Rolling device used for manufacturing of composite boards for treadmill

A rolling device and composite board technology, which is applied in the field of fitness equipment, can solve the problems of manpower consumption and low efficiency, and achieve the effect of convenient pick and place, long distance and meeting the needs of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

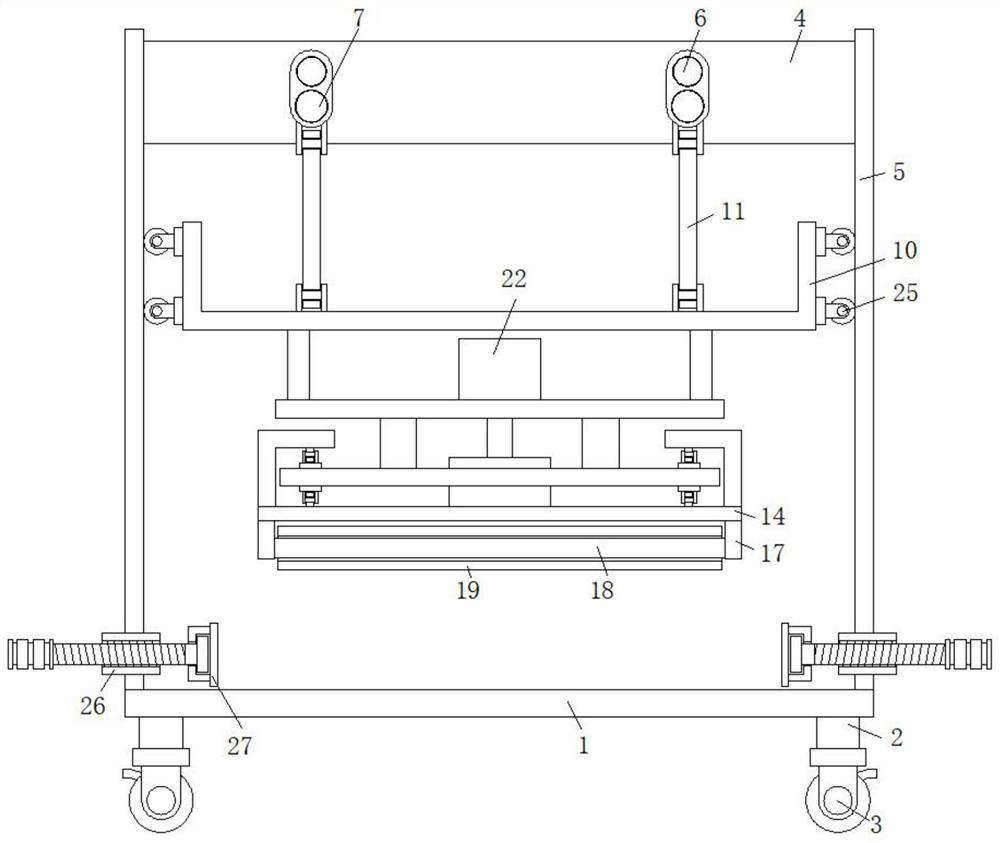

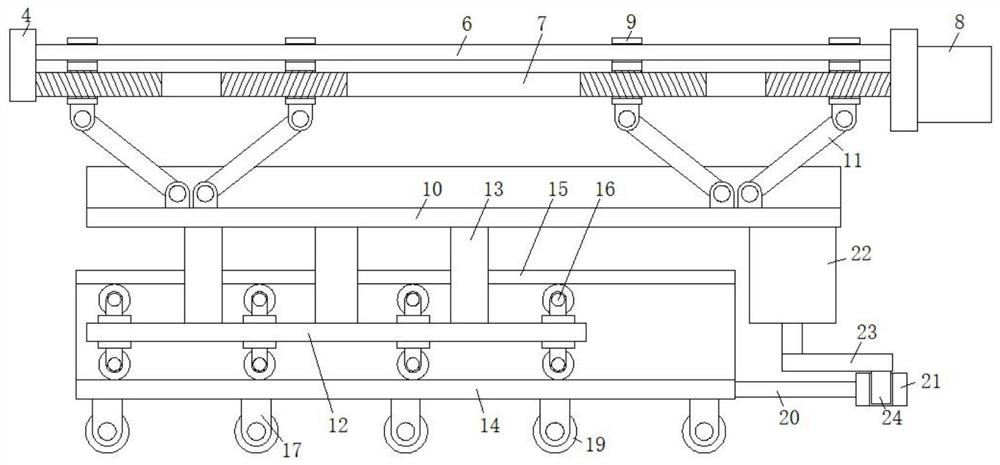

[0023] refer to Figure 1-3 , a rolling device for processing a composite board for a treadmill, comprising a base plate 1, two mounting plates 4 arranged in parallel are arranged vertically above the base plate 1, and a support is fixedly connected between the two ends of the mounting plate 4 and the base plate 1 Plate 5, track bar 6 and cross bar 7 are arranged between two mounting plates 4, the two ends of track bar 6 are fixedly connected with mounting plate 4 respectively, the two ends of cross bar 7 are respectively connected with mounting plate 4 rotation, and One side of the mounting plate 4 is fixedly equipped with a motor one 8 by bolts, and the output shaft of the motor one 8 is connected with the transmission between the cross bar 7. Several screw groove groups are arranged on the outside of the rod body of the cross rod 7, and each screw groove group includes The two ends of the threaded grooves in opposite directions, the outer threaded sleeves of the threaded gr...

Embodiment 2

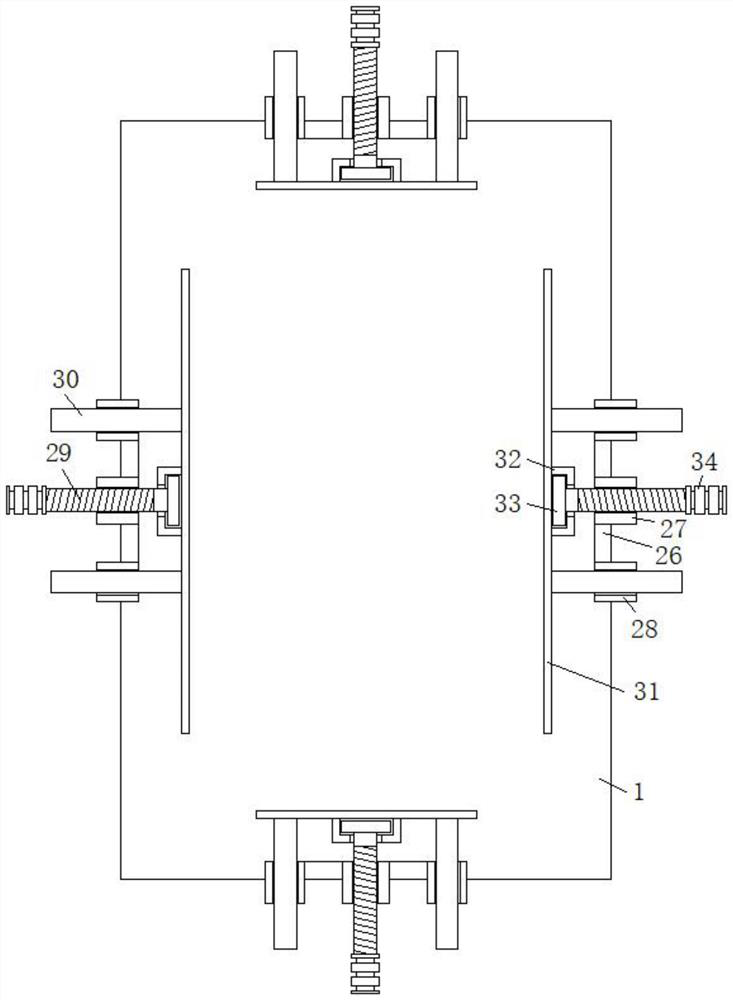

[0026] like Figure 1-3 As shown, this embodiment is basically the same as Embodiment 1. Preferably, the position-limiting mechanism includes a vertical plate 26, which is fixedly connected to the top side of the bottom plate 1, and the middle part of the vertical plate 26 is provided with a through hole 1 through which Hole 1 is fixedly connected with a threaded cylinder 27, and the two ends of the vertical plate 26 are fixedly connected with a limiting cylinder 28. The internal thread of the threaded cylinder 27 passes through a threaded rod 29, and the internal thread of the limiting cylinder 28 slides through a sliding rod 30, and the vertical plate 26 are respectively provided with a side pressing plate 31 on one side close to each other, and one end of the slide bar 30 is fixedly connected with one side of the side pressing plate 31, and one side of the side pressing plate 31 is fixedly connected with a rotating seat 32, and the rotating seat 32 is connected with a rotati...

Embodiment 3

[0029] like Figure 1-3 As shown, this embodiment is basically the same as Embodiment 1. Preferably, four corners of the bottom of the bottom plate 1 are fixedly connected with legs 2 , and locking universal wheels 3 are installed at the bottom of the legs 2 .

[0030]In this embodiment, the mobility of the device is greatly improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com