Full-automatic non-quenched-and-tempered steel forge piece production line

A non-quenched and tempered steel, fully automatic technology, applied in the field of forgings manufacturing, can solve problems such as non-creative features and undisclosed key technical points, and achieve the effects of stable quality indicators, natural environment protection, and clean production environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

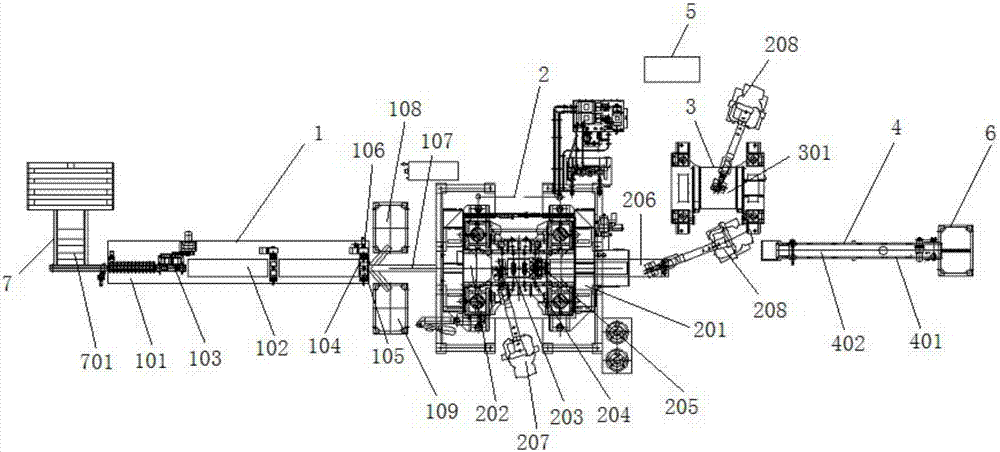

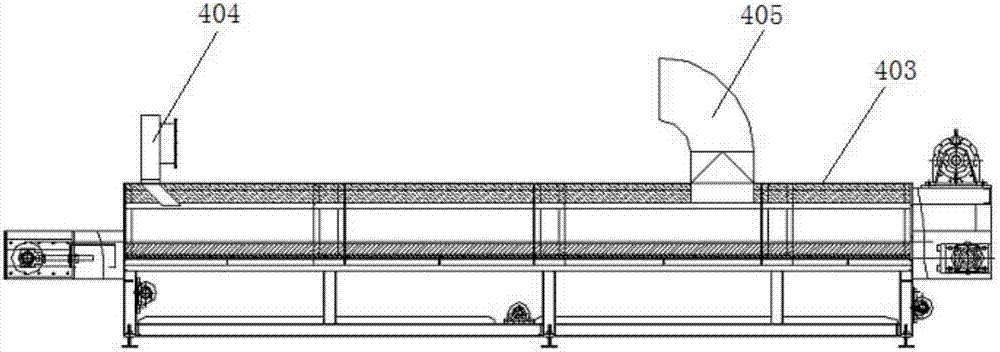

[0039] see figure 1 , a fully automatic production line for non-quenched and tempered steel forgings, including sequentially connected heating equipment 1, forging equipment 2, trimming and punching equipment 3, cooling temperature control conveyor chain 4, finished product box 5 and a programmable control system,

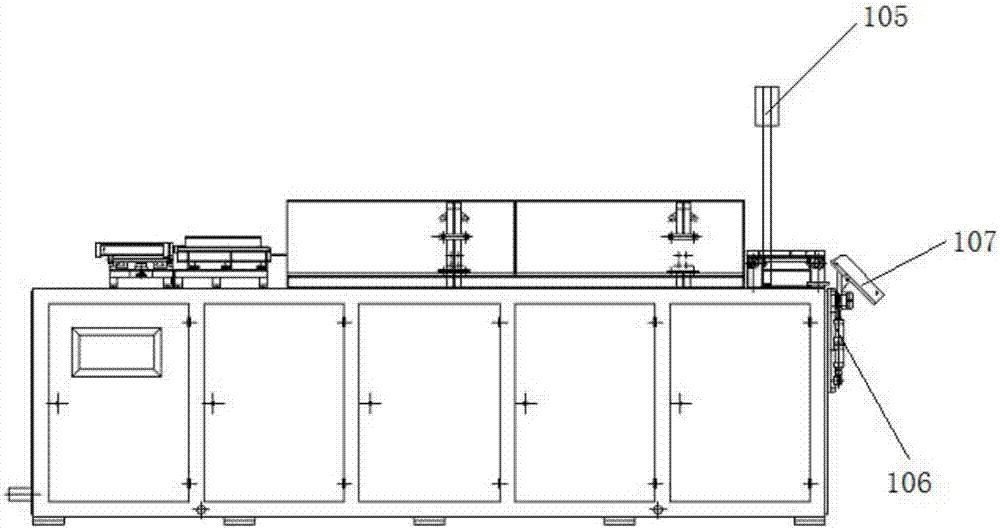

[0040] The heating equipment 1 comprises a frame 101, the frame 101 is provided with a furnace 102 along the length direction, the inlet of the furnace 102 is provided with a pushing device 103, and the outlet of the furnace 102 is provided with a temperature measuring and sorting device 104, combined with figure 2 The temperature measuring and sorting device 104 includes an infrared thermometer 105 arranged on the upper part of the outlet end of the furnace 102, and a sorting cylinder 106 connected with the signal of the infrared thermometer 105. The piston rod end of the sorting cylinder 106 is provided with a qualified Part slideway 107, burnt piece slideway an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com