Patents

Literature

66results about How to "Guaranteed pressing accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

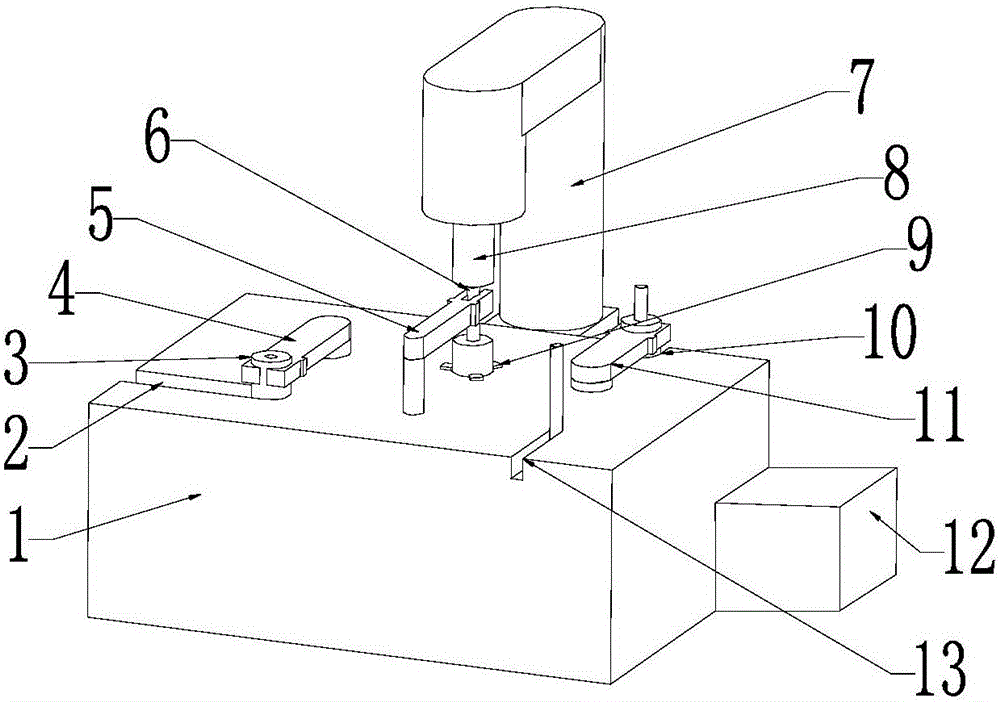

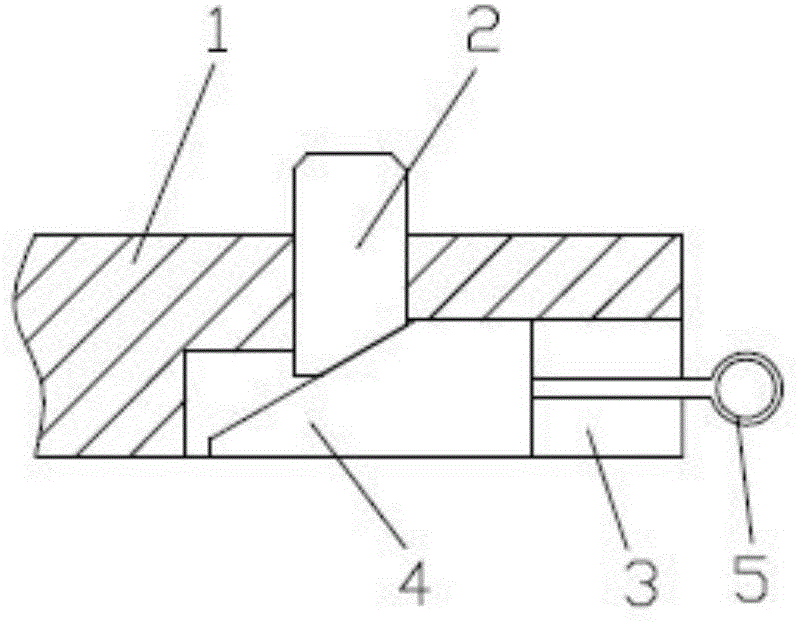

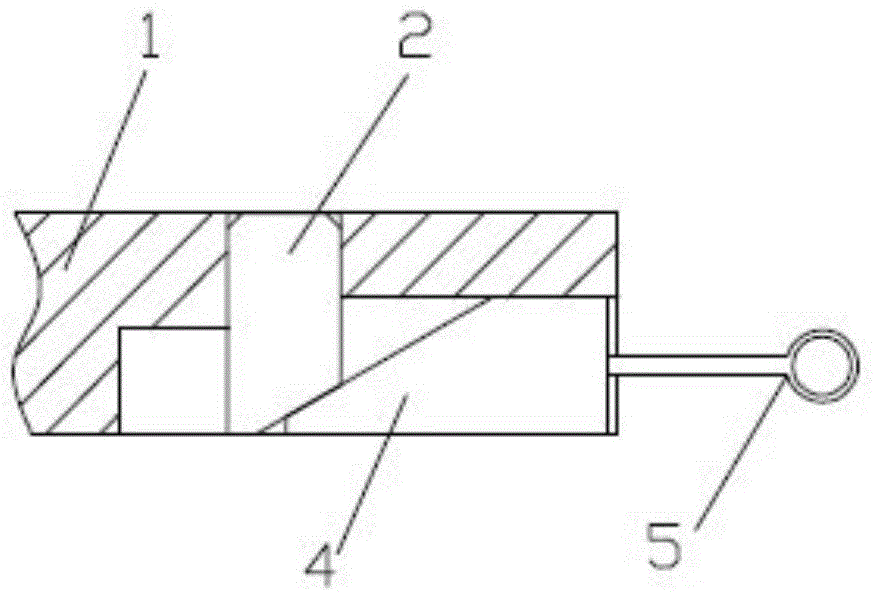

Bush fixture

ActiveCN102069376AGuaranteed pressing accuracyGuaranteed to control the pressing forceMetal working apparatusEngineeringBar pressing

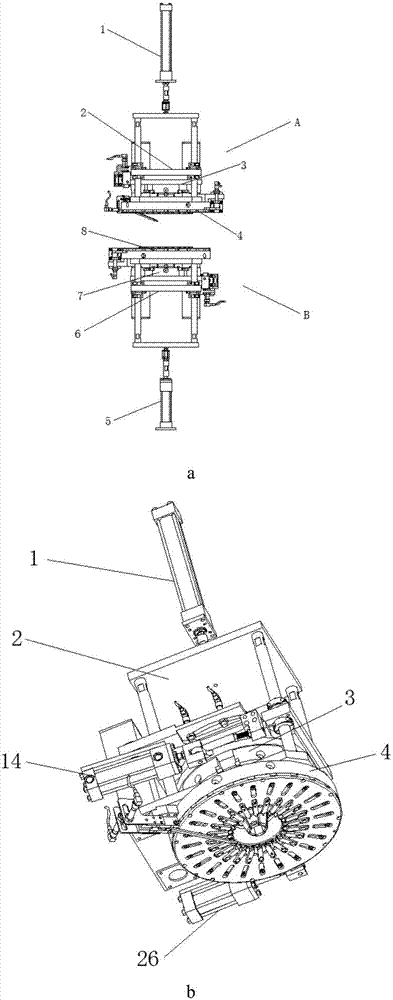

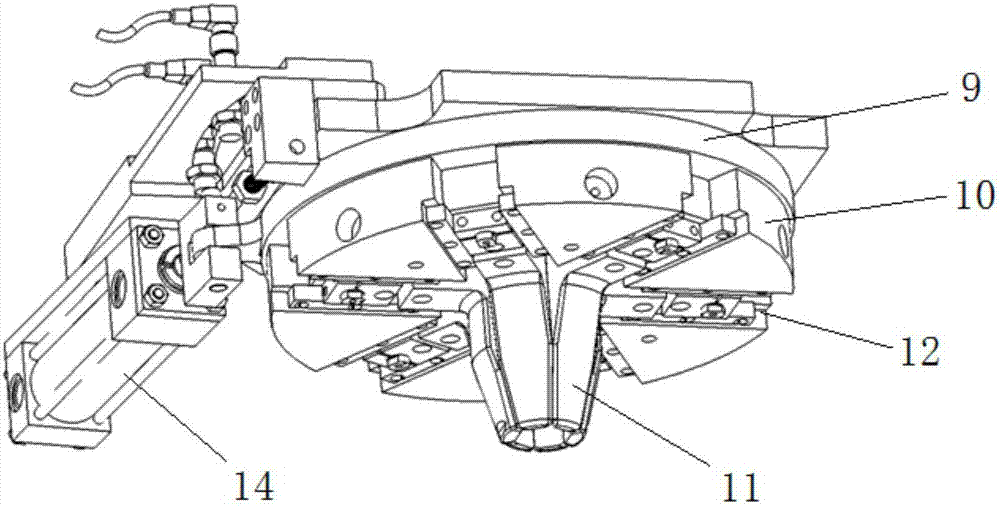

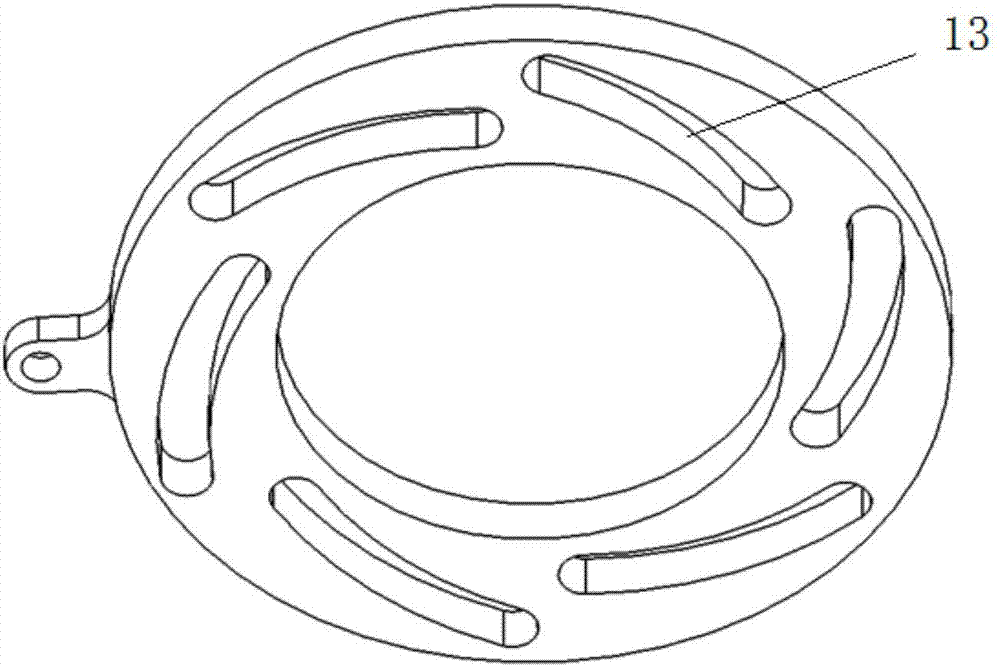

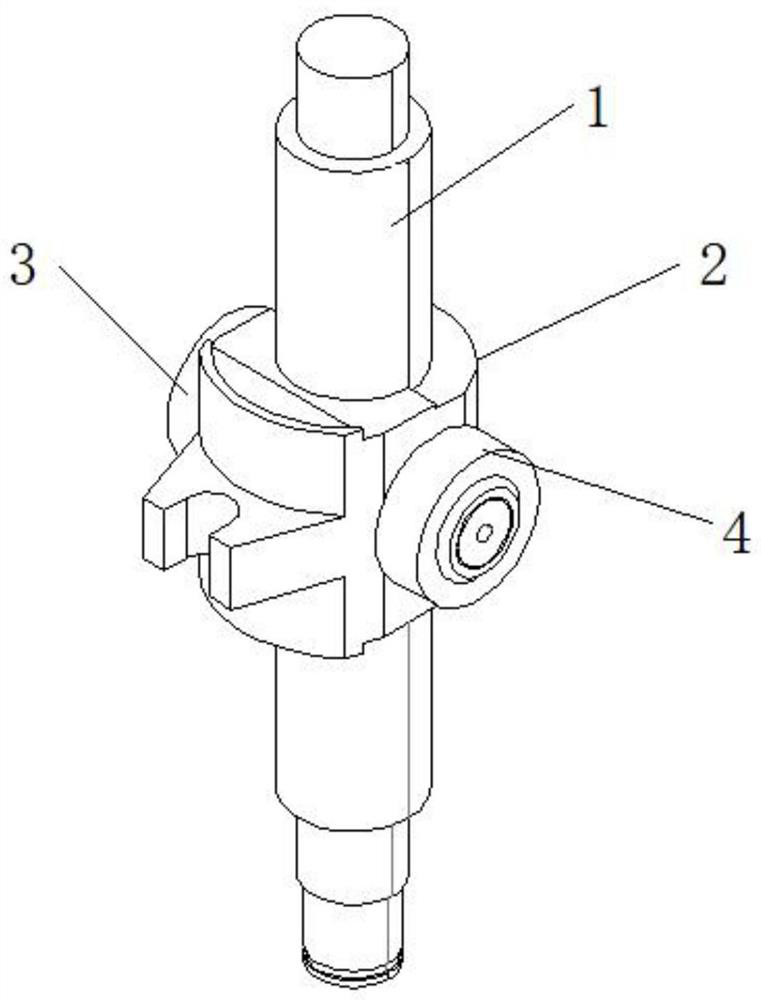

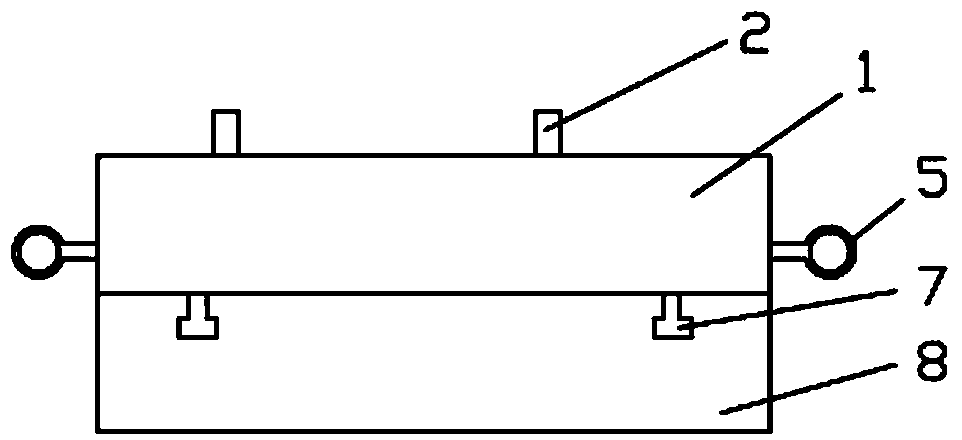

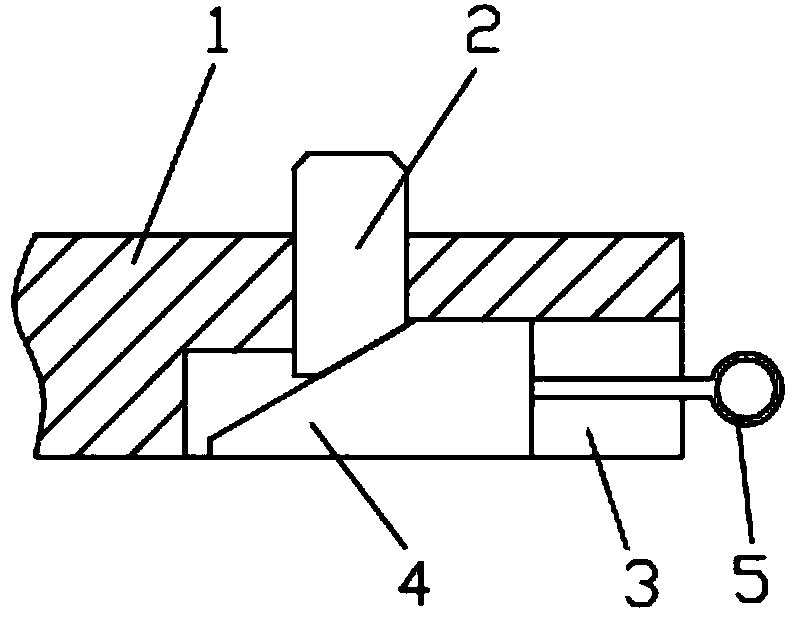

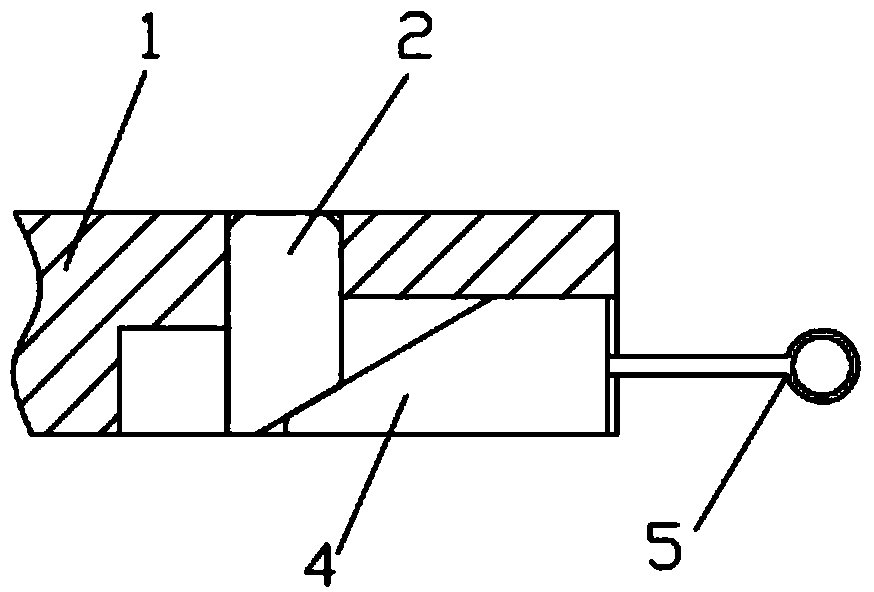

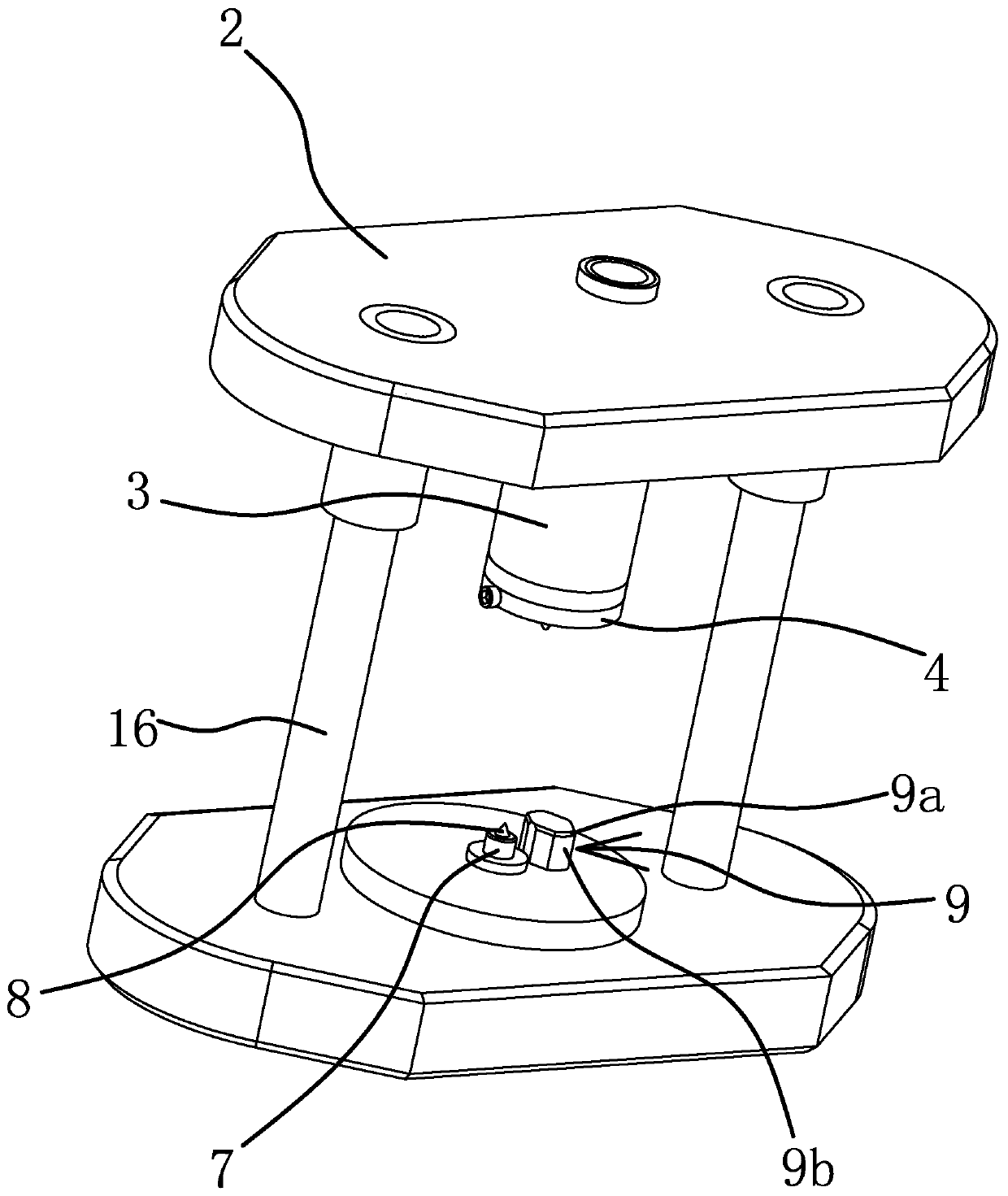

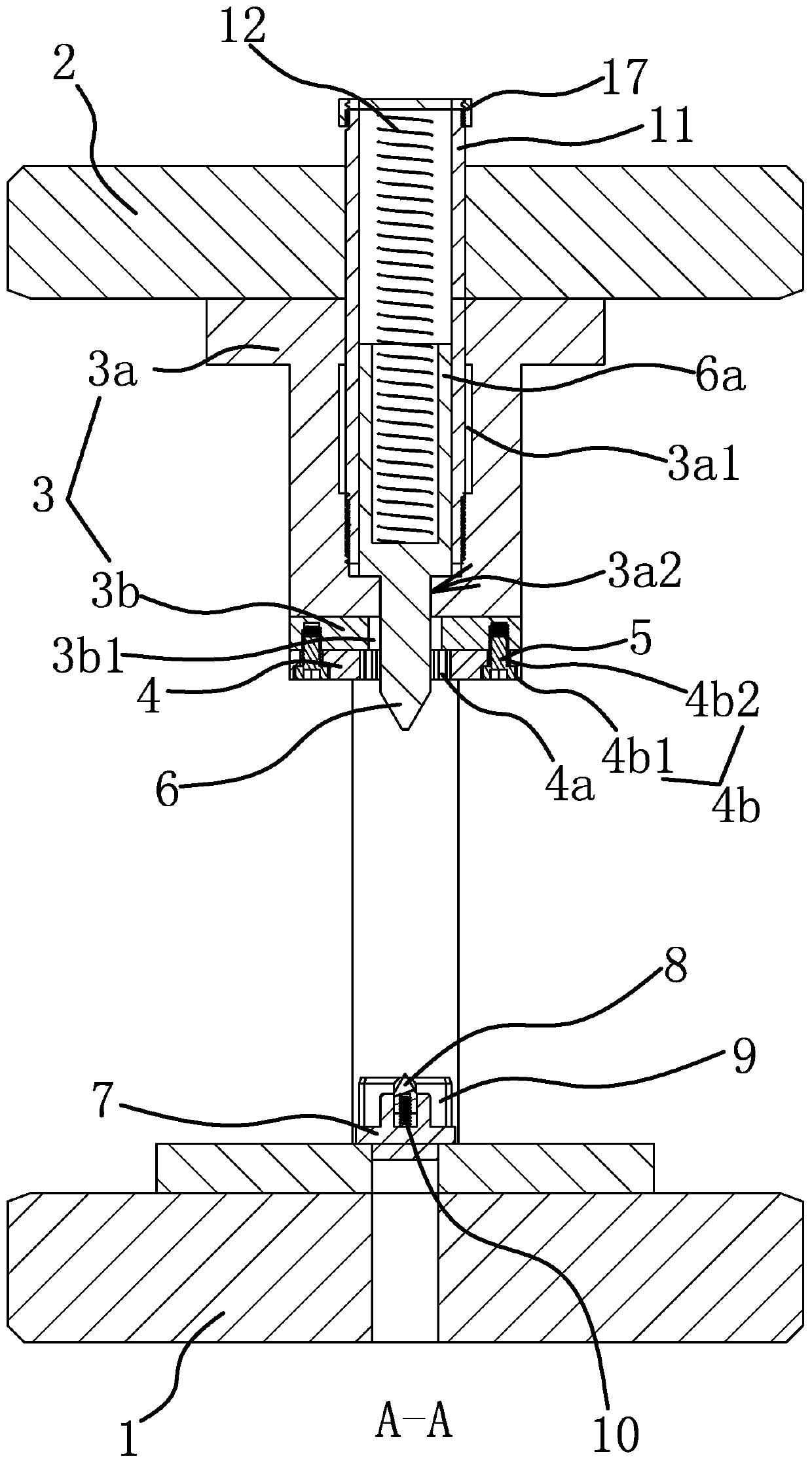

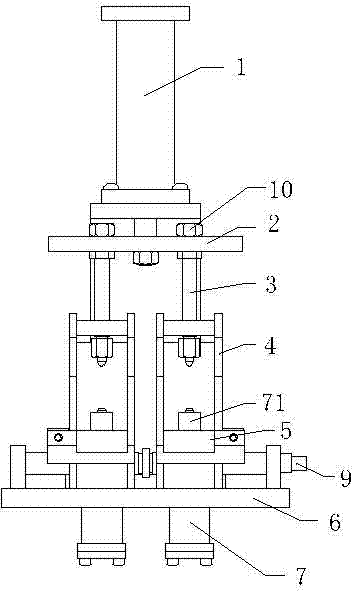

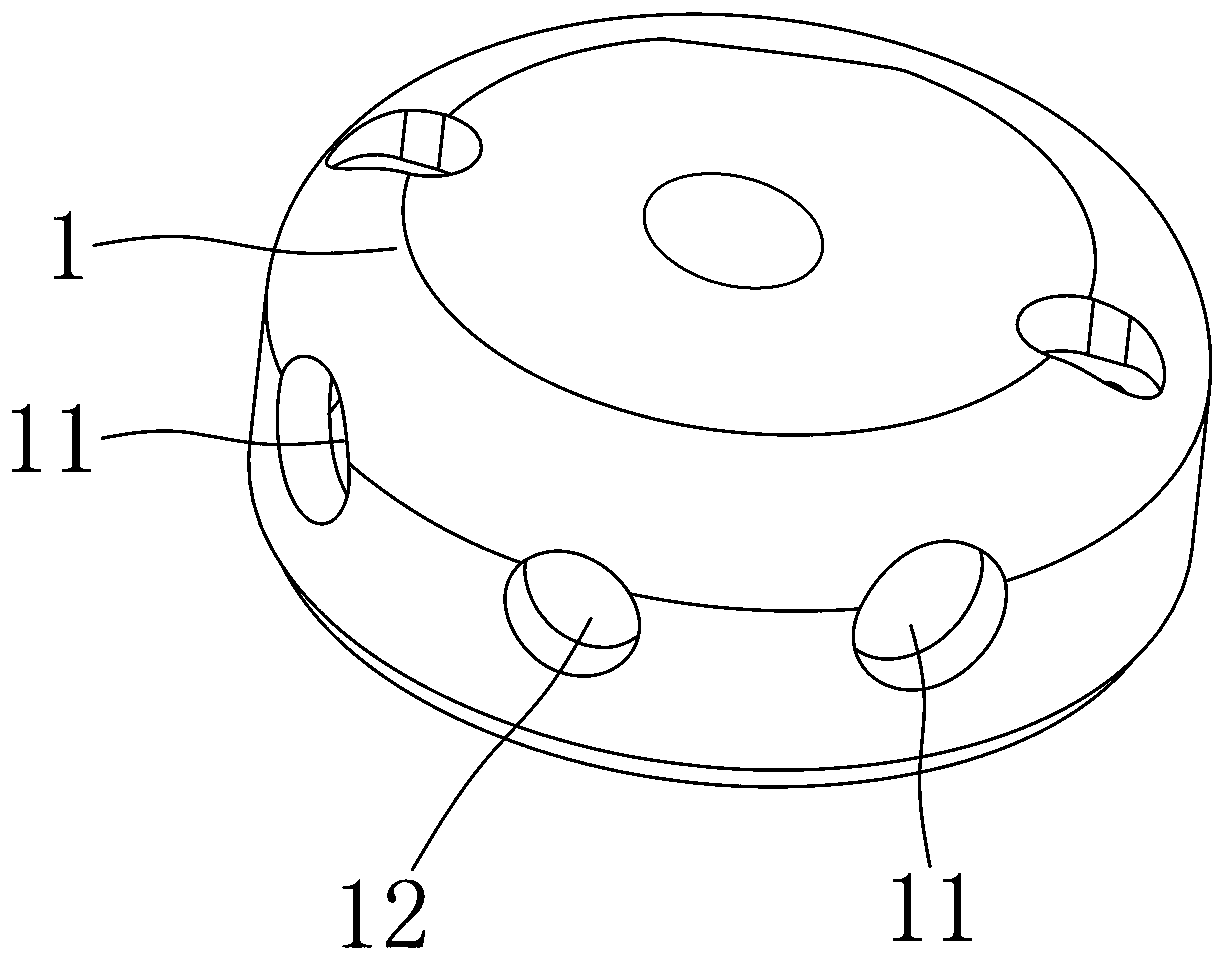

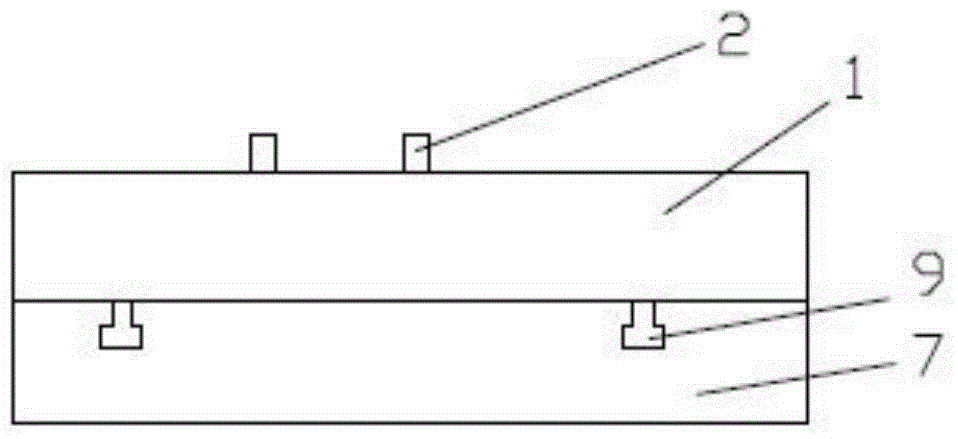

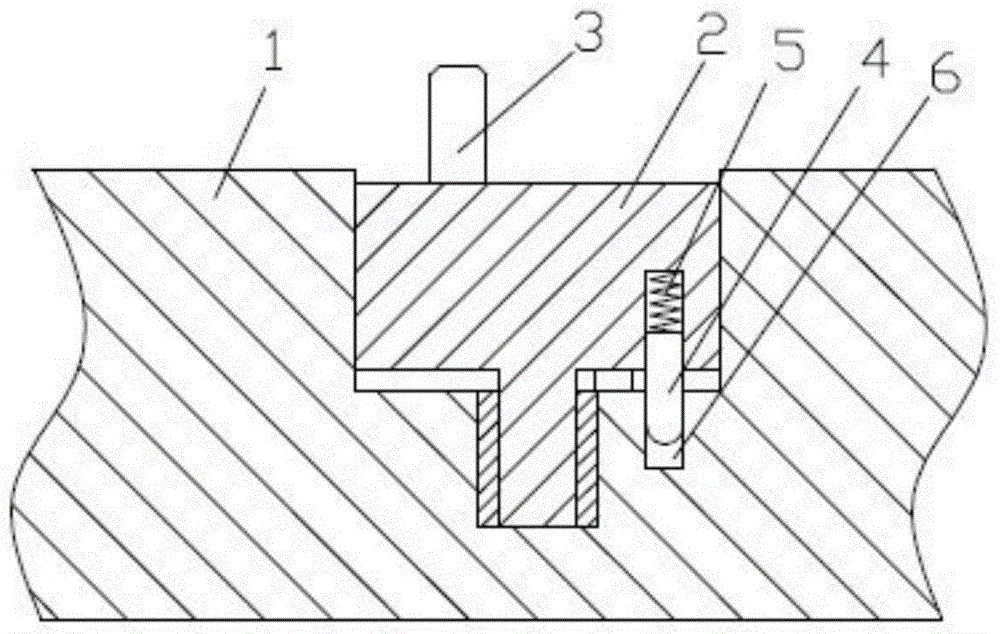

The invention relates to a bush fixture. The bush fixture comprises a body and a table, wherein a pressure rod device, the pressure rod fixing plate of the pressure rod device and a drive element matched with the pressure rod device are arranged on the body; the pressure rod device comprises at least a pair of pressure rods; support carriages corresponding to the pressure rods respectively are movably connected to the table; one end of every pressure rod is movably connected to the pressure rod fixing plate; the other end of every pressure rod is sleeved on the corresponding support carriage; every support carriage is provided with a product positioning device and a returning device; the product positioning device is connected with the returning device; and the returning device is provided with a bush installation rod which is matched with the product positioning device. The bush fixture can be used for pressing bushes on multiple types of automobile frames, can ensure pressing precision and control pressing force, can adjust a positioning fixture to accomplish pressing action according to the sizes of the automobile frames and the distances among the bushes on the automobile frames, and improves assembling efficiency and accuracy.

Owner:泛美汽车零部件(宁波)有限公司

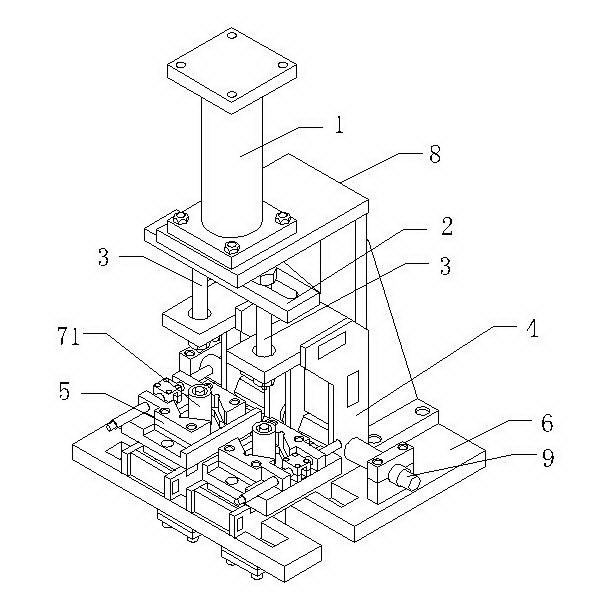

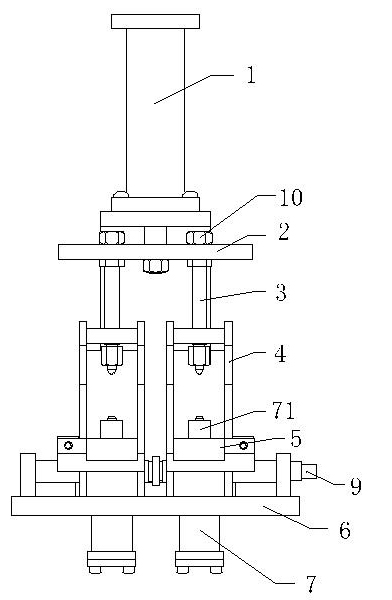

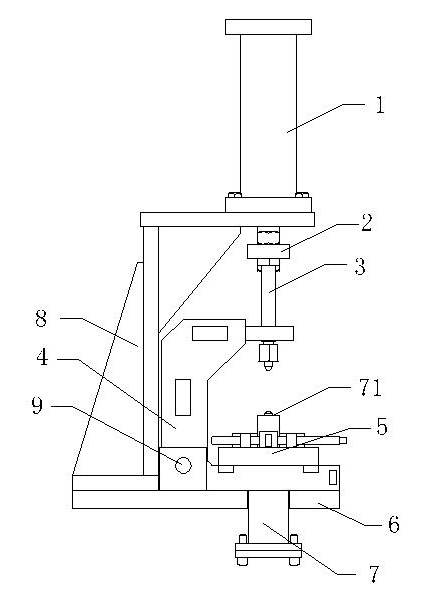

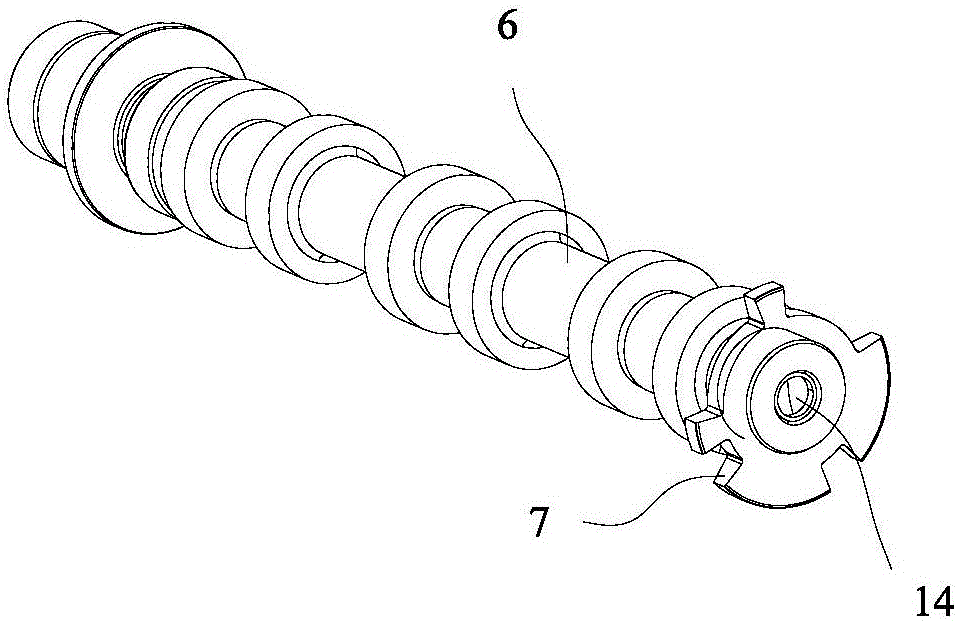

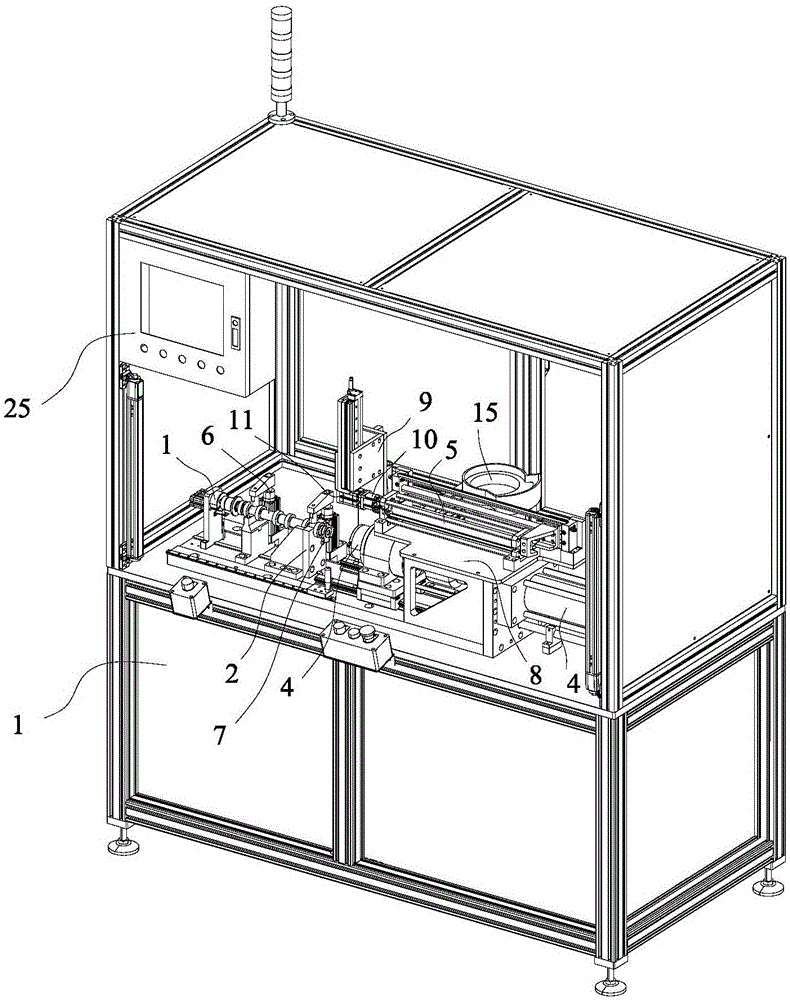

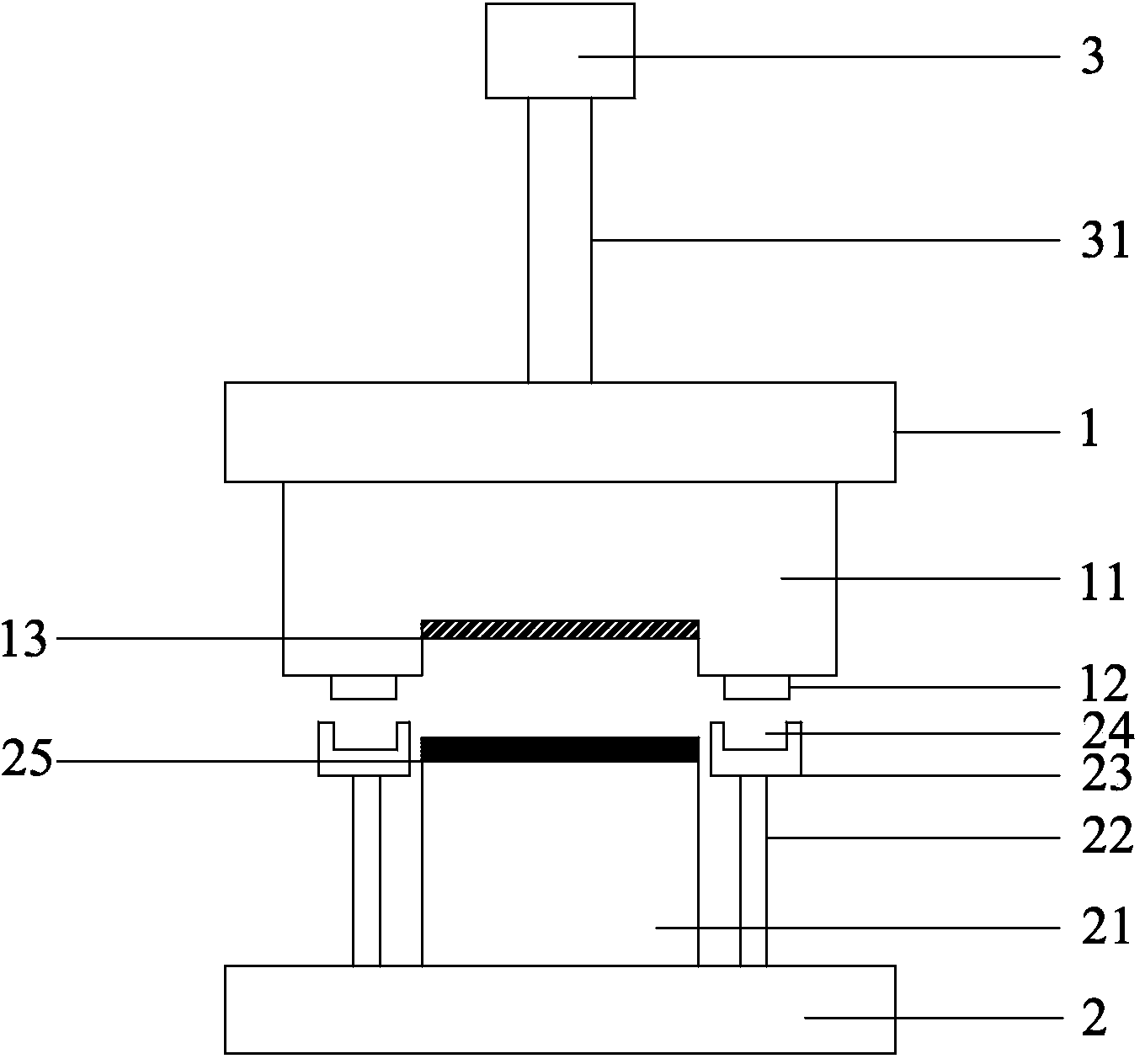

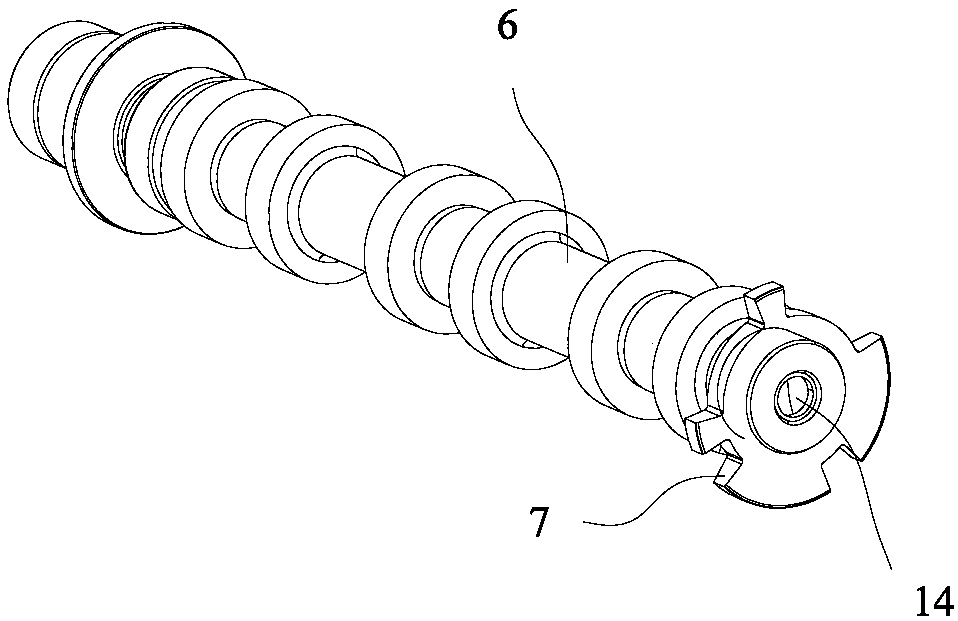

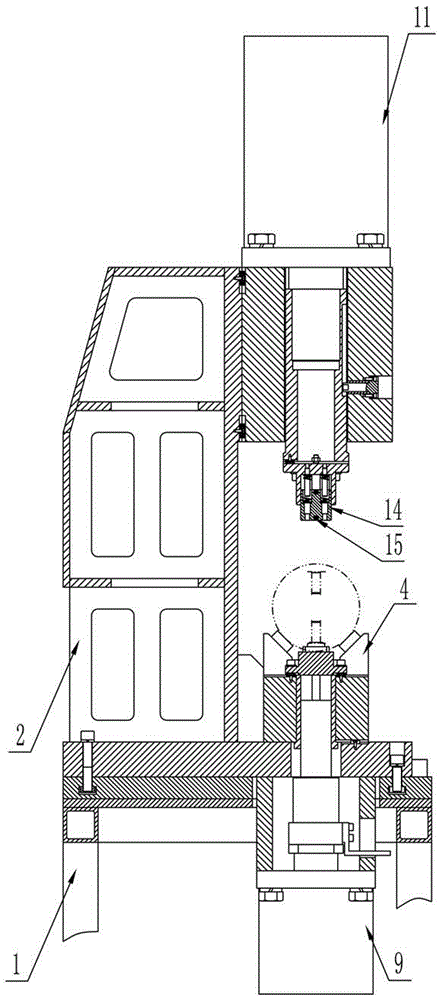

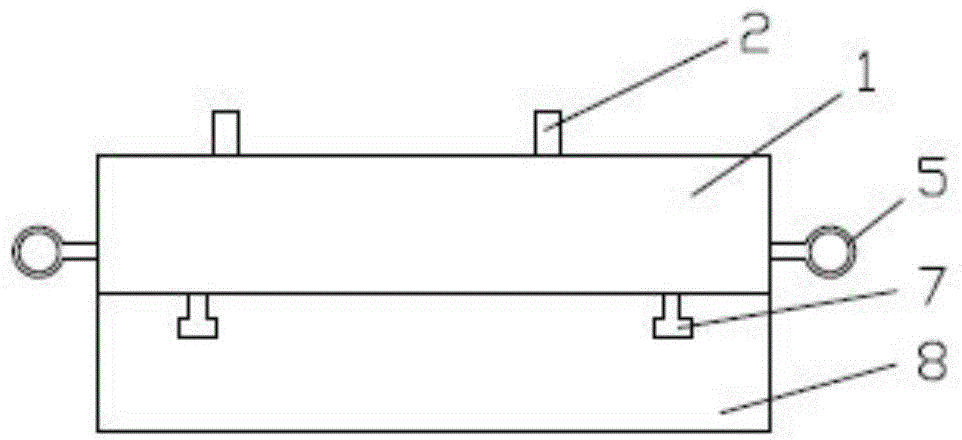

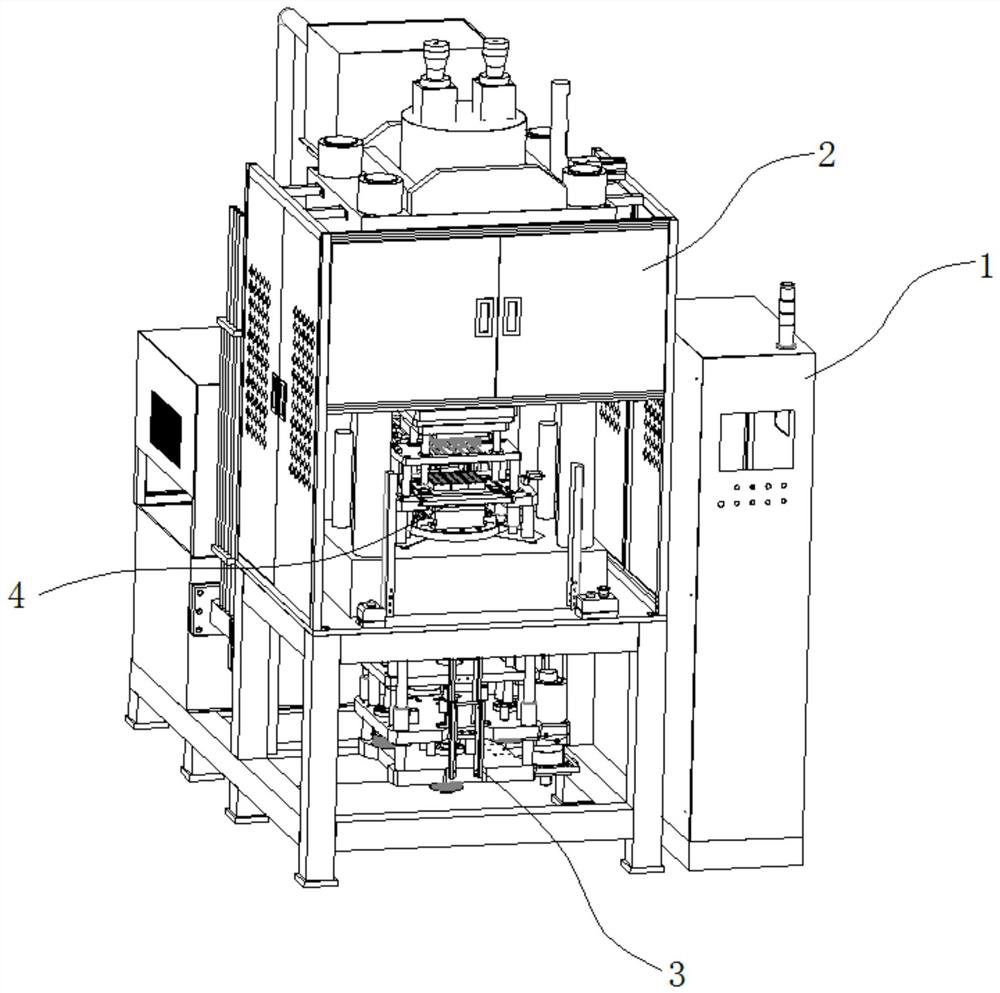

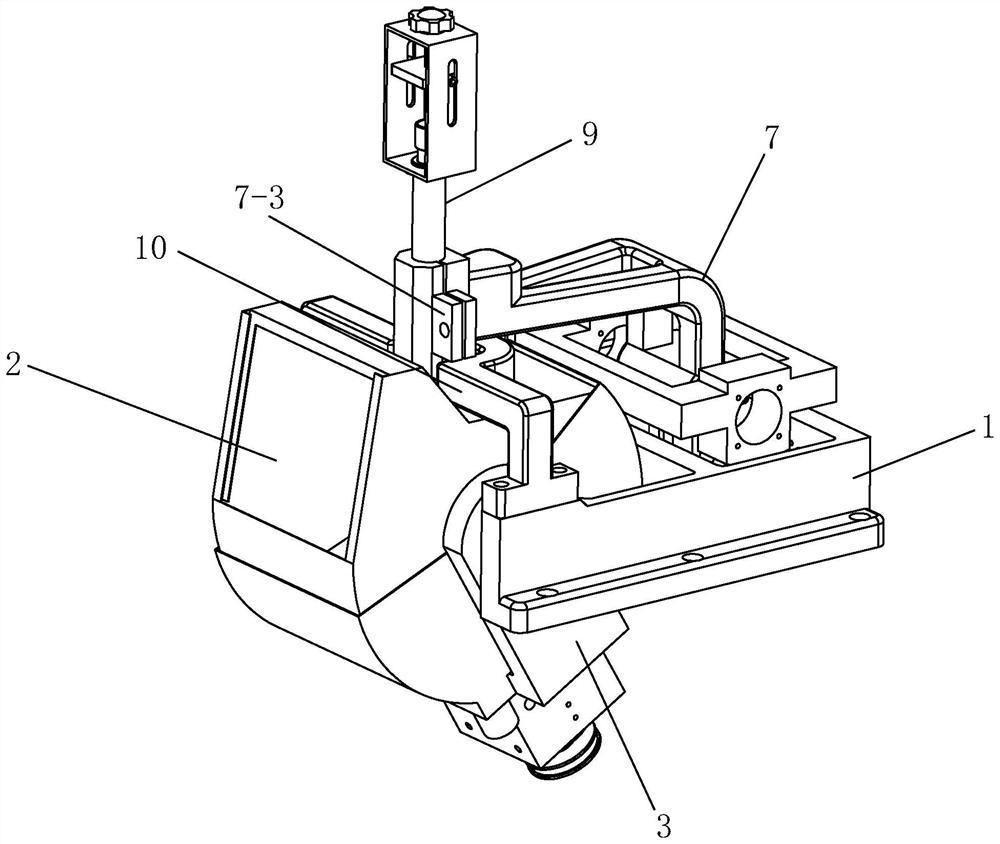

Camshaft assembly jig

ActiveCN106217032AImprove press fit accuracyIncrease productivityCamsAssembly machinesEngineeringCamshaft

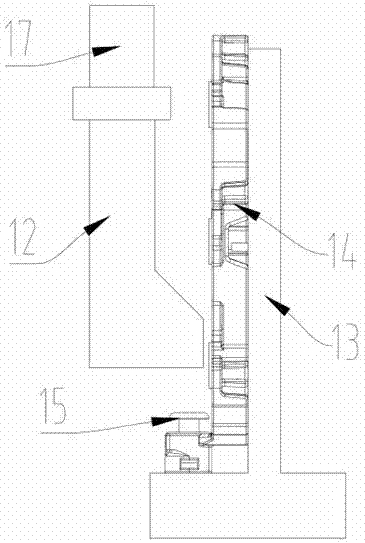

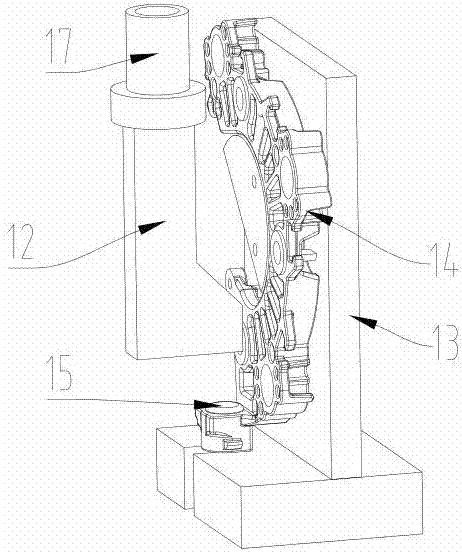

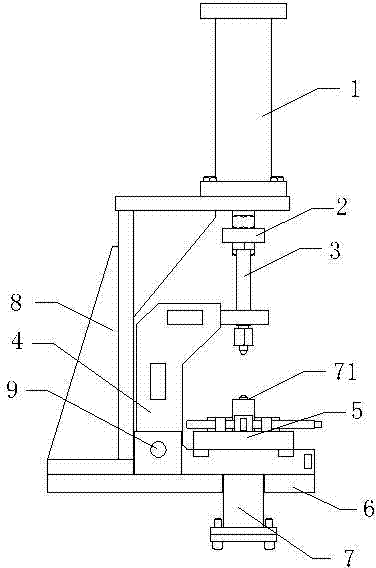

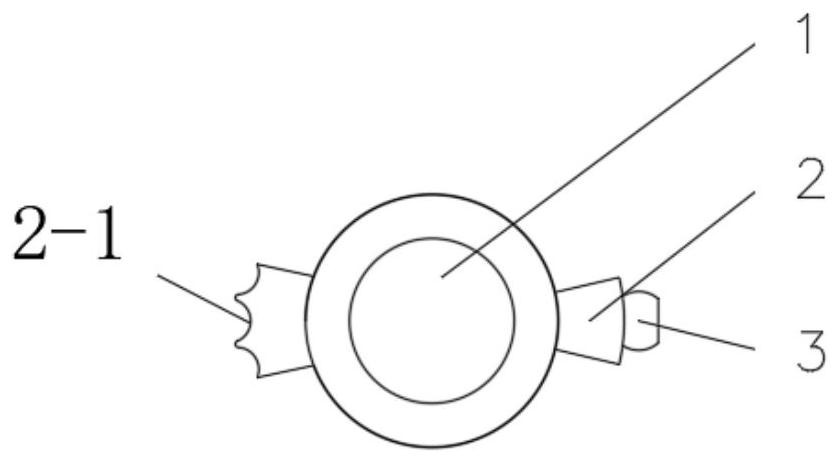

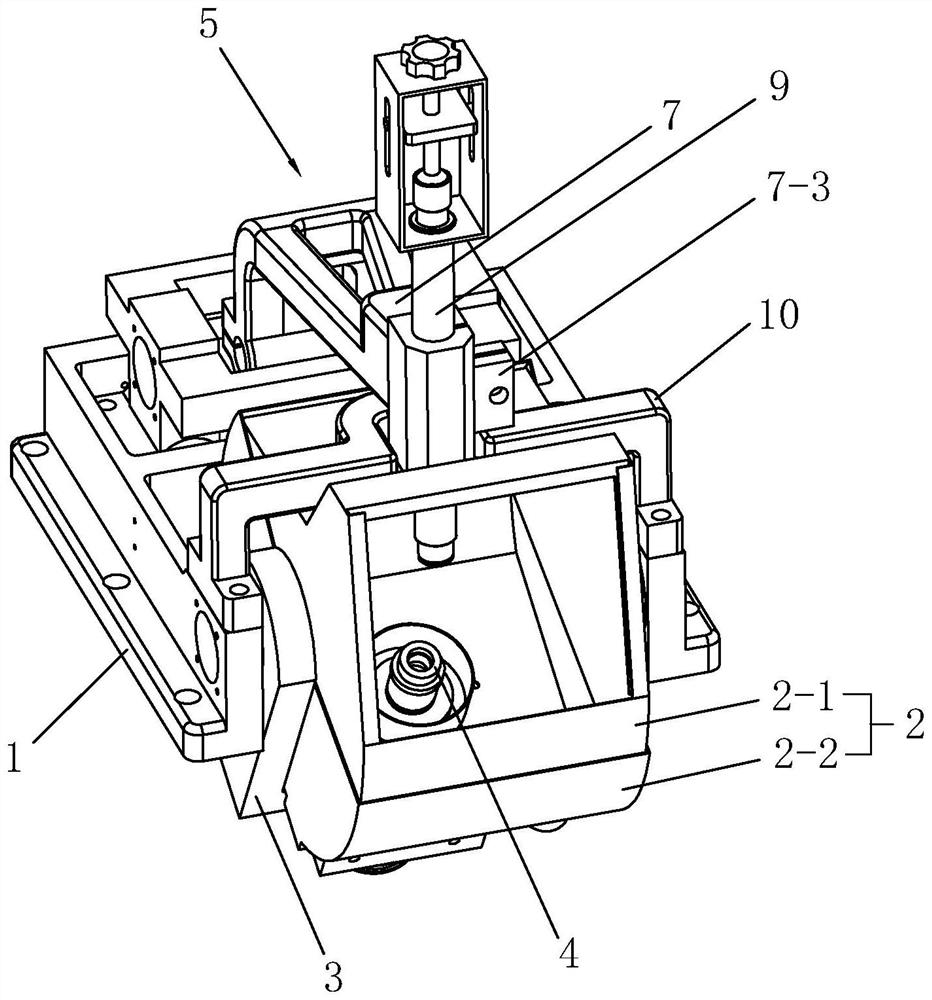

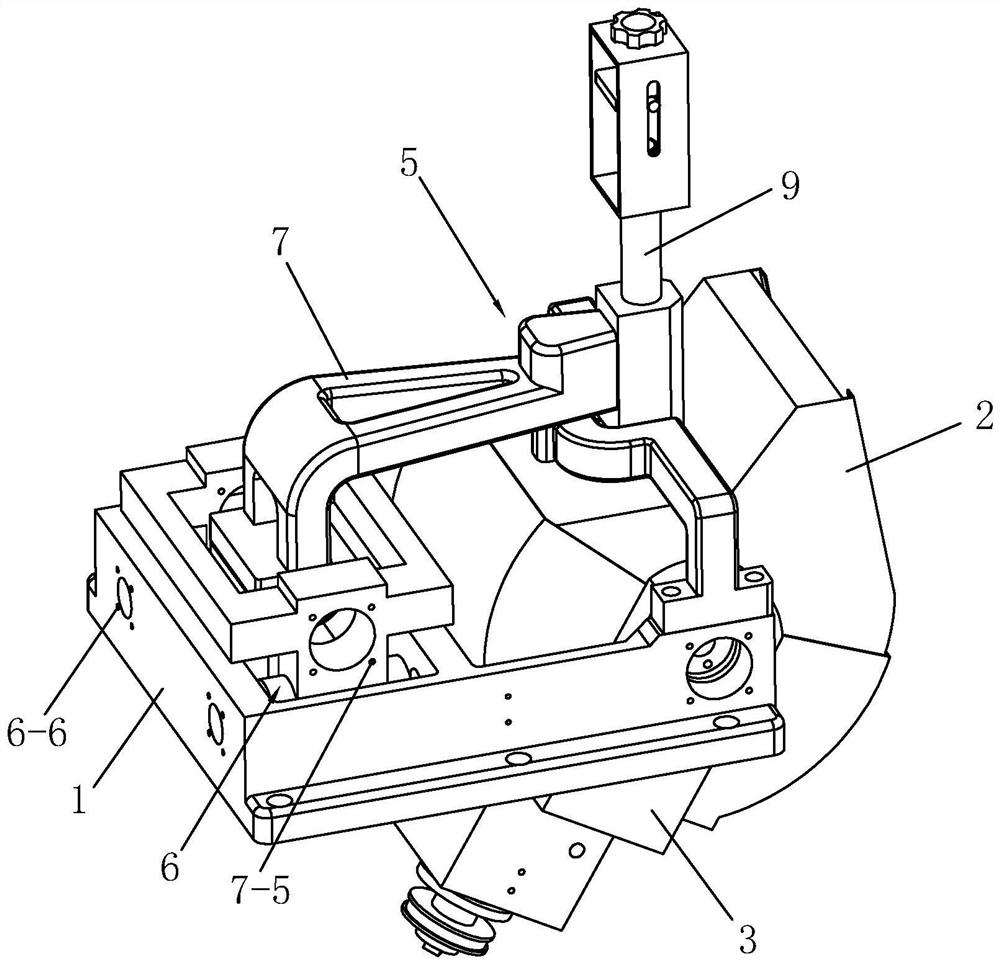

The invention discloses a camshaft assembly jig. The camshaft assembly jig comprises a base (1), a fixture (2), a press fitting part (3) and a power driving part (4), and further comprises a first installation rack (8), a second installation rack (9), a material rack (5), a grab hand (10) and a first driving mechanism (11),wherein the first installation rack (8) and the second installation rack (9) are arranged on the base (1), the material rack (5) is arranged on the first installation rack (8) and used for containing a plurality of signal wheels (7), the grab hand (10) is used for grabbing the signal wheels (7) in the material rack (5), the first driving mechanism (11) is arranged on the second installation rack (9) and used for driving the grab hand (10) to grab the signal wheels (7) and place the signal wheels (7) on the press fitting part (3), and the driving end of the first driving mechanism (11) is connected with the grab hand (10). According to the camshaft assembly jig, by adopting the structure, automatic feeding can be carried out when press fitting is carried out on a camshaft and a signal wheel, and therefore, the accuracy of press fitting and the production efficiency can be improved.

Owner:宁波圣龙智造凸轮轴有限公司

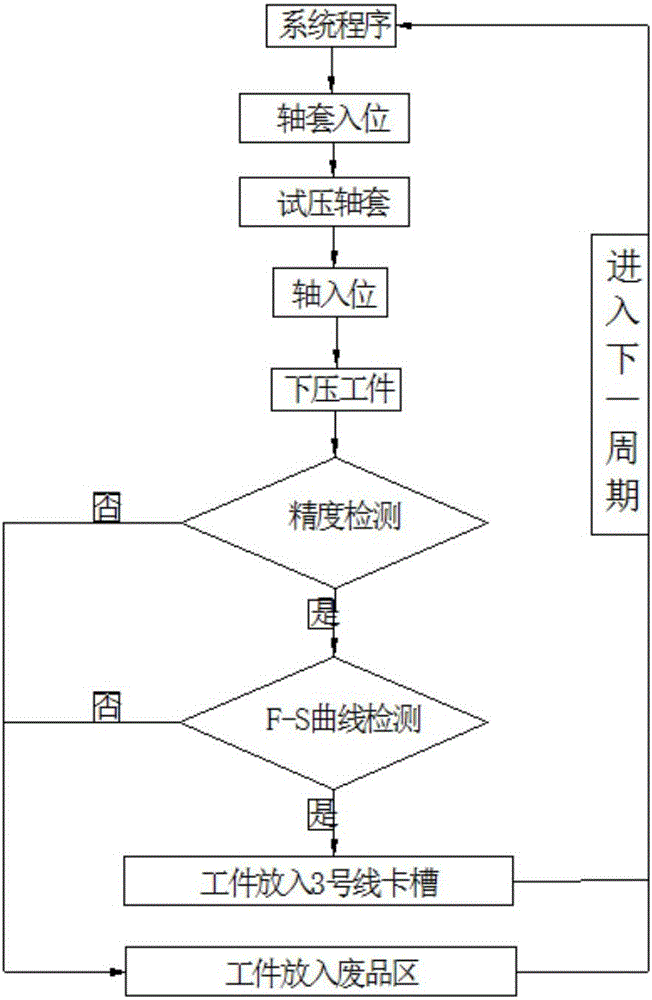

Shaft hole interference assembly automatic press mounting device and method

InactiveCN106378607ASimple structureGuaranteed pressing accuracyMetal working apparatusComputer moduleWaste product

The invention discloses shaft hole interference assembly automatic press mounting device and method. The automatic press mounting device comprises a workbench, a first manipulator, a second manipulator, a third manipulator, a three-jaw chuck, a press machine, a grating sensor, a multimeter, a control module, a waste product recycling tank, a first clamping groove, a second clamping groove and a third clamping groove; the first clamping groove, the second clamping groove and the third clamping groove are formed in the workbench; the press mounting sequence is as follows: shaft sleeve locating, shaft sleeve pressure testing, shaft locating, shaft hole press mounting, accuracy detection, F-S curve detection and assembly part fetching. According to the shaft hole interference assembly automatic press mounting device and method, the assembly accuracy is high, the reliability of an assembly part is good, the needed technical requirements can be well met, the reject rate is reduced, the press mounting efficiency is high, the whole structure is simple, the safety performance is good, the automation degree is high, the manpower and the material resources are greatly saved, and the shaft hole interference assembly automatic press mounting device and method are suitable for being popularized to various modernized shaft hole interference assembly automatic press mounting pipelines.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

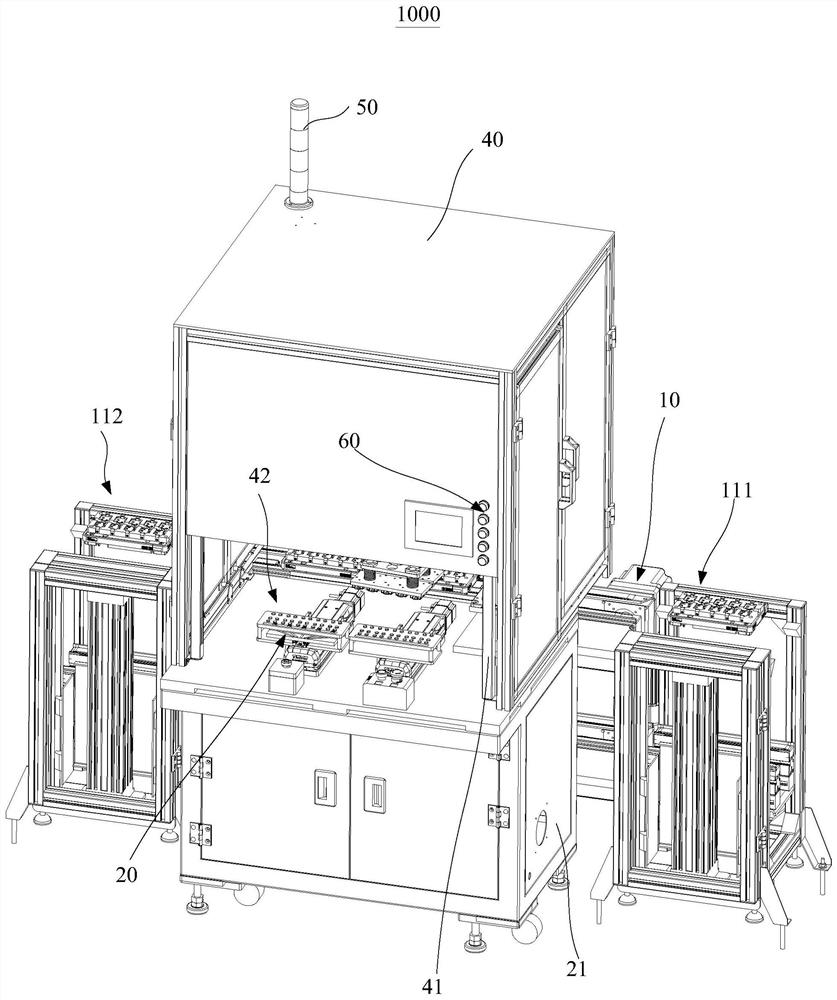

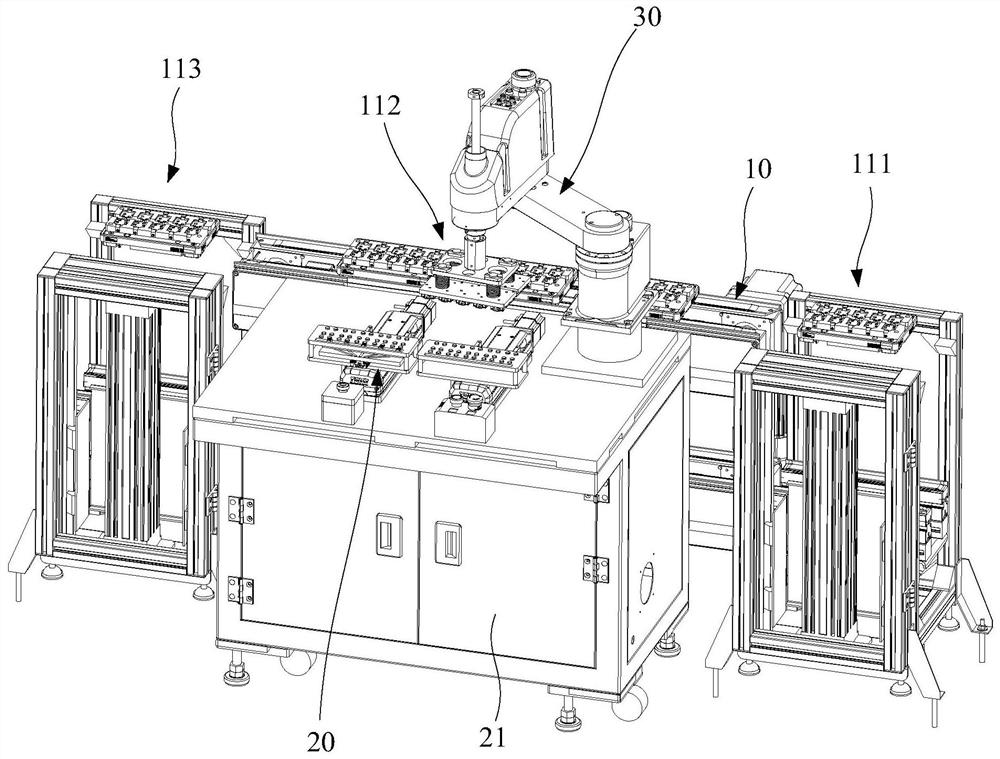

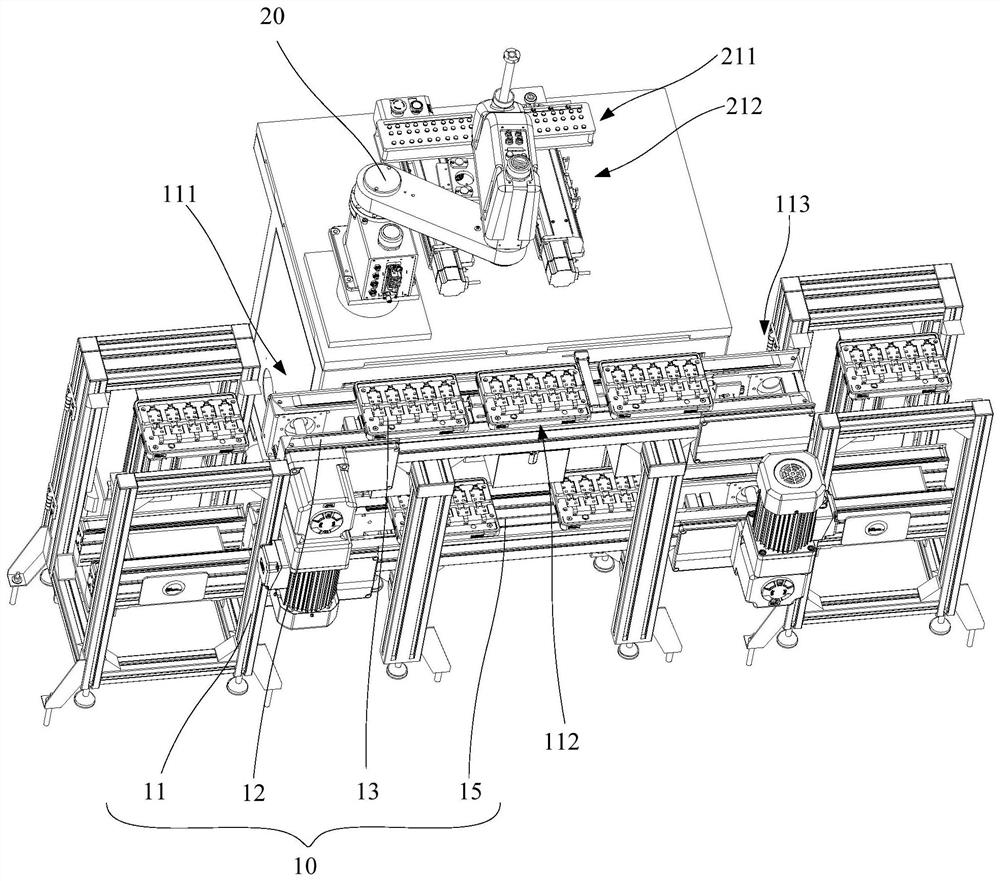

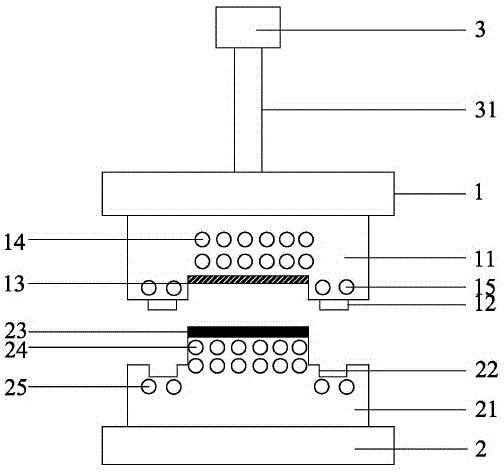

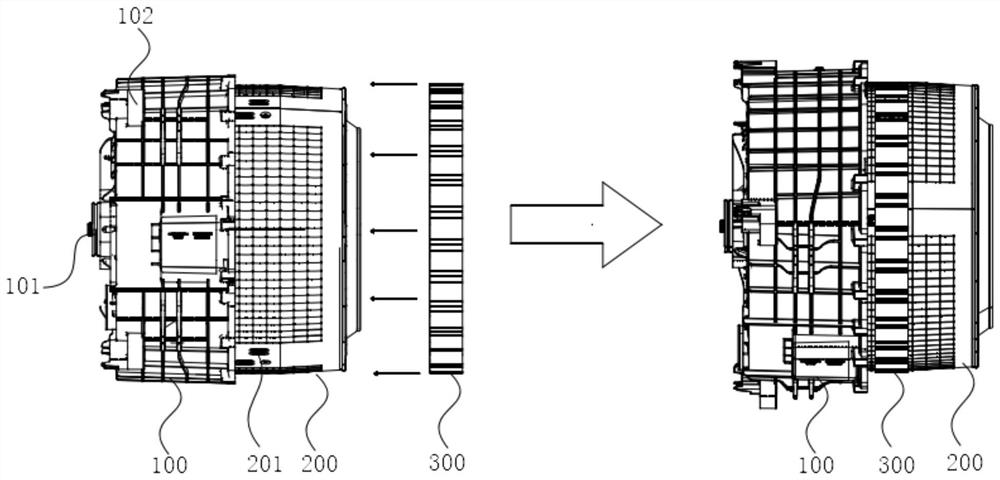

Automatic laminating device for multilayer circuit board

ActiveCN111615271AGuaranteed pressing accuracyGuaranteed pass rateCharge manipulationMultilayer circuit manufactureFlexible circuitsComposite plate

The invention discloses an automatic laminating device for a multilayer circuit board. The automatic laminating device for the multi-layer circuit board comprises a composite board conveying mechanism, a flexible board conveying mechanism and a laminating mechanism, the composite board conveying mechanism is provided with a feeding station, a material taking station and a discharging station whichare arranged in sequence, and the composite board conveying mechanism is used for conveying a composite circuit board from the feeding station to the material taking station. The flexible board conveying mechanism is provided with a laminating station and is used for conveying the flexible circuit board to the laminating station, the laminating mechanism is used for moving the composite circuit board located at the material taking station to the laminating station to be laminated with the flexible circuit board located at the laminating station, and then the laminated circuit board is conveyed to the discharging station through the laminating mechanism and the composite board conveying mechanism. According to the technical scheme, the composite circuit board and the flexible circuit boardcan be automatically laminated, the production takt and the yield are greatly improved, the laminating precision is ensured, and meanwhile, the manual operation intensity is effectively reduced.

Owner:江苏拓斯达机器人有限公司

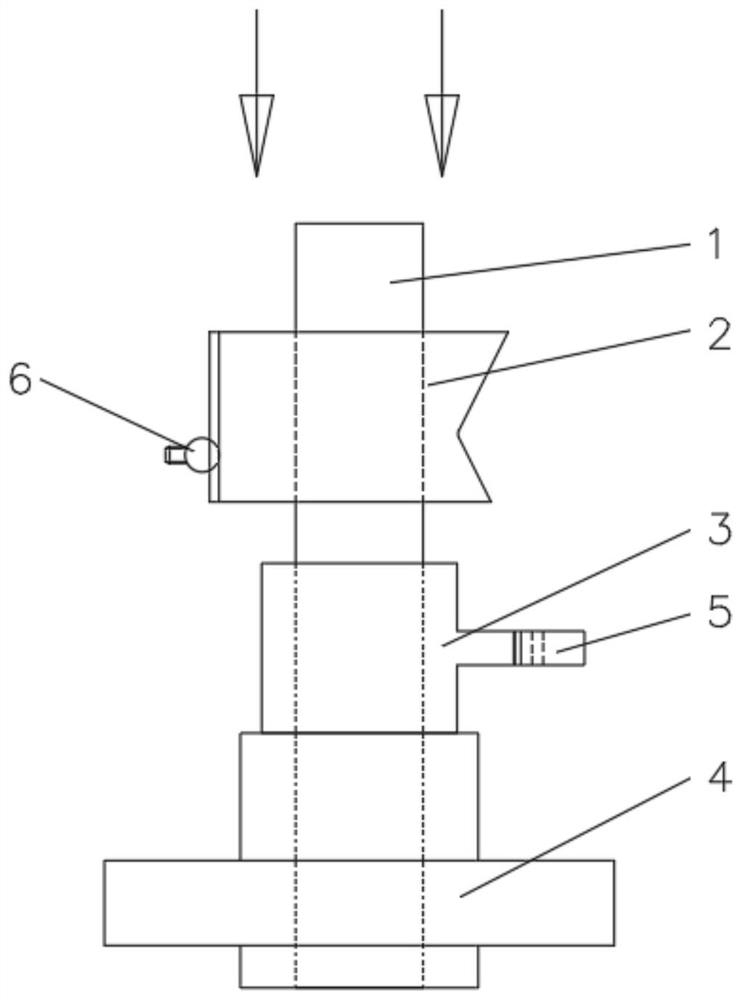

Water-cooling bending mould for automobile accessory machining

InactiveCN104923673AEasy to use and flexiblePlace stableShaping toolsVehicle componentsMachine partsPressure transmission

The invention is suitable for the field of automobile accessory machining, and provides a water-cooling bending mould for automobile accessory machining. The water-cooling bending mould for automobile accessory machining comprises a male mould machining part and a female mould machining part which is arranged at the upper end of the male mould machining part and matched with the male mould machining part, the female mould machining part is communicated with a pressure machine through a pressure transmission shaft, and the control end of the pressure machine is connected with a controller. The water-cooling bending mould for automobile accessory machining has the advantages of being simple in structure, strong in practicability, flexible and controllable in pressing, good in springback preventing effect and good in cooling and shaping effect.

Owner:LIUZHOU WEIQI NUMERICAL CONTROL MACHINERY

Springback prevention bending mold for machining automobile spare parts

The invention discloses a springback prevention bending mold for machining automobile spare parts. The springback prevention bending mold comprises a male mold machining part and a female mold machining part which is placed at the upper end of the male mold machining part and matched with the male mold machining part. The springback prevention bending mold for machining automobile spare parts is characterized in that the male mold machining part comprises a lower fixing plate and a male mold fixed at the upper end of the lower fixing plate, buffer bearing parts are arranged on the two sides of the male mold, the buffer bearing parts comprise telescopic supporting pillars and bearing tables fixed at the upper ends of the supporting pillars, the bearing tables are provided with positioning grooves, and the initial position of each bearing table and a platform at the top end of the male mold are placed in the same horizontal line; the female mold machining part comprises an upper fixing plate and a female mold fixed at the lower end of the upper fixing plate, and a positioning table of the female mold is provided with positioning protrusions used for being matched with the positioning grooves; the female mold machining part is communicated with a press machine through a pressure transmission shaft. The springback prevention bending mold has the advantages of being simple in structure, high in practicability, good in springback prevention effect and the like.

Owner:DALIAN ORIENT METAL

Camshaft assembly tooling

ActiveCN106217032BImprove press fit accuracyIncrease productivityCamsAssembly machinesEngineeringCamshaft

The invention discloses a camshaft assembly jig. The camshaft assembly jig comprises a base (1), a fixture (2), a press fitting part (3) and a power driving part (4), and further comprises a first installation rack (8), a second installation rack (9), a material rack (5), a grab hand (10) and a first driving mechanism (11),wherein the first installation rack (8) and the second installation rack (9) are arranged on the base (1), the material rack (5) is arranged on the first installation rack (8) and used for containing a plurality of signal wheels (7), the grab hand (10) is used for grabbing the signal wheels (7) in the material rack (5), the first driving mechanism (11) is arranged on the second installation rack (9) and used for driving the grab hand (10) to grab the signal wheels (7) and place the signal wheels (7) on the press fitting part (3), and the driving end of the first driving mechanism (11) is connected with the grab hand (10). According to the camshaft assembly jig, by adopting the structure, automatic feeding can be carried out when press fitting is carried out on a camshaft and a signal wheel, and therefore, the accuracy of press fitting and the production efficiency can be improved.

Owner:宁波圣龙智造凸轮轴有限公司

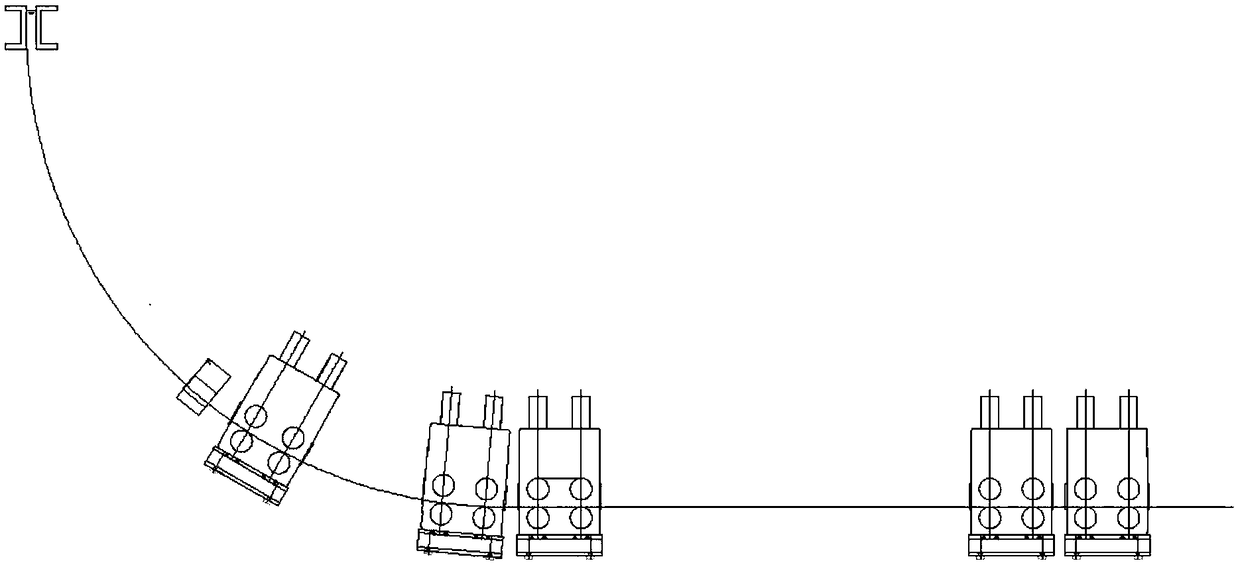

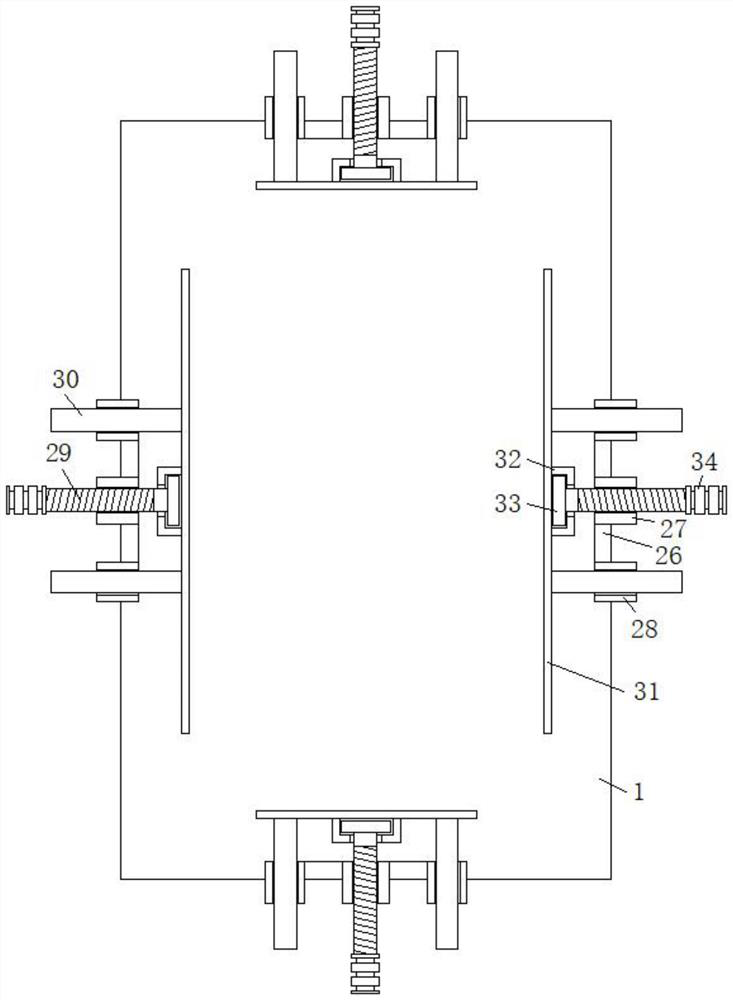

Memorial archway type tension leveler and small billet continuous casting machine applying same for reduction

The invention discloses a memorial archway type tension leveler. The memorial archway type tension leveler comprises a memorial archway type frame, at least two sets of tension-straightening rollers and lifting driving mechanisms, wherein the memorial archway type frame comprises a base, an upper framework and a plurality of rows of stand column frames, each set of tension-straightening rollers are located between two adjacent rows of stand column frames, and comprise one upper tension-straightening roller and one lower tension-straightening roller, the lifting driving mechanisms are installedon the upper framework, the number of the lifting driving mechanisms is the same as the number of the sets of the tension-straightening rollers, displacement sensors are installed on the upper portions of the lifting driving mechanism, the lower portions of the lifting driving mechanisms are connected with upper tension-straightening roller lifting frames, the upper tension-straightening rollersare rotationally arranged in the upper tension-straightening roller lifting frames, the lower tension-straightening rollers are rotationally installed on the stand column frames, sliding rails are arranged on one sides, facing the tension-straightening rollers, of the stand column frames, and the lifting driving mechanisms drive the upper tension-straightening roller lifting frames to slide up anddown in the sliding rails. The memorial archway type structure is simple and compact, is good in framework rigidity and has a stable guiding function, the reduction amount is controlled accurately, and the quality of a casting blank is guaranteed. The invention further discloses a small square billet continuous casting machine applying the memorial archway type tension leveler for reduction.

Owner:CONTINUOUS CASTING TECH ENG OF CHINA

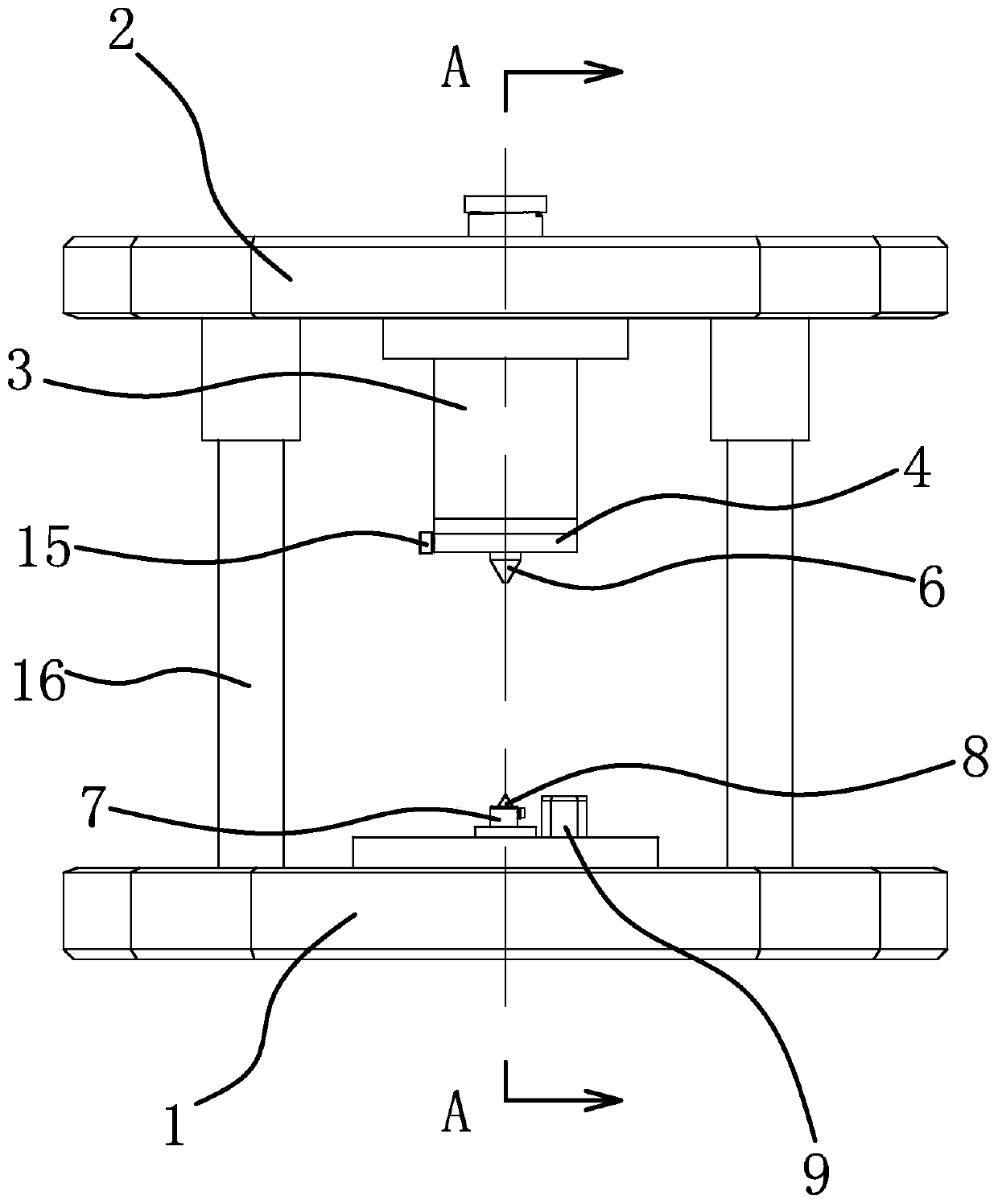

Shaft part pressing fitting device

ActiveCN107971728AHigh degree of automationImprove controllabilityMetal working apparatusMechanical engineeringDislocation

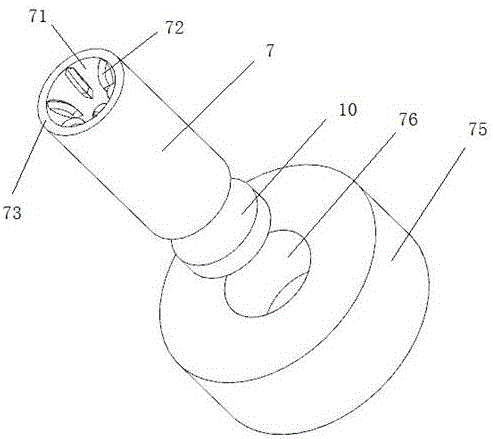

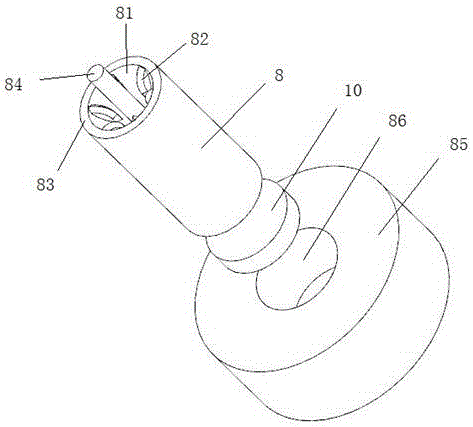

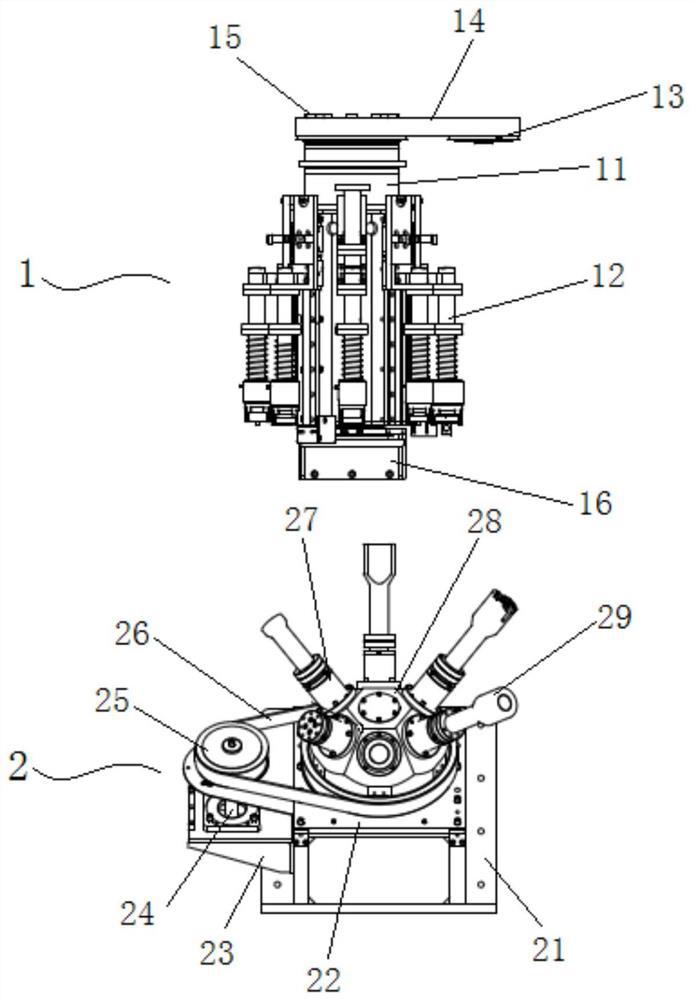

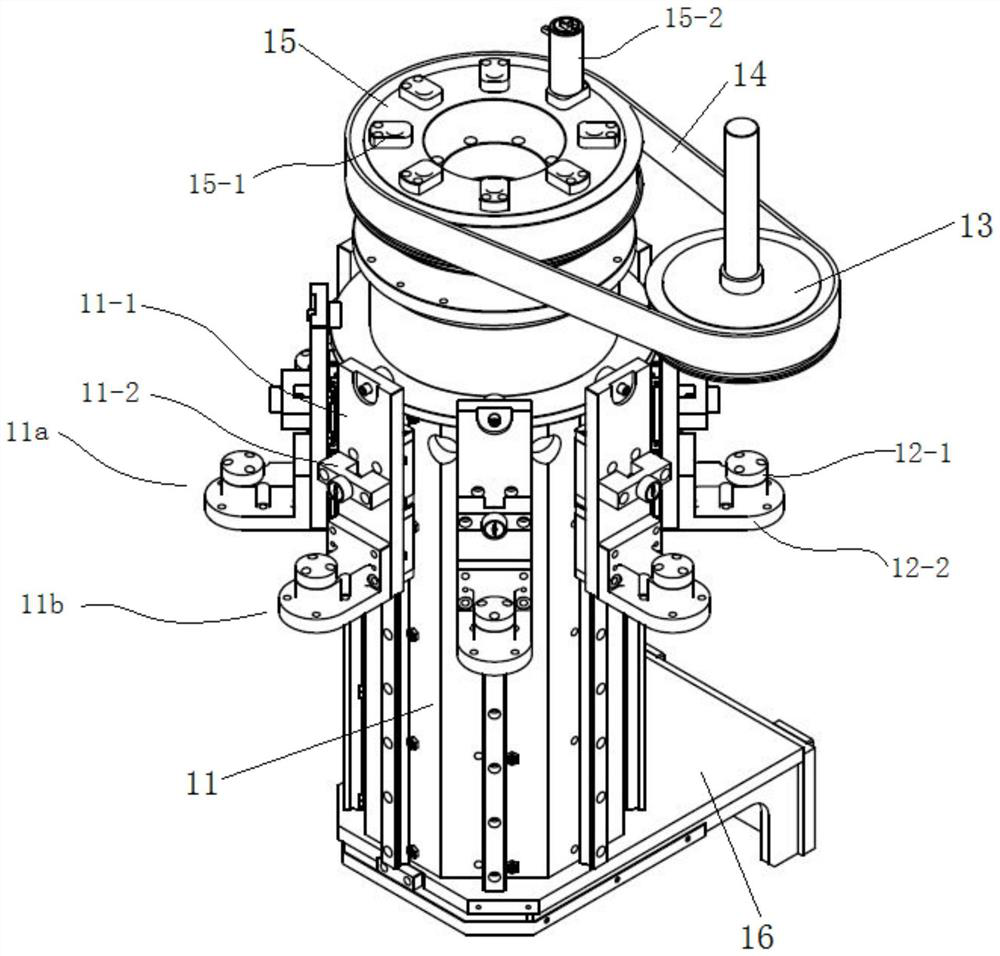

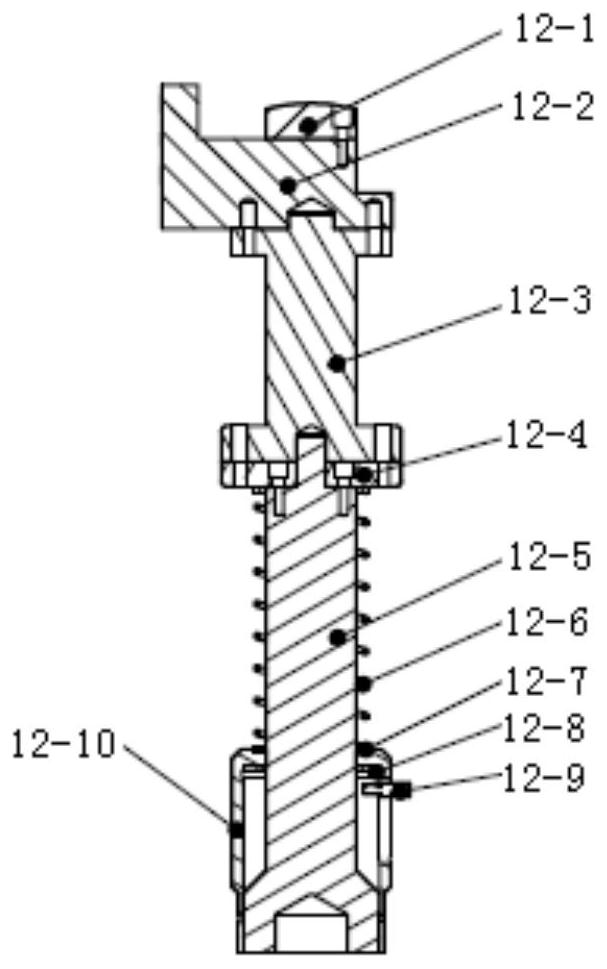

The invention discloses a shaft part pressing fitting device, and belongs to the technical field of shaft sleeve part assembly equipment. The problem that circumferential coiling and pressing fittingdislocation are easily caused in the pressing fitting process in the prior art are solved. The shaft part pressing fitting device comprises an upper stamping part and a lower stamping part. The upperstamping part and the lower stamping part move relatively so as to achieve fitting of shaft parts. The upper stamping part comprises a first power assembly, an upper frame body, an upper pressing block assembly and a first adjusting disk assembly. The output end of the first power assembly is installed at the upper end of the upper frame body. The upper pressing block assembly is fixed on the lower portion of the upper frame body. The first adjusting disk assembly is arranged on a frame body at the lower end of the pressing block assembly. The lower stamping part comprises a second power assembly, a lower frame body, a lower pressing block assembly and a second adjusting disk assembly. The output end of the second power assembly is installed at the lower end of the lower frame body. By means of the shaft part pressing fitting device, circumferential rim coiling and unsmooth pressing fitting which are caused by slight dislocation in the pressing fitting process are avoided effectively,and the defective percentage is reduced effectively.

Owner:成都宁翔机械制造有限责任公司

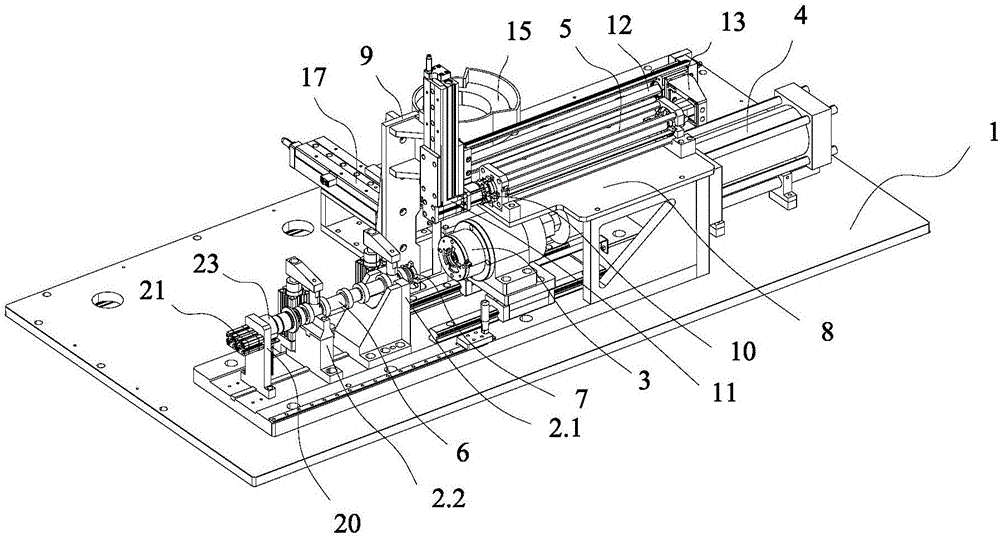

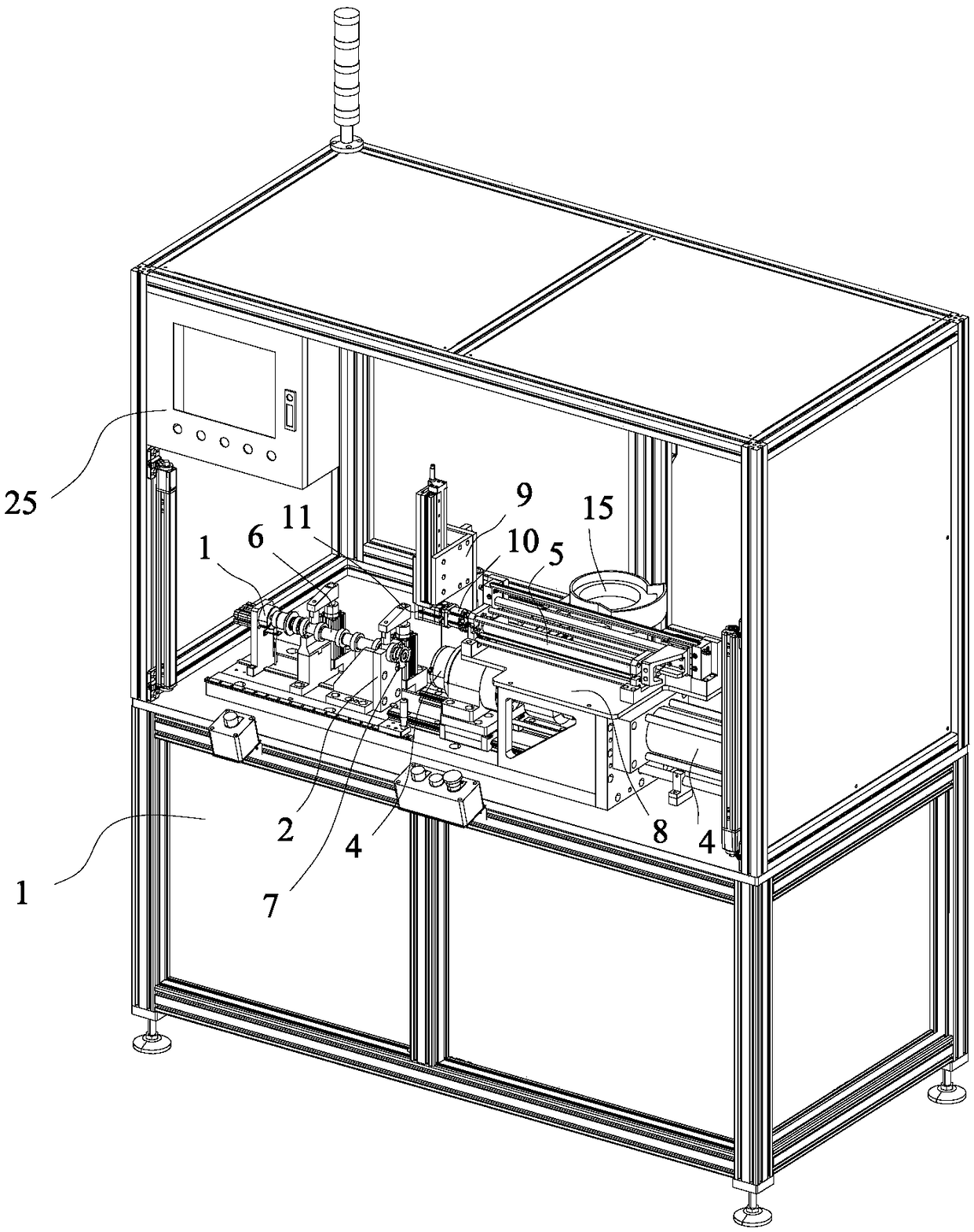

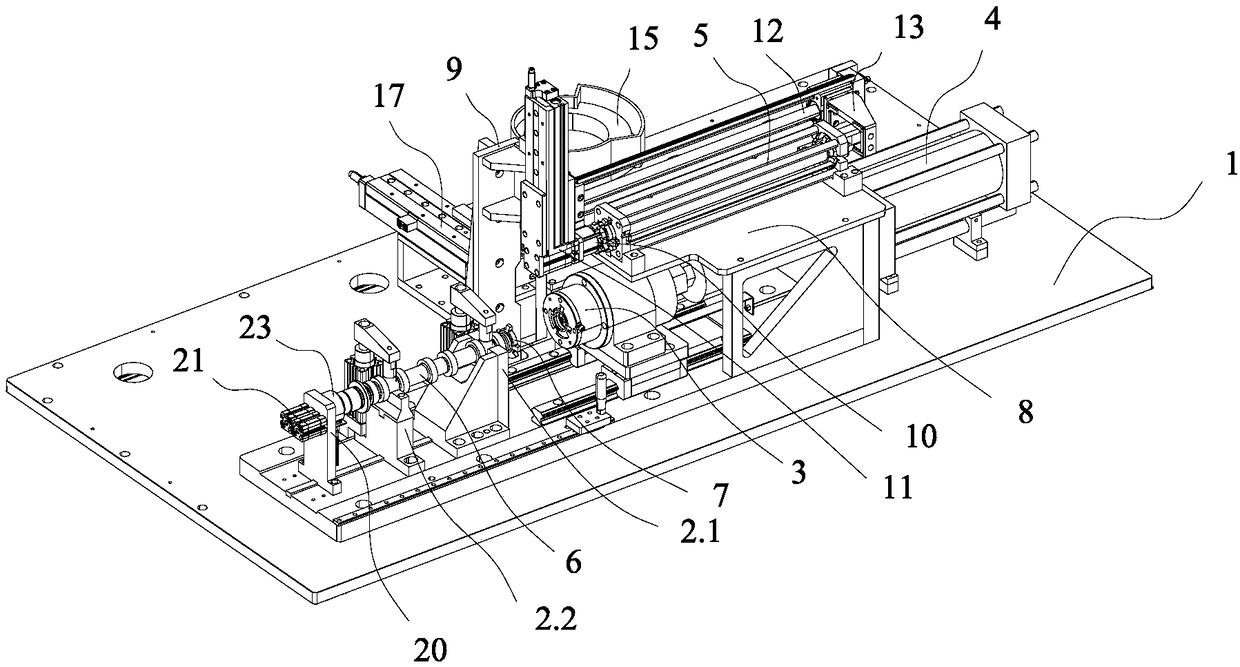

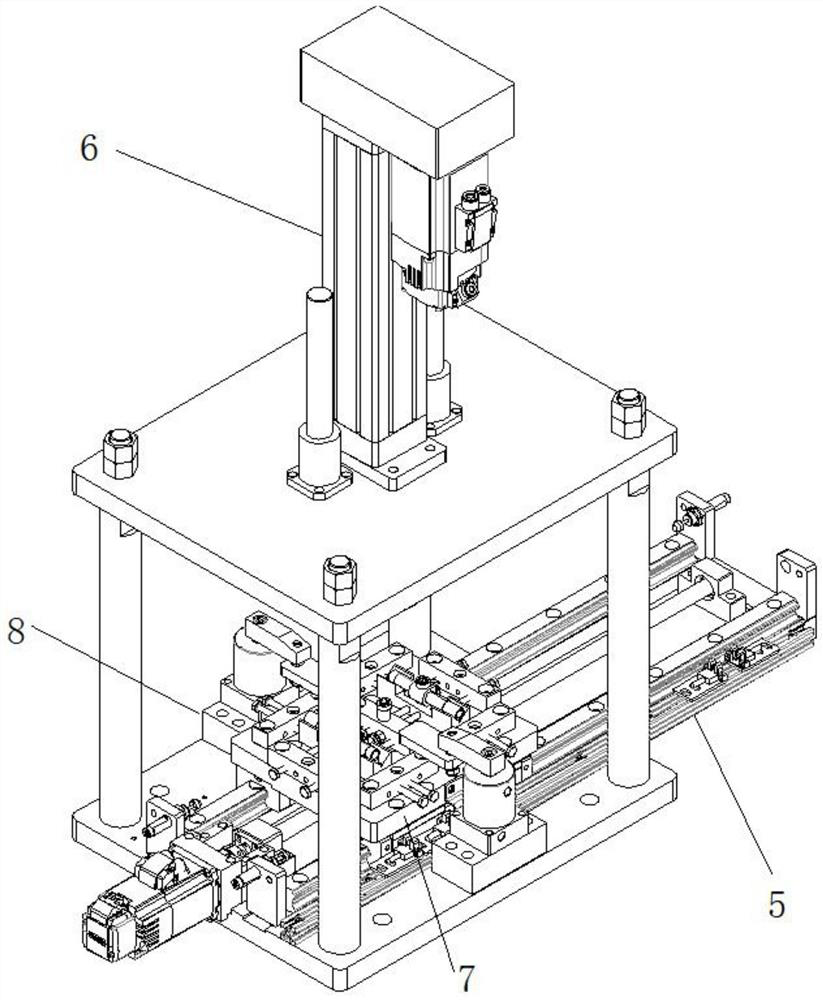

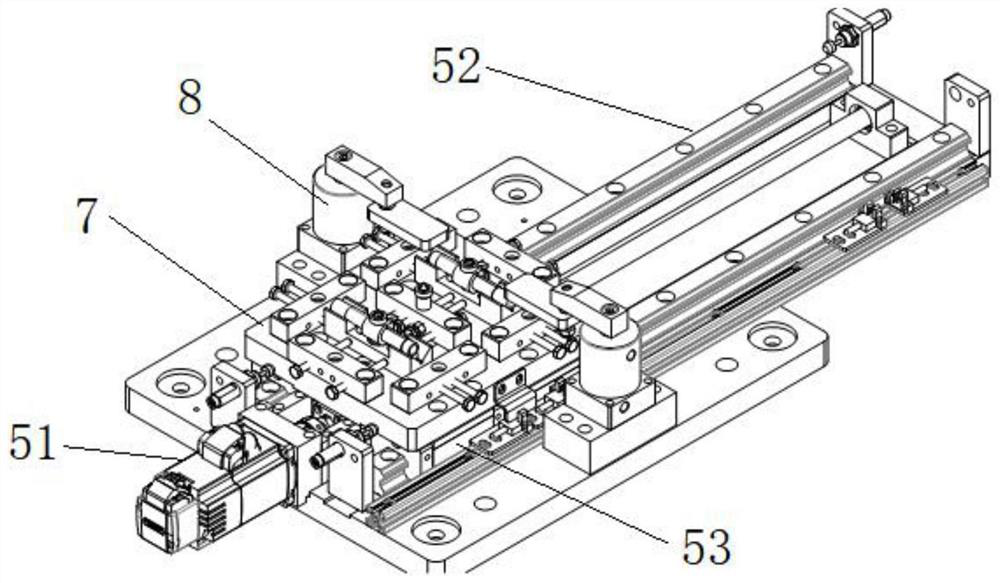

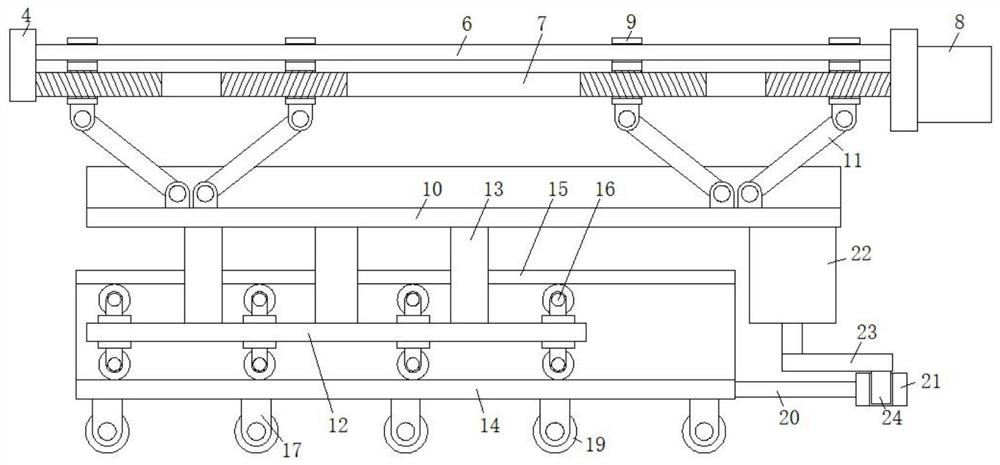

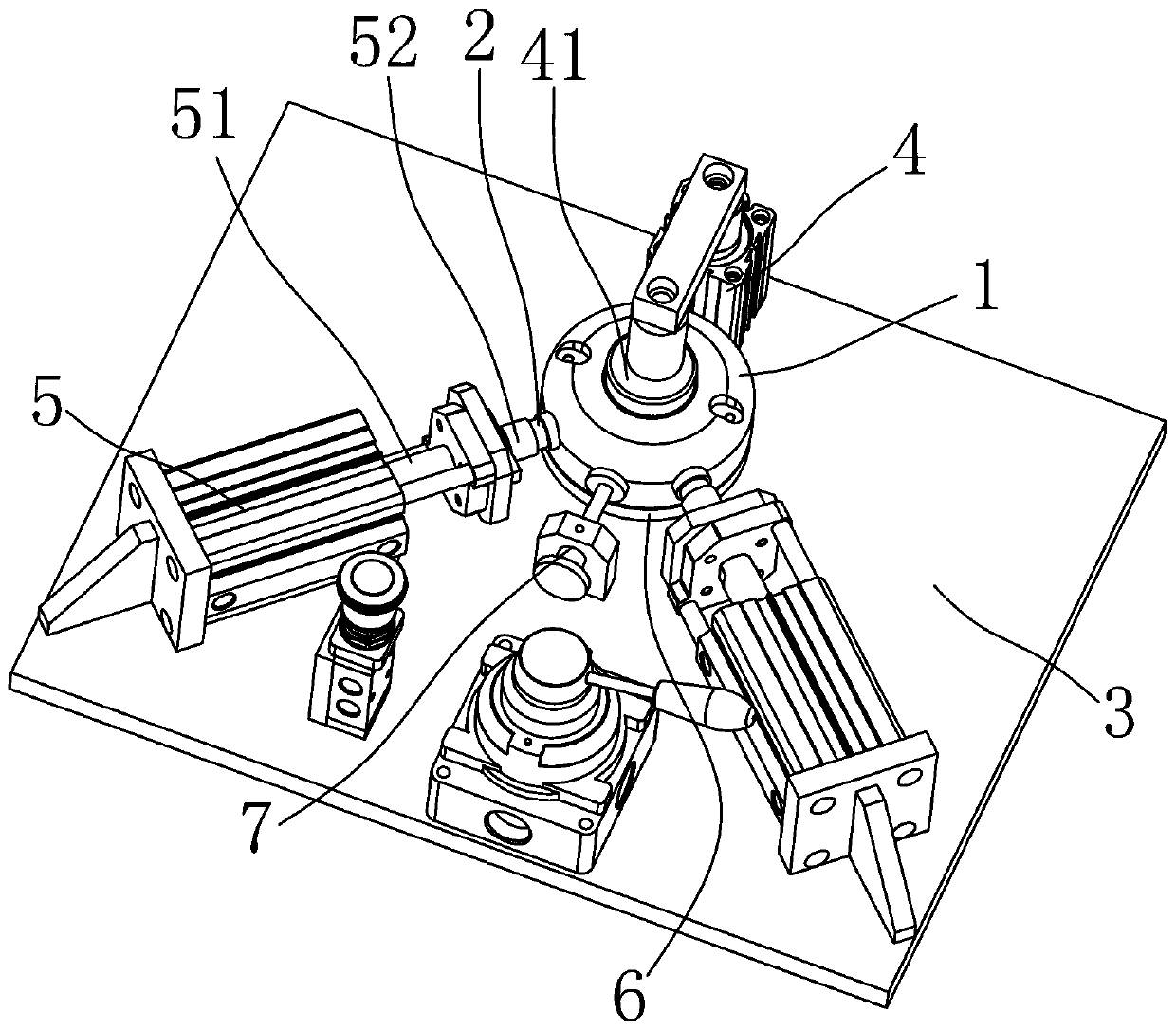

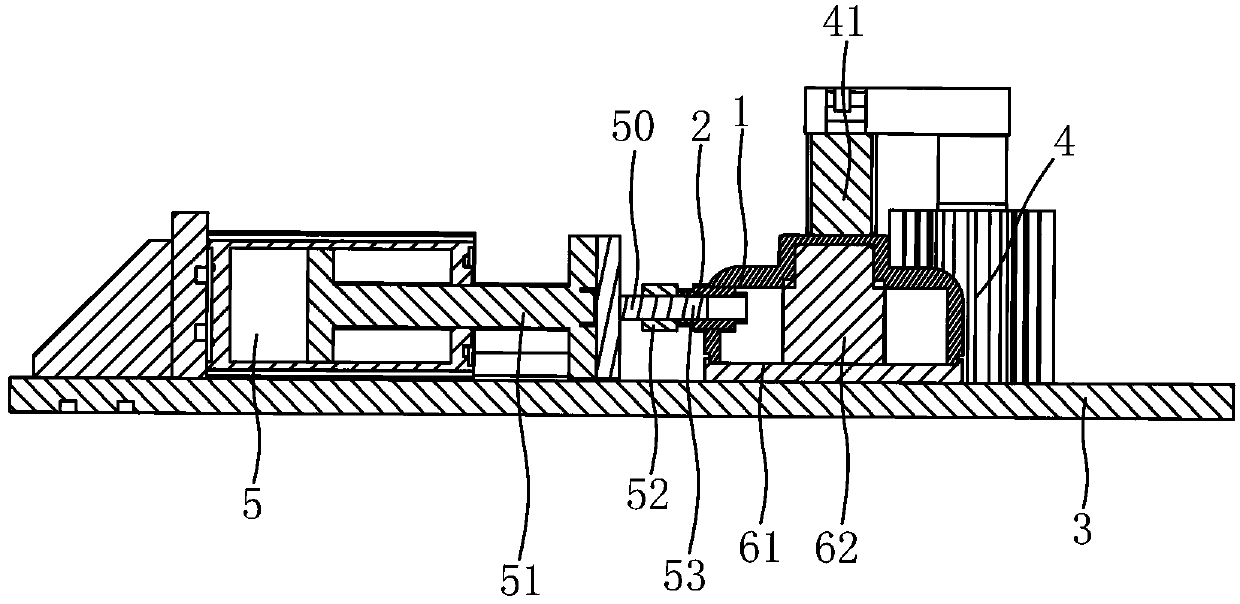

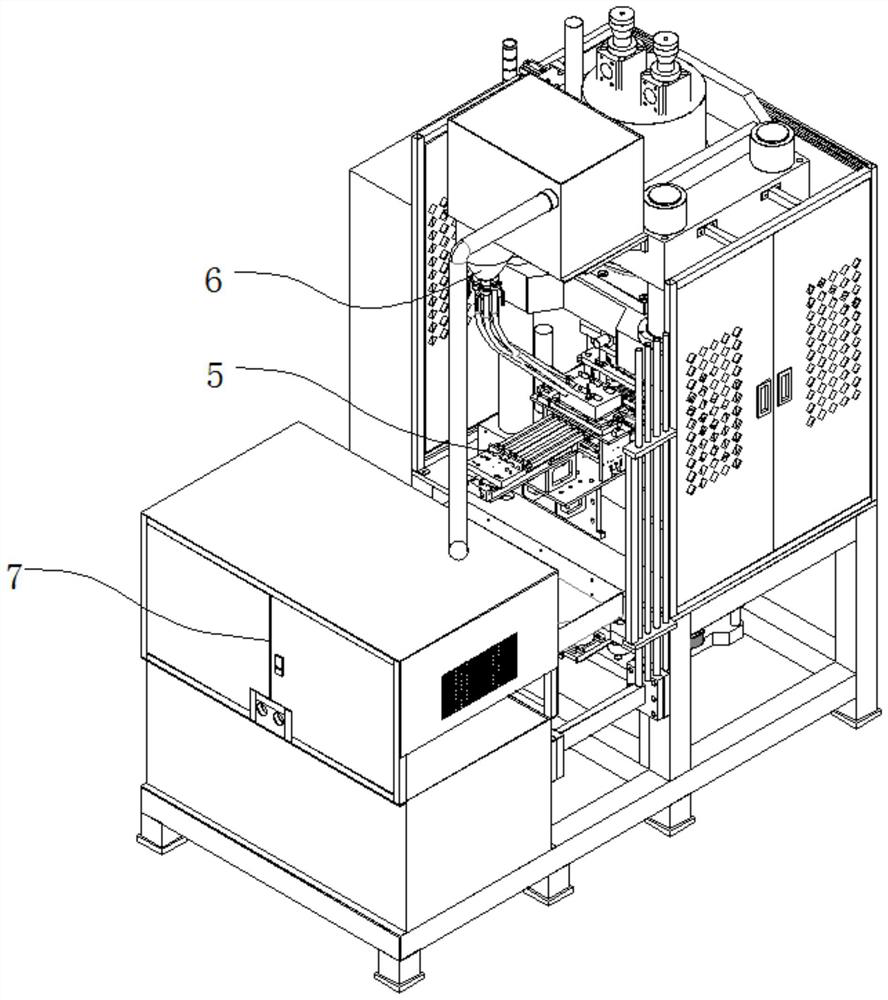

Automatic press-fitting system and assembling method for ball screw pair supporting sleeves

The invention relates to an automatic press-fitting system and assembling method for ball screw pair supporting sleeves, belongs to the technical field of automatic assembly, and solves the problems of low assembly precision and complex operation of a mode of assembling the supporting sleeves by manual press-fitting, hot-fitting or cold-fitting in the prior art. The automatic press-fitting system comprises a sliding rail mechanism, a press fitting mechanism, a sliding clamp, an auxiliary positioning mechanism and a turnover mechanism, wherein the sliding clamp is used for loading the positioning support sleeves and ball screw pairs; the sliding clamp can slide on the sliding rail mechanism; the press-fitting mechanism is provided with a telescopic pressing head, and the supporting sleeves can be clamped into supporting sleeve clamping grooves of the telescopic pressing head and fixed through the auxiliary positioning mechanism; the supporting sleeves comprise a first supporting sleeve and a second supporting sleeve; the press-fitting mechanism can press-fit the first supporting sleeve on ball screw pairs by pressing the telescopic pressing head; the turnover mechanism can turn over the ball screw pairs, and the second supporting sleeve is pressed after the ball screw pairs are turned over. Automatic pressing of the ball screw pair supporting sleeves is achieved.

Owner:BEIJING MECHANICAL EQUIP INST

Positioning pressing machine for bi-directionally adjusting clamp position

ActiveCN104384891ASolve a single problemImprove applicabilityWork holdersMetal working apparatusEngineeringMechanical engineering

The invention discloses a positioning pressing machine for bi-directionally adjusting a clamp position and belongs to the technical field of clamps. The positioning pressing machine comprises a frame and a positioning clamp located on the frame, wherein the positioning clamp comprises a workbench panel, a clamp base plate and a positioning pin; the clamp base plate is located on the workbench panel; a pin hole is formed in a top surface of the clamp base plate; a through slot communicated with the pin hole is formed in a side face of the clamp base plate; a wedge block is arranged in the through slot; the bottom surface of the positioning pin is arranged as a slope and is resisted against a wedge-shaped surface of the wedge block; the slope is matched with the wedge-shaped surface of the wedge block; the height of the positioning pin is not more than the thickness of the clamp base plate; a handle extending out of the clamp base plate is arranged on an end part of the wedge block; two horizontally formed slide slots are formed in the clamp base plate; the slide slots pass through the upper and lower surfaces of the clamp base plate; two longitudinally formed T-shaped slots are formed in the upper surface of the workbench panel. Different positioning pins are used for different product workpieces, so that the applicability and efficiency of the pressing machine are promoted.

Owner:湖南插旗菜业有限公司

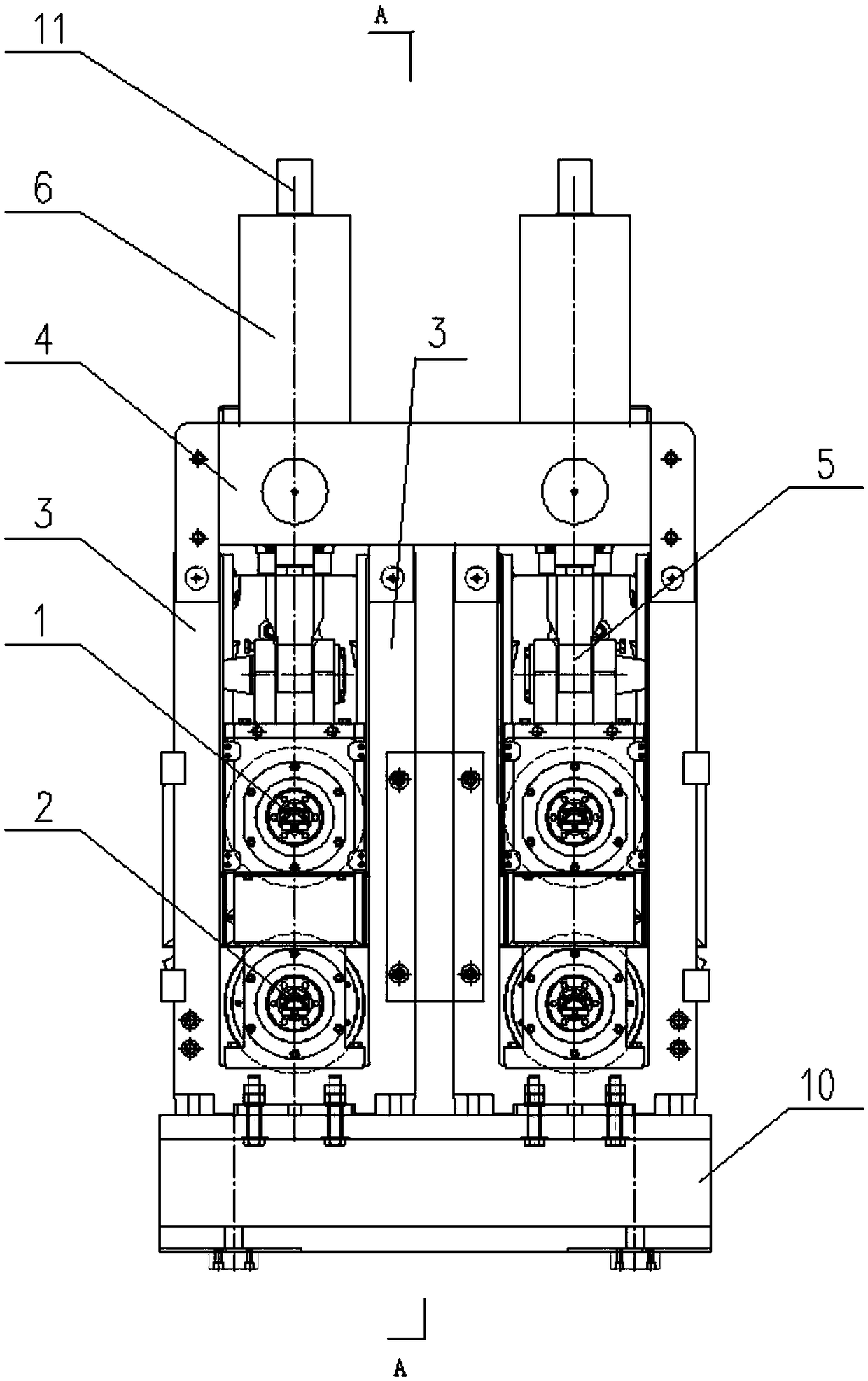

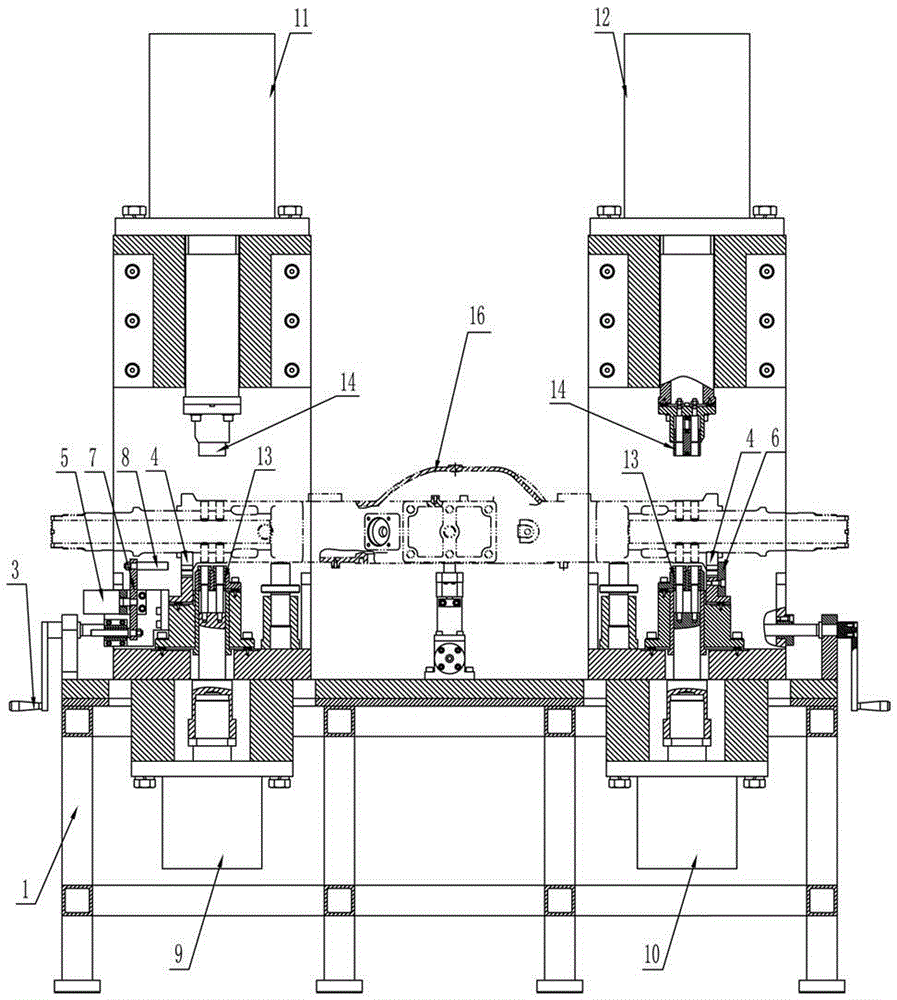

Central axle housing and semi-axial casing pipe assembly positioning pin pressing machine

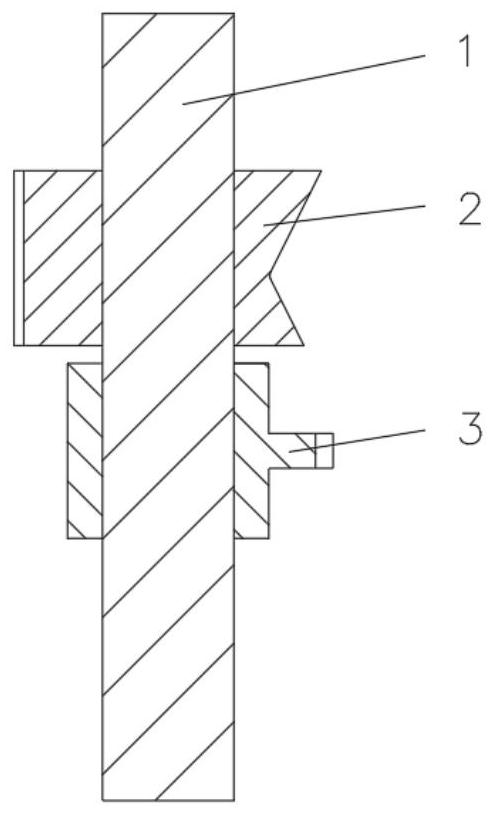

PendingCN106624731AGuaranteed pressing accuracyUniform and stable pressureVehicle componentsMetal working apparatusHydraulic cylinderPiston rod

The invention provides a central axle housing and semi-axial casing pipe assembly positioning pin pressing machine. The pressing machine includes a rack; a bed is arranged on the rack; the bed and the rack are slidingly connected; a positioning mechanism and a pressing mechanism are arranged on the bed; the positioning mechanism includes an axial positioning mechanism and a radial positioning mechanism; the radial positioning mechanism includes two V-shaped positioning plates; the axial positioning mechanism includes a thin oil cylinder and an axial limiting plate, and the thin oil cylinder is horizontally fixed; a push rod is arranged on a piston rod of the thin oil cylinder; the push rod and the axial limiting plate are arranged coaxially; the pressing mechanism includes a first hydraulic cylinder, a second hydraulic cylinder, a third hydraulic cylinder, and a fourth hydraulic cylinder; the first hydraulic cylinder and the second hydraulic cylinder are vertically arranged on the lower end of the bed; the third hydraulic cylinder and the fourth hydraulic cylinder are vertically arranged on the upper end of the bed; the fourth hydraulic cylinder and the second hydraulic cylinder are arranged correspondingly; the third hydraulic cylinder and the first hydraulic cylinder are arranged correspondingly; lower positioning sleeves are arranged on piston rods of the first hydraulic cylinder and the second hydraulic cylinder; and upper positioning sleeves are arranged on piston rods of the third hydraulic cylinder and the fourth hydraulic cylinder. The pressing machine is good in pressing quality, can reduce the working intensity of workers, and can improve the assembly efficiency.

Owner:HUBEI UNIV OF AUTOMOTIVE TECH

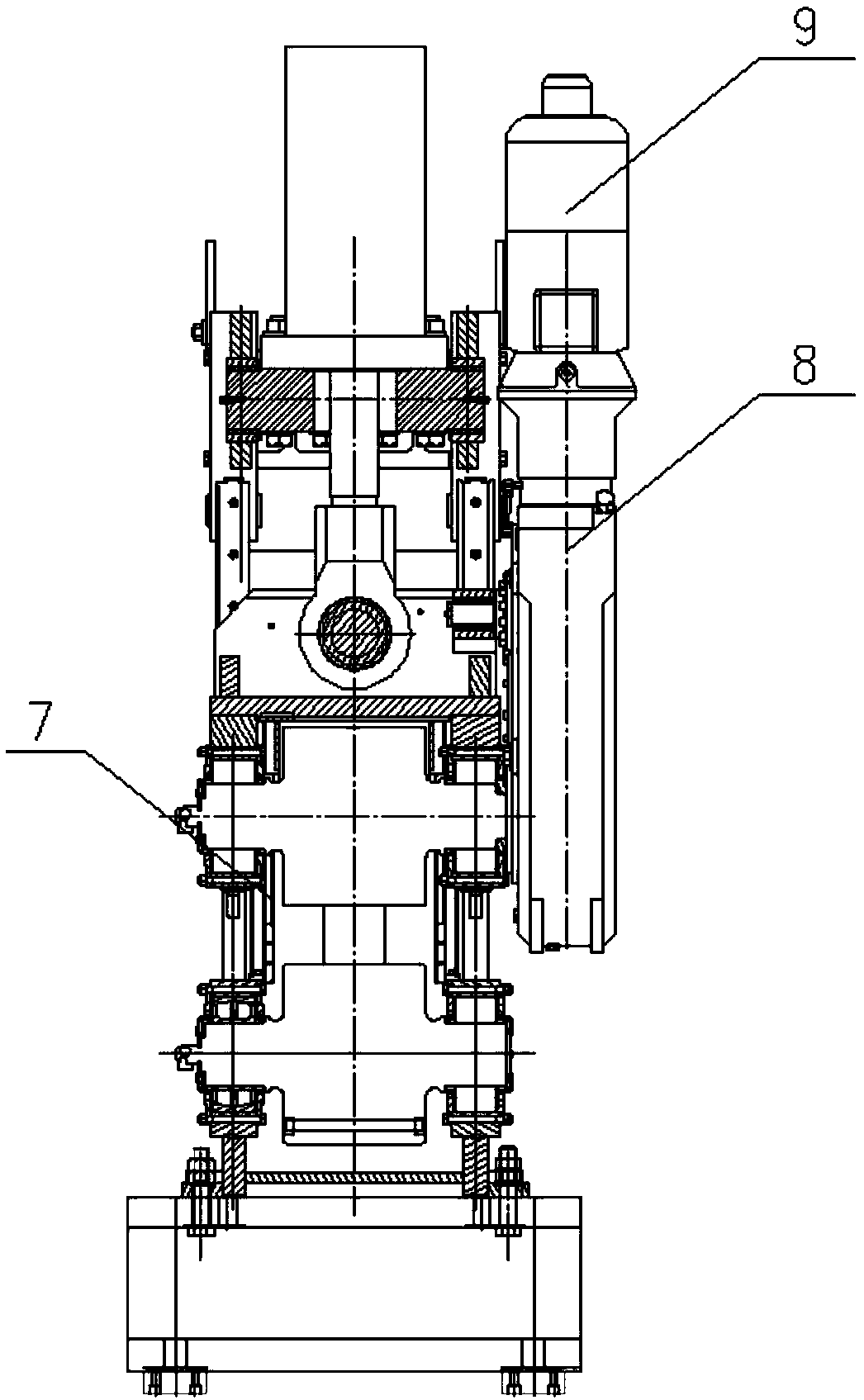

Crankshaft throw timing sprocket press-fitting device

The invention provides a crankshaft throw timing sprocket press-fitting device and belongs to the technical field of press-fitting equipment. Through the crankshaft throw timing sprocket press-fittingdevice, the problems that the timing angle is not easy to control and the product qualified rate is low during press-fitting are solved. The crankshaft throw timing sprocket press-fitting device comprises a base and a die carrier. A die head is fixed to the die carrier. A mounting block is fixed to the lower end face of the die head through fasteners. The center of the mounting block is providedwith a mounting groove in the same shape with a timing sprocket in a through mode. A floating center is slidably arranged in the die head in the vertical direction. The lower end of the floating center penetrates through the center of the mounting groove. A locating block is fixed to the base. A lower center is arranged in the center of the locating block. The axis of the lower center and the axisof the floating center are collinear. A pin capable of being inserted into a throw pin hole of a throw is arranged in the position, close to the locating block, of the base. A friction structure usedfor preventing the timing sprocket from going out is arranged in the mounting groove. The crankshaft throw timing sprocket press-fitting device has the advantages that the timing angle is easy to control, the press-fitting precision is high, the qualified rate is high, the structure is simple and the like.

Owner:TAIZHOU HONGXIN CRANKSHAFT

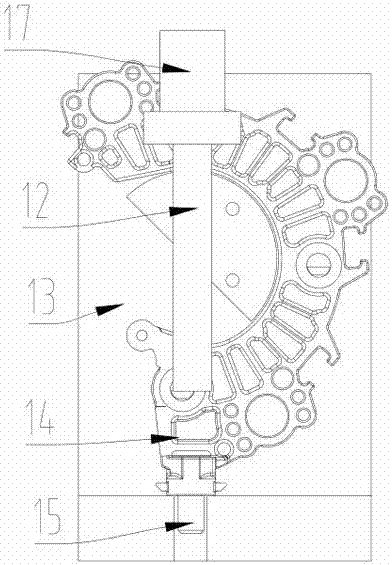

Rectifier B and screw rod pressing clamp

PendingCN107571175AReduce die change timeIncrease productivityWork holdersMetal working apparatusEngineeringMechanical engineering

The invention discloses a rectifier B and screw rod pressing clamp. The rectifier B and screw rod pressing clamp comprises a mold handle connected to an upper mold of a pressing device, a substrate connected to a lower mold of the pressing device, a pressing head arranged on the mold handle and used for pressing downwards a B and screw rod, guiding columns symmetrically arranged on the substrate,and a slider formed at an avoiding position of the substrate and connected with the guiding columns in a sliding manner; and the substrate is provided with a groove matched with the head of the B andscrew rod. The rectifier B and screw rod pressing clamp has the beneficial effects that compared with a traditional pressing clamp, the mold changing time is saved, and the production efficiency is improved; the situation that an electrode plate tips over in the pressing process is avoided, and therefore the pressing precision is guaranteed; and the situation that because of deformation of the pressing head, the installing precision does not reach the standard is reduced.

Owner:JIANGSU YUNYI ELECTRIC

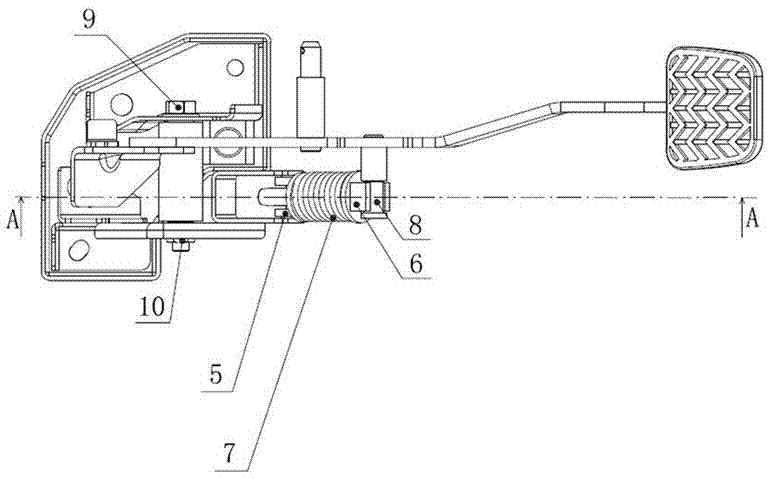

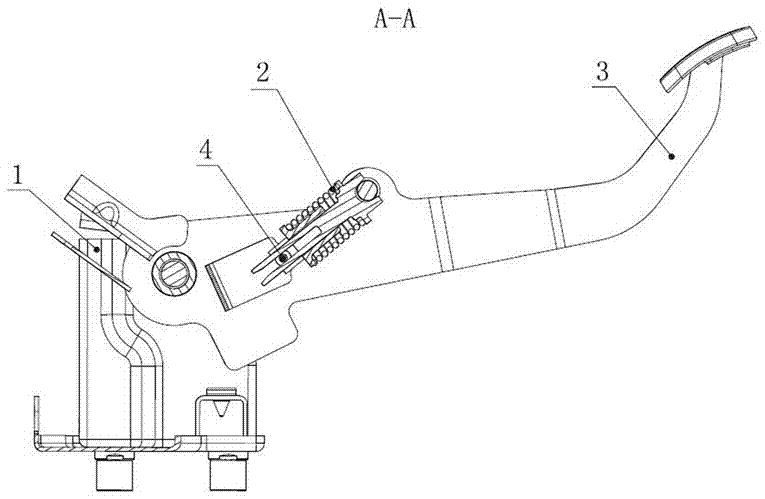

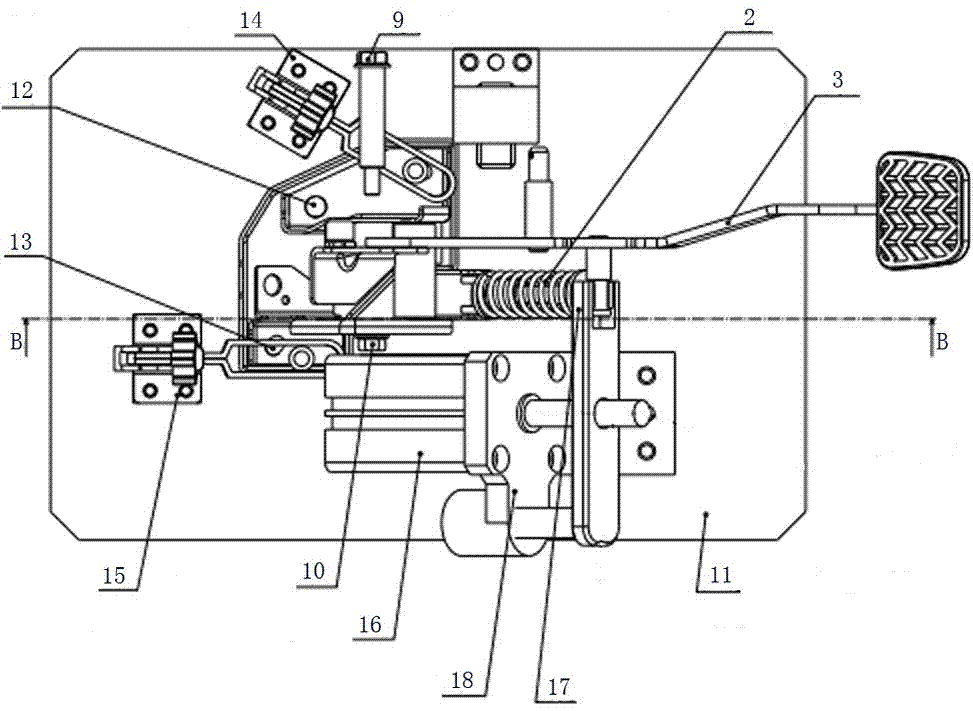

Press-fitting fixture for spring of pedal

InactiveCN107127718AImprove assembly efficiencyReduce labor intensityMetal-working hand toolsEngineeringPiston rod

The invention provides a press-fitting fixture for a spring of a pedal. The fixture comprises a fixture body; the fixture body comprises a base; a limiting mechanism for limiting a pedal support component assembly and a pressing mechanism for pressing a boosting spring component assembly are arranged on the base; the limiting mechanism comprises a first positioning pin, a second positioning pin, a first pressing plate and a second pressing plate; the pressing mechanism is correspondingly arranged in front of the limiting mechanism and comprises an air cylinder arranged vertically upwards; a pressing head is fixedly connected onto a piston rod of the air cylinder; a clamping groove corresponding to a guide rod in the boosting spring component assembly is arranged at one end of the pressing head; the pressing head is clamped at the upper part of the guide rod during use; and a limiting plate is arranged on an end cover of the air cylinder. The fixture is simple in structure, easy to manufacture, short in adjustment period, low in cost, beneficial to increase of the enterprise benefit and capable of being popularized for use.

Owner:DONGFENG SHIYAN BODY PART CO LTD

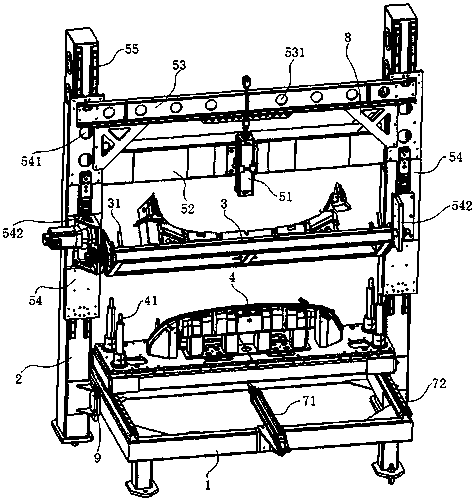

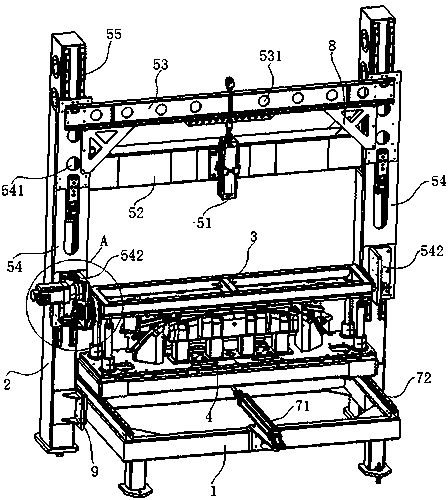

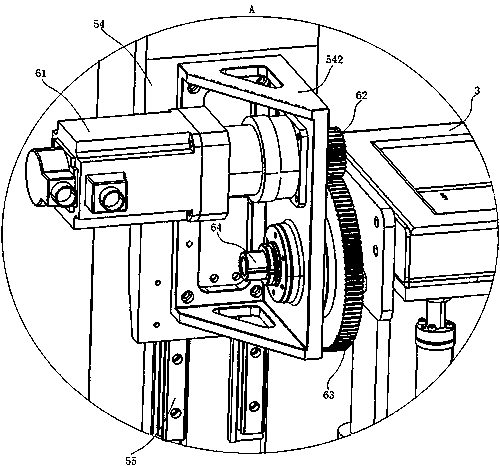

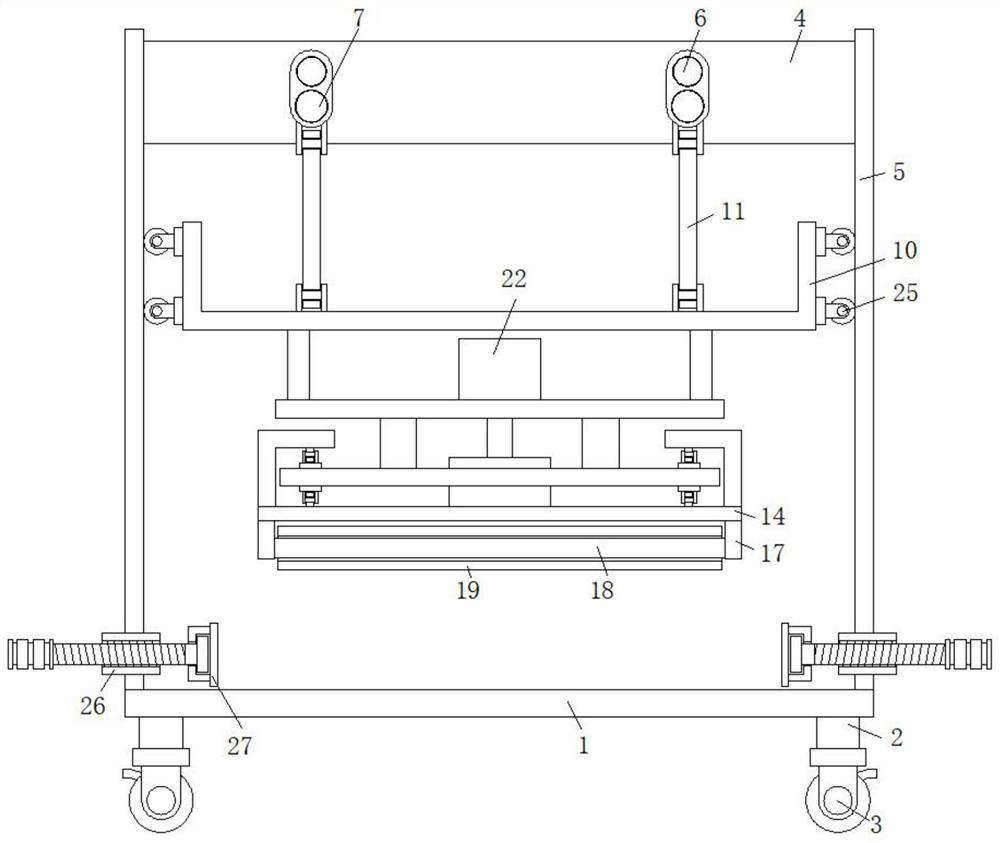

Rotary press fit tool and press fit method for plastic exterior trimming part

The invention discloses a rotary press fit tool and a press fit method for a plastic exterior trimming part, and relates to the field of plastic exterior trimming part manufacturing. The tool comprises two stand columns located on the left side and the right side of a base respectively, an inner plate workbench and an outer plate workbench, wherein the inner plate workbench is arranged on the base, the outer plate workbench is located over the inner plate workbench, the outer plate workbench is arranged between the two stand columns in a lifting mode through a lifting mechanism, the lifting mechanism is slidably arranged on the two stand columns, the two ends of the outer plate workbench are correspondingly mounted on two mounting plates of the lifting mechanism, and a rotating mechanism for driving the outer plate workbench to rotate is arranged on one mounting plate. The tool integrates the inner plate workbench and the outer plate workbench, so that the working efficiency and the space utilization rate are improved, and the labor equipment cost is saved. Meanwhile, a whole frame body for installing the inner and outer plate workbenches is universal, and the press fit requirementof different products can be met by replacing the inner and outer plate workbenches.

Owner:WUHU HENGXIN AUTO INTERIOR TRIM COMPANY

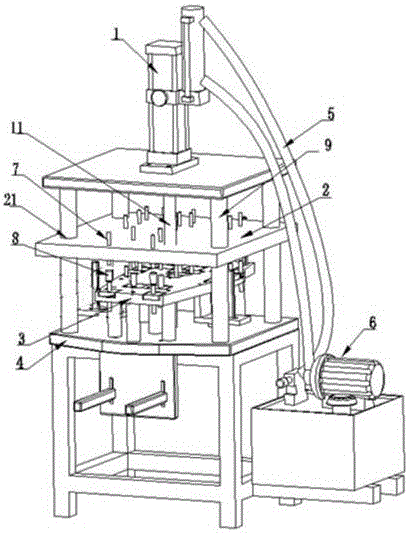

Auxiliary leveling device for pressing of rivets

InactiveCN106799452AThe pressing position is accurateReduce in quantityMultilayer circuit manufactureEngineeringRiveting machines

The invention relates to an auxiliary leveling device for pressing of rivets. The auxiliary leveling device comprises a hydraulic oil cylinder, a first mounting plate, a second mounting plate and a base. The hydraulic oil cylinder is connected with a hydraulic station through an oil pipe, and the hydraulic oil cylinder is provided with an execution rod. The first mounting plate is connected with the execution rod, a plurality of upper punches are distributed on the first mounting plate, the second mounting plate is arranged on the base, and a plurality of lower punches corresponding to the upper punches are distributed on the second mounting plate. The first mounting plate is located above the second mounting plate, and a workpiece can be placed between the first mounting plate and the second mounting plate. The upper punches are arranged on the first mounting plate, and the lower punches are arranged on the corresponding second mounting plate so that stamping riveting of a plurality of rivets on one surface or in one direction can be completed in one-time stamping, the number of operators and the number of riveting machines are reduced, and the field use space is saved; and operation is easy, the labor intensity of the operators is reduced, and the production efficiency is improved.

Owner:HUIZHOU ZHONGJING ELECTRONICS TECH CO LTD

Rolling device used for manufacturing of composite boards for treadmill

InactiveCN111890483ARealize the rolling processIncrease distancePlywood pressesVeneer pressesElectric machineryComposite plate

The invention discloses a rolling device used for manufacturing of composite boards for a treadmill. The rolling device comprises a bottom plate; two assembly plates which are parallel to each other are arranged right above the bottom plate; supporting plates are fixedly connected between the two ends of the assembly plates and the bottom plate; rail rods and cross rods are arranged between the two assembly plates; two ends of each rail rod are separately fixedly connected to the assembly plates; two ends of each cross rod are separately rotatably connected to the assembly plates; besides, a motor I is fixedly arranged on one side of one assembly plate through bolts; output shafts of the motor I are in driving connection to the cross rods; a plurality of thread groove groups are arranged on the outer side of a rod body of each cross rod; each thread groove group comprises thread grooves with opposite directions on two ends; nut bushes sleeve outer side threads of the thread grooves; and besides, the nut bushes slidably sleeve the outer side of a rod body of the corresponding rail rod. By adopting the rolling device, the rolling precision and effect of the composite boards used forthe treadmill are ensured; labor is saved; use is convenient; production efficiency is improved; and using requirements of people in production and life are met.

Owner:怀宁县盛林木业有限公司

Longitudinal and horizontal two-way adjusting clamp

The invention discloses a longitudinal and horizontal two-way adjusting clamp, and belongs to the technical field of clamps. The clamp comprises a working table panel, a clamp bottom plate positioned on the working table panel, and a positioning pin, wherein a pin hole is formed in the top surface of the clamp bottom plate; the positioning pin is installed in the pin hole; a through groove communicated with the pin hole is formed in the side surface of the clamp bottom plate; a wedge block is arranged in the through groove; the bottom surface of the positioning pin adopts an inclined plane and is propped against with the wedge surface of the wedge block; the inclined plane is matched with the wedge surface of the wedge block; the height of the positioning pin is not greater than the thickness of the clamp bottom plate; a handle extending out of the clamp bottom plate is arranged at the end part of the wedge block; two horizontally formed sliding grooves are formed in the clamp bottom plate; the sliding grooves penetrate through upper and lower surfaces of the clamp bottom plate; two longitudinally formed T-shaped grooves are formed in the upper surface of the working table panel. The vertical lifting positioning of the positioning pin is realized through the back and forth sliding of the wedge block, the positioning pin is reliable in positioning, different positioning pins are used for different product work pieces, and the applicability and the efficiency of the clamp are improved.

Owner:YUEYANG BAOLI TEXTILE

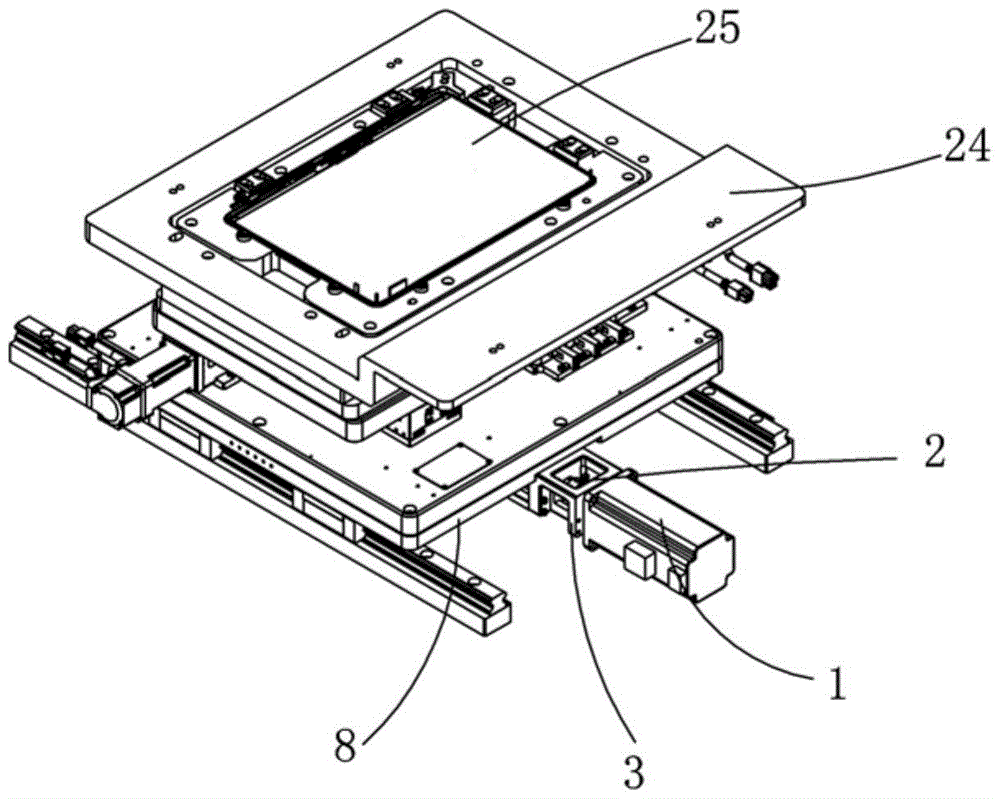

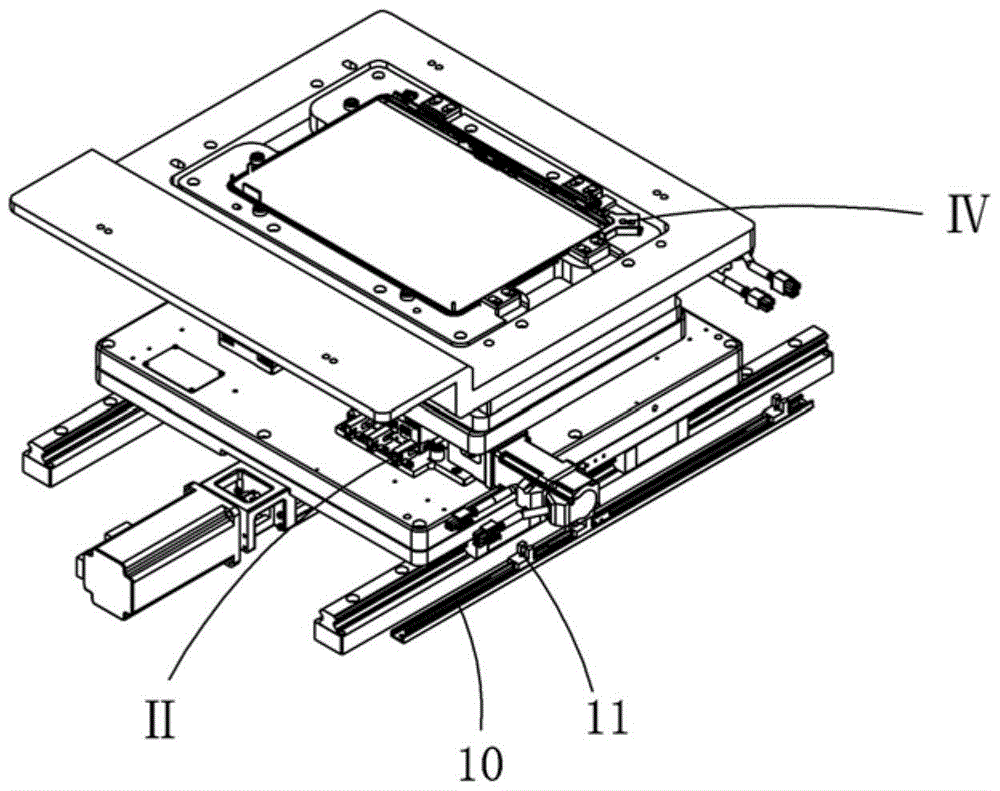

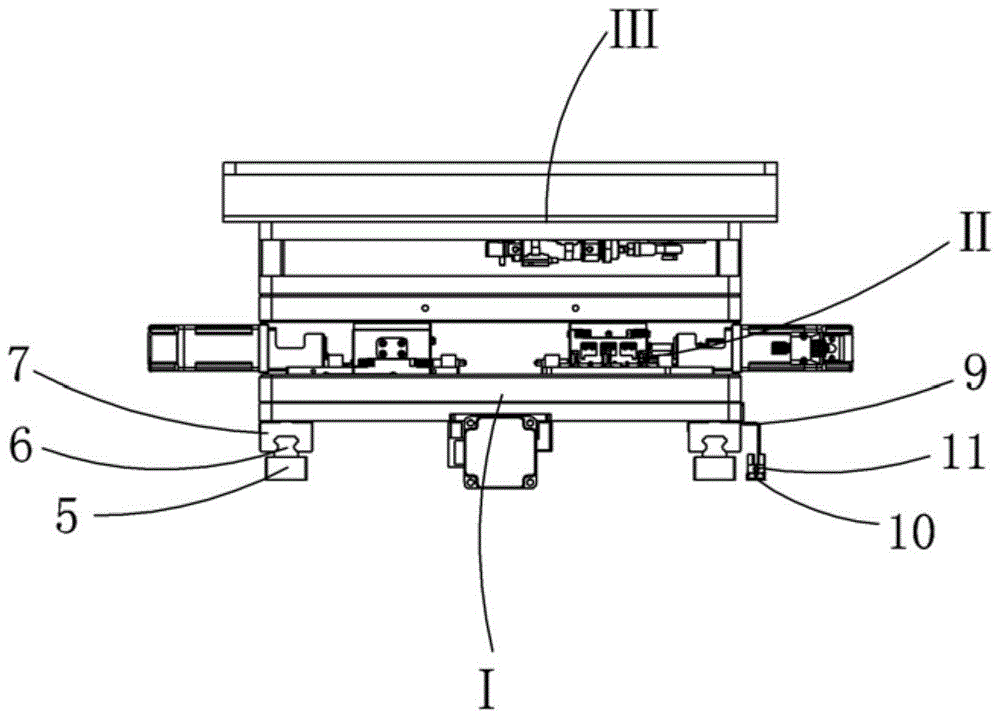

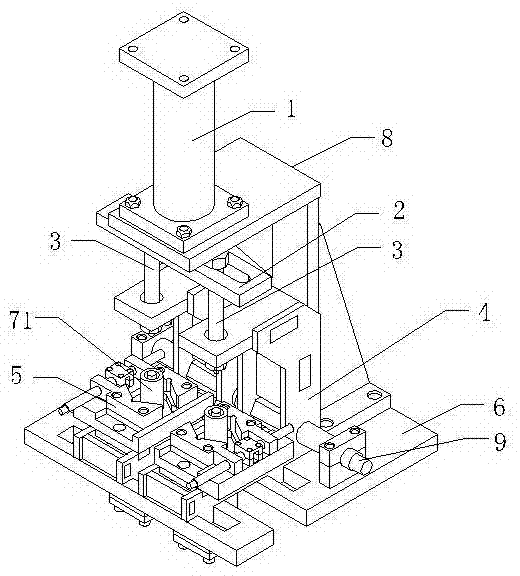

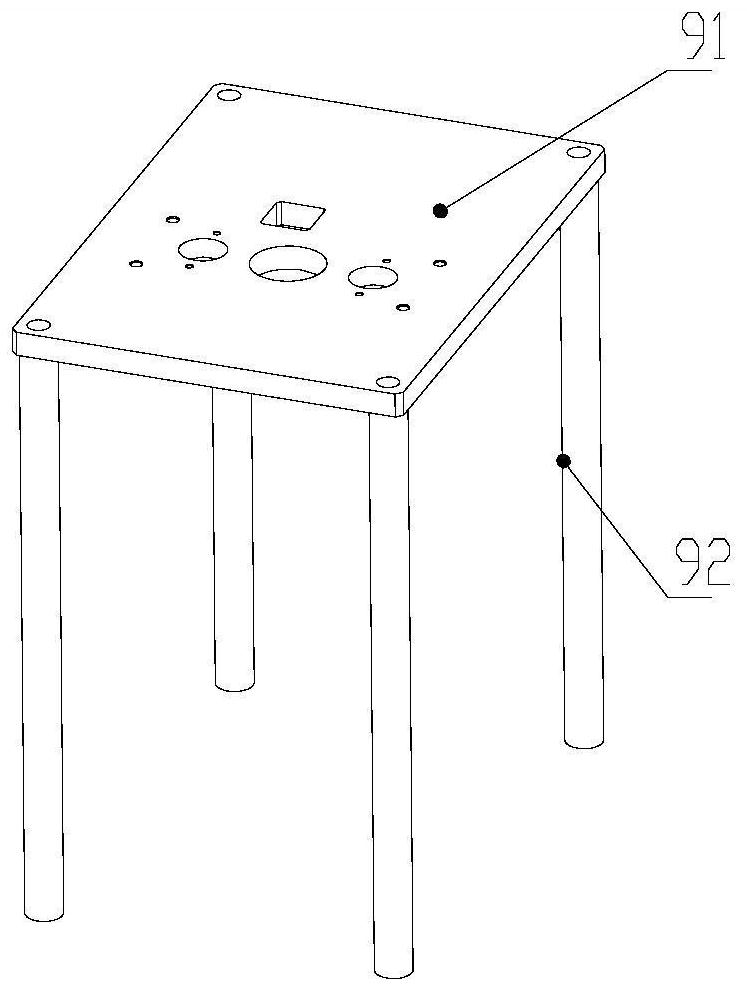

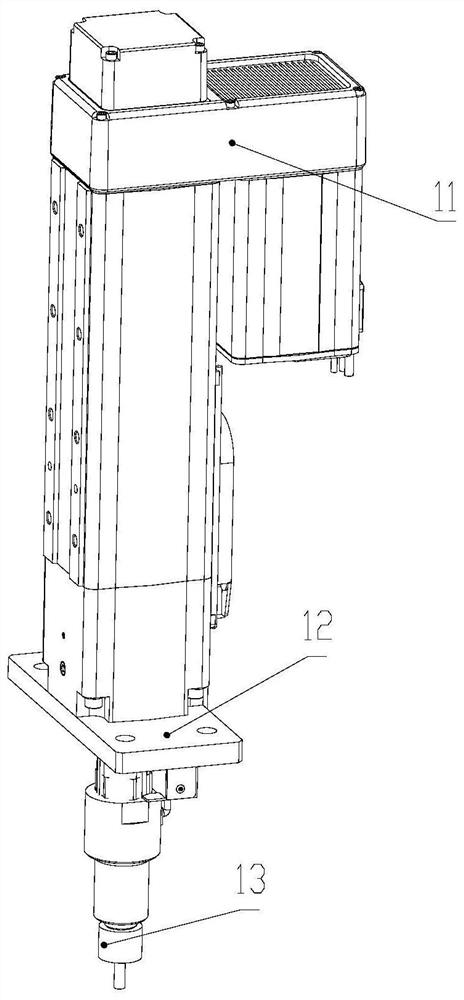

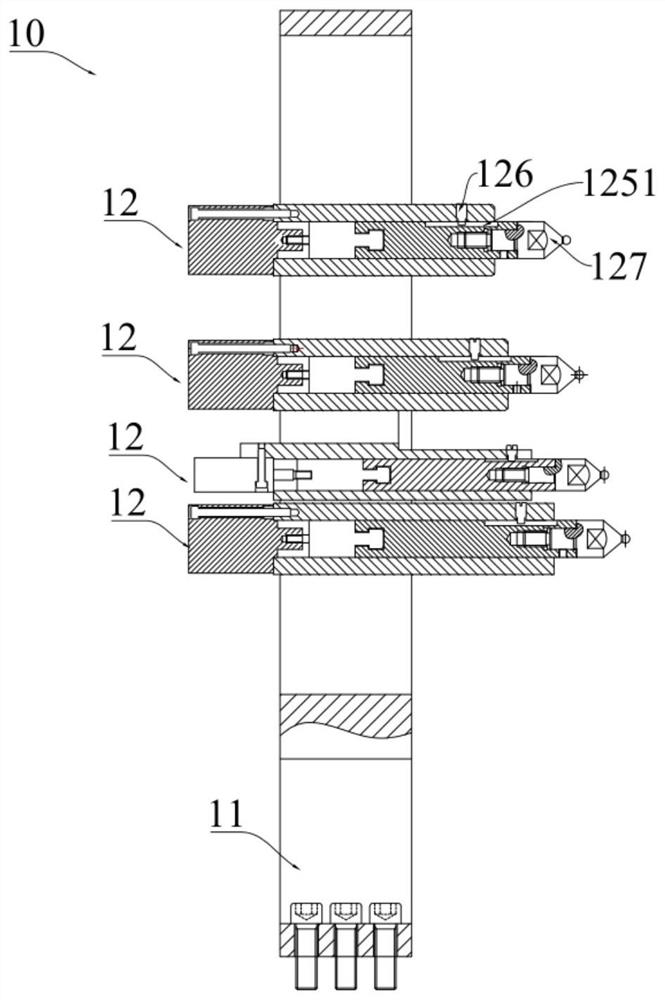

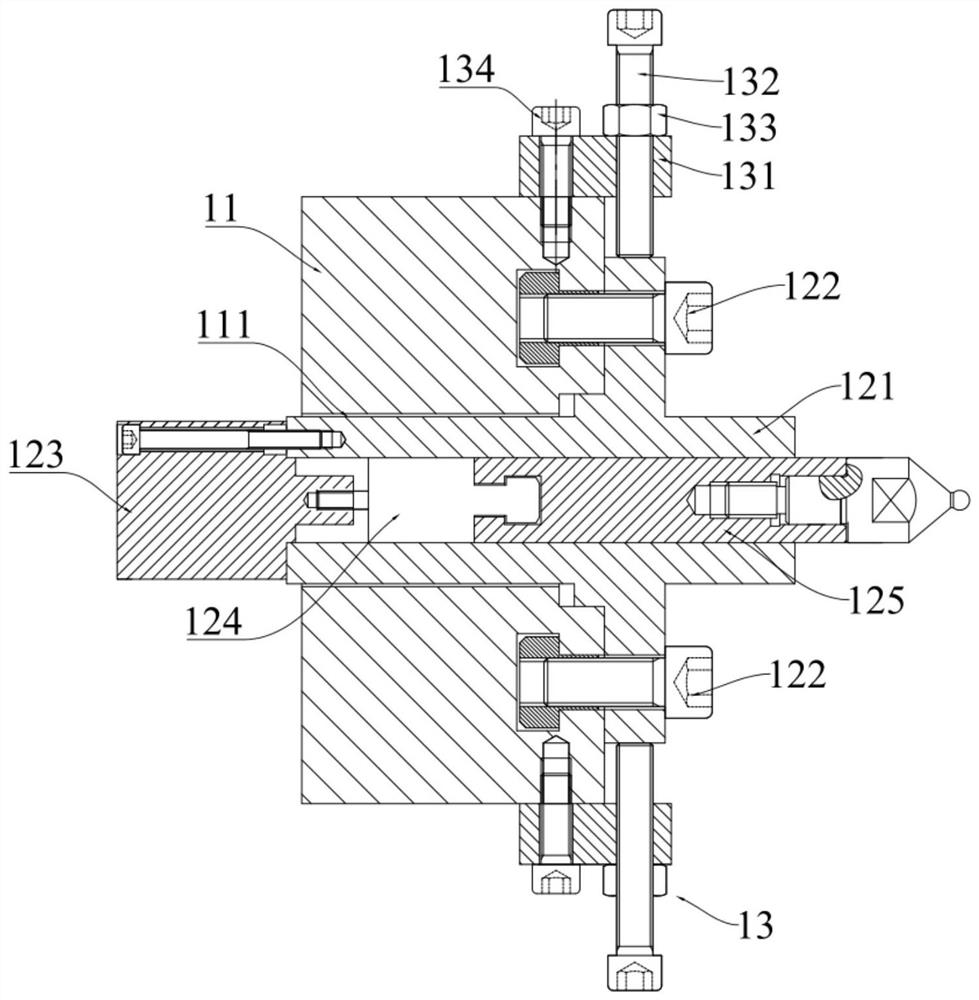

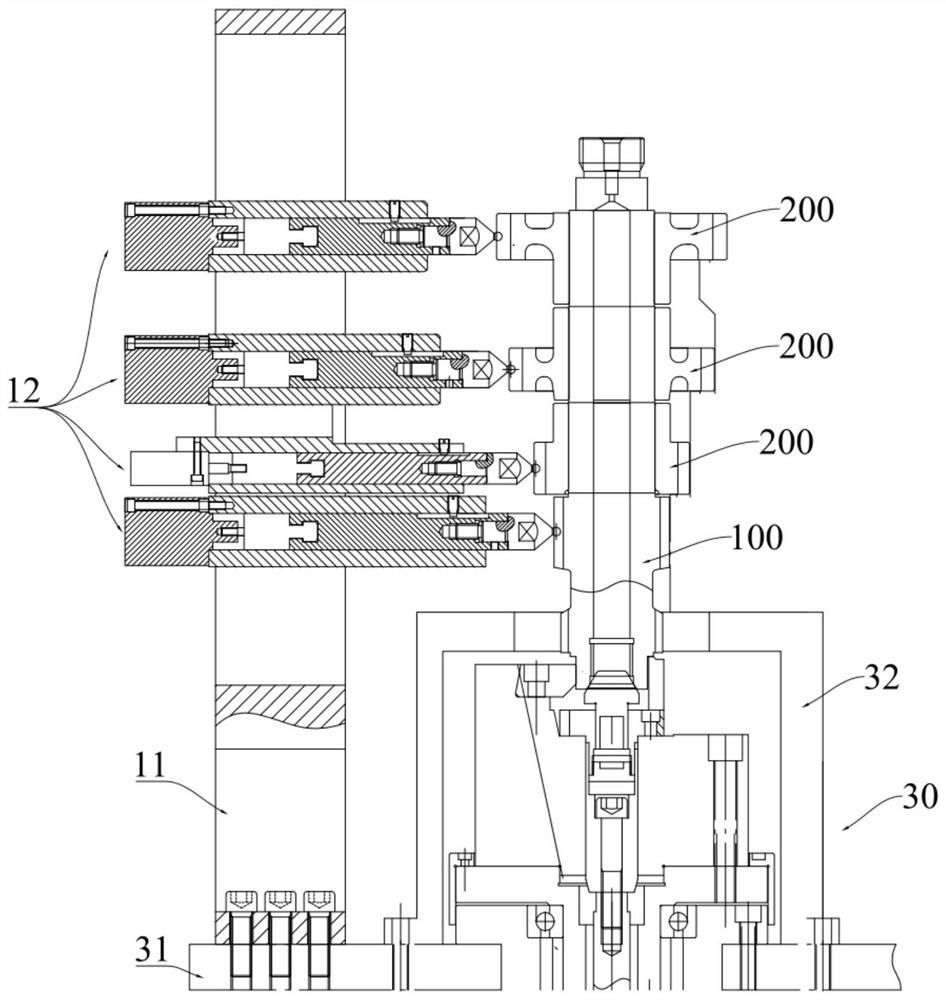

a carrier mechanism

ActiveCN104859276BAccurate adjustment positionGuaranteed pressing accuracyLamination ancillary operationsLaminationFlangeElectrical and Electronics engineering

The invention relates to a carrier mechanism. A moving plate is mounted on a Y-axis mechanism of the carrier mechanism; a three-axis alignment platform is mounted on the moving plate; a carrier base plate is mounted on the three-axis alignment platform; a carrier supporting plate is mounted on the carrier base plate through carrier supporting seats; a carrier is positioned on the carrier supporting plate through a carrier fixing plate; carrier suction cups are arranged at a middle square groove of the carrier fixing plate; positioning columns are arranged on a left-side flange and a front-side flange respectively; carrier stopping blocks are arranged on a right-side flange and a back-side flange respectively; the carrier mechanism further comprises a clamping mechanism, a carrier cylinder of the clamping mechanism is mounted at the bottom of the carrier supporting plate, the front end of the carrier cylinder is connected with a carrier cylinder connecting rod penetrating through the carrier supporting plate and the carrier fixing plate respectively, and the upper end of the carrier cylinder connecting rod is connected with a carrier clamping block. The Y-axis mechanism of the carrier mechanism can drive the carrier to move in the Y-axis direction, the three-axis alignment platform can adjust the position of the carrier accurately, and a product on the carrier can be positioned by the positioning columns, stopped by the carrier stopping blocks and clamped by the clamping mechanism.

Owner:BOZHON PRECISION IND TECH CO LTD

Bush fixture

ActiveCN102069376BGuaranteed pressing accuracyImprove assembly efficiencyMetal working apparatusEngineeringDriven element

The invention relates to a bush fixture. The bush fixture comprises a body and a table, wherein a pressure rod device, the pressure rod fixing plate of the pressure rod device and a drive element matched with the pressure rod device are arranged on the body; the pressure rod device comprises at least a pair of pressure rods; support carriages corresponding to the pressure rods respectively are movably connected to the table; one end of every pressure rod is movably connected to the pressure rod fixing plate; the other end of every pressure rod is sleeved on the corresponding support carriage;every support carriage is provided with a product positioning device and a returning device; the product positioning device is connected with the returning device; and the returning device is provided with a bush installation rod which is matched with the product positioning device. The bush fixture can be used for pressing bushes on multiple types of automobile frames, can ensure pressing precision and control pressing force, can adjust a positioning fixture to accomplish pressing action according to the sizes of the automobile frames and the distances among the bushes on the automobile frames, and improves assembling efficiency and accuracy.

Owner:泛美汽车零部件(宁波)有限公司

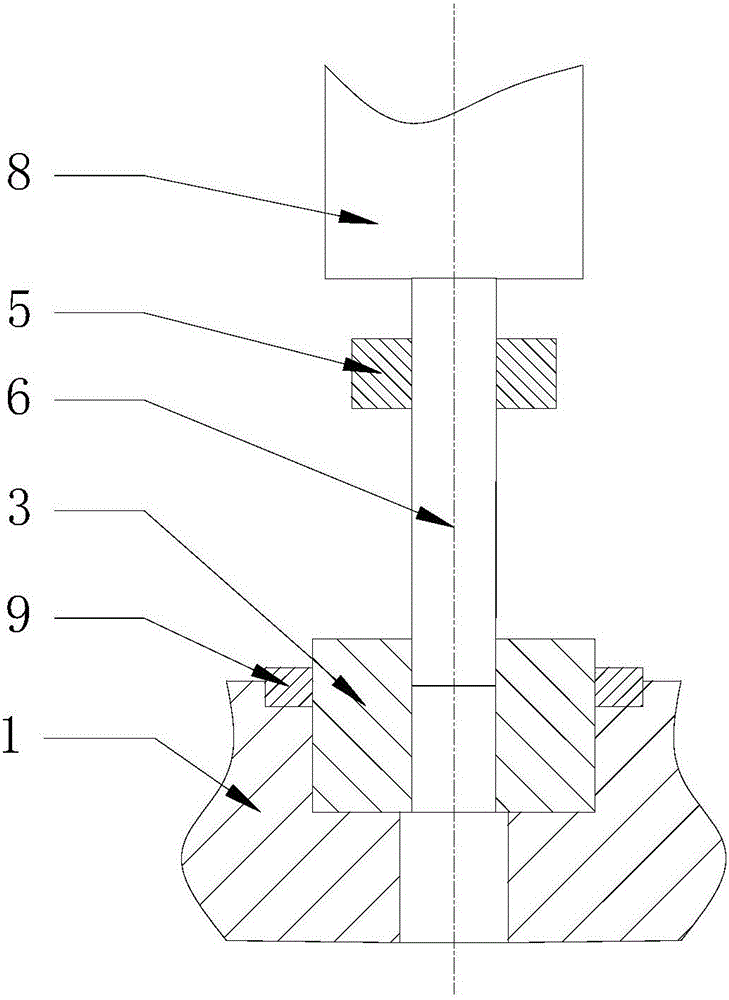

Press-fitting positioning device for gear selecting and shifting waveform block of manual transmission

PendingCN112628390AGuaranteed pressing accuracyGuaranteed coaxialityGearing controlControl theoryMechanical engineering

The invention discloses a press-fitting positioning device for gear selecting and shifting waveform block of manual transmission. The press-fitting positioning device comprises a base, a U-shaped positioning block and a guide rod, the U-shaped positioning block and the guide rod are installed on the base, a positioning hole is formed in the base, the positioning hole is used for fixing the end part of a gear selecting and shifting shaft, the U-shaped positioning block matches with a shifting block on the gear selecting and shifting shaft and used for limiting the shifting block to rotate around the axis of the gear selecting and shifting shaft, and a cylindrical surface is arranged on the guide rod, matches with the waveform area of the waveform block and is used for carrying out radial positioning and axial guiding on the waveform block. Therefore, according to the press-fitting positioning device for the gear selecting and shifting waveform block of the manual transmission, axial direction limiting is conducted through the waveform block working area in the press-fitting process, the problem that the coaxiality of the gear selecting and shifting shaft and the pressing head is poor can be solved, axial whole-process positioning can be further conducted on the waveform block, the coaxiality of the gear selecting and shifting rod and the pressing head in the pressing process of the waveform block can be reliably ensured, and the pressing precision of the waveform block is ensured.

Owner:山东上汽汽车变速器有限公司

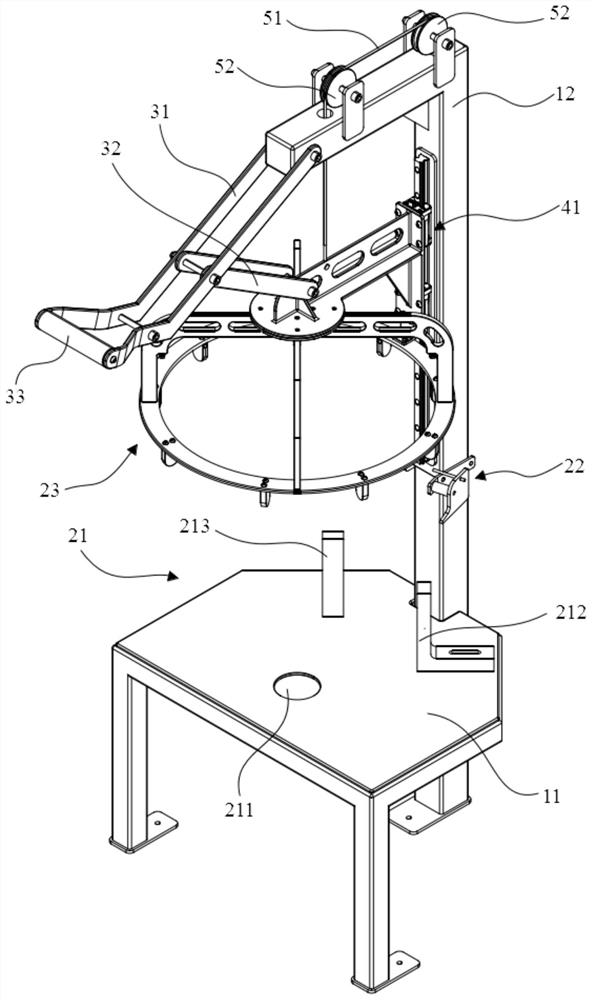

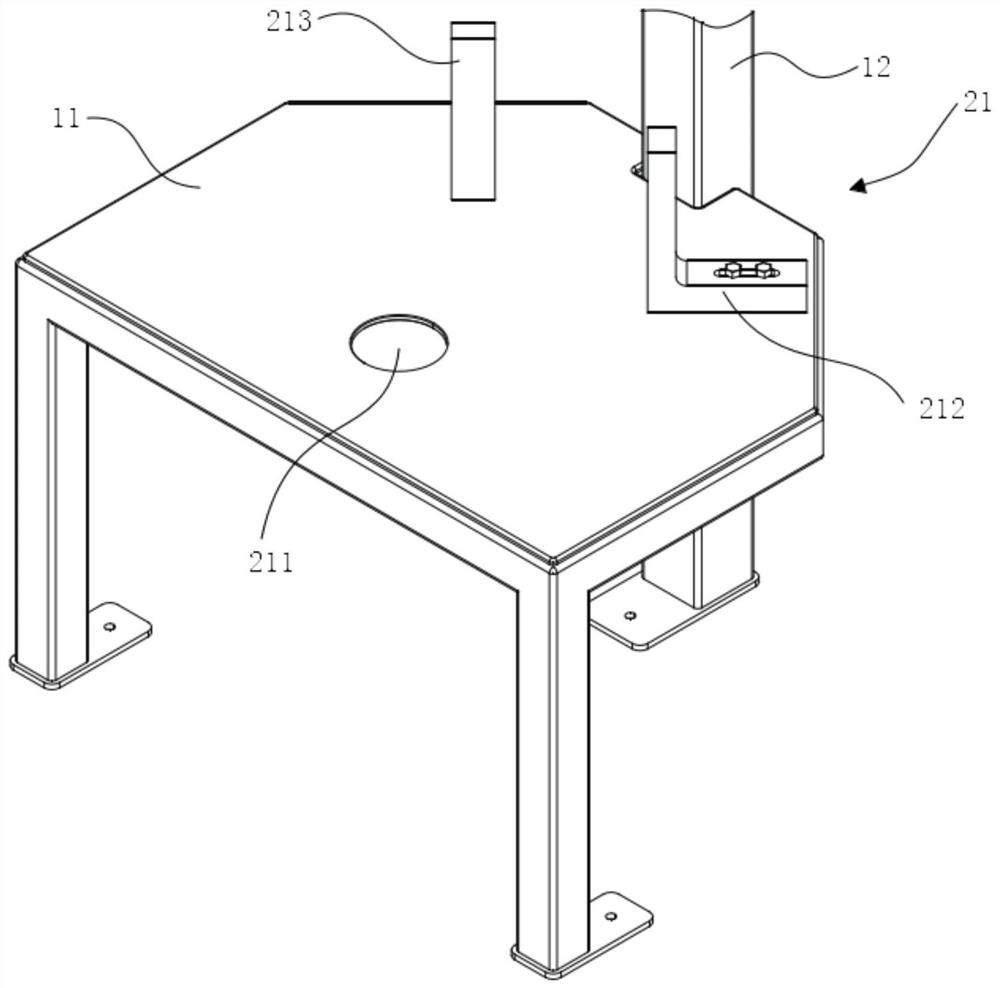

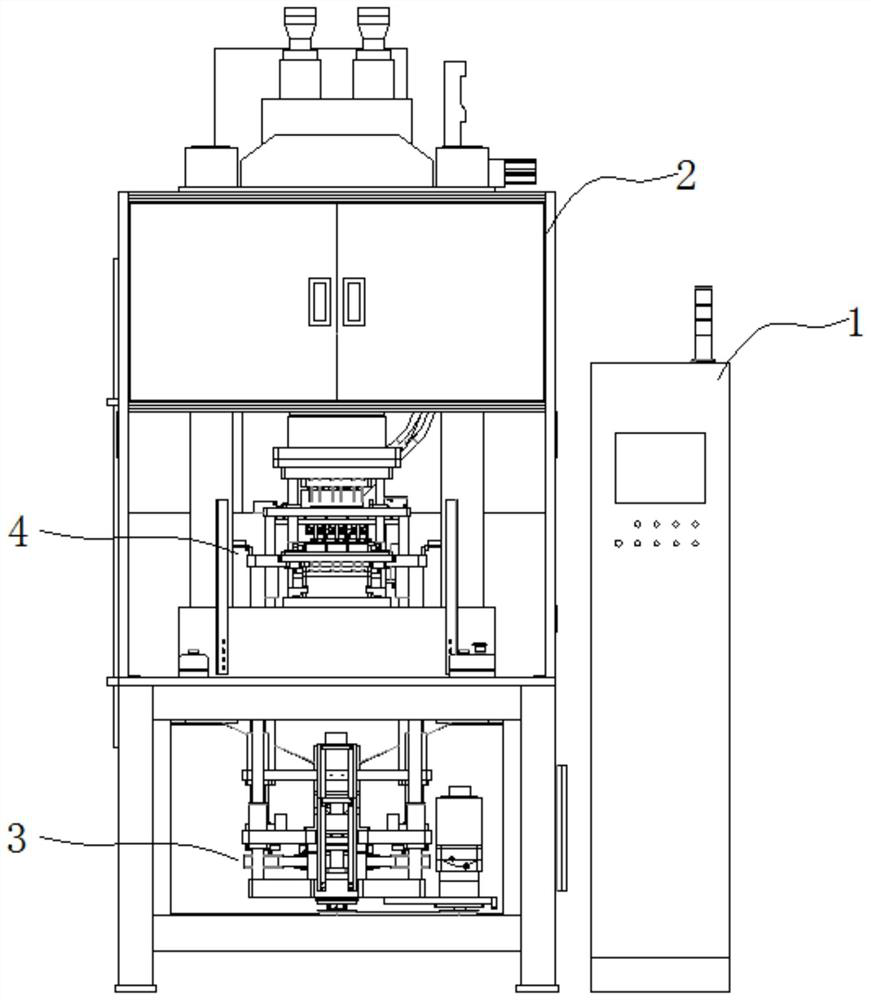

Press-fitting equipment of washing machine barrel hoop

ActiveCN111716090AGuaranteed pressing accuracyPrecise positioningMetal working apparatusLaundry washing machineEngineering

The invention relates to the technical field of washing machine manufacturing, and discloses press-fitting equipment of a washing machine barrel hoop. The press-fitting equipment is used for press-fitting a cylinder hoop on an inner cylinder of a cylinder assembly and comprises a rack, a positioning device and a press-fitting device, wherein the rack comprises a workbench and a supporting frame, the positioning device comprises an outer cylinder positioning device arranged on the workbench, an inner cylinder positioning device arranged on the supporting frame and a cylinder hoop positioning device, and the press fitting device is connected with the cylinder hoop positioning device and can drive the cylinder hoop positioning device to move in the axis direction of the cylinder assembly. According to the press-fitting equipment, accurate positioning of the cylinder hoop and the inner and outer cylinders after press fitting is achieved through the positioning device, stable and reliable movement of the cylinder hoop is achieved through the press fitting device, the press fitting precision of the cylinder hoop is guaranteed, the problems of positioning and the press fitting in the assembling process of the inner cylinder and the cylinder hoop of a washing machine are solved, the positioning device has the advantages of being simple in structure, convenient to operate, low in cost,high in reliability and the like.

Owner:FOSHAN HAIER DRUM WASHING MACHINE +1

Brush holder support and rear end cover press fitting device

PendingCN110936140ARealize high-precision pressingHigh positioning accuracyMetal working apparatusStructural engineeringBar pressing

The invention aims to provide a brush holder support and rear end cover press fitting device capable of realizing high-precision press fitting of a brush holder support. The device is characterized bycomprising a bottom plate, wherein a pressing mechanism and a plurality of press-fitting mechanisms are arranged on a bottom plate, an upper pressing block is arranged at an output end of the pressing mechanism, the upper pressing block moves downwards or upwards under the action of the pressing mechanism, the press-fitting mechanism comprises a press, the pressing machine is provided with a transversely-arranged telescopic pressing rod, a pressing head and a positioning part are arranged at a front end of the telescopic pressing rod, the pressing head is located on a rear side of the positioning part, the positioning part extends forwards, the shape and the size of a circumferential outer edge of the positioning part are the same as those of an inner edge of a brush holder support to bepressed, and a part or all of circumferential outer edges of the pressing head are located on the circumferential outer side of the circumferential outer edge of the positioning part to form a step structure.

Owner:HENGDIAN GRP INNUOVO ELECTRIC

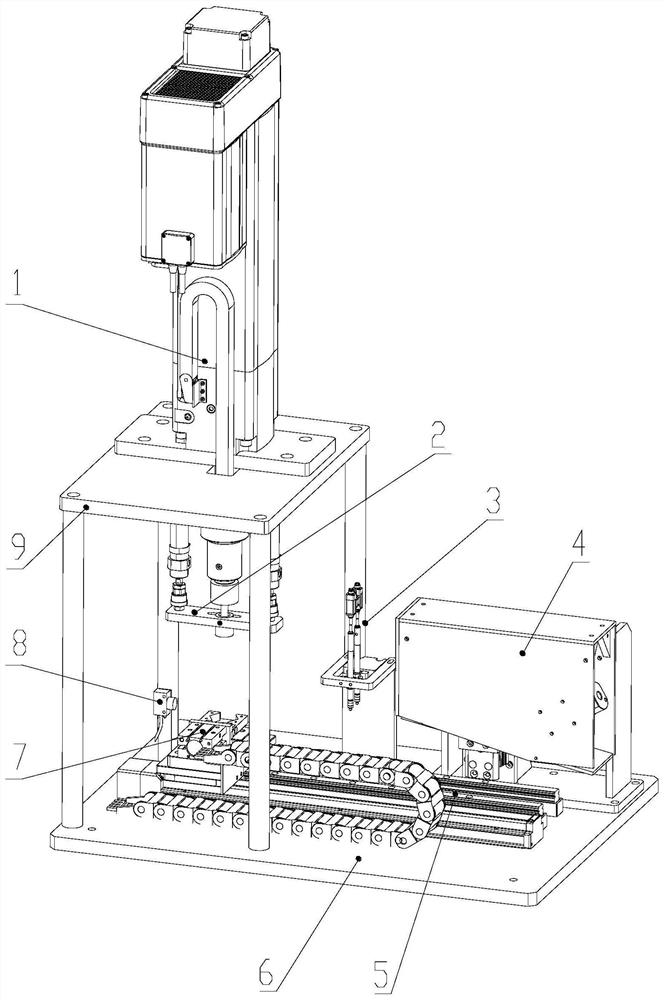

200T servo oil pressure integrated inductor powder forming machine

PendingCN113492551AGuaranteed pressing accuracyIncrease productivityInductances/transformers/magnets manufactureShaping pressInductorProcess engineering

The invention discloses a 200T servo oil pressure integrated inductor powder forming machine. The powder forming machine comprises an oil press, an electric appliance control box, a lower servo module, a forming die, a powder feeding module, a powder containing barrel and a servo pressurizing oil pump. wherein the oil press is located at the right side of the electric appliance control box; the electric appliance control box is located on the top of the forming die; the lower servo module is located at the bottom of the forming die; the powder containing barrel is located at the rear side of the electric appliance control box; the powder feeding module and the servo pressurizing oil pump are both located at the rear side of the forming die; the lower servo module comprises a middle die displacement lead screw fixing plate; and the right side of the middle die displacement lead screw fixing plate is fixedly connected with a middle die up-down movement servo motor fixing plate. The 200T servo oil pressure integrated inductor powder forming machine is suitable for pressing in a high-precision one-mold multi-cavity production mode; and the production efficiency is improved while the pressing precision is guaranteed, manpower can be saved by additionally arranging an automatic feeding and discharging machine in the later period, and unmanned production is achieved.

Owner:昆山欣建群精密工业有限公司

Motor pin shearing and gear press-fitting device and method

PendingCN113695848AImprove work efficiencyConsistent pin heightOther manufacturing equipments/toolsElectric machineGear wheel

The invention discloses a motor pin shearing and gear press-fitting device and method. The motor pin shearing and gear press-fitting device comprises a servo press-fitting mechanism, a gear placing mechanism, a pin height detection mechanism, a pin shearing mechanism, a transfer mechanism, a working platform, a motor clamping mechanism, a motor sensor and a supporting platform, wherein the transfer mechanism is installed on the working platform and used for conveying a motor clamped in the motor clamping mechanism to carry out gear press-fitting, pin detection and pin shearing procedures. According to the invention, the pin shearing and gear press-fitting work of the motor can be completed in one device, the working efficiency is high, the pin heights are consistent, and the percent of pass is greatly improved.

Owner:NANJING AOLIAN AE&EA

AMT gearbox middle shaft helical tooth aligning mechanism, press fitting device and press fitting method

InactiveCN113458713AHigh precisionAchieving angular positioningMetal working apparatusGearing detailsGear wheelManufacturing engineering

The invention discloses an AMT gearbox middle shaft assembly helical tooth aligning mechanism, a press fitting device and a press fitting method, and relates to the technical field of AMT gearbox gear press fitting. The AMT gearbox middle shaft assembly helical tooth aligning mechanism comprises a positioning seat and a tooth aligning assembly, wherein a mounting hole is formed in the positioning seat; and the tooth aligning assembly comprises a bushing, a driving part, a connecting rod and a positioning pin, the bushing is mounted in the mounting hole in a matched manner, the driving part is fixedly arranged on the bushing or the positioning seat, the connecting rod and the positioning pin are movably arranged in the bushing, the connecting rod is connected with the driving part and the positioning pin, and the positioning pin can be driven by the driving part to move and abut against the interior of a tooth groove of a helical tooth gear set. Angular positioning can be conducted on the helical tooth gear set, the press-fitting precision of the helical tooth gear set is ensured, and the connecting rod and the positioning pin can be protected and guided.

Owner:FAW JIEFANG AUTOMOTIVE CO

Rotary press-fitting device and press-fitting system

The invention discloses a rotary press-fitting device and a press-fitting system. The rotary press-fitting device is provided with a combined pressing head and a combined reverse leaning pressing head in a matched manner. The combined pressing head is provided with a self-rotating pressing head body; a plurality of lower pressing heads are arranged on the pressing head body in the axial direction; the combined reverse leaning pressing head is provided with a self-rotating reverse leaning index plate, and a plurality of reverse leaning heads are arranged on the reverse leaning index plate; and during press fitting, at least one lower pressing head and at least one reverse leaning head are in the same axial direction through rotation of the pressing head body and rotation of the reverse leaning index plate. By means of the combined pressing head, press fitting of various workpieces can be achieved without remodeling or changing the assembling technology, and the production efficiency is improved; the same pressing head can be compatible with two or more parts, and eight pressing heads at the station can be compatible with used workpieces, so that the use cost of equipment is reduced; and the technical problem of multi-variety press fitting is solved, and the flexibility of the equipment is improved on the premise that the stability of the equipment is guaranteed.

Owner:BAOJI FAST GEAR

Multi-workpiece positioning press fitting machine with adjustable fixture position

InactiveCN104308500AImprove stabilitySolve a single problemWork holdersMetal working apparatusEngineeringMechanical engineering

The invention discloses a multi-workpiece positioning press fitting machine with an adjustable fixture position. The multi-workpiece positioning press fitting machine belongs to the field of press fitting equipment, and comprises a rack and a positioning fixture located on the rack, wherein the positioning fixture comprises a working table panel, a fixture bottom plate located on the working table panel, and at least two positioning blocks; the positioning blocks are respectively in a circular shape and are rotatably arranged on the fixture bottom plate; positioning pins are fixedly arranged on the positioning blocks; blind holes are formed in the lower surfaces of the positioning blocks; limiting pins are arranged in the blind holes; a spring is arranged between the limiting pins and the hole bottom faces of the blind holes; limiting holes are formed in positions, corresponding to the limiting pins, of the fixture bottom plate; the fixture bottom plate is provided with two horizontally arranged sliding chutes which are communicated to the upper surface and the lower surface of the fixture bottom plate; two longitudinally arranged T-shaped grooves are formed in the upper surface of the working table panel. The positions of the positioning pins are rotated and changed through the positioning blocks, and different positioning pins are used for different product workpieces, so that the applicability of the press fitting machine is improved.

Owner:湖南南山矿泉水有限公司

Long-period high-precision polishing mechanism of lens polishing machine

PendingCN114102342AImprove installation stability and reliabilityImprove long-cycle polishing accuracyGrinding carriagesOptical surface grinding machinesPolishingEngineering

The invention relates to the technical field of lens polishing machines, and discloses a long-period high-precision polishing mechanism of a lens polishing machine, which solves the technical problem of how to improve the installation stability and reliability of a pressure mechanism at present, and comprises a base, a water bucket, a swing arm, a main shaft and a pressure mechanism, the swing arm is installed at one end of the base and can swing with an installation shaft of the swing arm as a shaft core, the main shaft is installed in a swing arm hole and arranged in the water bucket, the water bucket is divided into a fixed bucket body and a swing bucket body, the upper side of the fixed bucket body is fixed to the lower side of the bridge, the two sides and the lower side of the swing bucket body are fixed to the inner side face of the swing arm, and the pressure mechanism is installed on the base. According to the technical scheme, the mounting stability of the pressure arm is improved through the mounting structure of the X-axis holding hole and the Y-axis holding hole, and mounting errors similar to screw loosening caused by long-period equipment machining are basically avoided, so that the purpose of high-precision polishing machining is achieved.

Owner:江西吉铖光电有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com