Patents

Literature

336results about "Forge furnaces" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

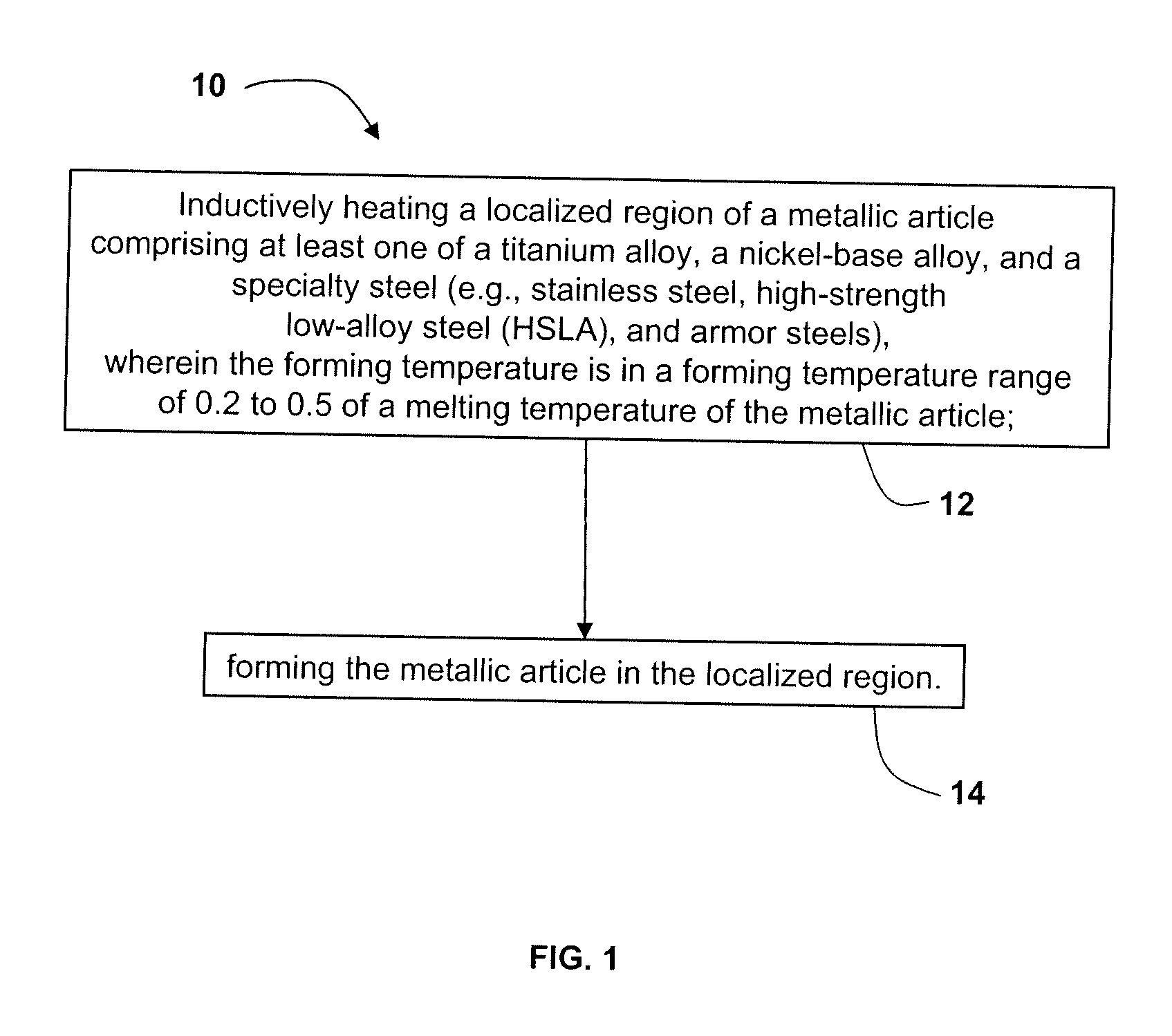

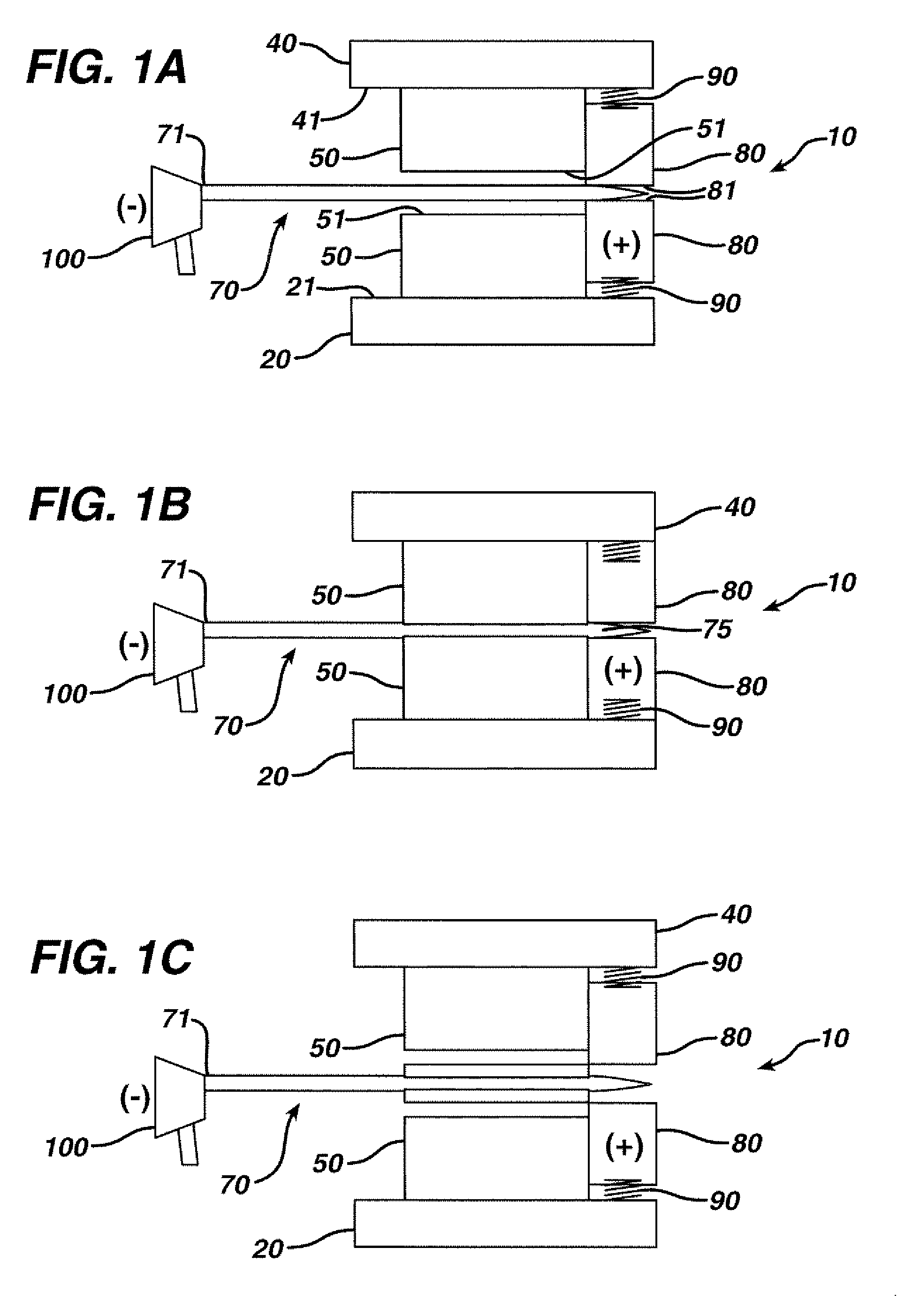

Elevated Temperature Forming Methods for Metallic Materials

A method of forming a metallic article includes directly and / or indirectly inductively heating a localized region of a metallic article to a forming temperature. The metallic article may comprise materials selected from titanium alloys, nickel-base alloys, and specialty steels, e.g., stainless steel, high-strength low-alloy steel, armor steel alloys, and the like. The forming temperature may be in a forming temperature range of 0.2 to 0.5 of a melting temperature of a metallic material comprising the article. The metallic article is formed in the localized region. Devices for indirectly and directly inductively heating a localized region of a metallic article are disclosed. Articles including metallic articles processed according to the methods and / or devices taught herein also are disclosed.

Owner:ATI PROPERTIES

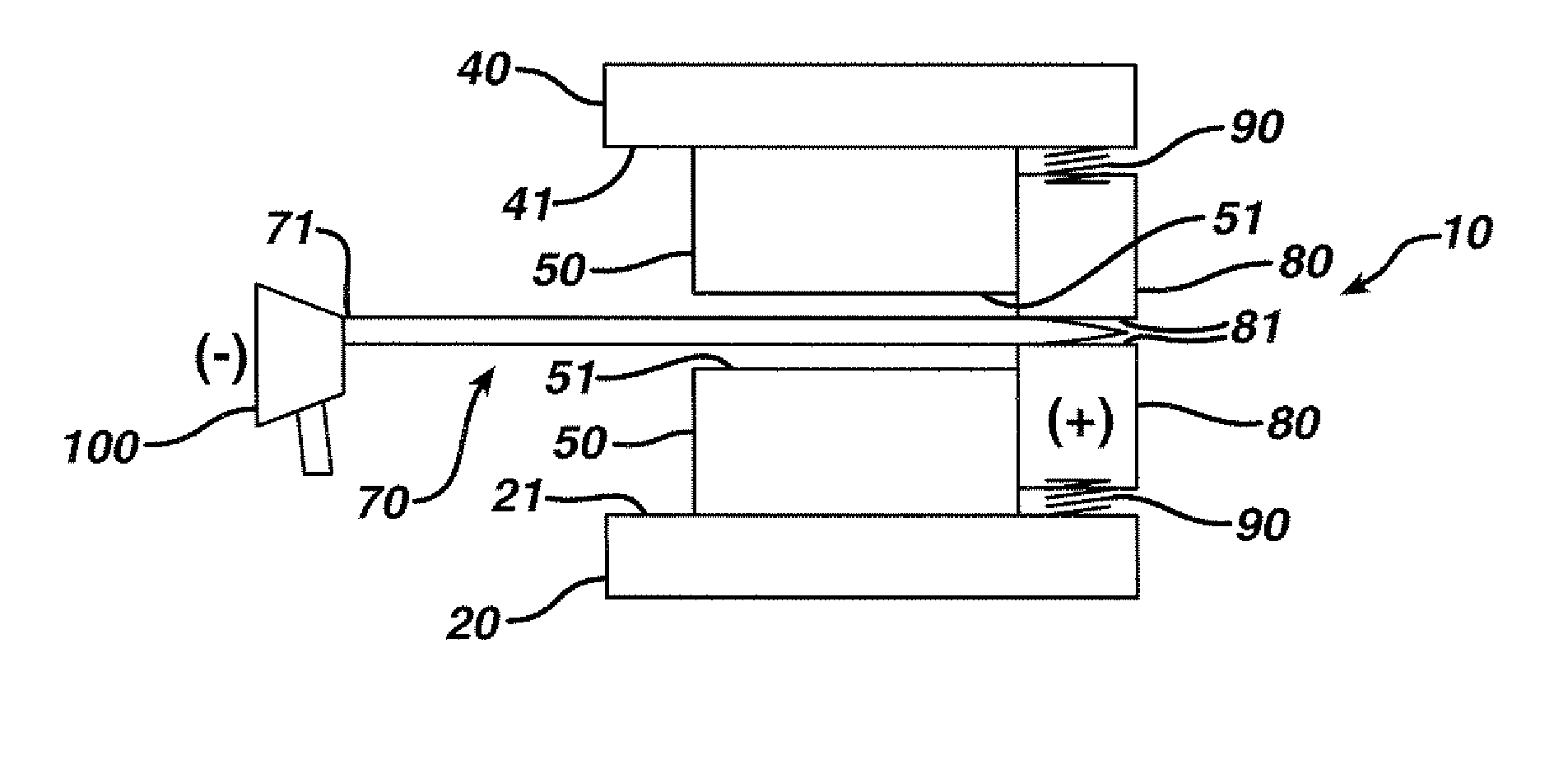

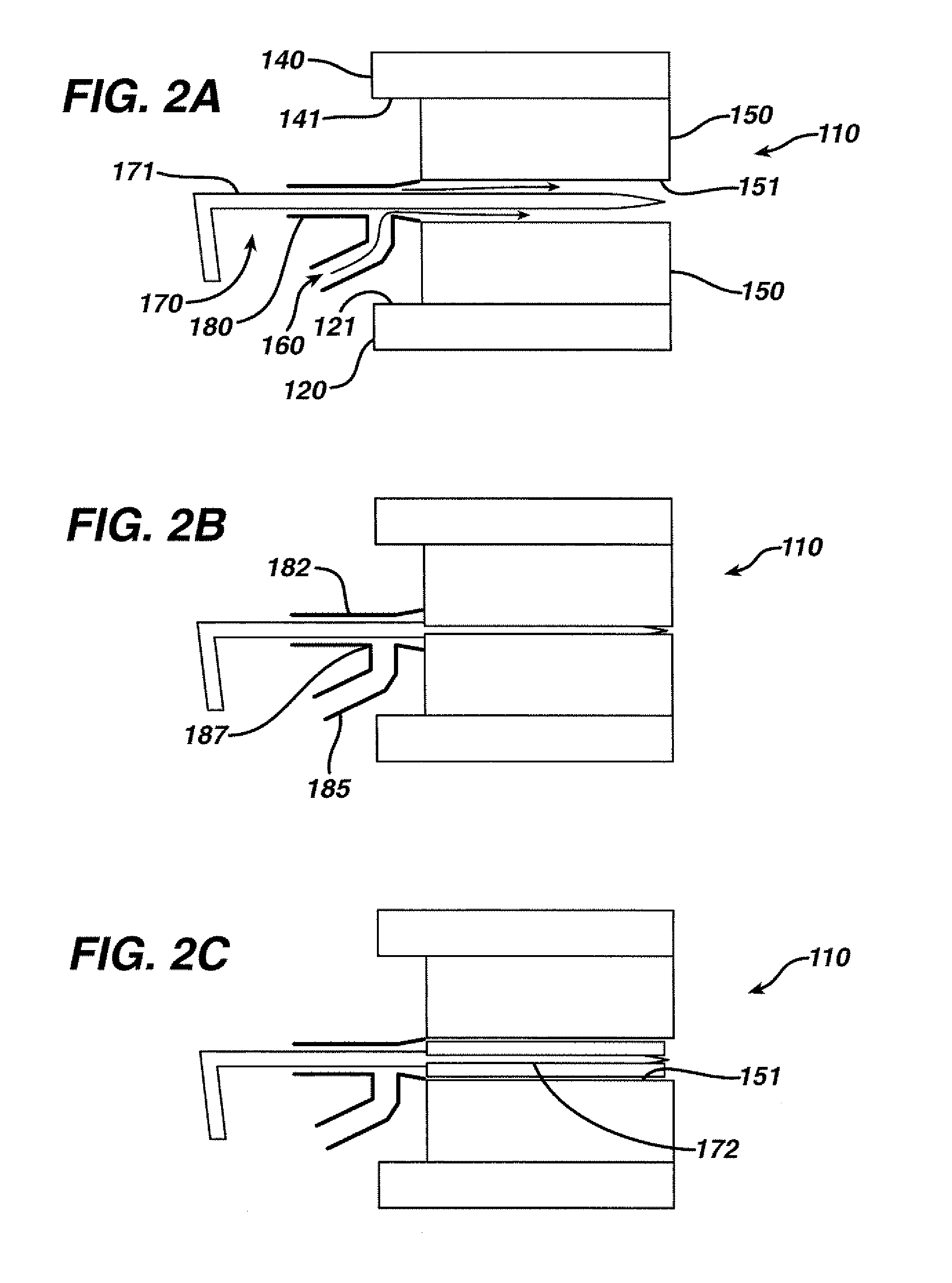

Thermal forming of refractory alloy surgical needles and fixture and apparatus

A method of thermal forming of refractory alloy suture needles is disclosed. Needle blanks made from refractory alloys are used to form surgical needles, which are heated to a temperature above the ductile to brittle transition temperature but below the recrystallization temperature of the refractory alloy. The heated needle blanks are then mechanically formed into a surgical needle. A Fixture and an apparatus for forming refractory alloy surgical needles using this method are also disclosed.

Owner:ETHICON INC

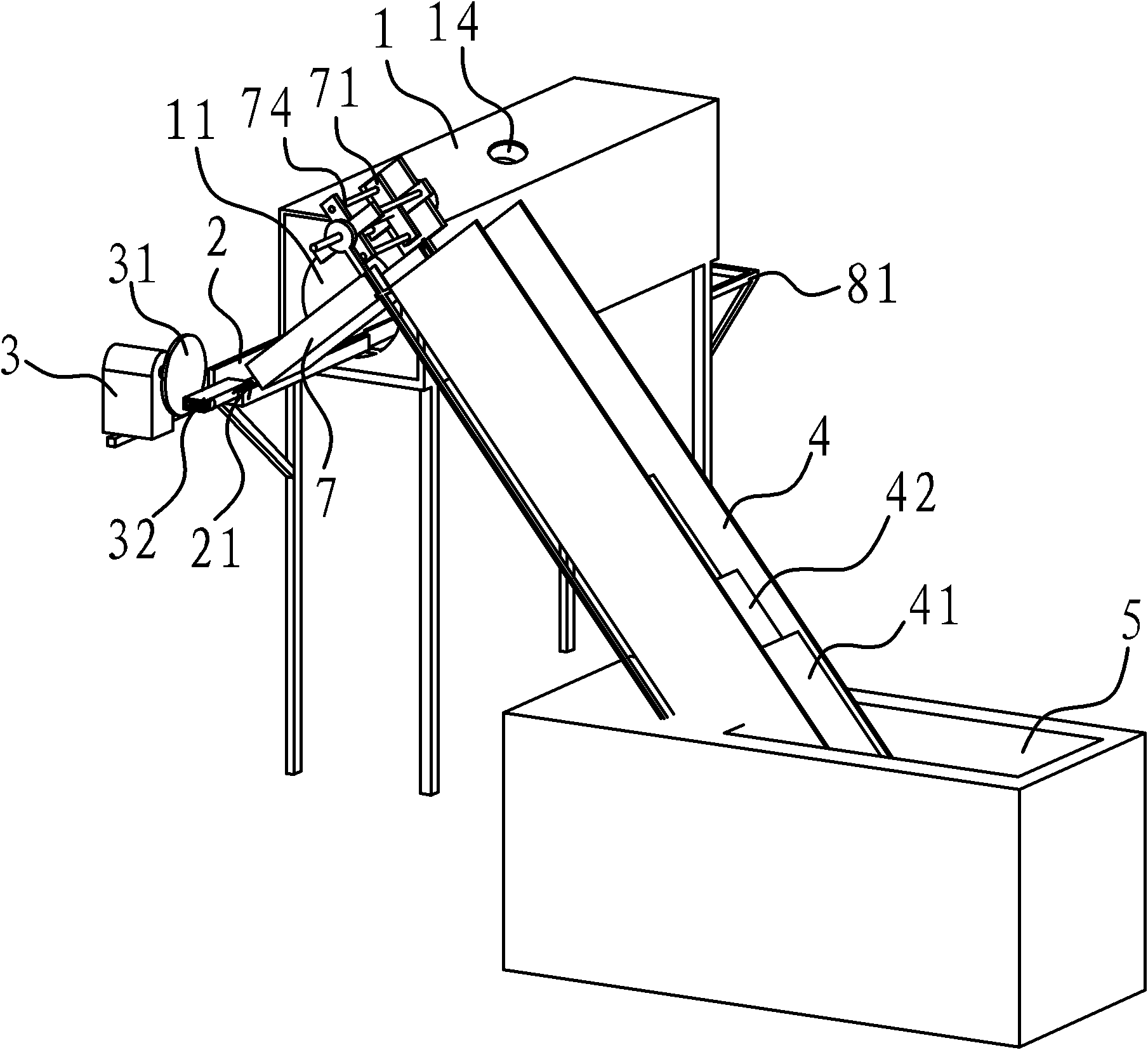

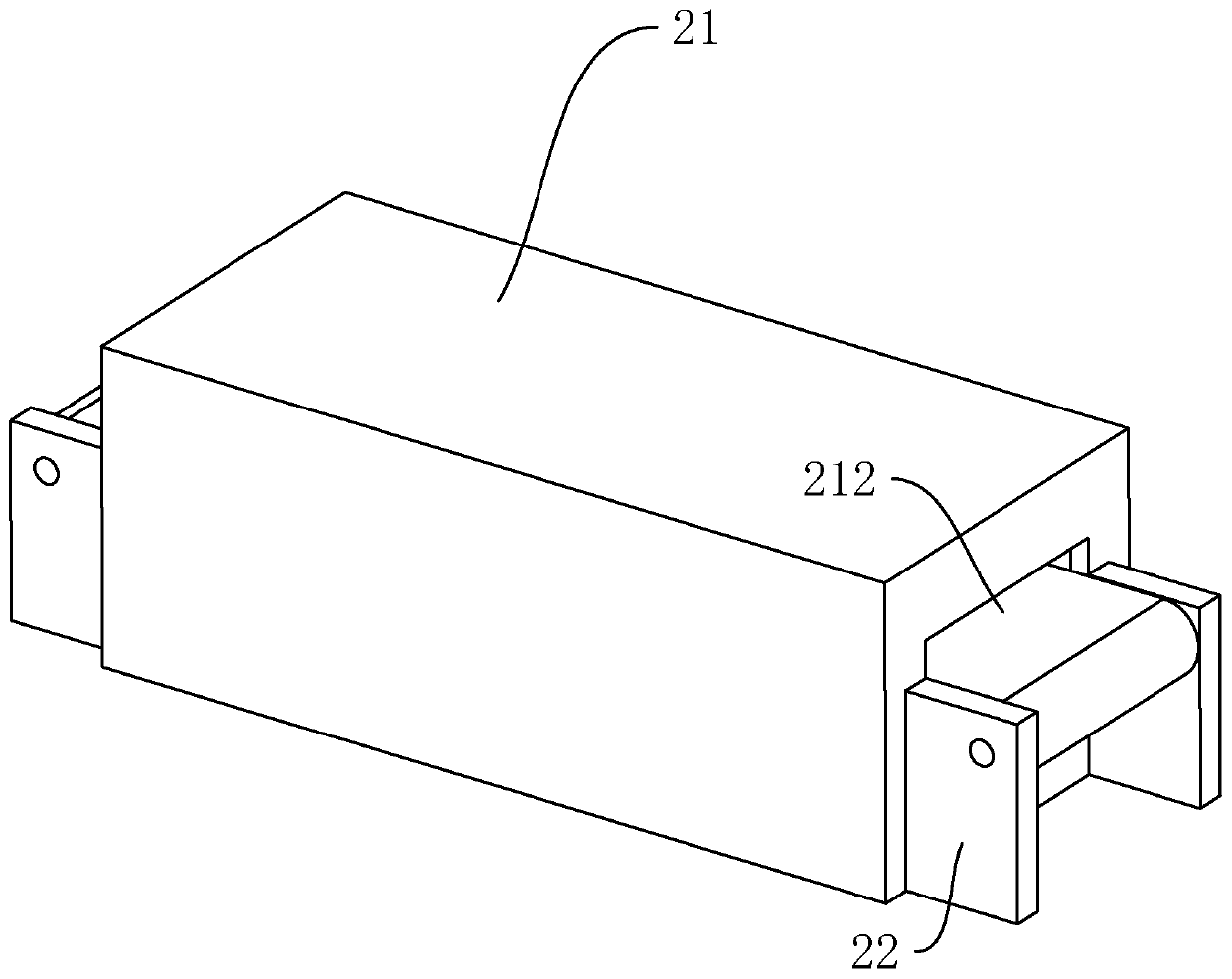

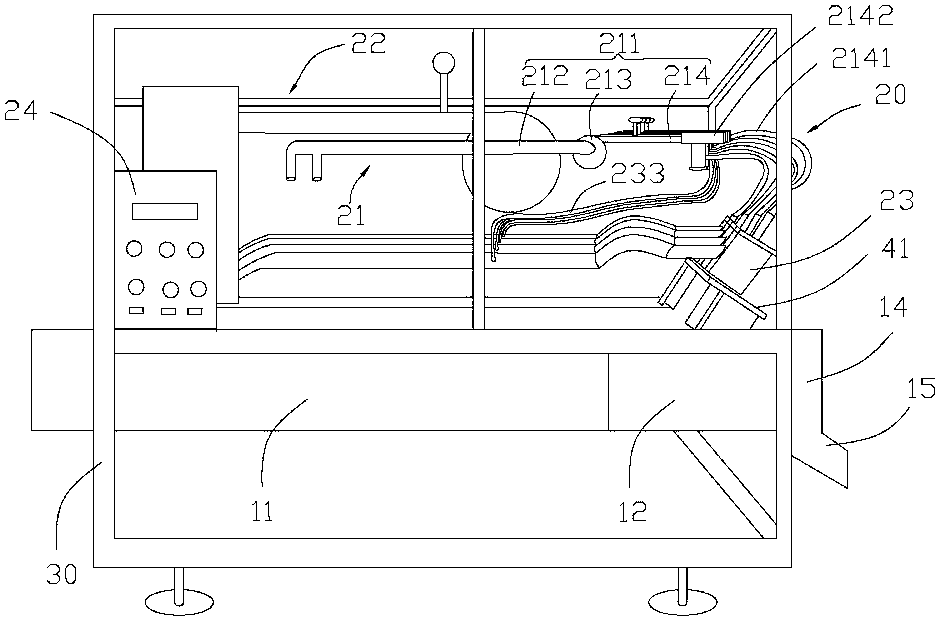

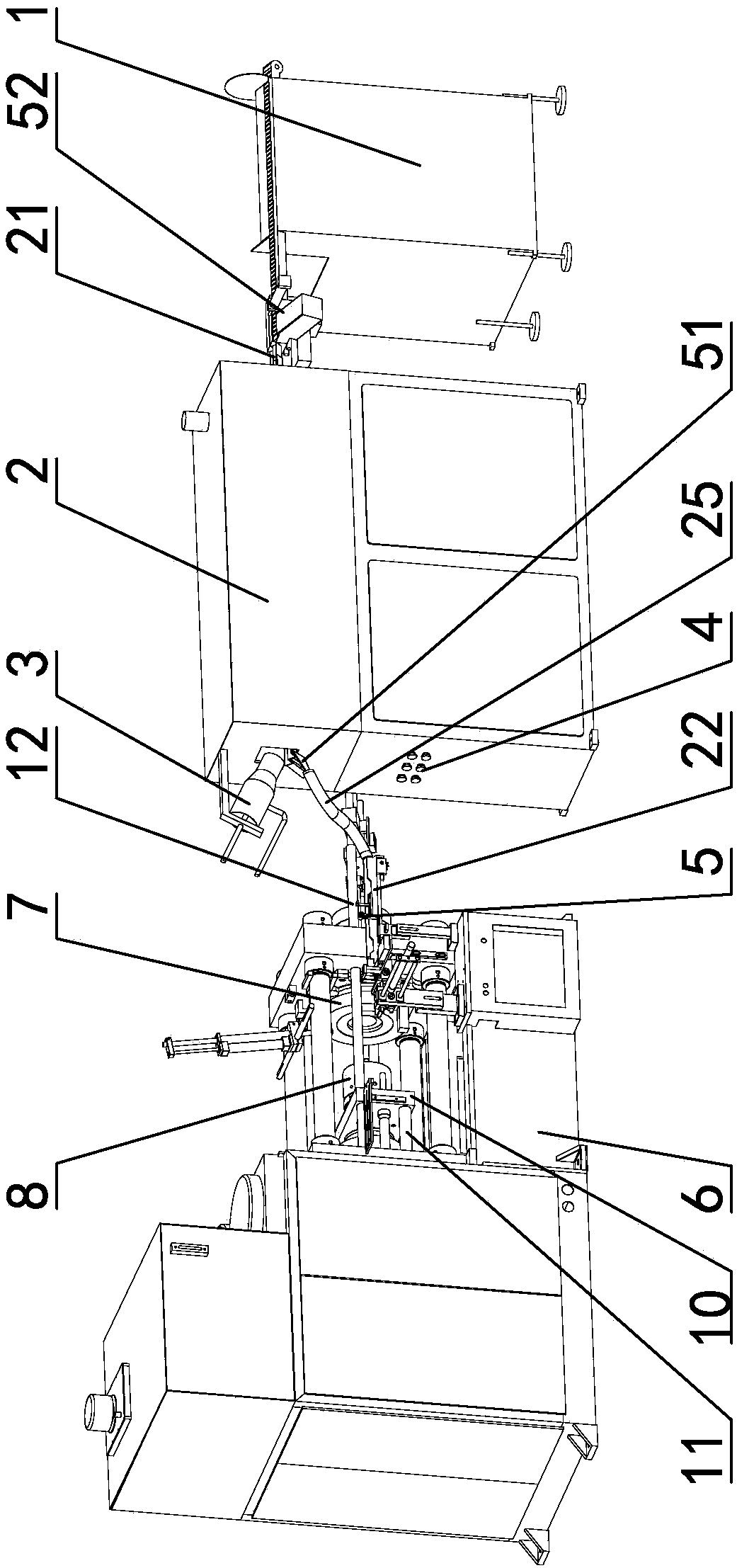

Continuous forging furnace

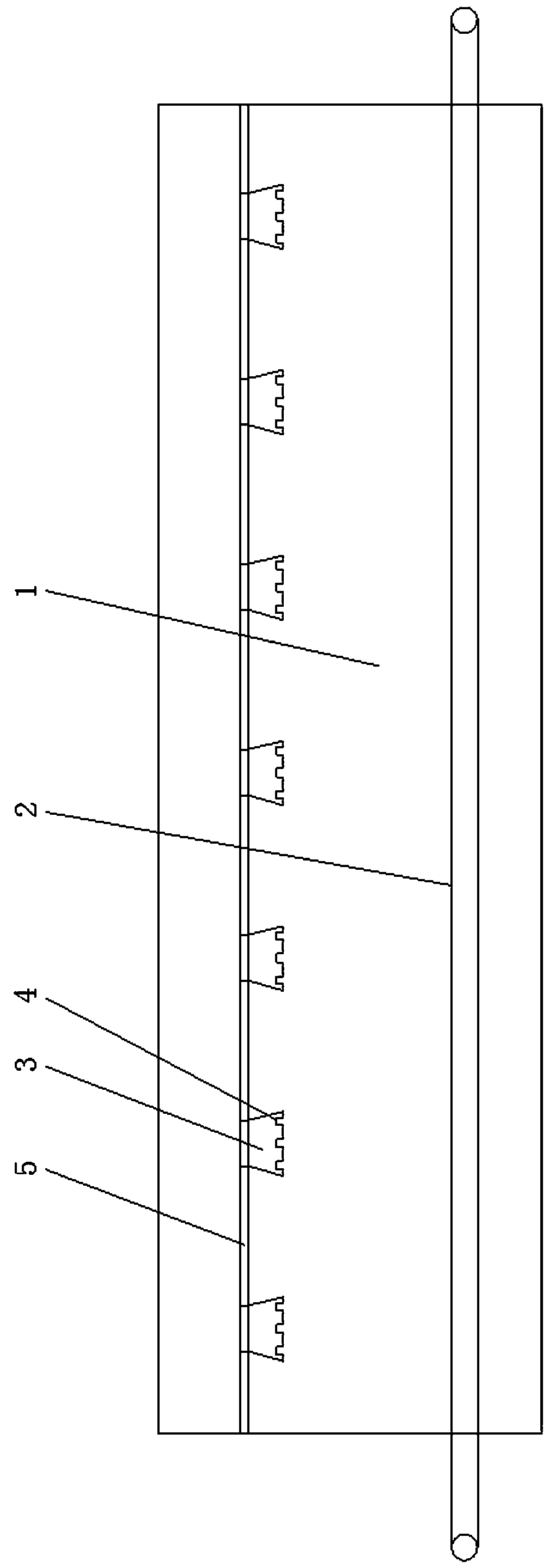

The invention relates to a continuous forging furnace. The continuous forging furnace comprises a furnace body, a gas mechanism and a combustion-supporting mechanism, wherein the furnace body comprises a hearth; the gas mechanism comprises a gas tube; the combustion-supporting mechanism comprises a combustion-supporting gas tube, and the gas provided by the gas mechanism passes through the gas tube to be mixed with the combustion-supporting gas which is provided by the combustion-supporting mechanism and passes through the combustion-supporting gas tube, so that the gas and the combustion-supporting gas are matched for burning so as to heat the hearth; the forging furnace also comprises a feeding mechanism and a waste heat utilizing mechanism, wherein the feeding mechanism comprises a plurality of feed driving pieces; the hearth is internally provided with a plurality of material guiding cylinders and is communicated with a material discharging hole, the plurality of feed driving pieces push heating pieces to the corresponding material guiding cylinders by turns; and the waste heat utilizing mechanism comprises a plurality of heat conduction pipe sleeves which are connected with the material discharging hole and the material feeding end of the furnace body and is sleeved with the combustion-supporting gas tube. The continuous forging furnace realizes the continuous heating as the plurality of feed driving pieces can push the heating pieces, and the waste heat utilizing mechanism can fully utilize the waste heat, so that the utilization ratio of the energy resources can be improved.

Owner:彭亦楚

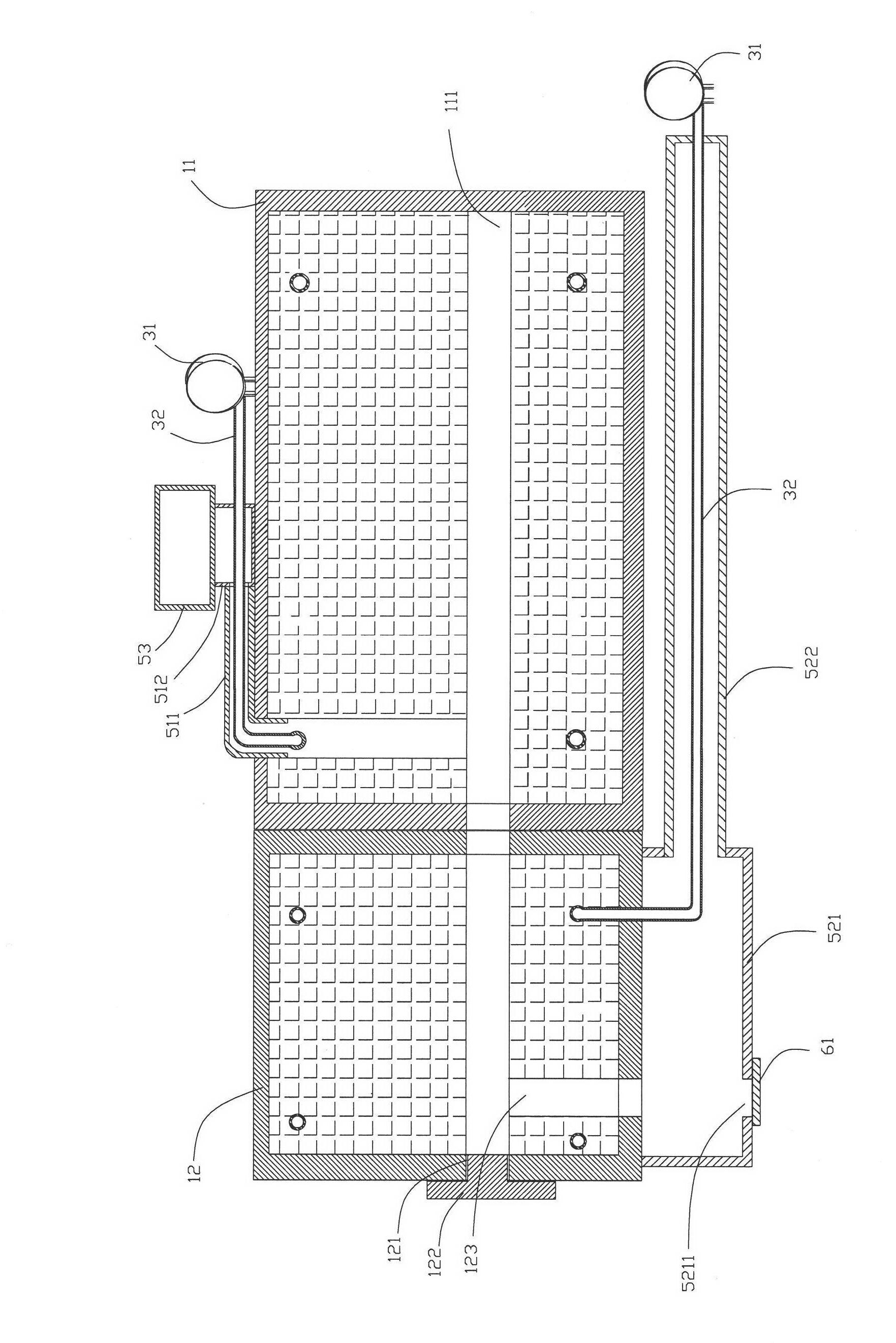

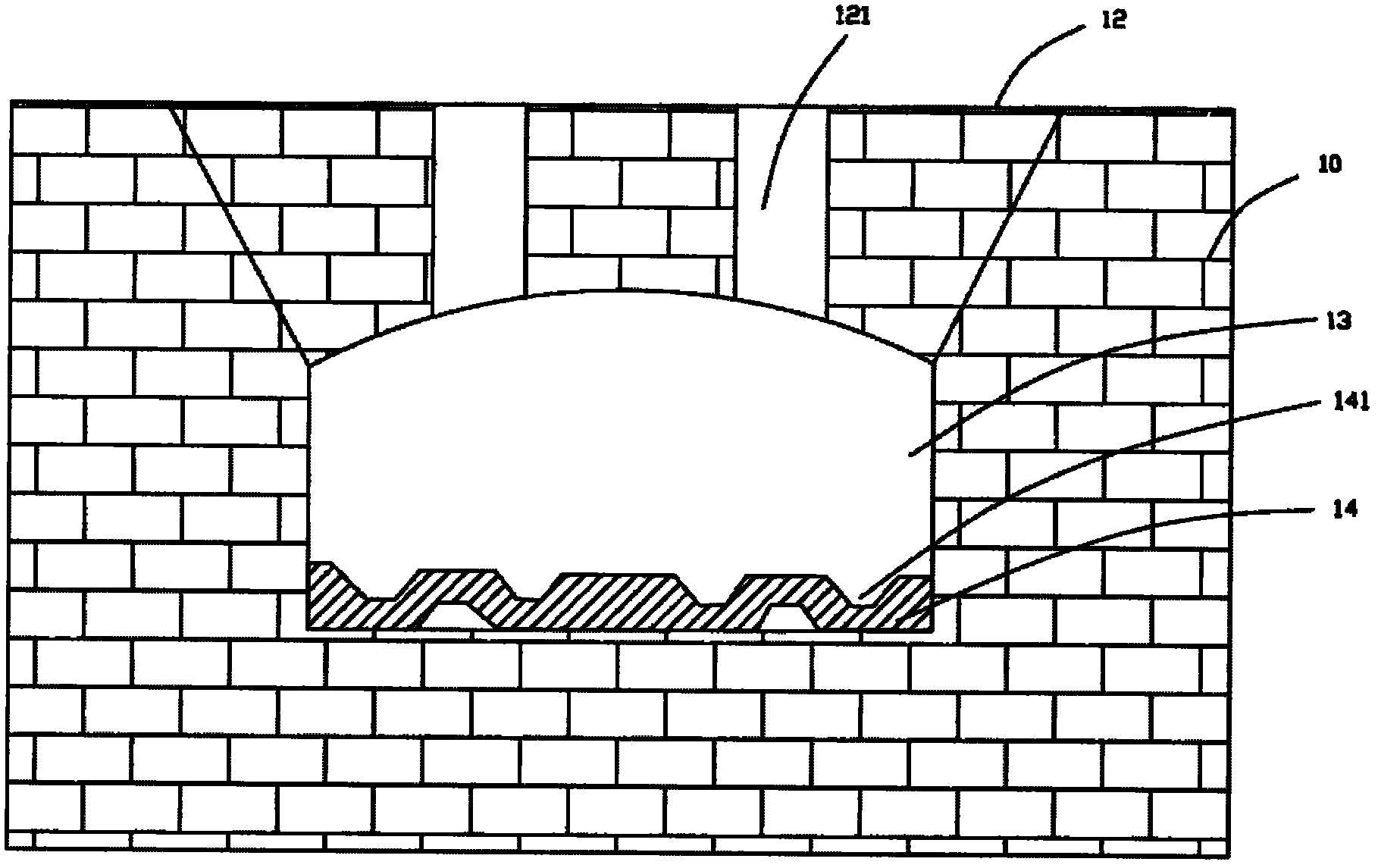

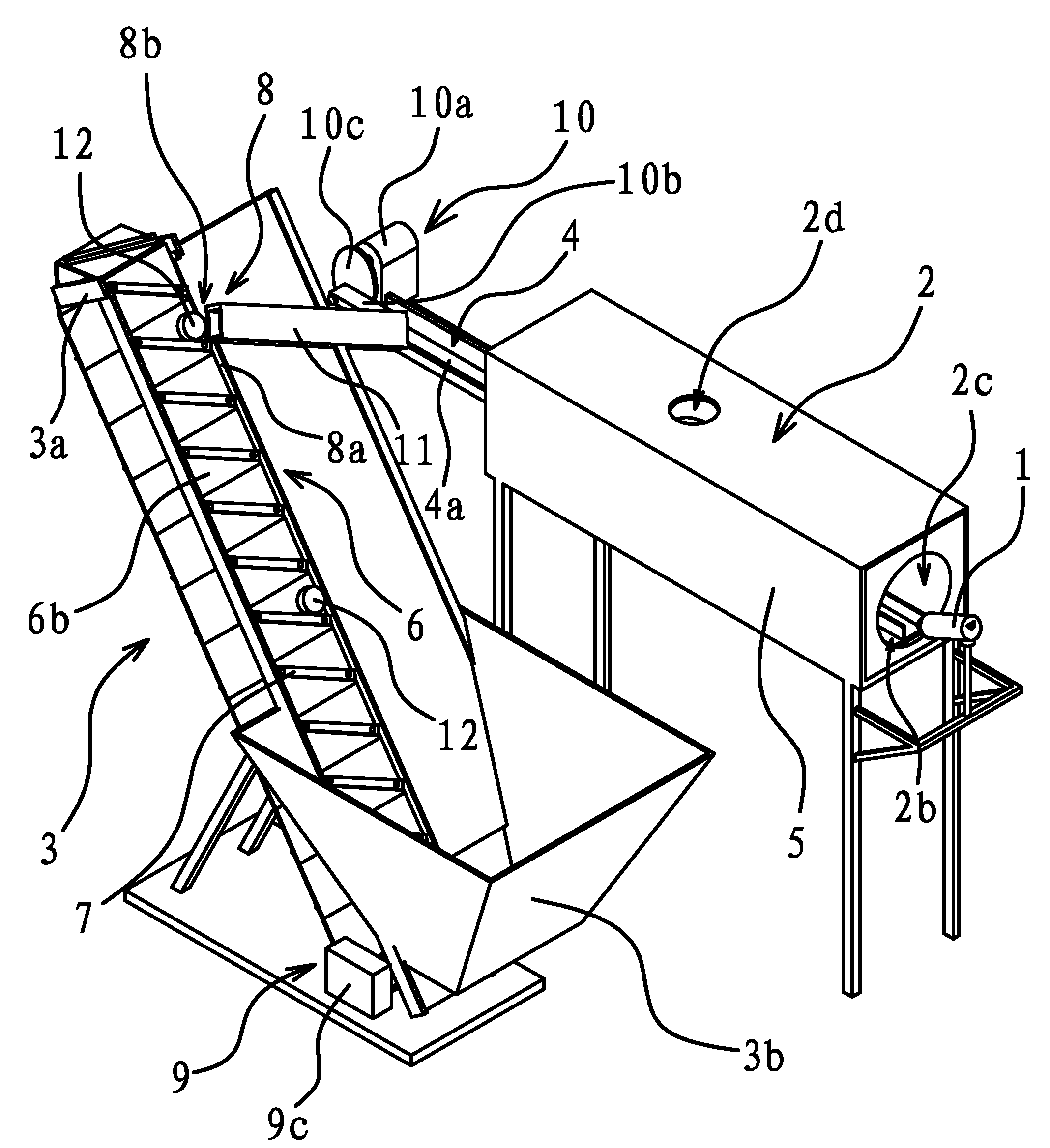

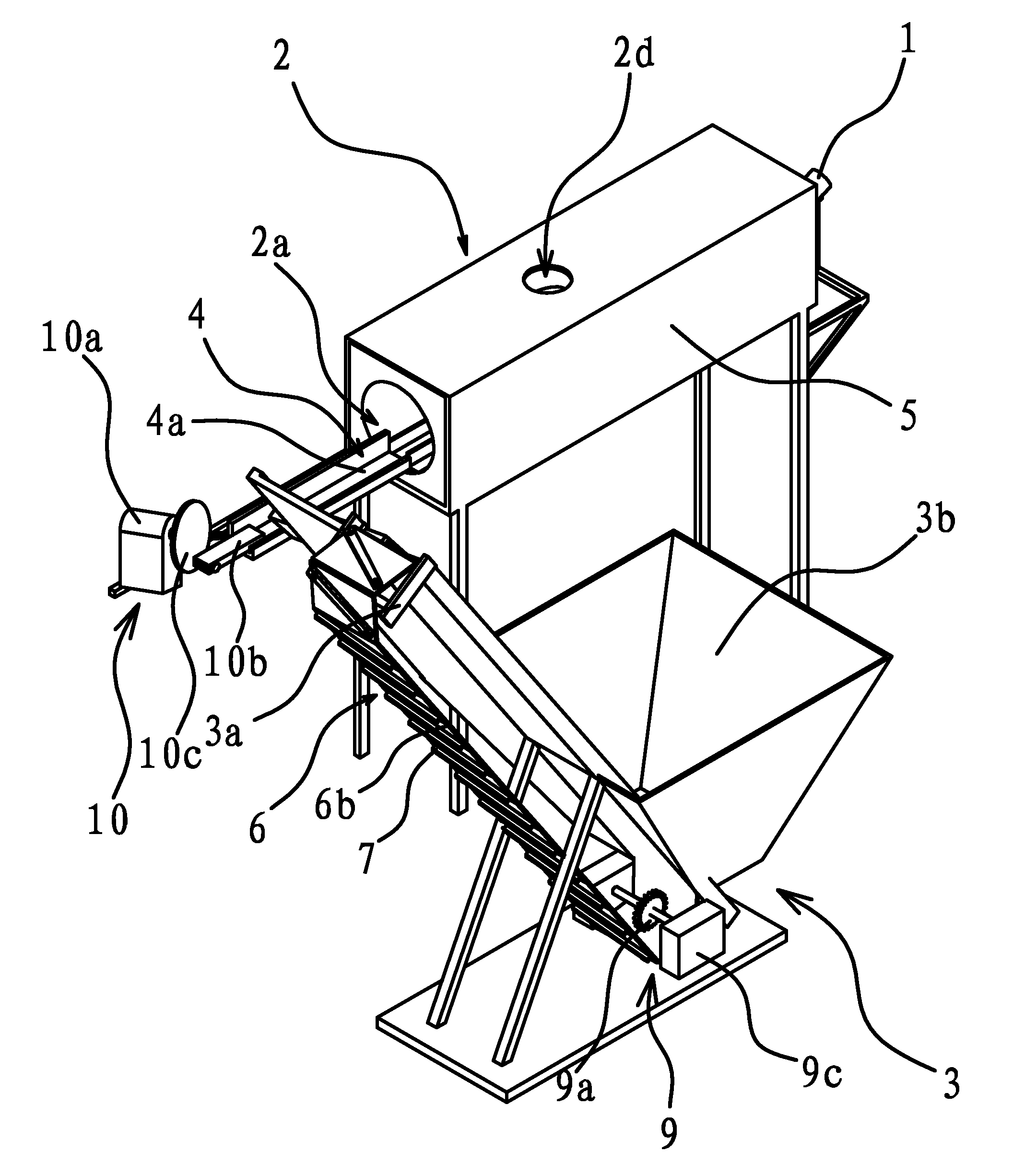

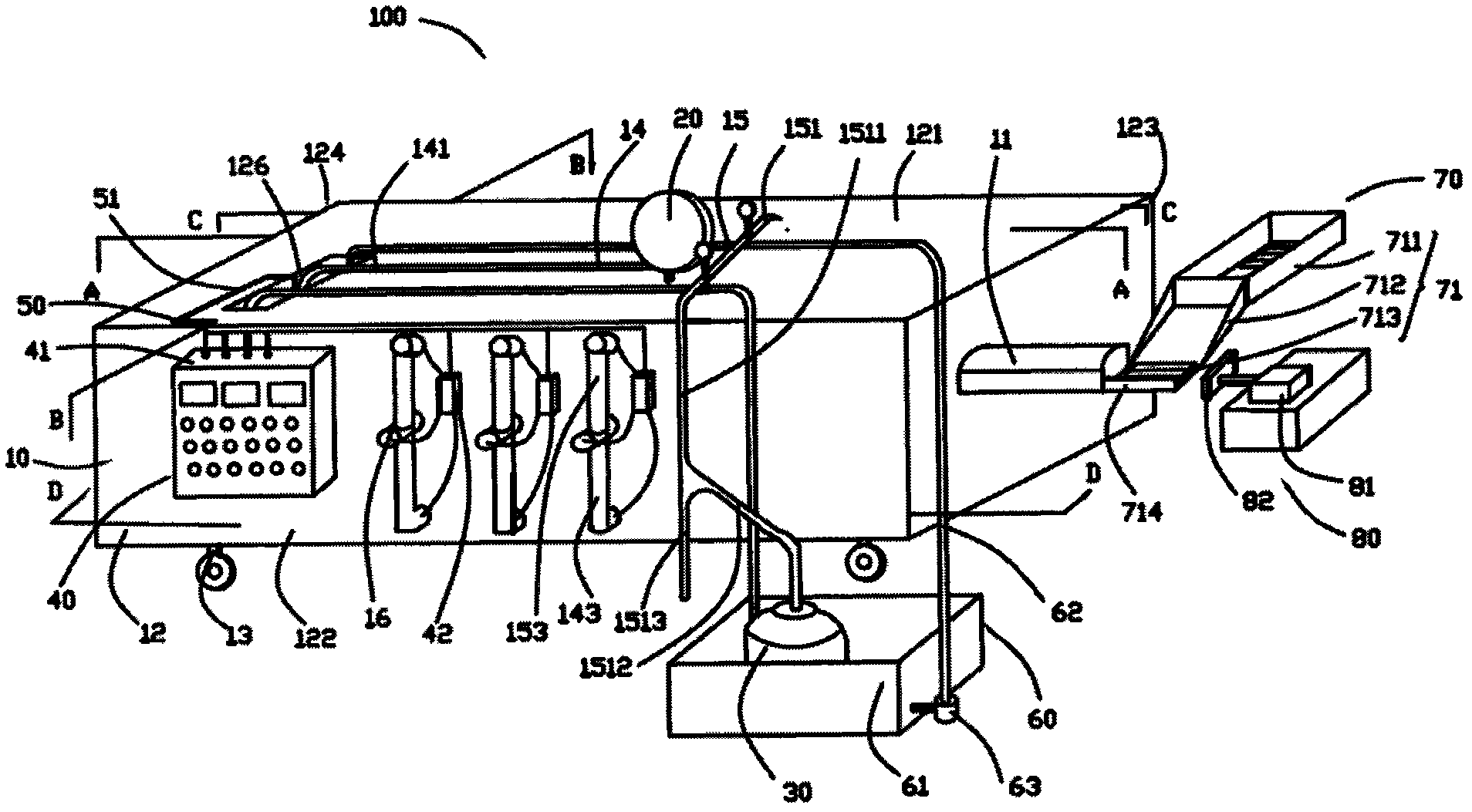

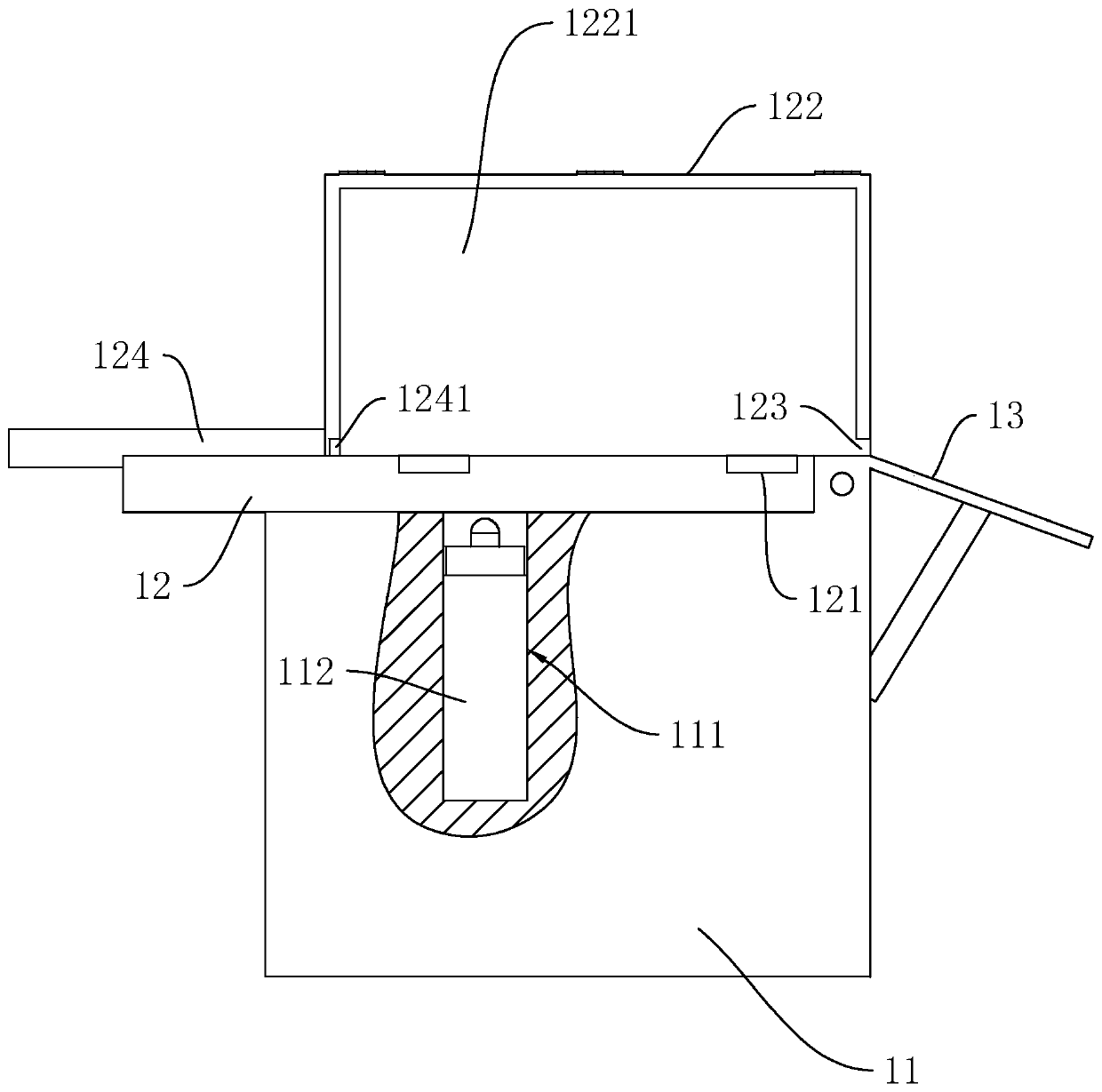

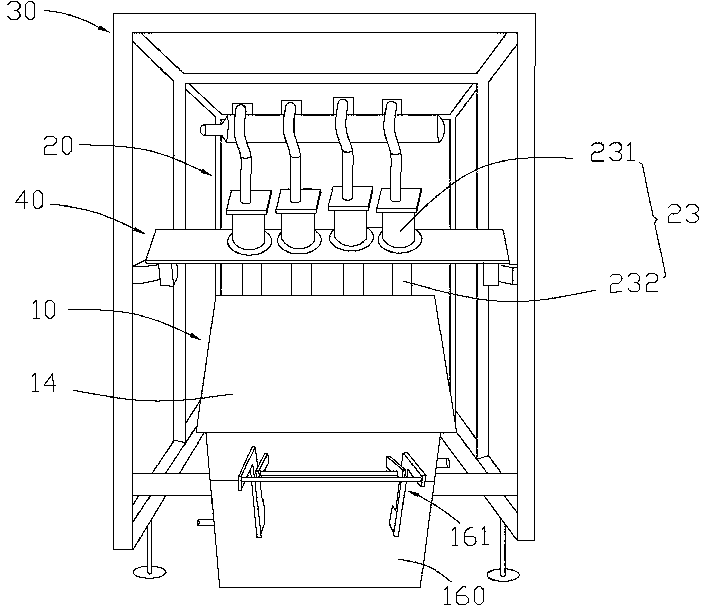

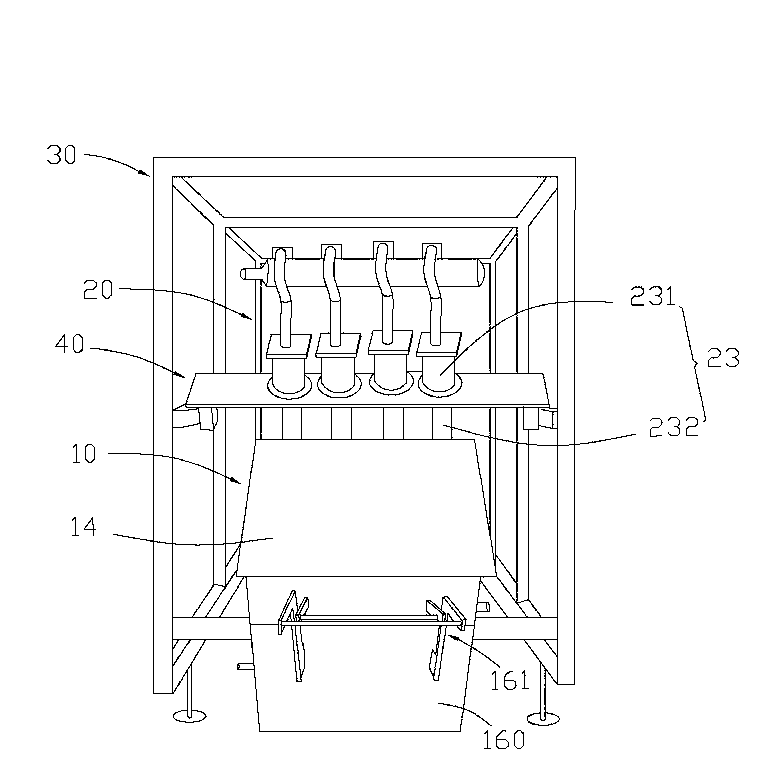

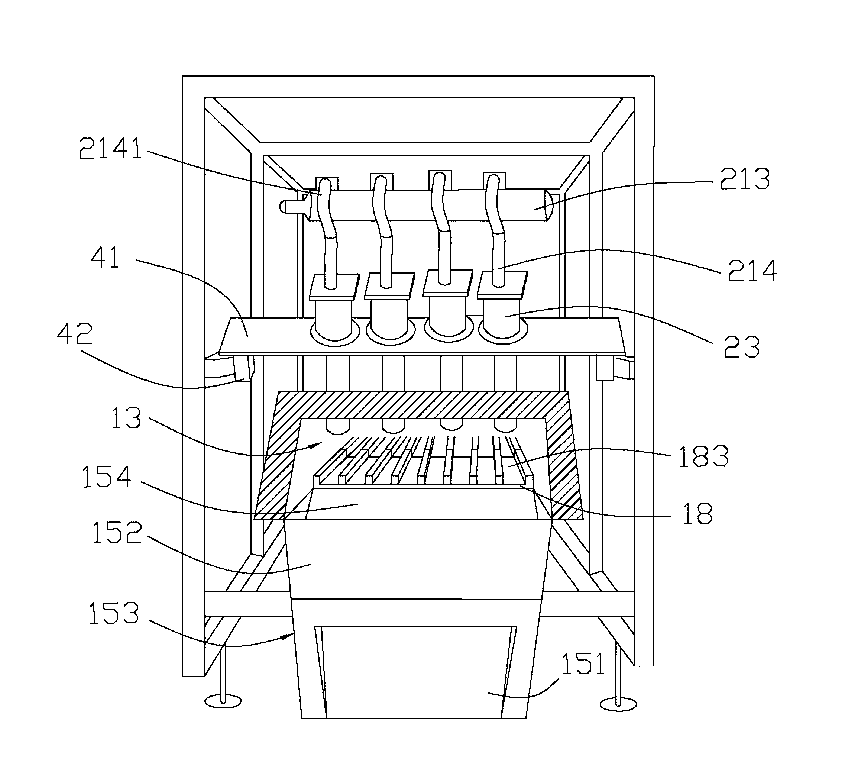

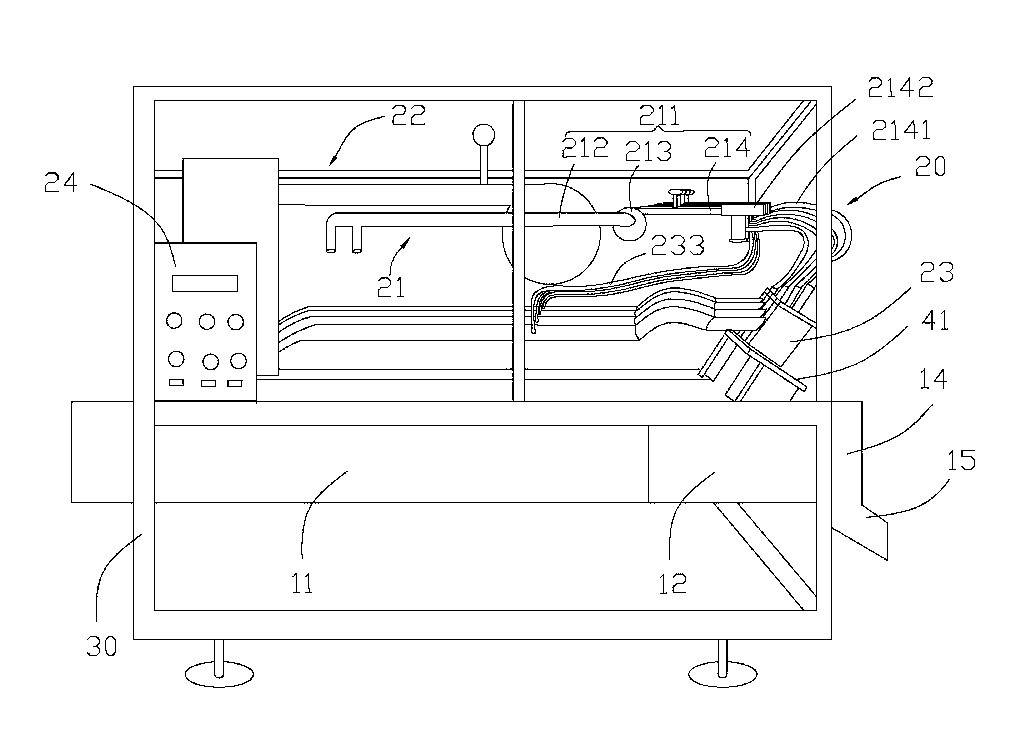

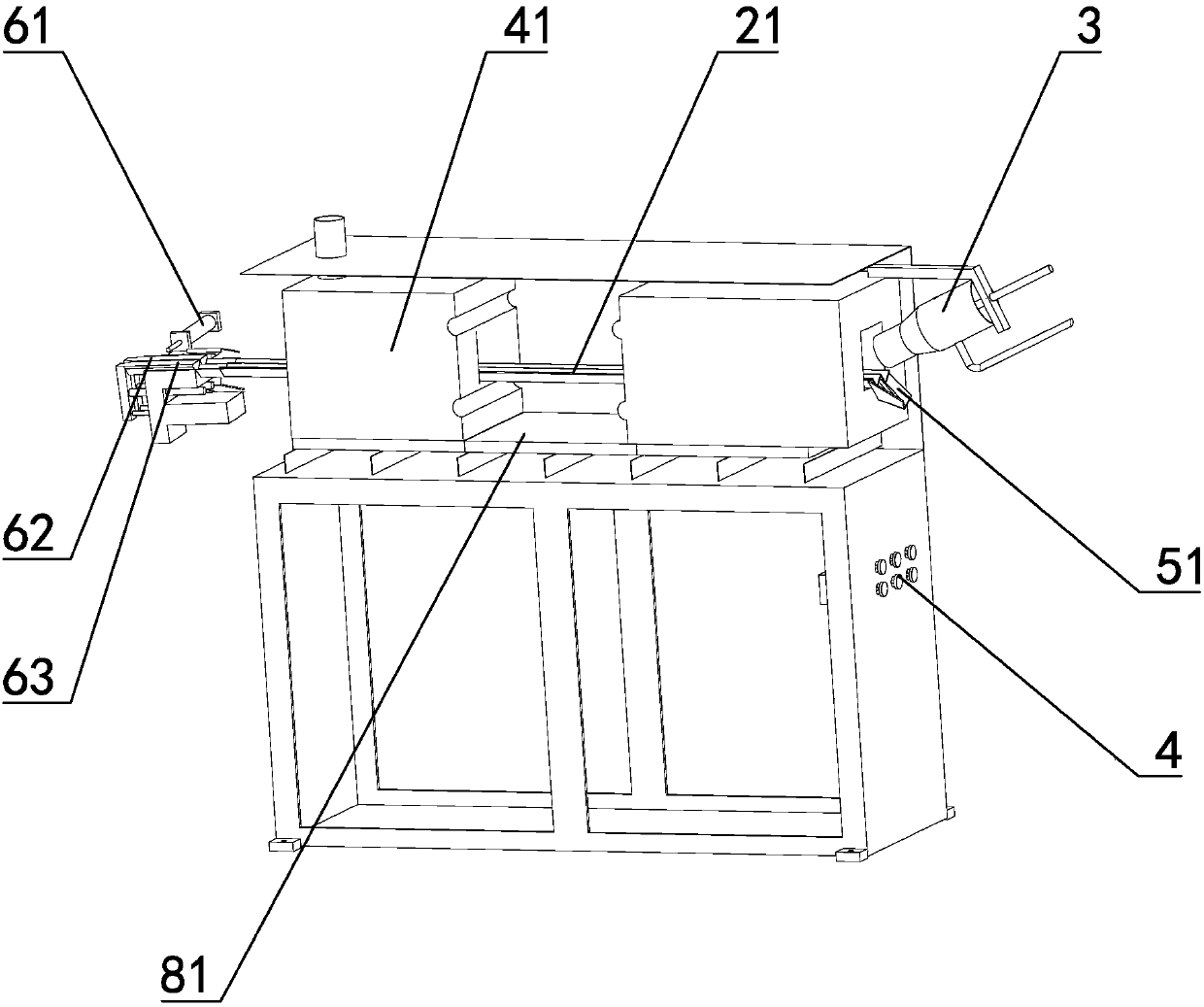

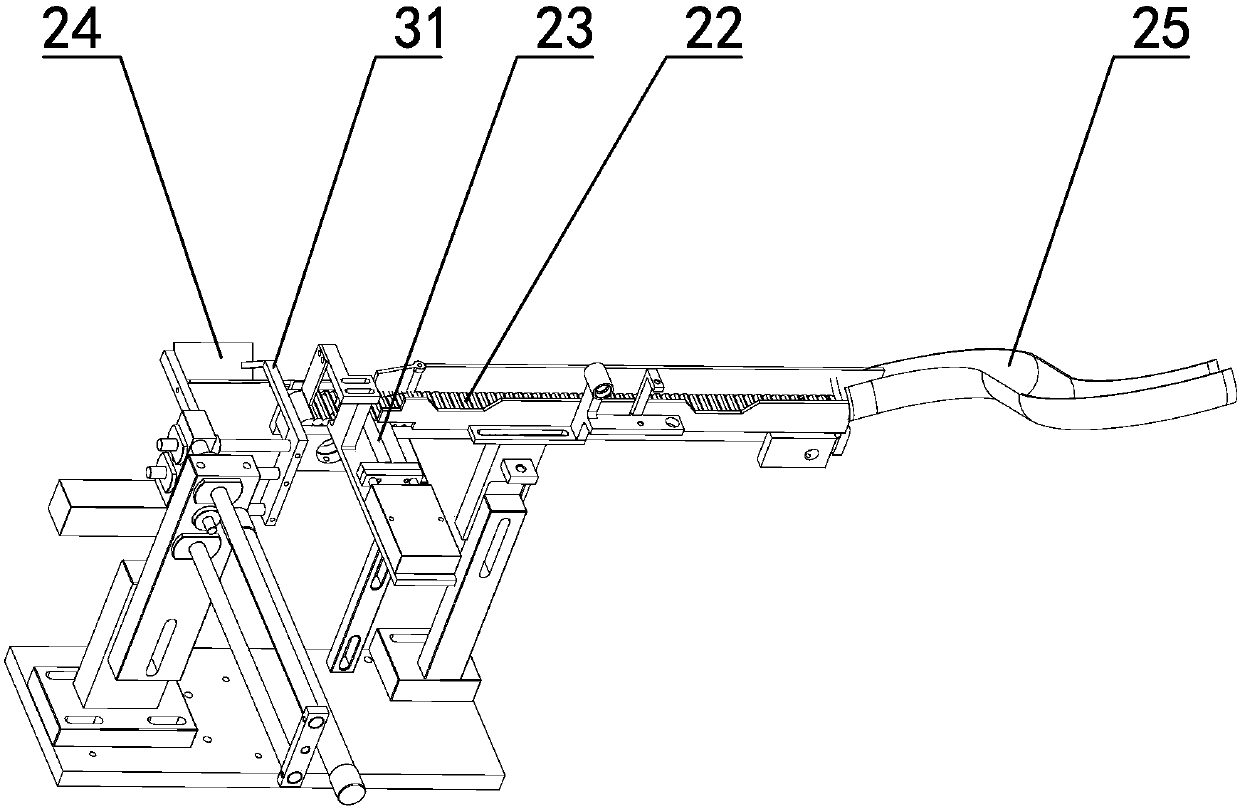

Forge heating furnace

ActiveCN102615235AHigh degree of automationReduce the amount of human laborForge furnacesEngineeringHeating furnace

The invention relates to a forge heating furnace. The forge heating furnace comprises a furnace body, a heating mechanism, a waste heat utilization mechanism and a feeding mechanism, wherein the furnace body comprises a furnace chamber; the heating mechanism heats the inner side of the furnace chamber; the waste heat utilization mechanism guides waste gases after burning in the furnace chamber so as to utilize the waste heat; the feeding mechanism comprises a clamping mechanism and a material pushing mechanism; the clamping mechanism automatically and continuously clamps materials to the entrance of the furnace chamber; and the material pushing mechanism automatically pushes the materials into the furnace chamber. The feeding mechanism of the forge heating furnace feeds materials by adoption of the clamping mechanism matching with the material pushing mechanism, the clamping mechanism can continuously clamp materials to the material pushing mechanism repeatedly, and the material pushing mechanism correspondingly pushes the materials to the furnace chamber, so that the automation degree is high, the manpower labor input is reduced, and the forging efficiency is greatly increased.

Owner:彭亦楚

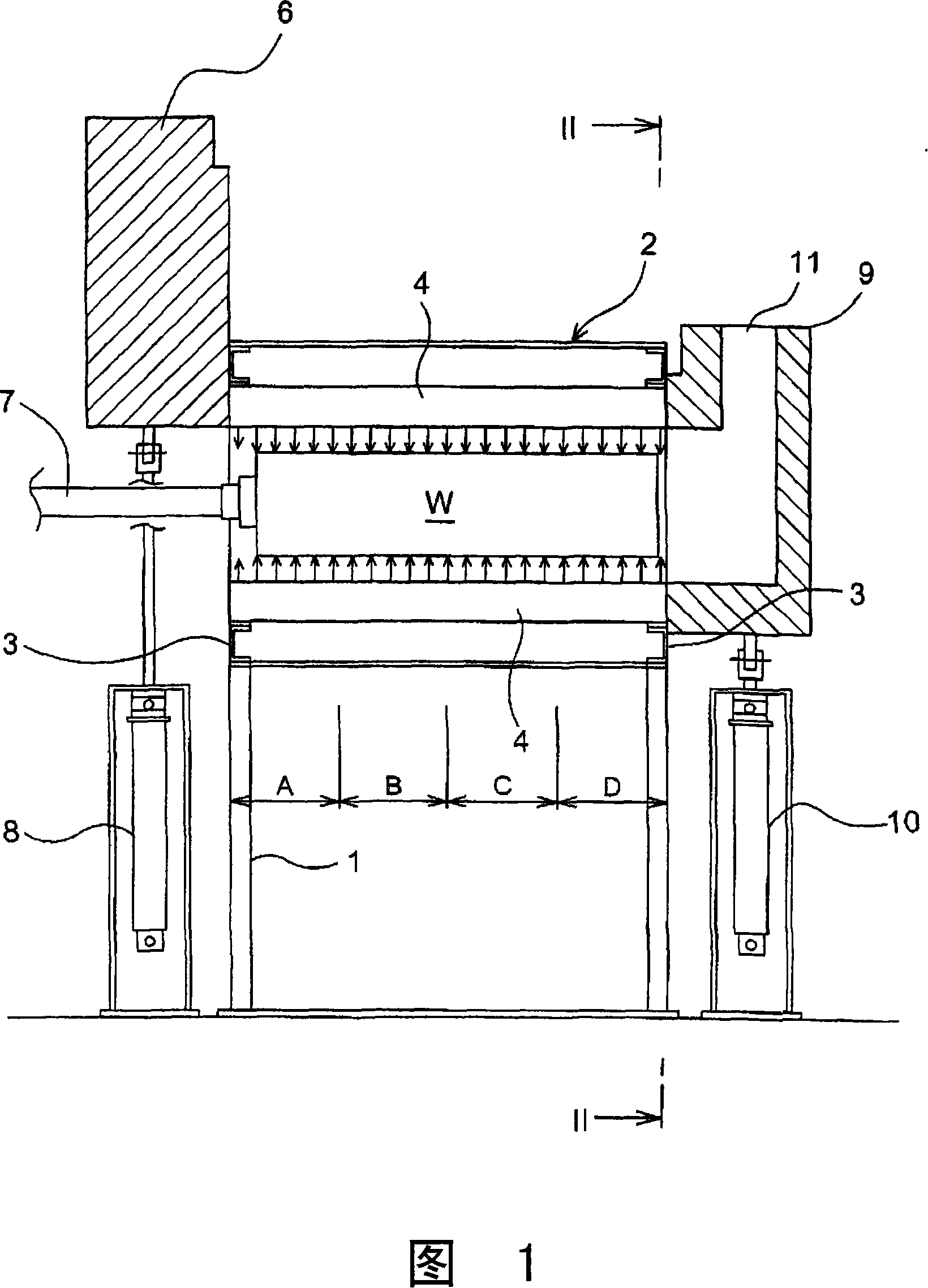

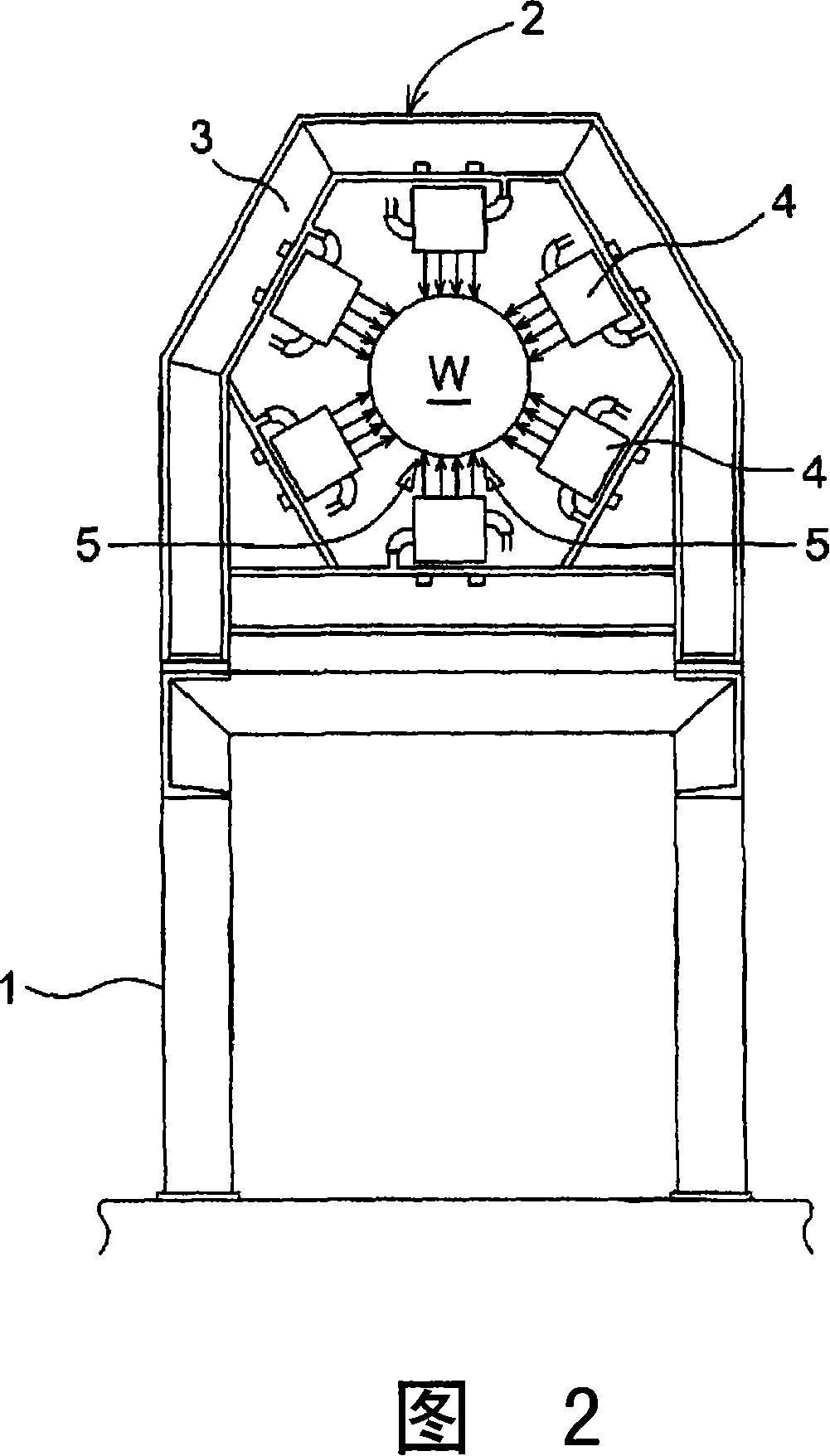

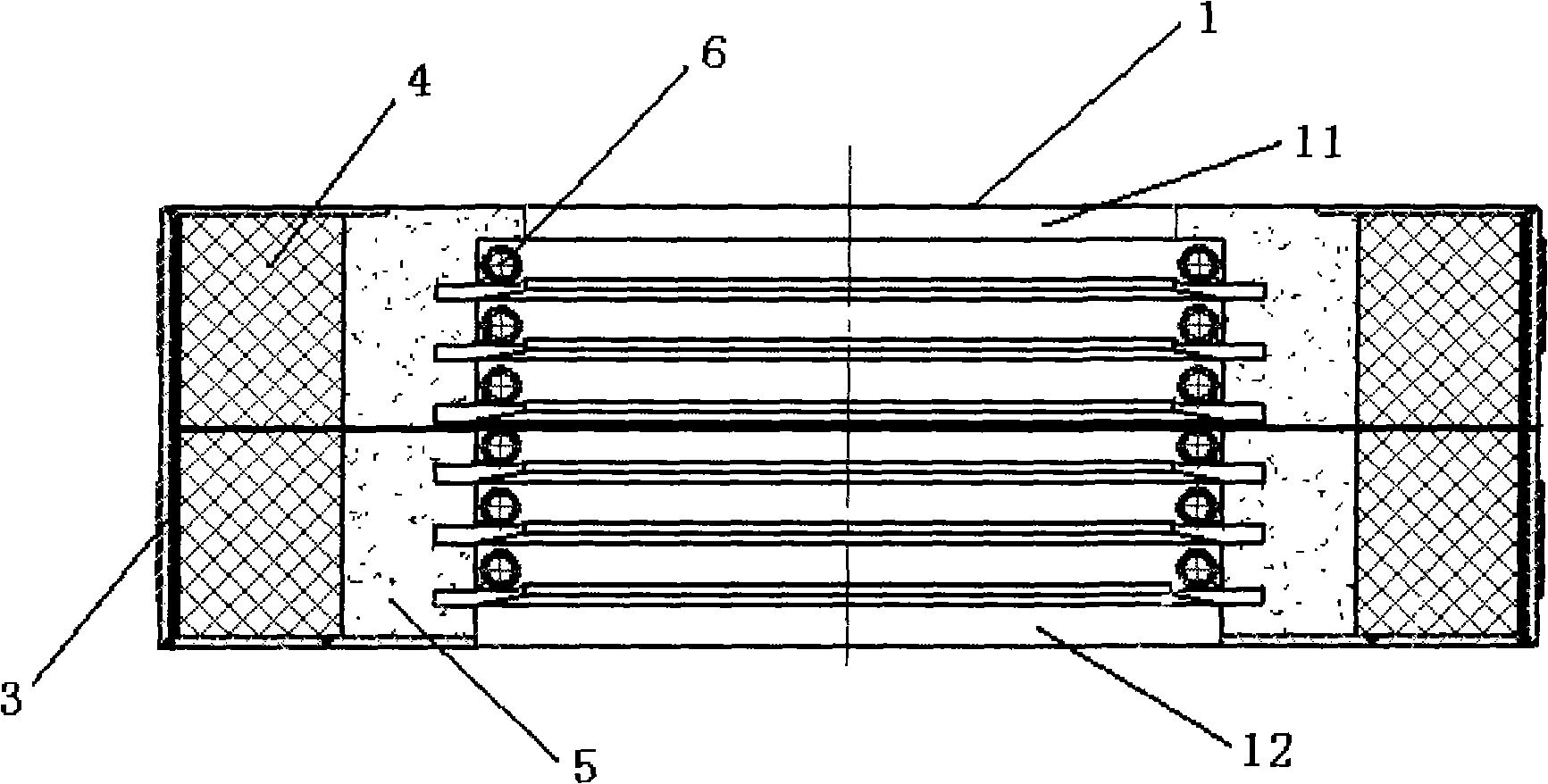

High-strength aluminum alloy isothermal direction-change open die forging method and device

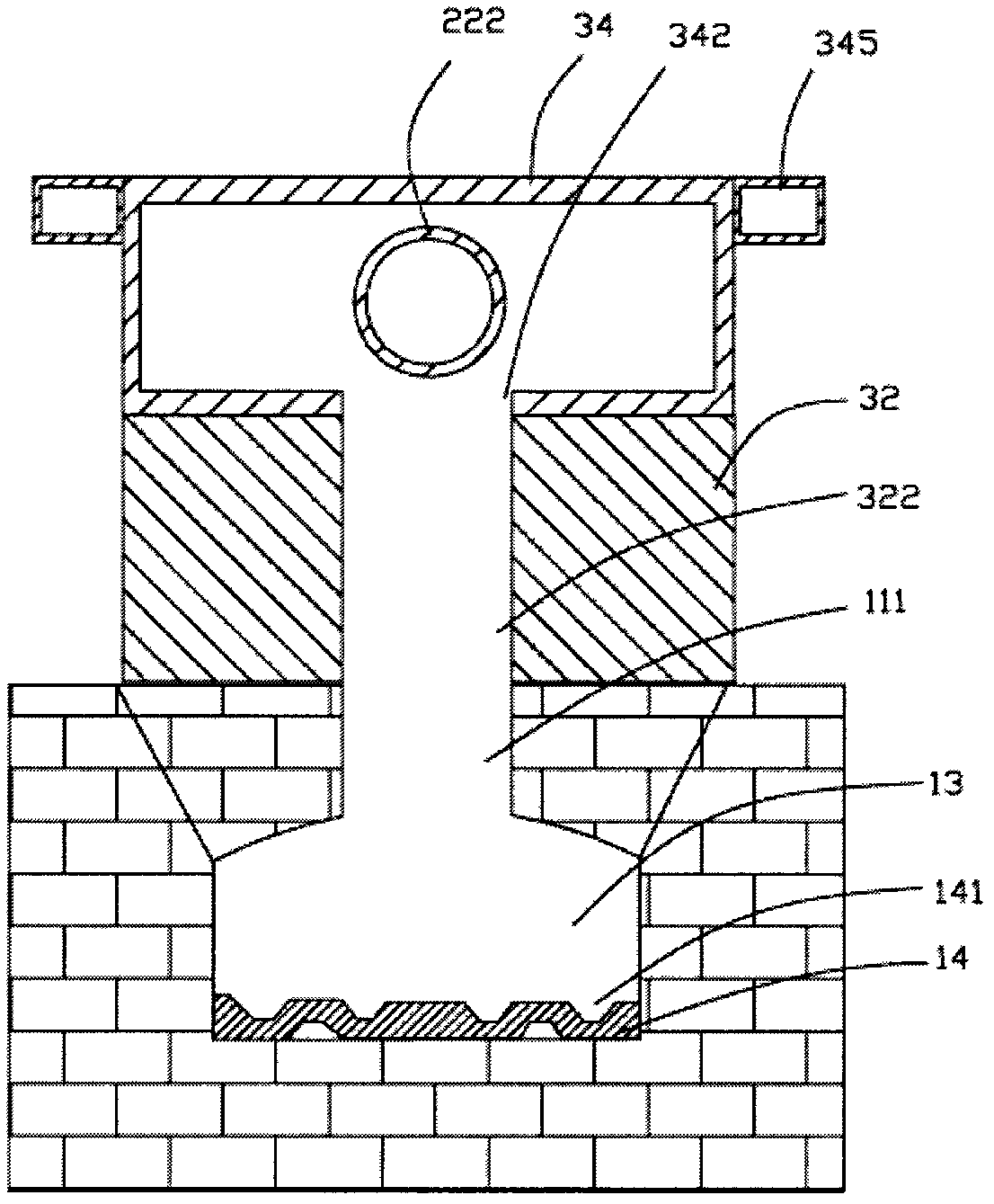

ActiveCN101941039AConstant and uniform temperatureEasy to organizeForge furnacesFurnace temperatureStructure property

The invention relates to a high-strength aluminum alloy isothermal direction-change open die forging method which comprises the following steps: heating preprocessed high-strength aluminum alloy blank in a direction-change isothermal forging heating holding furnace at the temperature of 350-450 DEG C, and keeping the furnace temperature unchanged; and according to the structure property indices required by the blank, repeatedly upsetting and drawing the blank in the direction-change isothermal forging heating holding furnace until the blank reaches the design size of the forge piece. The isothermal direction-change open die forging device comprises a heating furnace and a forging press, wherein the furnace body is installed on the forging platform of the forging press; the forging rammer of the forging press is installed in a through hole in the furnace bottom plate; and the forging head of the forging press is installed in a through hole in the furnace top plate. The invention has the advantages of simple technique, convenient operation, and low tendency to recrystallization, enables the high-strength aluminum alloy to be under isothermal conditions all through the direction-change open die forging process, does not need to heat the blank again in the forging process, improves the quality of the forge piece and enhances the forging efficiency; and the forge piece has the advantages of sufficient structure deformation, uniform deformation at each part, and low tendency of cracking. The forge piece has favorable structure properties, and is suitable for industrial production.

Owner:CENT SOUTH UNIV

Heating furnace before forging

The invention provides a heating furnace before forging, which belongs to the technical field of machinery and solves the problems of severe production environment, low work efficiency and large energy waste when traditional heating equipment before forging works. The heating furnace before forging comprises a heating device and a furnace body, wherein the furnace body is provided with a feed opening and a discharge opening, an automatic feeding mechanism is arranged at the feed opening of the furnace body, a conveying device capable of conveying a blank from the feed opening to the discharge opening is arranged in the furnace body, the heating device is arranged on the furnace body and used for heating the blank conveyed in the furnace body, and a heat insulating device is also arranged on the side wall of the furnace body. When in working, the heating furnace before forging has the advantages of good working environment, simple operation, high work efficiency, less energy waste and high quality of processed products.

Owner:杨少华

Inner heating furnace

InactiveCN101862805AHigh degree of automationLabor savingForge furnacesWorking environmentHeating furnace

The invention provides an inner heating furnace, which belongs to the technical field of machinery. The invention solves the problems of lagged heating mode before forging the existing bar materials, severe work environment and the like. The inner heating furnace comprises a heating device and a furnace body, wherein the furnace body is provided with a material inlet and a material outlet, an automatic feeding mechanism is arranged at the material inlet of the furnace body, a conveyer capable of conveying blanks from the material inlet to the material outlet is arranged in the furnace body, the heating device is arranged on the furnace body and is used for heating the blanks conveyed in the furnace body, and a heat insulation device is also arranged on the side wall of the furnace body. The inner heating furnace has the advantages of high atomization degree and labor saving. The bar materials are heated in the sealed furnace body, the operation environment of workers is good, and in addition, energy sources can be saved.

Owner:杨少华

Forging furnace

The invention relates to a forging furnace, which comprises a furnace body, an air source and a fuel gas source; a heating cylinder is arranged in the furnace body, and penetrates through two ends of the furnace body; an air pipe, a fuel gas pipe and a mixed gas pipe are arranged on the furnace body; one end of the air pipe is connected with the air source; one end of the fuel gas pipe is connected with the fuel gas source; the other end of the air pipe and the other end of the fuel gas pipe are converged and then are connected with one end of the mixed gas pipe; the other end of the mixed gas pipe extends to a part adjacent to the heating cylinder; a burner nozzle and an ignition valve are arranged in the mixed gas pipe; and through placing a forging piece into the heating cylinder and opening an air source and the fuel gas source, air and fuel gas are blown out from the burner nozzle, and are in mixed combustion through the ignition of the ignition valve to heat the heating cylinder and further heat the forging piece in the heating cylinder. The forging furnace has a simple structure, heats the heating cylinder therein after the fuel gas is mixed with the air, avoids the condition that the forging piece is heated through coal burning traditionally, makes the best of burning fuel gas, and improves the utilization ratio of energy.

Owner:彭亦楚

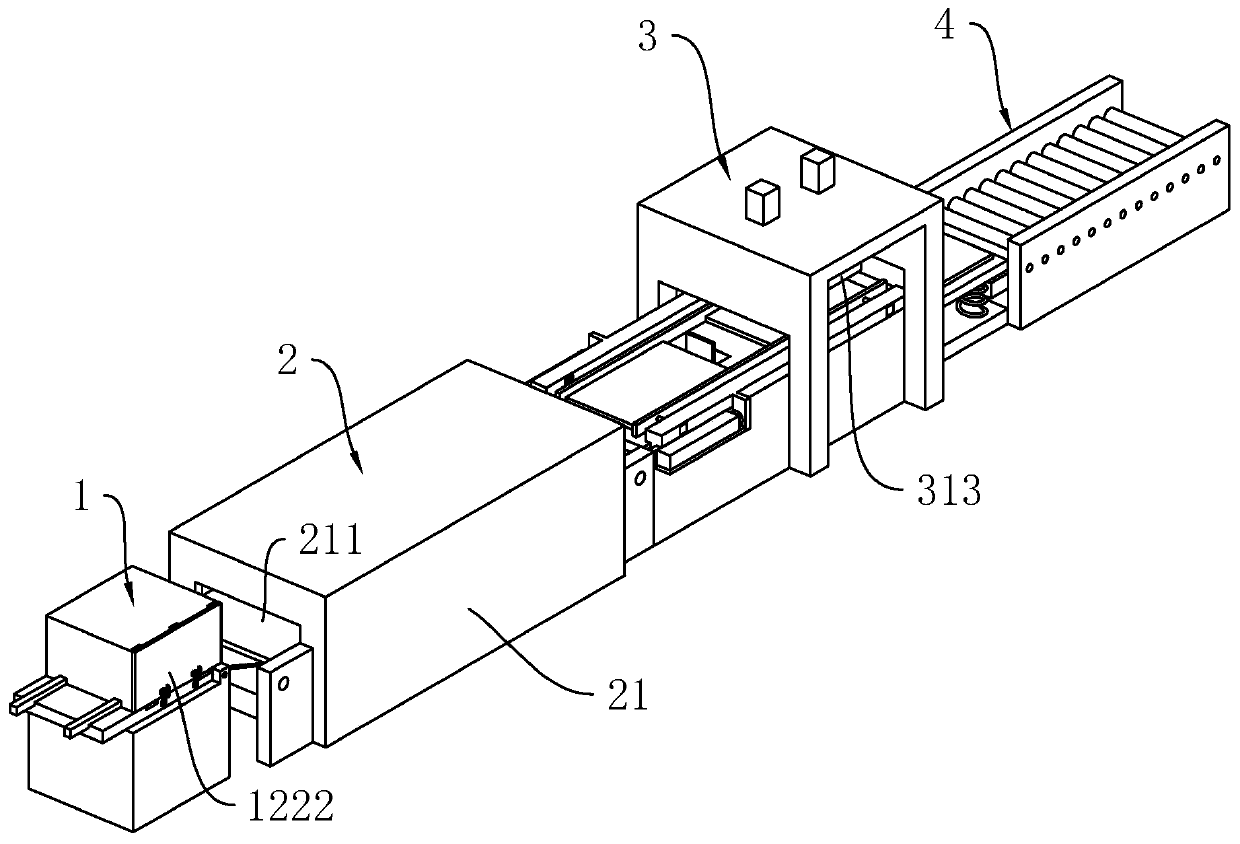

Steel plate hot forging continuous production equipment

ActiveCN109848346AReduce riskEasy to useForging/hammering/pressing machinesForging press detailsSheet steelReciprocating motion

The invention relates to steel plate hot forging continuous production equipment comprising a loading assembly, a heating assembly and a forging and pressing assembly. The heating assembly comprises aheating furnace. The heating furnace is internally horizontally provided with a conveying device, the forging and pressing assembly comprises a base, the upper surface of the base is flush with the upper surface of the conveying device, the length direction of the base is the same as the conveying direction of the conveying device, and the base comprises a temporary storage table capable of abutting against one end of the conveying device and a working table with one end abutting against the other end of the temporary storage table; the upper side, corresponding to the working table, of the base is provided with a forging and pressing head capable of doing reciprocating motion in the vertical direction, the two sides of the base are each provided with a moving frame and a first driving mechanism capable of driving the moving frame to move in the length direction; and the sides, getting close to each other, of the moving frames are provided with clamping plates with the length the sameas the length of the base and second driving mechanisms capable of driving the clamping plates to move in the direction getting close to each other. The steel plate hot forging continuous productionequipment can realize automatic continuous work from heating to forging and pressing of a workpiece, the working efficiency is improved, and the dangerous effect is reduced.

Owner:青岛宏联电器有限公司

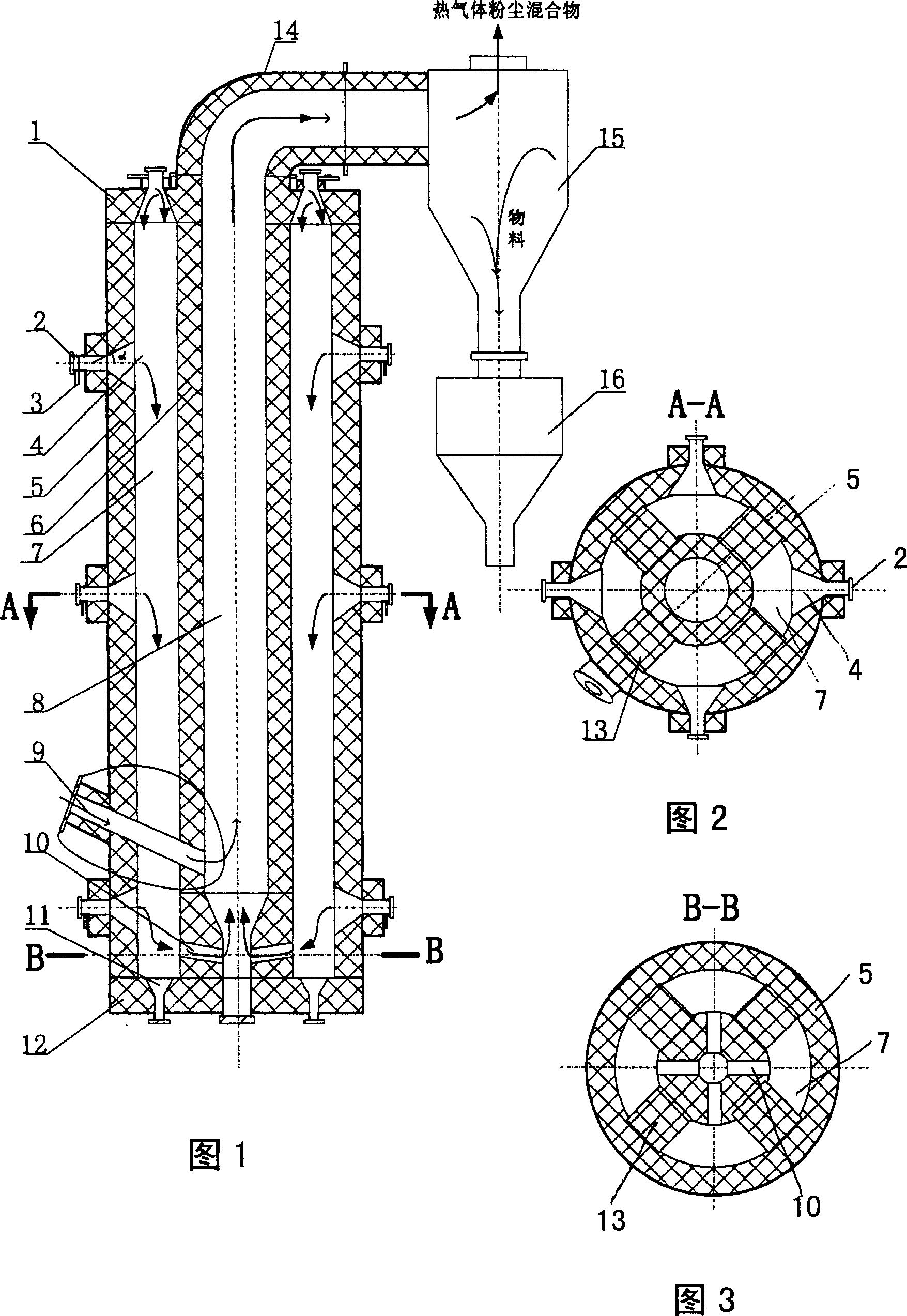

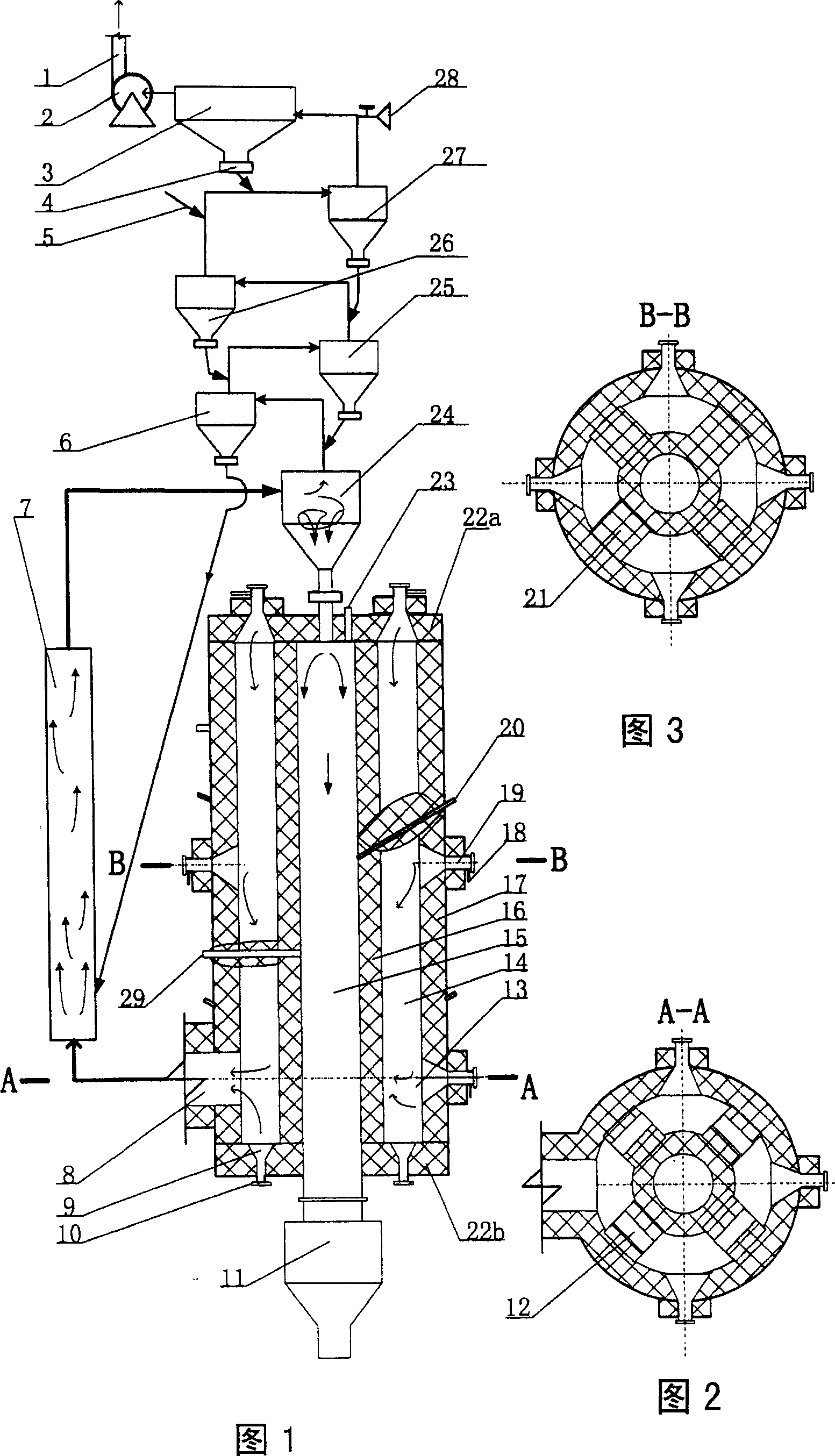

Blaze insulating fluidized forge furnace

InactiveCN1631573AFast mass transferReduce energy consumptionForge furnacesCombustion chamberEngineering

The invention is about the fire stove, which concerns fire equipment technique field. The invention makes use of firing heat the stove indirectly, avoiding the direct contact of fire and material, so it overcome the material over fire phenomenon, at the same time, the smoke go to the stove up to down, increasing the heat time for a time. Compared with the fire material directly, it increases the heat effect by much time. The material in the invention can stop for some seconds to hours, the temperature of the stove is 500-1300 degC, the difference in temperature is between minus 5 and plus 5 degC. The invention transfers the heat fast, the temperature in the stove is even, and it uses low energy.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

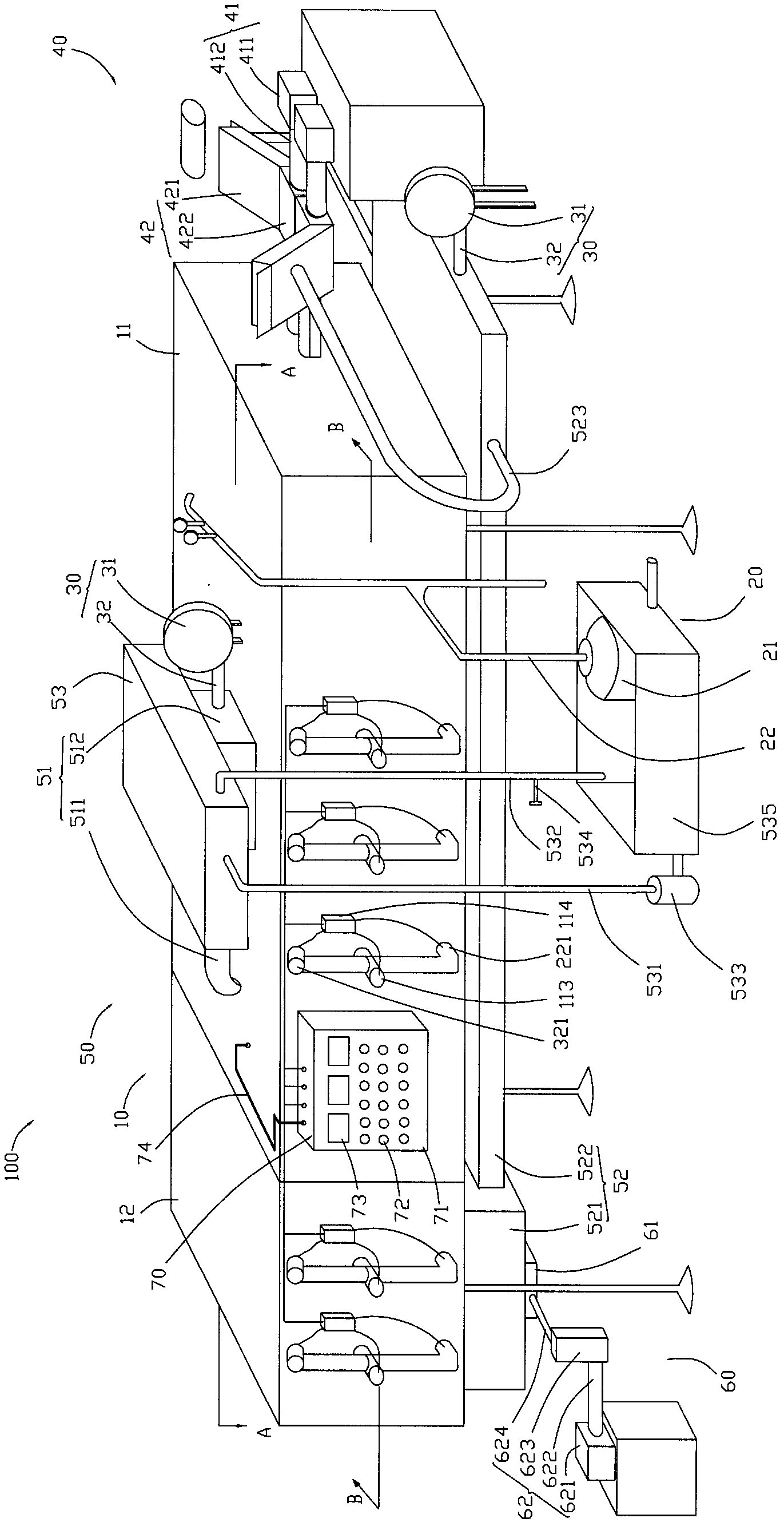

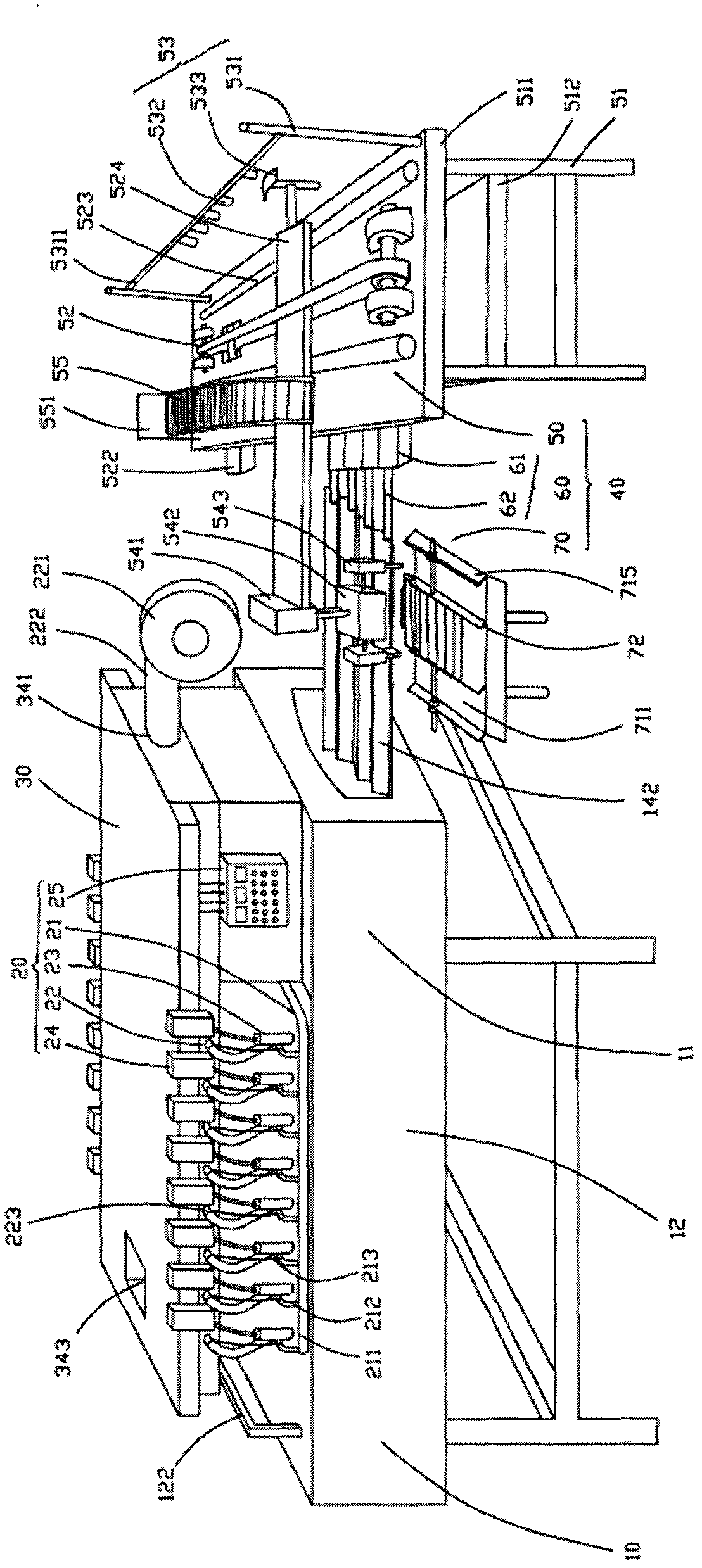

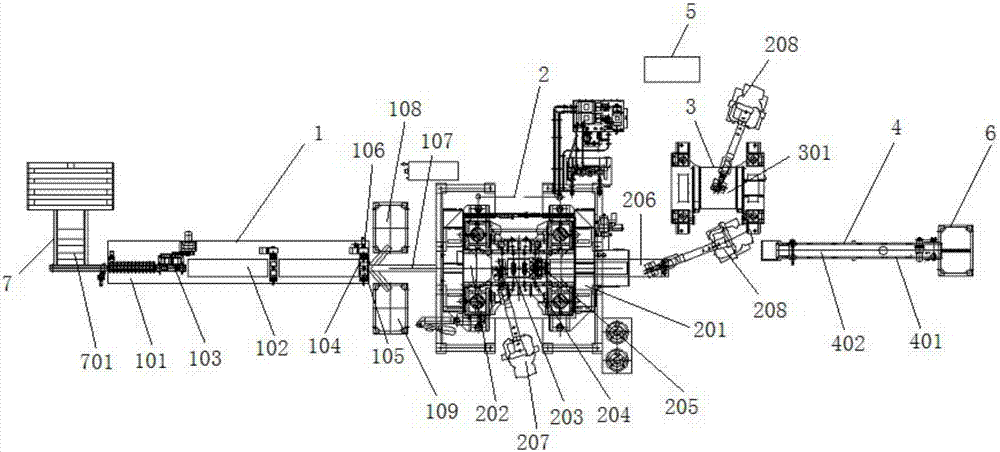

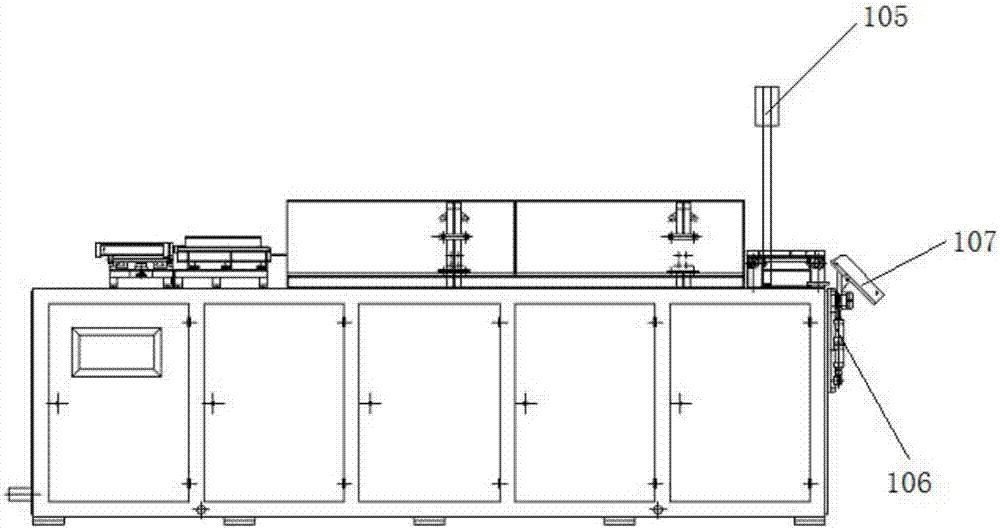

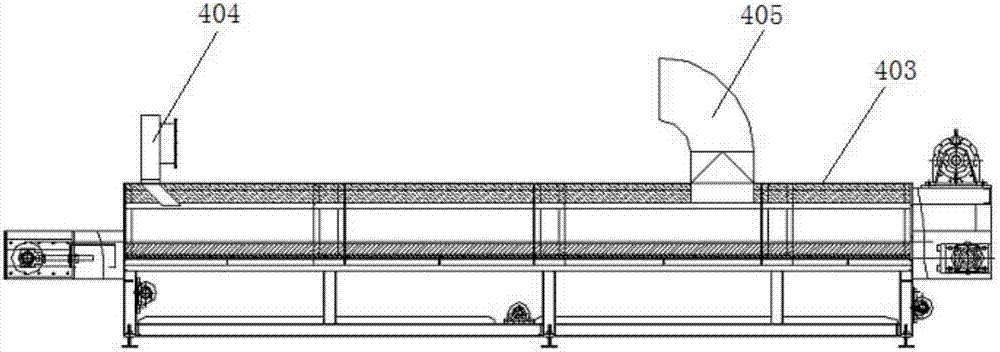

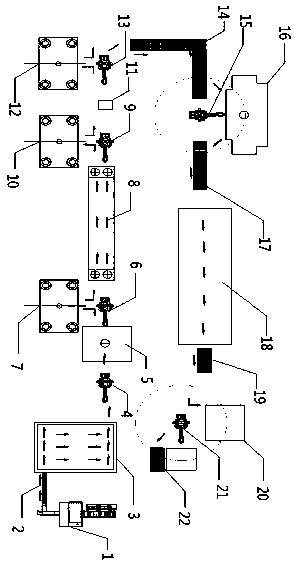

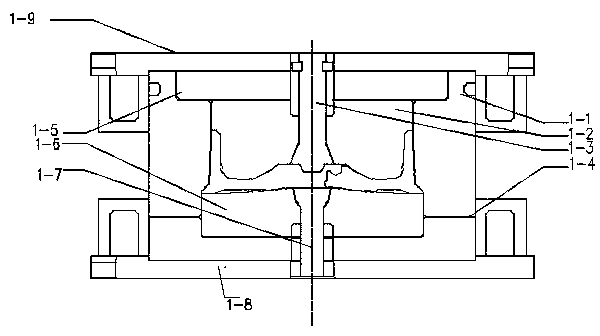

Full-automatic non-quenched-and-tempered steel forge piece production line

ActiveCN107442726AEmission reductionImprove electricity efficiencyForging/hammering/pressing machinesForging press drivesProduction linePunching

The invention discloses a full-automatic non-quenched-and-tempered steel forge piece production line. The production line comprises heating equipment, forging equipment, edge cutting and punching equipment, a cooling temperature control conveying chain, a finished product box and a programmable control system which are sequentially connected. According to the production line, a forge piece is heated at a time, continuous and automatic machining of multiple processes including upsetting, pre-forging molding, final forging molding, edge cutting, punching, heat treatment and the like is achieved, all machining processes need to be operated by one person, and the beneficial effects of being high in production efficiency and good in product quality are achieved.

Owner:CHONGQING VOCATIONAL INST OF ENG +1

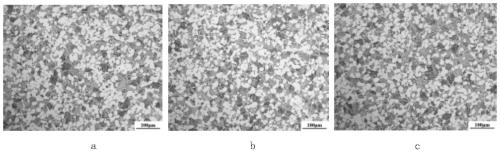

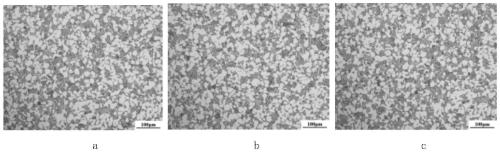

Forging method of Ti80 titanium alloy

ActiveCN111230012AEasy to operateGuaranteed to heat throughMetal-working apparatusForge furnacesTitanium alloyImpact toughness

The invention provides a forging method of a Ti80 titanium alloy. A segmented heating method is adopted before forging in a beta single-phase zone so as to ensure that a titanium alloy billet is through heated and effectively avoid the excessive growth of grains. According to the forging method, the titanium alloy billet deforms sequentially from a temperature above a phase transition point to a temperature below the phase transition point, so that the sufficient deformation amount per heating number is ensured, and the cracking of the titanium alloy billet is prevented. The Ti80 titanium alloy bar prepared by the forging method has the uniform structure at head, middle and tail parts; the primary alpha phase is equiaxial, and the content of the primary alpha phase is 60%-80%; after the bar is annealed at the temperature of 100 DEG C under the phase transition point, the head, middle and tail parts of the bar have stable mechanical properties, the room temperature tensile strength is greater than or equal to 900MPa, the yield strength is greater than or equal to 750MPa, the elongation percentage is greater than or equal to 8%, the percentage reduction of area is greater than or equal to 15%, and the impact toughness at the temperature of minus 10 is greater than or equal to 35J / cm<2>; and the Ti80 titanium alloy bar has uniform structure and stable performances at each part, and meets the requirements of current marine applications. The forging method has the characteristics of simple operation and strong operability.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

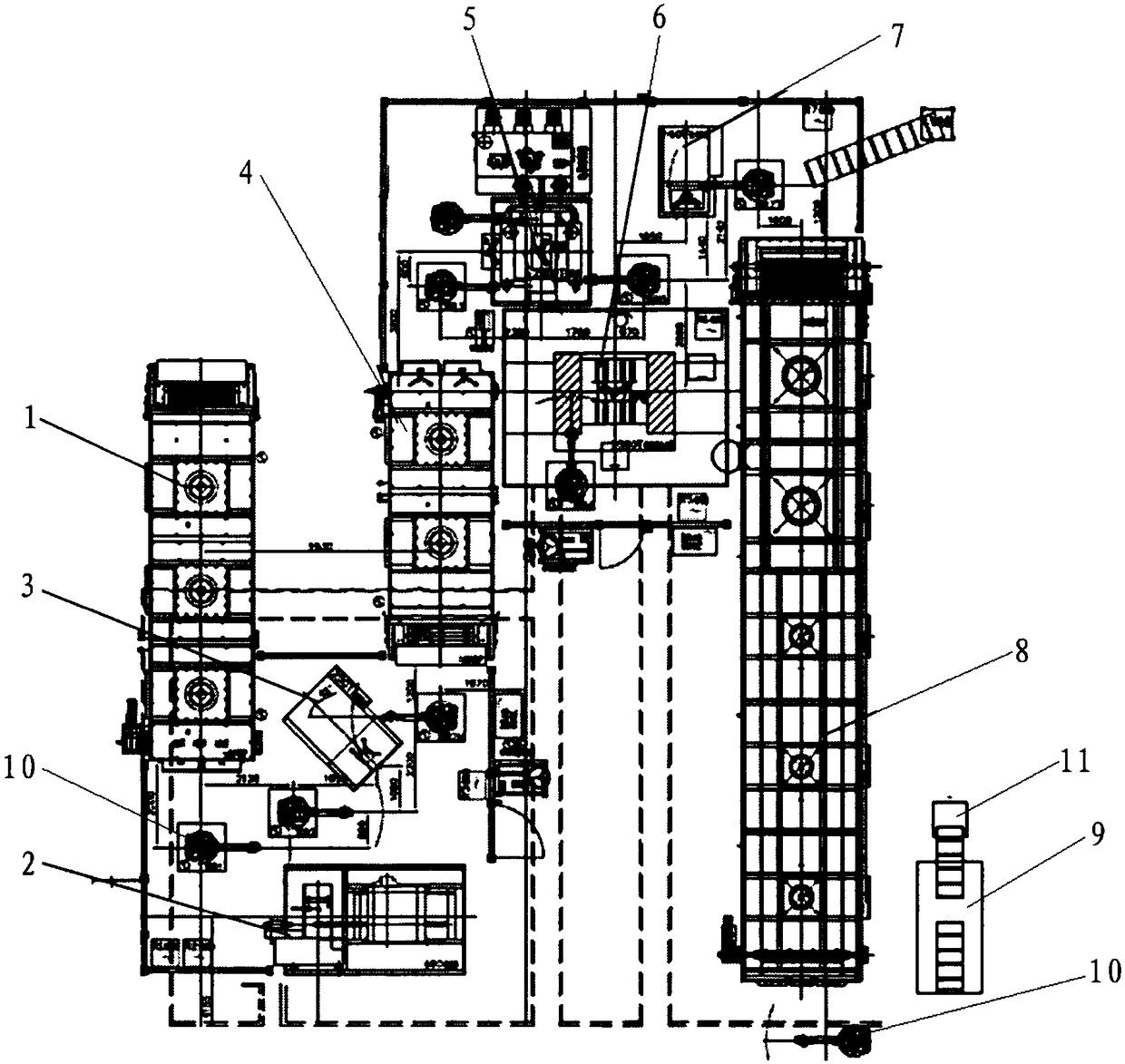

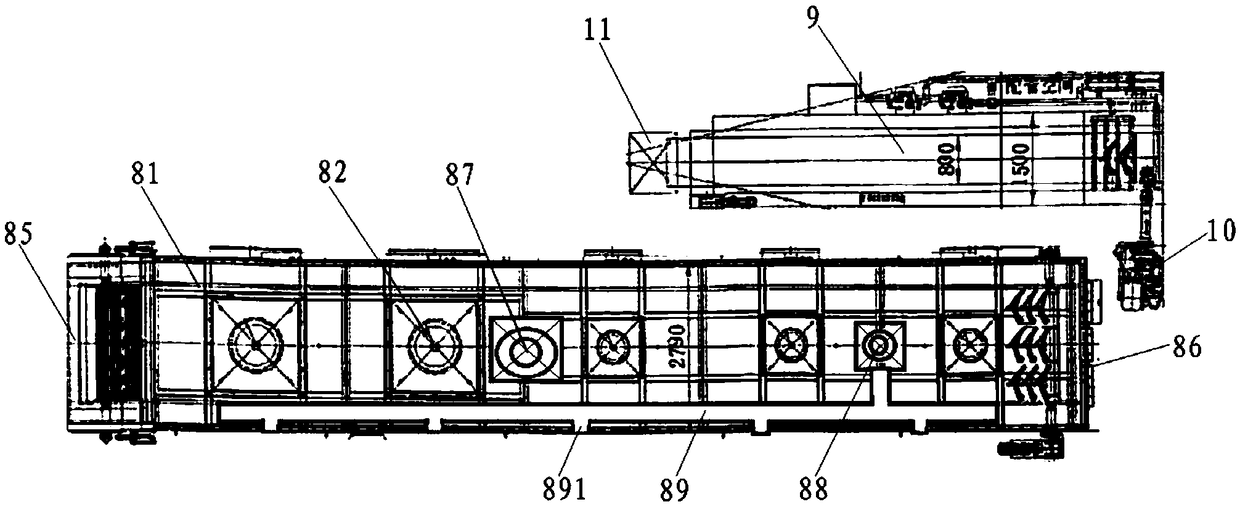

Automobile control arm forging production line and forging forming technology

PendingCN108817307AReduce labor intensityImprove working environmentRailway componentsForging/hammering/pressing machinesSolution treatmentProduction line

The invention discloses an automobile control arm forging production line. The production line comprises a blank making area, a die forging area and a heat treatment area which are sequentially arranged according to a production technology. A plurality of mechanical arms used for conveying workpieces are arranged among the areas. The blank making area comprises a first heating furnace and a rollerforging machine. The die forging area comprises a second heating furnace and a die forging press machine set, the die forging press unit is used for forging forming of a blank obtained after secondary heating, and the workpieces are conveyed to the heat treatment area through the mechanical arms. The heat treatment area comprises a solution treatment furnace and a cooling device, the solution treatment furnace is used for carrying out solution treatment on the forged workpieces, the workpieces are conveyed to the cooling device through the mechanical arms, and a finished product bin is connected to a discharge port of the cooling device. The automobile control arm forging production line is reasonable in layout, high in automation degree and good in stability; the heat treatment area is additionally arranged, so that the production time is shortened, and the production efficiency is improved; and the heating process adopts jet flow heating, so that the heating speed and heating uniformity of the blank are improved, and the product quality is effectively improved.

Owner:海安金锻工业有限公司

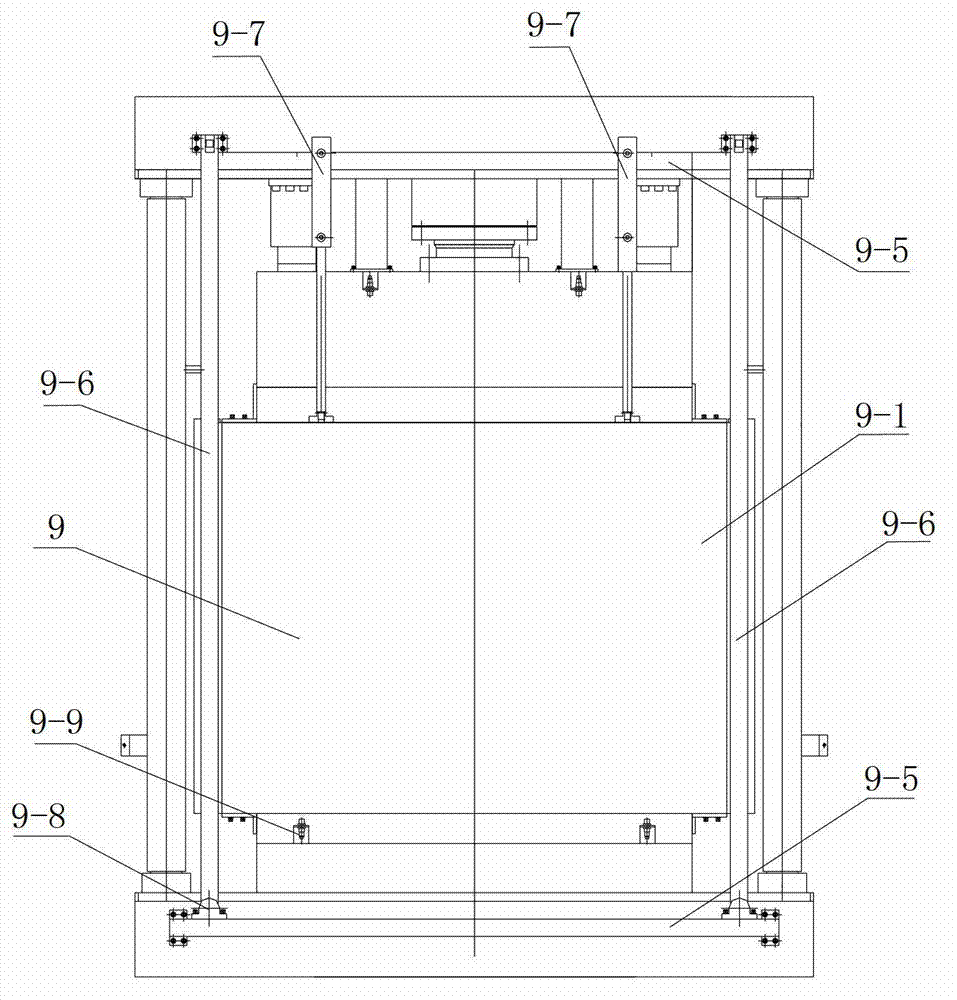

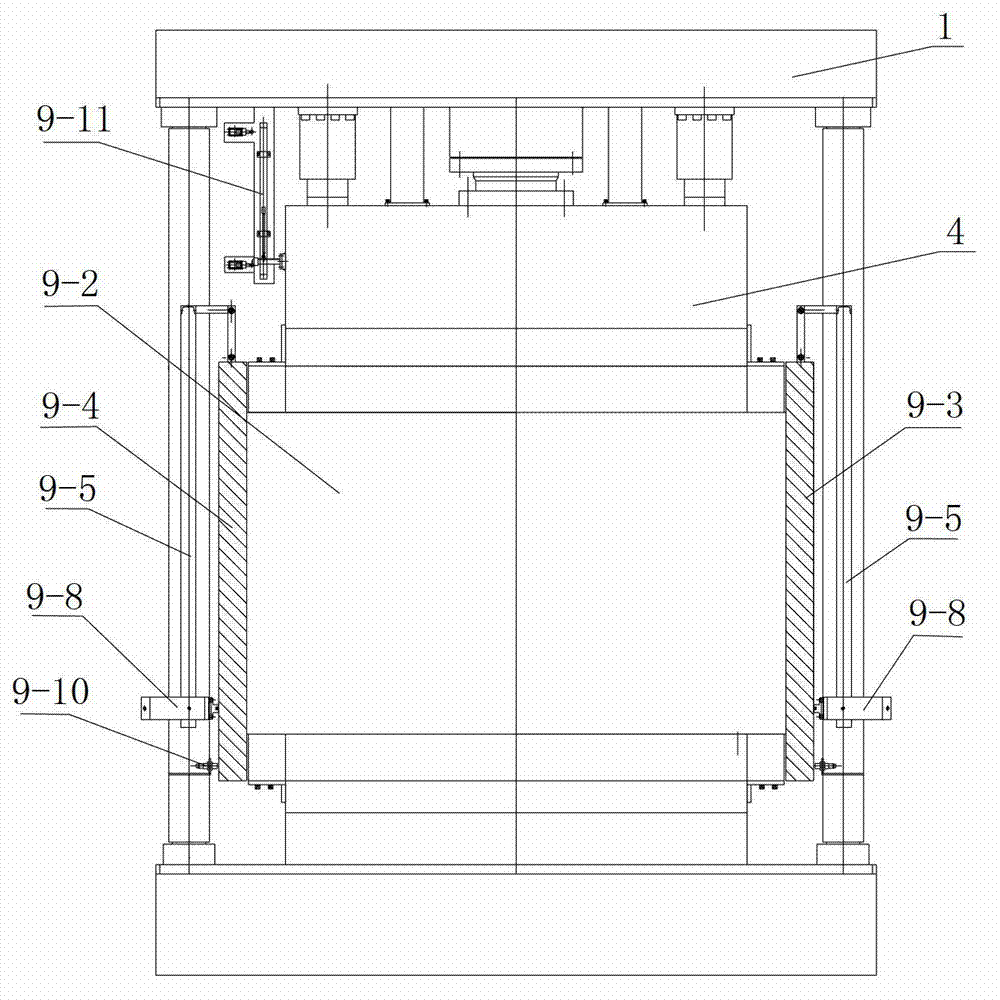

Movable closed isothermal forging die heating device

InactiveCN106391979AAvoid getting lostNo churnForging/hammering/pressing machinesForge furnacesEngineeringHeat losses

The invention discloses a movable closed isothermal forging die heating device. The movable closed isothermal forging die heating device comprises a heating furnace box. Holes the same as press die bases in size are formed in the upper end face and the lower end face of the heating furnace box. Guide rails are laid beside a press. A heating furnace can be accurately arranged on the press lower die base through the guide rails. The upper die base penetrates the hole formed in the upper end face of the heating furnace to enter the heating furnace. In the forging process, the heating furnace box is completely closed, and temperature losses are avoided. It is guaranteed that in the forging process, heat losses are avoided, the die and forged blank temperature is constantly unchangeable, reduction of the temperature of a forged blank in the forging process is avoided, forging cracking of a deformation temperature sensitive material is eliminated, and superplastic deformation of a metal material is better achieved. The movable closed isothermal forging die heating device is easy to manufacture, and real isothermal forging can be achieved.

Owner:AECC AVIATION POWER CO LTD

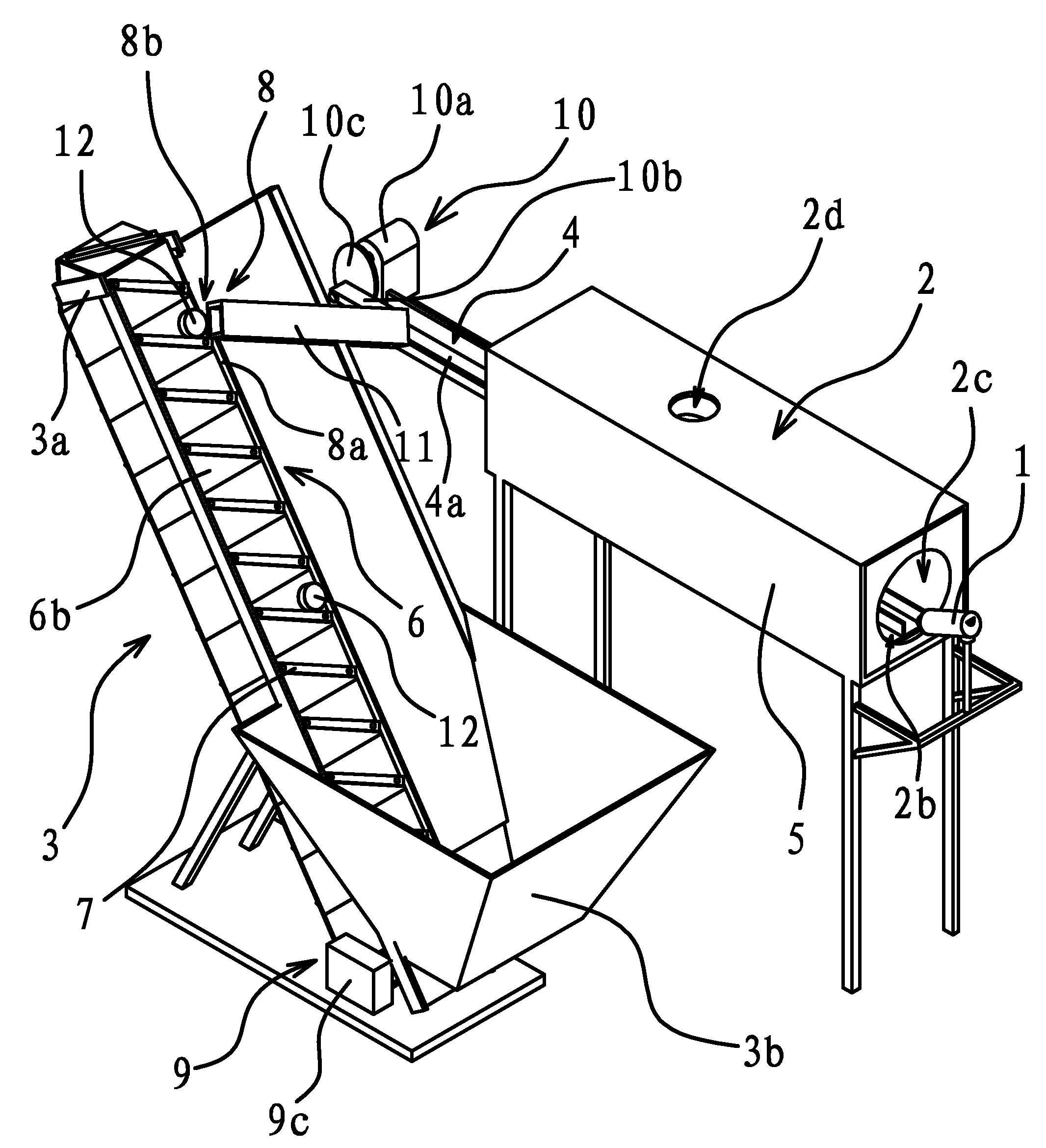

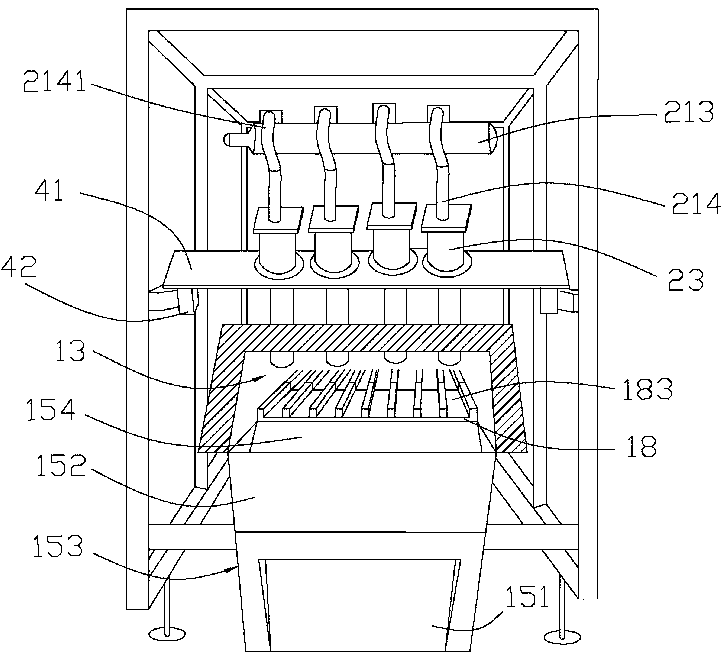

Continuous forging heating furnace

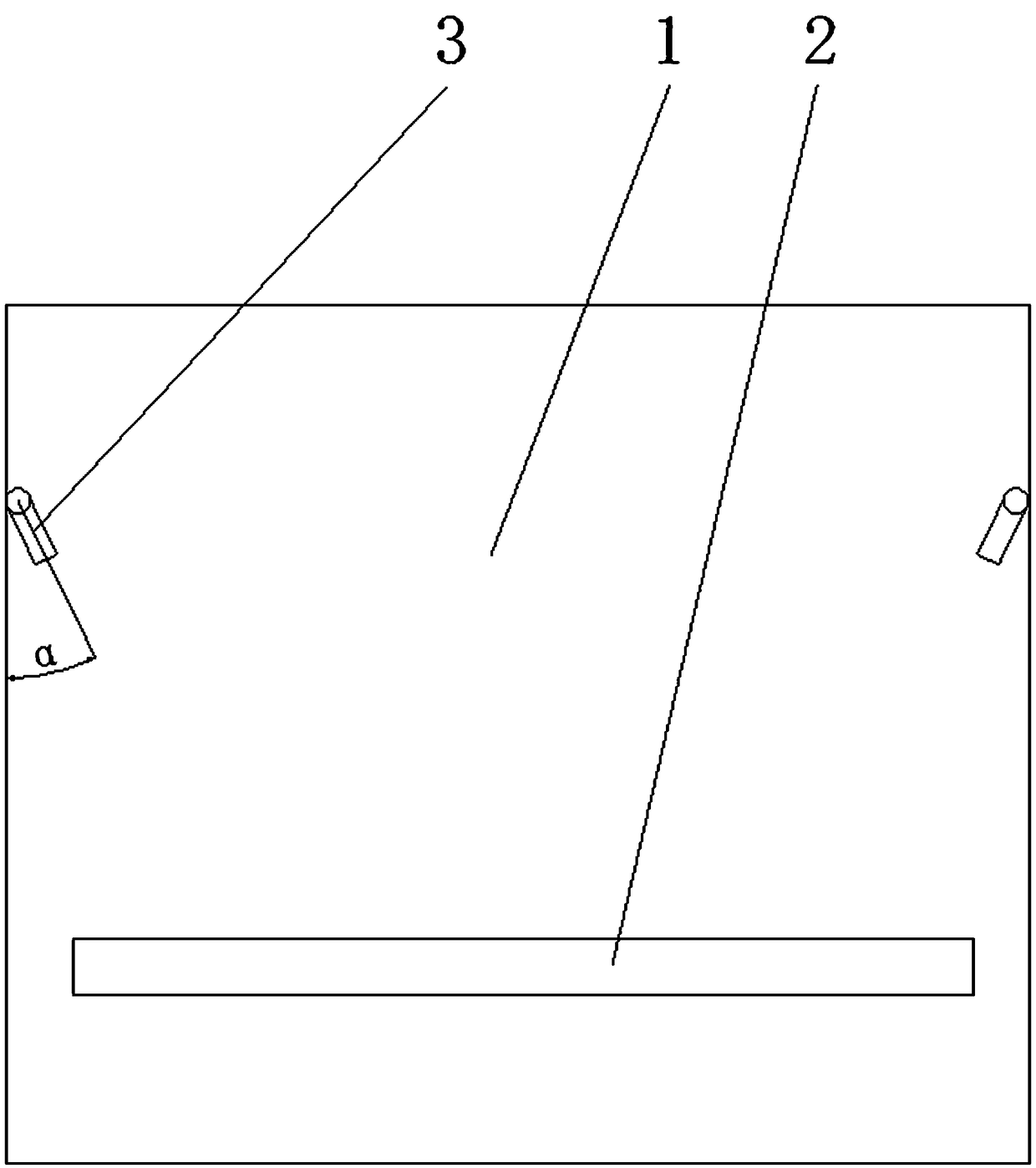

ActiveCN103302223AMeet the temperature requirementsEasy to saveForge furnacesAcute angleHeating furnace

The invention provides a continuous forging heating furnace which comprises a furnace body, a heating mechanism and a machine frame; the furnace body and the heating mechanism is arranged on the machine body; the furnace body comprises a furnace chamber which runs through the furnace body; a furnace wall as well as the feeding end and the discharging end of the furnace body are correspondingly formed; a guide groove is formed in the furnace chamber; the heating mechanism comprises a plurality of burners; the burners are installed at the discharging end close to the furnace body and the top part of the furnace body, and enter into the furnace chamber through the furnace wall in a way that acute angles are formed between the directions of the burners and the material guiding direction. The continuous forging heating furnace can fully preheat materials and facilitates heat energy conservation and utilization.

Owner:彭亦楚

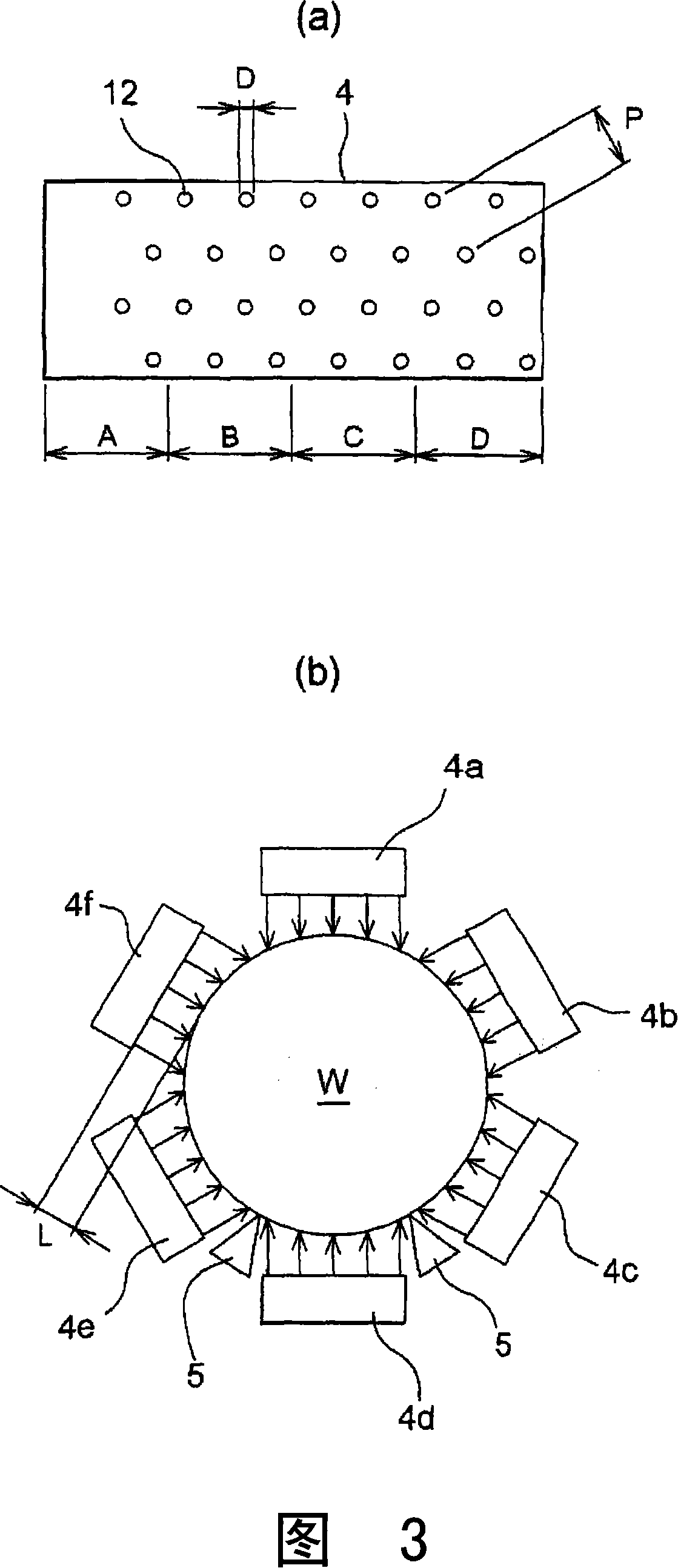

Steel blank heating device

InactiveCN101152655AMore than heatingExceed thermal efficiencyCharge supportsMaintainance of heating chambersCombustorEngineering

A billet heating mechanism comprises a body casing (2) composed of a frame (3) without furnace wall and with communicated inside and outside; a slide track (5) for supporting the billet (W) filled in the body casing (2) under the atmosphere condition; and a plurality of pure oxygen or oxygen boosting combustors (4) arranged on the body casing (2) for making the burning flame to strike the total length and full circumference of the billet (W) to heat the billet (W). The ratio of the diameter (D) of the nozzle (12) of the combustor (4) and the distance (L) between the outer surface of the billet (W) and the nozzle (12) is defined from 0.02 to 0.04, the interspace (P) between the nozzles 12 is 30 to 50 times of the diameter (D) of the nozzle. Adopting the invention, the heating ability and heat efficiency exceed the electromagnetic induction heating mode can be realized.

Owner:CHUGAI RO CO LTD

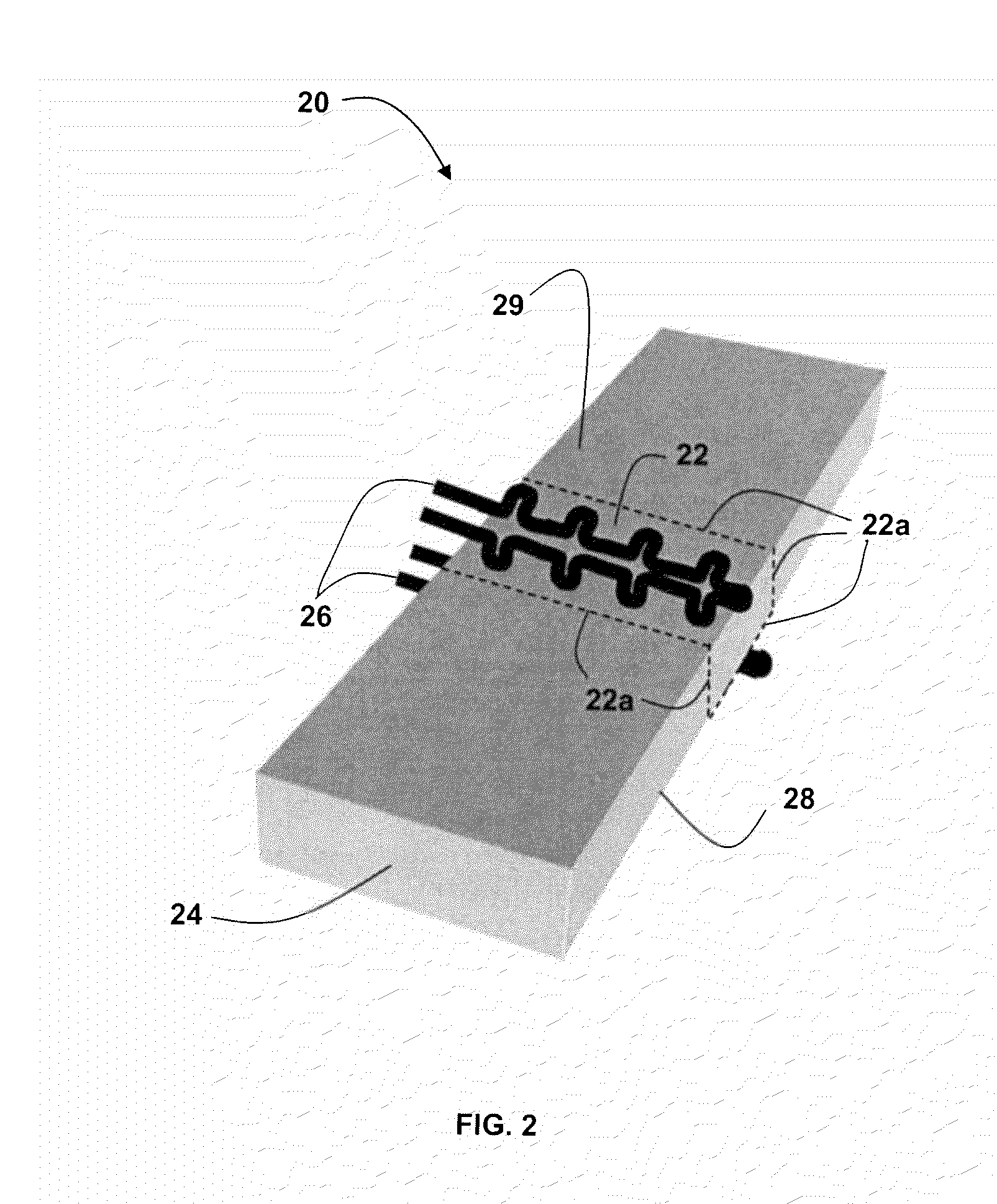

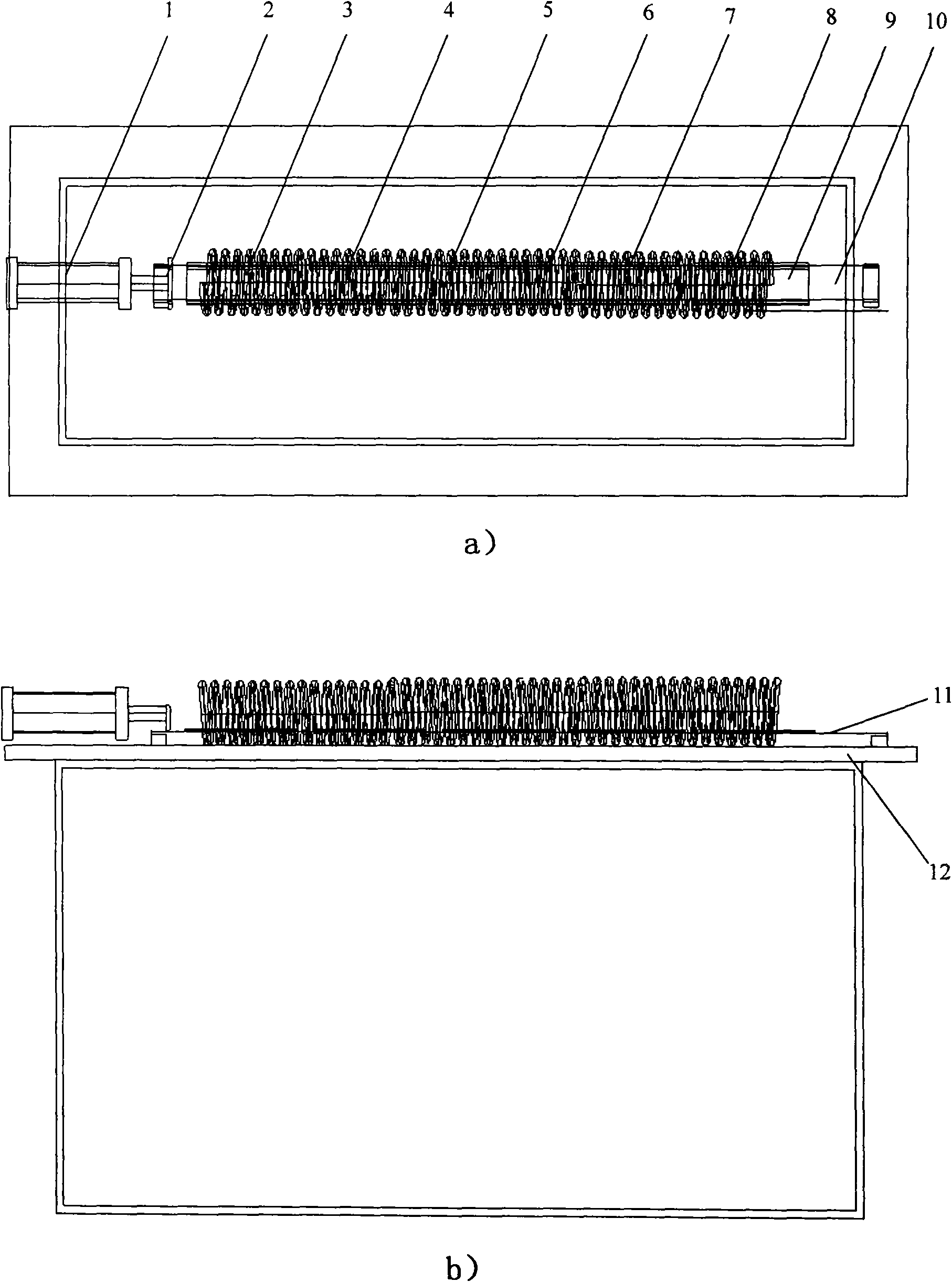

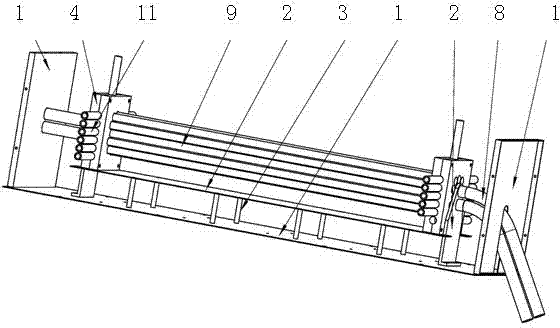

Horizontal type device for reheating semi-solid metal blank material

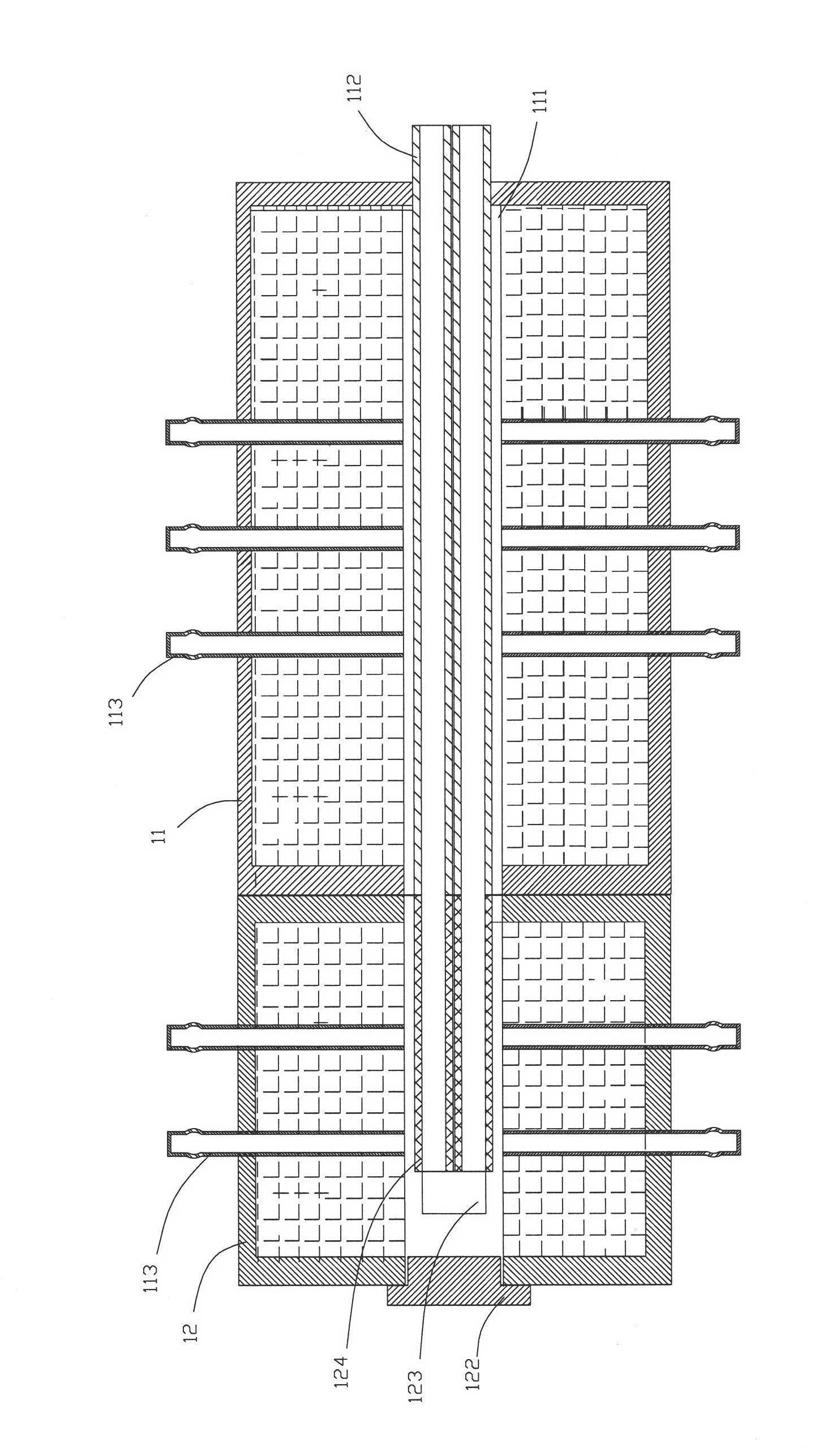

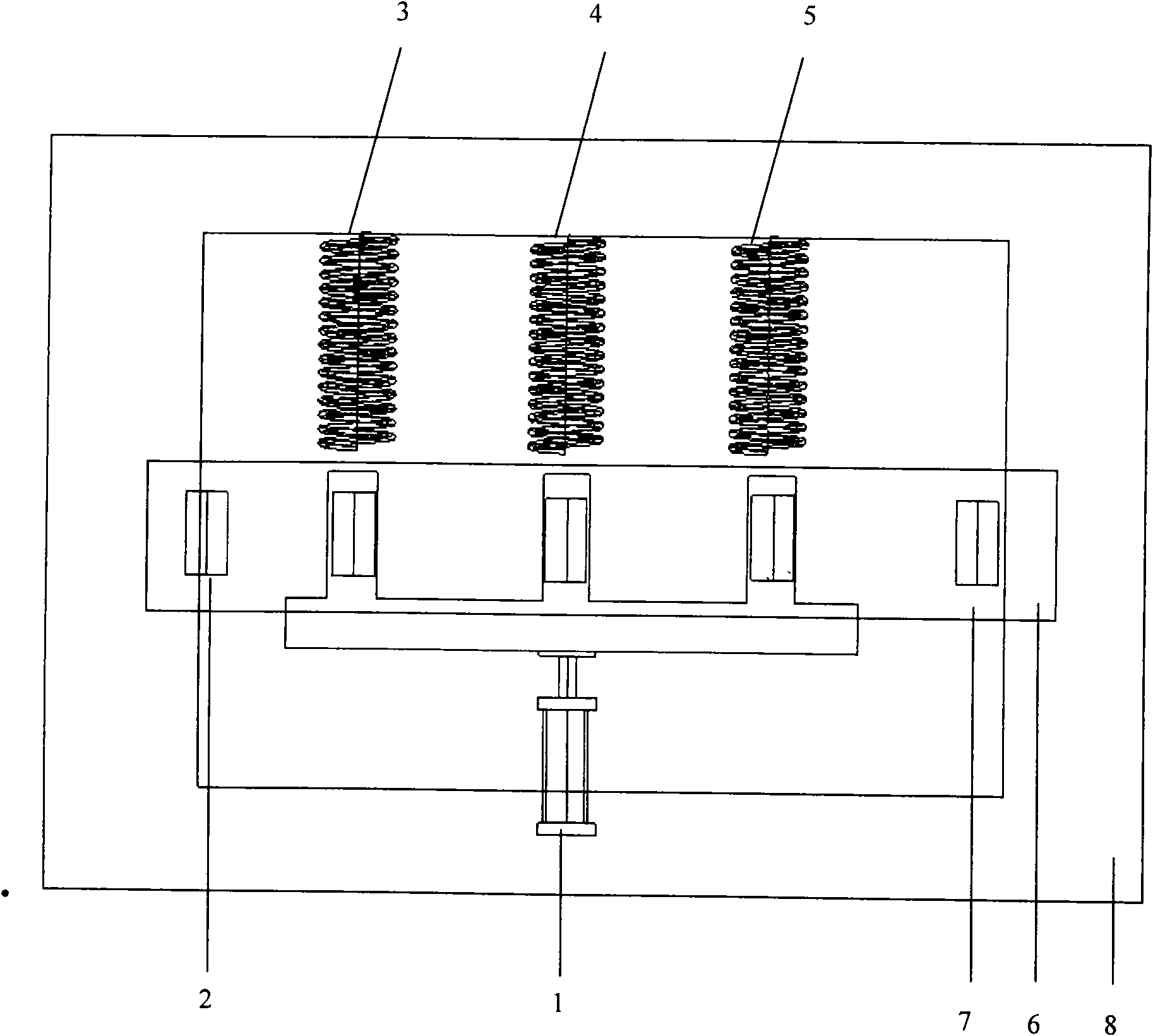

The invention relates to a horizontal type device for reheating a semi-solid metal blank material, which comprises an induction heating power supply, an induction heating mechanism, and a blank material carrying mechanism, and is provided with five stations, such as at least three material heating stations, a material placing station and a material discharging station, wherein the induction heating mechanism adopts three sections of induction heating coils which are separately and horizontally arranged, and all the induction heating coils are mutually electrically communicated and arranged on the three material heating stations respectively; the blank material carrying mechanism comprises a feed mechanism and a blank material transporting device; the blank material transporting device is a delivering device processing in front of each station; and the feed mechanism is positioned in front of each induction heating coil. The induction heating three-section heating mode is selected to make the heating of the blank material and the distribution of the temperature field more even and reasonable. The horizontal structure is adopted, the blank material cannot collapse or discharge fluid, and the blank material transportation is simple and convenient because of a large contact surface between the blank material and a supporting part. The blank material is allowed to have a higher liquid phase fraction, which is convenient for the thixotropic forming of more complicated parts.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG

Mould heating furnace for isothermal forging

The invention relates to a mould heating furnace for isothermal forging. The mould heating furnace is characterized in that: (1) the heating furnace mainly comprises an outer furnace and an inner furnace, the outer furnace has a large annular structure, and the inner furnace is a cylindroid consisting of a fireproof layer and is sleeved in the center of the inner cavity of the outer furnace; and (2) an outer furnace heating element is made of resistance wires which are annularly equidistantly distributed on the inner edge surface of the inner cavities of the upper furnace body and the lower furnace body from up to down; and an inner furnace heating element is made of a resistance belt; and the resistance belt is wound into a loop shape and is uniformly hung on the outer surface of the cylinder of the inner furnace. Compared with the prior art, the heating furnace heats large and super-large circular overall frame isothermal forging moulds with single holes, ensures the normal heating speed and solves the problems that large temperature gradient change influences the moulds and k403 materials have thermosensitivity when heated.

Owner:SHAANXI HONGYUAN AVIATION FORGING

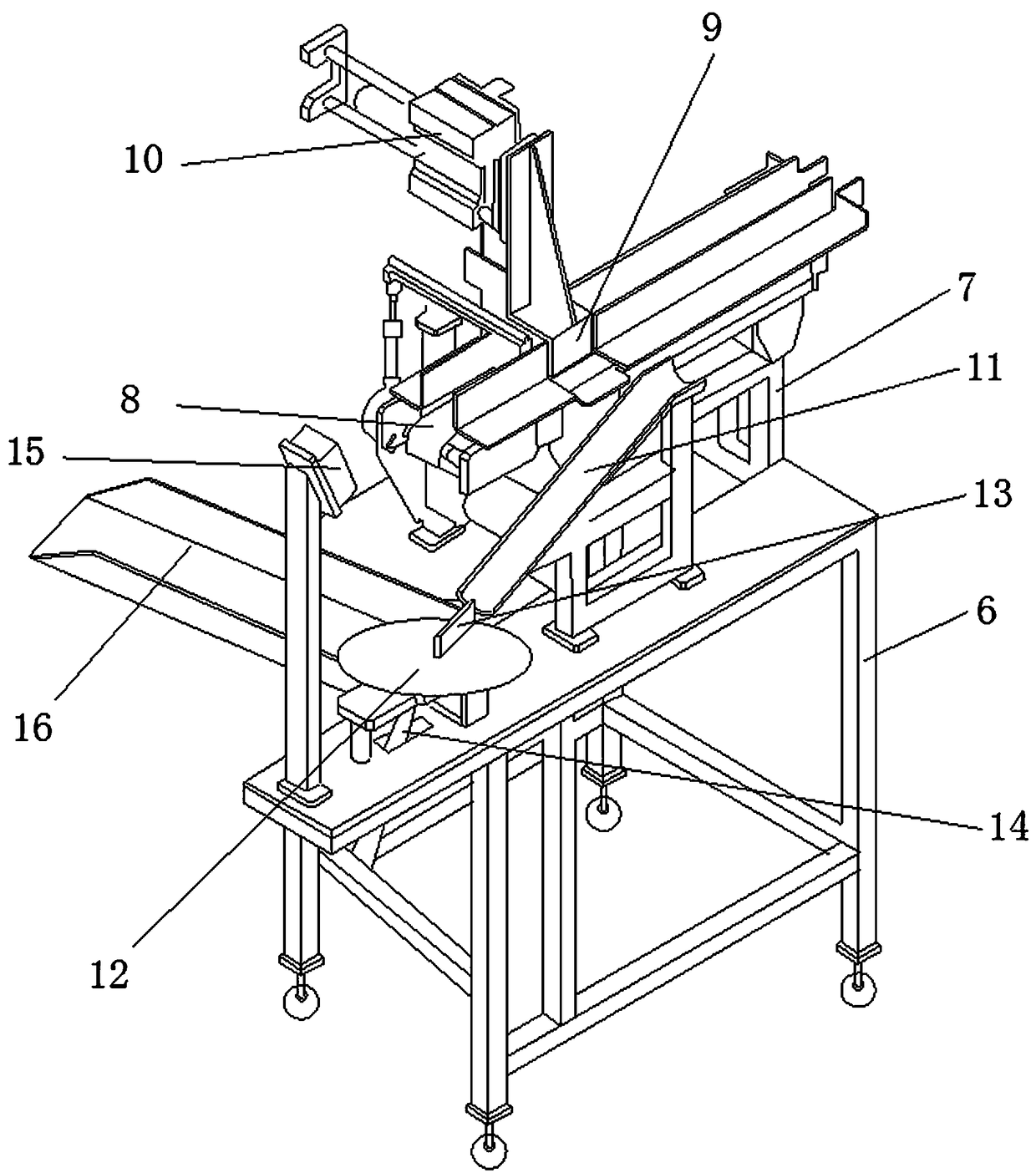

Heating furnace for continuous forging production

The invention provides a heating furnace for continuous forging production. The heating furnace comprises a furnace body, a heating mechanism and a frame, the furnace body and the heating mechanism are arranged on the frame, the furnace body comprises furnace walls, a hearth, a feed end and a discharge end, the hearth is enclosed by the furnace walls, a guide groove is formed in the hearth, the heating mechanism comprises a plurality of burners, the burners penetrate the furnace walls and enter the hearth, the discharge end is provided with a discharge frame, the discharge frame comprises a bottom wall, the bottom wall is connected with the bottom surface of the hearth, and an included angle is formed between the bottom wall of the discharge frame and the horizontal feeding direction of the hearth and ranges from 35 degrees to 45 degrees, so that materials cannot stick to the bottom wall and can smoothly slide out, the impact force on a furnace door is small, and the furnace door cannot deform or be damaged.

Owner:彭亦楚

Vehicle wheel automatic closed-die forging production line, vehicle wheel automatic closed-die forging production technology and aluminum alloy vehicle wheel

PendingCN109623286AImprove mechanical propertiesImprove physical performanceRimsForging press detailsProduction lineManufacturing technology

The invention relates to the technical field of automobile wheel hub manufacturing, and particularly discloses a vehicle wheel automatic closed-die forging production line, a vehicle wheel automatic closed-die forging production technology and an aluminum alloy vehicle wheel. The vehicle wheel automatic closed-die forging production technology comprises the steps of bar material saw cutting, bar material preheating, vehicle wheel blank rock rolling pressing, vehicle wheel blank initial forging closed die forging, vehicle wheel blank final forging closed die forging, vehicle wheel blank chambering, window and central hole punching, compound forging, spinning, vehicle wheel blank heat treatment and a vehicle wheel machining. With the vehicle wheel automatic closed-die forging production technology, the pressing technology of aluminum alloy wheels is simplified, the cost, time and manpower needed for secondary machining and shaping in the later period are greatly saved, and the safety andthe working efficiency of equipment in manufacturing are improved; and additionally, workpiece conveying and feeding are accurate in positioning and convenient to operate, the automation degree is high, and therefore, the requirements of an automatic manufacturing technology of aluminum alloy wheels can be met.

Owner:CITIC DICASTAL

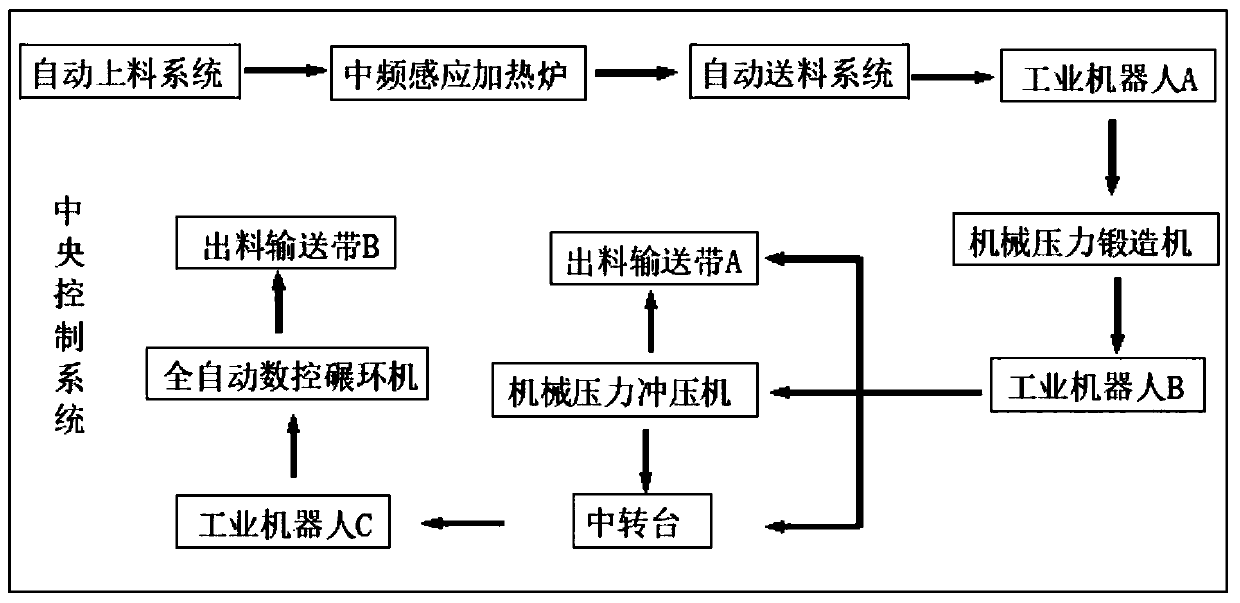

Flexible automatic forging production line and working process thereof

InactiveCN110405132AImprove the level of flexibilityImprove versatilityHandling devicesForge furnacesNumerical controlControl area

The invention provides a flexible automatic forging production line and a working process thereof. The flexible automatic forging production line comprises an operation area and a control area, wherein the operation area comprises a medium-frequency induction heating furnace, a mechanical pressure forging machine, a mechanical press, a full-automatic numerical control ring rolling machine, an automatic charging system, an automatic feeding system, a discharging and conveying system and an industrial robot carrying system; and the control area comprises a central control system which is electrically connected with an operation area. Compared with a common industrial mechanical arm type automatic forging line, the central control system is used for unified regulation and control, the production of a single-category product is changed into the production of a multi-category product in a mode of calling all production units, so that the flexibility level of the production line is greatly improved; and meanwhile, through the reasonable division of labor of a plurality of industrial robots, a task is completed by a plurality of industrial robots by being decomposed into a plurality of steps, so that the production efficiency is greatly improved.

Owner:泰州浙华机械精锻有限公司

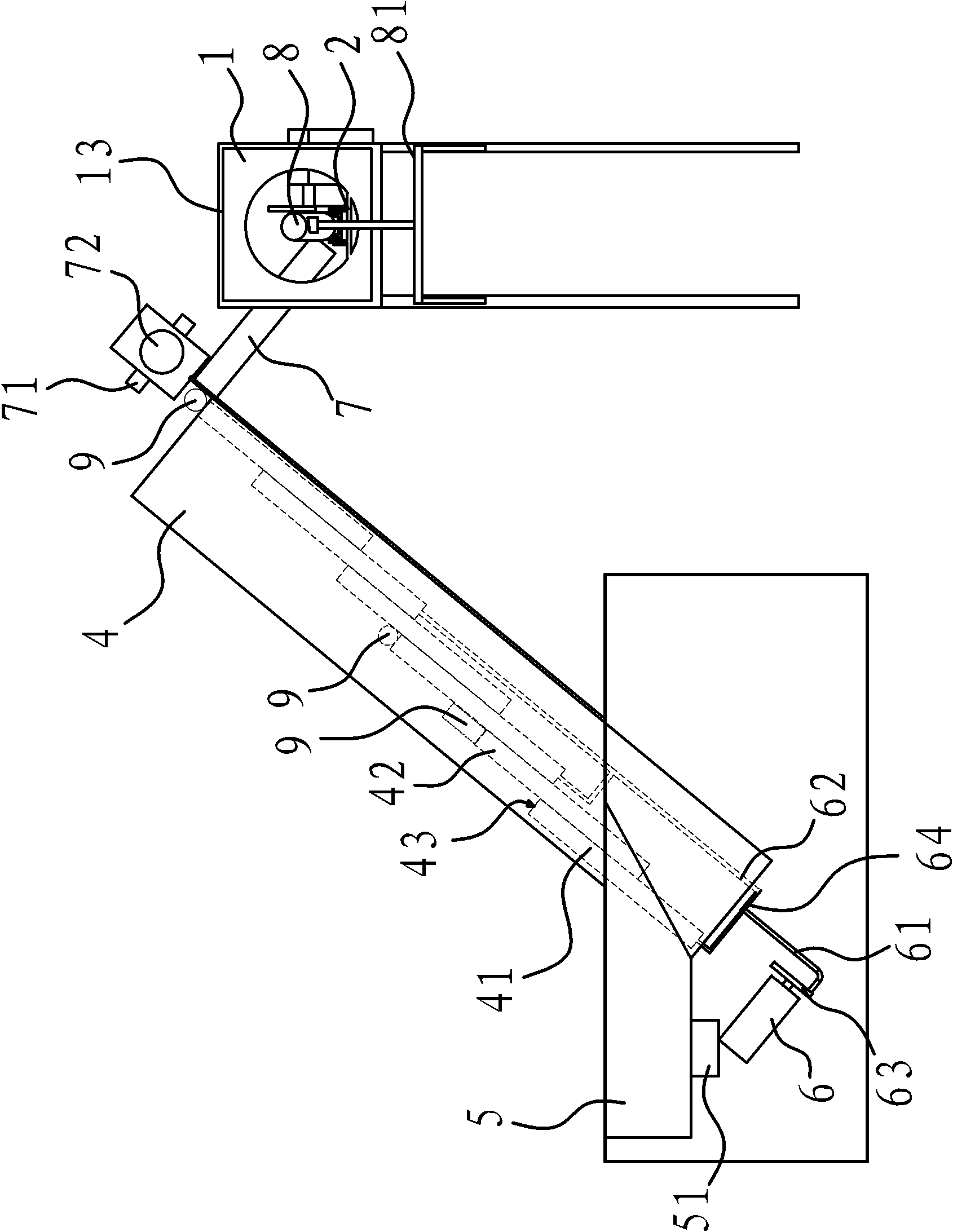

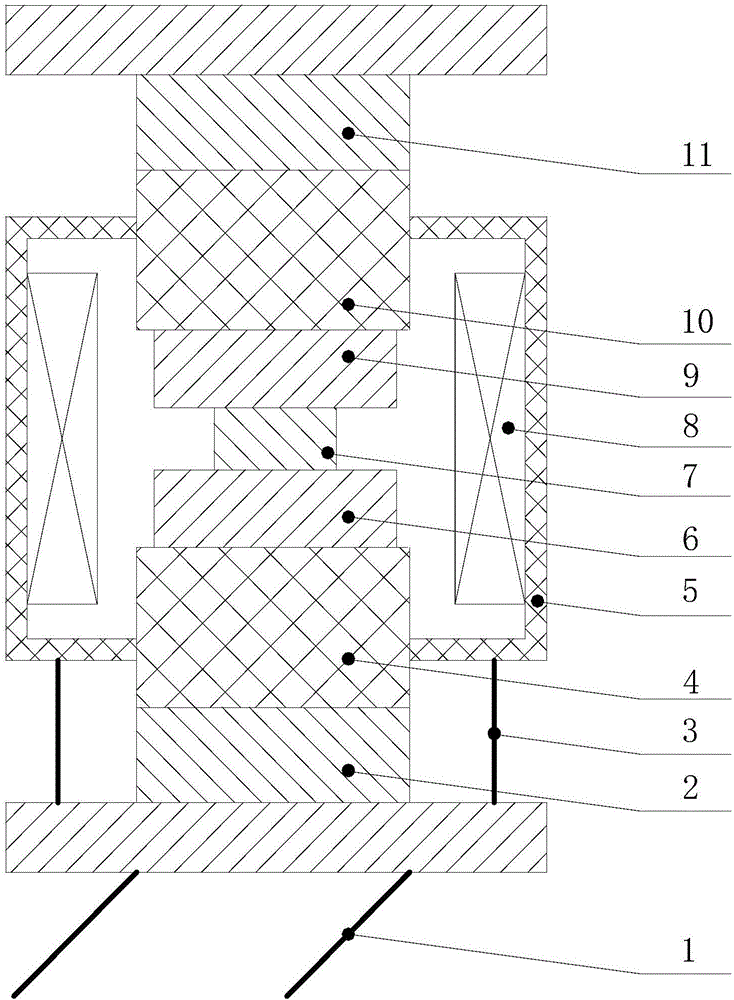

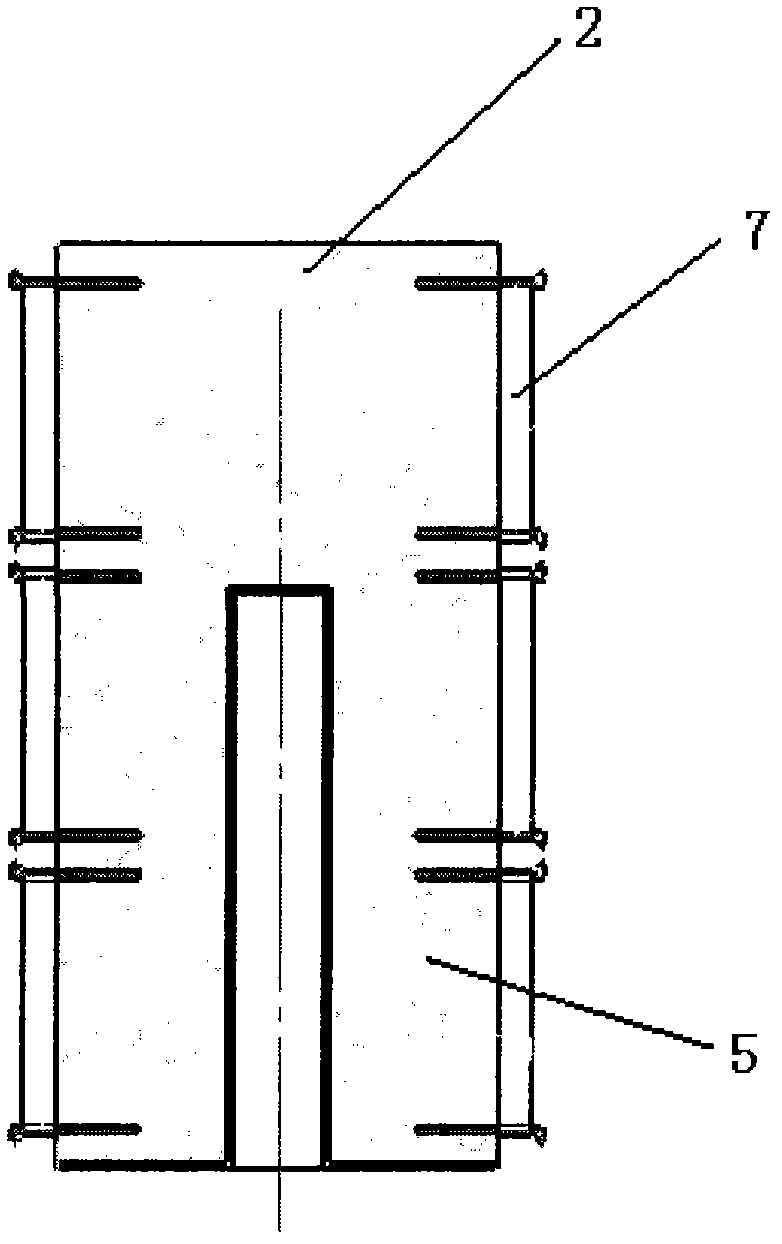

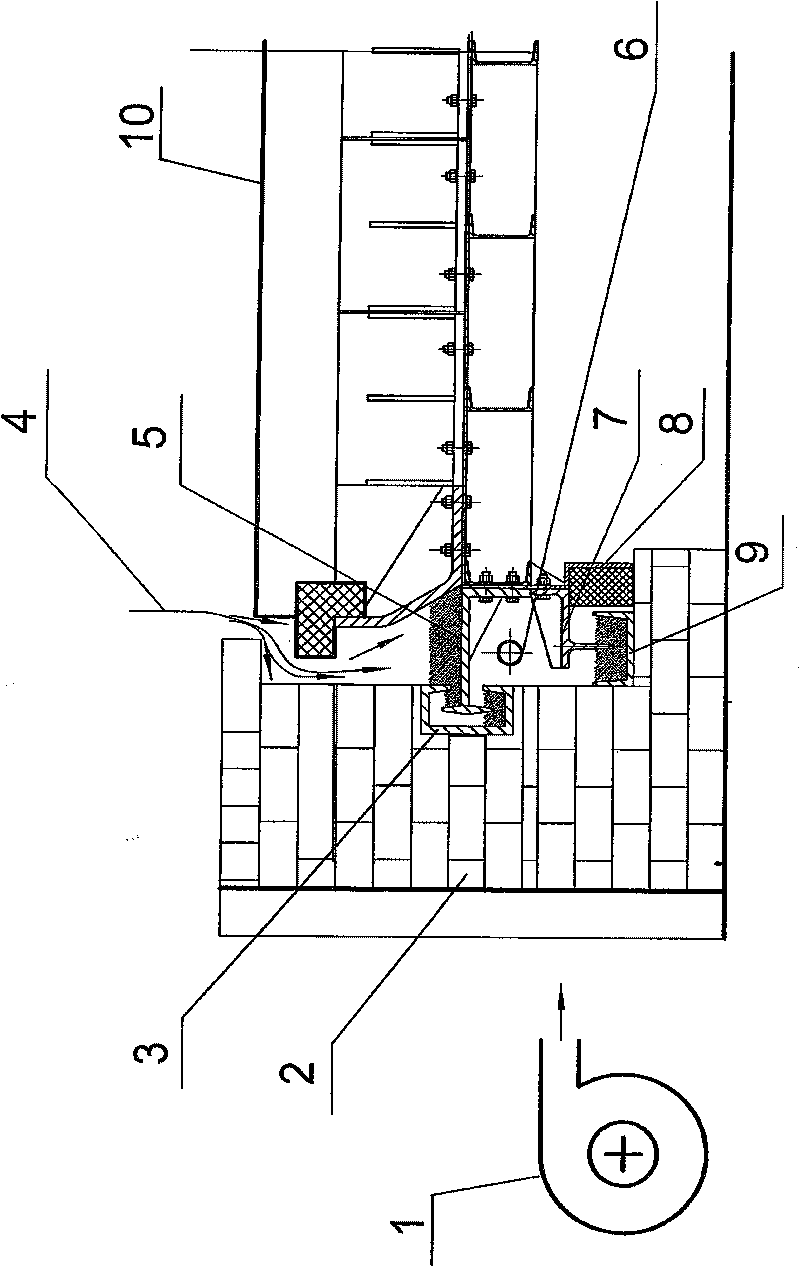

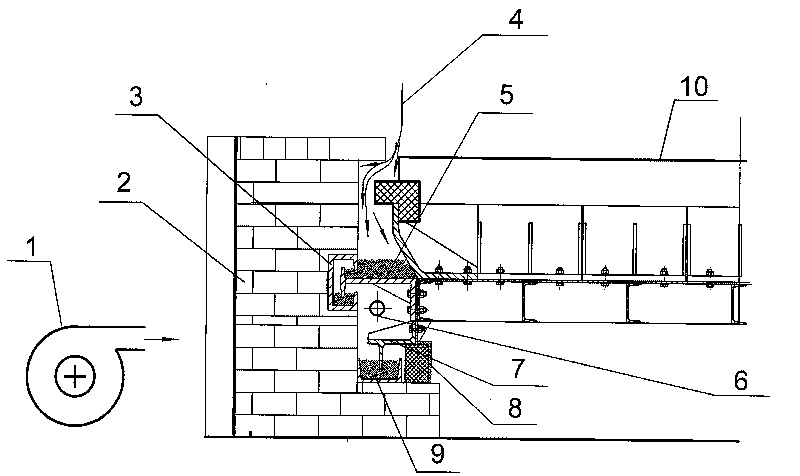

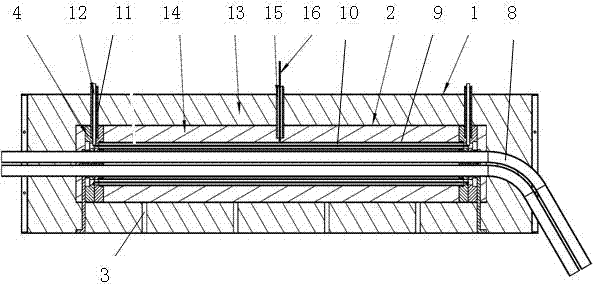

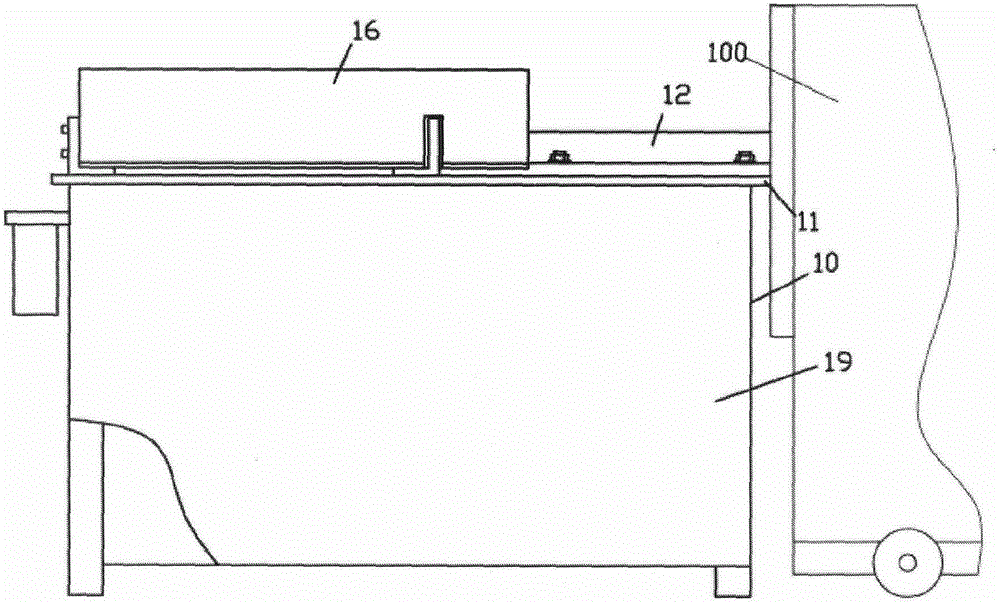

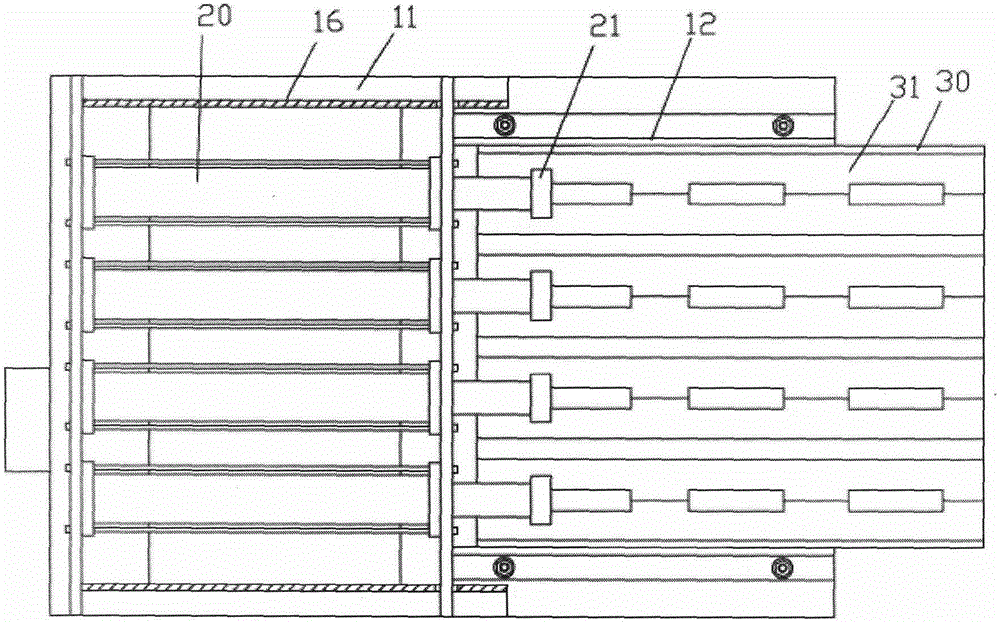

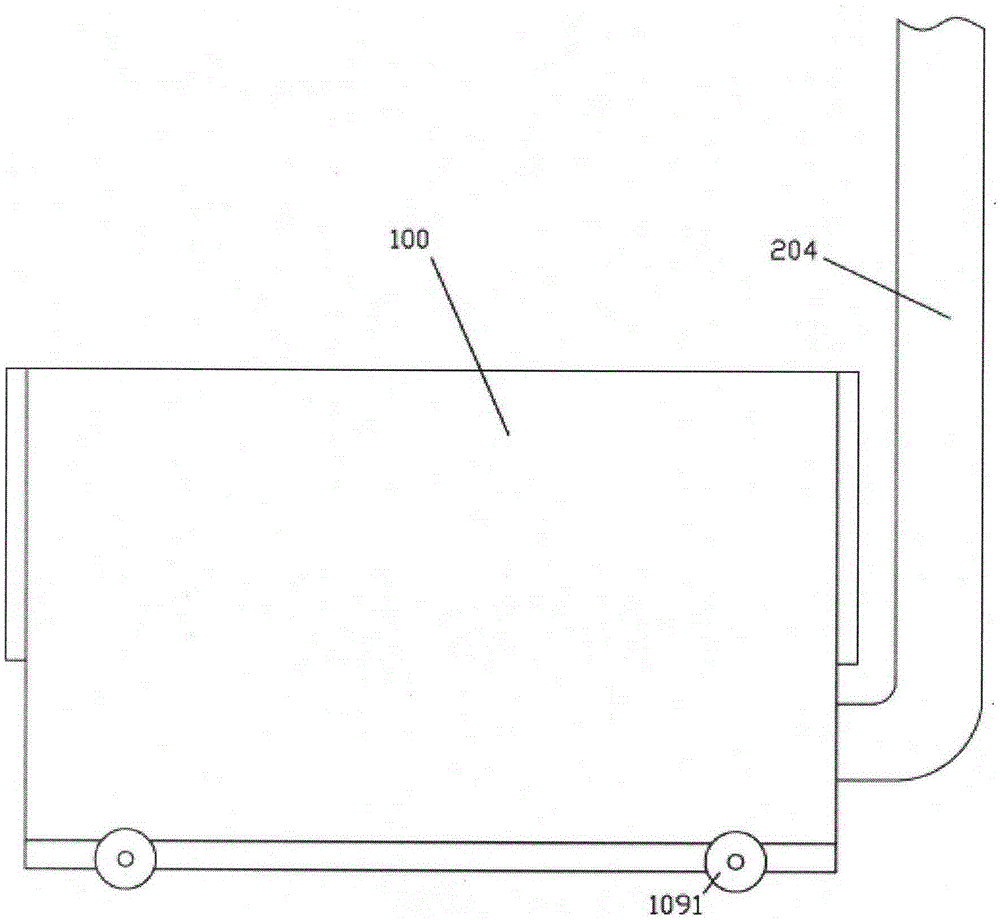

Sand seal structure for trolley of desktop forging furnace

The invention relates to a sand seal structure for a trolley of a desktop forging furnace, which comprises a heating furnace (2), a trolley (10), a high temperature sand seal groove (3) and a high temperature sand seal cutter (5), wherein the high temperature sand seal groove (3) is embedded in the furnace wall of the heating furnace (2); the high temperature sand seal cutter (5) has a T-shaped structure; an air duct (6) is arranged under the high temperature sand seal cutter (5) and is connected with a centrifugal blower (1); the furnace wall of the heating furnace (2) under the high temperature sand seal cutter (5) is provided with a low temperature sand seal groove (9) and heat insulating cellucotton (8); a low temperature sand seal cutter (7) is arranged under the air duct (6); the low temperature sand seal groove (9) and the high temperature sand seal groove (3) are arranged in a step shape; the lower end of the low temperature sand seal cutter (7) is arranged in the low temperature sand seal groove (9); the upper part of the low temperature sand seal cutter (7) is fixedly connected with the side of the trolley (10); and the heat insulating cellucotton (8) is arranged on one side of the low temperature sand seal groove (9) close to the hearth of the heating furnace (2). By starting from modifying the sand seal structure and a mounting mode, the temperature of the bottom of the trolley is greatly reduced, and the working time of the sand seal cutters and the sand seal grooves is improved so as to prolong the service life of the trolley.

Owner:JIANGYIN ZENKUNG FORGING CO LTD

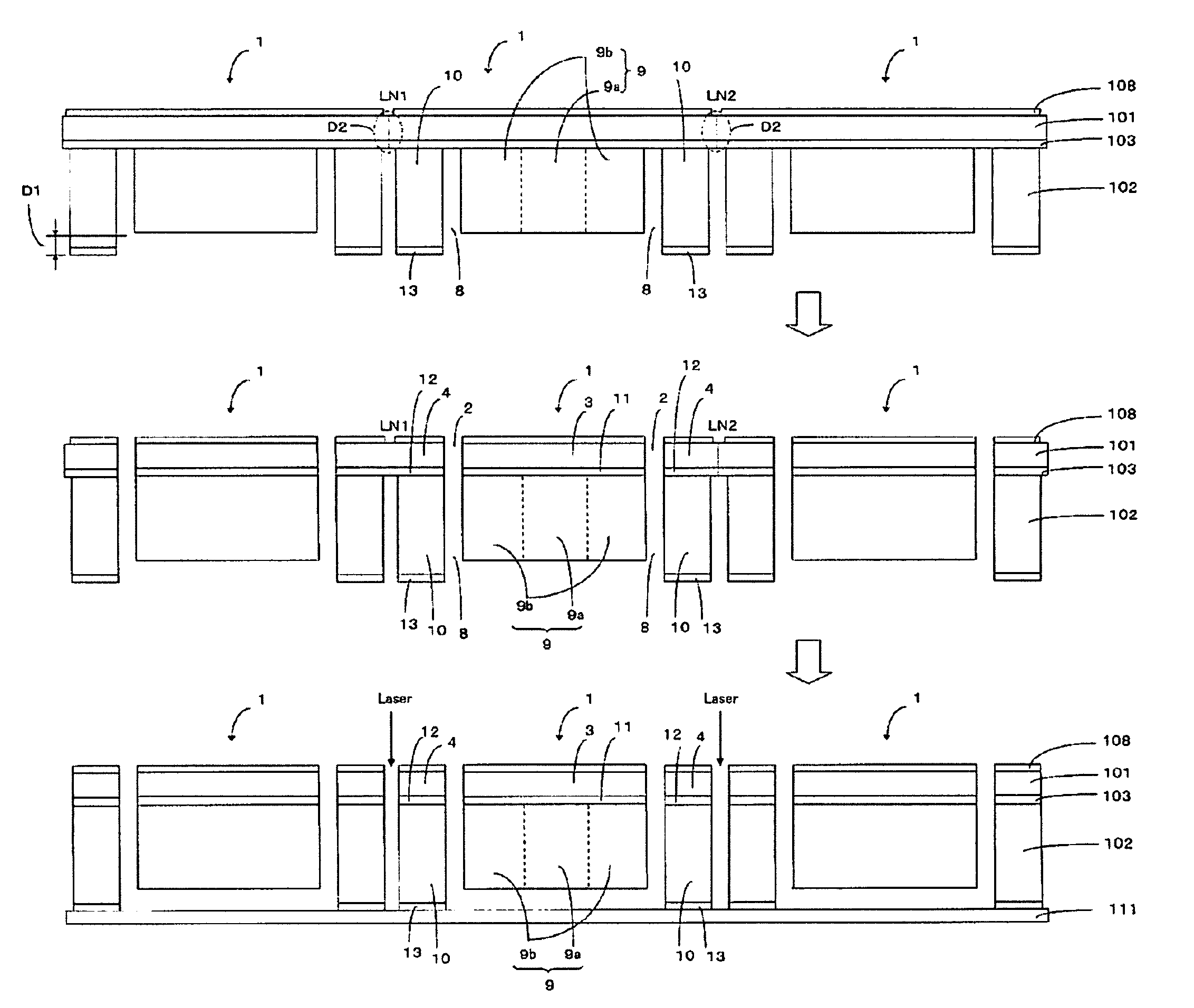

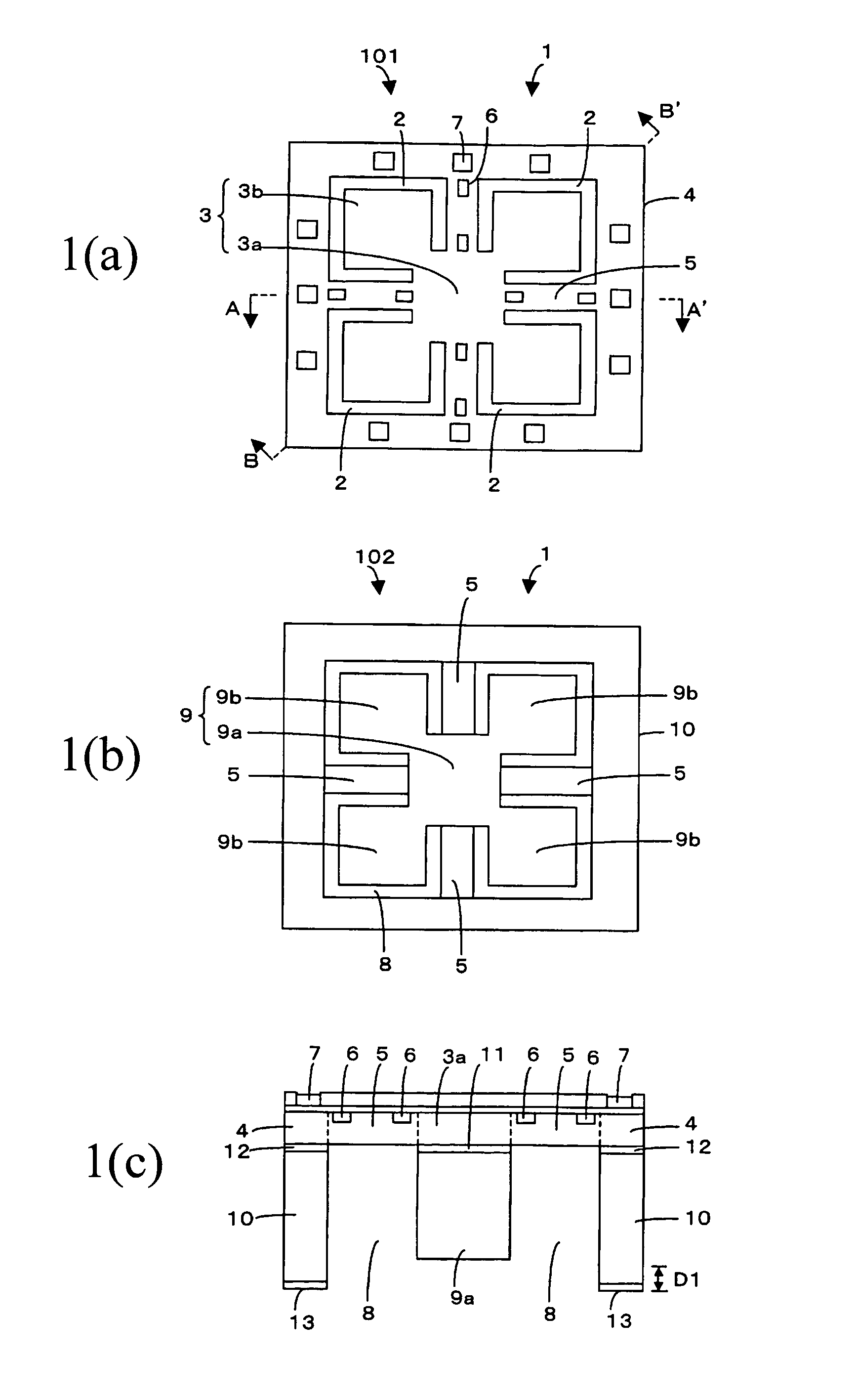

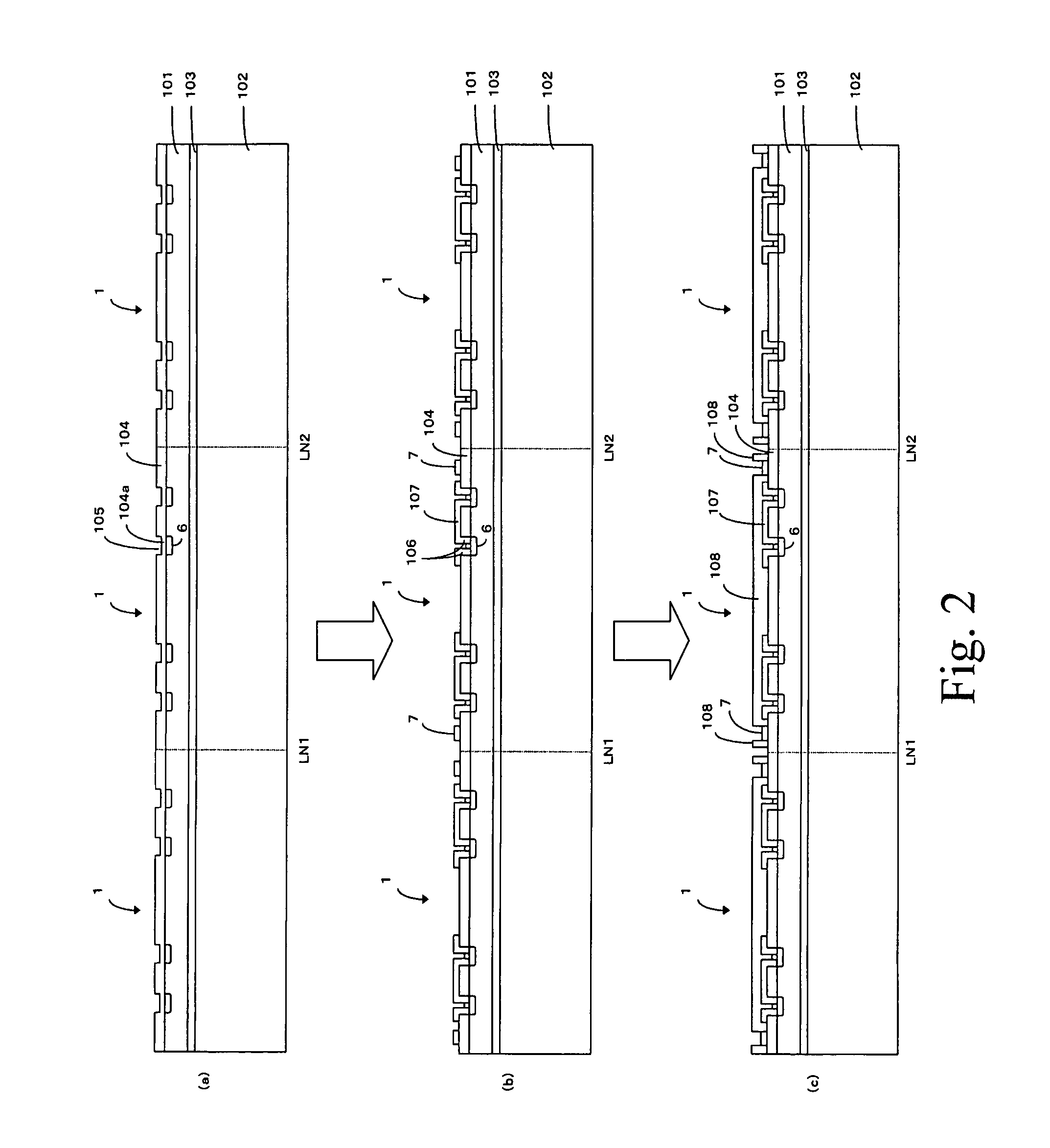

Method for forming individual semi-conductor devices

InactiveUS20060046437A1Damage suppressionAcceleration measurement using interia forcesSemiconductor/solid-state device manufacturingDevice materialSemiconductor

The present invention provides a method that forms individual semiconductor devices from a semiconductor substrate including a first face having a first region in which micro-mechanical elements are formed and a second region which surrounds the first region and in which a scribe line is formed, and a second face having a third region which is opposed to the first face and corresponds to the first region in which the micro-mechanical elements are formed and a fourth region which surrounds the third region and corresponds to the second region. The method includes steps of thinning the fourth region of the second face which corresponds to the scribe line formed in the second region of the first face, and cutting the semiconductor substrate along the scribe line formed in the second region of the first face.

Owner:LAPIS SEMICON CO LTD

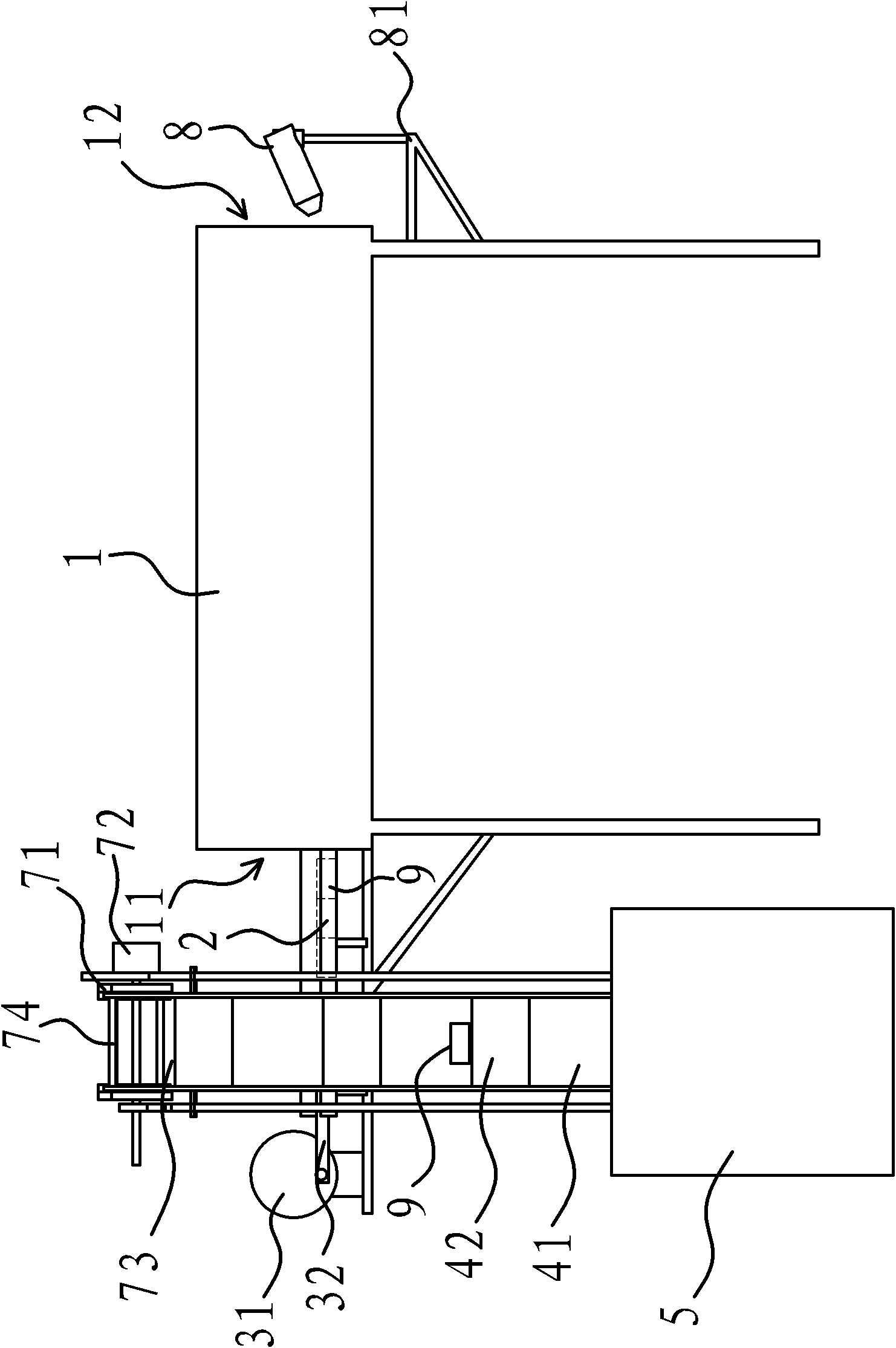

Horizontal-type workpiece hot press

PendingCN107598049AEasy to detectAutomate your transportationForging press detailsForging press drivesHydraulic cylinderCombustion

The invention discloses a horizontal-type workpiece hot press which comprises a lifting machine, a calcinator, a screening and conveying device and a press body. The screening and conveying device isconnected with the lifting machine hoist, the calcinator and the press body. The outlet end of the calcinator is provided with a fire-spitting lamp which spits a fire towards the calcinator. A controlvalve is arranged on the calcinator to control supply of combustion gas connected with the fire-spitting lamp. Blank materials which are cleared and arranged through the lifting machine are conveyedthrough the screening and conveying device to pass through the calcinator firstly, then pass through a detection probe to be screened, and then enter the press body. The press body comprises a rack, apress main body and a stamping machine head, wherein the press main body and the stamping machine head are arranged on the left side and the right side of the rack correspondingly. The stamping machine head is mounted on a mounting plate and connected with a hydraulic cylinder. A push rod assembly and a limiting rod assembly drive the mounting plate and the stamping machine head to get close to the press main body, and the hydraulic cylinder drives the stamping machine head to form the blank materials in a stamped mode towards the press main body. Automatic feeding, calcination, conveying andforging forming of the blank materials are achieved, products are fully-automatically integrally formed, and intelligent control is achieved on all parts.

Owner:叶进军

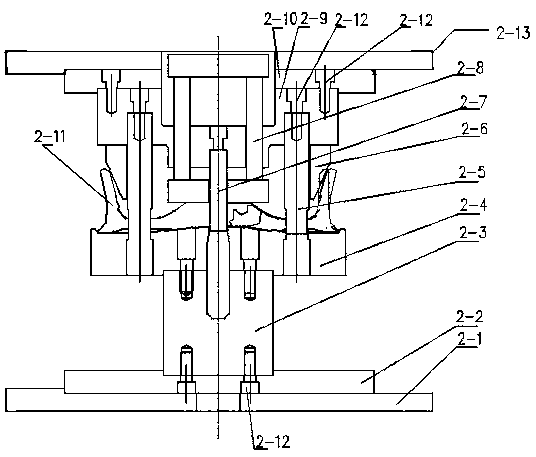

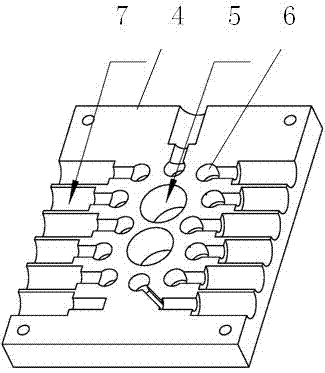

Automobile hub flange closed type precise die forging method

ActiveCN108145049AIncrease profitHigh precisionHeating/cooling devicesForge furnacesMedium frequencyEngineering

The invention relates to a flange die forging method, in particular to an automobile hub flange closed type precise die forging method. The automobile hub flange closed type precise die forging methodmainly solves the technical problems that in the prior art, the effect of molding during forging is poor, a later-process is needed for multiple kinds of cutting machining, the material waste is increased, the later-process production cost is improved, and the precision-machined production efficiency is reduced, and as the follow-up multiple cutting processes damage a metal flow line, adverse effects on the product strength are caused. The method includes the steps that a medium-frequency inducing furnace is used for heating bars, and the bars at the temperature exceeding the temperature scope are automatically removed; a mechanical press is started to conducting upsetting on the bars, and drum shapes are formed through upsetting; the mechanical press is started to conduct dummying on thebars, and the length of an overall hub flange is obtained through dummying; and the mechanical press is started to conduct precision forging on the bars, a disc and all rollaway nests of the overallhub flange are obtained through precision forging, and the finished automobile hub flange is obtained after cooling.

Owner:浙江万鼎精密科技股份有限公司

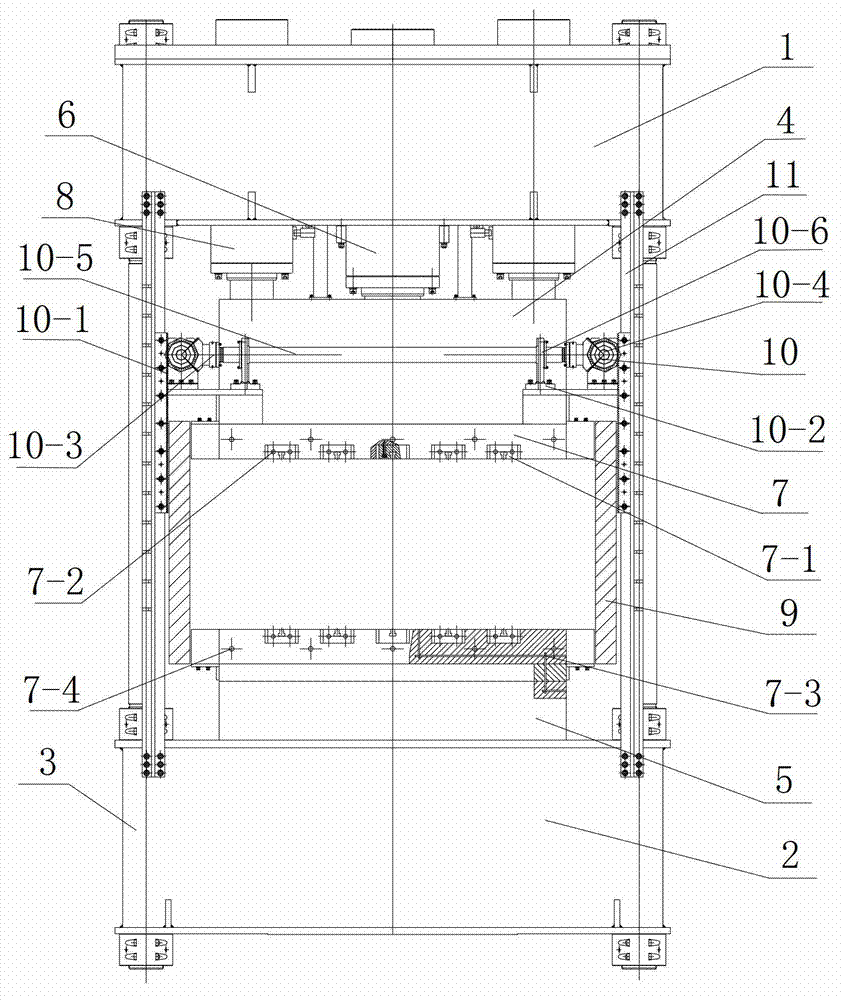

Superplastic diffusion bonding hot-forming press for titanium alloy sheet part

ActiveCN102921857AAvoid damageQuality assuranceForging press detailsForge furnacesTitanium alloyProcessing cost

The invention relates to a superplastic diffusion bonding hot-forming press for a titanium alloy sheet part, which comprises a three-beam four-post type machine body, a working oil cylinder, a slide block and a movable worktable, wherein the three-beam four-post type machine body comprises an upper cross beam, a lower cross beam and a upright post. The superplastic diffusion bonding hot-forming press is characterized in that platforms made of ceramics and steel materials are respectively fixed on the lower plane of the slide block and the upper plane of the movable worktable; a synchronous adjusting mechanism for ensuring the pressing precision of the press in the forging process is installed among four corners of the upper cross beam and the lower cross beam through a support frame; and a heat insulation device is installed on the periphery of a working area of the press. The superplastic diffusion bonding hot-forming press has the advantages that the temperature of the forging press can be guaranteed not to be greatly lost, the pressing temperature during workpiece pressing is in a high-temperature state of 1000 DEG C continuously, and a mould is not required to be repeatedly heated in the forging process, so that the quality of pressed workpieces is ensured; the energy sources can also be greatly saved, the processing cost is reduced, and the production efficiency is improved; and the self parallelism degree of the slide block in the downward movement can be automatically adjusted by the synchronous adjusting mechanism to ensure the pressing precision of the titanium alloy sheet part in the forging process.

Owner:TIANJIN TIANDUAN PRESS CO LTD

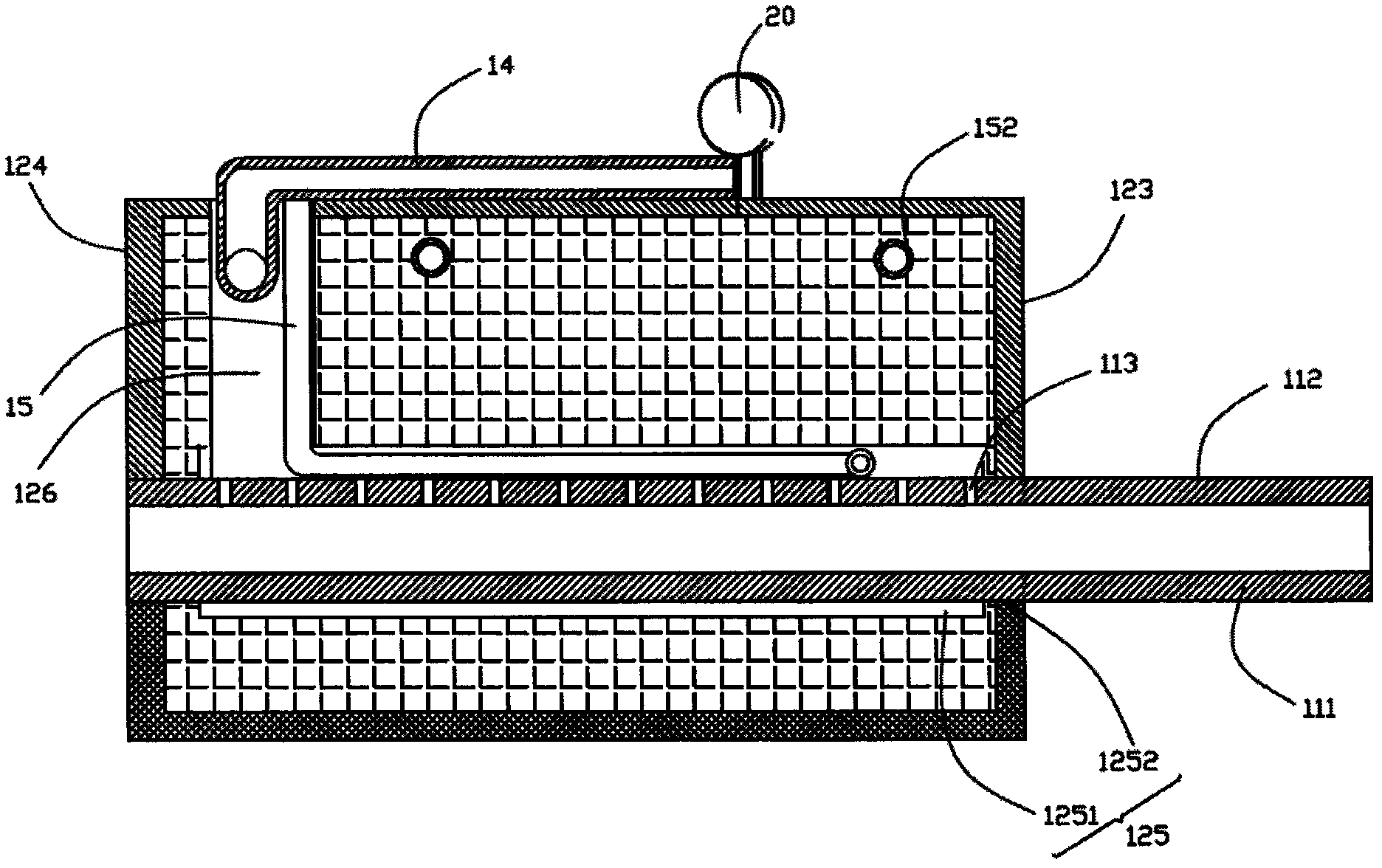

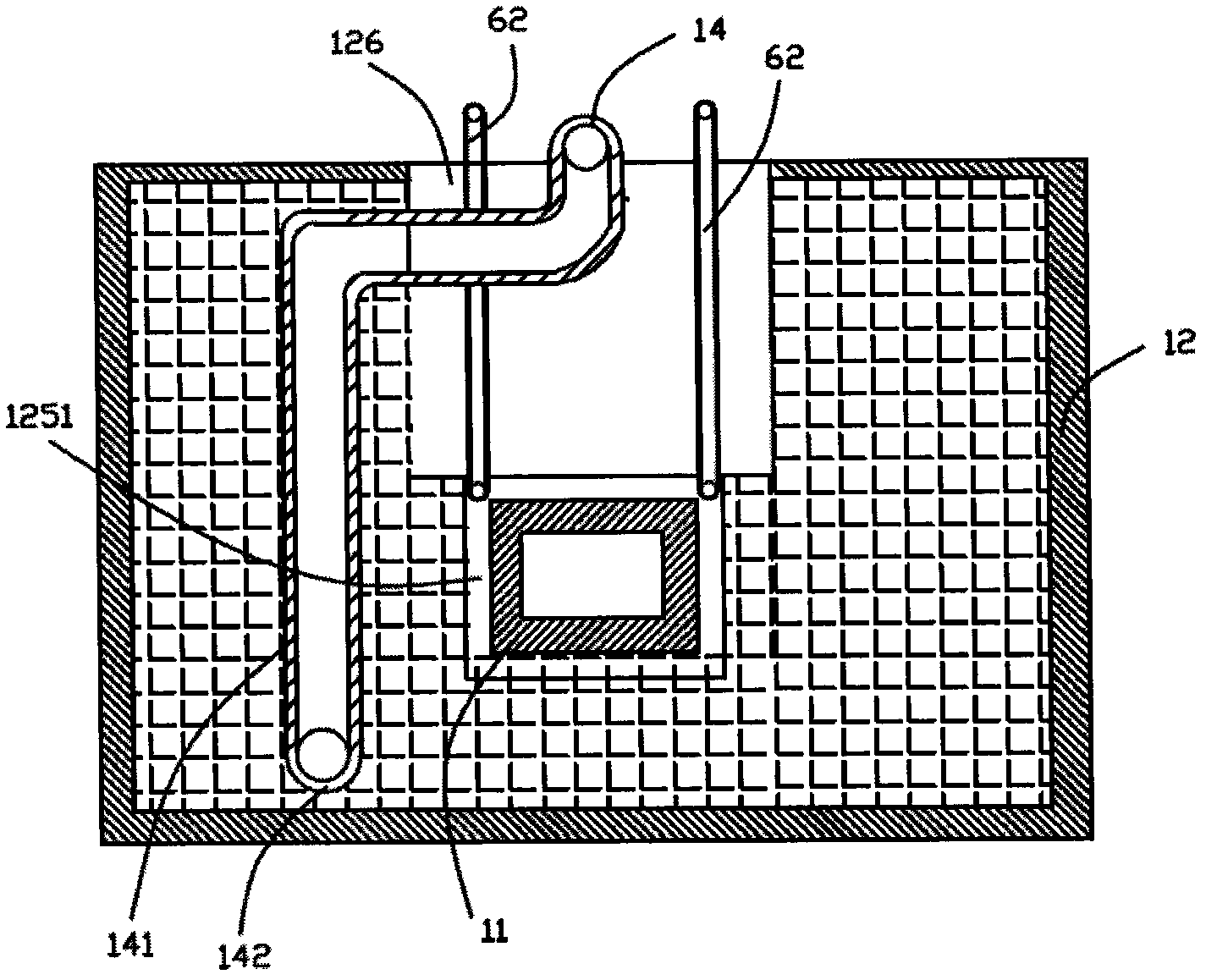

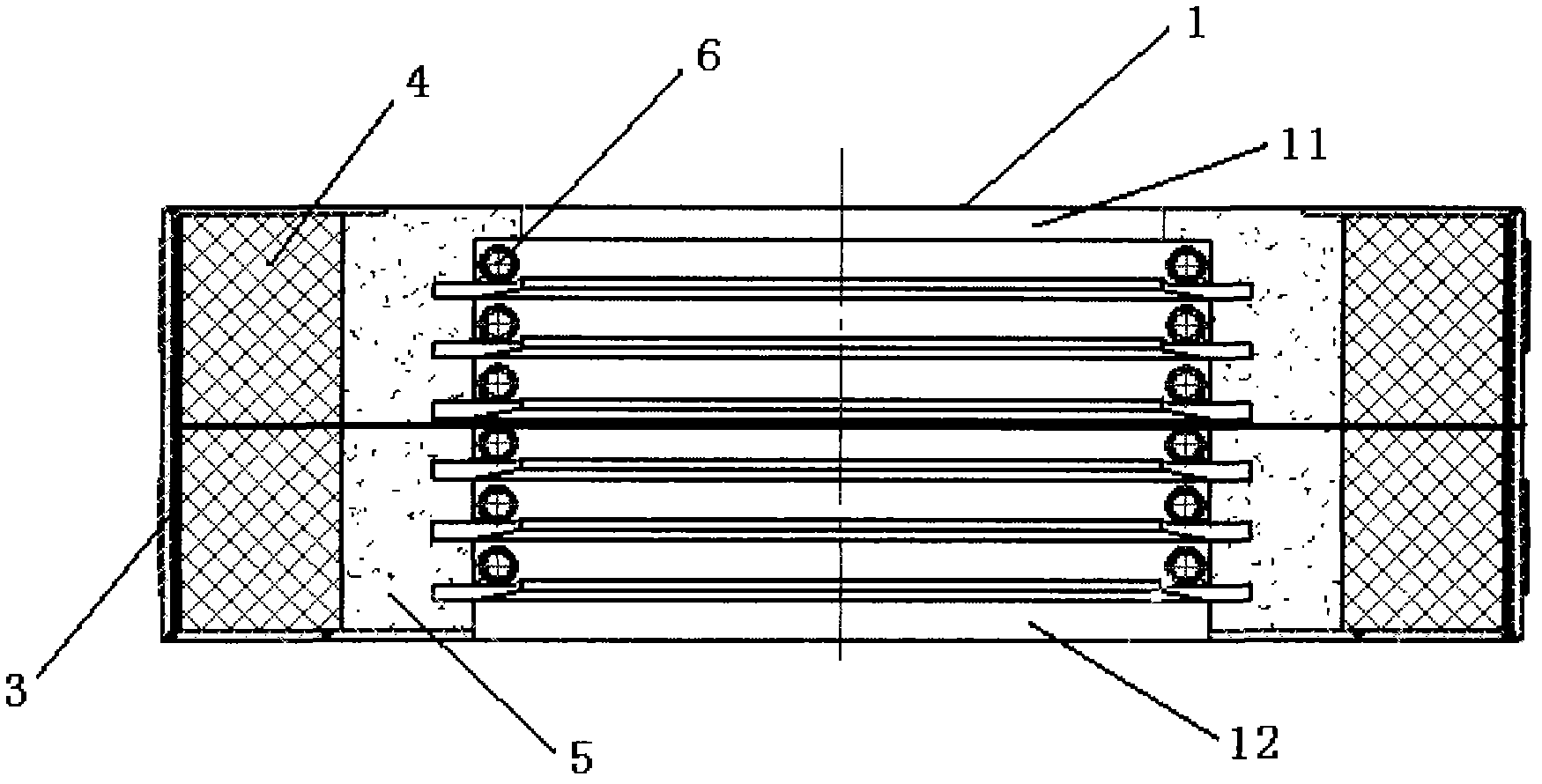

Valve pre-forging constant temperature heating furnace

ActiveCN102357624AAccurate control of the furnace temperatureImprove heating efficiencyForge furnacesInsulation layerEngineering

The invention relates to a heating furnace, in particular to a valve pre-forging constant temperature heating furnace. The heating furnace comprises an inner furnace frame and an outer furnace frame, wherein the inner furnace frame is arranged in the outer furnace frame through a strut; a bracket is respectively arranged at two ends of the inner furnace frame; a feeding guide rail, a furnace wirepipe and a cooling bar are arranged on the bracket; two ends of the feeding guide rail extend out of the outer furnace frame respectively; a furnace wire is arranged in the furnace wire pipe, two ends of the furnace wire are fixedly connected with the cooling bar, and the other end of the cooling bar is connected with an external circuit; an outer heat insulation layer is arranged between the outer furnace frame and the inner furnace frame, and an inner heat insulation layer is arranged between the inner furnace frame and the furnace wire pipe; and a temperature sensor sleeve passes through the inner furnace frame and the outer furnace frame and is fixed on the inner heat insulation layer and the outer heat insulation layer, and a temperature sensor is arranged on the temperature sensor sleeve. The heating furnace can be used for heating a blank to a forgeable temperature range, is high in heating efficiency, and can accurately control the tapping temperature of the blank so as to greatly save the production cost and improve the quality of the product.

Owner:RES INST OF ZHEJIANG UNIV TAIZHOU

Environment-friendly biomass particle forging furnace

The invention discloses an environment-friendly biomass particle forging furnace. The environment-friendly biomass particle forging furnace comprises an automatic feeding device, a forging furnace cavity shell, a combustion furnace body and an exhaust smoke filtering device. The automatic feeding device is arranged in front of the forging furnace cavity shell. The combustion furnace body is arranged on the side edge of the forging furnace cavity shell. The exhaust smoke filtering device is arranged behind the forging furnace cavity shell. An exhaust pipe of the exhaust smoke filtering device is fixed to the forging furnace cavity shell and is communicated with an exhaust through hole in the forging furnace cavity shell. The environment-friendly biomass particle forging furnace can carry out automatic feeding, ash formed by waste generated by forge pieces can be left in an ash collecting through groove, and the ash is removed in the non-shutdown state. Meanwhile, ash and waste generated by fuel can be prevented from blocking a circulation hole, and the combusting and heating effects are guaranteed. Particle scrap filtering is carried out on the combusted smoke firstly, then the combusted smoke enters a water tank to be filtered again, accordingly, not too many scraps or particles are accumulated in the water tank, the service life is prolonged, and frequent water changing or cleaning is not needed.

Owner:HANGZHOU YINGFA FURNACE TECH CO LTD

Flame-proof moving bed calcination device

InactiveCN1799725AEfficient use ofAvoid direct contactForge furnacesFurnace temperatureCombustion chamber

The invention relates to a muffle moving bed incineration device, which can solve the problems of local temperature overheating of incinerator which can cause overheating material, can strengthen the heating speed of incineration material, and can effectively utilize the discharged energy when burning fuel in the burning chamber. The invention utilizes the high-temperature flame and high-temperature smoke to indirectly heat the incinerator of moving bed; the high-temperature smoke can quickly enter high-velocity fluidized bed; the high-temperature gas can form gas-solid high-velocity fluidized mixing heating on the preheated material, therefore, the high-temperature gas and material can generate effective high-velocity heat and mass transfer; the material which has been heated to demanded temperature via the gas-solid separation of high-temperature gas-solid separator is fed into the incinerator of moving bed to be incinerated; the separated gas is used to preheat material; the hot material is fed into storehouse via the cooling discharge device; the average residence time of material in the incinerator of said muffle moving bed incinerator can be adjust between several minutes to hours, while the incinerator temperature is controlled between 500-1200Deg. C and the furnace temperature difference is controlled in í‚5Deg. C.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

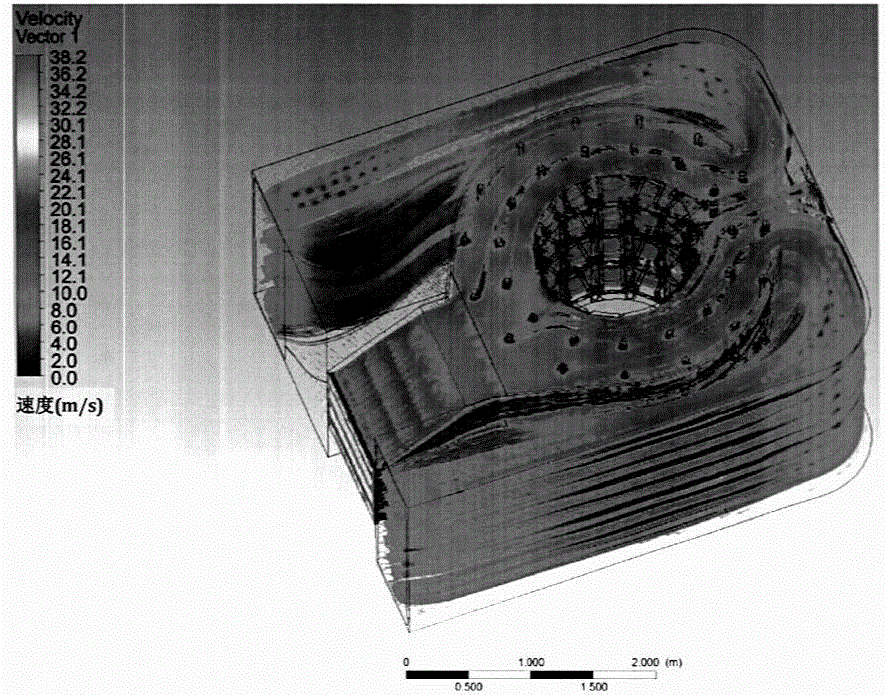

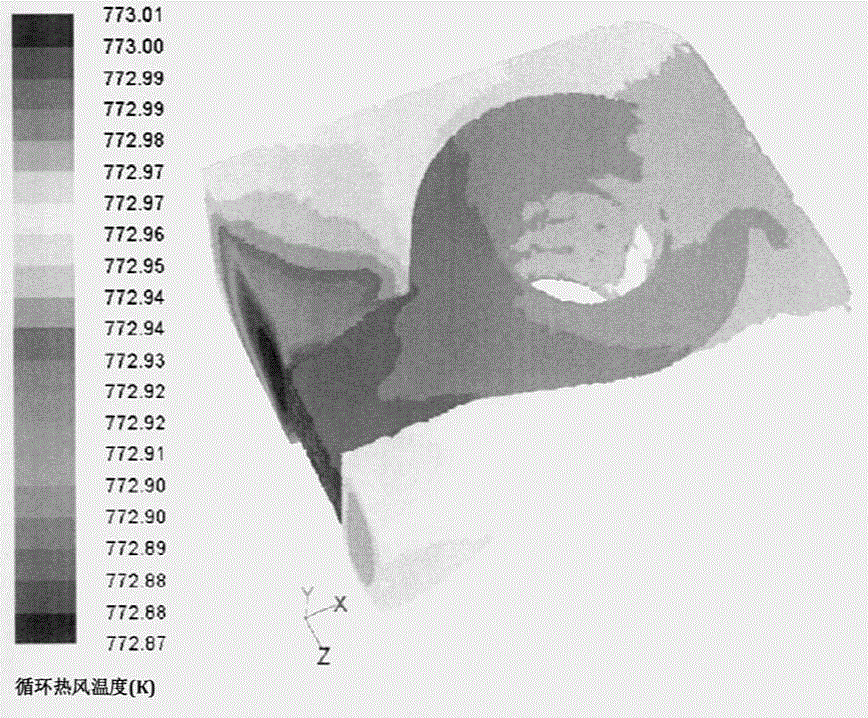

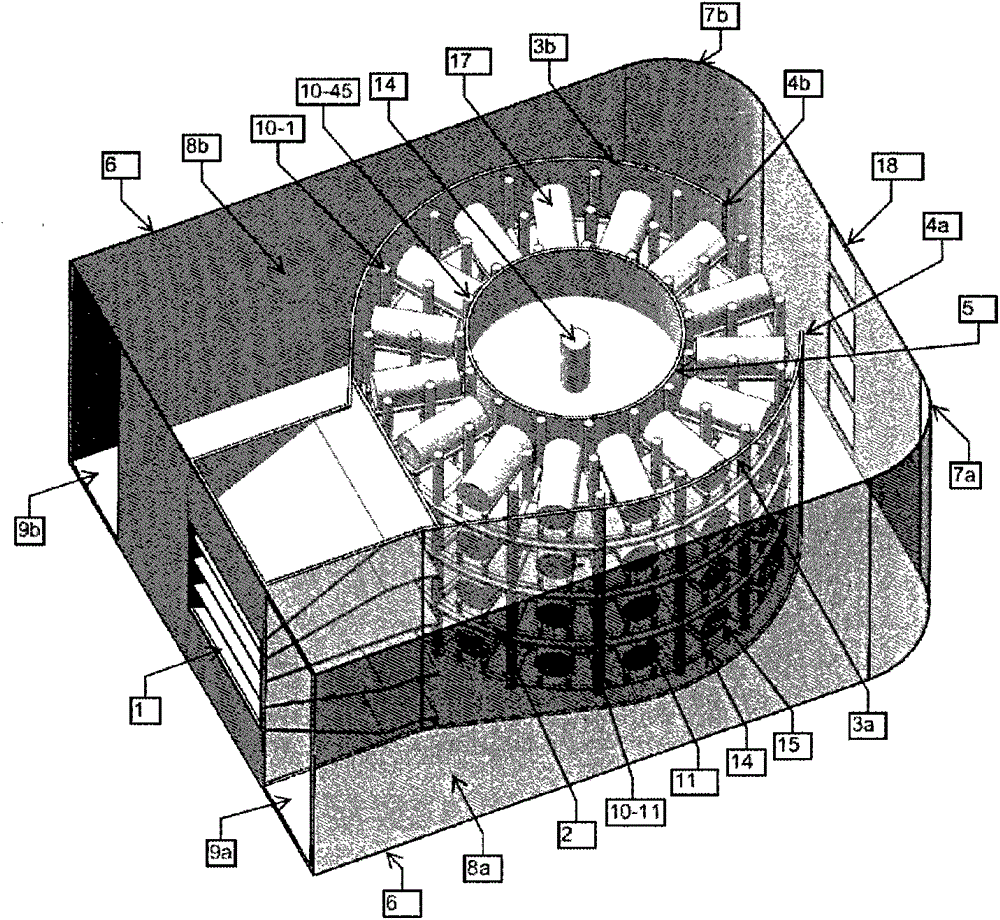

Rotary quick uniform low-energy heating furnace structure for metal billets

The invention discloses a rotary quick uniform low-energy heating furnace structure for metal billets and is applicable to the field of metal forge and press. The rotary quick uniform low-energy heating furnace is characterized in that the rotary quick uniform low-energy heating furnace structure is provided with layered hot-air inlet air deflectors (1), a layered circular air deflector (2), biarc inner air deflection walls (3), a central closed air deflection cylinder (5), an outer air deflection wall (6), double horizontal air-return passages (8), return hot-air inlet structures (9), a rotary spindle (14), a long round pipe set (10) supporting multilayer horizontal ring sets (11), and short round pipe sets (15) supporting a rack storing billets (17). The outer air deflection wall is provided with multiple layers of furnace doors (18), a driving mechanism drives the spindle (14) to rotate, a heating device provides hot air, and the hot air circulates by a fan. The problems about high-speed uniform distribution of hot air, quick and uniform heating, efficient low-energy utilization, air leak and suction of the furnace doors are solved. The heating furnace structure is compact, low in hot-air flow resistance and energy consumption, fast and uniform in heating and quite applicable to heating aluminum alloy bars.

Owner:高鸿

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com