Superplastic diffusion bonding hot-forming press for titanium alloy sheet part

A technology of diffusion connection and superplasticity, which is applied in the field of forging machinery, can solve the problems of increasing forging difficulty, increasing manufacturing cost, affecting work efficiency, etc., and achieves the effect of ensuring pressing accuracy, reducing processing cost and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

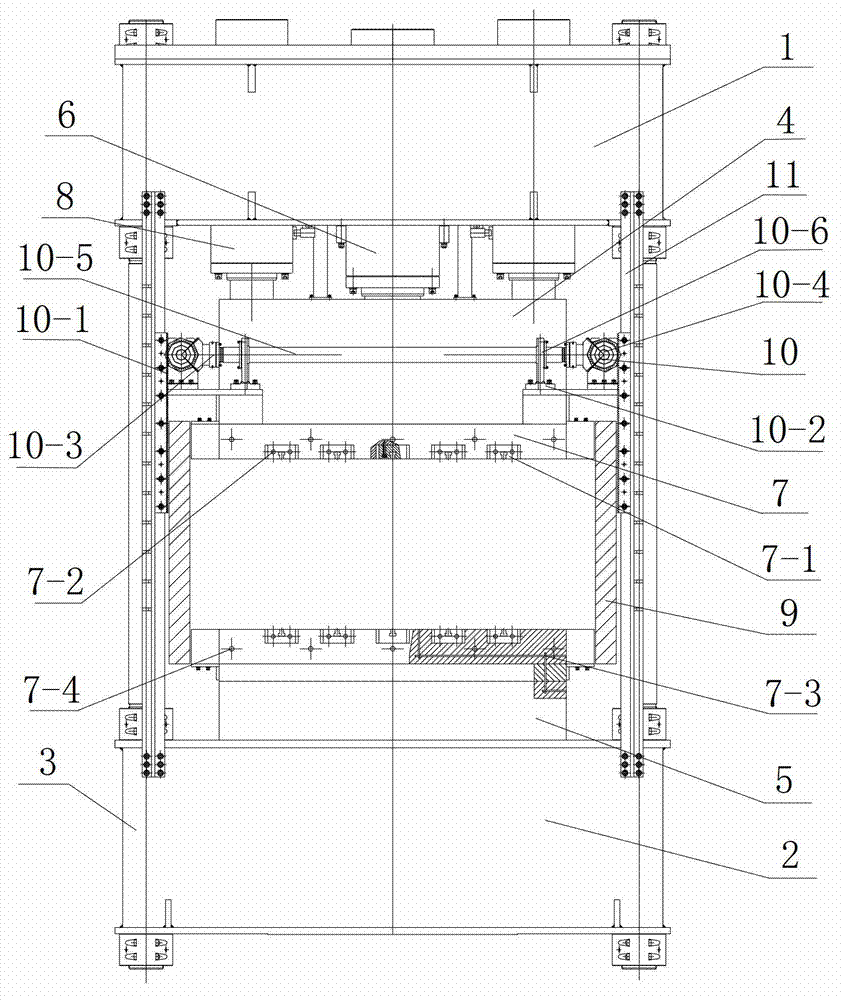

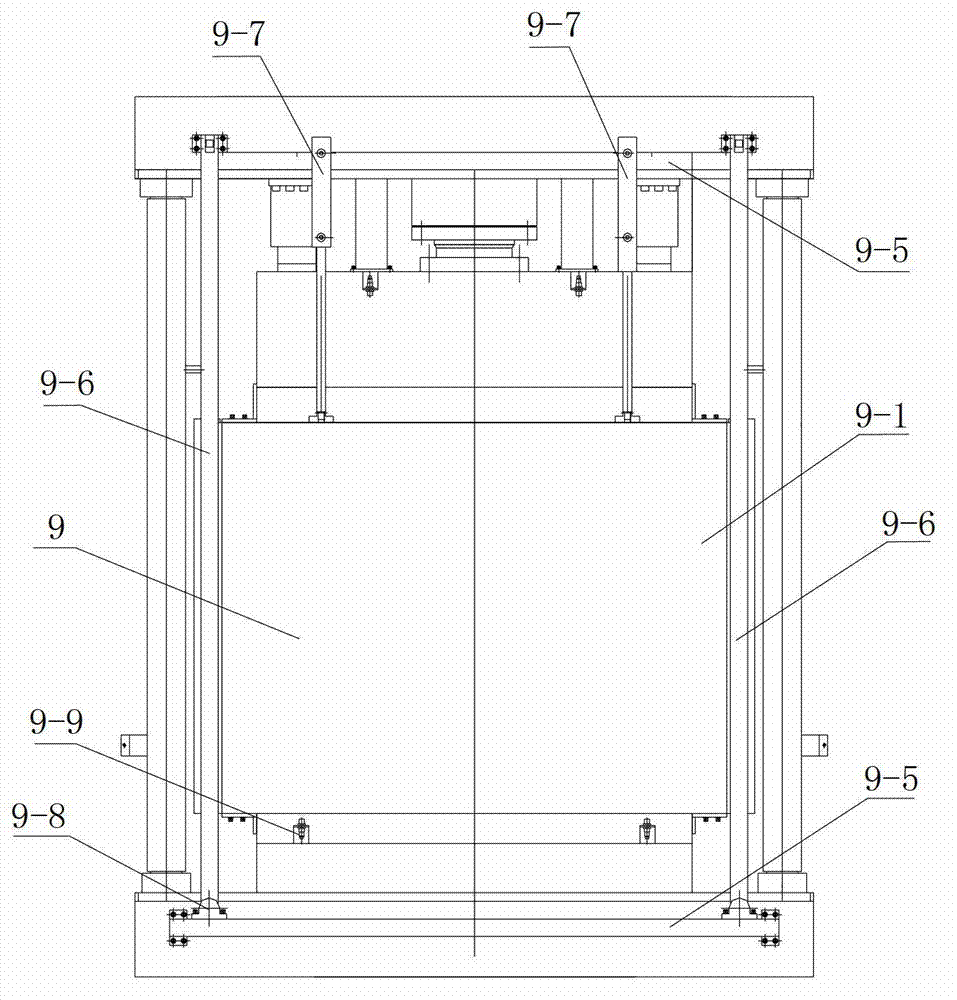

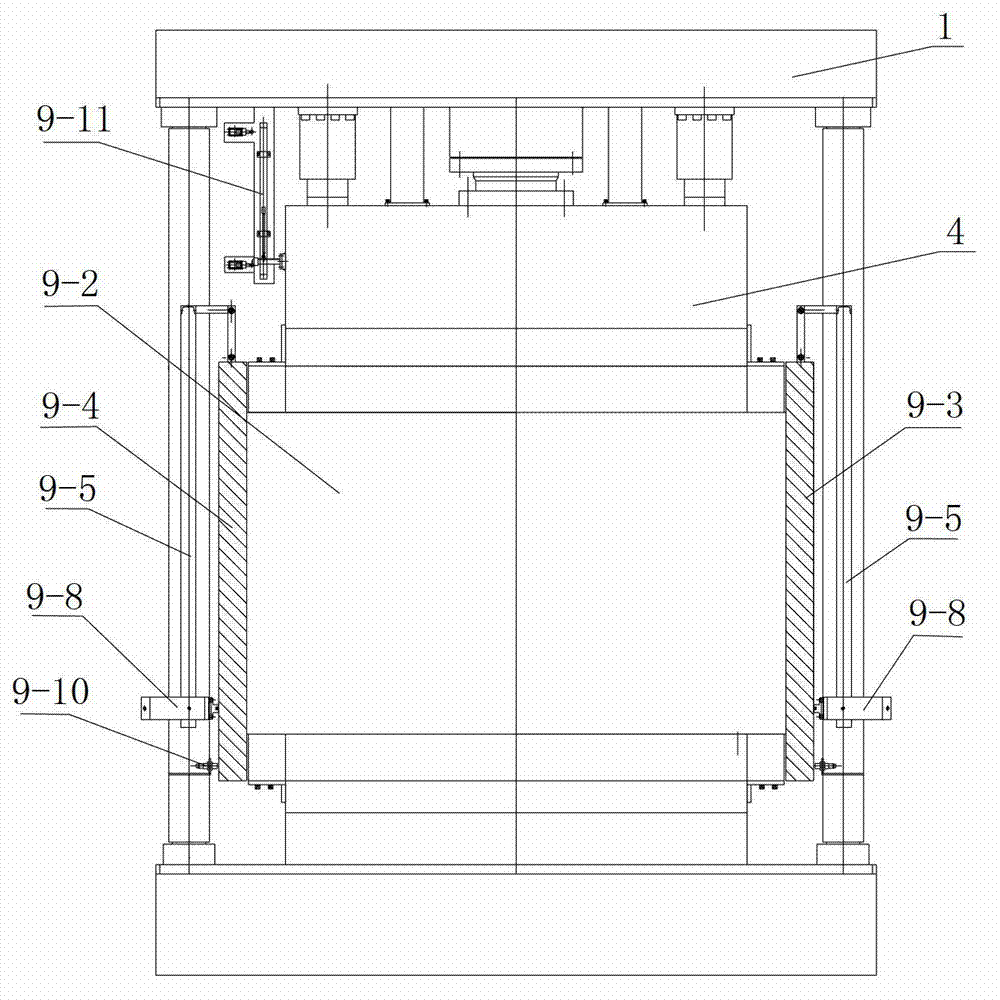

[0022] see Figure 1-Figure 4 , a thermoforming press for superplastic diffusion connection of titanium alloy thin plate parts, including a three-beam four-column fuselage composed of an upper beam 1, a lower beam 2 and a column 3, a working oil cylinder 6 and a side cylinder 8 installed on the upper beam, and a working cylinder The slide block 4 connected with the oil cylinder and the mobile workbench 5 arranged on the lower beam. The lower plane of the slider is fixed with an upper platform 7 made of ceramic and steel materials, the upper plane of the mobile worktable is fixed with a lower platform 7A made of ceramic and steel materials, and the four corners of the upper beam and the lower beam pass through The support 11 is equipped with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com