Aluminum nitride multilayer-ceramic leadless platy carrier packaging shell

A technology of multi-layer ceramics and ceramic shells, which is applied in the direction of electric solid-state devices, semiconductor devices, semiconductor/solid-state device components, etc. Problems such as low integration, to achieve the effect of solving high-density, high-power packaging, high air tightness, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

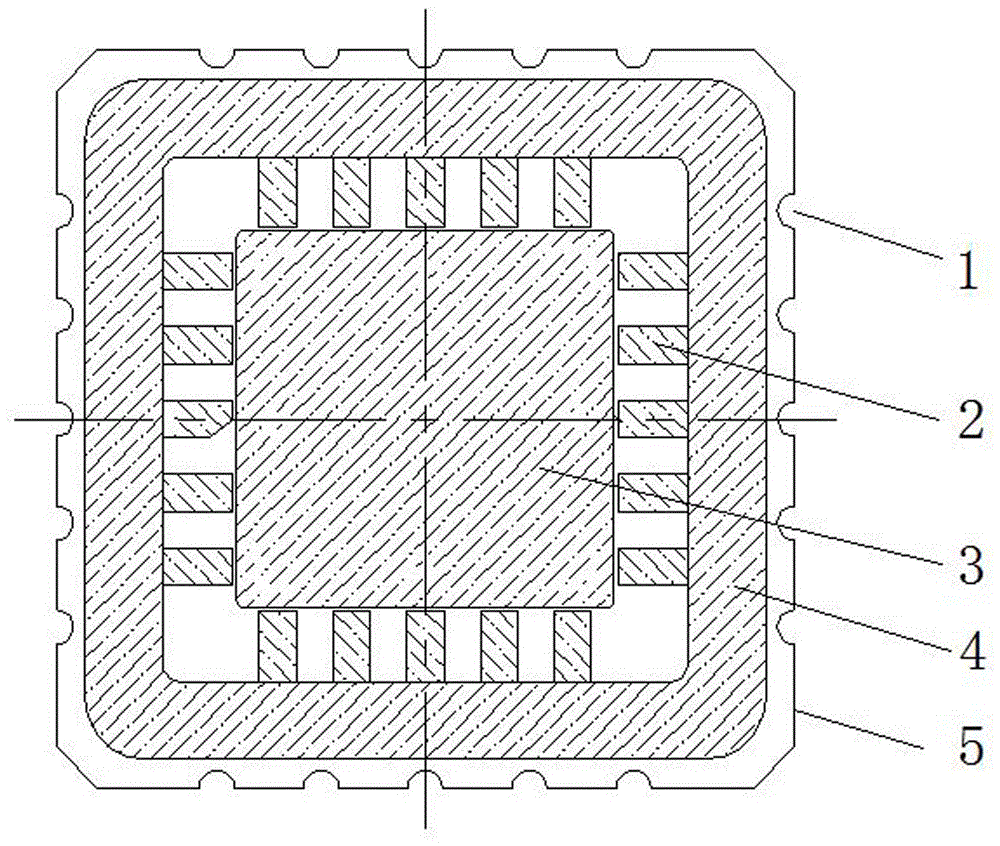

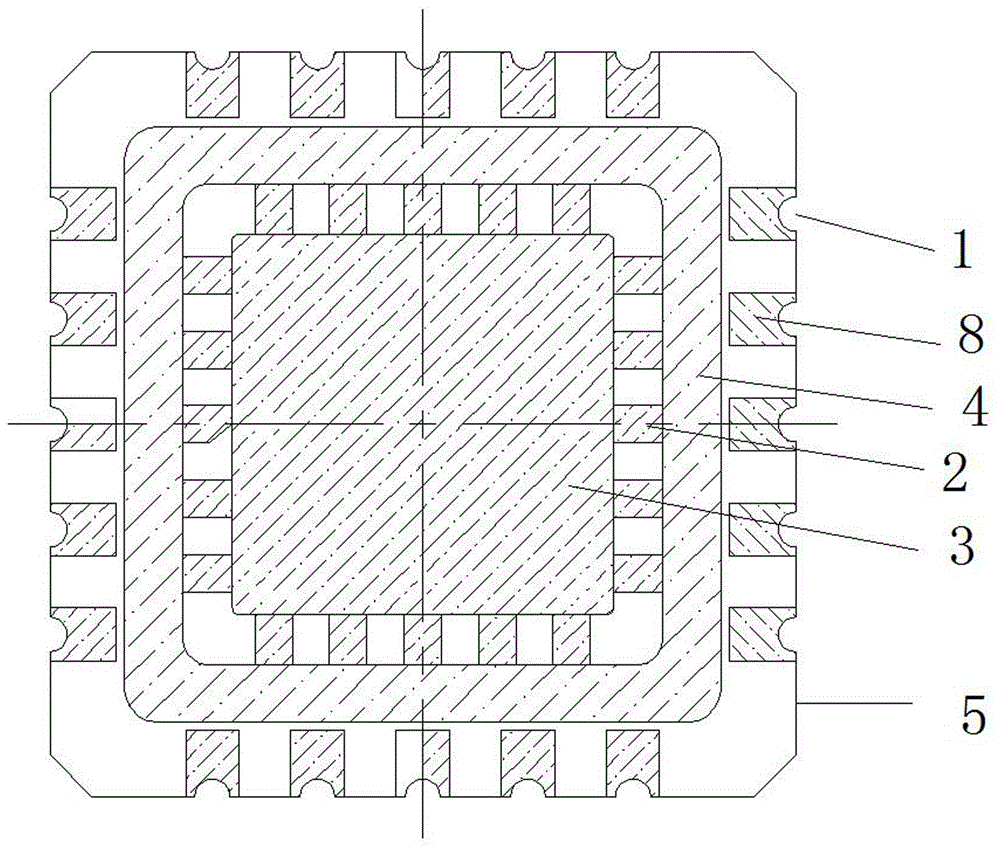

[0026] The present invention includes a ceramic shell 5, the ceramic shell 5 is made of aluminum nitride material, and the front and back sides of the ceramic shell 5 are respectively provided with an upper cavity 7 and a lower cavity 6, see figure 2 , image 3 , the lead-out pad 8 is arranged on the lower surface of the ceramic shell 5, the bottom of the upper cavity 7 and the lower cavity 6 is provided with a bonding area 3 for bonding chips or passive devices, and the surrounding area 3 is provided with The wire bonding area 2, the wire bonding area 2 is connected to the chip bonded on the bonding area 3 with a bonding wire, and the terminal pad 8 is connected to the wire bonding area 2.

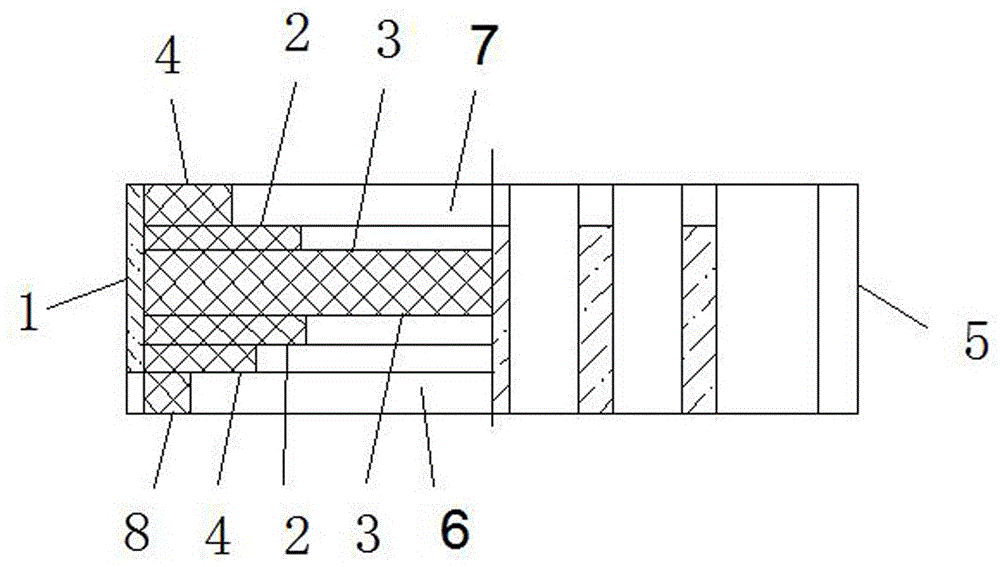

[0027] see figure 1 As shown, two groups of metal conduction grooves 1 are arranged on the opposite two outer walls, the metal layer of the i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com