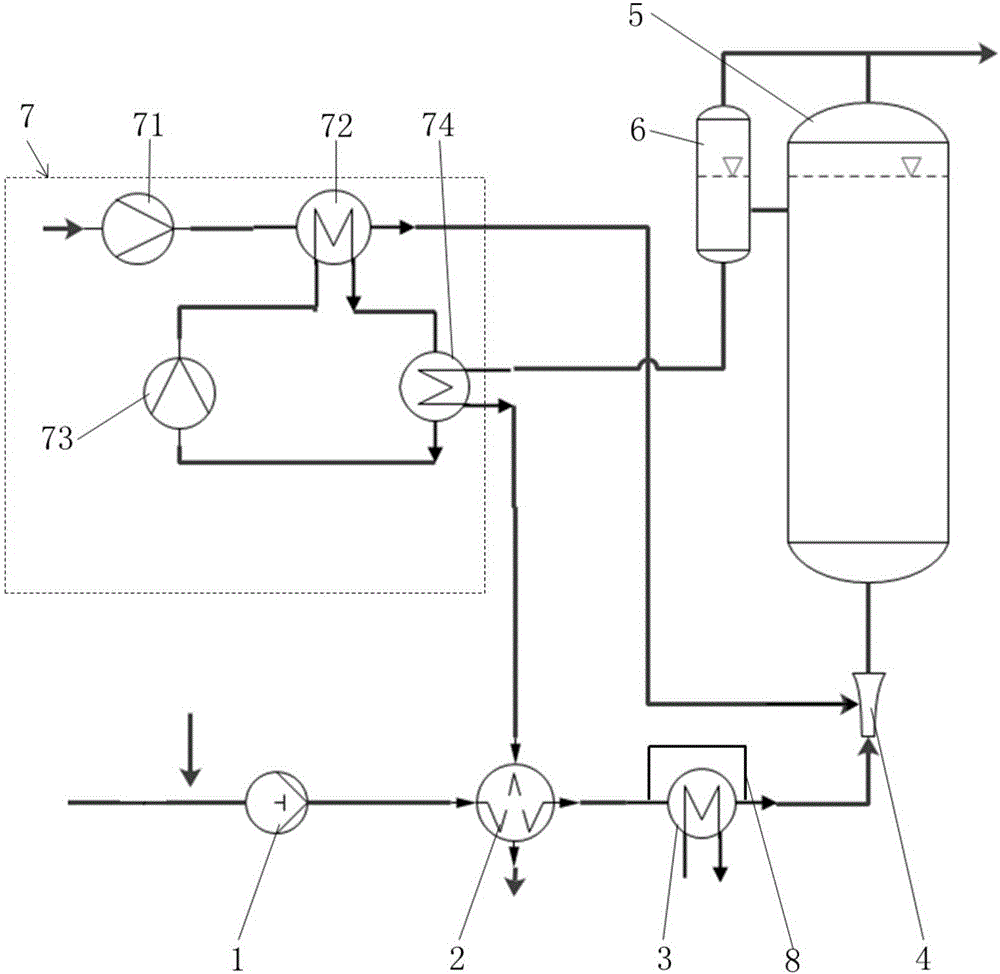

[0067] This embodiment provides a continuous wet oxidation process for degrading high-concentration organic wastewater, which is used to treat ammoximation wastewater. The chemical components of wastewater are mainly cyclohexanone, cyclohexanone oxime, and sodium hydroxide, including The catalyst introduction process, waste water pressurization process, waste water heat exchange process, mixing process, reaction process and separation process are carried out sequentially through the direction; the oxidant pressurization process is also included, which is connected with the mixing process.

[0068] Step 1: Carrying out a catalyst introduction process, a waste water pressurization process, and a waste water heat exchange process sequentially along the flow direction of the waste water to be treated. Specifically: add CuSO to the waste water to be treated 4 and AgNO 3 Composite homogeneous catalyst, CuSO 4 and AgNO 3 The mass ratio is 3:1, and the added quality is 3% of the wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com