Patents

Literature

540results about How to "Reduce heating energy consumption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

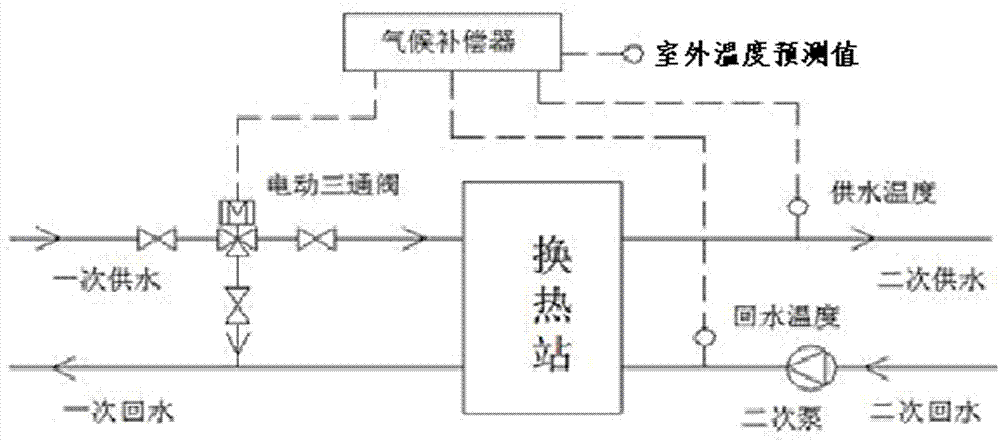

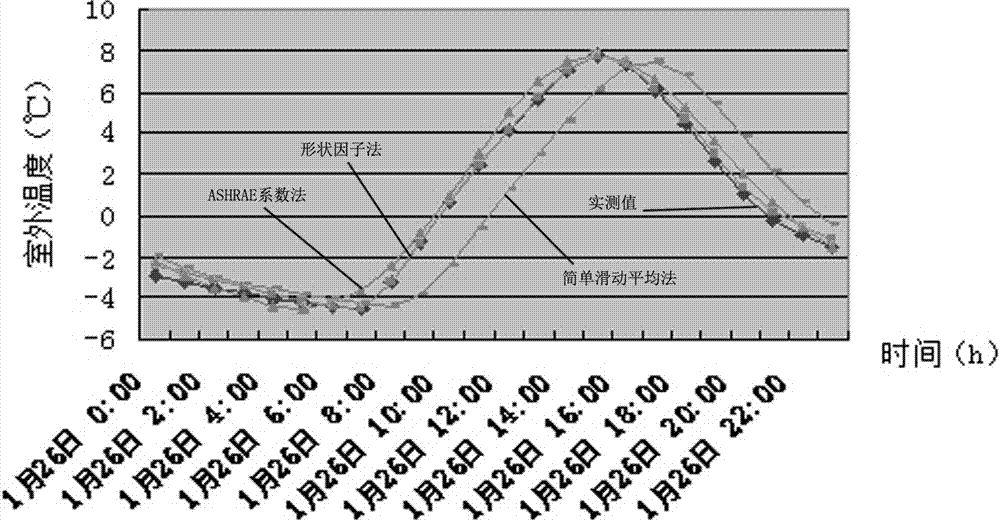

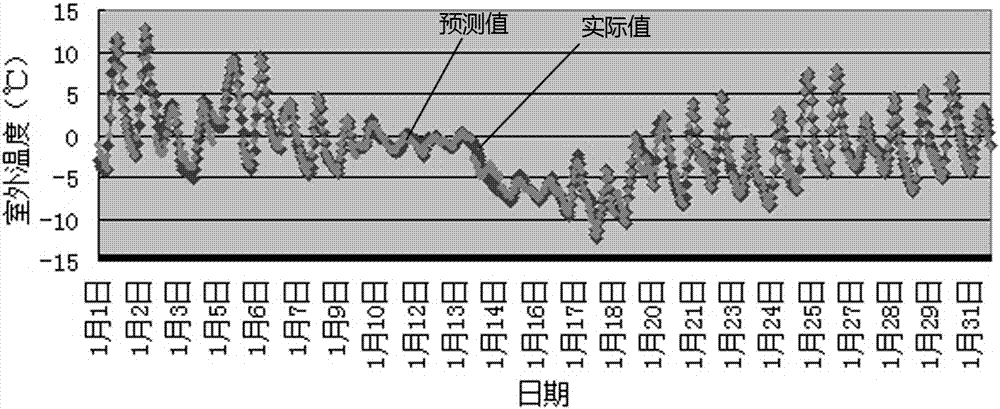

Dynamic climate compensation method for centralized heating

ActiveCN107120721AStable indoor temperatureEnsure heating qualityLighting and heating apparatusSpace heating and ventilation detailsHysteresisValue set

The invention discloses a dynamic climate compensation method for centralized heating. Firstly, the outdoor temperature is predicted, water supply and return temperatures are adjusted some time ahead according to the predicted value of the outdoor temperature, and the hysteresis of pipe network adjustment in the manner that adjustment is performed while sampling is overcome. The outdoor temperature of the next day is predicted according to local historical meteorological data and weather forecast of the meteorological department, and the value is used as basic data for prediction of a thermal load; and then the thermal load is predicted, that is, the thermal load curve of the next day is calculated according to the outdoor temperature. With the method, the outdoor temperature is reasonably predicted so as to realize advanced dynamic adjustment of a climate compensator; heating medium parameters of a heating system are adjusted by the aid of an adjusting model according to the thermal load value set in advance, a heat source is changed from original wide passive heating into active heating, on the premise that the indoor temperature for the user is stable, the operation adjusting indictor of the heating system within the specified time are given in advance, the heating efficiency is improved, and the heating energy consumption is reduced.

Owner:石家庄华浩能源科技有限公司

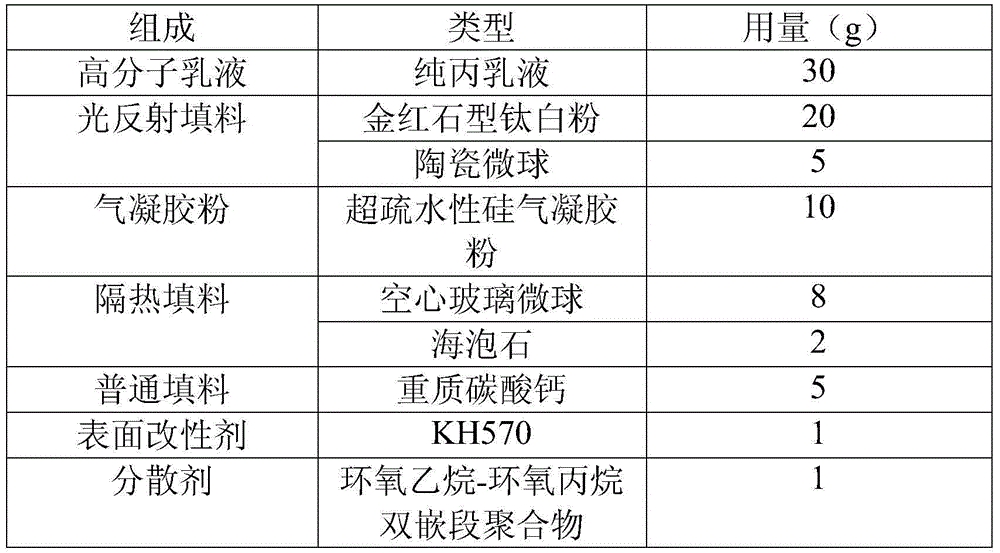

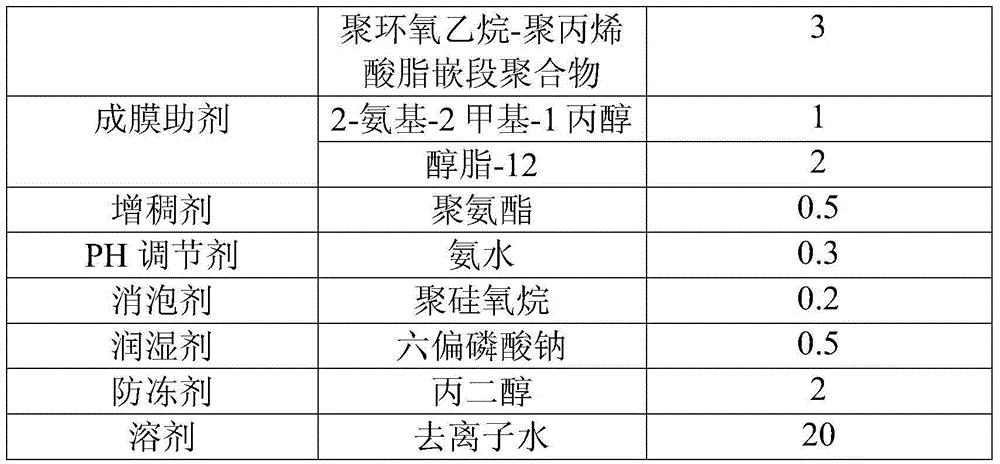

Waterborne energy-saving building coating and preparation method thereof

ActiveCN106700789AGet rid of the shortcomings of severely limited application fieldsIncreased hemispherical emissivityAntifouling/underwater paintsPaints with biocidesGreen environmentEmulsion

The invention specifically relates to a multifunctional green environment-friendly waterborne energy-saving building coating and a preparation method thereof, belonging to the technical field of energy-saving building coatings. The multifunctional high-efficiency energy-saving building coating comprises, by weight, 25 to 50% of a high polymer emulsion, 5 to 30% of a light-reflection filling material, 1 to 5% of aerogel powder, 5 to 10% of a heat-insulation filling material, 5 to 15% of a common filling material, 1 to 2% of a surface modifier, 1 to 5% of a dispersing agent, 0.1 to 4% of a film-forming aid, 0.1 to 2% of a thickening agent, 0 to 1% of an antifoaming agent, 0.01 to 0.5% of a pH regulating agent, 0.1 to 2% of a wetting agent and 0.5 to 2% of an antifreezing agent, with the balance being deionized water. The coating provided by the invention has heat-insulation and cooling effect in summer and heat preservation effect in winter, is applicable to energy-saving reconstruction of buildings in tropical zones and subtropical zones, and has the characteristics of safety, no toxicity, environment friendliness and no pollution; moreover, the coating has good weatherability, contamination resistance, flexibility and scrubbing resistance.

Owner:SHENYANG RES INST OF CHEM IND

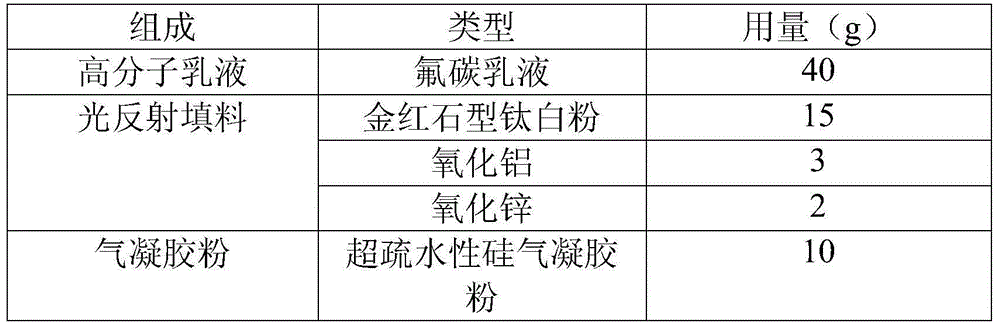

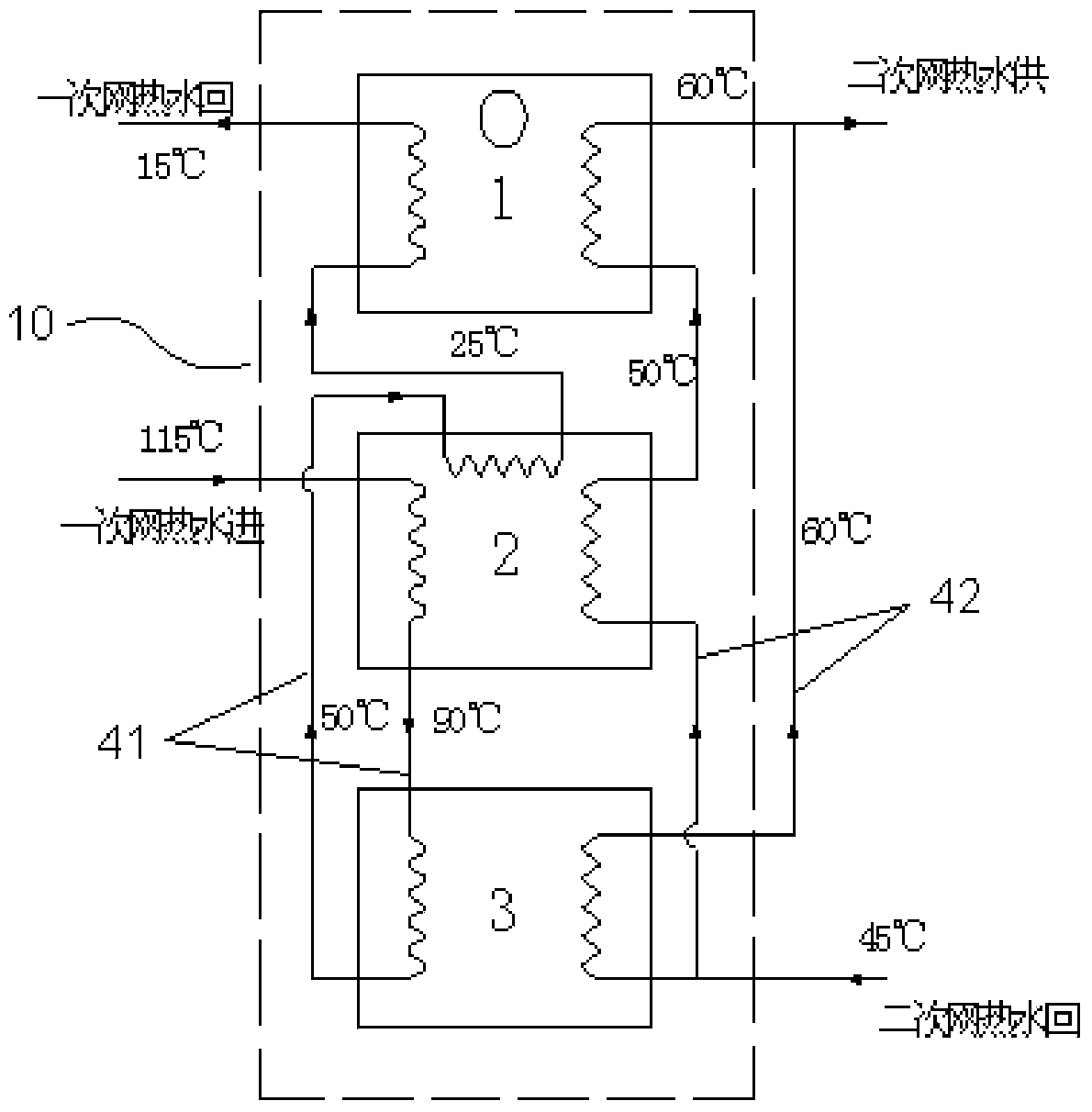

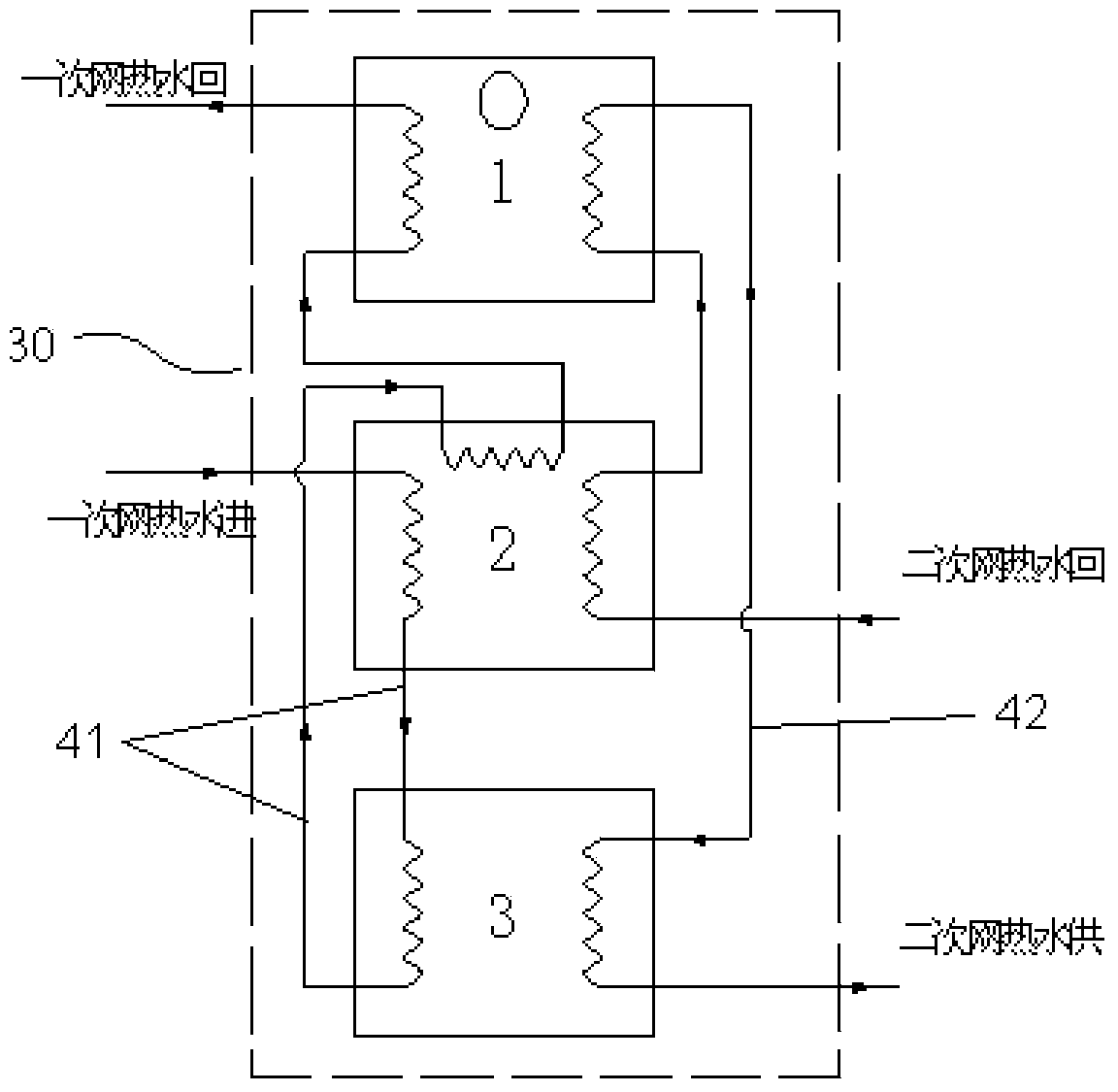

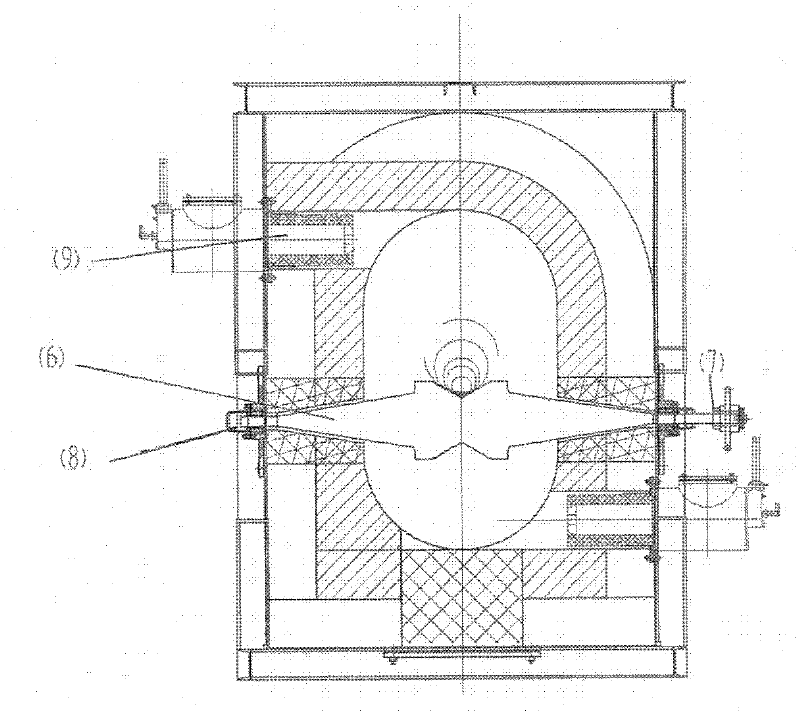

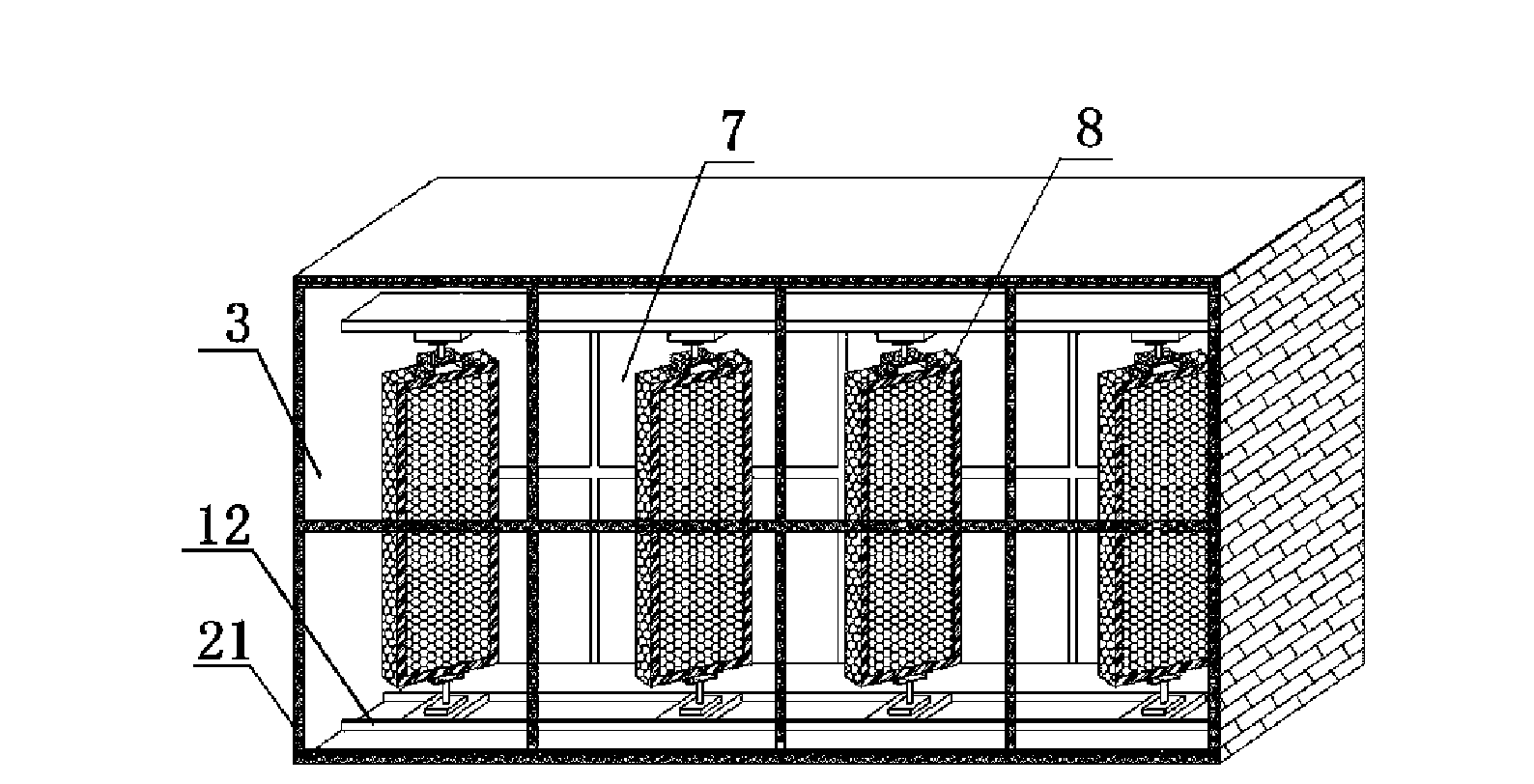

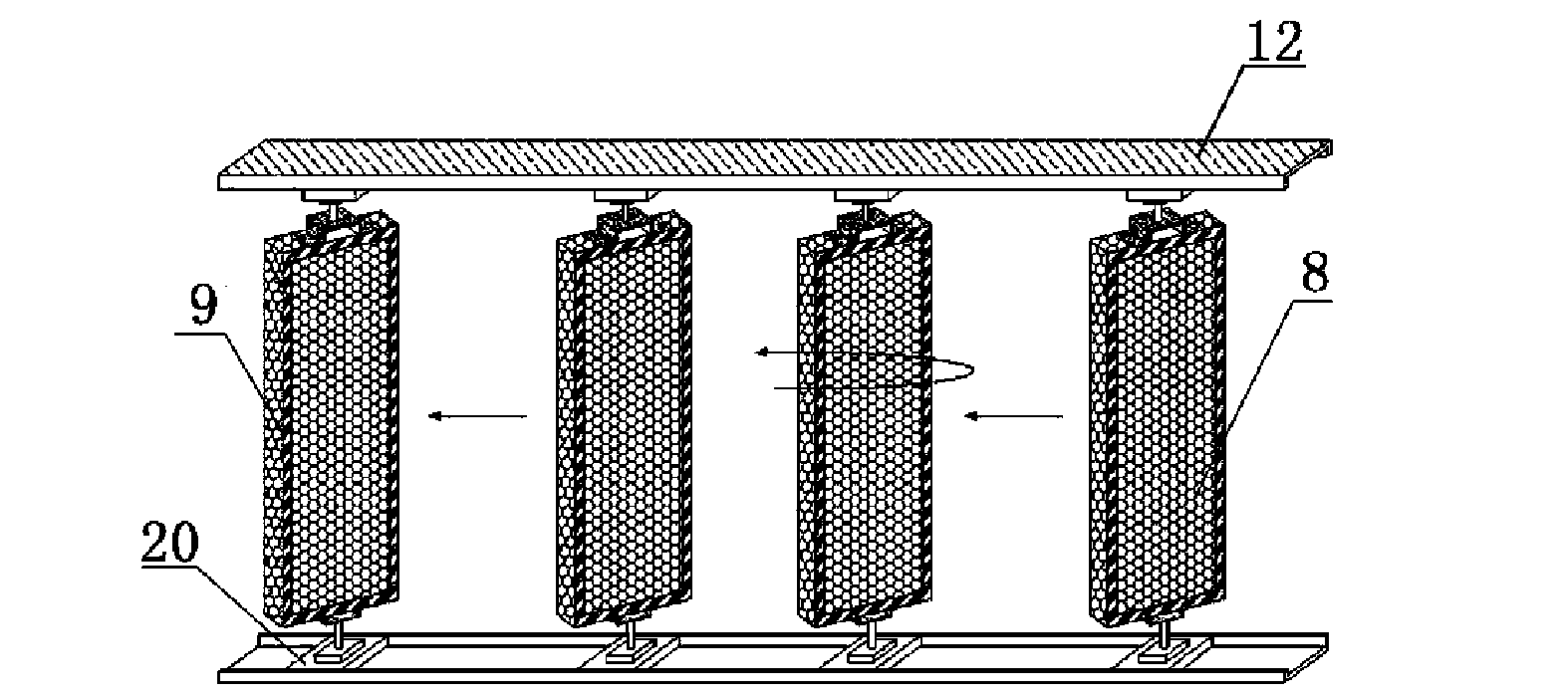

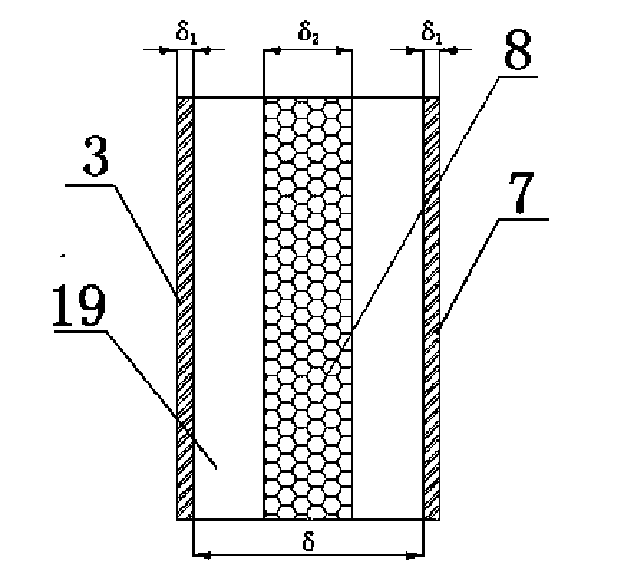

Combined type heat exchange unit

InactiveCN103673035AReduce initial investmentReduce water pump running power consumptionLighting and heating apparatusEnergy efficient heating/coolingHeating systemEvaporator

Owner:TSINGHUA UNIV

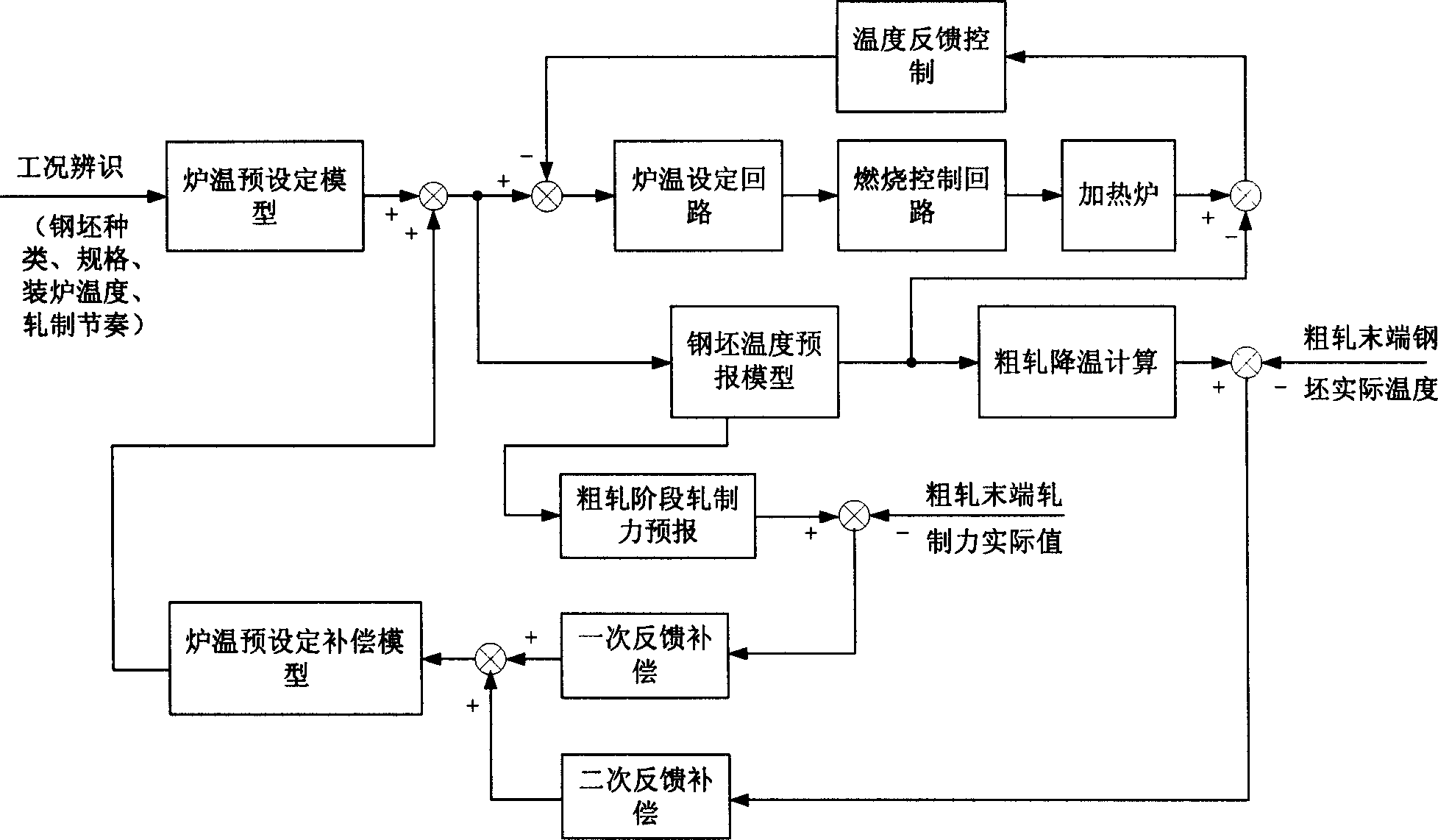

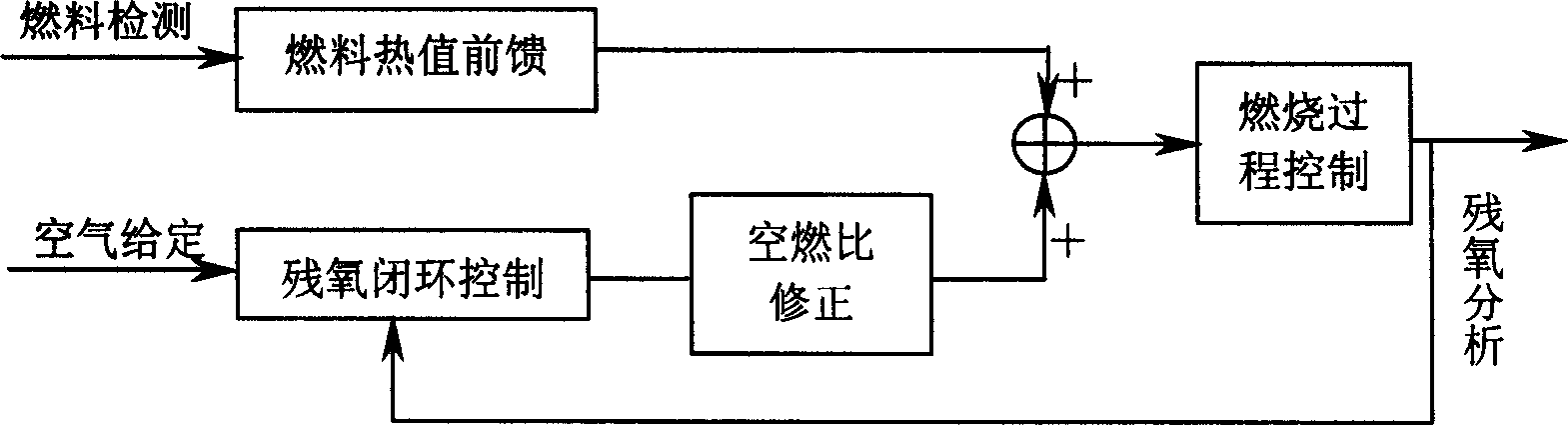

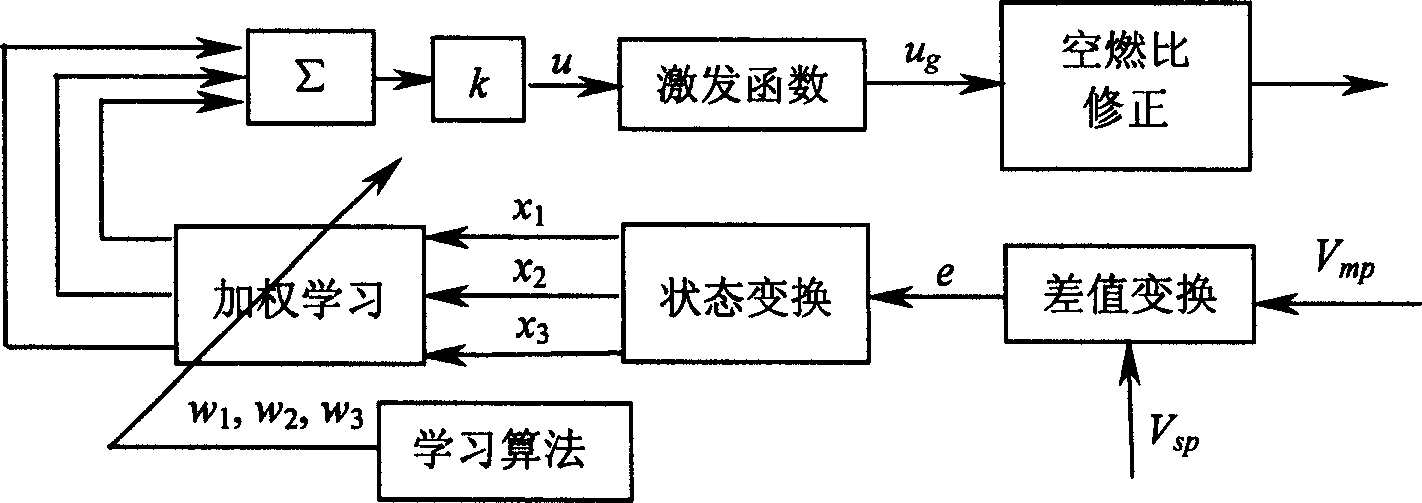

Heating furnace comprehensive optimizing controlling system designing and controlling method for hot rolling process

InactiveCN1644257AReduce the total energy consumption of productionAchieve optimal controlTemperature control deviceAdaptive controlProduction lineControl system design

A design and control method for the optimizing control system of intermediate rolling mill and heating furnace in order to improve the heating quality of billet in the heating furnace and save energy features that the heating furnace and intermediate rolling mill constitute a closed loop system, the information (rolling force, temp, etc) is fed back to heating furnace for dynamically changing the heating temp, and the optimizing control strategy and control algorithm are used in the billet heating process.

Owner:DALIAN UNIV OF TECH

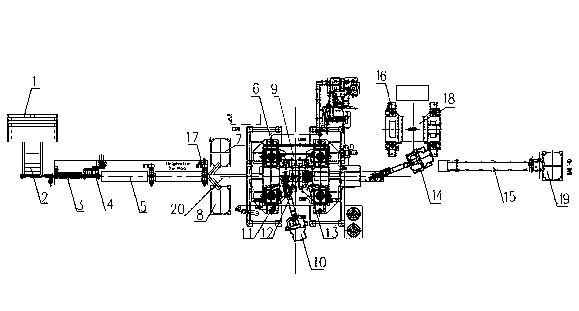

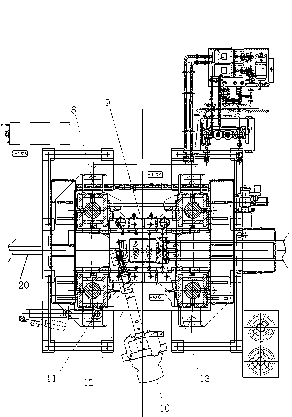

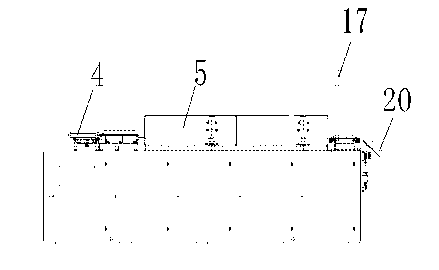

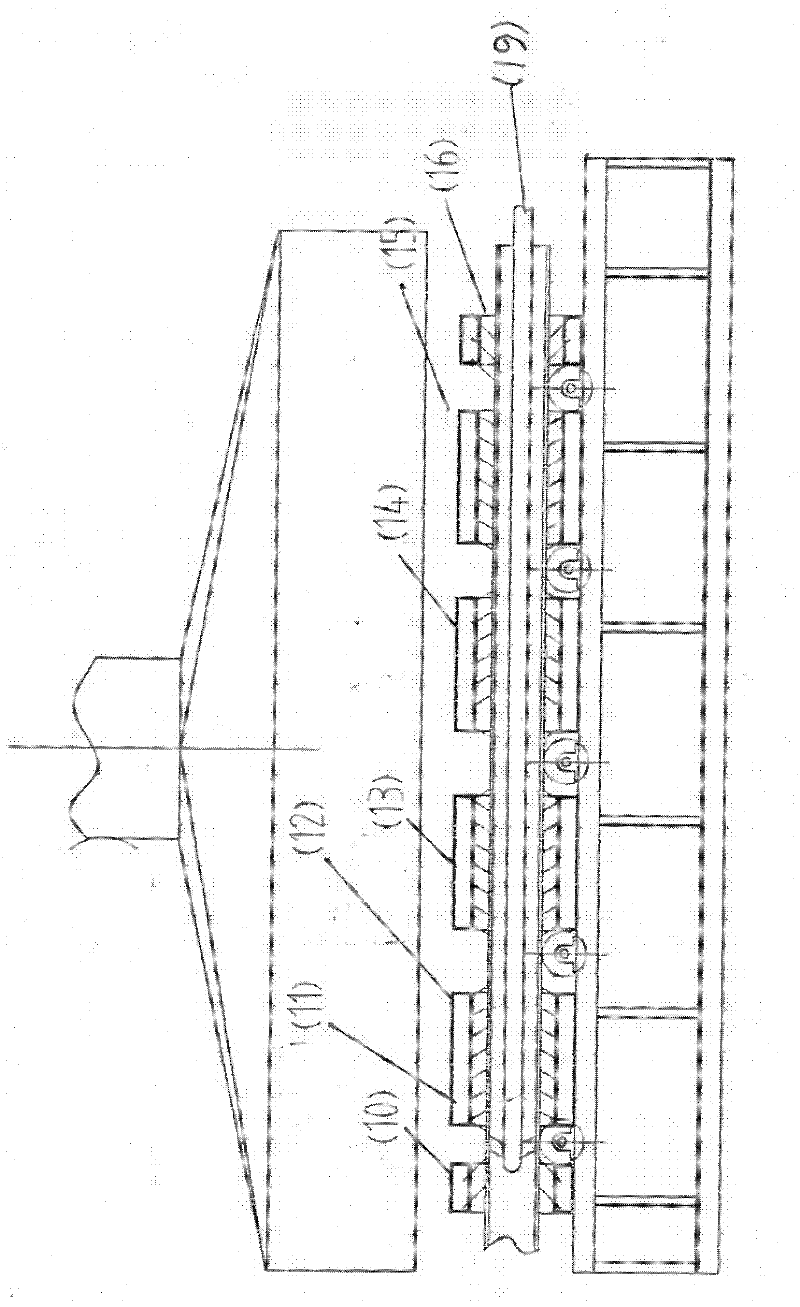

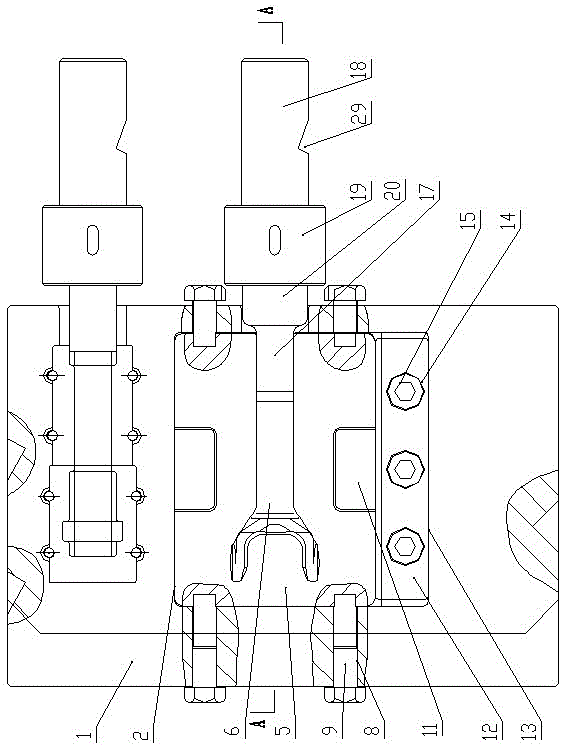

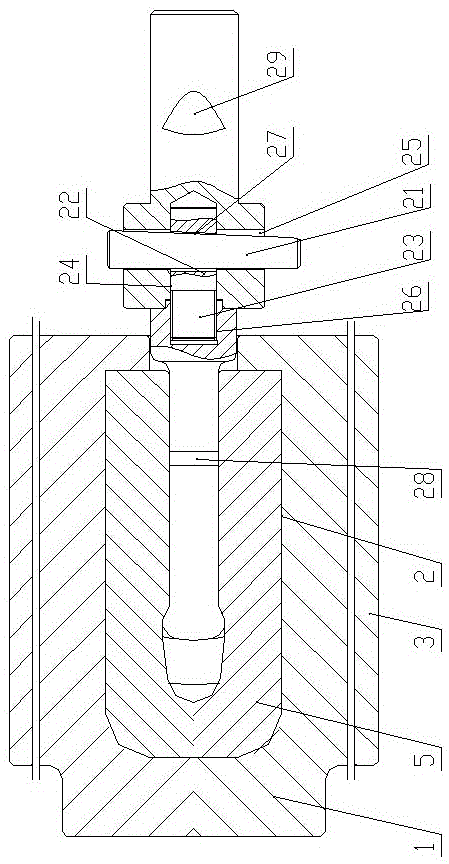

Production device and production technology for non-quenched and tempered steel forge piece automatic forging

InactiveCN103230997AEmission reductionImprove electricity efficiencyHandling devicesEngineeringUltimate tensile strength

The invention relates to the technical field of metal hot processing, in particular to the technical field of production device and production technology for non-quenched and tempered steel forge piece automatic forging. The device comprises a forging system, a feeding system and a discharging system, wherein the feeding system is arranged at the front end of the forging system, the discharging system is arranged at the rear end of the forging system, the forging system comprises an electric heating furnace connected with rear part of the feeding system, a forging pressing machine is connected with the rear part of the electric heating furnace, an edge trimmer is connected with the rear part of the discharging system, and the discharging system is connected with the rear part of the edge trimmer. According to the device provided by the invention, defects in the prior art is overcame, the full automatic line technology that the forge piece is heated once and is controlled by one worker is realized, is energy-saving and cost-reducing, labor saving, the outer surface and the inner quality of the forge piece is improved, and the service life is prolonged; as the mechanical property of each part of the forage is close to one anther, the forge piece quality and safety performance are improved, and the non quenched and tempered steel forging piece is high in tensile strength, fatigue strength and machinability.

Owner:ANHUI ANHUANG MACHINERY

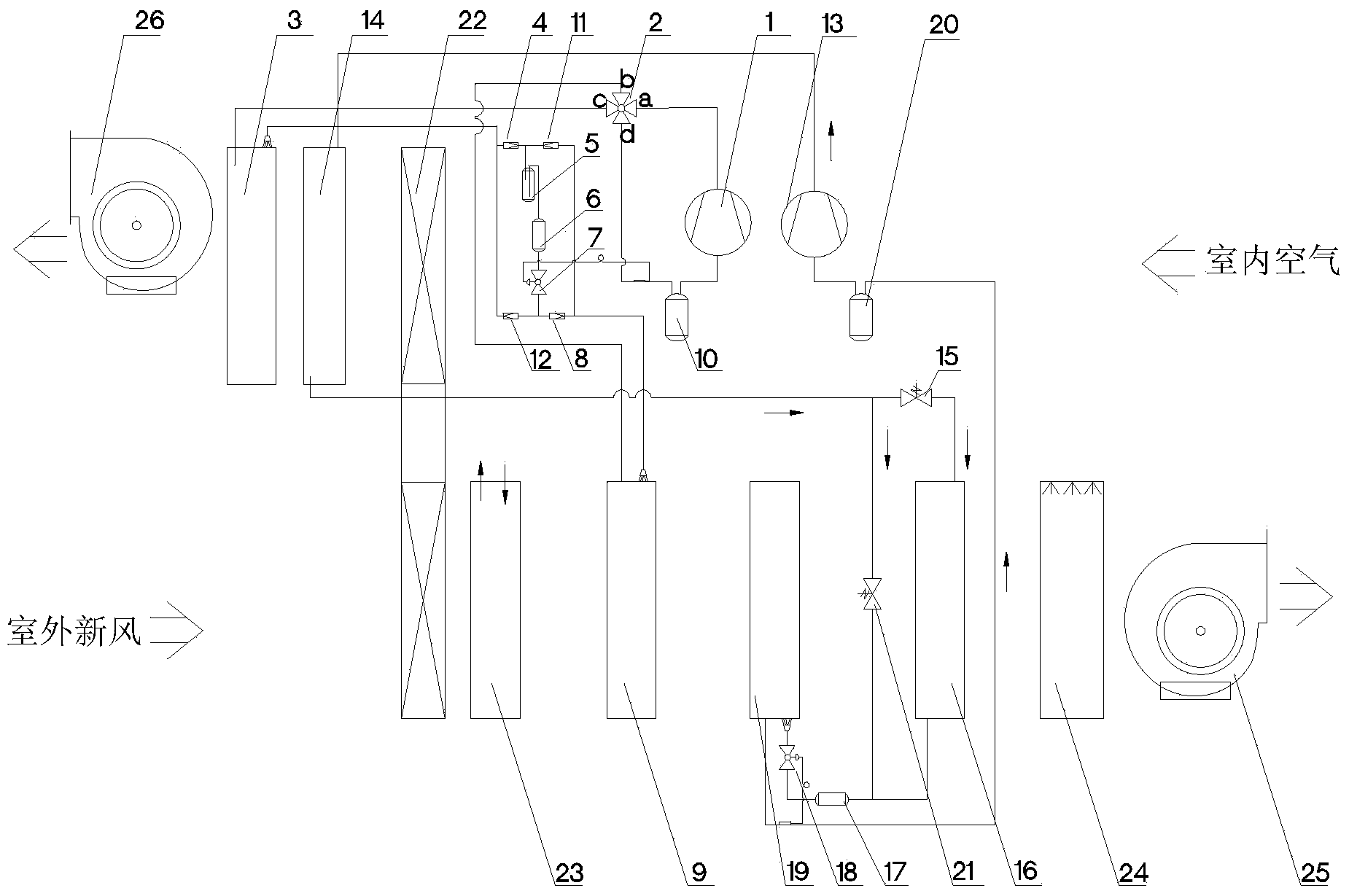

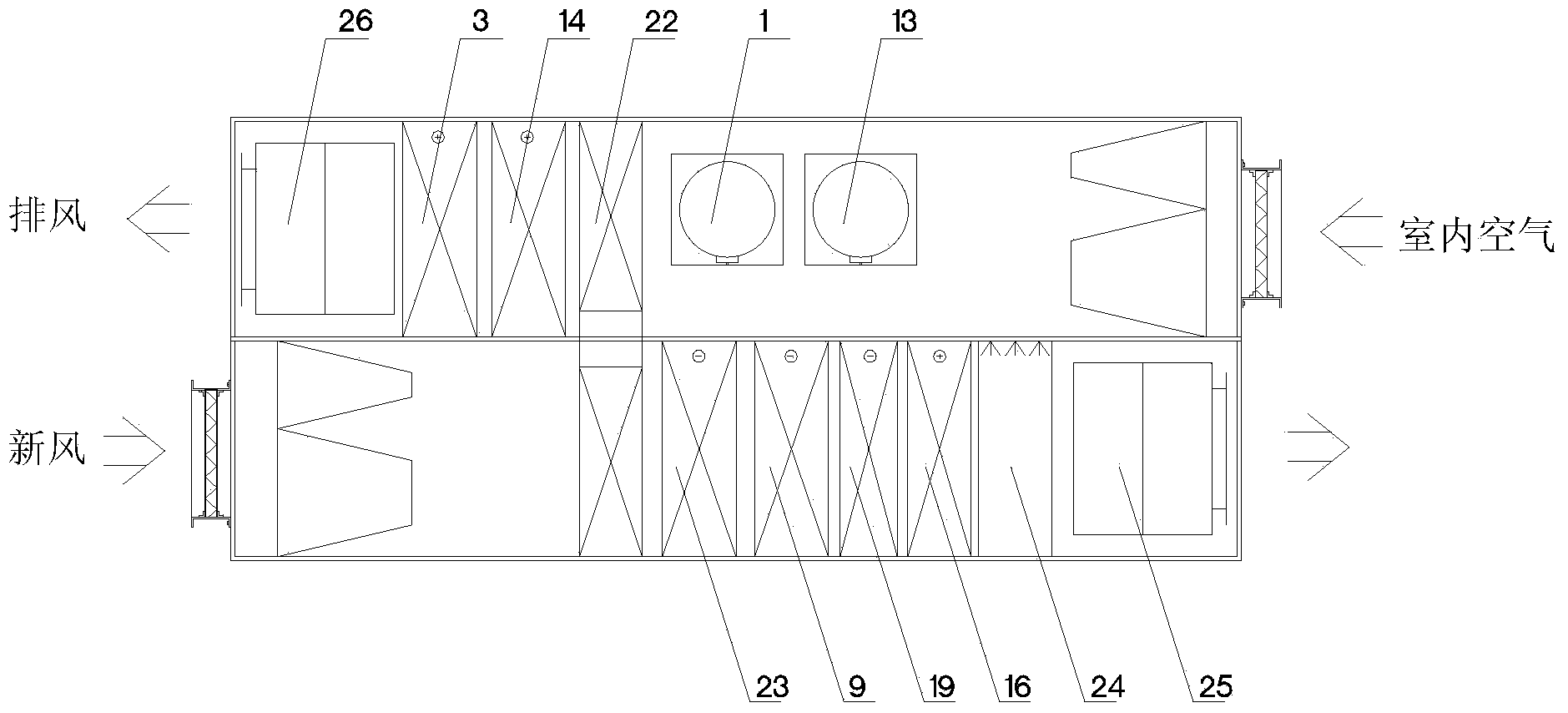

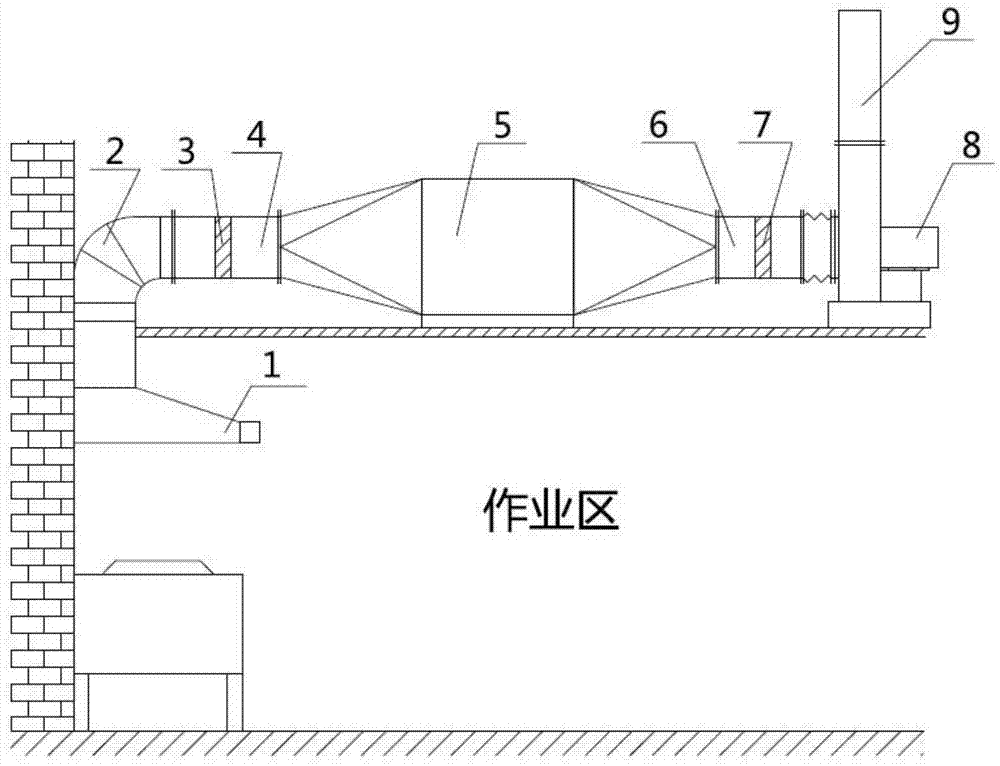

Heat pipe heat recovery all fresh air dehumidification air-conditioning device

InactiveCN104266277AAvoid mixingReduce cooling energy consumptionIndirect heat exchangersCompression machines with reversible cycleFresh airEngineering

The invention discloses a heat pipe heat recovery all fresh air dehumidification air-conditioning device. The heat pipe heat recovery all fresh air dehumidification air-conditioning device is composed of heat pump devices, heat pipes, a surface air cooler, a humidifier, a fresh air channel unit and an exhaust channel unit. One set of the heat pump devices comprises a compressor, a four-way reversing valve, a condenser, an evaporator, a refrigerating fluid flow direction control device and a throttle device, wherein the refrigerating fluid flow direction control device is composed of a reservoir, a dry filter, a throttle device and four one-way valves; the other set of the heat pump devices is composed of a compressor, two electromagnetic valves, two condensers, an evaporator and a throttle device. The heat pipe heat recovery all fresh air dehumidification air-conditioning device can dehumidify and cool and humidify and heat fresh air, and by means of an efficient heat recovery device, saves energy sources and can be widely applied to places with high requirements on the fresh air.

Owner:SOUTHEAST UNIV

Method and device for purifying catering oil smoke by utilizing synergistic effect of low temperature plasma and catalysts

ActiveCN103785276AReduce purification efficiencyMeet emission control requirementsDispersed particle separationParticulatesPartial oxidation

The invention discloses a method and device for purifying particulate matters and volatile organic compounds in catering oil smoke by utilizing a synergistic effect of low temperature plasma and catalysts. The method comprises the following steps: enabling the oil smoke to sequentially pass through a low temperature plasma reaction area and a catalytic reaction area, wherein the volatile organic compounds contained in the oil smoke are partially oxidized in the low temperature plasma reaction area and are further oxidized in the catalytic reaction area. On the front section of the low temperature plasma reaction area, the particulate matters contained in the oil smoke are separated, removed or charged by alternately arranged positive and negative polarity high-voltage discharge; on a transition section of the low temperature plasma reaction area, particles with positive charges and negative charges are close and are subjected to coagulation growth; on a rear section of the low temperature plasma reaction area, the particles are continuously subjected to the coagulation growth and are captured and separated. According to the method, the function of efficiently purifying the volatile organic compounds is increased; the efficiency of removing the particulate matters contained in the oil smoke is relatively high; the normal temperature operation can be realized, the fouling resistance is high, and the method is particularly suitable for being used for performing oil smoke treatment in public places such as various dining halls, public houses and hotels.

Owner:BEIHANG UNIV

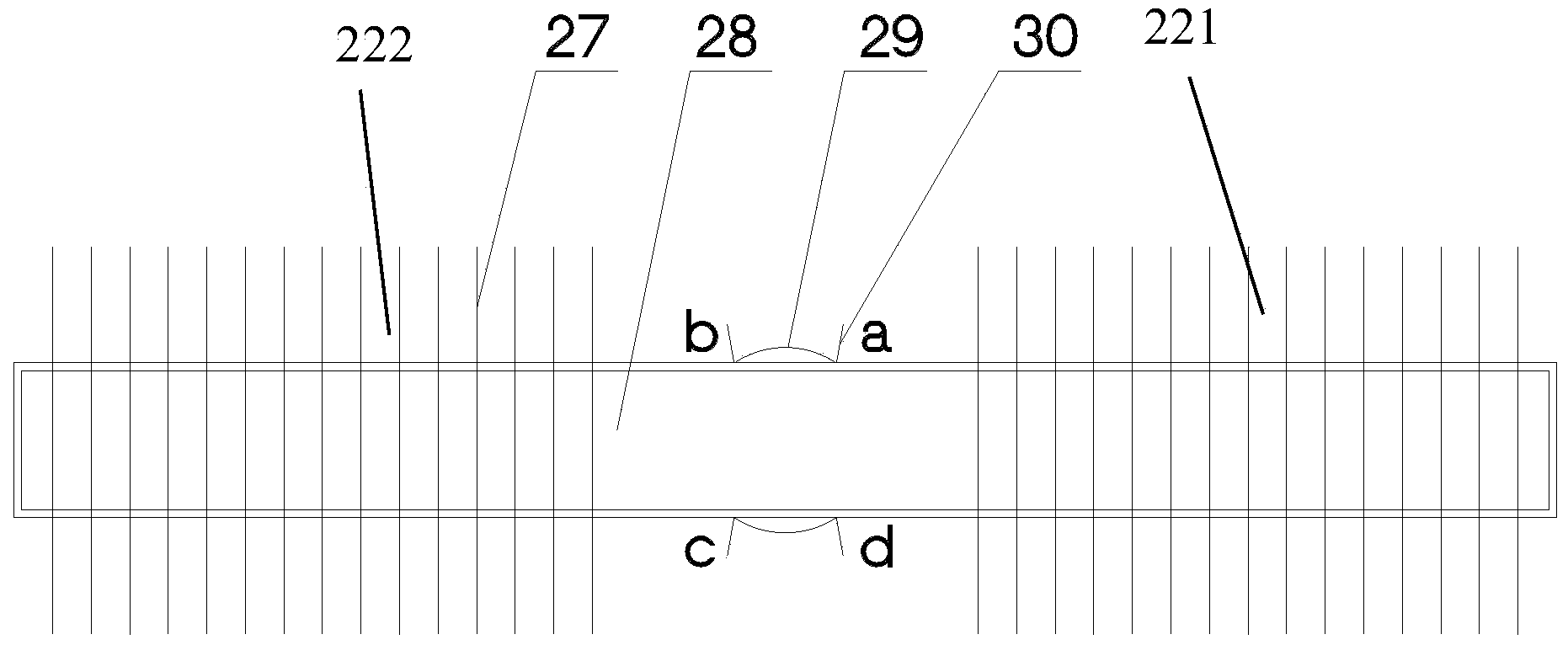

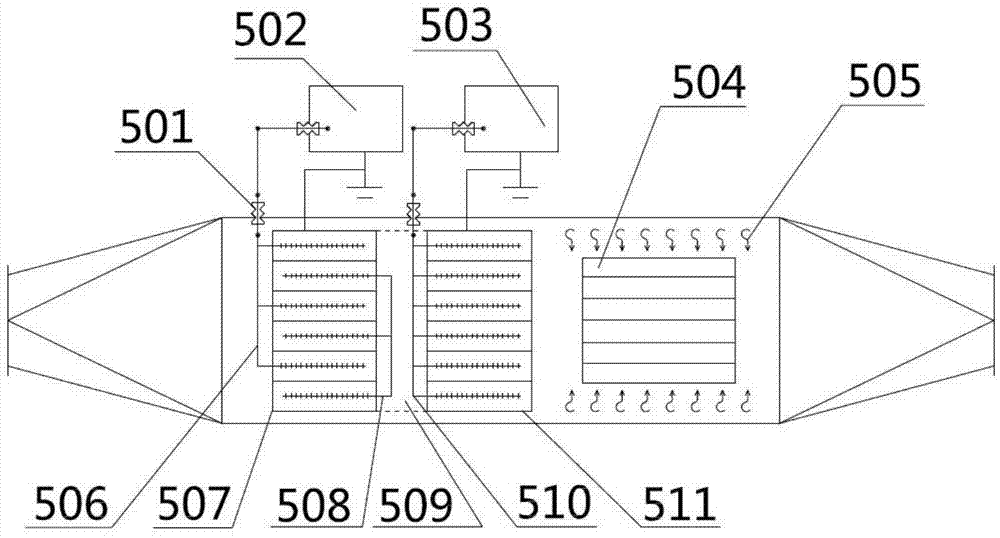

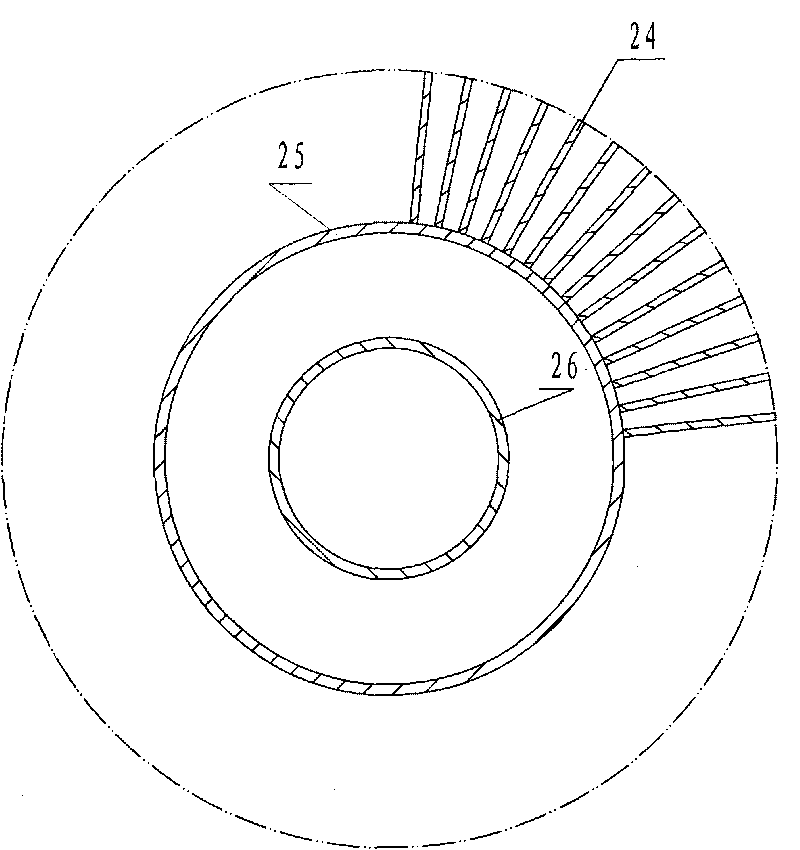

Rotary Dehumidification and Air Conditioning System Using Heat Pipe Heat Recovery and Ultrasonic Enhanced Regeneration

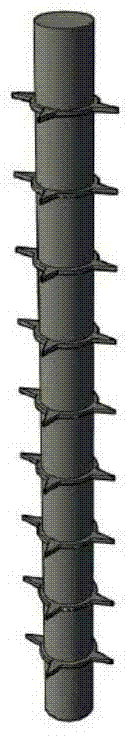

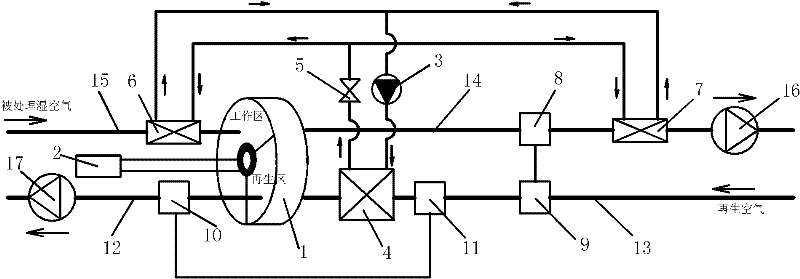

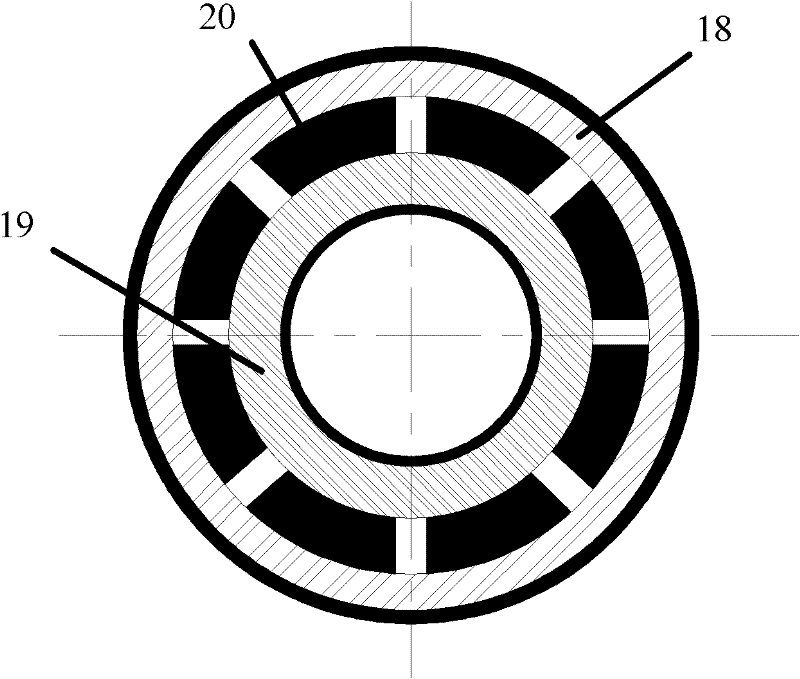

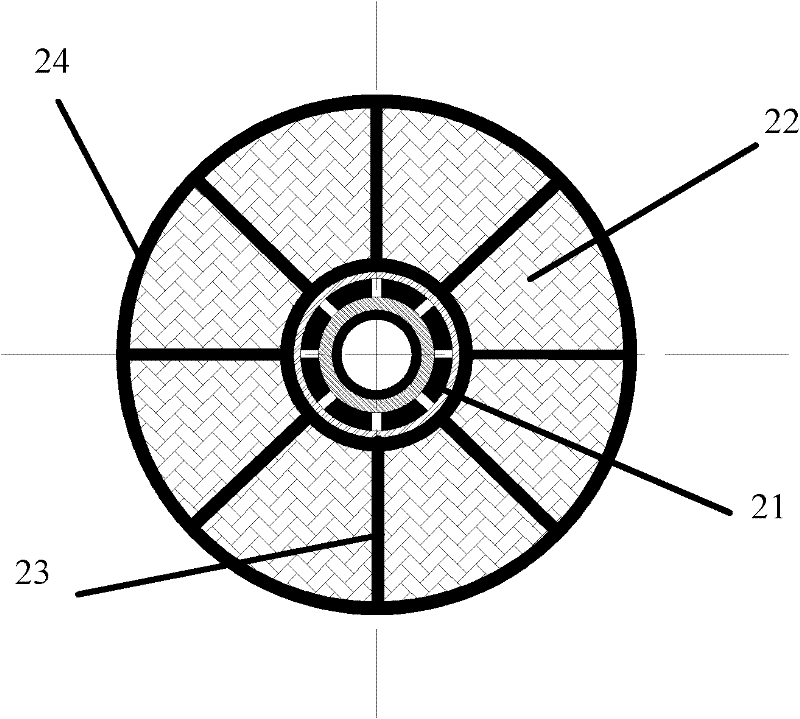

ActiveCN102261703AReduce heating energy consumptionImprove work efficiencyDucting arrangementsHeat recovery systemsHigh energyEngineering

The invention discloses a runner dehumidification air-conditioning system adopting heat pipes for heat recovery and adopting ultrasound for enhancing regeneration, which comprises an ultrasonic dehumidification runner, an ultrasonic generator, a compressor, a condenser, a throttle valve, a first evaporator, a second evaporator, a first heat pipe, a second heat pipe, a regenerated air outlet channel, a regenerated air inlet channel, a processed air outlet channel, a processed air inlet channel, a processed air feeder and a regenerated air exhaust fan, wherein the ultrasonic dehumidification runner comprises a local radiation rod-shaped ultrasonic transducer, moisture-absorbing material, a partition plate and a housing; and the local radiation rod-shaped ultrasonic transducer comprises an outer cover plate, an inner cover plate and a piezoelectric ceramic wafer. The characteristic of high energy efficiency of a medium-high temperature heat pump is utilized for heating regenerated air, the characteristic of high heat conduction of heat pipe elements is utilized for recycling latent waste heat, the ultrasonic regeneration enhancing technology is utilized for reducing the requirements of a runner dehumidizer on the temperature of the regenerated air, and the energy-saving purpose of the dehumidification air-conditioning system is finally achieved.

Owner:博拓(苏州)新能源技术有限公司

Method for producing mash gas from municipal sludge through dry method anaerobic fermentation

ActiveCN101935139ASmall volumeReduce heating energy consumptionWaste processingWaste based fuelBiomassChemistry

The invention relates to a method for producing mash gas from municipal sludge through dry method anaerobic fermentation, which belongs to the field of solid waste reclamation, and can overcome the difficulties difficult mass transfer, difficult gas overflow and the like caused by dewatered sludge which has high viscosity, no fluidity, no gaps and the like. The method comprises the following steps of: performing biological pre-drying on the dewatered sludge, and stacking the dewatered sludge in an aerobic environment for 2 to 3 days; adding the material after the biological pre-drying into anaerobic granular sludge or biogas residues to perform inoculation, and performing static starting for 6 to 8 days; performing acidogenic fermentation on the material under an aerobic or anaerobic condition, performing spiral band type or anchor type stirring, and adjusting the pH if necessary; performing methanogenesis fermentation on the material after acid production under an anaerobic condition, performing extruding type stirring, keeping the temperature of the material to be 35+ / -1 DEG C, and keeping the pH between 6.6 and 7.5; and performing refluxing inoculation on part of the biogas residues, and performing aerobic compost stabilization on the rest of the biogas residues. The method can be used for beneficial utilization of the municipal sludge and the recovery of biomass energy sources, and compared with wet fermentation, the method can save equipment investment and land occupation.

Owner:TONGJI UNIV

Low-temperature rolling production method of high-performance 20CrMnTi gear steel

ActiveCN108906884AOptimizing the heating process systemReduce heating energy consumptionTemperature control deviceWork treatment devicesHeating furnaceMechanical property

The invention belongs to the field of special steel production machining of metallurgical industries and particularly relates to a low-temperature rolling production method of high-performance 20CrMnTi gear steel. With 20CrMnTi continuous casting slabs as raw materials, the method comprises the following working processes of heating, descaling, rough rolling, continuous rolling, water penetrationand cold rolling, finish rolling of a rod material sizing reduction unit and cooling through a cold bed in sequence, and finally a finished product rod material is obtained. According to the low-temperature rolling production method of the high-performance 20CrMnTi gear steel, the heating technical system of a heating furnace is optimized, the heating energy consumption is reduced, the productioncost is reduced, and the environment is protected; the high-performance 20CrMnTi gear steel is obtained, grain size control, rigidity control and mechanical property control over the high-performance20CrMnTi gear steel are superior than control in a common rolling technology, the metallographic structure of the high-performance 20CrMnTi gear steel is ferrite and pearlite, the rigidity is generally 170-220 HBW, the grain size of the high-performance 20CrMnTi gear steel is small and even, the grain size of the rolled round steel at least reaches 9.0 grade, and the comprehensive mechanical properties of the high-performance 20CrMnTi gear steel are superior than those of the common rolling technology.

Owner:DAYE SPECIAL STEEL CO LTD

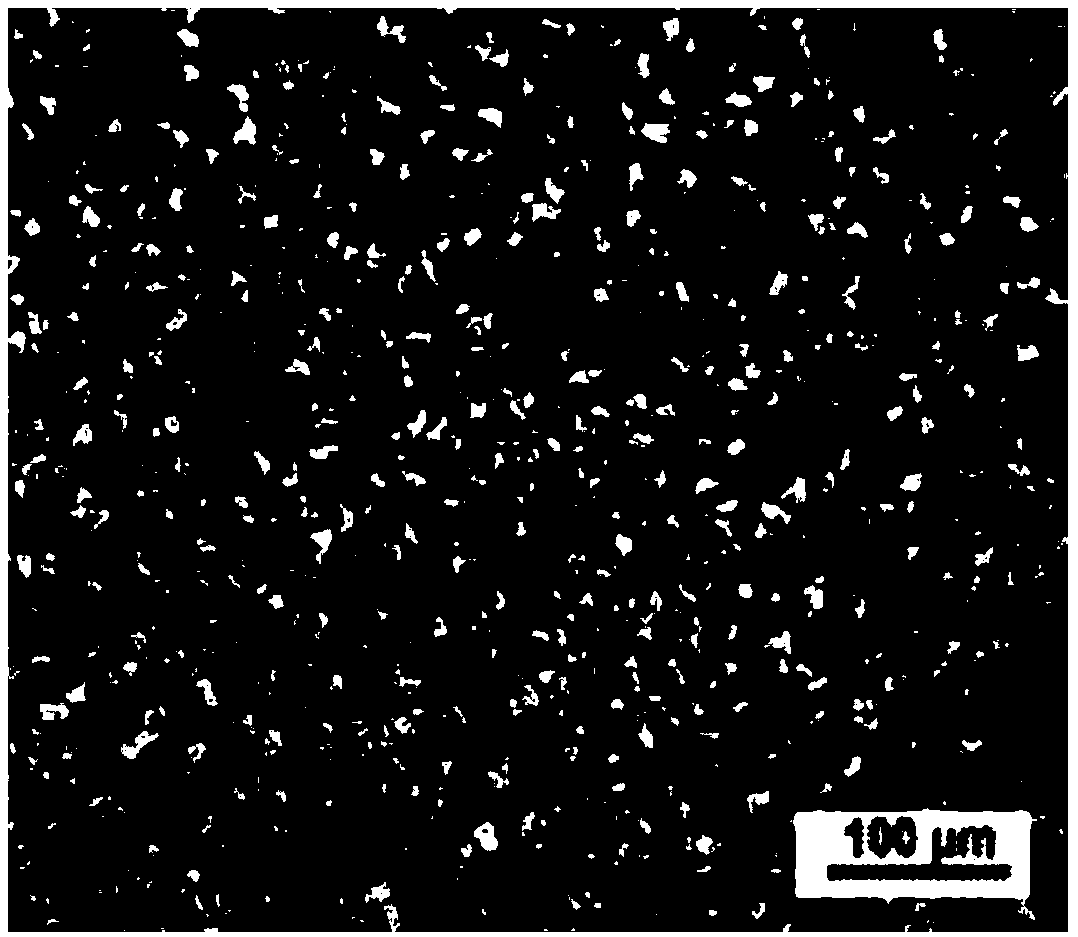

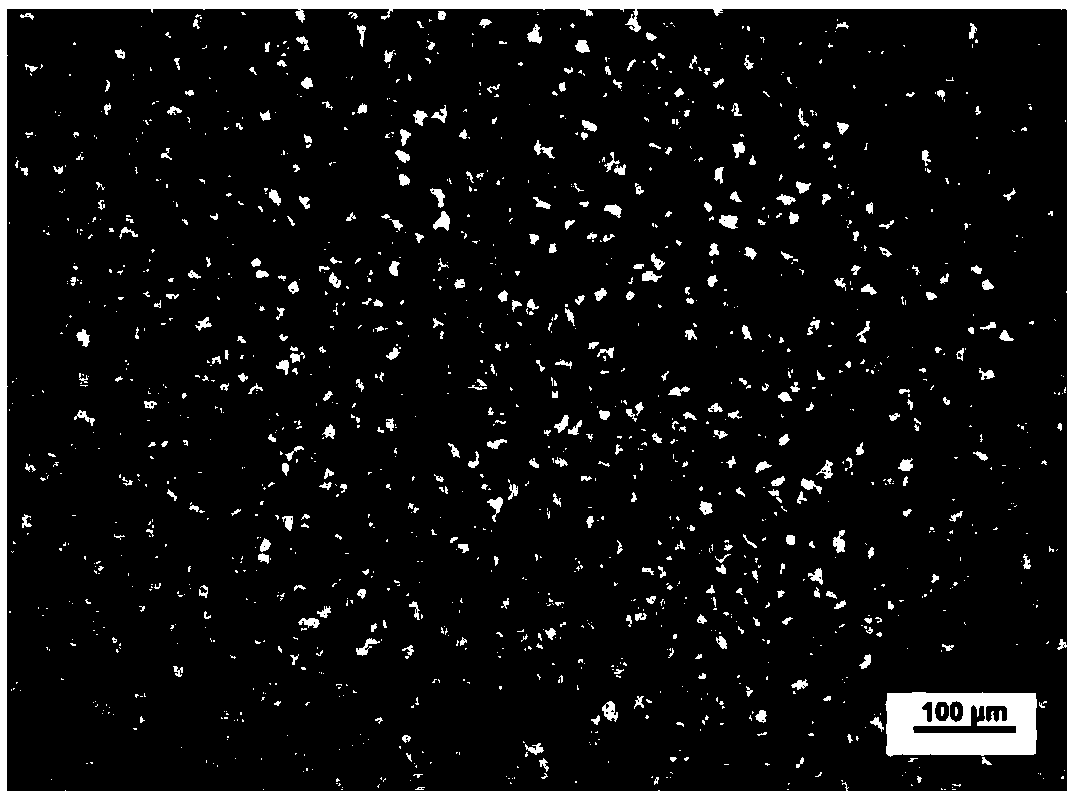

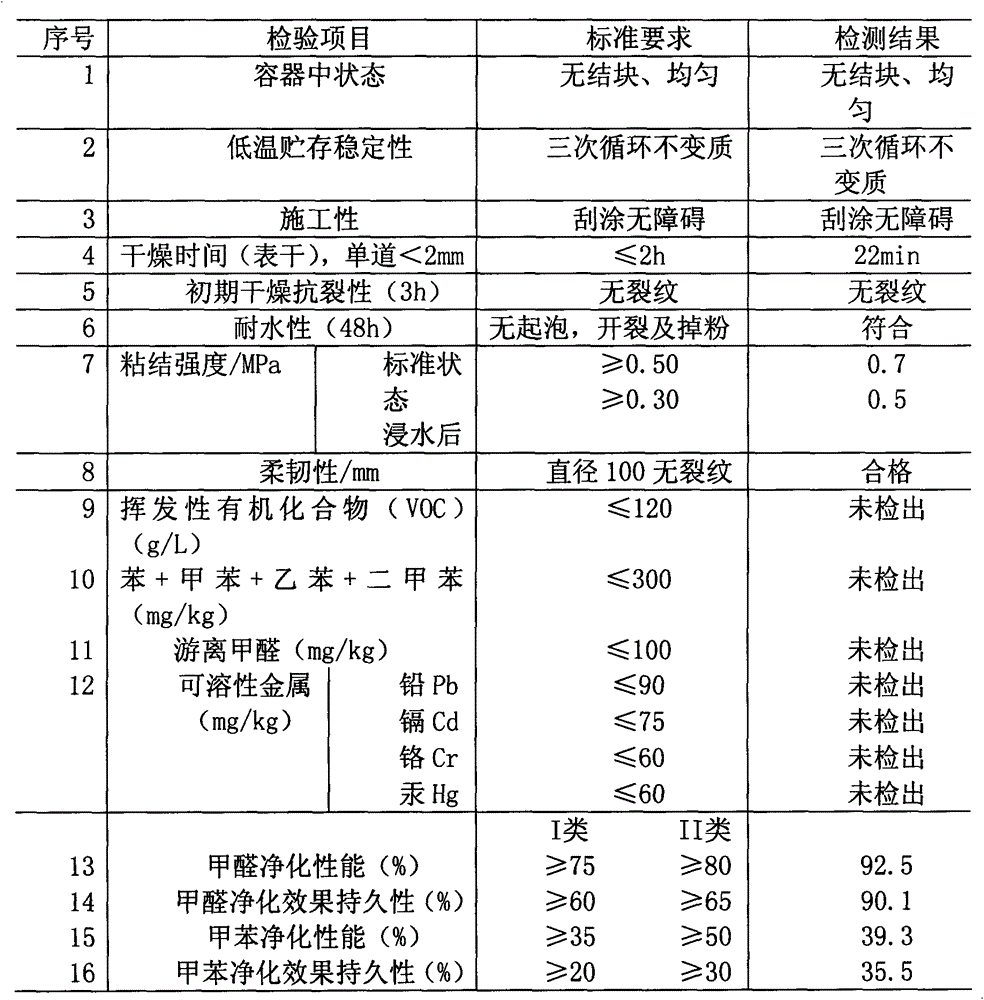

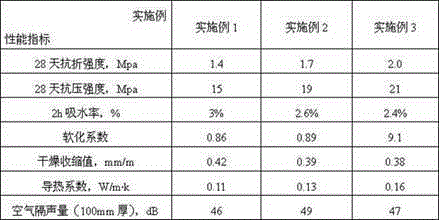

Multifunctional diatom ooze

InactiveCN103146264AAntibacterial and mildew resistantRaise the room temperatureAntifouling/underwater paintsPaints with biocidesMass ratioCarvacryl acetate

The invention discloses multifunctional diatom ooze. The multifunctional diatom ooze is prepared by comprising the following steps: compounding vinyl acetate-VAE copolymer emulsion with silica sol into a film forming matter according to mass ratio of 1:1; by taking diatomite as a humidifying filler, macromolecular water-absorbent resin as a humidifying agent, phase-change energy-accumulating microcapsules as an energy-accumulation thermoregulation filler and anion antibacterial additive as an antibacterial mouldproof material, stirring and mixing by conventional coating production equipment under the matching of various auxiliaries. The multifunctional diatom ooze has multiple functions of automatically regulating and controlling the temperature, absorbing and dissipating moisture, resisting bacteria and mould, refreshing air, removing harmful gas, releasing negative ions, is sound-proof, reducing noise and is ecological and environment-friendly, and is capable of lowering the interior temperature by about 3 DEG C in summer, and increasing the interior temperature by about 2 DEG C in winter, so that the electricity of an air conditioner can be saved by 30% in summer, and the warming energy consumption can be saved by 20% in winter, and the multifunctional diatom ooze has good popularization and application prospects.

Owner:北京国泰瑞华精藻硅特种材料有限公司

Method for preparing piperazine pyrophosphate

The invention discloses a method for preparing piperazine pyrophosphate. The method is a method A or a method B; in the method A, piperazine sulfate and phosphoric acid are mixed in a molar ratio of 1:1 in a reaction device and the mixture is subjected to dehydration condensation at the temperature of between 150 and 300 DEG C to form the piperazine pyrophosphate; and in the method B, piperazine sulfate and phosphoric acid are subjected to dehydration condensation in a molar ratio of 1:1 at the temperature of between 120 and 260 DEG C in a reaction device in the presence of an inert solvent, wherein the inert solvent has the boiling point of more than or equal to 100 DEG C, and the using amount of the inert solvent is more than three times the total weight of the piperazine sulfate and the phosphoric acid.

Owner:SHANGHAI RES INST OF CHEM IND

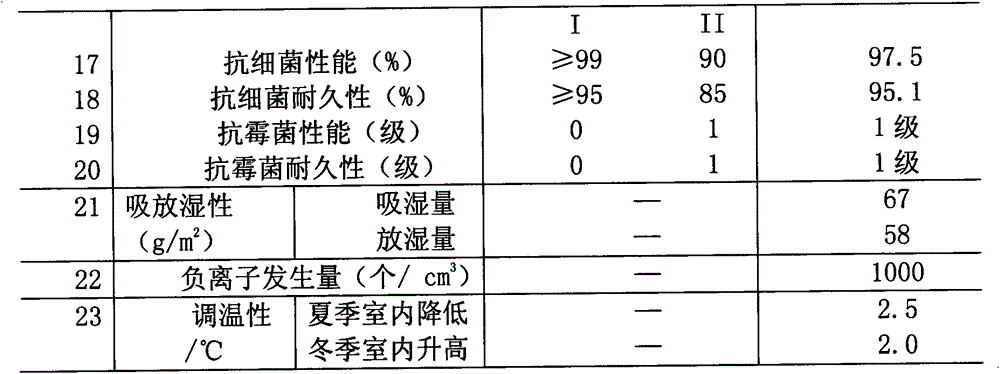

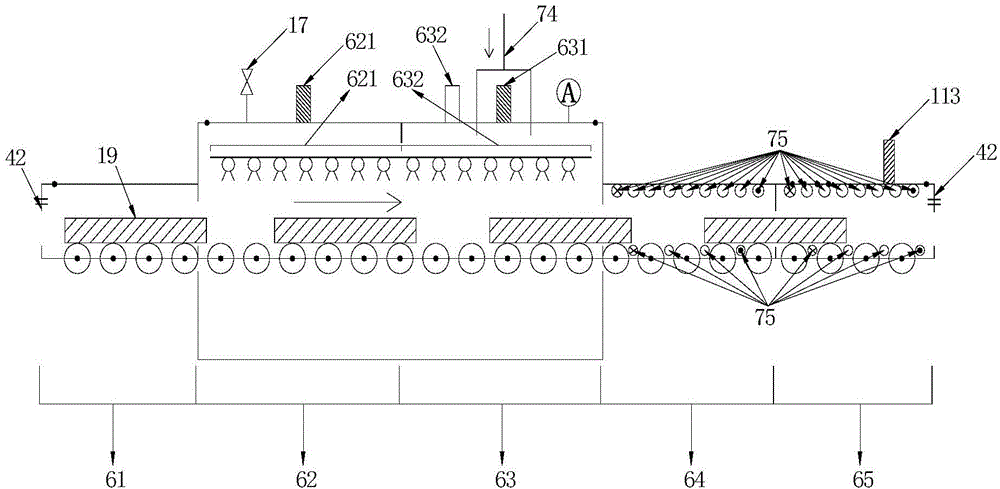

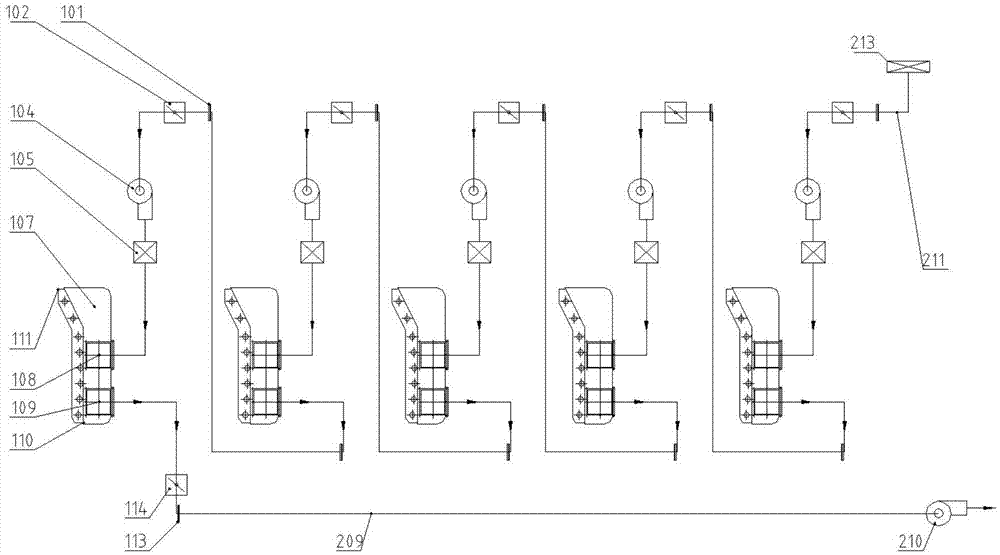

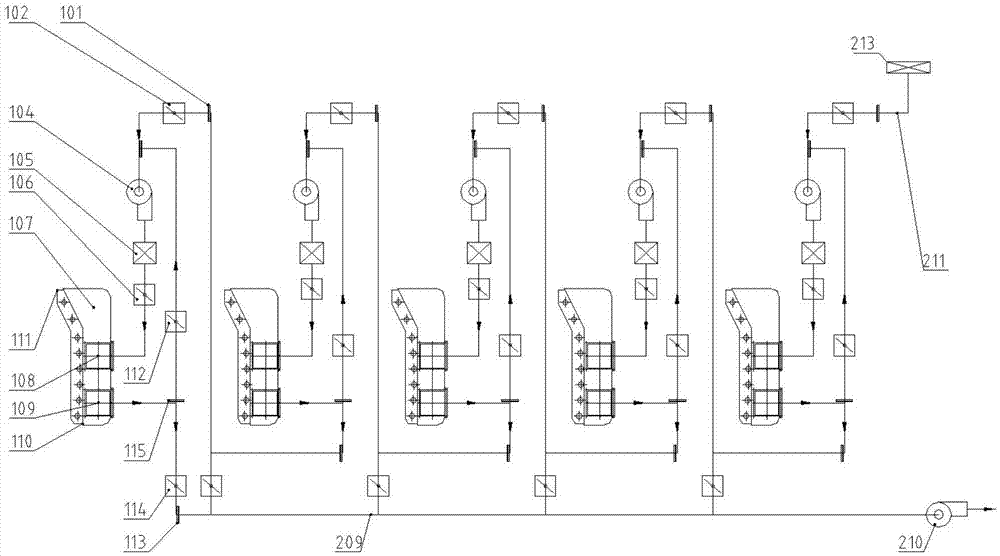

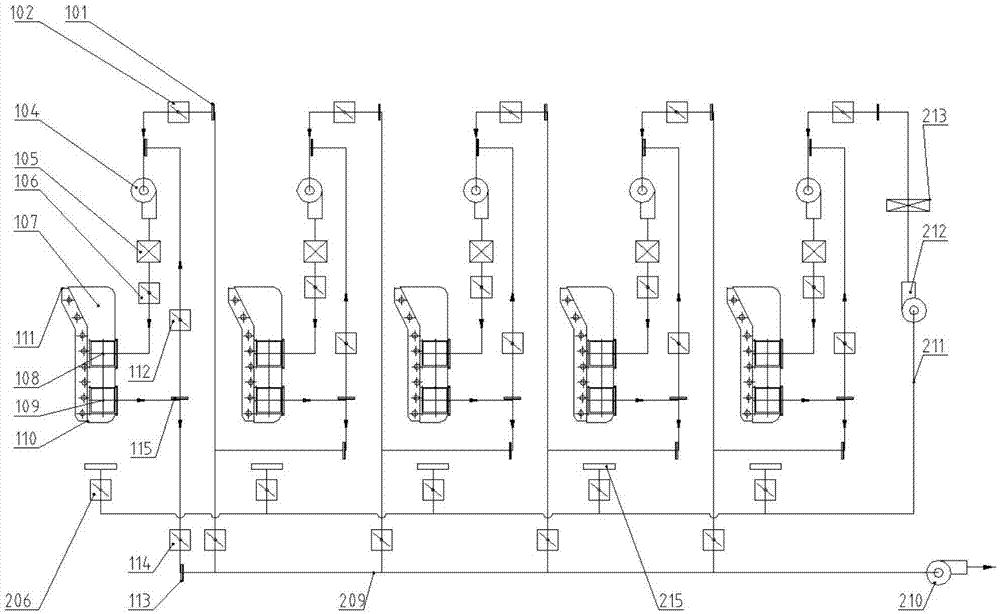

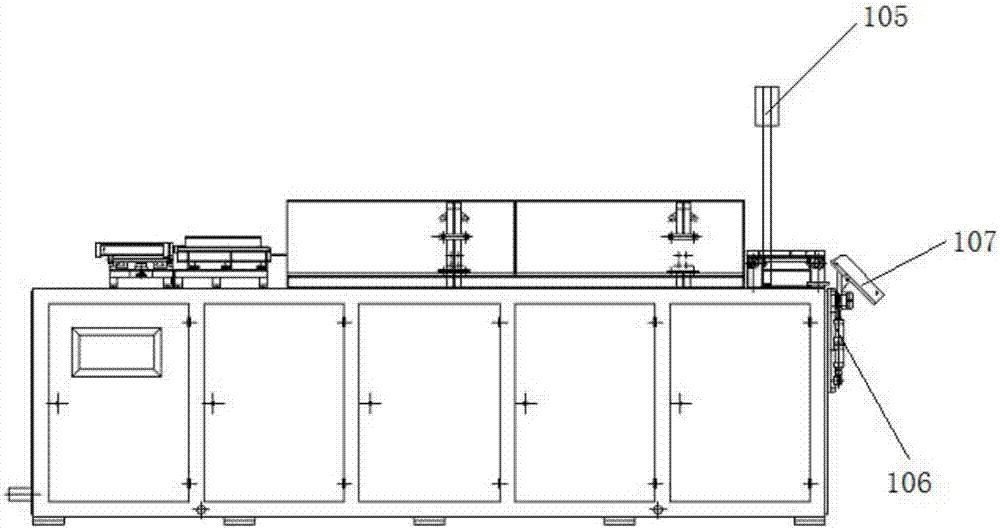

Continuous coating production system of sheet substrates

ActiveCN104060236AReduce stress lossComply with glass safety performance requirementsVacuum evaporation coatingSputtering coatingProduction lineComposite film

The invention discloses a continuous coating production system of sheet substrates. The continuous coating production system comprises a feeding area, a working area and a discharge area, all of which are orderly communicated with each other; the feeding area comprises a sheet feeding table; the working area comprises a plurality of pre-vacuumizing chambers, a first transition chamber, a coating deposition chamber, a quick atmosphere annealing chamber and a plurality of pre-vacuumizing chambers orderly in the coating process flow direction; the discharge area comprises a discharge table; each chamber of the working area is provided with the desired vacuum environment. The continuous coating production system further comprises a transporting device capable of realizing linear transmission; the transporting device penetrates through the whole feeding area, the working area and the discharge area. The continuous coating system has the advantages that the regional continuous film deposition and annealing of a one-layer or multi-layer composite film containing a hot color coating material in the same production line are realized, the production efficiency is obviously improved, and meanwhile, the material loss cost of the material in the off-line annealing process after coating is reduced. Due to unique structural design of the system, the problem of tempering stress loss can be obviously solved; the stress of the tempered glass based smart glass produced by the system is up to the stress standard of the national building energy-saving safety glass, namely greater than or equal to 90Mpa.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

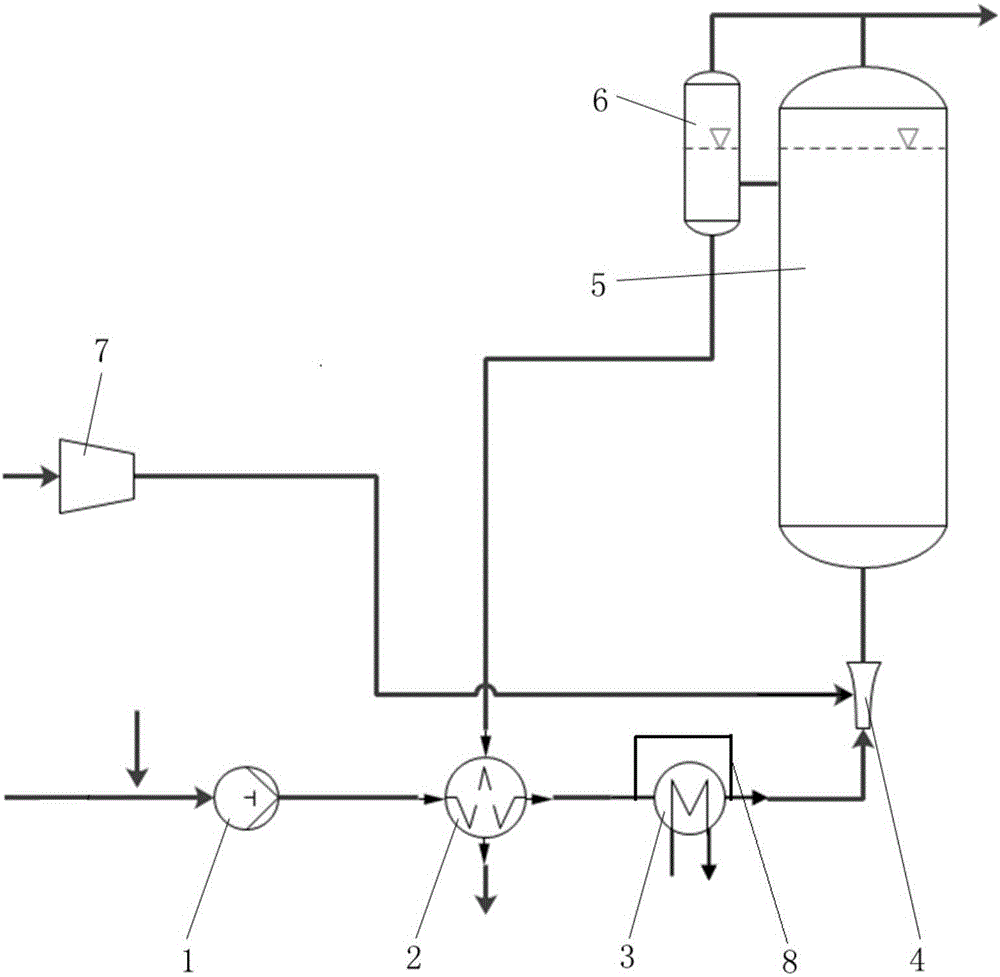

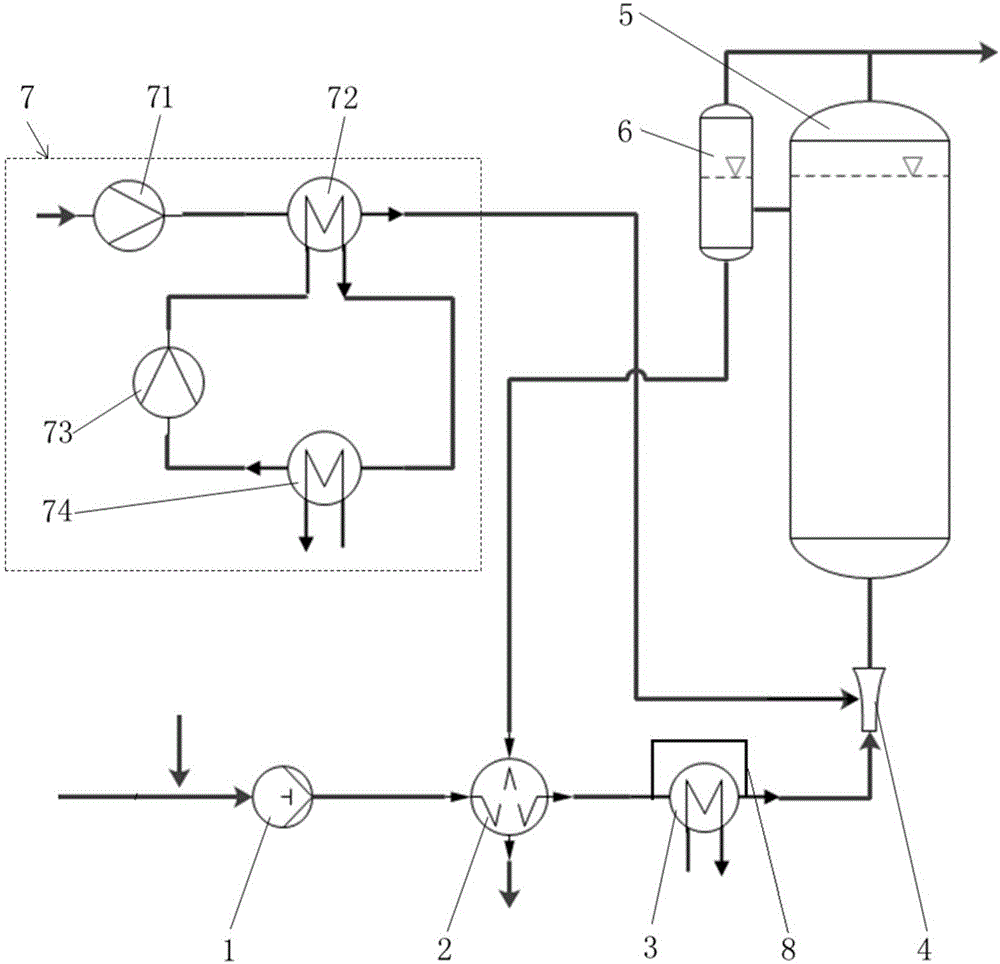

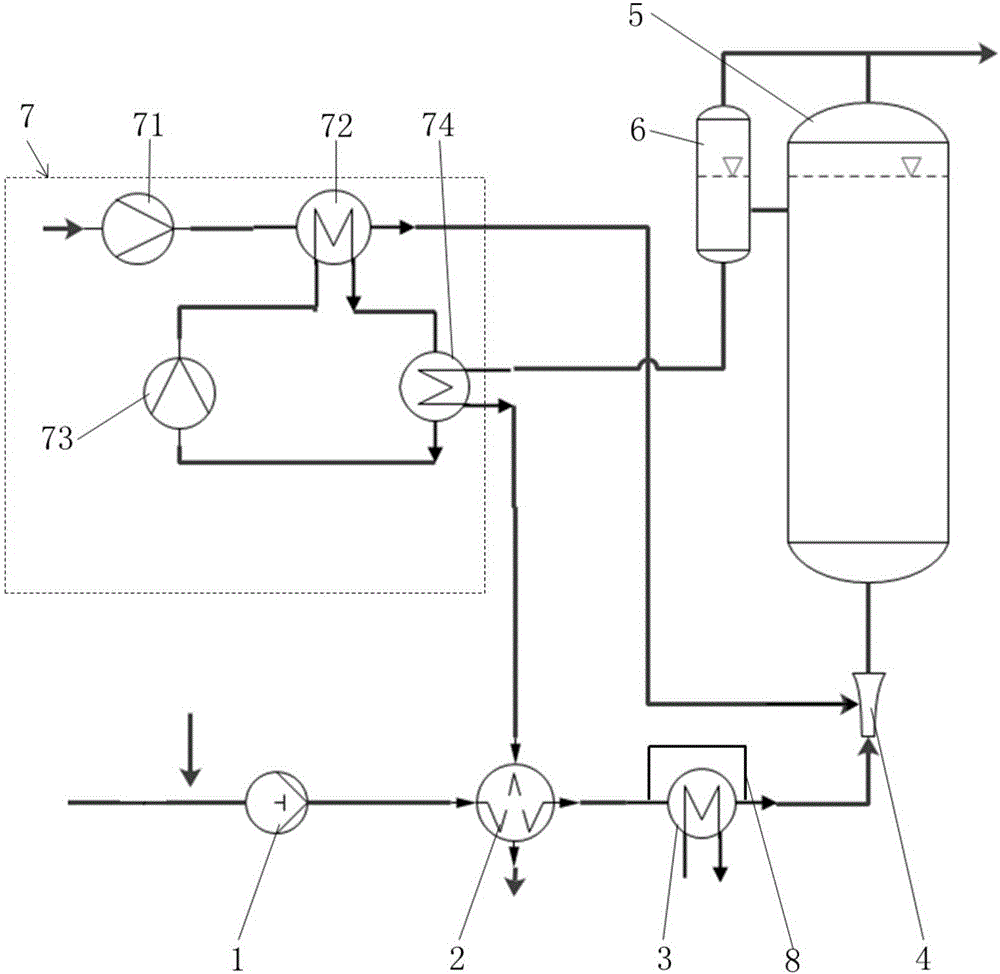

Continuous wet oxidation process for degrading high concentration organic waste water and equipment thereof

PendingCN106348421AEasy to handleSave spaceSpecific water treatment objectivesWater contaminantsHigh concentrationEnergy consumption

The invention discloses a continuous wet oxidation process for degrading high concentration organic waste water, belonging to the field of water treatment. The continuous wet oxidation process for degrading high concentration organic waste water comprises the procedures: a waste water pressurizing procedure: pressurizing waste water to be treated; a waste water heat exchange procedure: carrying out direct and / or indirect heat exchange on the pressurized waste water and treated waste water so the temperature of the pressurized waste water rises; an oxidizer pressurizing procedure: pressurizing an oxidizer; a mixing procedure: thoroughly mixing the pressurized and heated waste water with the pressurized oxidizer; a reaction procedure: causing the mixed waste water and the oxidizer to generate oxidation reaction, obtaining the treated waste water and generating gas; and a separation procedure: continuously separating the treated waste water from gas. The continuous wet oxidation process for degrading high concentration organic waste water has the advantages of high efficiency, less energy consumption, stability of operation and the like.

Owner:羿太环保科技(上海)有限公司

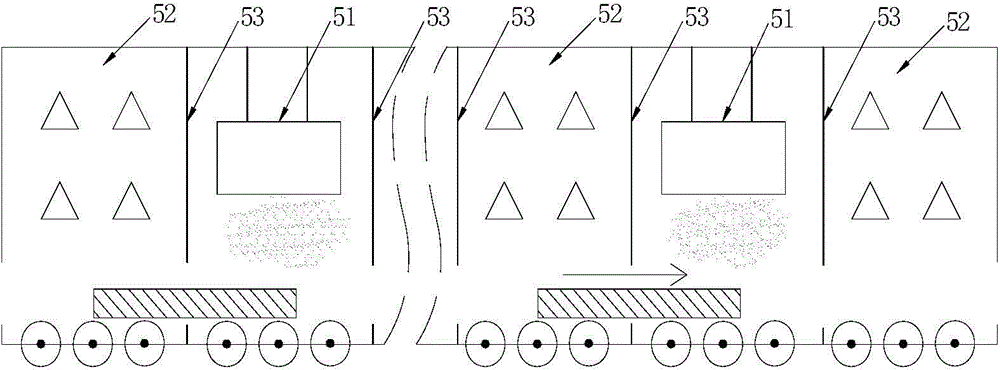

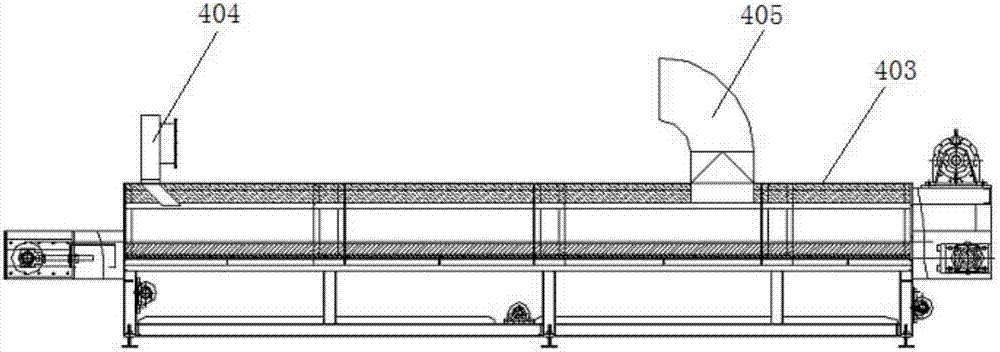

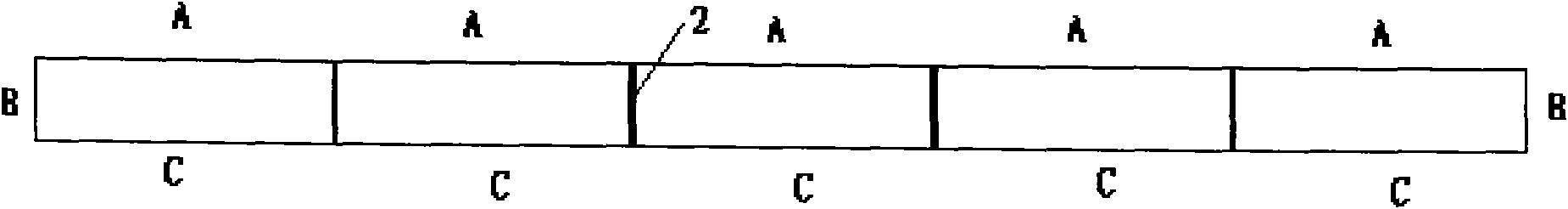

Tandem drying system

ActiveCN105444536AEasy to set upReduce exhaust air volumeDrying gas arrangementsPretreated surfacesWaste management

The invention provides a tandem drying system. The tandem drying system comprises at least two drying units, wherein each drying unit comprises a unit air supply fan and a drying box; a unit air inlet and a unit air outlet are formed in each drying unit; a drying box air inlet and a drying box air outlet are formed in each drying box; each unit air inlet is connected with the corresponding drying box air inlet; each unit air outlet is connected with the corresponding drying box air outlet; an exhaust air inlet which is connected with the unit air outlet of the last drying unit is formed in an exhaust air header pipe; a supply air outlet which is connected with the unit air inlet of the first drying unit is formed in a supply air header pipe; in every two adjacent drying units, the unit air outlet of the former drying unit is connected with the unit air inlet of the latter drying unit; each unit air supply fan is arranged between the corresponding unit air inlet and the corresponding drying box air inlet; and an exhaust air fan is arranged on the exhaust air outlet of the exhaust air header pipe. The tandem drying system has the advantages of simplicity and stability, easiness in adjustment, small exhaust air amount, low energy consumption, no potential safety hazards, low environment protection cost and the like.

Owner:VERBOCA ENERGY SAVING TECH CO LTD

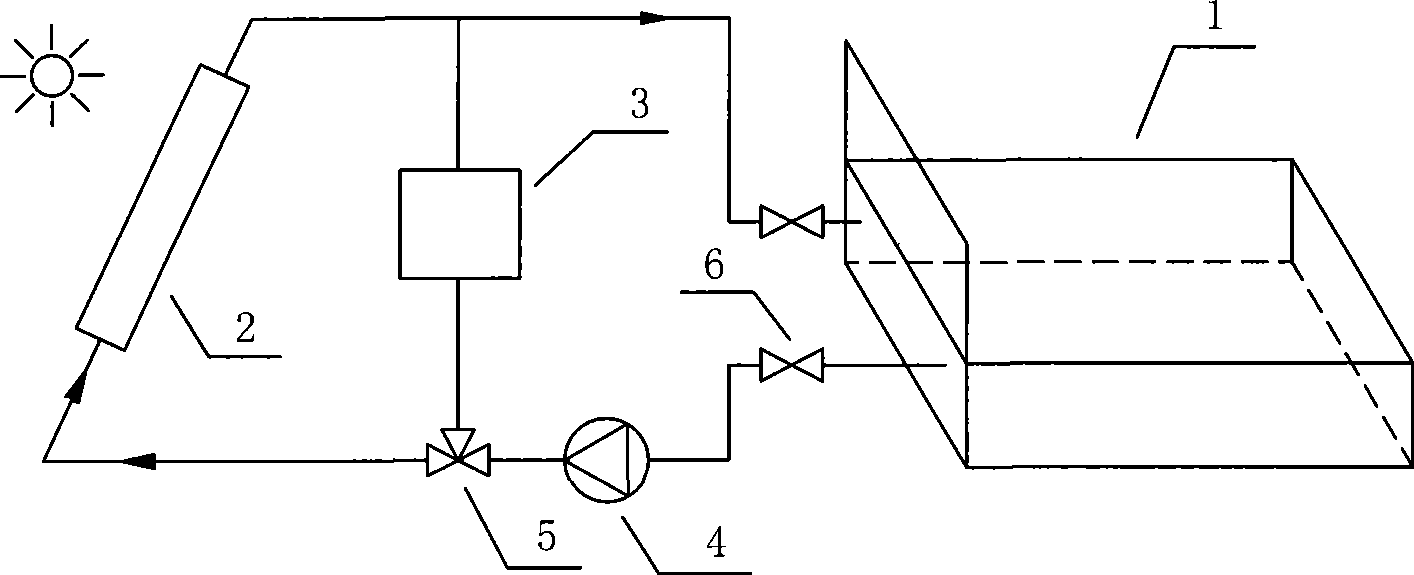

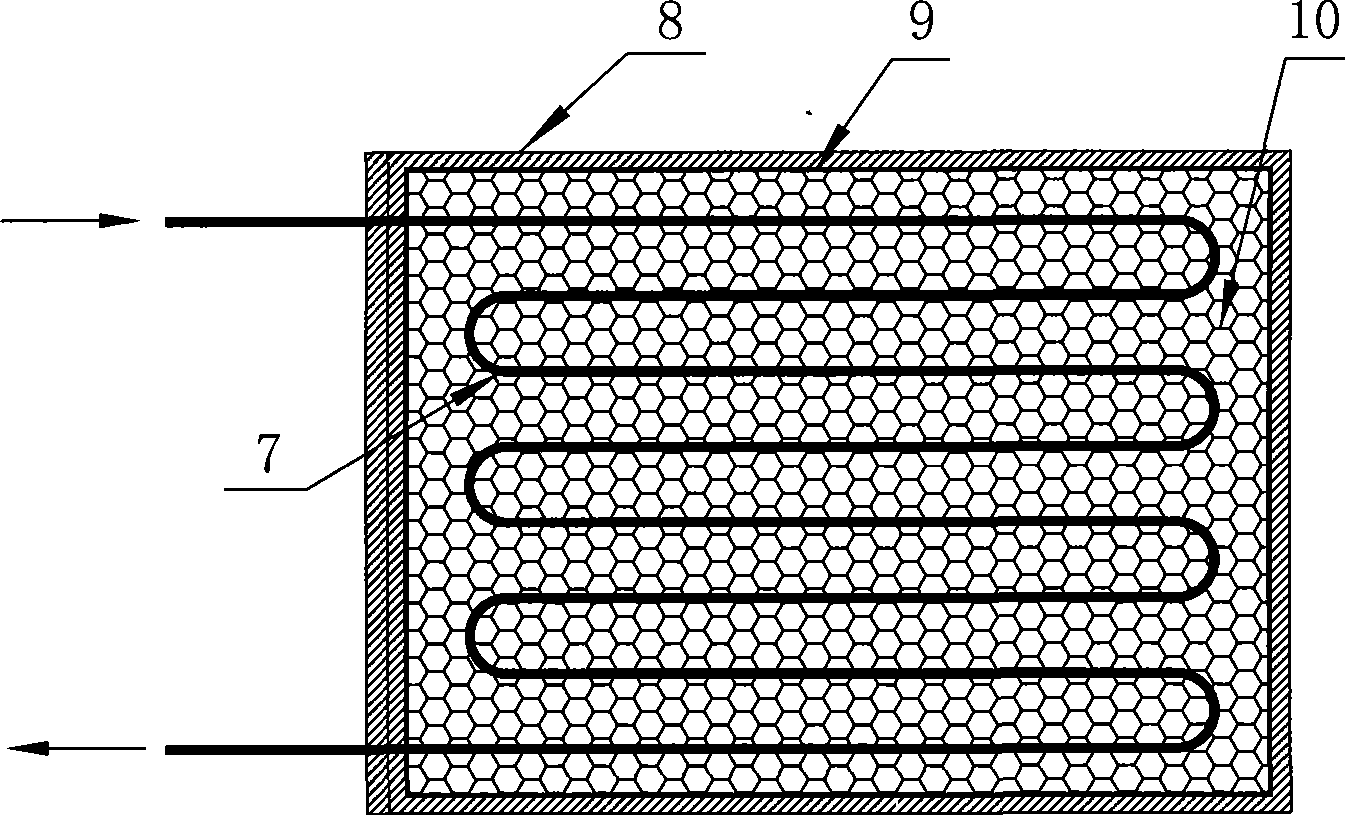

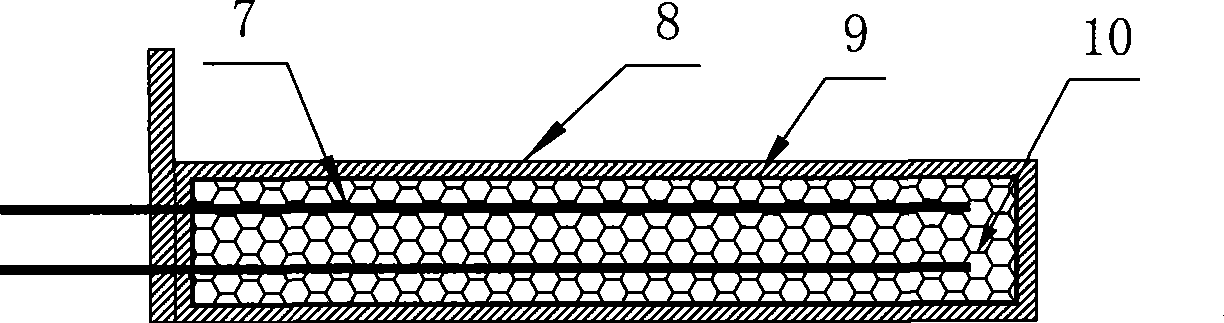

Solar heating system combined with bedding apparatus

InactiveCN101476750AReduce heating energy consumptionReduce areaCentral heating with accumulated heatLighting and heating apparatusCollector deviceHeating system

The invention relates to a solar energy heating system combined with a sitting and lying appliance, which comprises a sitting and lying appliance, a solar energy collector, an auxiliary heat source, a circulating pump, and correlative pipelines and valves, wherein a sealed inner shell is arranged in the sitting and lying appliance, a phase change heat-accumulating material is filled in the sealed inner shell, a heat exchange pipe is embedded in the phase change heat-accumulating material, the inlet and outlet ends of the heat exchange pipe are provided with valves, the heat exchange pipe is connected with the inlet and outlet valves, the circulating pump and the solar energy collector through a pipeline to form a closed loop, and a heat transfer fluid is filled in the heat exchange pipe. The heat exchange pipe can be a series type coil pipe or a parallel connection coil pipe, and can be arranged in a single layer or a plurality of layers. The sitting and lying appliance has the functions of both a heat accumulator and a heat radiator. The solar energy heating system making use of the solar energy, phase change heat accumulation and the sitting and lying appliance combination is clean, comfortable and safe, and can greatly reduce the area of the heat accumulator to improve the efficiency of the heat accumulator while building a local heat comfortable environment.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

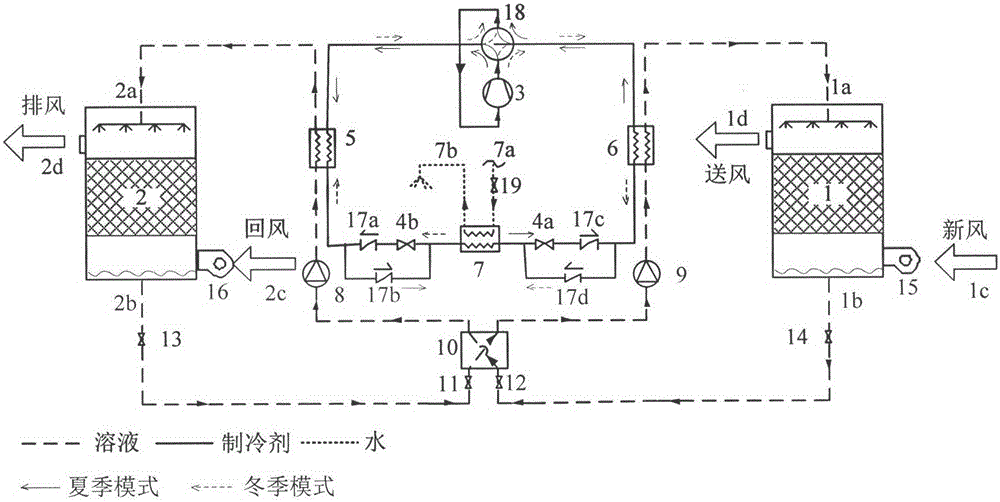

Heat pump driving solution moisture regulating and domestic hot water preparing system realizing energy balance

ActiveCN104456798AReduce the temperatureImprove dehumidification effectLighting and heating apparatusAir conditioning systemsEnergy balancedEngineering

The invention discloses a heat pump driving solution moisture regulating and domestic hot water preparing system realizing energy balance. The system is characterized by comprising a heat pump circulating system and a solution moisture regulating system, the heat pump circulating system comprises a frequency-variable compressor, a four-way reversing valve, a solution cooling condenser, a stop valve, a throttling valve and an evaporator, and a water-cooling condenser is introduced to prepare domestic hot water; the solution moisture regulating system comprises a dehumidifier, a regenerator, a solution pump, a solution heat exchanger, a solution valve and a fan. The heat pump driving solution moisture regulating and domestic hot water preparing system combines a solution circulating system, the heat pump system and a domestic water preparing system, and domestic water is prepared by utilizing redundant condensing heat of a refrigerant while solution moisture regulating is realized through driving of a heat pump, so that system energy balance and effective utilization of energy resources are realized, and comprehensive performance of the system is improved.

Owner:NANJING UNIV OF TECH

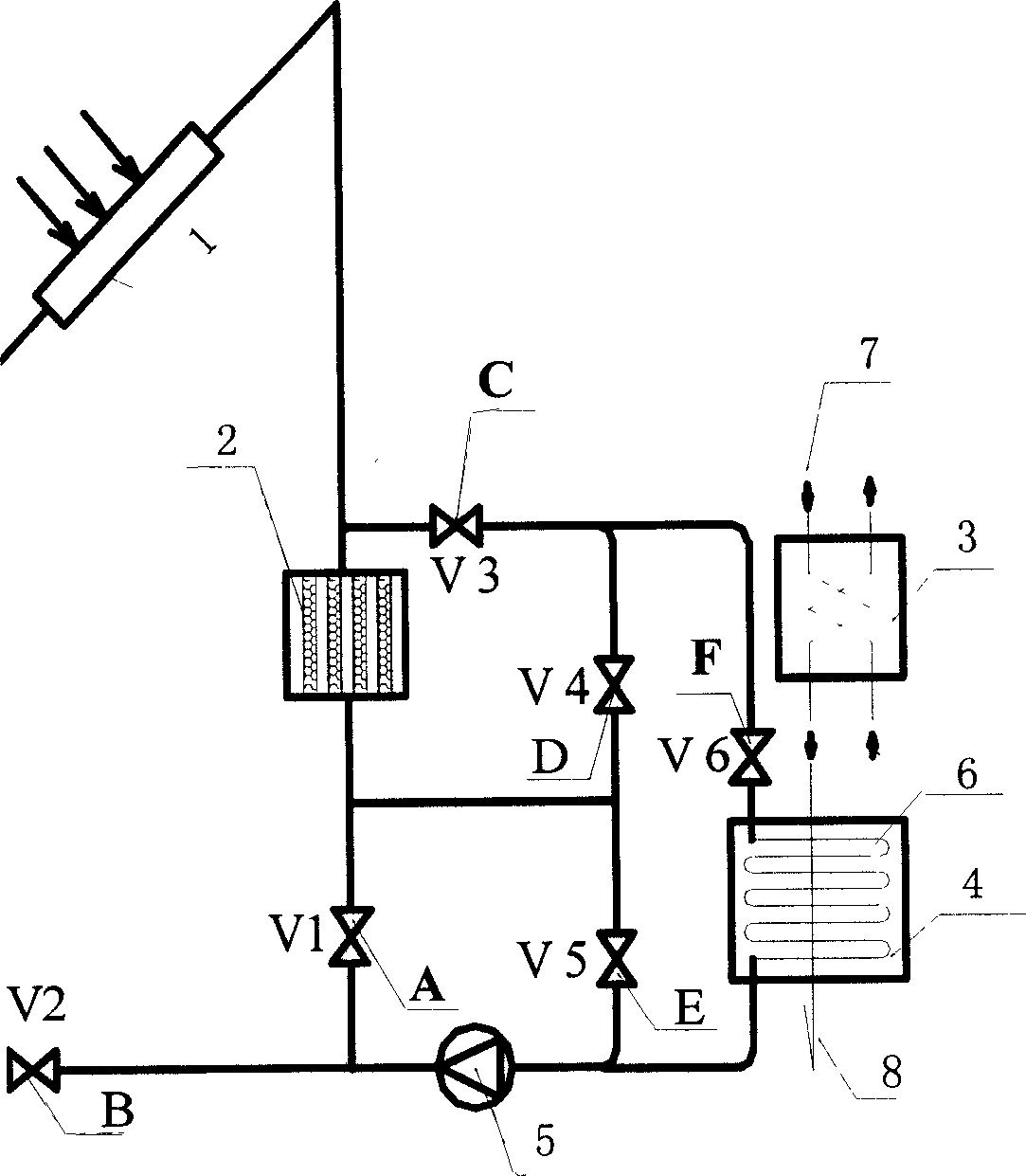

Full heat recovery fresh air energy-saving system of using solar phase transformation thermal storage

InactiveCN1912477AIncrease profitEfficient collectionLighting and heating apparatusAir conditioning systemsThermal energyEngineering

An energy saving system utilizing neat accumulation of solar energy phase transition to provide complete heat recovery air is featured as utilizing heat collector of solar energy to convert solar energy to be hot water, utilizing phase transition heat accumulation unit to accumulate solar energy and to change solar energy to be heat energy by using hot water as heat media, utilizing air / water heat exchanger to heat air being completely heat- recovered by complete heat-recovery heat exchanger then sending heated air to air-conditioning room.

Owner:BEIJING UNIV OF TECH

Waterproof phase-change heat storing plaster wallboard formed by reinforcing straw fibers

ActiveCN105060830AHigh strengthImprove waterproof performanceSolid waste managementCement boardPhase change

The invention discloses a waterproof type phase-change heat storing plaster wallboard formed by reinforcing straw fibers. The plaster wallboard is compounded from the following raw materials in percentage by weight: 20-60% of plaster gelate materials, 10-25% of phase-change heat storing microcapsules, 1-7% of a composite water repellent, 25-55% of mineral micro powder, 0.1-0.6% of straw fibers, 0.8-1.5% of a binder, 1-5% of an exciting agent and 0.2-1.5% of a water reducing agent. The preparation method comprises the following steps of: 1) firstly, adding the plaster gelate materials, the mineral micro powder, the straw fibers and the exciting agent into a reaction kettle, adding water, and uniformly stirring the plaster gelate materials, the mineral micro powder, the straw fibers, the exciting agent and the water so as to obtain a material A; 2) sequentially adding the phase-change heat storing microcapsules, the composite water repellent, the binder and the water reducing agent into the reaction kettle, and stirring the material A, the phase-change heat storing microcapsules, the composite water repellent, the binder and the water reducing agent once again so as to obtain a material B; and 3) directly pouring the material B in the reaction kettle into a mold through a grouting pump so as to obtain the phase-change heat storing plaster wallboard, wherein a fiber cement board is arranged on the inner surface of the mold. The waterproof type phase-change heat storing plaster wallboard disclosed by the invention has the advantages of being suitable for operation under humid environment, simple in production technology and environment-friendly.

Owner:MAANSHAN MCC17 ENG TECH CO LTD

Method for enhancing dry-process fermentation stability of sludge by adding kitchen waste

ActiveCN102030456AReduce heating energy consumptionSmall volumeBio-organic fraction processingClimate change adaptationGeneration rateEnergy recovery

The invention relates to a method for enhancing dry-process fermentation stability of sludge by adding kitchen waste, belonging to the field of solid waste recycling. The invention can solves the problems of low acidifying degree of hydrolysis, insufficient substrates for producing methane, overhigh pH value, ammonium salt accumulation, inhibition of gas generation and the like caused by high viscosity of dewatered sludge, high TS concentration, low C / N value and the like. The method comprises the following steps: pulverizing kitchen waste, mixing the kitchen waste and dewatered sludge in the weight ratio of 1:10-15, putting the mixture in a fermentation tank to ferment, and sufficiently stirring, wherein in the fermentation process, the temperature of the materials is kept at 35+ / -1 DEG C, and the oxidation-reduction potential is smaller than or equal to -300mV; when the pH value rises to 7.5 and the methane content rises to higher than 35%, adding the kitchen waste into the fermentation tank again in batches, wherein the addition amount of the kitchen waste each time accounts for 5-10 wt% of the dewatered sludge, the pH value of the mixed materials is preferably greater than or equal to 6.6, and the preferable addition time is when the pH value of the materials rises to higher than 7.5; and when the methane content is lower than 35% and the gas generation rate obviously decreases, finishing the fermentation. The invention can be used for municipal sludge recycling and energy recovery. Compared with wet fermentation, the invention can save equipment investment and soil occupation.

Owner:TONGJI UNIV

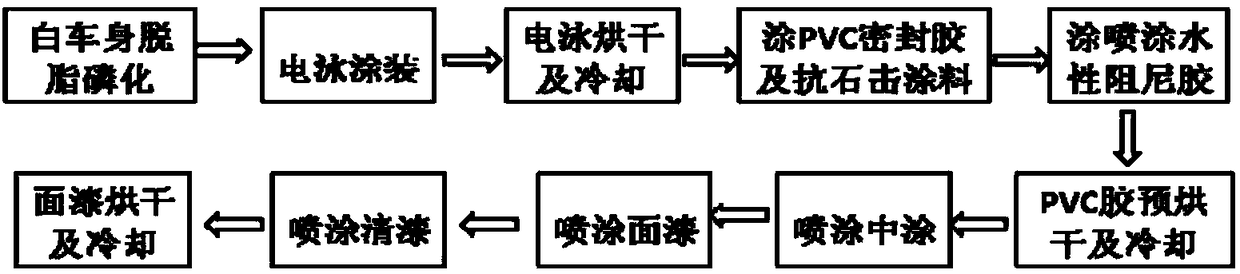

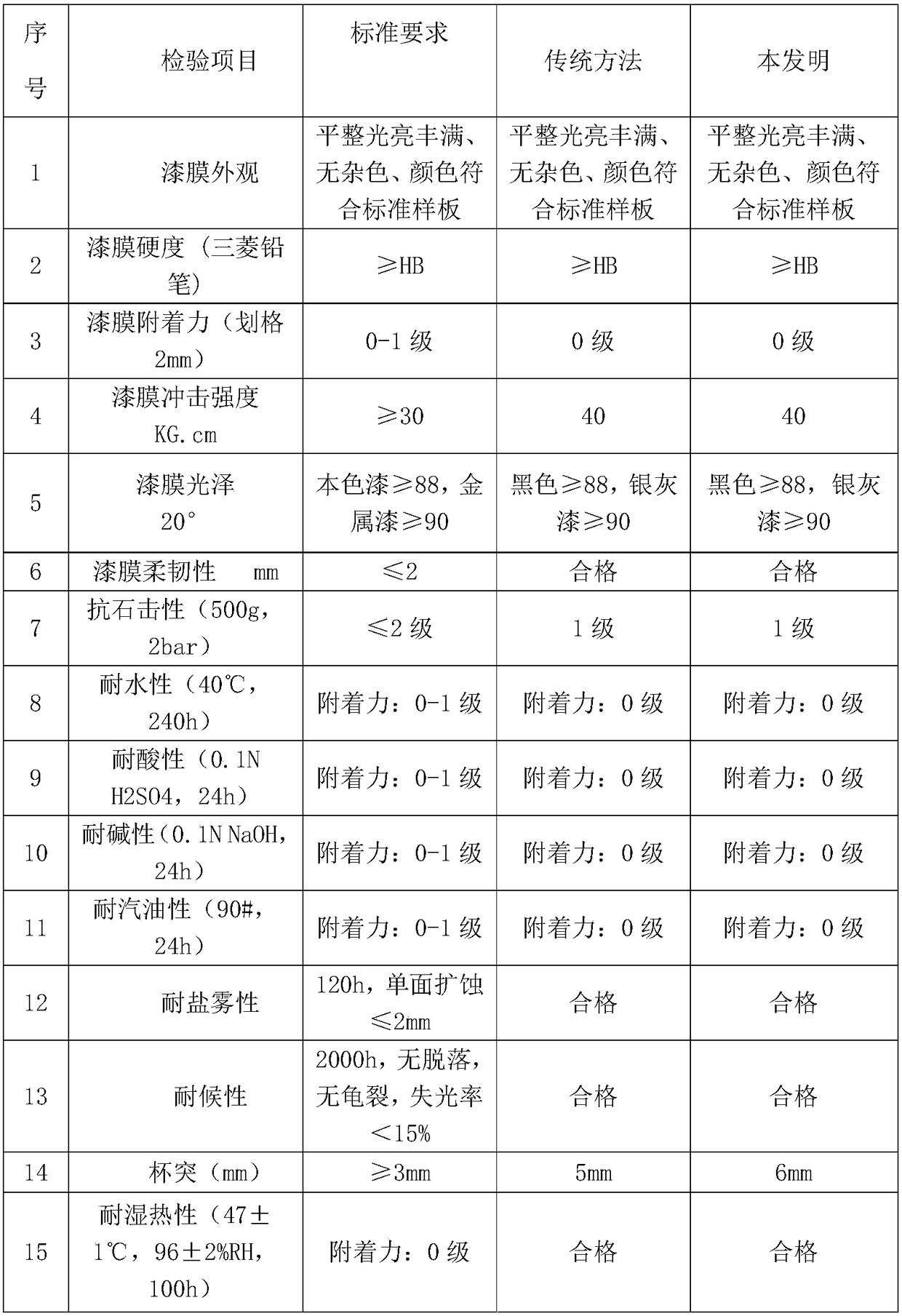

Automobile body coating method

InactiveCN108360043AReduce consumptionLow costLiquid surface applicatorsElectrophoretic coatingsCoated surfaceCooking & baking

The invention discloses an automobile body coating method. The automobile body coating method comprises the following steps of white automobile body coating degreasing and phosphating, electrophoreticcoating, electrophoretic drying and cooling, coating of a PVC sealant and anti-stone coating, spraying of damping adhesive, pre-drying and cooling of PVC adhesive, spraying of floating coat, sprayingof finishing coat, spraying of varnish and drying and cooling of the finishing coat. According to the automobile body coating method, medium-low-temperature degreasing is adopted, low-temperature phosphating is adopted for phosphating, and little or no steam heating is used according to room temperature conditions; high solid coat is used, the floating coat and the finishing coat are subjected towet-on-wet coating and then subjected to baking, and the floating coat drying process and the post-grinding process of the floating coat are omitted; through appropriate processes, equipment design and reasonable process parameter setting and monitoring, the coating surface quality state of the automobile body in each process is controlled; and the energy-saving automobile body coating method hasthe low energy consumption and low VOC.

Owner:HUNAN GEELY AUTOMOBILE COMPONENTS +1

Method for refrigerating filature with no need of boiling cocoons

InactiveCN1446951AModerately absorbentReduce adhesive forceMechanical treatmentEngineeringThermal water

A cold storage method without boiling for reeling silk includes cold storage of fresh cocoon, loading in netted basket, putting in vacuum tank, vacuumizing, hot water osmosis, discharging water and repeating relative steps. Its advantages are high efficiency and high quality.

Owner:SICHUAN UNIV TIANYOU BIOLOGIC ENG

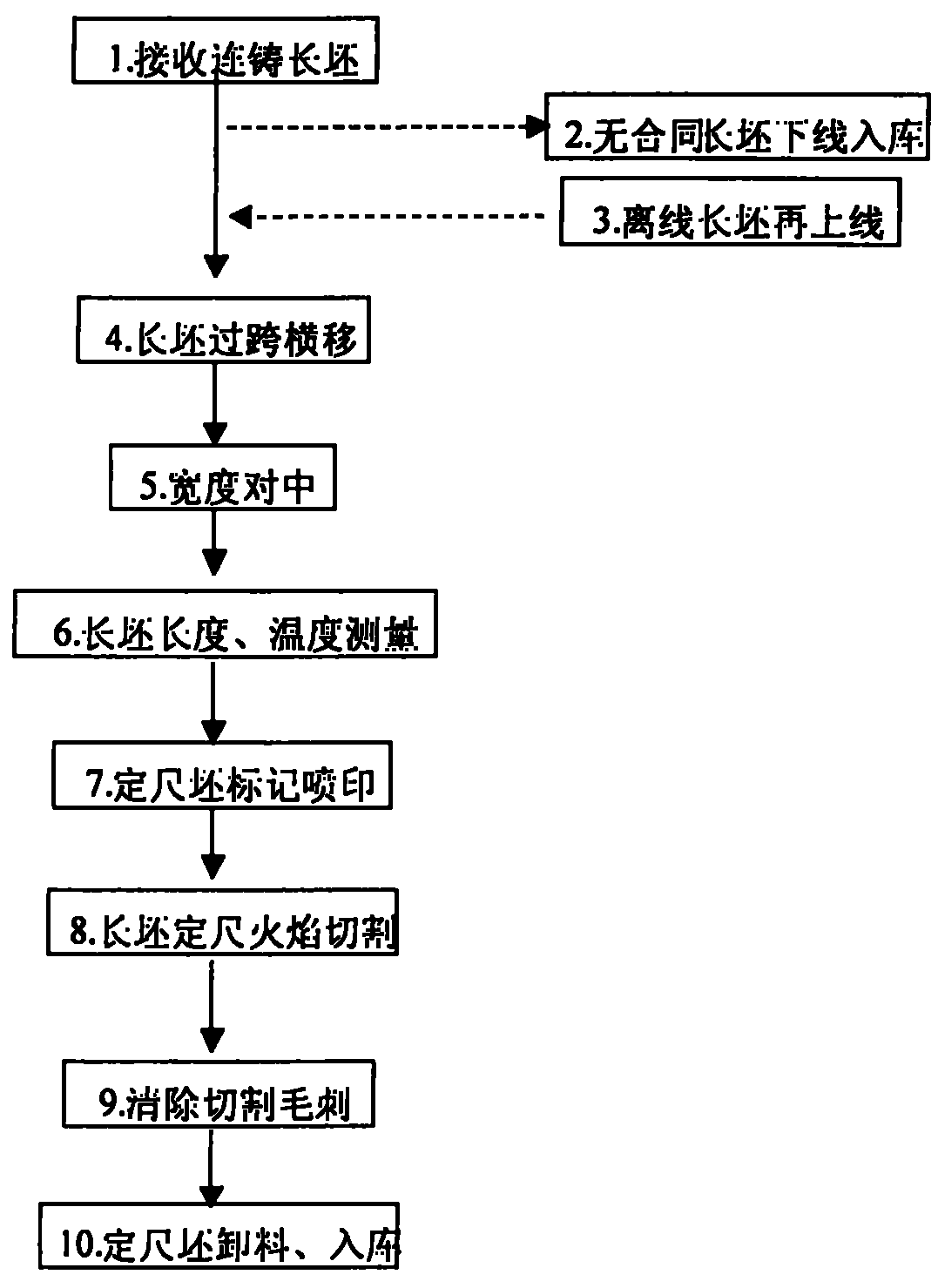

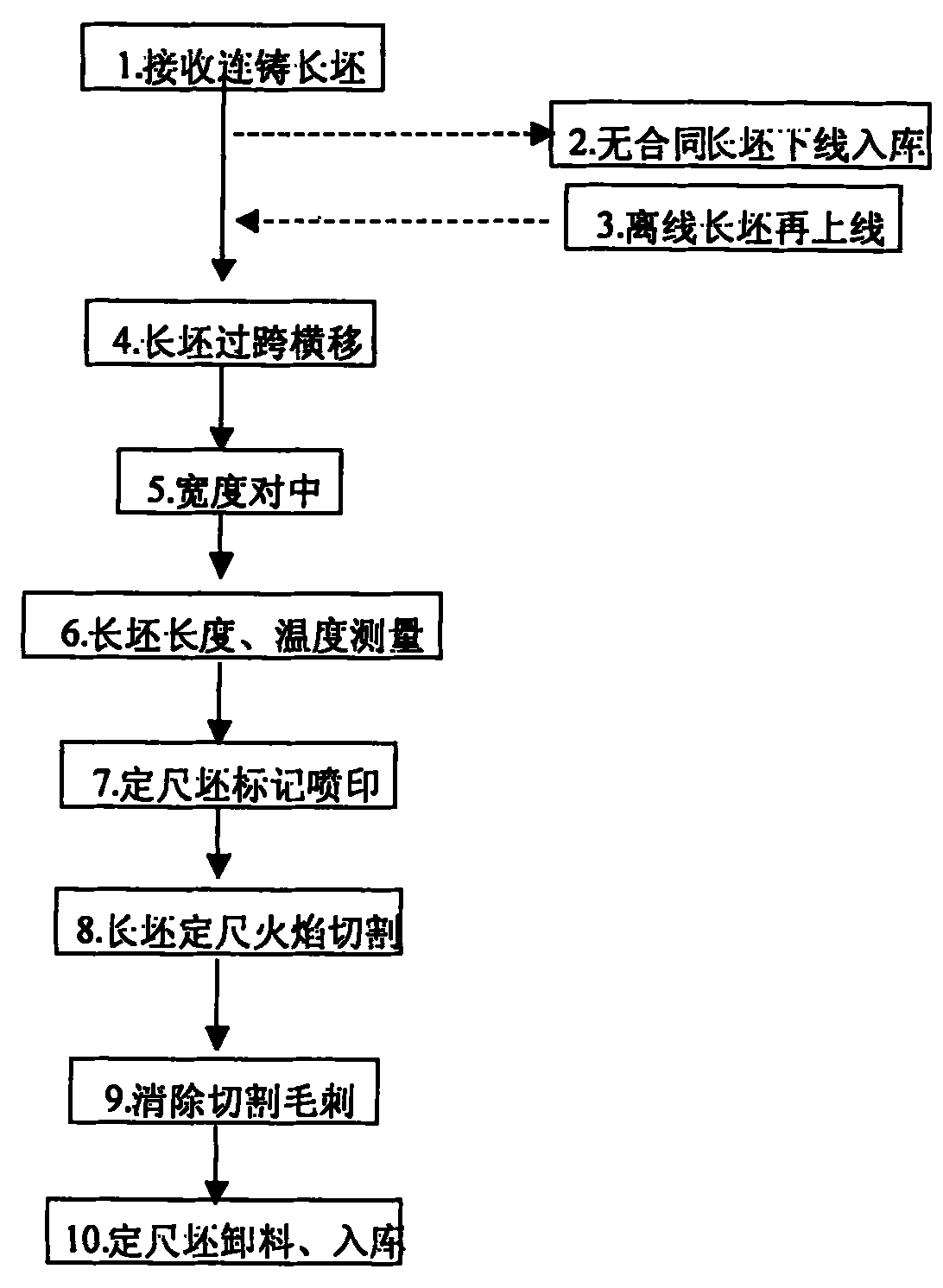

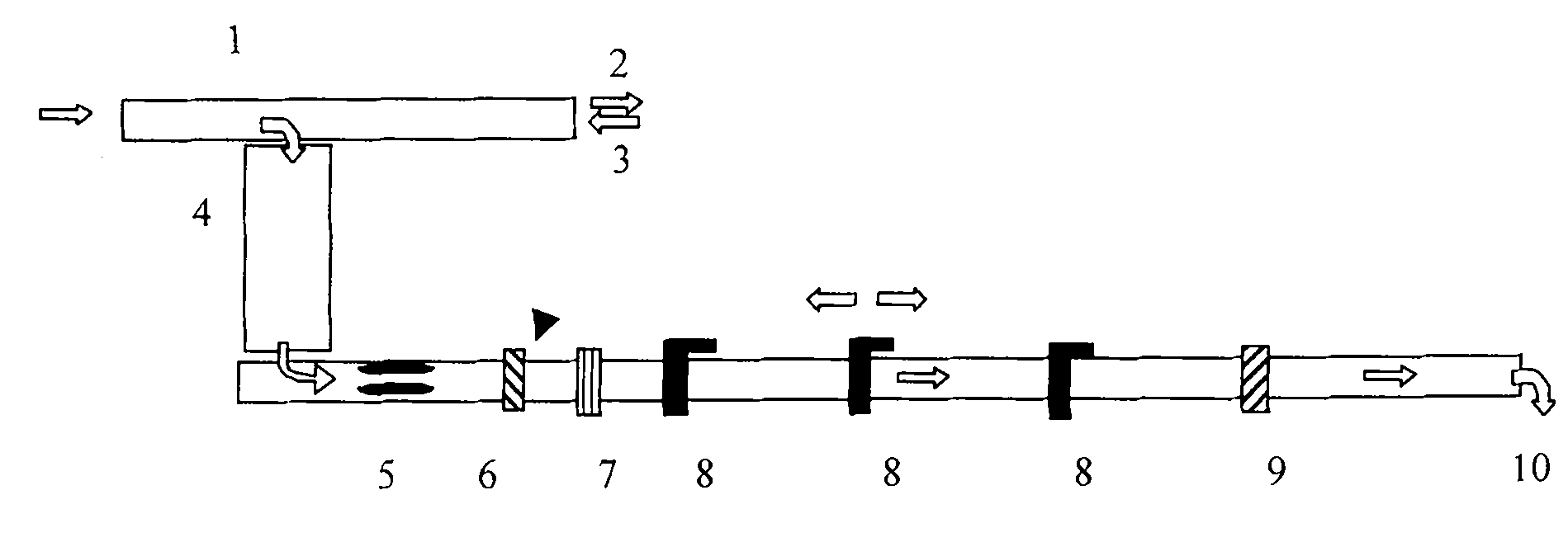

Process for online cut-to-length cutting production of continuous casting slabs for heavy plate mill

The invention relates to a process for the online cut-to-length cutting production of continuous casting slabs for a heavy plate mill. The process comprises the following steps: long slab reception; span-transversing; width centering; length and temperature measurement; cut-to-length slab mark spraying; cut-to-length cutting; cutting burr removing; unloading; and storing, wherein three pairs of flame cutting machines are distributed in a series-connection manner on the cutting line. Accordingly, the process of the invention is capable of simultaneously cutting two long slabs on-line according to various requirements for cut-to-length cutting; the process of the invention has the advantages of high production efficiency and small equipment occupied area; the cut-to-length cutting procedure has little impact on the main production line for continuous casting and heavy-plate milling; the process is capable of carrying out the mixed cutting process on cold and hot slabs, thus being favoring for the hot-loading and hot-feeding processes of slabs. Accordingly, the process of the invention is widely applicable to the online cut-to-length cutting production of the continuous casting slabs for the heavy plate plant.

Owner:BAOSHAN IRON & STEEL CO LTD

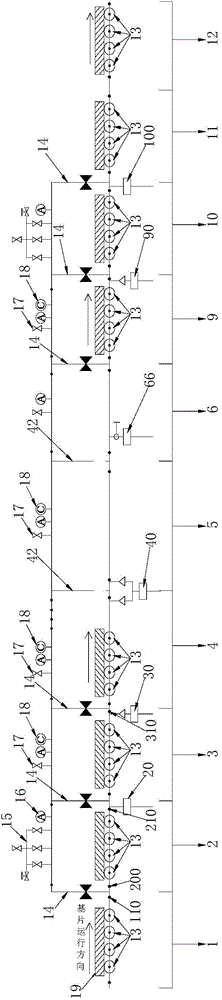

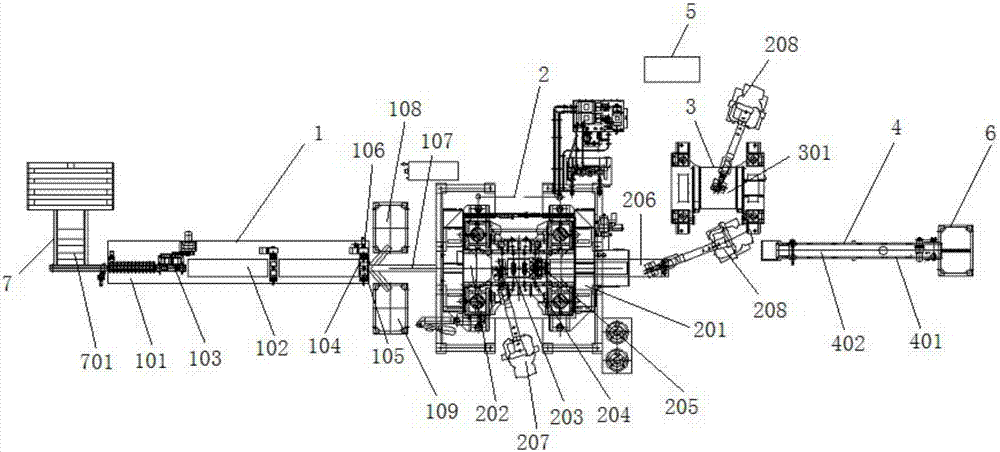

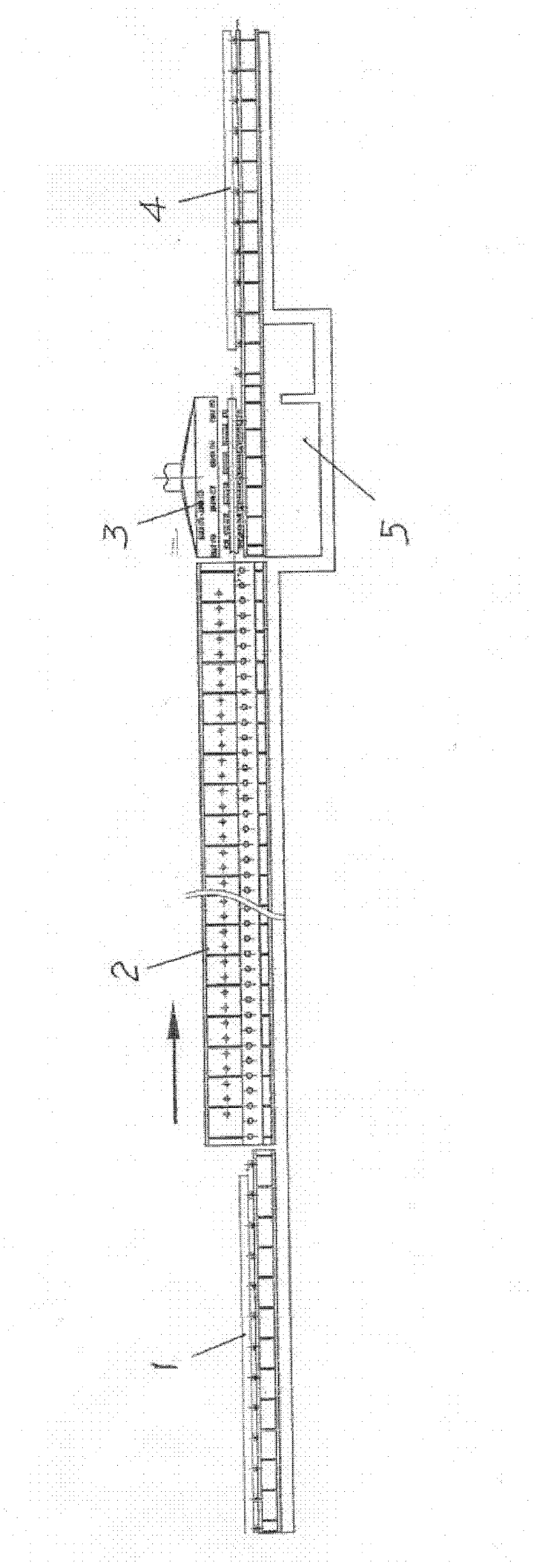

Full-automatic non-quenched-and-tempered steel forge piece production line

ActiveCN107442726AEmission reductionImprove electricity efficiencyForging/hammering/pressing machinesForging press drivesProduction linePunching

The invention discloses a full-automatic non-quenched-and-tempered steel forge piece production line. The production line comprises heating equipment, forging equipment, edge cutting and punching equipment, a cooling temperature control conveying chain, a finished product box and a programmable control system which are sequentially connected. According to the production line, a forge piece is heated at a time, continuous and automatic machining of multiple processes including upsetting, pre-forging molding, final forging molding, edge cutting, punching, heat treatment and the like is achieved, all machining processes need to be operated by one person, and the beneficial effects of being high in production efficiency and good in product quality are achieved.

Owner:CHONGQING VOCATIONAL INST OF ENG +1

Continuous Quenching Line for Large Diameter Tube and Bar

ActiveCN102268523ALow costImprove product quality performanceFurnace typesHeat treatment furnacesAutomatic controlAutomated control system

A continuous quenching line for large-diameter tube and bar materials is provided. Along the moving direction of tube and bar materials, a V-shaped inclined roll transmission continuous heating furnace is connected to an end of an automatic material charging machine; a multifunctional quenching machine is connected to an end of the V-shaped inclined roll transmission continuous heating furnace; the multifunctional quenching machine is connected to an automatic material discharging machine; a water collecting pool is disposed at the lower part of the multifunctional quenching machine; an automatic control system controls the devices from the automatic material charging machine to the automatic material discharging machine; continuous horizontal heat processing of alloy steel, stainless steel, light alloy bar and tube materials with a diameter of 100-800 mm and a length of above 2000 mm (a wall thickness of below 100 mm) can be performed. During the heating and quenching processes, the material both moves forward and performs self-rotation, does not bend or deform, is heated and quenched uniformly, and has a deep quenched layer, and the invention has the functions of performing quenching, solid solution treatment, normalization processing, annealing processing and the like of alloy tool steel tube and bar materials, alloy structure steel tube and bar materials, heat resistant steel tube and bar materials, various stainless steel tube and bar materials, aluminium alloy tube and bar materials, and the like.

Owner:ARES IND FURNACE TIANJIN

Formaldehyde-free bamboo glulam and manufacturing method thereof

ActiveCN101934538AFill in the gapsReduce heat energy consumptionWood veneer joiningEmulsionPolyvinyl acetate

The invention relates to a formaldehyde-free bamboo glulam. The bamboo glulam is formed by splicing bamboo splints through radial surfaces and gluing the bamboo splints through tangential surfaces, wherein an adhesive of an adhesive layer arranged for splicing the radial surfaces is a polyvinyl acetate emulsion adhesive (white latex) or aqueous high-molecular isocyanate adhesive (API); and the adhesive of the adhesive layer arranged for gluing the tangential surfaces is the isocyanate adhesive. The invention also provides a method for preparing the bamboo glulam; and the method comprises the following steps of: preparing materials; applying the adhesive to the radial surfaces of the bamboo splints; splicing the tangential surfaces; applying the adhesive to the tangential surfaces of a single-layer bamboo laminated sheet; assembling the tangential surfaces; gluing the tangential surfaces; and performing post-processing and the like, wherein the adhesive used in the step of applying theadhesive to the radial surfaces is the white latex or API; and the adhesive used in the step of applying the adhesive to the tangential surfaces of the single-layer bamboo laminated sheet is the isocyanate adhesive. Due to the adoption of an aldehyde-free adhesive, the amount of the released formaldehyde of the bamboo glulam is below 0.1mg / L, and the gluing performance of the sheet is improved and the machining energy loss is reduced by applying the white latex or the API used in the splicing of the radial surfaces.

Owner:蔡宝珍

Mobile heat-insulating louver and automatic control method thereof

InactiveCN101787844AImprove insulation effectImprove insulation performanceTemperatue controlPower-operated mechanismAutomatic controlWindow shutter

The invention discloses a mobile heat-insulating louver and an automatic control method thereof. The louver comprises a window frame and louver blades in the window frame, wherein the louver blades are connected with a louver border covered at the periphery of the louver blades; the two ends of the louver border are connected with fixed rotating shafts, one end of each rotating shaft is connected with a rotating motor, and the other end is connected with a bearing; a shell of the rotating motor and an outer race of the bearing are respectively and fixedly connected with a sliding body; each rotating motor and a sliding motor are respectively connected with the rotating command output end and the sliding command output end of a CPU (central processing unit); the set input end of a calculator is used for inputting a temperature threshold value and a motion threshold value, the signal input end of the calculator is connected with a temperature sensor and a radiation sensor, and the signal output end of the calculator is connected with a controller. The controller is used for receiving calculating results of the calculator and controlling the opening degree, the opening direction, the spreading or the retracting conditions of the louver blades. The invention can strengthen the heat insulating property and the air tightness of an outer window in winter, reduce heat absorbing of the outer window in summer, ensure smooth ventilation and improve the heat insulating performance of houses.

Owner:CHINA ARCHITECTURE DESIGN & RES GRP CO LTD

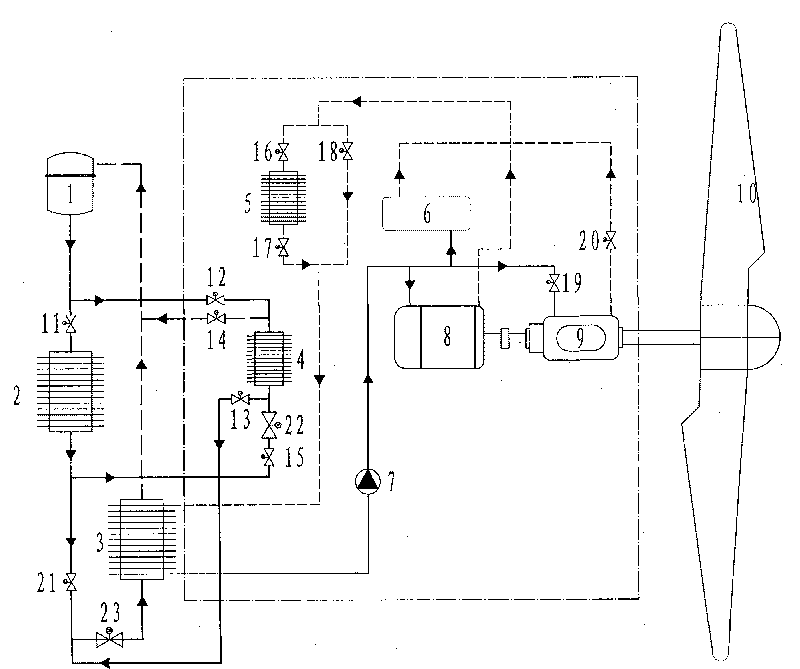

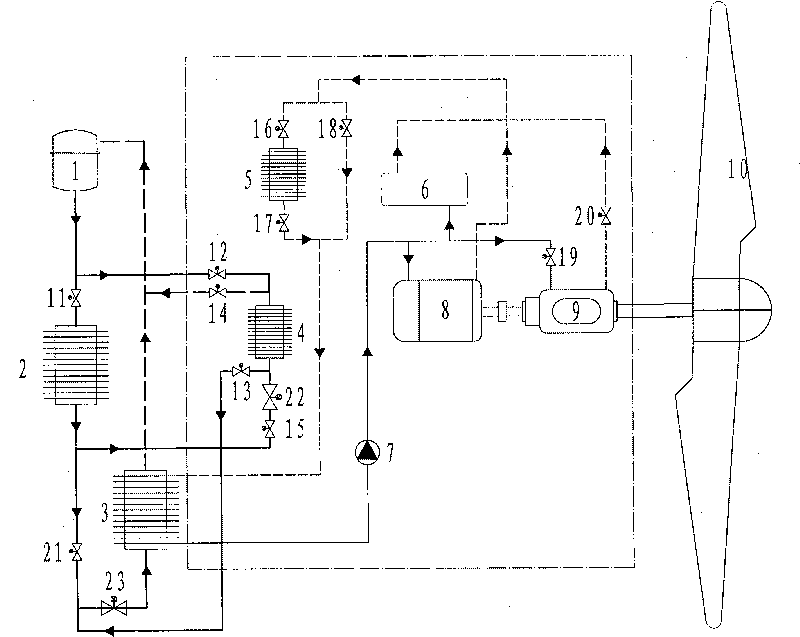

Energy-saving engine room heat regulation system of high-power wind driven generator

InactiveCN101705921AMeet thermal requirementsGuaranteed safe operationMachines/enginesWind energy generationWind drivenClosed loop

The invention relates to an energy-saving engine room heat regulation system of a high-power wind driven generator, which is used for solving the problem of heat regulation of wind driven generators. The heat regulation system consists of a refrigeration circulating system and a liquid cooling circulating system, wherein the refrigeration circulating system is arranged outside the engine room of the generator and is a refrigerant closed loop comprising a compressor, a condenser, a main electromagnetic expansion valve and an evaporator; the liquid cooling circulating system comprises a frequency-conversion control cabinet, a generator, a gearbox, an evaporator and a circulating pump, the frequency-conversion control cabinet, the generator and the gearbox are connected together in parallel and then connected with the evaporator and the circulating pump to form a secondary refrigerant closed loop, and the evaporator is formed by an inner pipe and an outer pipe which are sleeved together; the inner pipe is connected into the refrigeration circulating system; and a cavity between the inner pipe and the outer pipe is connected into the liquid cooling circulating system. The heat regulation system organically combines a refrigerating device and a heating device, has strong cooling capacity and low cooling and heating energy consumption and can guarantee the safe and efficient operation of the high-power wind driven generator.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

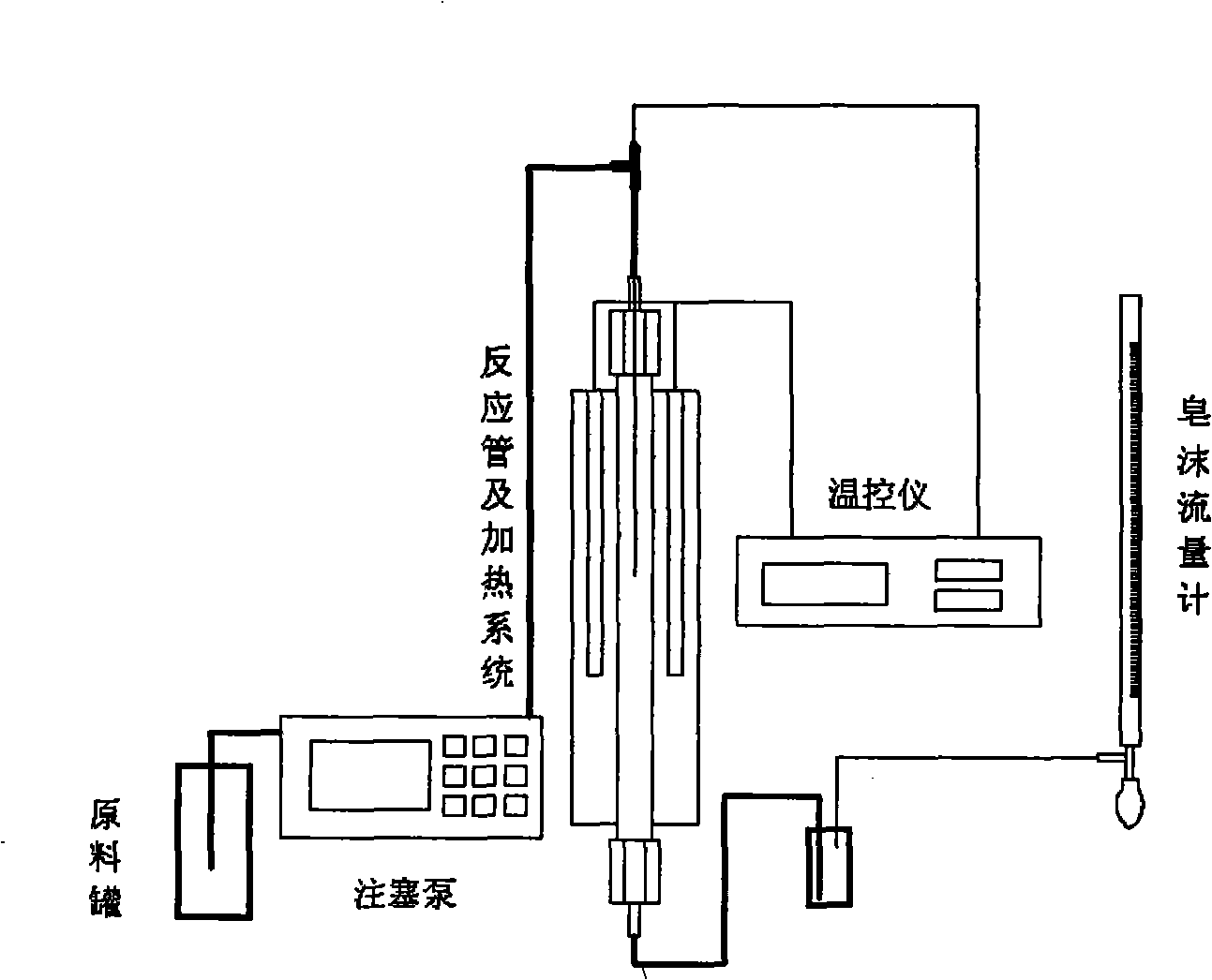

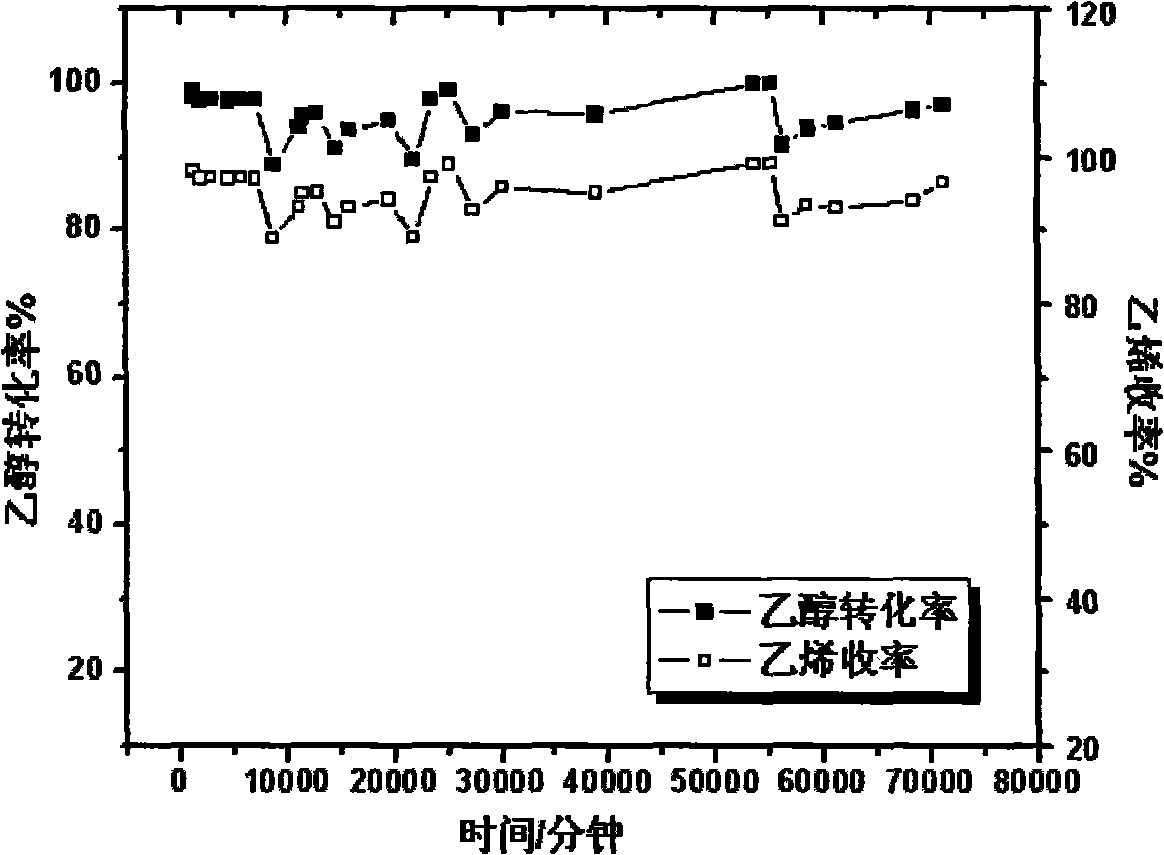

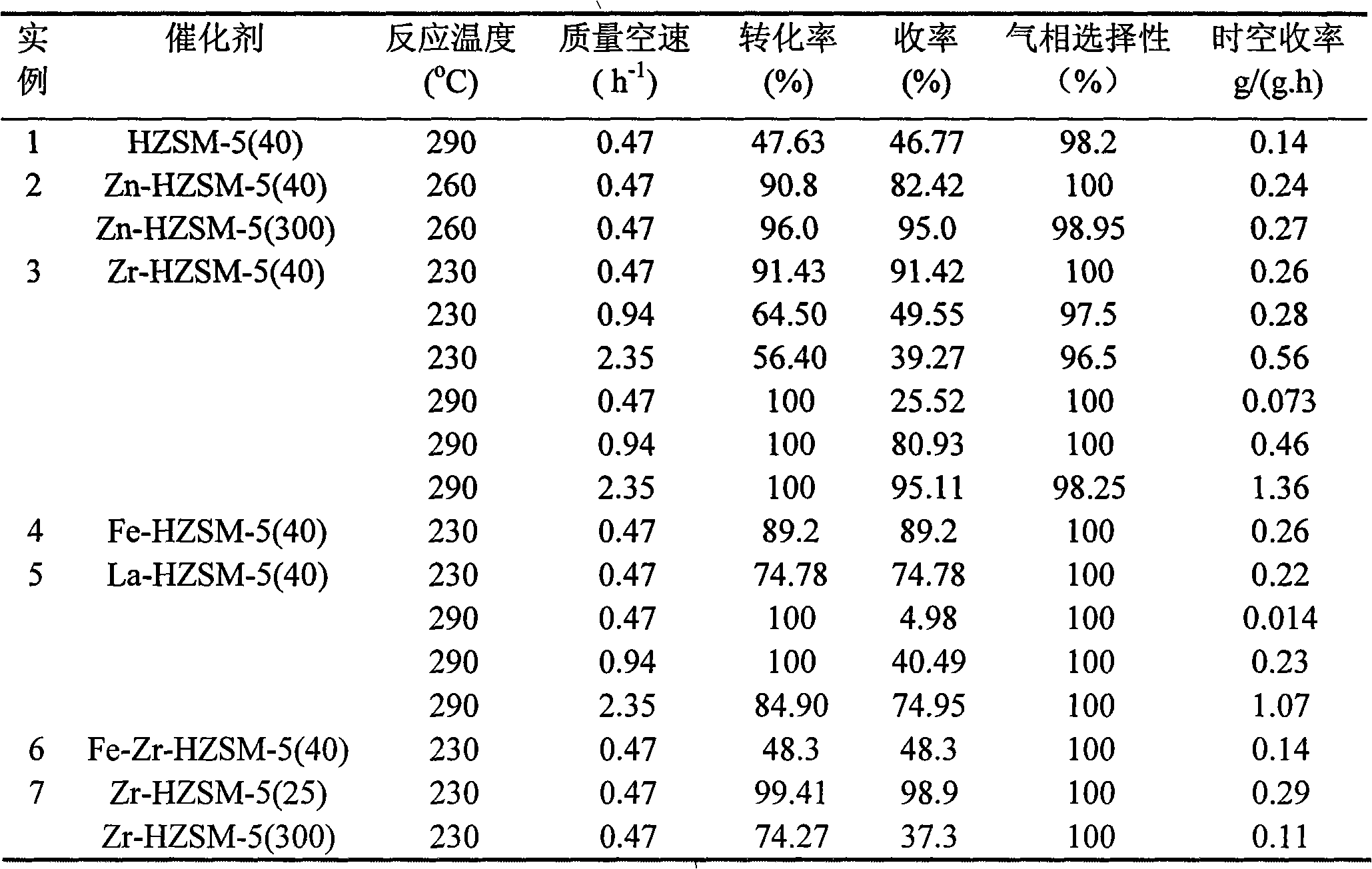

Ethylene prepared by catalytic dehydration of ethylene

InactiveCN101274285AReduced tendency to coke inactivationIncrease one-way productionMolecular sieve catalystsHydrocarbon from oxygen organic compoundsReaction temperatureFixed bed

The invention relates to a catalyst used in a reaction for producing ethylene by ethanol dehydration, which is characterized in that the catalyst of the invention consists of HZSM-5, in which one or a plurality of kinds of active metallic components with the ratio of 0.5 to 7 percent of by weight to the skeleton silica-alumina is 5 to 300. In the reaction for producing ethylene by ethanol dehydration, the reactant ethanol solution does not need to have preliminary gasification and use inert diluent gas, but directly enters into a fixed bed fluid catalytic reactor for implementing the reaction. The catalyst and the reaction technique of the invention can achieve high conversion rate and high selectivity for converting ethanol to ethylene under the conditions of normal pressure, reaction temperature of 200 to 290 DEG C and reactant airspeed of 0.1-10h<-1>, and with 10 to 100 percent of the ethanol water solution as raw reaction materials. Under optimized conditions, the ethanol conversion rate and the ethylene selectivity both approximate 100 percent. The catalyst of the invention is used for the reaction for producing ethylene by ethanol dehydration, and has the outstanding features of wide concentration range of the raw reaction material solution, lower reaction temperature and wider airspeed range, does not need the preliminary gasification of the raw reaction material solution, does not use the inert diluent gas, and has high catalyst activity and selectivity as well as long catalytic life.

Owner:HUNAN UNIV

Horizontal forging technology for middle-sized spline shaft yoke

ActiveCN105583351AEasy to installImprove consistencyRailway componentsForging/hammering/pressing machinesHeating temperatureMaterials science

A horizontal forging technology for a middle-sized spline shaft yoke comprises the following steps that firstly, blanking is carried out, the diameter of a blank is 55 mm, the material 40Cr is adopted, and the length of the blank is 295 mm; secondly, upsetting is carried out, the end of the blank is heated, the heating temperature is 1,150 DEG C, the heated blank is a blank to be upset, then, the blank to be upset is placed in a spline shaft yoke cavity of a pre-forging female die of a spline shaft yoke horizontal forging die on a horizontal forging machine, then, a power drive end drives a pre-forging male die to carry out upsetting on the blank to be upset, and a pre-forged piece blank is formed after upsetting is finished; and thirdly, finish forging is carried out, the pre-forged piece blank is taken out and placed in a spline shaft yoke cavity of a finish forging female die of the spline shaft yoke horizontal forging die on the horizontal forging machine, the horizontal forging machine is operated, the power drive end drives a finish forging male die to conduct upset-extruding on the pre-forged piece blank, and a finish forged piece is formed after upset-extruding is finished. According to the horizontal forging technology, the design is reasonable, the structure is simple, the forged piece is easy to form, and the rejection rate of the forged piece is greatly reduced; and the production efficiency is improved, and the production cost and the die manufacturing cost are reduced.

Owner:XUCHANG ZHONGXING FORGING +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com