Energy-saving engine room heat regulation system of high-power wind driven generator

A technology for wind turbines and regulating systems, applied in wind turbine components, wind engines, wind power generation, etc., can solve the problems of reduced efficiency of wind turbines, large power consumption, energy waste, etc., to ensure safe and efficient operation , Cooling and heating energy consumption is low, and the effect of reducing heating power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

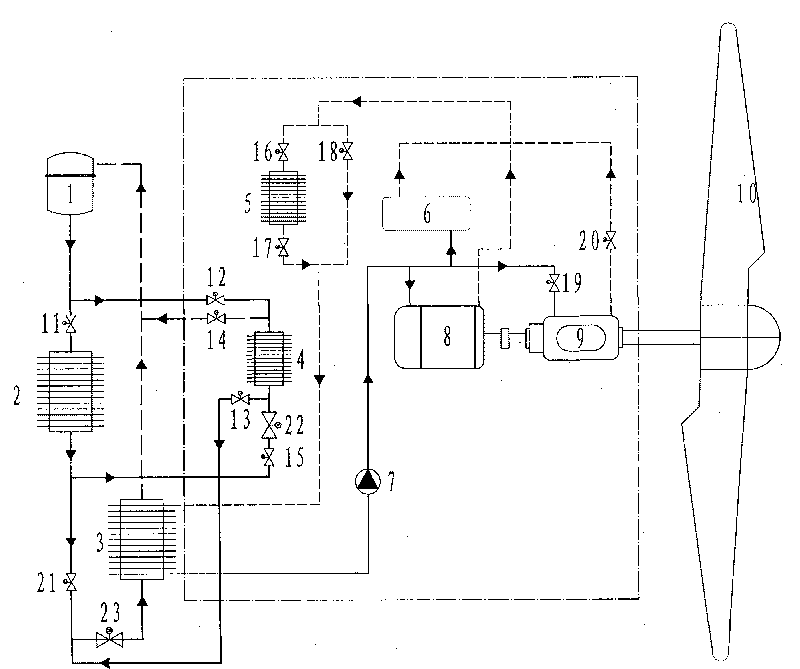

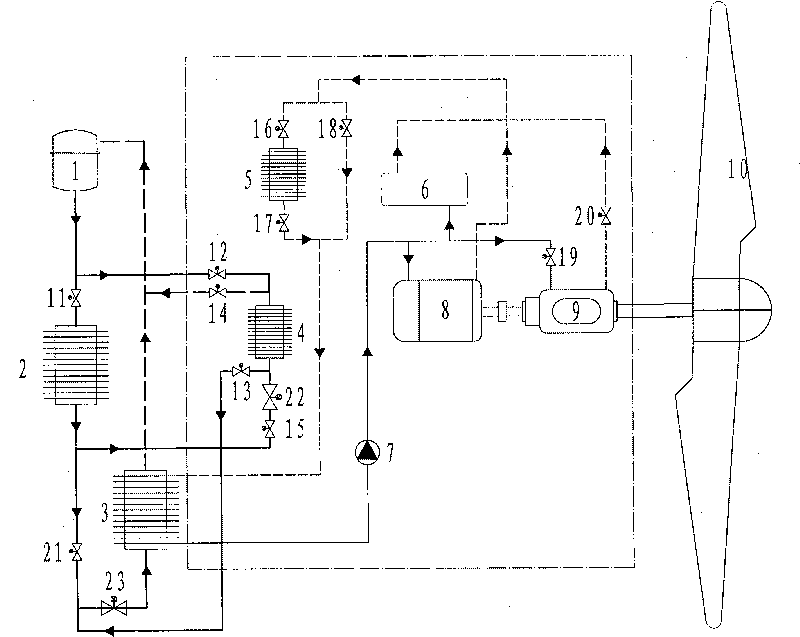

[0023] The present invention adopts a cooling and heating comprehensive allocation method based on the refrigeration cycle for the wind power generator cabin, generator 8, gear box 9 and frequency conversion control cabinet 6, and can automatically select the optimal operation according to the changes in the natural environment outside the cabin and the operating conditions of the components in the cabin The method maximizes the use of natural air cooling and component heat dissipation to realize energy-saving, high-efficiency, safe and stable operation of wind turbines.

[0024] see figure 1 , the present invention comprises the refrigerating system that is made up of compressor 1, condenser 2, evaporator 3, two-way heat exchanger 4, auxiliary electromagnetic expansion valve 22, main electromagnetic expansion valve 23 and by evaporator 3, heating heat exchanger 5, A refrigerant system composed of a frequency conversion control cabinet 6, a refrigerant circulating pump 7, a ge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com