Patents

Literature

62results about How to "Guaranteed rolling effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

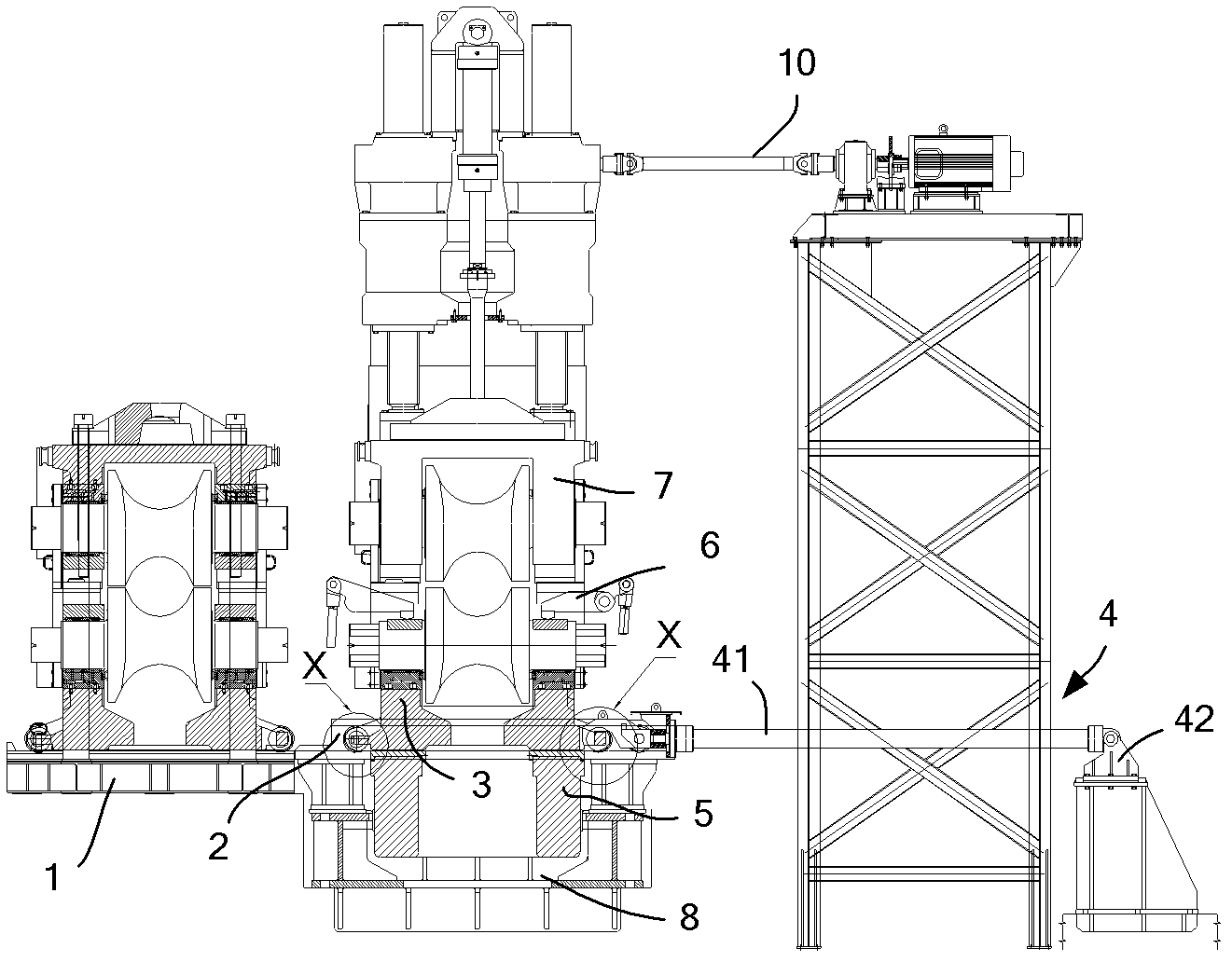

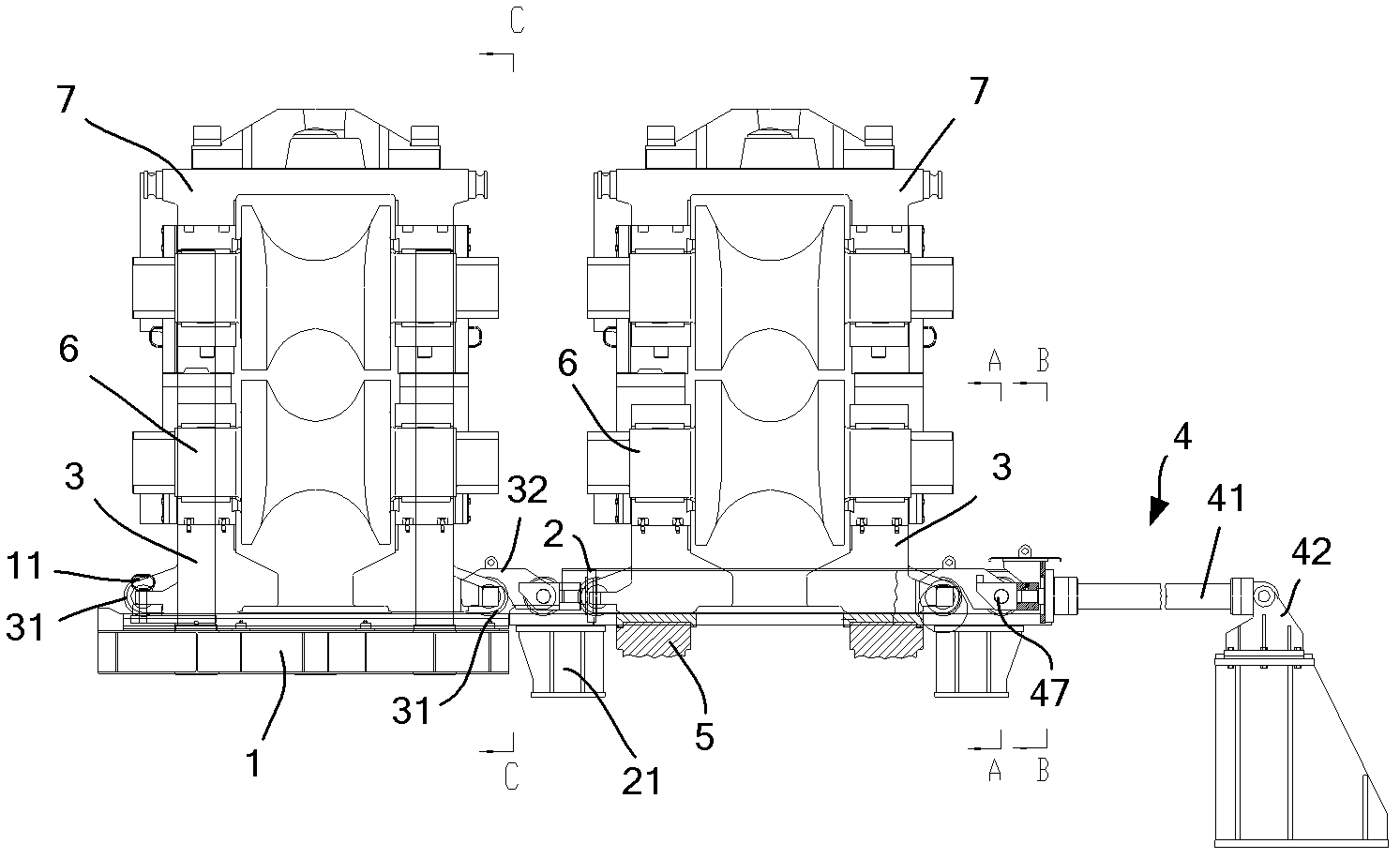

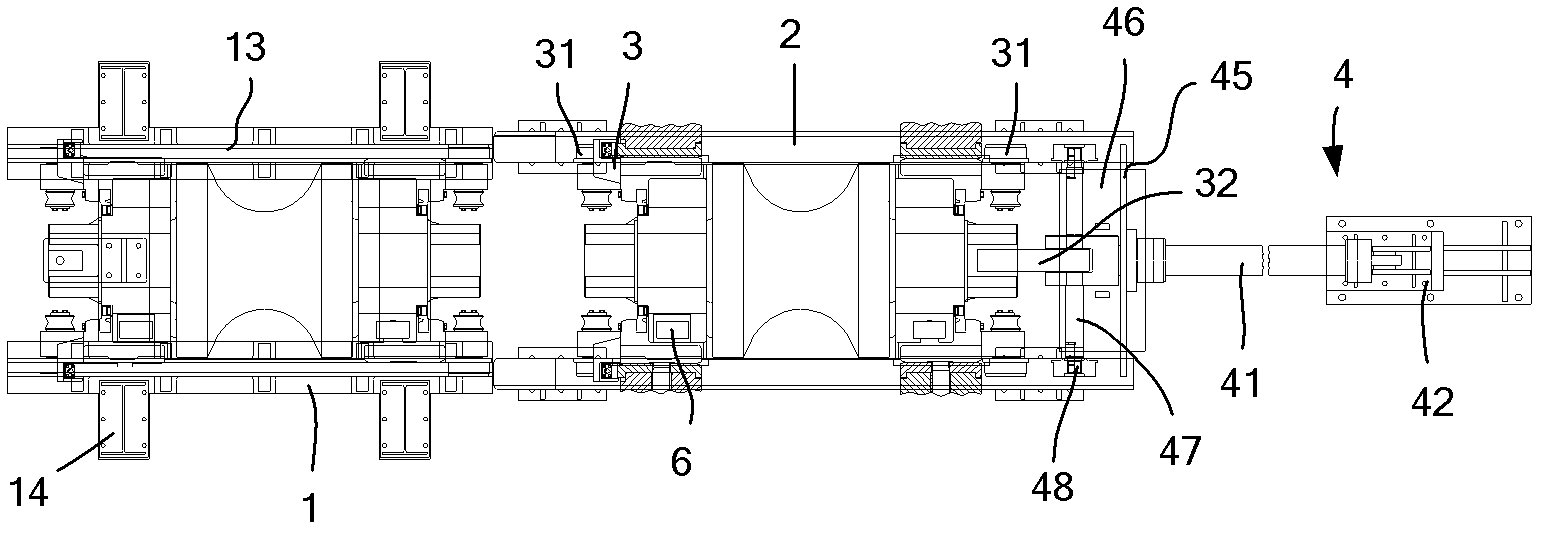

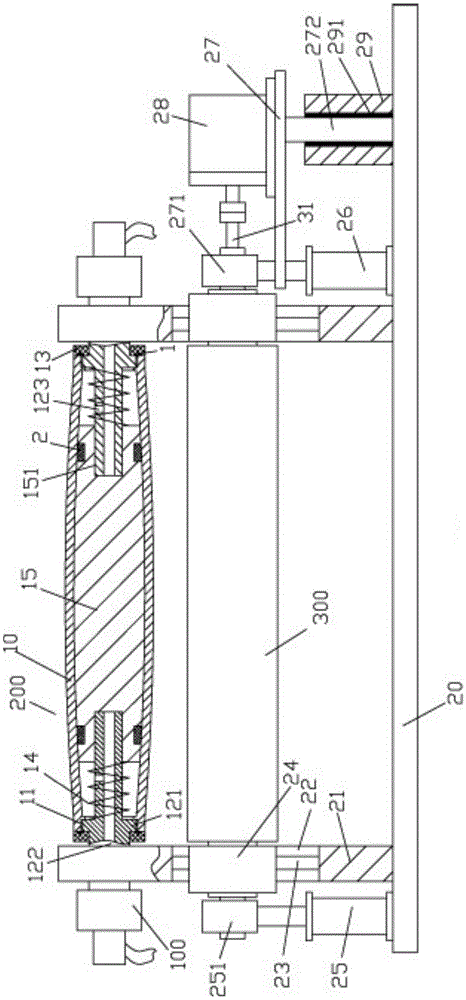

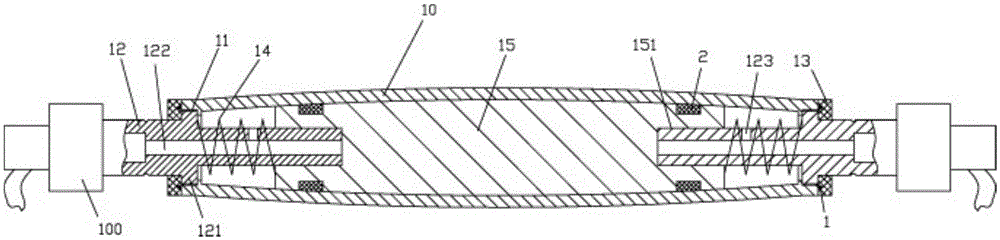

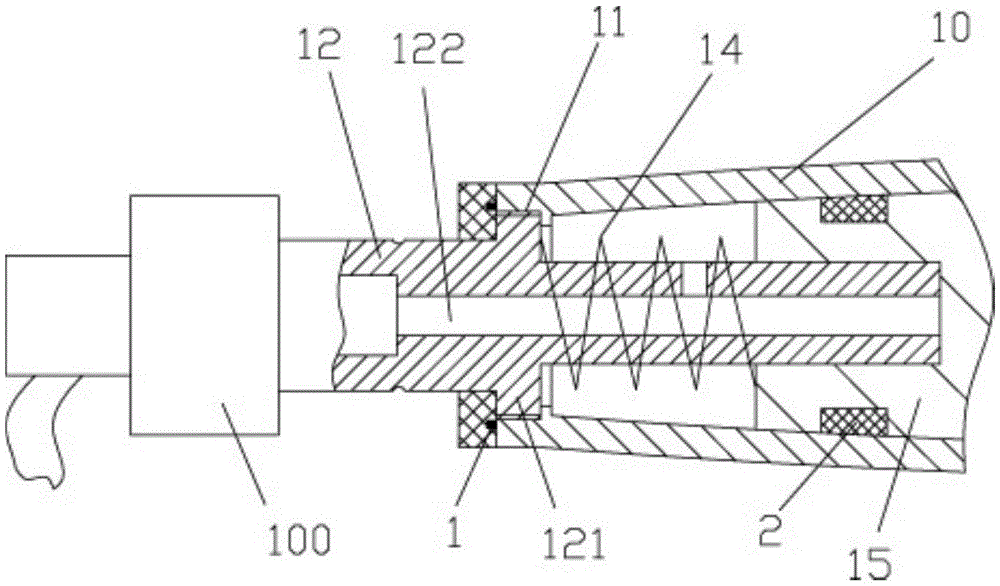

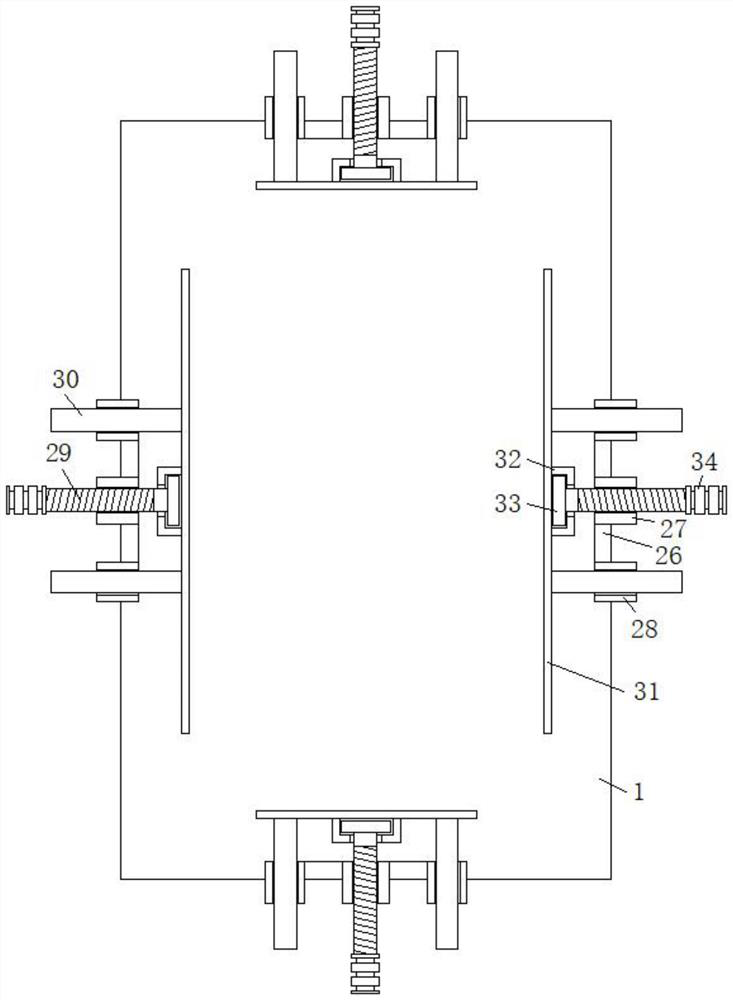

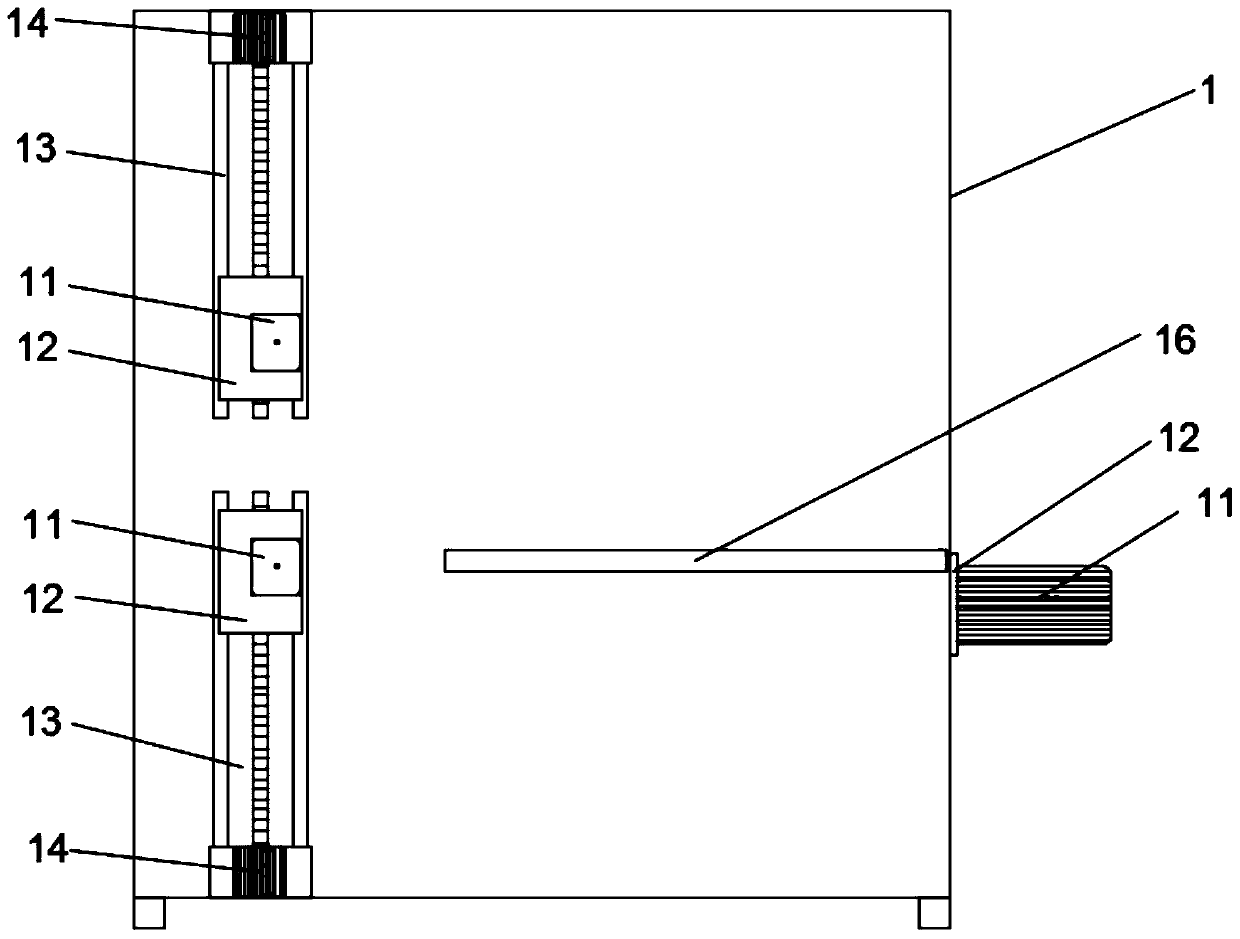

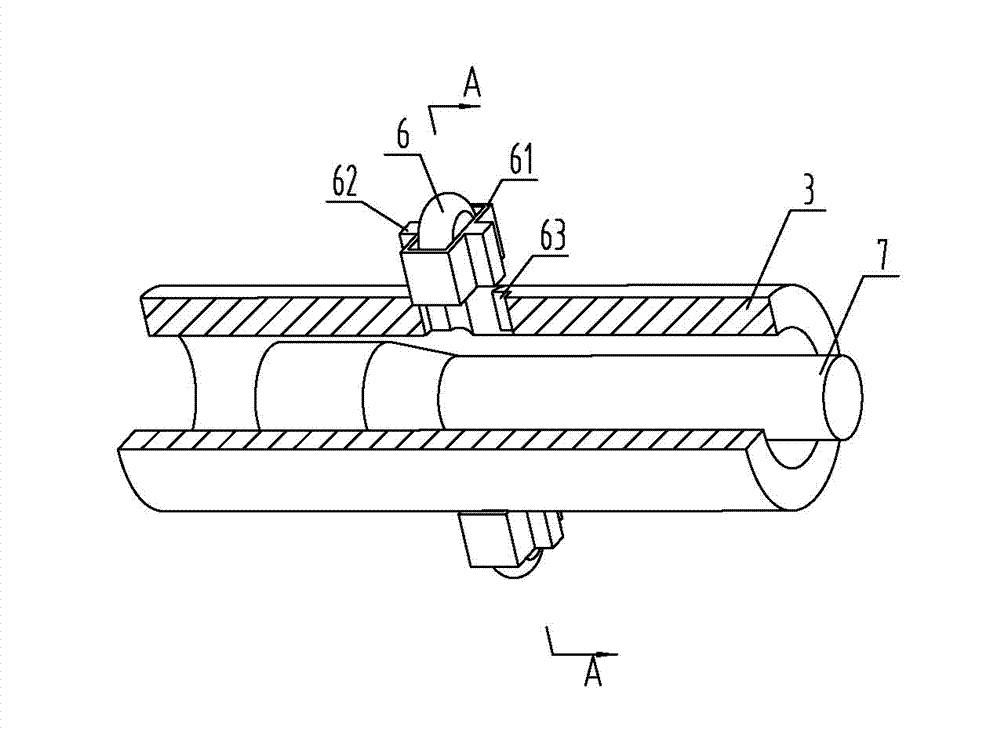

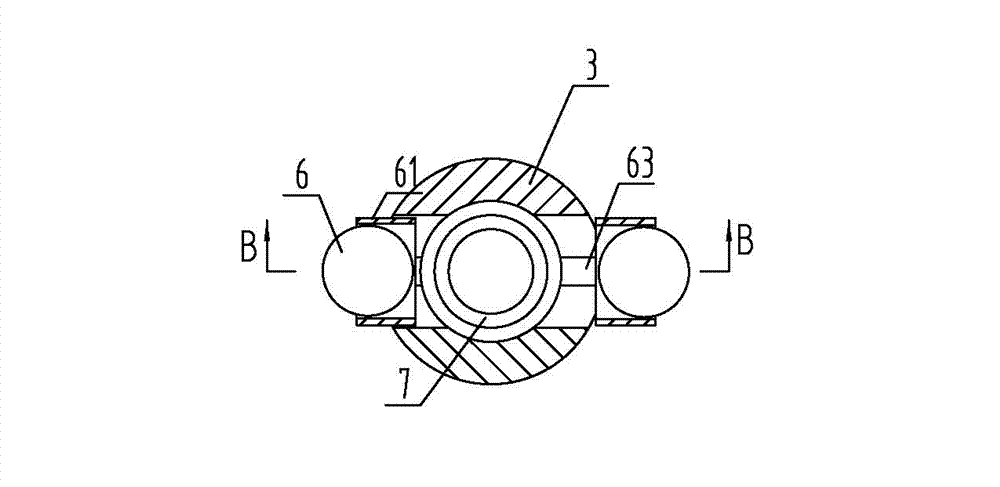

Device for replacing rollers of pilger seamless tube mill

ActiveCN102441575ASo as not to damageReduce frictional resistanceMetal rolling stand detailsMetal rolling arrangementsPush pullIdler-wheel

Owner:TAIYUAN HEAVY IND

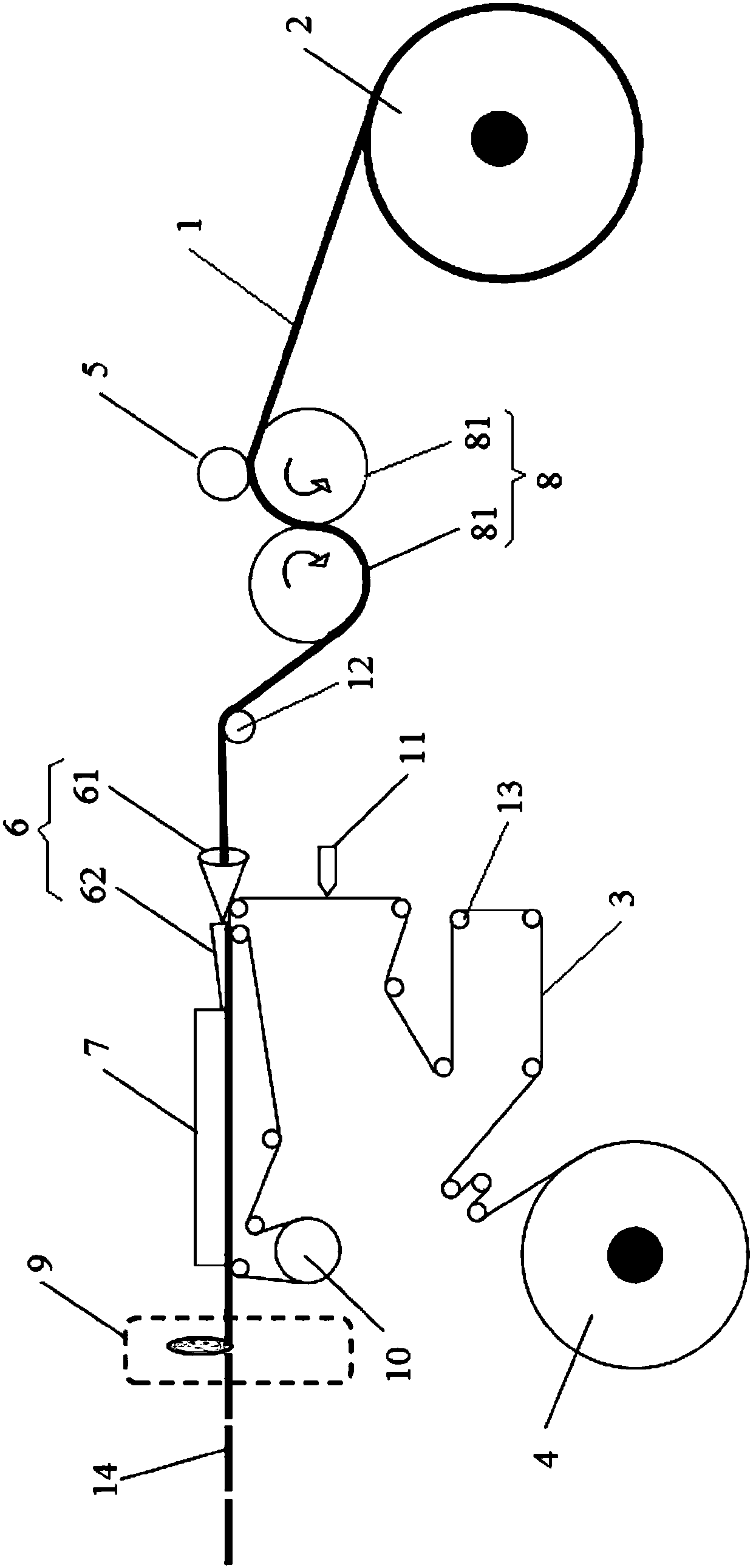

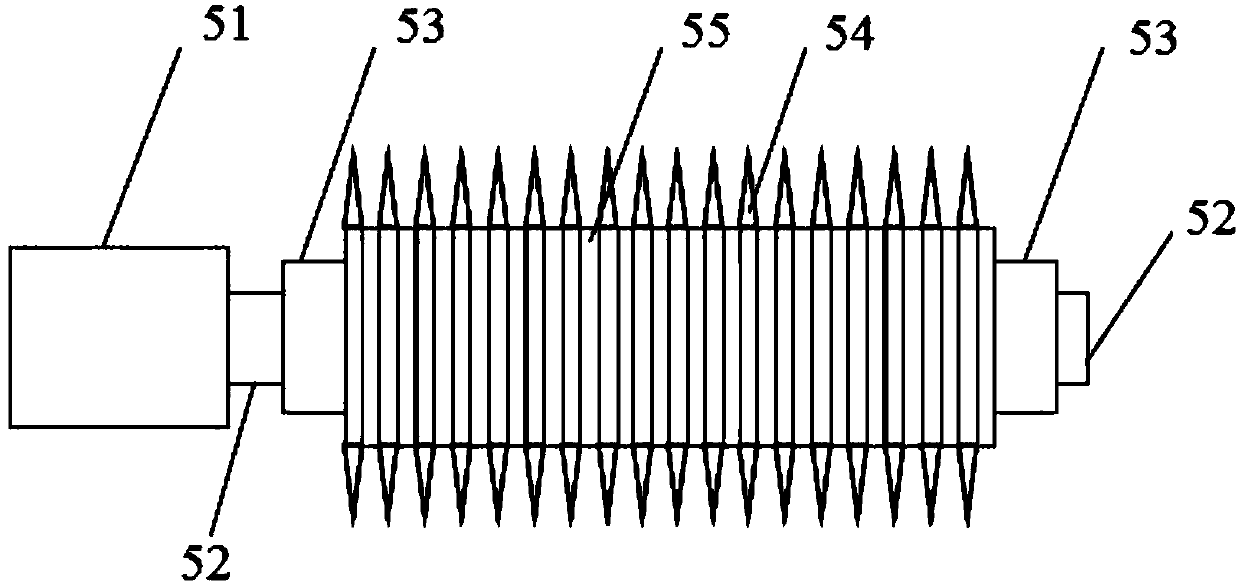

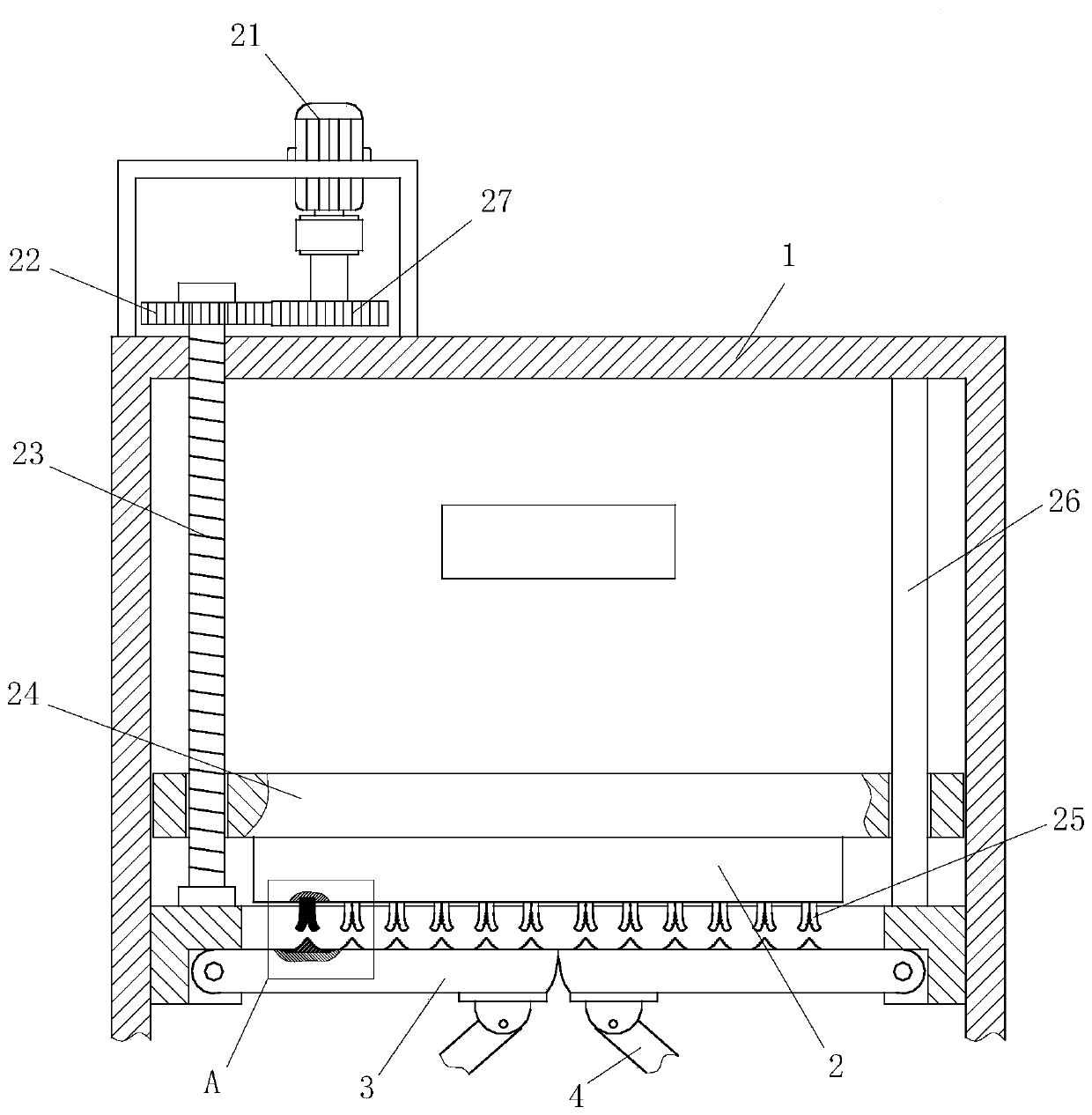

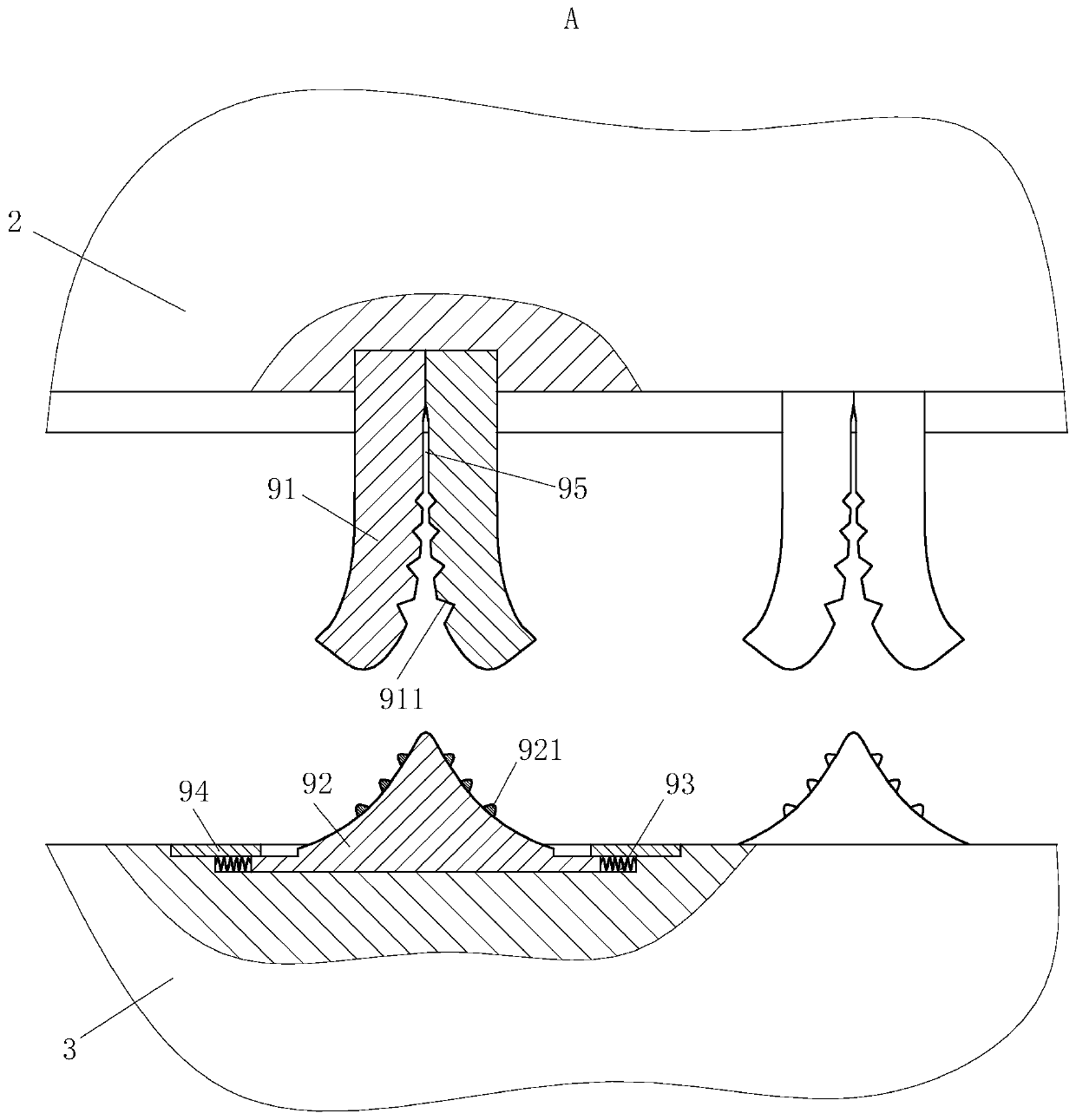

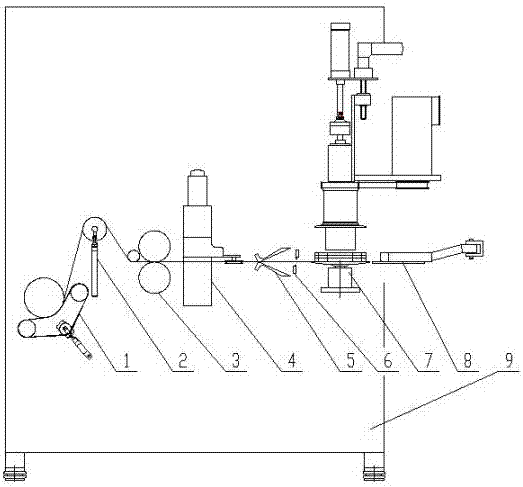

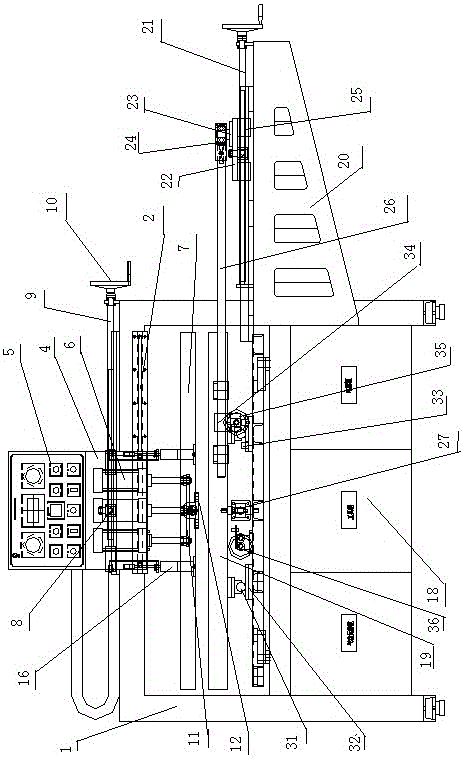

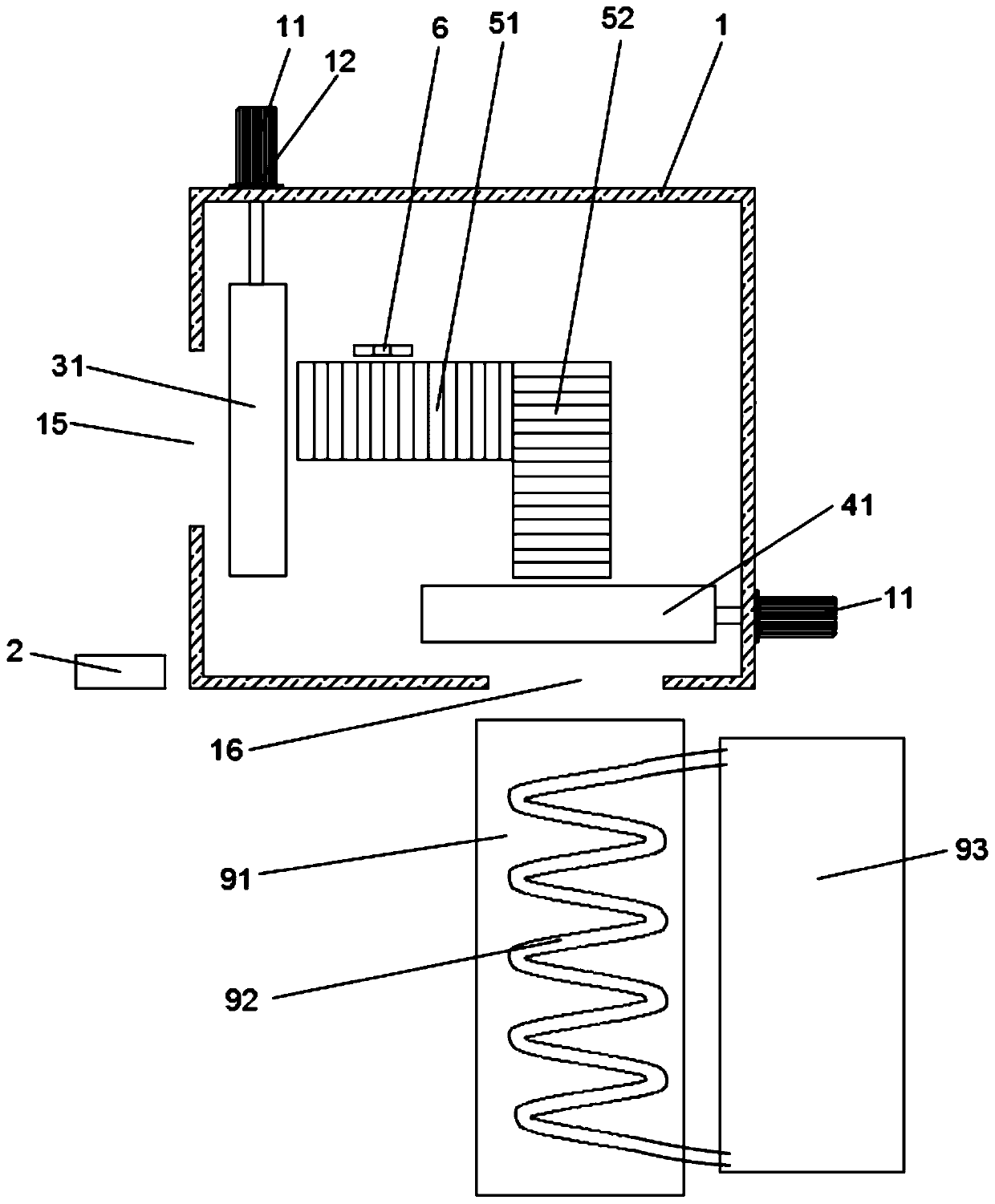

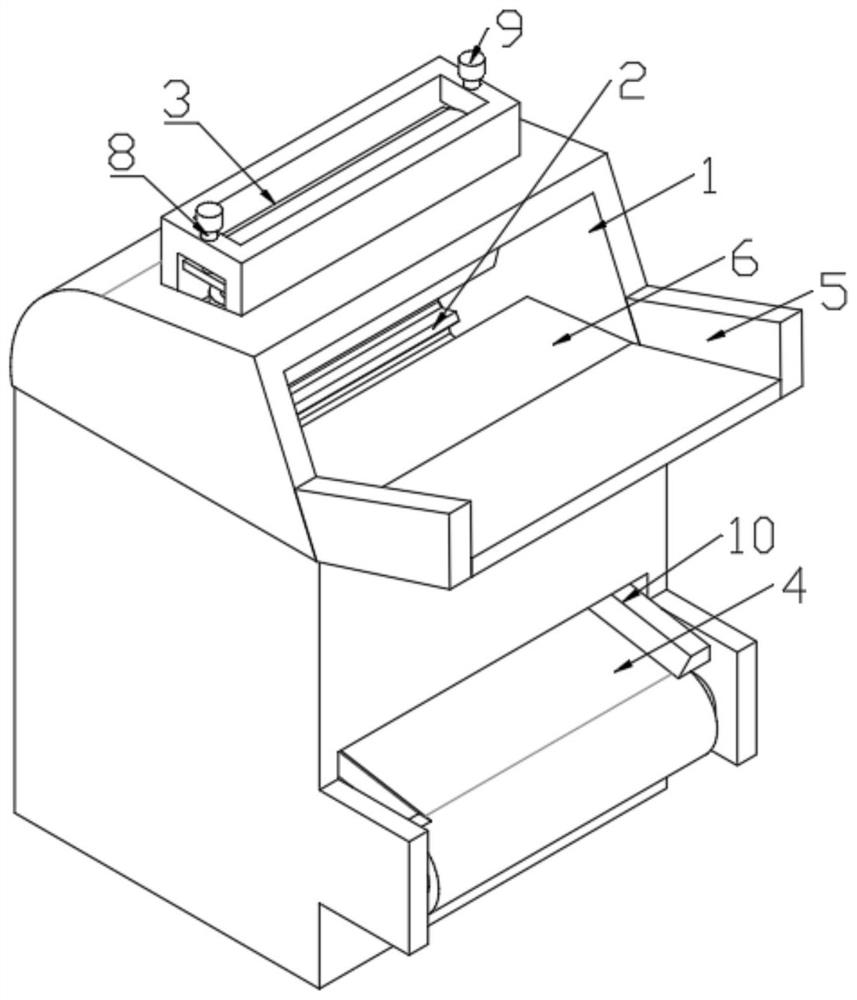

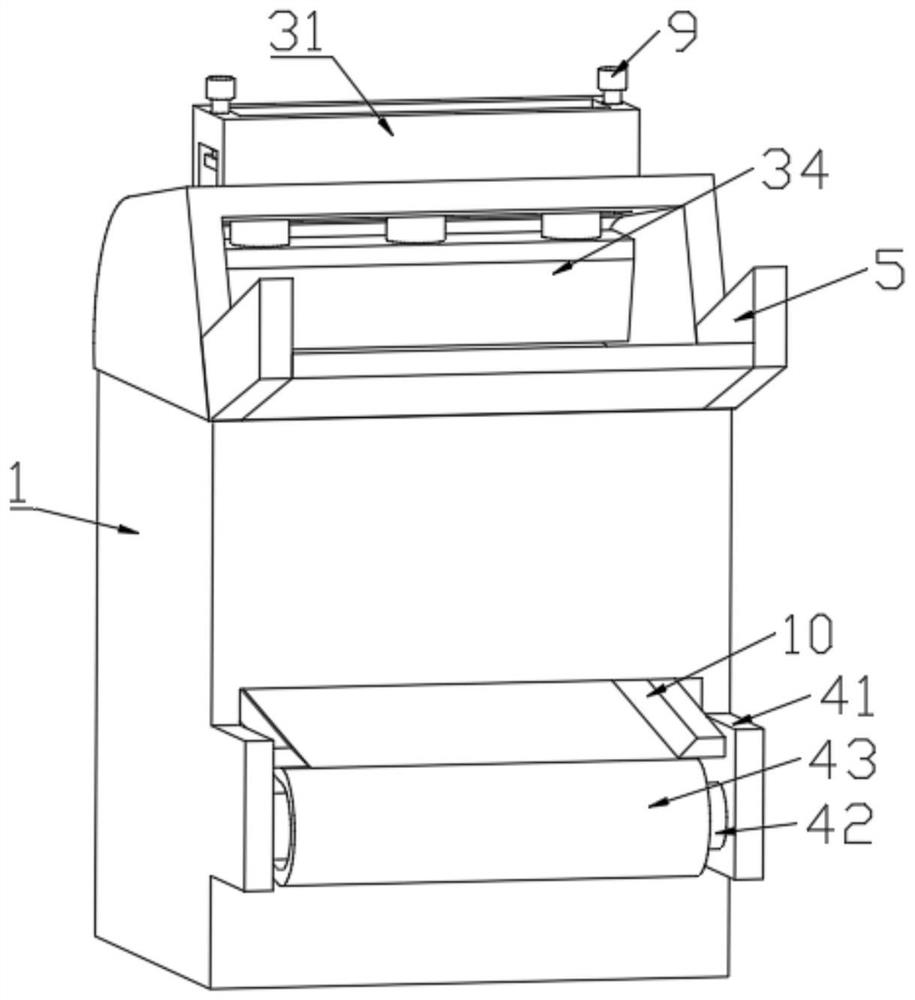

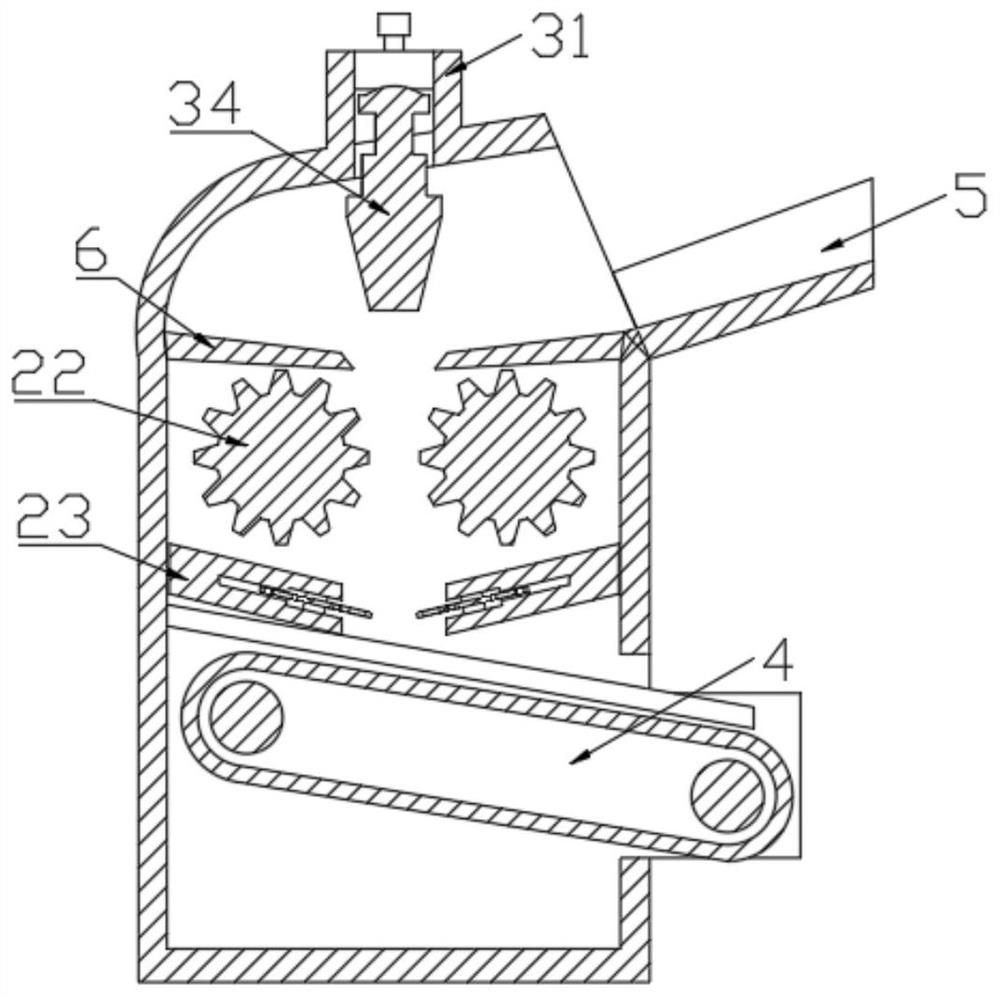

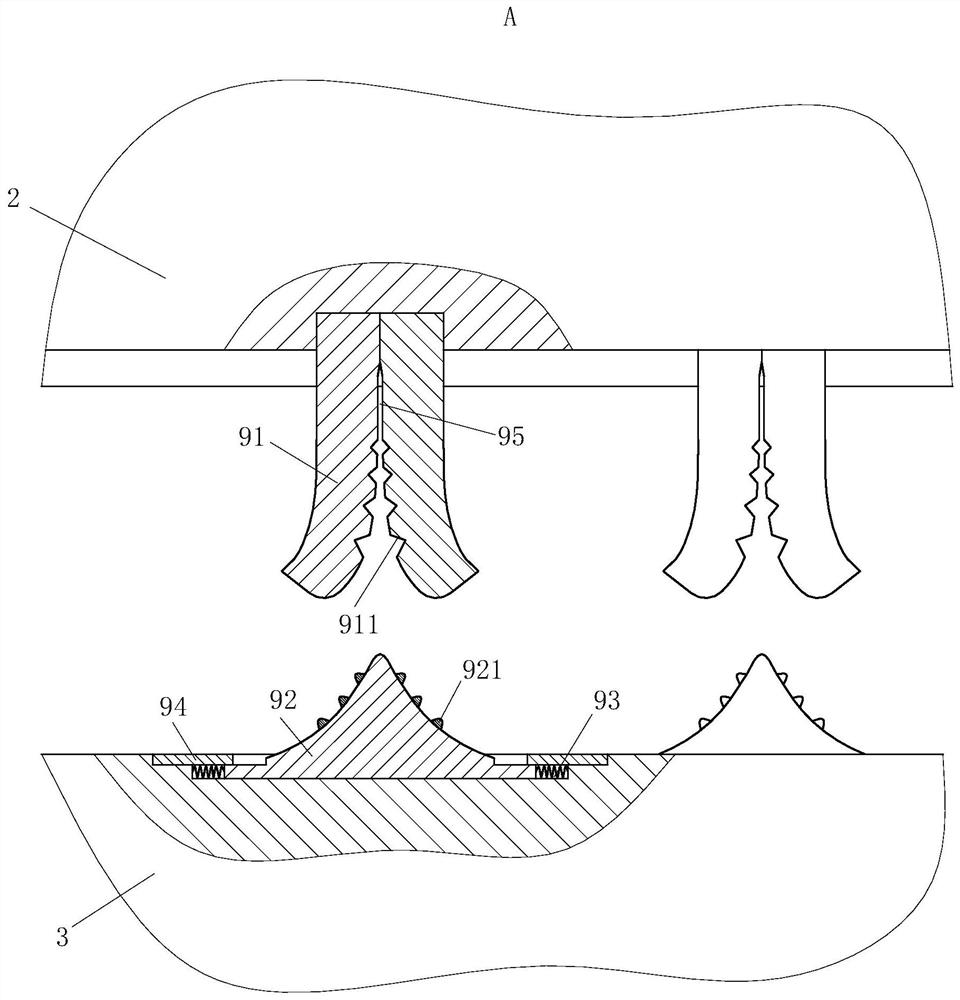

Novel online shredding and forming equipment for sheet paper fuming section base bar for tobacco

InactiveCN110063517AReduce manufacturing stepsGuaranteed rolling effectTobacco preparationTobacco smoke filtersEngineeringBiochemical engineering

Owner:SHANGHAI TOBACCO GRP CO LTD +1

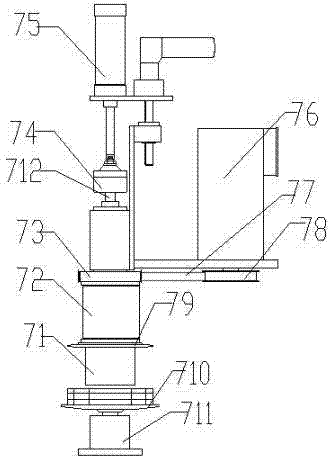

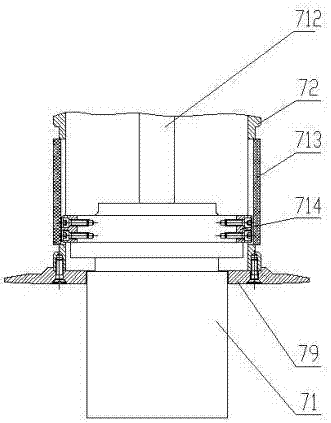

Turntable type UV laminator

InactiveCN103846191AGuaranteed Segmentation AccuracyGuaranteed uptimeLaminationPretreated surfacesBiochemical engineeringRaw material

Owner:HUNAN TENYUM INTELLIGENT EQUIP

Preparation process of high-performance 7-series aluminum alloy sheet

The invention belongs to the technical field of aluminum alloy manufacturing, and relates to a preparation process of a high-performance 7-series aluminum alloy sheet. The alloy comprises smaller thanor equal to 0.10% of Si, smaller than or equal to 0.15% of Fe, 1.7-1.9% of Cu, 2.4-2.55% of Mg, 5.8-6.0% of Zn, smaller than or equal to 0.24% of Cr, smaller than or equal to 0.04% of Ni, smaller than or equal to 0.03% of Ti, smaller than or equal to 0.05% of Mn, and smaller than or equal to 0.15% of impurities (with a single impurity being smaller than or equal to 0.05%), with the balance beingAl. By improving the formula and the process, the unevenness and the performance uniformity of the prepared aluminum alloy sheet in the width direction are guaranteed, and the problem that an ultra-large-width aluminum alloy coil prepared by an existing rolling process has poor performance uniformity and flatness in the width direction is solved.

Owner:TIANJIN ZHONGWANG ALUMINUM IND CO LTD

High silicon steel for thin slab casting and rolling production and preparation method thereof

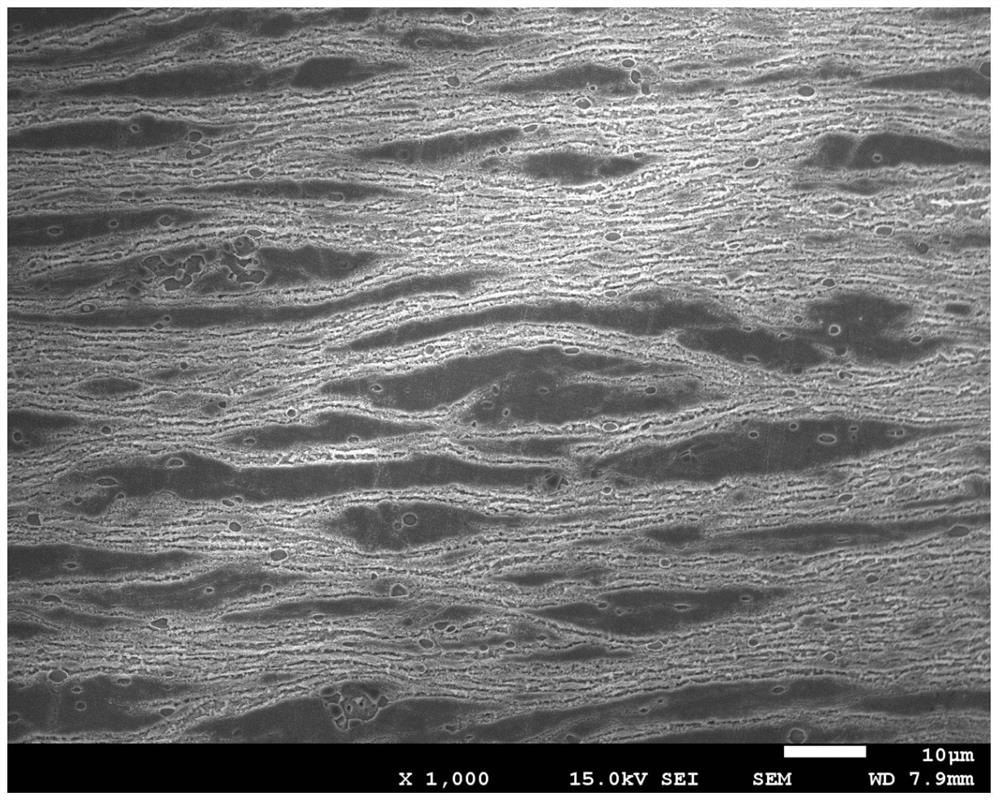

The invention discloses high silicon steel for thin slab casting and rolling production. The high silicon steel comprises the following components in percentage by weight: less than or equal to 0.003 percent of C, 4.5-7.0 percent of Si, 0.25-1.0 percent of Mn, less than or equal to 0.008 percent of Al, less than or equal to 0.0050 percent of S, less than or equal to 0.0030 percent of N and less than or equal to 20PPm of [O]. The preparation method comprises the following steps: smelting; casting; heating the cast slab; rolling; coiling; insulating in a bell-type furnace; performing warm-rolling, namely performing cold rolling at a temperature of 150 to 500 DEG C; and annealing at a high temperature. On the basis of the conventional thin slab casting and rolling equipment, a proper casting process is adopted, the columnar crystal ratio is improved, and the columnar crystal size is reduced; and the hot-rolling process is controlled, a fine fiber structure is obtained, and the warm-rolling property is guaranteed. The high silicon steel with good processability and magnetic performance can be produced.

Owner:武汉钢铁有限公司

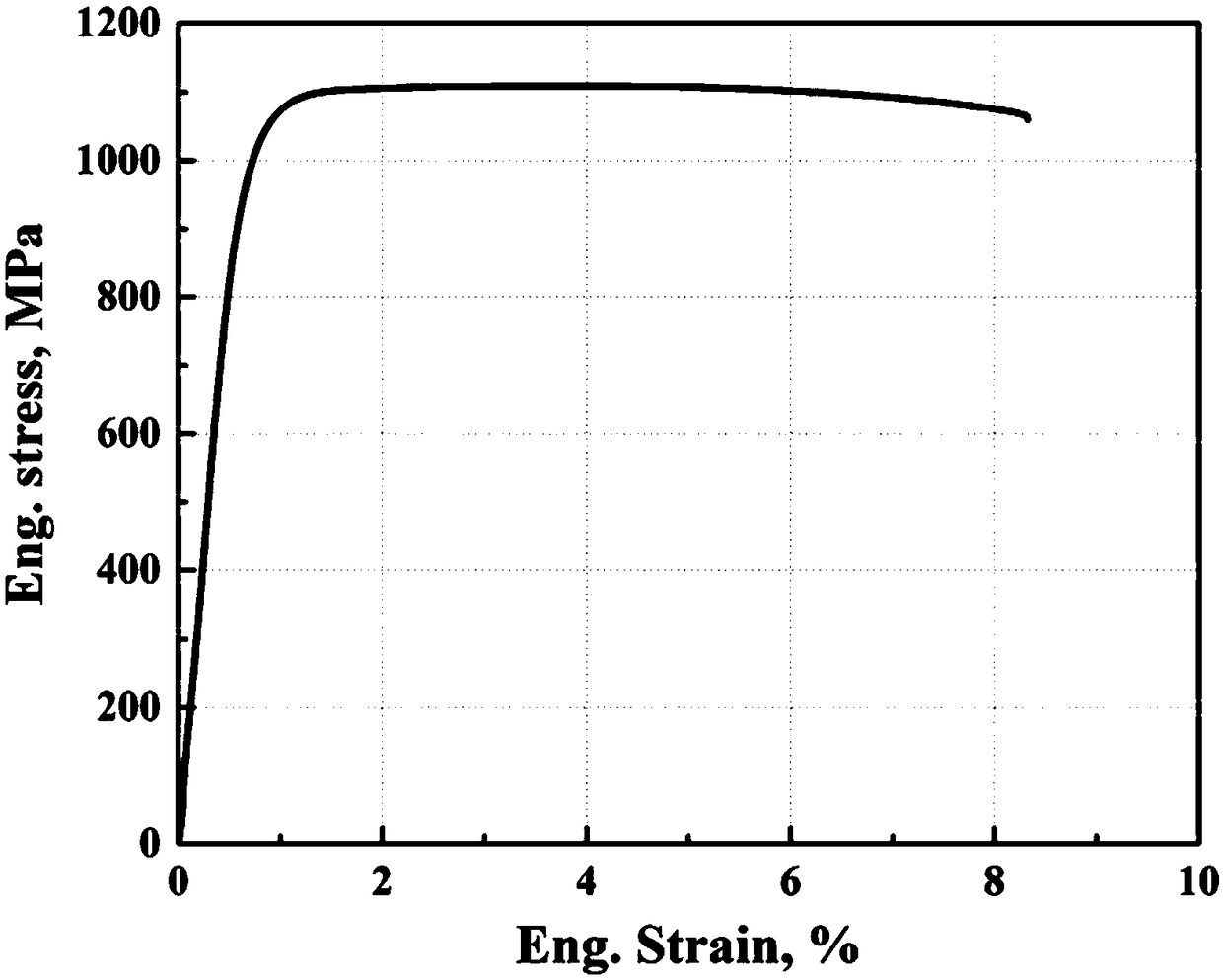

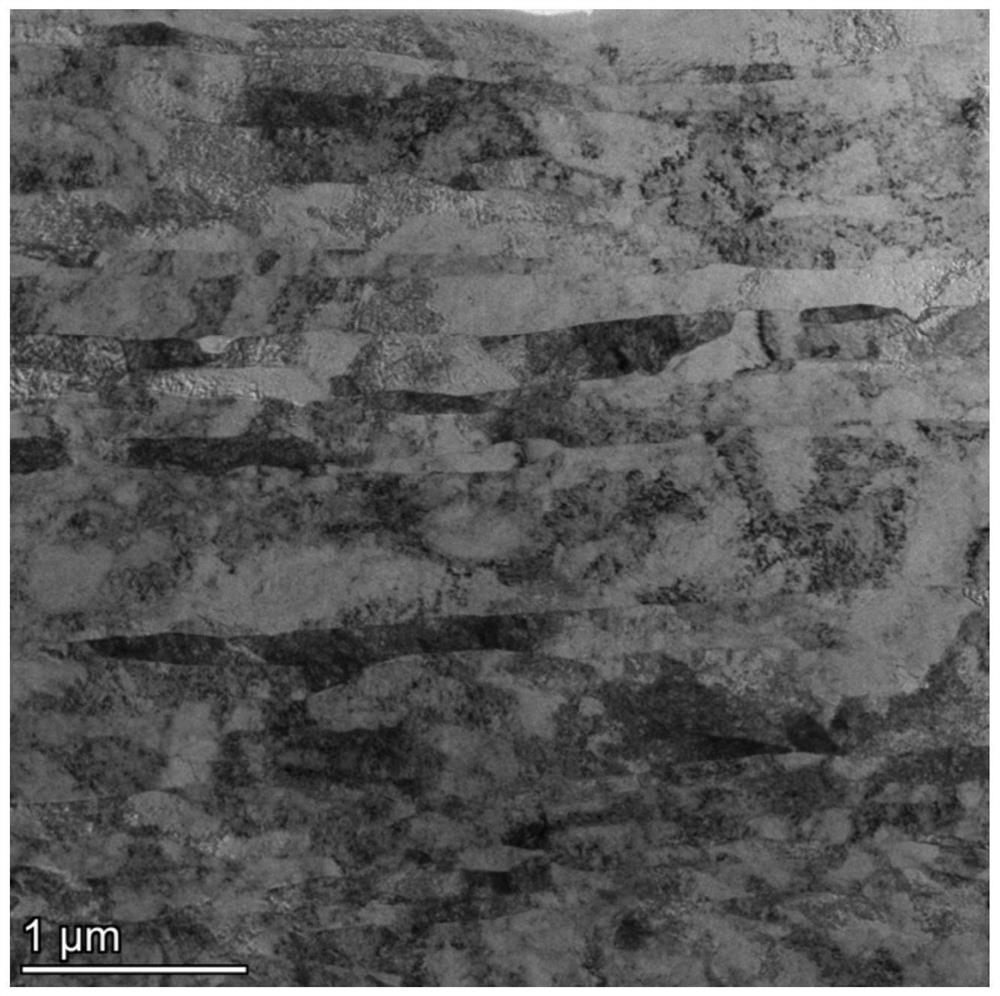

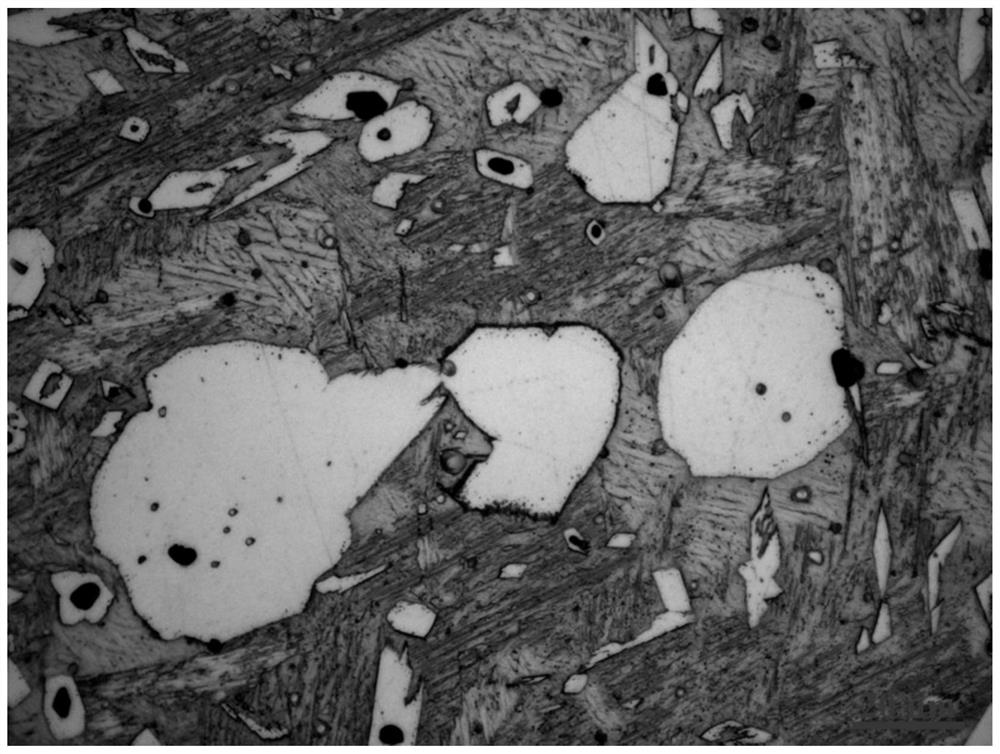

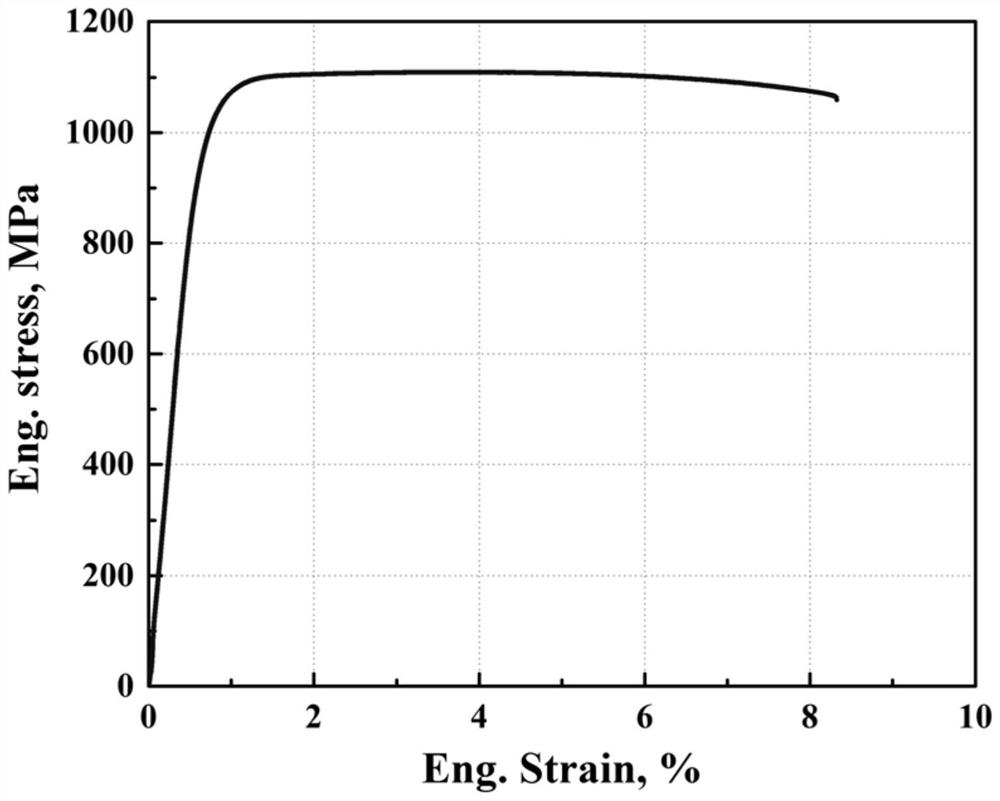

Preparation method of high-strength superfine dual-phase laminated QAl10-4-4 aluminum bronze alloy plates

The invention relates to a preparation method of high-strength superfine dual-phase laminated QAl10-4-4 aluminum bronze alloy plates. According to the preparation method, firstly, a dual-phase organization is regulated and heated, a raw material of QAl10-4-4 aluminum bronze alloy is treated in a thermal treatment furnace for 2-5 hours at a temperature of 850-920 DEG C, then the heated material issubjected to severe deformation through asymmetric continuous rolling and symmetric continuous rolling sequentially, and finally the rolled material is subjected to thermal treatment after deformation. An alpha phase of a face-centered cubic Cu-based solid solution and a beta phase of a body-centered cubic structure in an obtained structure obtained from thermal treatment are distributed in laminations, and a large amount of k phases of intermetallic compounds are dispersed inside the laminations and at boundaries of the laminations. The high-strength superfine dual-phase laminated QAl10-4-4 aluminum bronze alloy plates have the advantages that yield strength is not smaller than 900MPa, tensile strength is not smaller than 1000MPa, hardness is not smaller than 390HV, and elongation at break is not smaller than 8%. Compared with the prior art, the preparation method not only can improve performance of the QAl10-4-4 aluminum bronze alloy, but also is simple in process, easy to operate and low in cost, and can be used to realize preparation of the large-size QAl10-4-4 aluminum bronze alloy plates.

Owner:SHANGHAI JIAO TONG UNIV

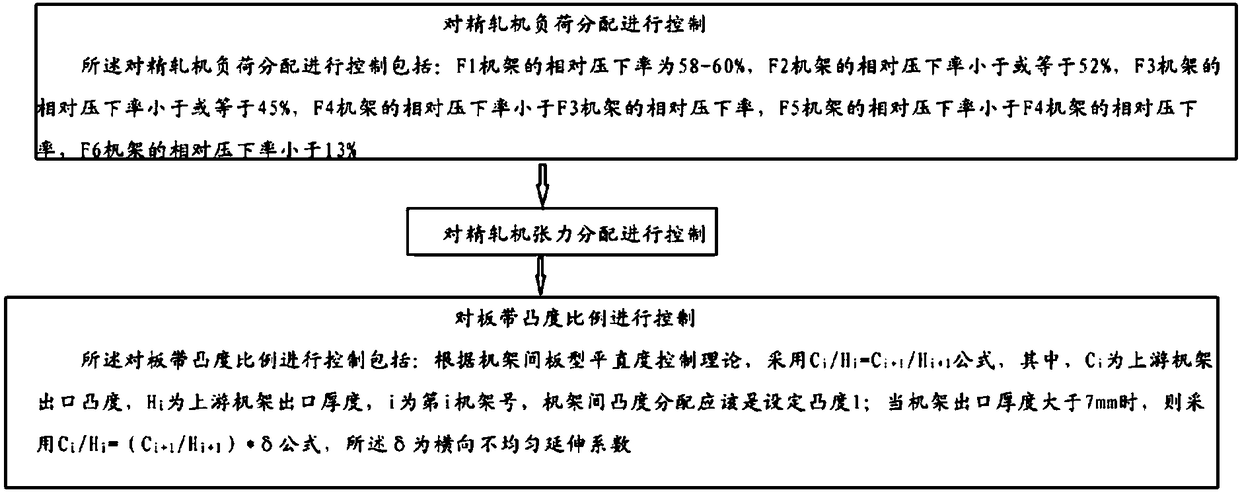

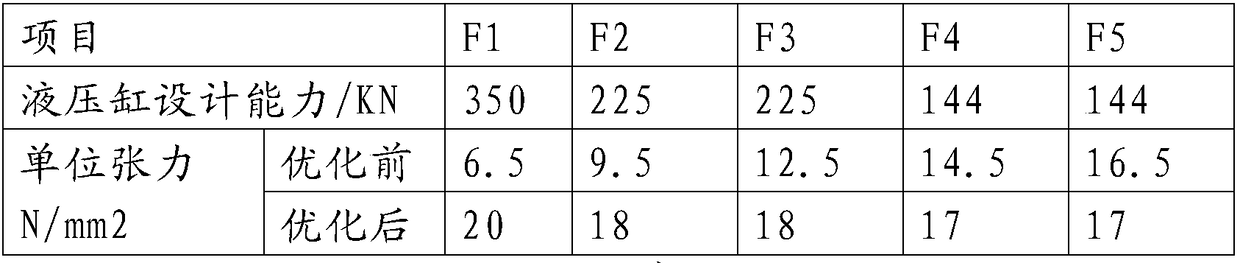

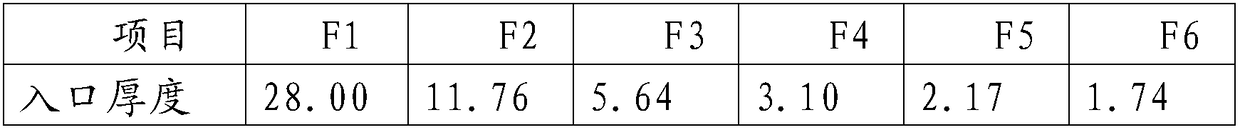

Finish rolling stability control method

ActiveCN108580561AImprove the problem of strong vibrationImprove efficiencyRoll force/gap control deviceTension/compression control deviceVibration ProblemEngineering

The invention discloses a finish rolling stability control method, and belongs to the technical field of rolling processes. The finish rolling stability control method comprises the following steps: the load distribution of a finish rolling machine is controlled; the tension distribution of the finish rolling machine is controlled; the plate strip convexity ratio is controlled; the control of theplate strip convexity ratio comprises the following steps: a formula of Ci / Hi=Ci+1 / Hi=1 is adopted according to a frame plate type straightness control theory, wherein Ci is the outlet convexity of anupstream frame, Hi is the outlet thickness of the upstream frame, and i is the ith frame number; the frame convexity distribution adopts the set convexity 1; and when the frame outlet thickness is larger than 7 mm, a formula of Ci / Hi=(Ci+1 / Hi+1)*delta is adopted, wherein delta is the transverse nonuniform extension coefficient. The finish rolling stability control method guarantees the stabilityin the finish rolling process, and solves the vibration problem of the rolling machine, the surface quality problem, the center wire control problem and the plate type problem.

Owner:BEIJING SHOUGANG CO LTD

Rapid crushing device for corn kernel processing

InactiveCN111097570AAvoid stickingCompletely brokenGrain treatmentsAgricultural scienceAgricultural engineering

The invention relates to the technical field of agricultural and sideline product processing, in particular to a rapid crushing device for corn kernel processing. The rapid crushing device comprises ashell, feeding ports are formed in the left side and the right side of the top end of the shell, a rolling mechanism is arranged on the lower sides of the feeding ports, a crushing mechanism is arranged on the lower side of the rolling mechanism, and a secondary crushing mechanism is arranged on the lower side of the crushing mechanism. According to the rapid crushing device, the rolling mechanism is arranged, corn kernels are crushed through a roller, and the corn kernels can be crushed more thoroughly; the crushing mechanism is arranged, the corn kernels in a crushing barrel can make full contact with crushing blades through vertical vibration of the crushing barrel, and the crushing effect is improved; and the interior of filter holes can be prevented from being blocked along with vertical vibration of the crushing barrel, and the secondary crushing mechanism is arranged, the corn kernels can be crushed again, the crushing process of the corn kernels is more comprehensive and sufficient, and the crushing effect can be improved.

Owner:应元芬

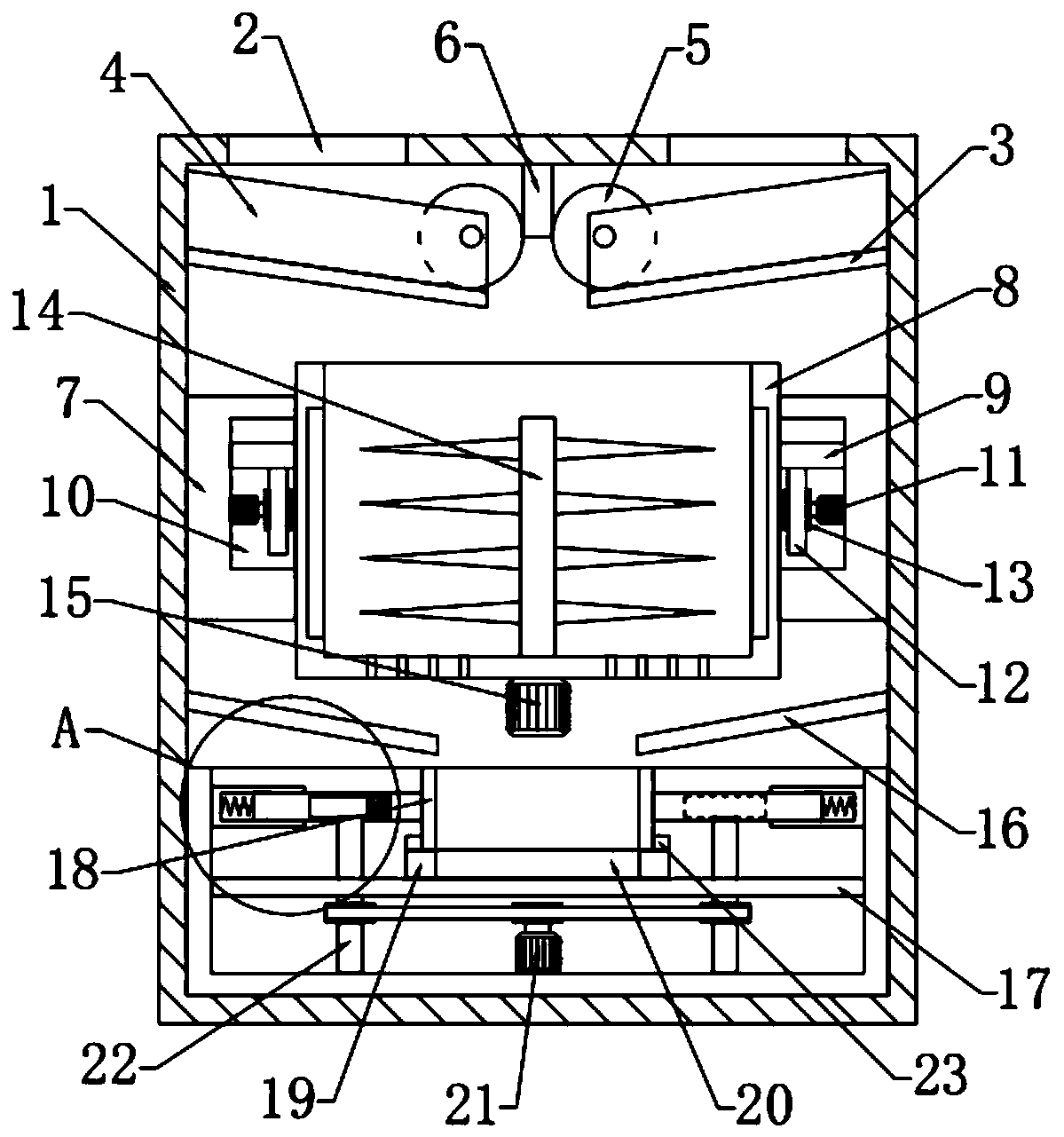

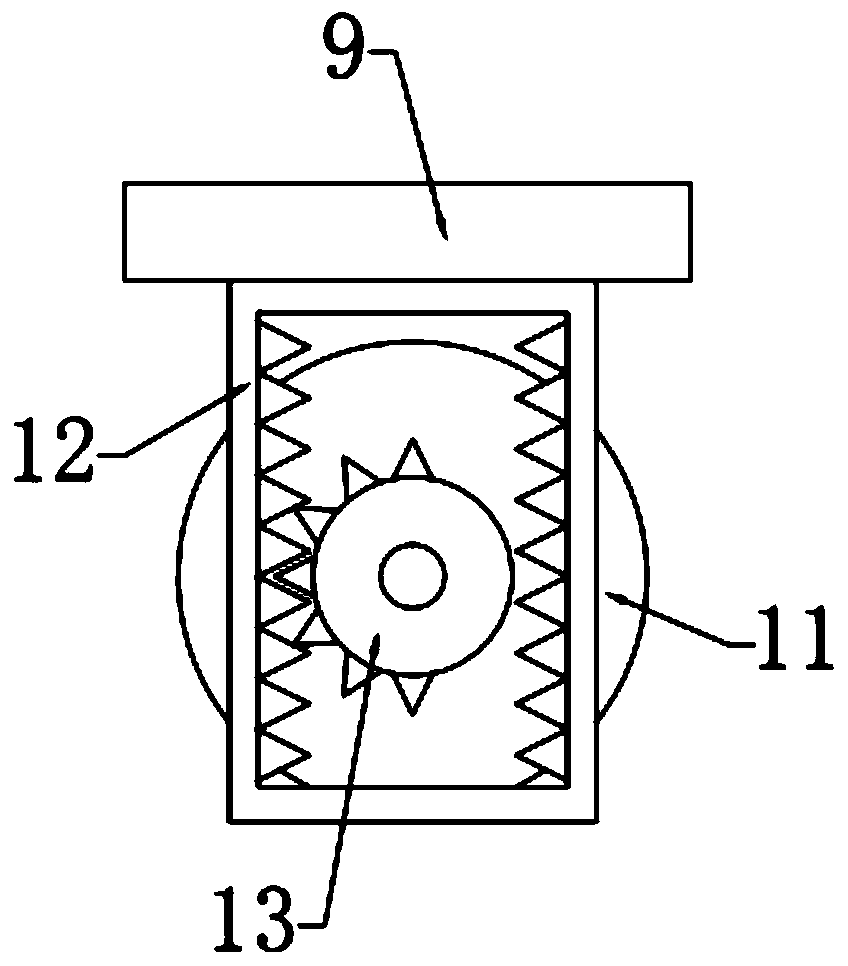

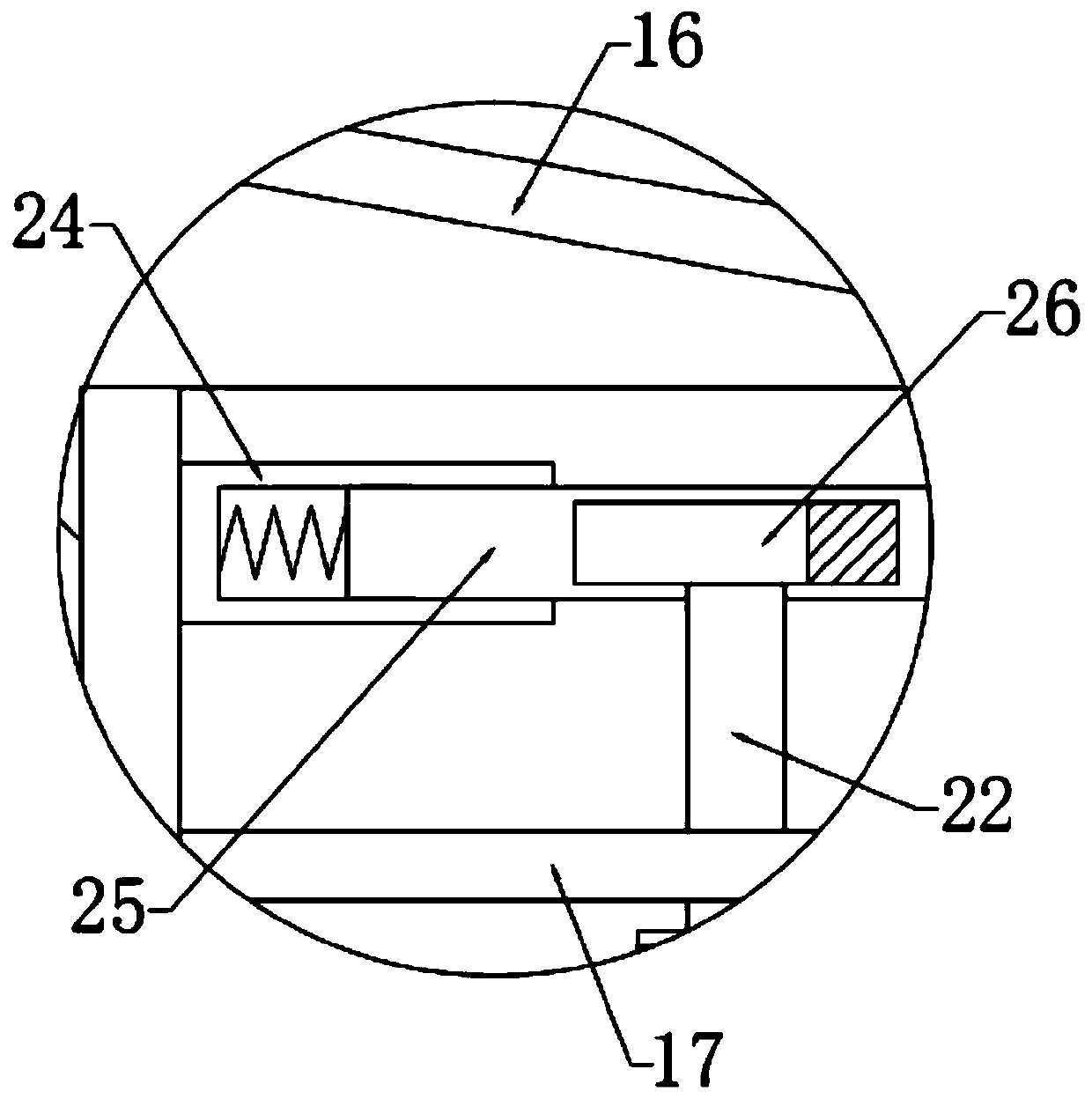

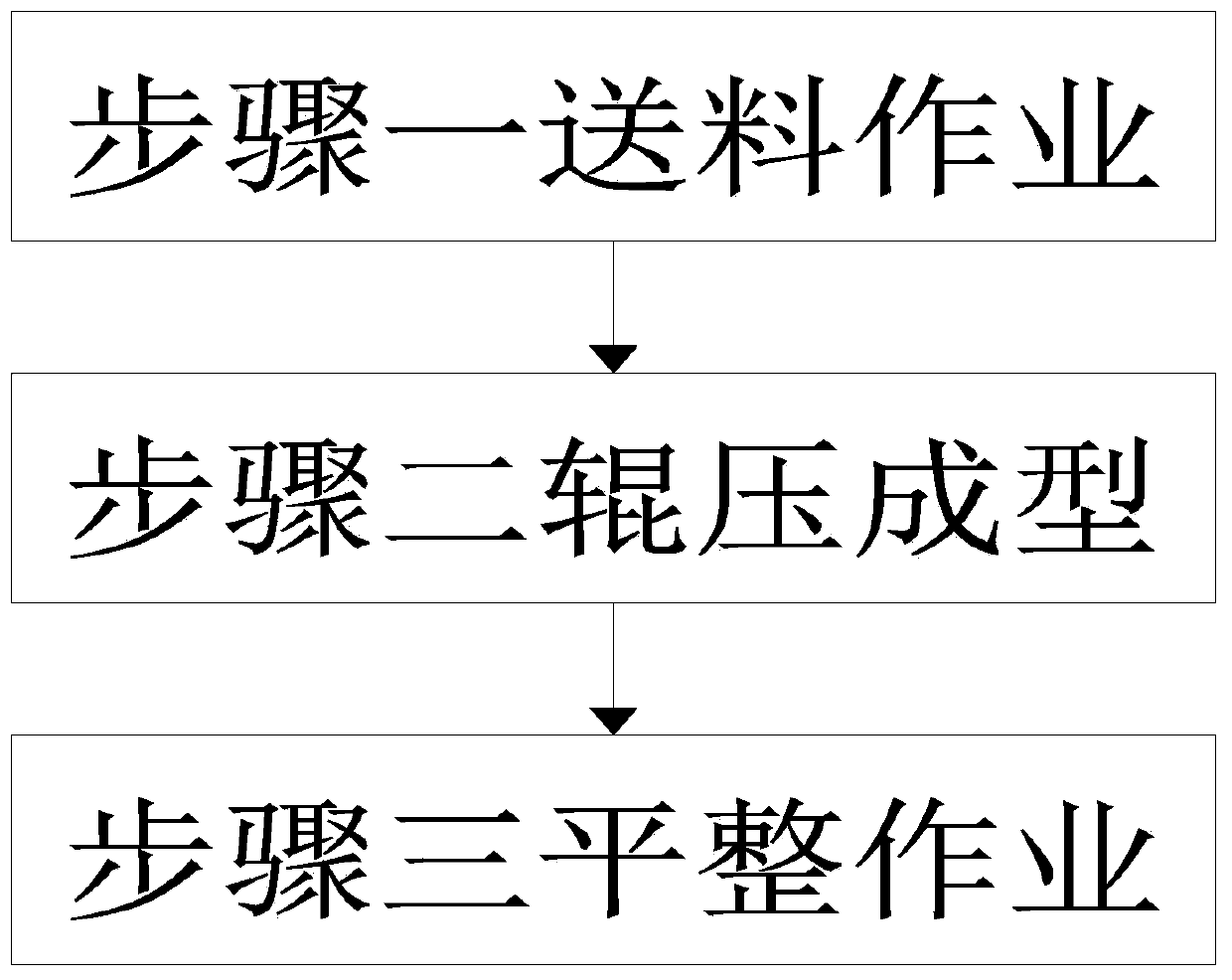

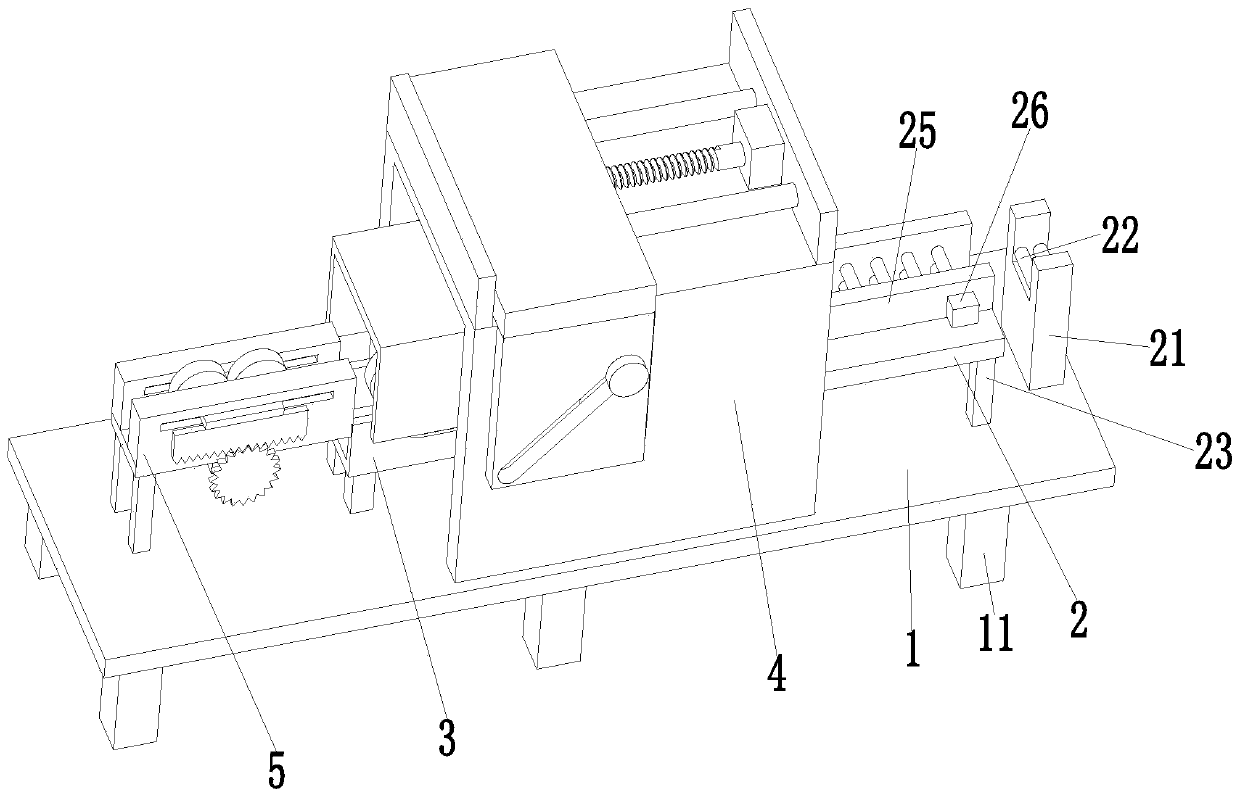

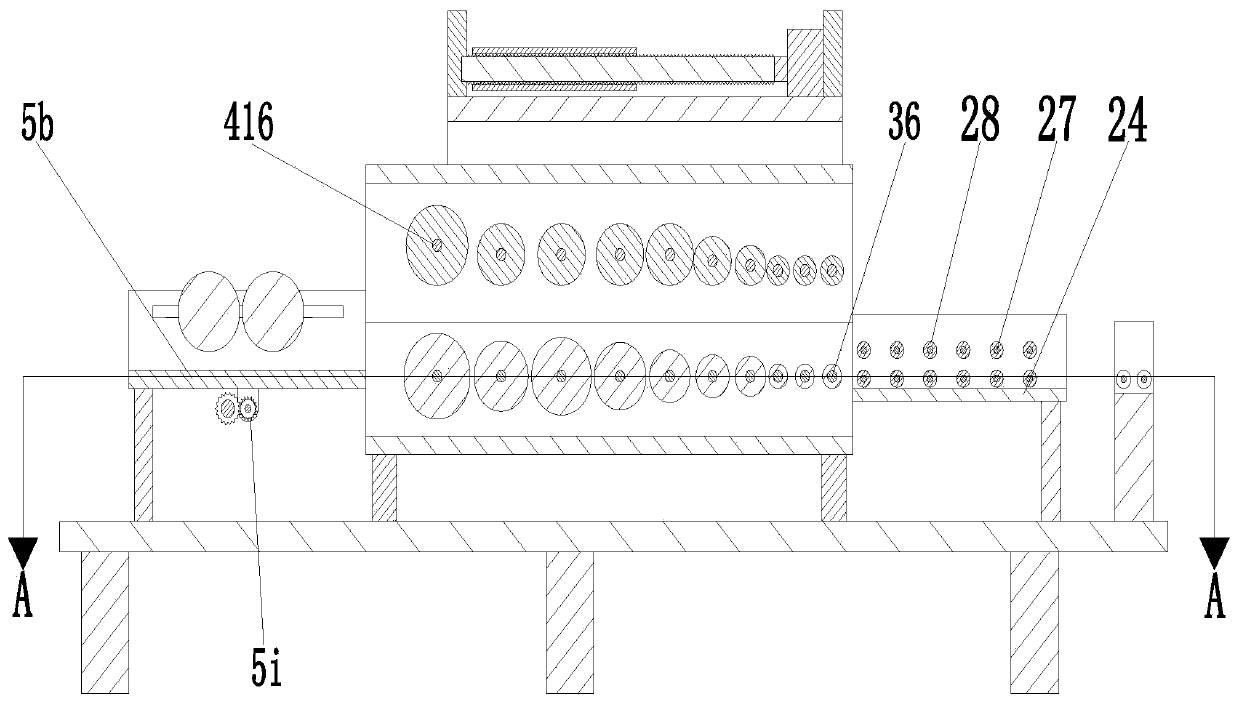

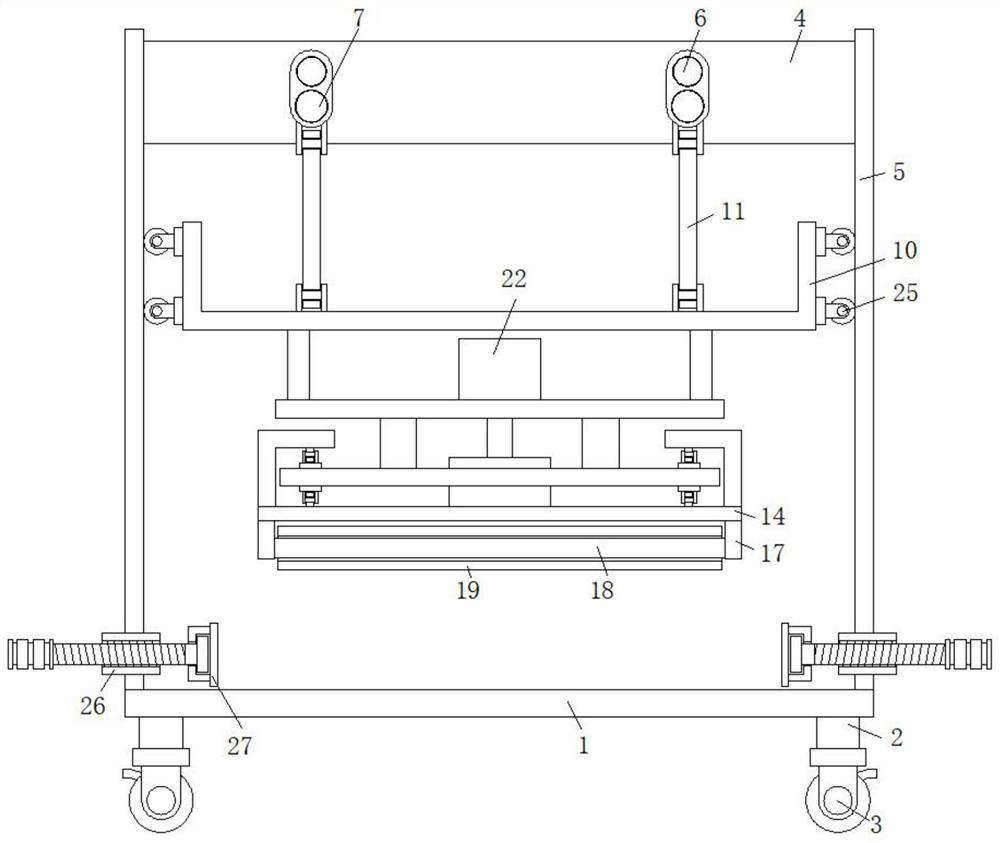

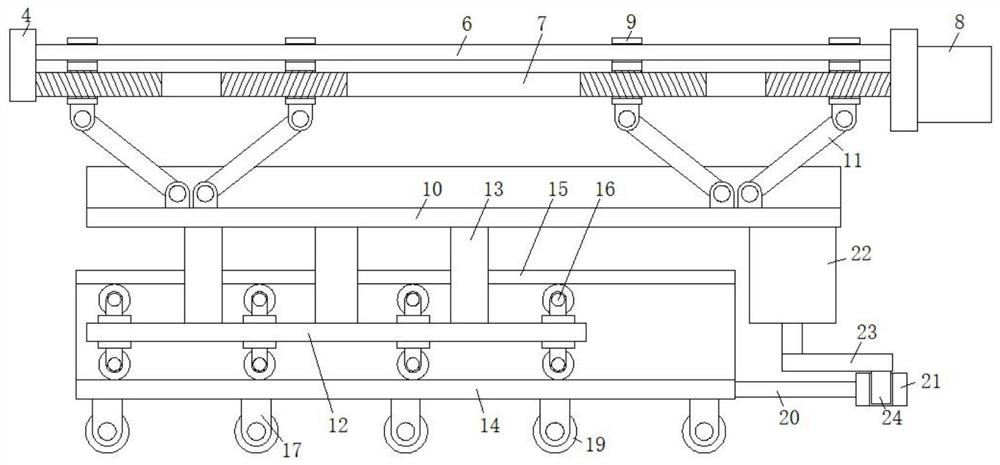

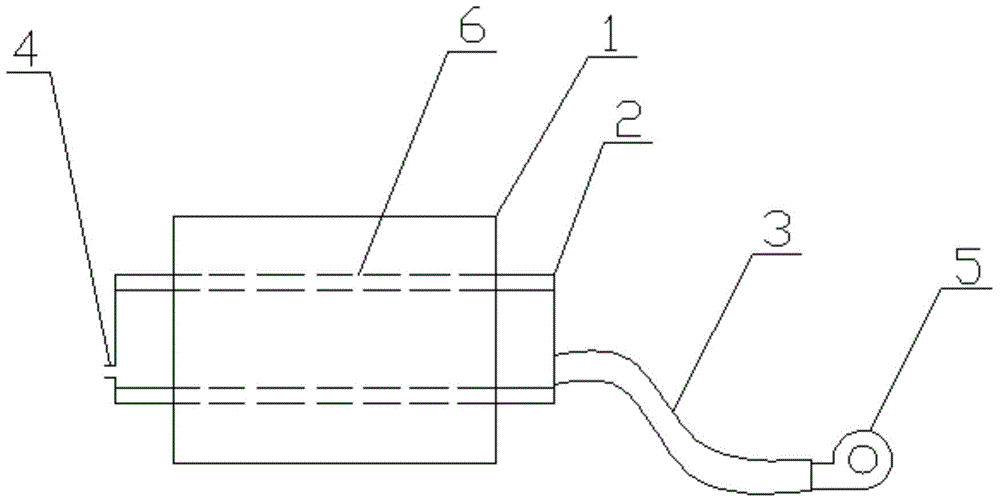

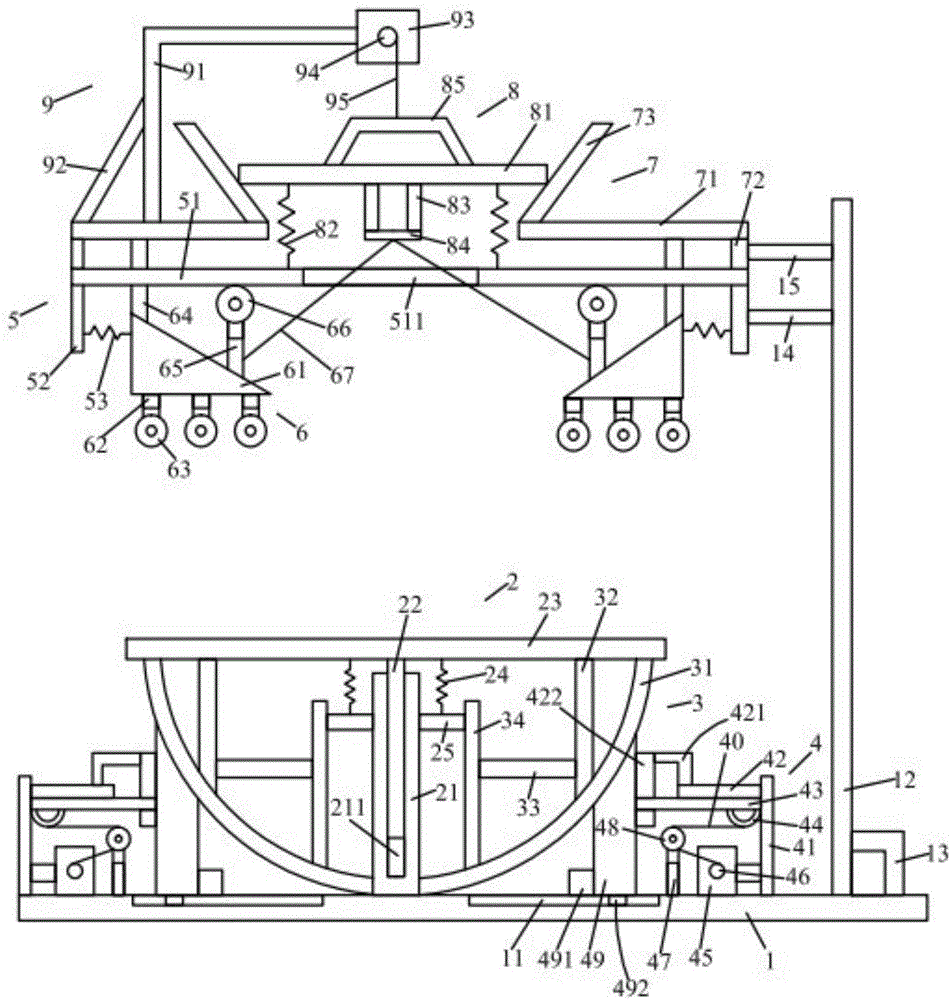

Roll-in forming method for building profile steel

ActiveCN111451331AGuaranteed rolling effectImprove stabilityMetal-working feeding devicesPositioning devicesBaseboardStructural engineering

The invention relates to a roll-in forming method for building profile steel. The roll-in forming method mainly comprises the following steps of feeding, roll-in forming, flattening and other variousworking procedures. Adopted roll-in equipment for the building profile steel comprises a baseboard, a feeding device, a roll-in device, a pushing device and a flattening device. The roll-in forming method can solve the following problems existing in roll-in forming for current building profile steel that a, when traditional building profile steel is subjected to roll-in forming, wrinkling of sidewalls and pressing marks of the bottoms often occur to the building profile steel after roll-in bending forming, residual linear sections exist at the ends of formed products, and the building profilesteel after roll-in is likely to bounce, which affects the use of the building profile steel; b, the building profile steel produced through an existing roll-in forming machine is out of flatness, the machining curvature is not uniform, obvious wavy machining defects or even distortion is prone to occur at edges in severe cases, the product quality is poor, equipment has complicated structures, many machining procedures are involved, materials are severely wasted, and the efficiency and quality of forming the building profile steel can be improved.

Owner:汕尾市宏昇钢结构有限公司

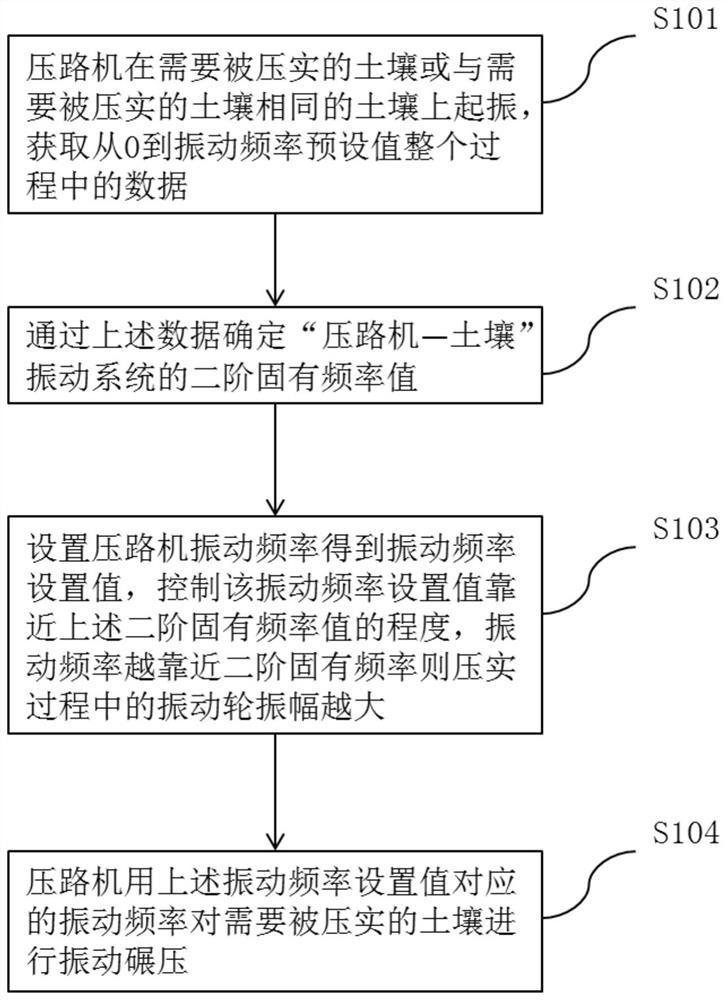

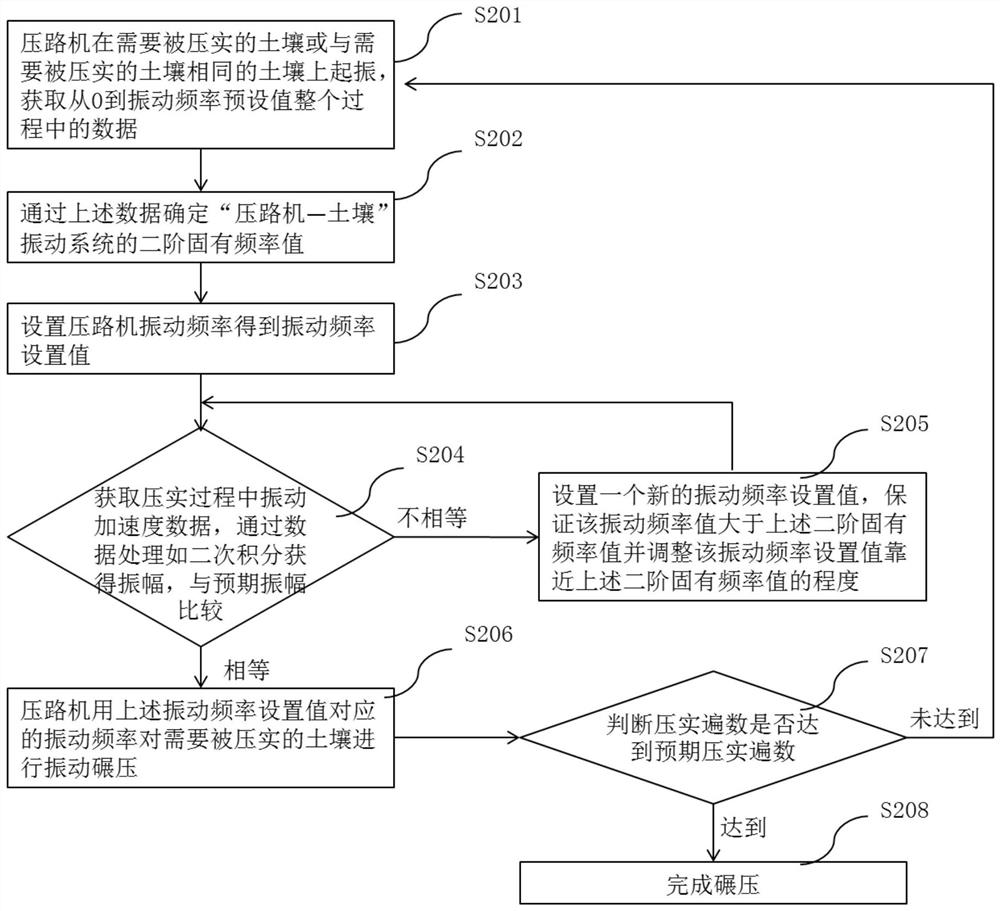

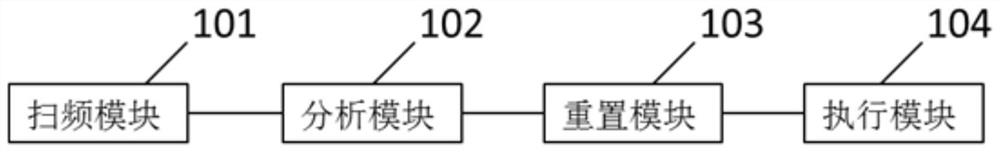

Variable amplitude control method, device and system for vibratory roller, and vibratory roller

PendingCN112482139AAmplitude changeSimple control methodRoads maintainenceVibration amplitudeData information

The invention discloses a variable amplitude control method for a vibratory roller. The method comprises the following steps: acquiring data information in the process of increasing the vibration frequency from zero to a preset value of the vibration frequency, wherein the data information is obtained by a road roller in to-be-pressed soil or soil the same as the to-be-pressed soil; obtaining a second-order inherent frequency value of the soil system of the road roller according to the data information; setting the vibration frequency of the road roller, obtaining a vibration frequency set value, and controlling the degree of the vibration frequency set value close to the second-order inherent frequency value; and controlling the road roller to vibrate and grind the soil to be pressed at the vibration frequency corresponding to the vibration frequency set value. A special vibration exciter structure or amplitude modulation oil cylinder or vibration wheel structure in the vibration wheel does not need to be adopted, the amplitude can be changed only by changing the vibration frequency, and the control method is simple and high in reliability.

Owner:XCMG CONSTR MACHINERY

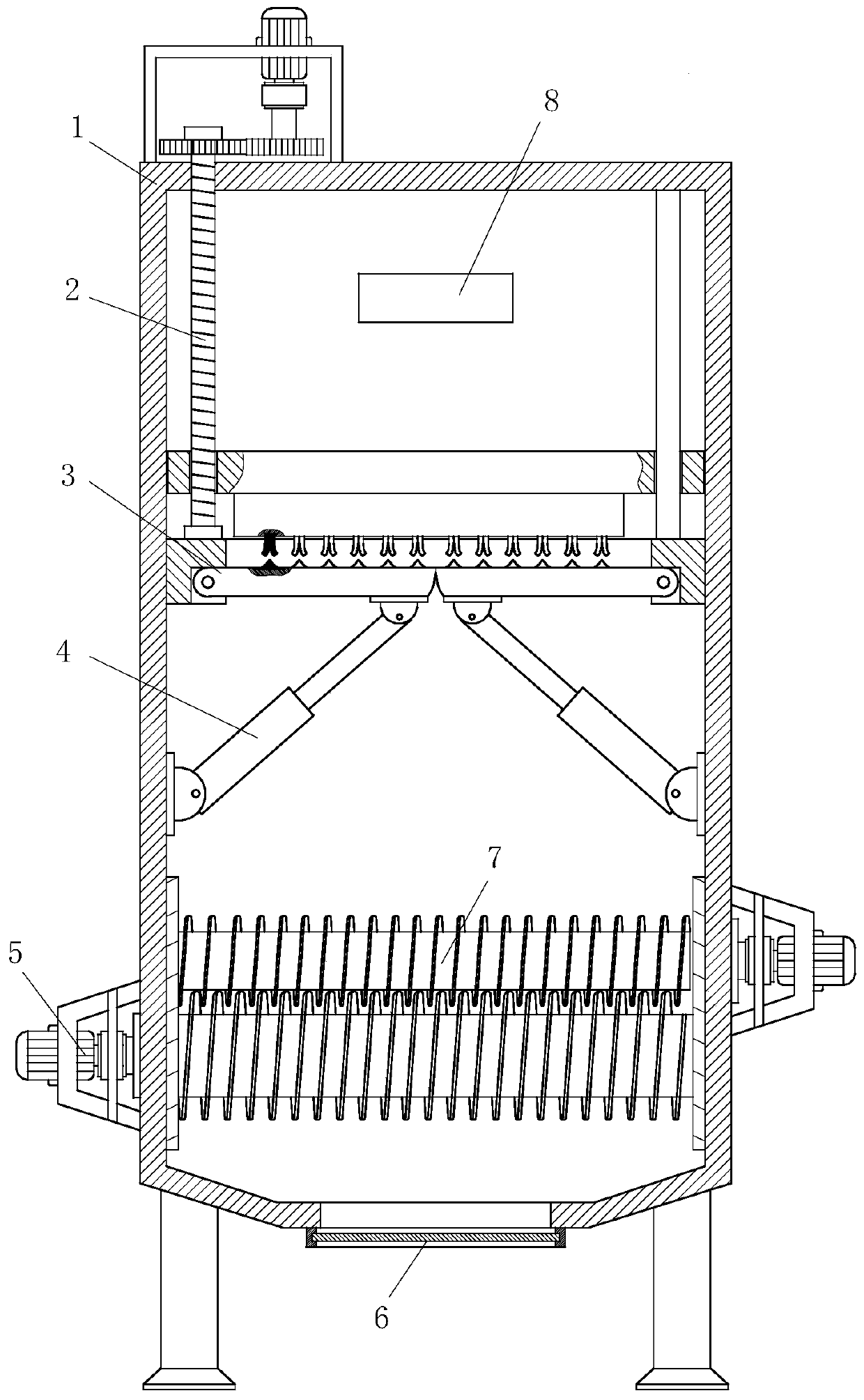

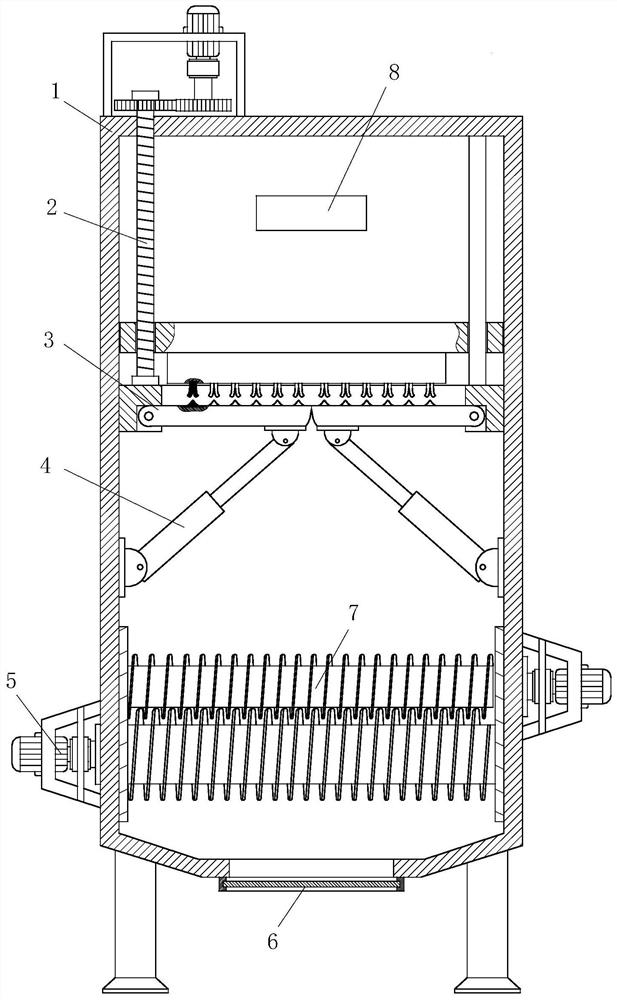

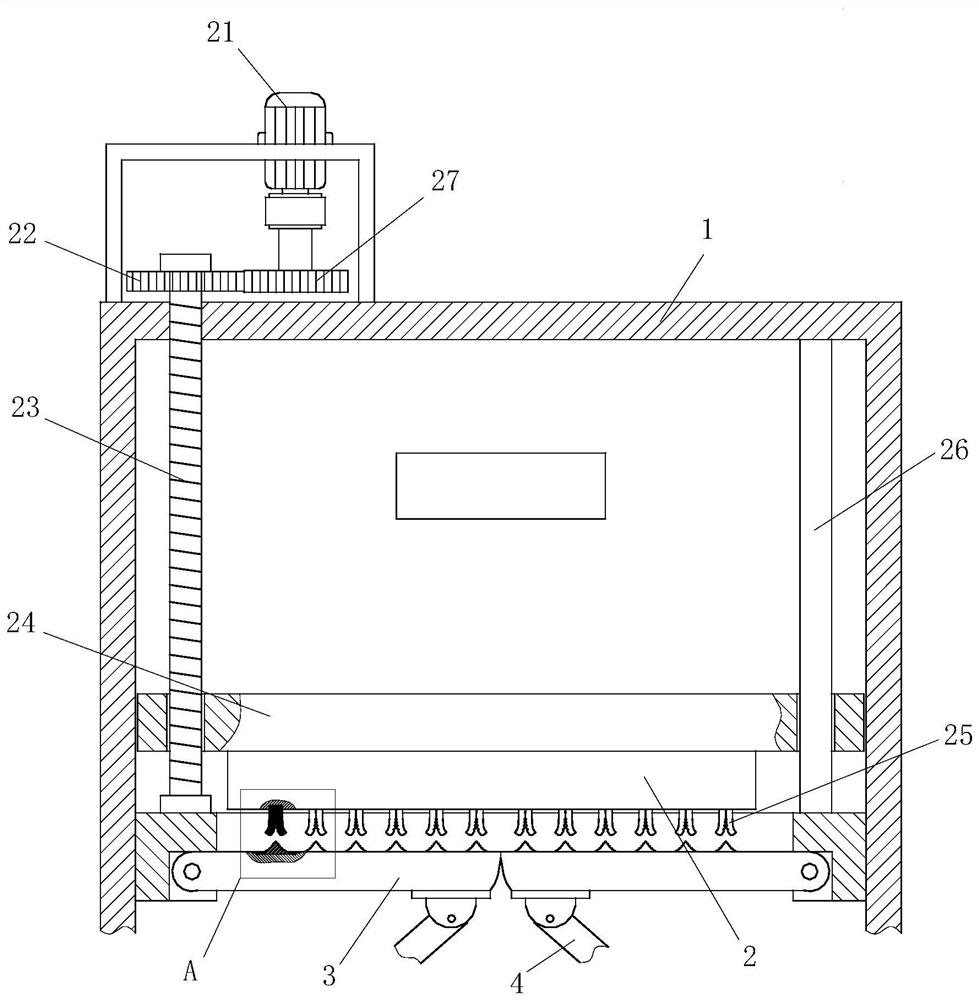

Solid waste treatment system with pre-treatment step

ActiveCN110237908AImprove stabilityImprove the crushing effectGrain treatmentsElectric machineryPre treatment

The invention belongs to the technical field of solid waste treatment, and in particular relates to a solid waste treatment system with a pre-treatment step. The system comprises a treatment box body, a primary crushing assembly and a crushing roller. A rotary sealing plate is arranged in the middle of the lower part in the treatment box body, the primary crushing assembly is arranged above the rotary sealing plate, and an electric hydraulic telescopic rod is connected between the lower end of the rotary sealing plate and the treatment box body. By arranging crushing knives in a combined manner, solid waste between an arc-shaped surface of an elastic arc plate and two side faces on a triangular slide block are ground, so that the crushing effect of the solid waste is improved. By mounting the triangular slide block on a chute in the sealing plate, on the one hand, a problem of transitional wear due to an excessive impact force as the single elastic arc plate is stressed is solved. On the other hand, the solid waste is paved on two crushing rollers uniformly, so that the probability that a crushing motor is burned is reduced, and the service life of the crushing motor is further prolonged.

Owner:山东同其数字技术有限公司

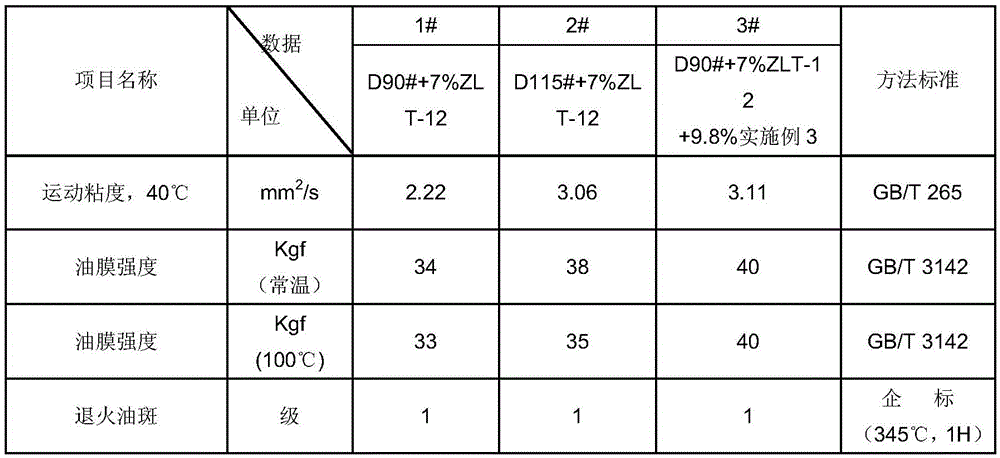

High-temperature additive for cold rolling of aluminum, and preparation and application thereof

ActiveCN105524684AImprove high temperature performanceReduce the chance of occurrenceThickenersAdditivesThiodipropionic acidBase oil

The invention provides a high-temperature additive for rolling oil used in cold rolling of aluminum strips, which belongs to the field of lubricant compositions. The high-temperature additive is composed of a low-molecular-weight thickening agent, an anti-oxidant and base oil, wherein the anti-oxidant is one or more selected from the group consisting of a hindered phenol anti-oxidant, an aromatic amine anti-oxidant, an thiodipropionic diester anti-oxidant and a phosphite anti-oxidant, and the mass percentage contents of the low-molecular-weight thickening agent, the anti-oxidant and base oil are 4 to 80%, 0.01 to 3% and 17 to 95%, respectively. According to the invention, through reasonable adjustment of the ratio of low-molecular-weight thickening agent to anti-oxidant to base oil, integral high temperature performance of the rolling oil can be improved in cold rolling of aluminum strips without changing conventional base oil, composite additives and process; and the high-temperature additive has guaranteed high lubricity at a high temperature, is easy to clean and reduces occurrence probability of annealing oil marks.

Owner:CHINALCO LUBRICANT TECH CO LTD

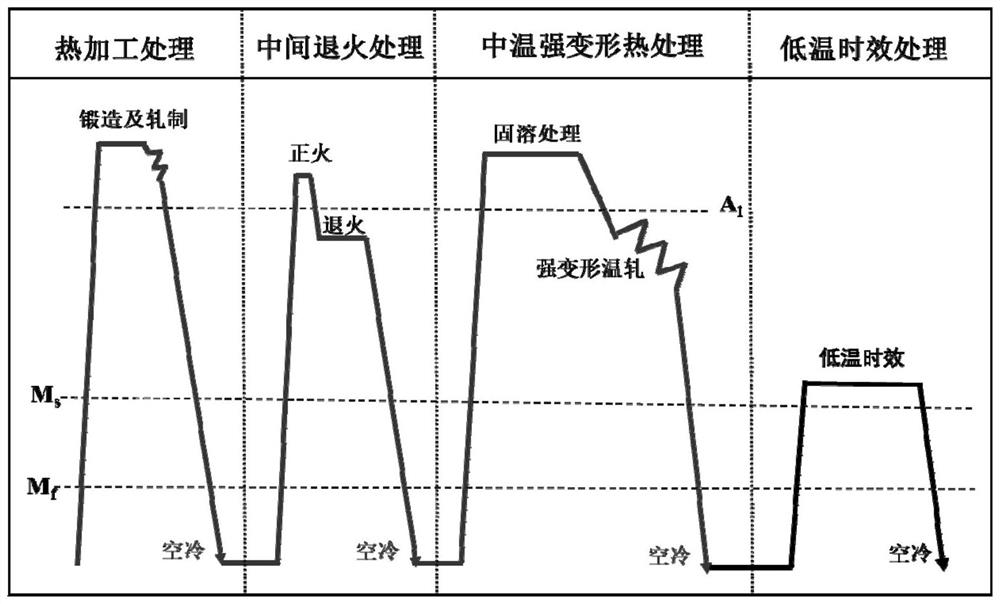

Air-cooled hardened steel plate with ultra-high strength, high toughness and ultra-fine structure and preparation process of air-cooled hardened steel plate

ActiveCN112063921AImprove plasticity and toughnessFacilitates microscopic stress-strain distributionFurnace typesHeat treatment furnacesSteel platesOxidation resistant

The invention relates to an air-cooled hardened steel plate with ultra-high strength, high toughness and an ultra-fine structure and a preparation process of the air-cooled hardened steel plate. The air-cooled hardened steel plate comprises the following components in percentage by mass: less than or equal to 0.08% of C, 0.1-0.35% of Si, 0.2-0.8% of Mn, 10-15% of Cr, 2.0-3.0% of W, 2.0-3.0% of Co,0.1-0.3% of V, 0.025-0.08% of Nb, 0.03-0.06% of N, 0.05-0.1% of Ta, 0.02-0.06% of Nd, less than or equal to 0.0005% of B and the balance of Fe and inevitable impurities. The preparation process comprises the steps of smelting, hot working treatment, secondary intermediate annealing treatment, medium-temperature strong deformation heat treatment and low-temperature aging treatment. Structural regulation and control are conducted through conventional equipment and production process, the martensite structure can be refined to the nanoscale, furthermore, a large number of nano-particles are separated out and distributed in a matrix in a dispersed mode, and the comprehensive performance of the low-carbon martensite steel plate is remarkably improved. Compared with the prior art, the preparedmaterial has ultrahigh strength, high toughness, good corrosion resistance, oxidation resistance, heat resistance and low-temperature performance. The preparation process is simple, industrial large-scale production is facilitated, production cost is low, production efficiency is high, and the product application range is wide.

Owner:SHANGHAI JIAO TONG UNIV

Fabric rolling mill with hydraulic adjusting roller

ActiveCN105603662AUniform rolling forceGuaranteed rolling effectLiquid/gas/vapor removal by squeezing rollersRolling mill

The invention discloses a fabric rolling mill with a hydraulic adjusting roller. The fabric rolling mill comprises the roller and a horizontal roll. Two ends of the roller are hinged to the upper portions of two vertical support plates of a framework, moving straight slots are formed in the lower portions of the two vertical support plates, limiting protruded strips are arranged on two inner side walls of each moving straight slot, moving blocks are inserted in the moving straight slots, the limiting protruded strips are inserted in vertical grooves in the side walls of the moving blocks, two ends of the horizontal roll are hinged onto the corresponding moving blocks, and a left pushing cylinder and a right pushing cylinder are fixed onto a bottom plate of the framework. The fabric rolling mill has the advantages that the horizontal roll can be pushed by the left pushing cylinder and the right pushing cylinder, so that the distance from the horizontal roll to the roller can be adjusted, and rolling effects can be guaranteed; the outer diameter of the outer wall of an outer rubber roller sleeve is gradually reduced from the outer wall of the middle of the outer rubber roller sleeve to two ends of the outer rubber roller sleeve, accordingly, the roller can be matched with a middle deformation position of the lower straight roll during rolling, deformation can be compensated, and uniform fabric rolling stress can be guaranteed.

Owner:林立荣

Rolling-pressing device for heat preservation film production and operation method thereof

ActiveCN109928244APrevent deviationThe rolling step is smoothWebs handlingEngineeringMechanical engineering

Owner:灵璧县浩翔信息科技有限公司

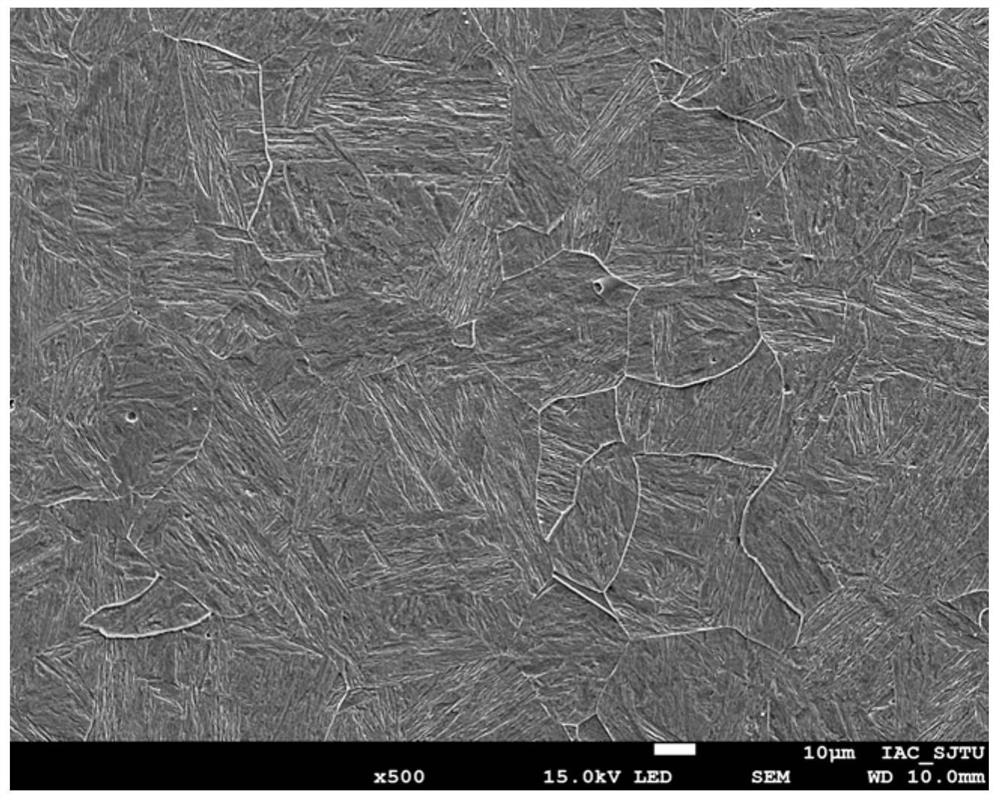

Preparation method of high-strength and tough ultra-fine dual-phase lamellar structure qal10-4-4 aluminum bronze alloy plate

The invention relates to a preparation method of high-strength superfine dual-phase laminated QAl10-4-4 aluminum bronze alloy plates. According to the preparation method, firstly, a dual-phase organization is regulated and heated, a raw material of QAl10-4-4 aluminum bronze alloy is treated in a thermal treatment furnace for 2-5 hours at a temperature of 850-920 DEG C, then the heated material issubjected to severe deformation through asymmetric continuous rolling and symmetric continuous rolling sequentially, and finally the rolled material is subjected to thermal treatment after deformation. An alpha phase of a face-centered cubic Cu-based solid solution and a beta phase of a body-centered cubic structure in an obtained structure obtained from thermal treatment are distributed in laminations, and a large amount of k phases of intermetallic compounds are dispersed inside the laminations and at boundaries of the laminations. The high-strength superfine dual-phase laminated QAl10-4-4 aluminum bronze alloy plates have the advantages that yield strength is not smaller than 900MPa, tensile strength is not smaller than 1000MPa, hardness is not smaller than 390HV, and elongation at break is not smaller than 8%. Compared with the prior art, the preparation method not only can improve performance of the QAl10-4-4 aluminum bronze alloy, but also is simple in process, easy to operate and low in cost, and can be used to realize preparation of the large-size QAl10-4-4 aluminum bronze alloy plates.

Owner:SHANGHAI JIAO TONG UNIV

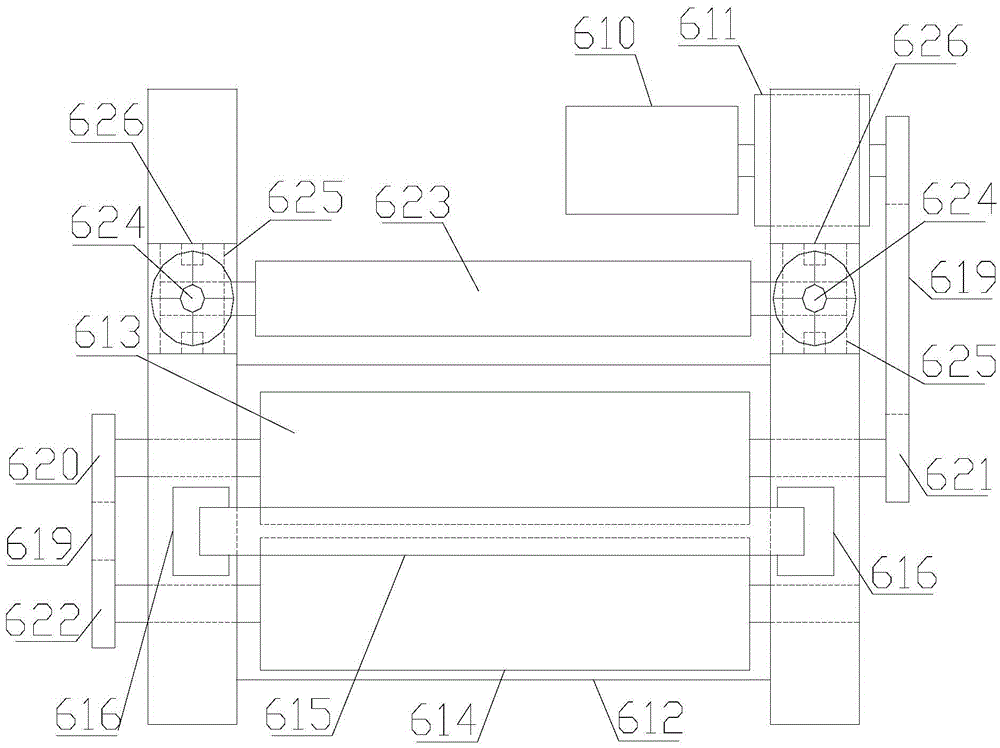

Rolling device used for manufacturing of composite boards for treadmill

InactiveCN111890483ARealize the rolling processIncrease distancePlywood pressesVeneer pressesElectric machineryComposite plate

The invention discloses a rolling device used for manufacturing of composite boards for a treadmill. The rolling device comprises a bottom plate; two assembly plates which are parallel to each other are arranged right above the bottom plate; supporting plates are fixedly connected between the two ends of the assembly plates and the bottom plate; rail rods and cross rods are arranged between the two assembly plates; two ends of each rail rod are separately fixedly connected to the assembly plates; two ends of each cross rod are separately rotatably connected to the assembly plates; besides, a motor I is fixedly arranged on one side of one assembly plate through bolts; output shafts of the motor I are in driving connection to the cross rods; a plurality of thread groove groups are arranged on the outer side of a rod body of each cross rod; each thread groove group comprises thread grooves with opposite directions on two ends; nut bushes sleeve outer side threads of the thread grooves; and besides, the nut bushes slidably sleeve the outer side of a rod body of the corresponding rail rod. By adopting the rolling device, the rolling precision and effect of the composite boards used forthe treadmill are ensured; labor is saved; use is convenient; production efficiency is improved; and using requirements of people in production and life are met.

Owner:怀宁县盛林木业有限公司

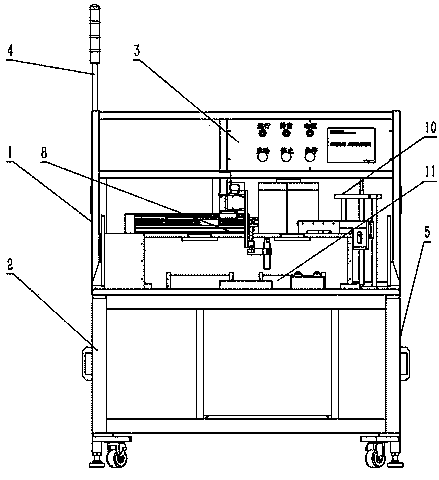

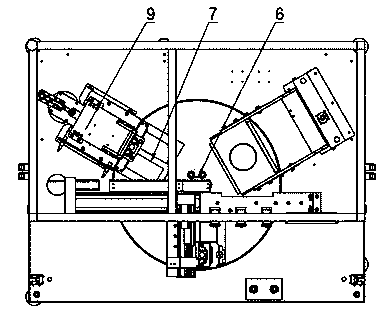

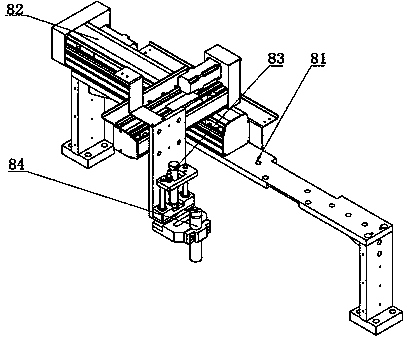

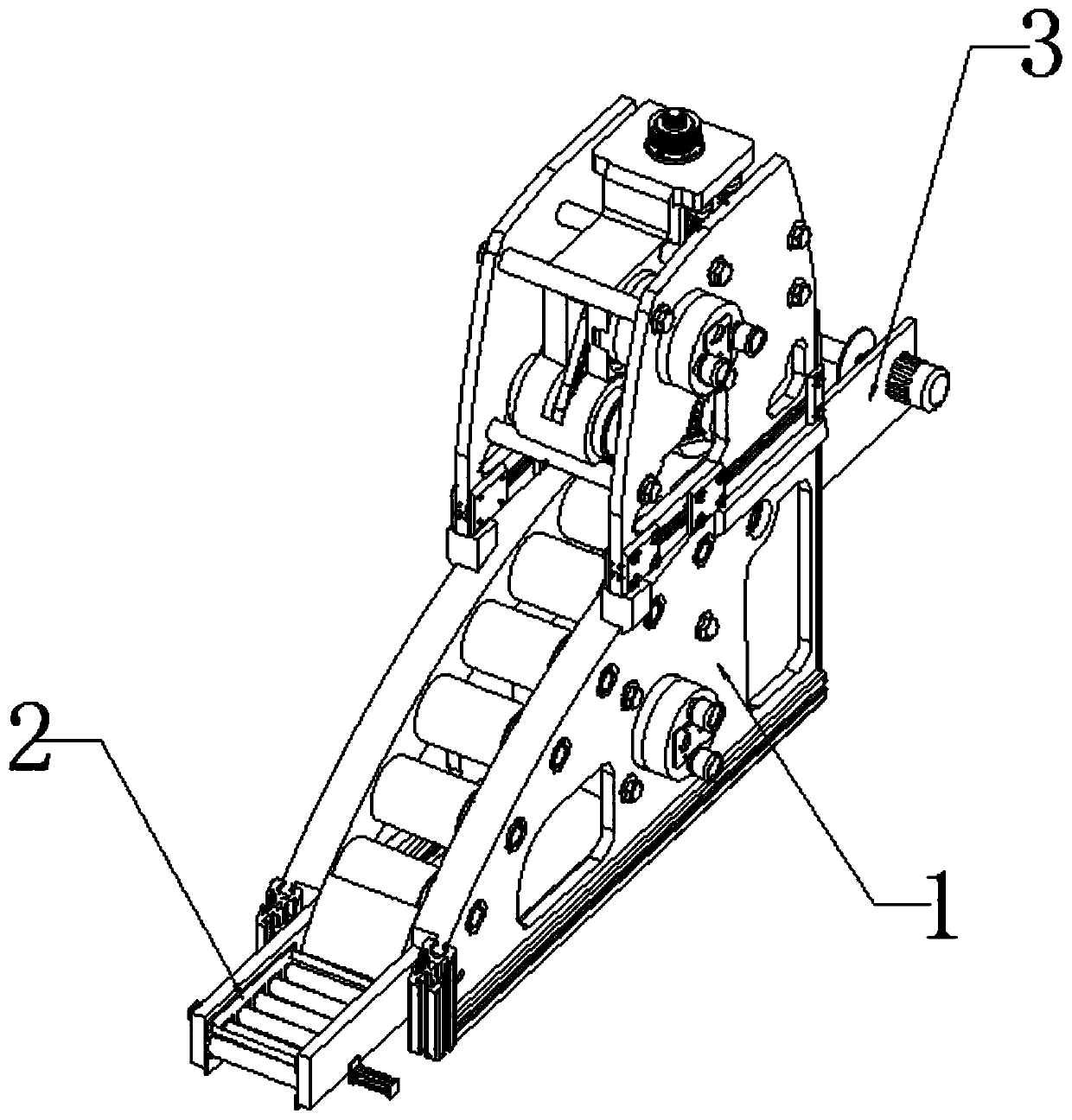

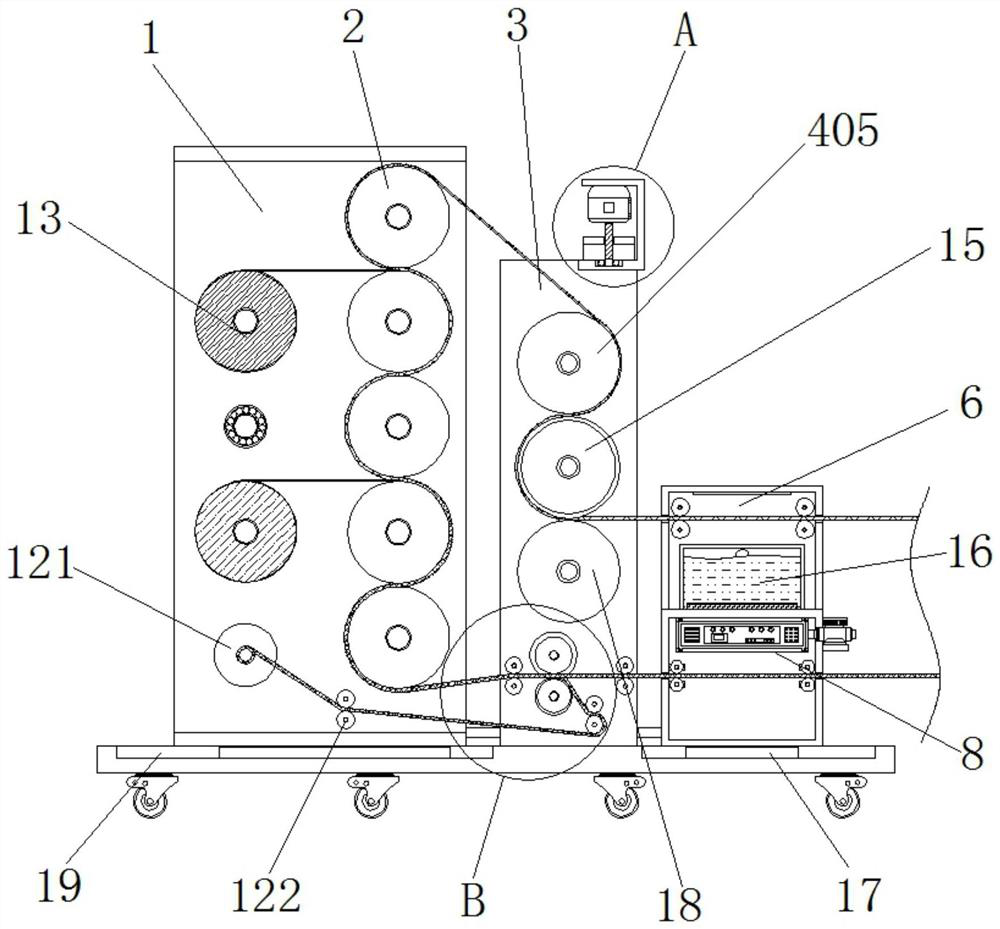

Full-automatic high-speed coil type wire winding machine

The invention discloses a full-automatic high-speed coil type wire winding machine. The machine comprises a rack, wherein a wire transmission mechanism, a tensioning mechanism, a meter counter, an arranging device, a quick wire clamping device, a wire cutting device, a mechanical clamping head and a coil forming device are arranged on the rack. According to the machine, the whole production work is automatically operated under the control of PLC program, and manual interference is avoided; the machine has the characteristics of being low in working intensity of workers, and high in automation degree; the coil forming device, the wire clamping device and a wire shearing device are improved in structure, so that the acting time is greatly reduced, and as a result, the time is saved.

Owner:JIANGSU SINGCHEER MACHINERY

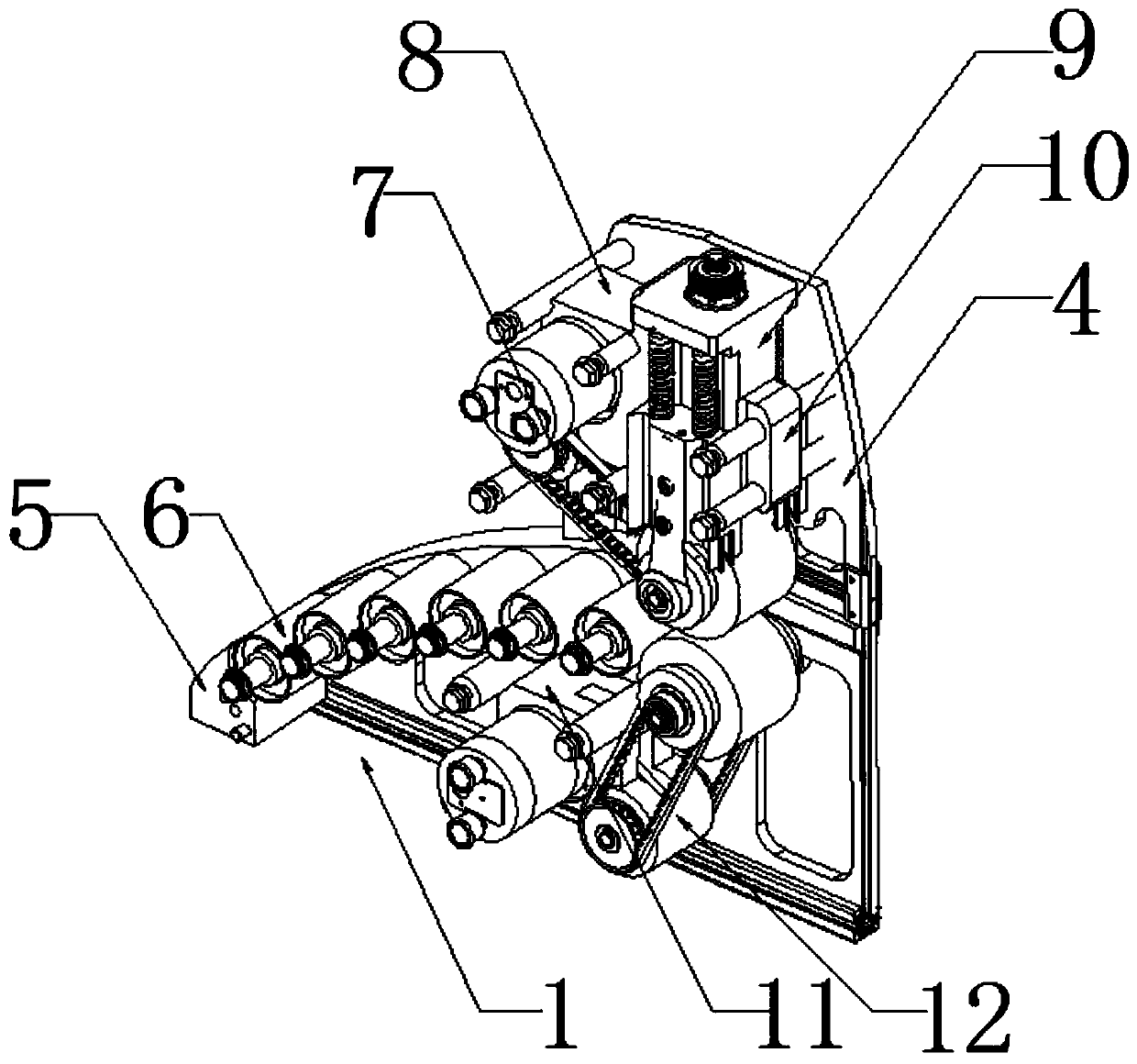

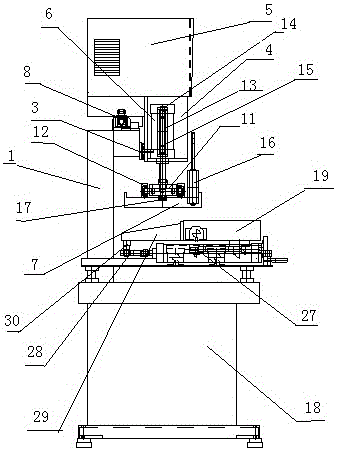

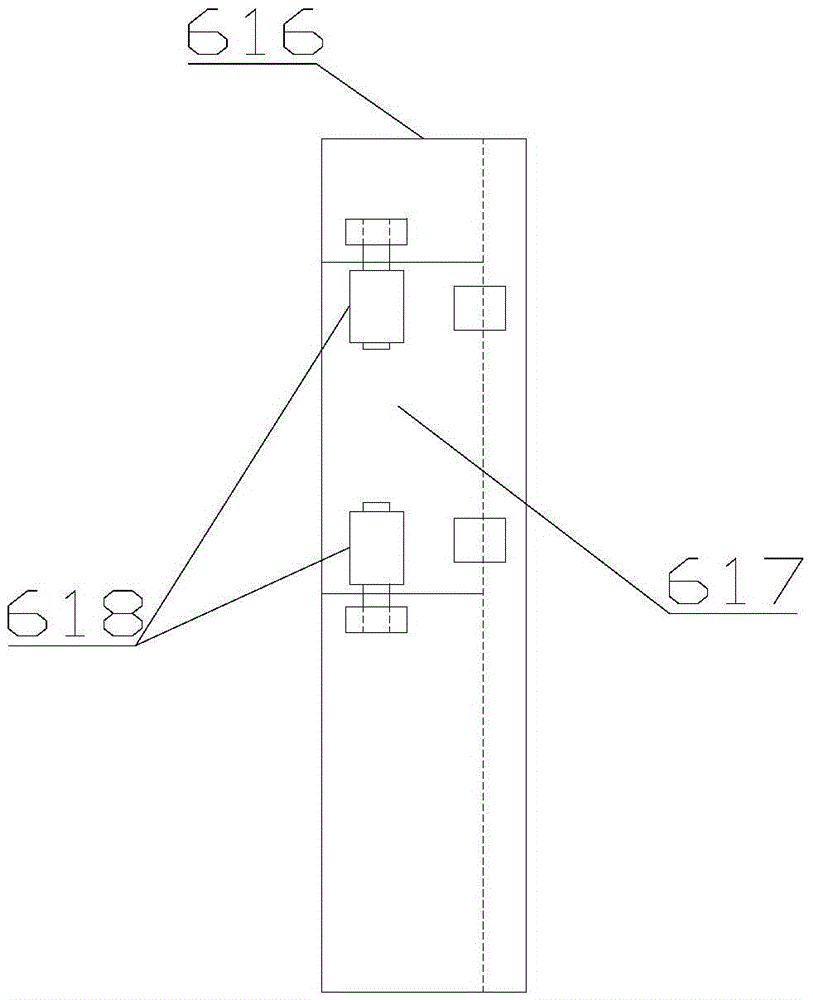

High-precision tip pipe rolling machine

ActiveCN106106387AHigh compressive strengthGuaranteed rolling effectRodsEngineeringMechanical engineering

The invention relates to the technical field of equipment machine manufacturing, in particular to a high-precision tip pipe rolling machine. The high-precision tip pipe rolling machine is provided with a machine body, and an upper working plate and a lower working plate are arranged on the machine body. The high-precision tip pipe rolling machine is characterized in that the machine body is composed of a pressing mechanism with the upper working plate, and a rotating rolling mechanism with the lower working plate; as the upper working plate capable of moving left and right is arranged in the pressing mechanism, the center of pressure gravity of a fishing rod to be rolled can be positioned through moving of the movable upper working plate, so that in the pressing process, it is ensured that the center of gravity is maintained in the middle of the fishing rod all the time, no deviation of pressure at the left large end and the right small end of the fishing rod exists, the small end can be pressed, and thus rolling is compact without warp; in the rotating rolling mechanism, as an arc rotating moving mode is adopted for the lower working plate and the center of gravity in rotation can move left and right, the rotating radius and the arc moving track are changed; the high-precision tip pipe rolling machine has the advantages that pressure is balanced, rolling is compact without warp, and the tensile strength of the tip of the fishing rod is high.

Owner:威海市通联精密机械有限公司

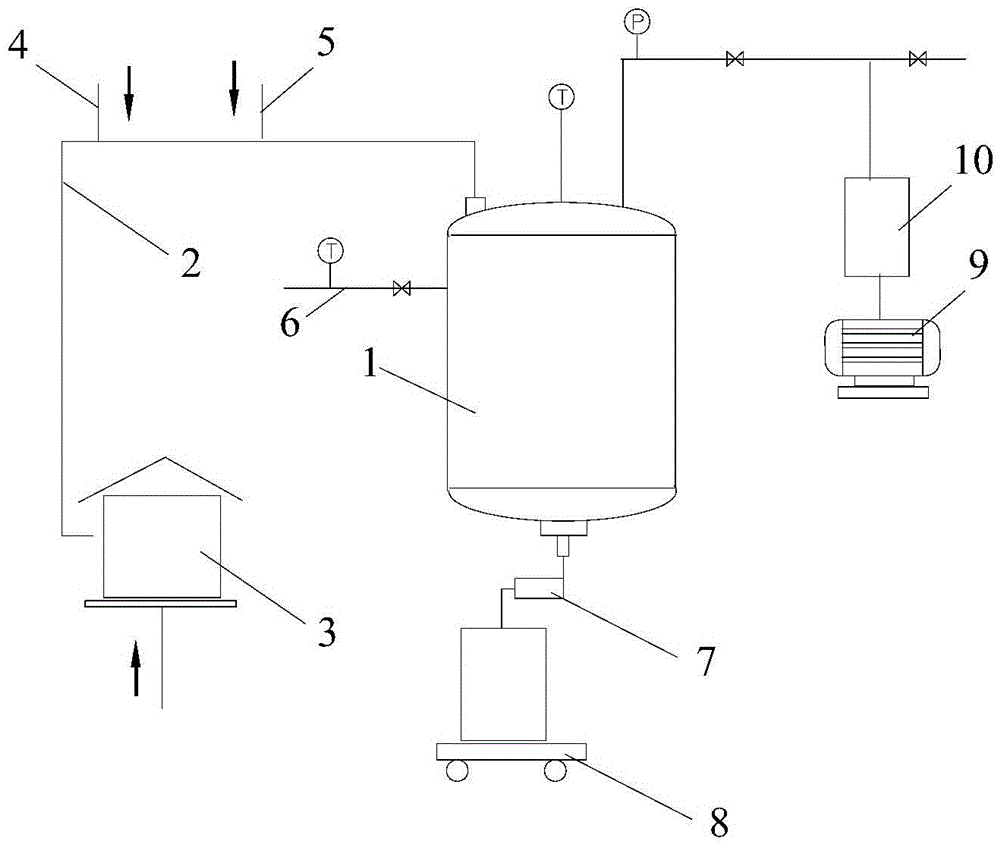

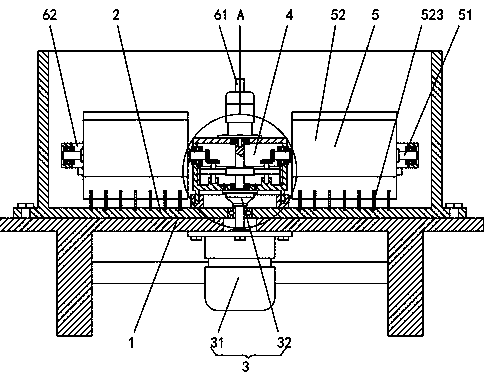

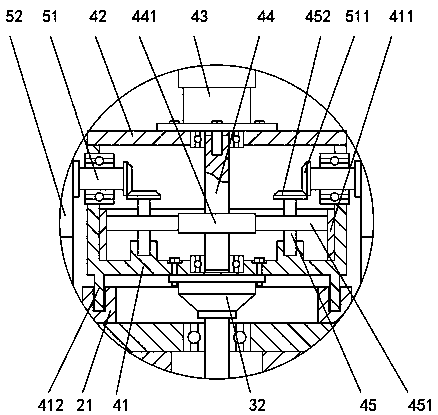

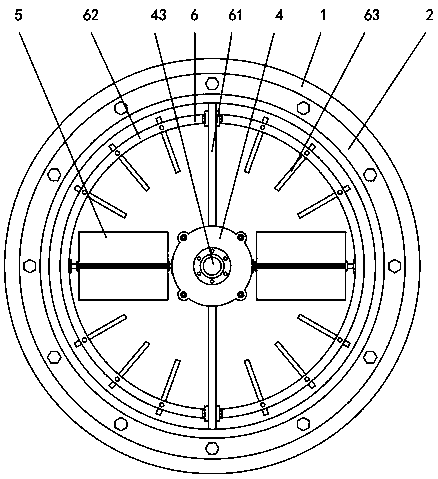

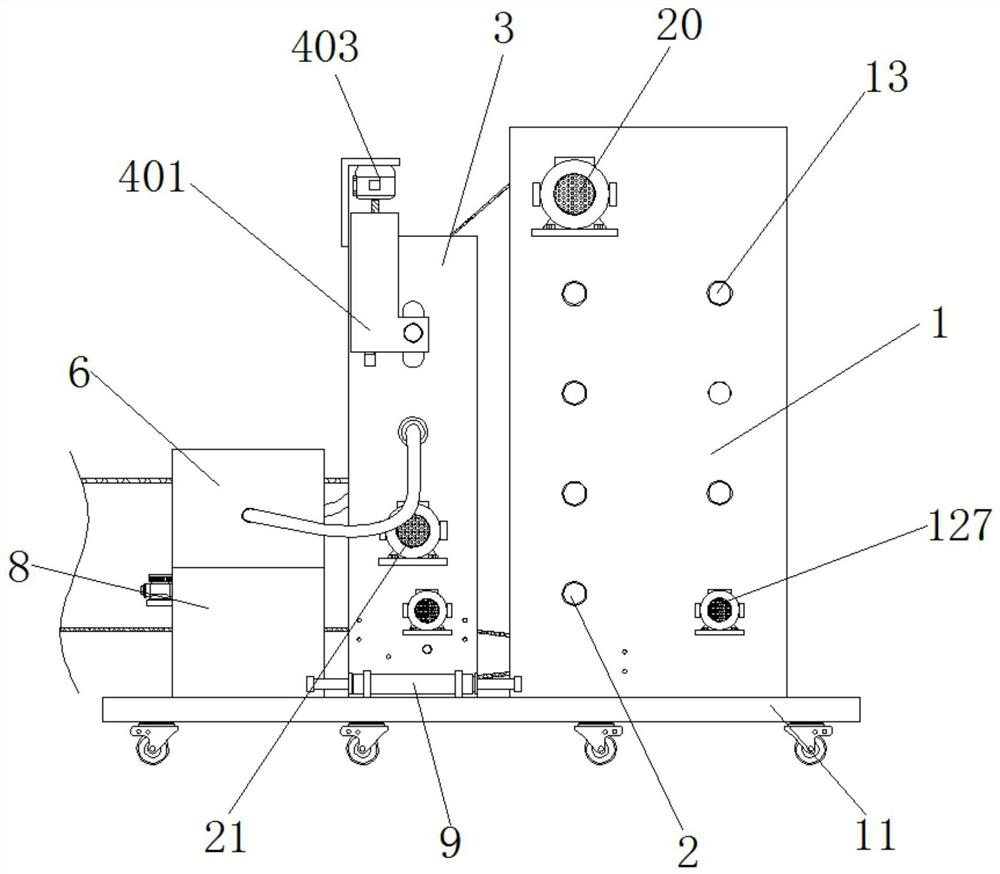

A foundry sand mixer

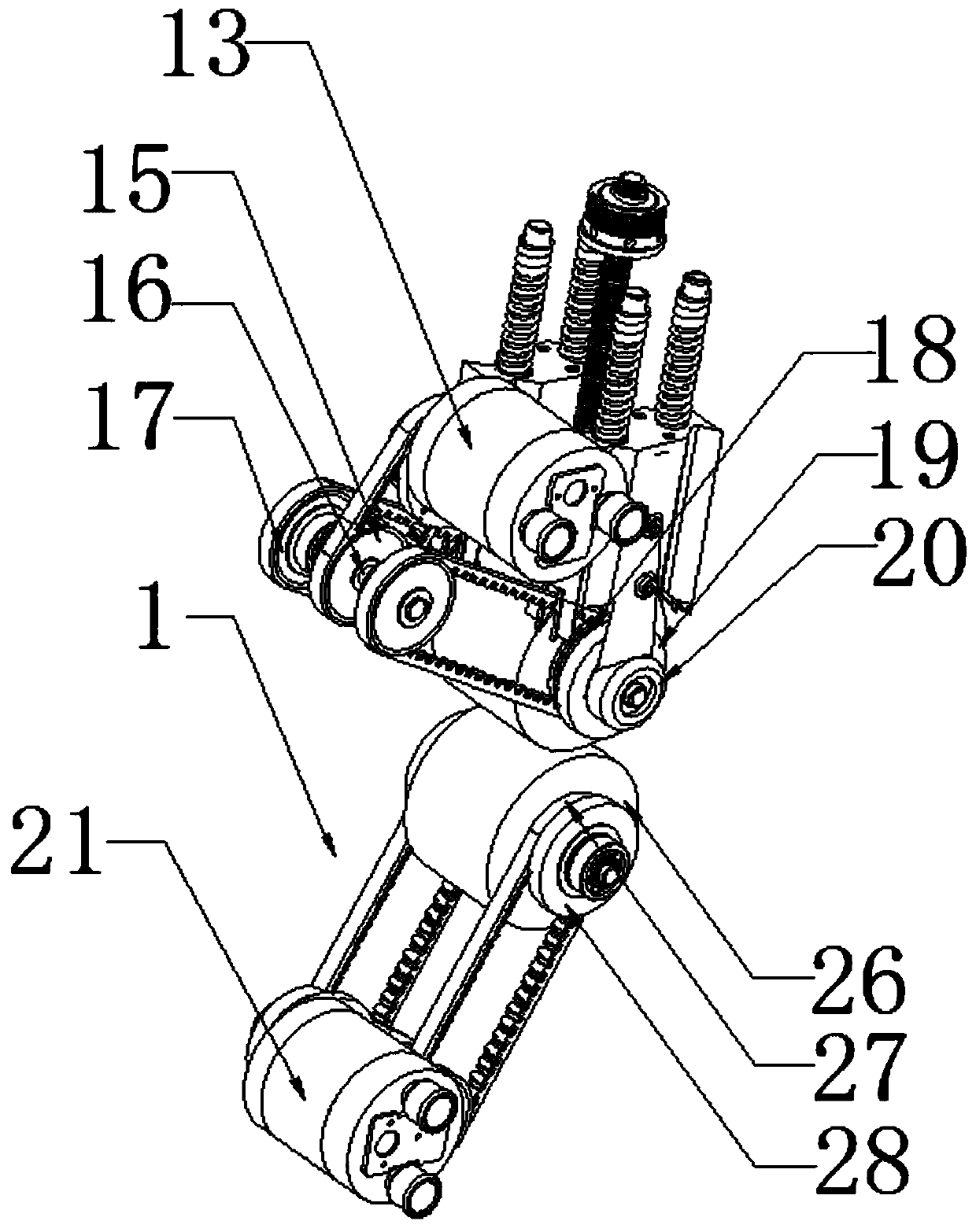

ActiveCN110315028BUniform and compact structureRealize and meet the needs of sand mixingMould handling/dressing devicesFoundryElectric machinery

The invention relates to a casting sand mixer. The casting sand mixer comprises a machine base, a round sand mixing hopper, a rotating motor assembly, a wheel train transmission mechanism, turning andgrinding assemblies and a scraping plate mechanism, the round sand mixing hopper is fixedly arranged on the machine base, the rotating motor assembly is fixedly arranged at the central position of the bottom of the machine base, the wheel train transmission mechanism is fixedly arranged at the top of the rotating motor assembly, the two turning assemblies are symmetrically and rotationally arranged on the wheel train transmission mechanism, and the scraping plate mechanism is fixedly arranged on the wheel train transmission mechanism; the rotating motor assembly can drive the wheel train transmission mechanism, the whole synchronous rotation formed by the turning and grinding assemblies and the scraping plate assembly is achieved, the wheel train transmission mechanism can drive the two turning and grinding assemblies to rotate. According to the casting sand mixer, the grinding roller and the sand turning structure of the casting sand mixer are uniform and compact in design and convenient to dismount and maintain, cleaning and rapid replacement of the grinding wheel structure are facilitated, and the efficiency and quality of sand mixing are ensured.

Owner:SHANXI HUAXIANG GRP CO LTD

Door sheet embossing device

InactiveCN105459709AAvoid deformationExtended service lifeLeather surface mechanical treatmentEmbossing decorationsEngineeringAir blower

The invention provides a door sheet embossing device which comprises a door sheet embossing device barrel and a roller shaft. The door sheet embossing device barrel and the roller shaft are connected through flange plates. The roller shaft is of a hollow structure, the two ends of the roller shaft are sealed, one end of the roller shaft is connected with an air inlet hose, and the other end of the roller shaft is provided with an exhaust outlet; an air blower is arranged at the other end of the air inlet hose, and the air inlet hose is connected with an air outlet of the air blower. Through vent holes are formed in the wall of the part, in contact with the door sheet embossing device barrel, of the roller shaft. The door sheet embossing device has the beneficial effects that the air blower is connected to one end of the roller shaft, air is blown in so as to cool the surface of the door sheet embossing device barrel, the door sheet embossing device barrel is protected against deformation caused by the overhigh temperature of the surface of the barrel, the service life of the door sheet embossing device barrel is prolonged, and the calendering effect is guaranteed.

Owner:天津名门门业有限公司

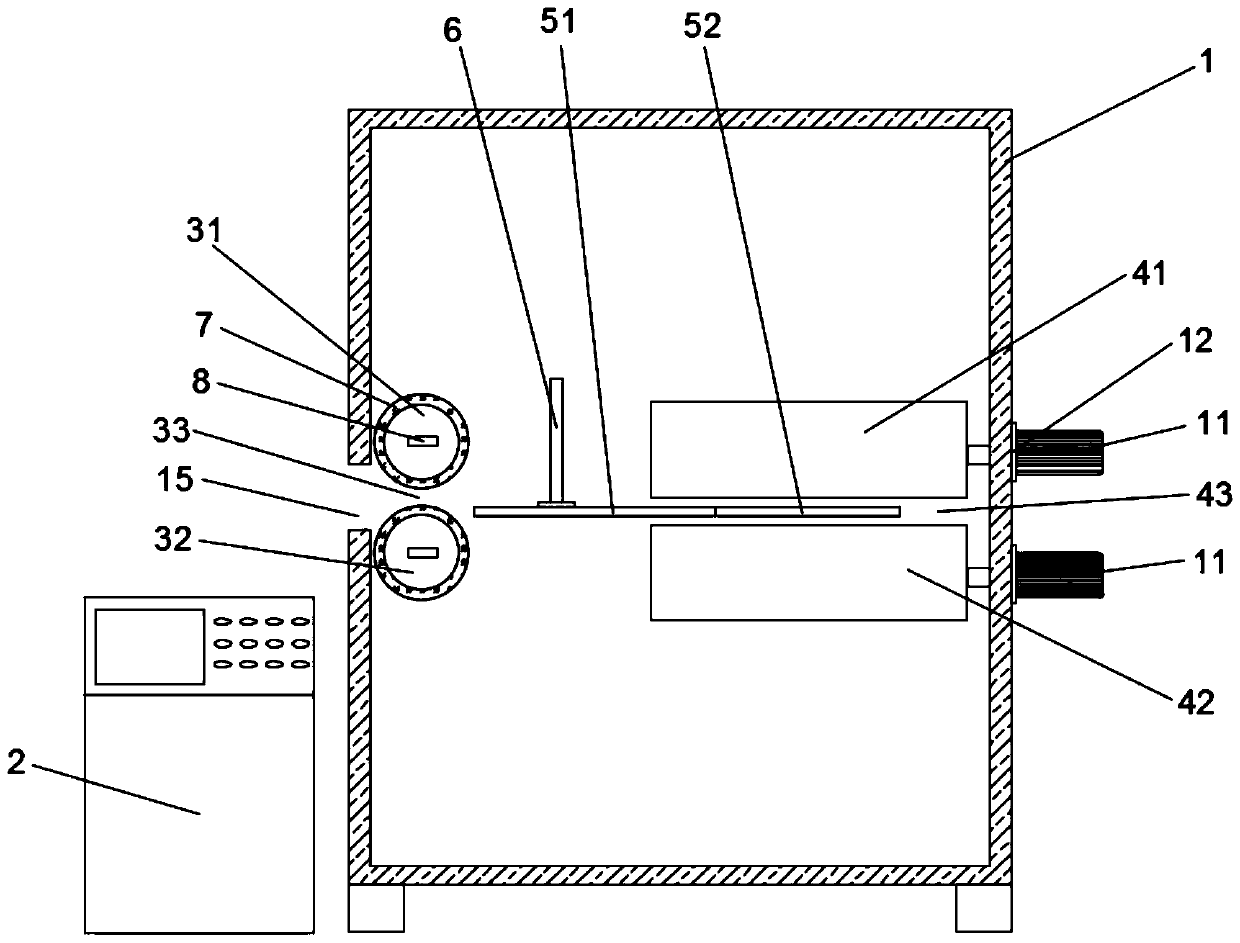

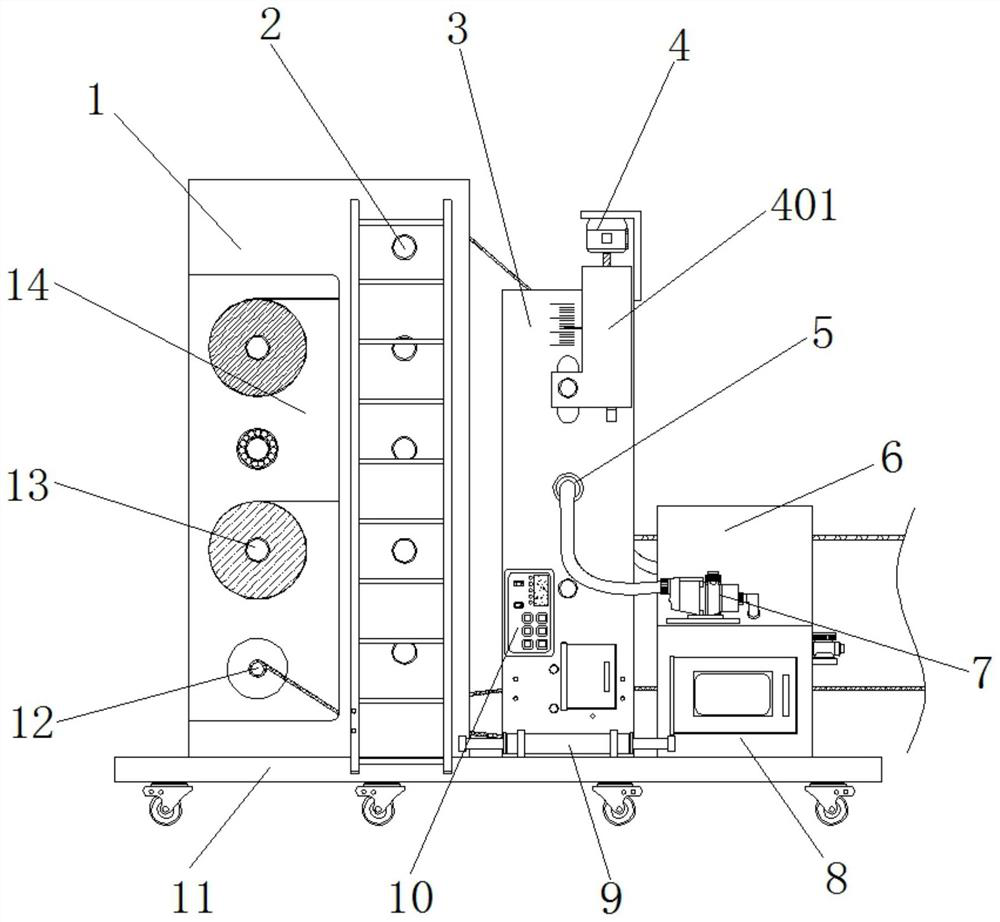

Intelligent natural rubber machining system and intelligent natural rubber machining method thereof

ActiveCN110103383AGuaranteed rolling effectGuarantee the quality of finished productsFlat articlesEngineeringMachining system

The invention provides an intelligent natural rubber machining system and an intelligent natural rubber machining method of the intelligent natural rubber machining system. A first roller group and asecond roller group are arranged and can calender the rubber twice; and meanwhile, the axis of the first roller group and the axis of the second roller group are perpendicular. A first conveyer belt and a second conveyer belt convey the rubber, the rubber calendered by the first roller group is conveyed by the first conveyer belt and the second conveyer belt to the second roller group, the secondroller group calenders the rubber in the other direction, and the calendering directions of the first roller group and the second roller group are perpendicular. In this way, the calendering effect generated in the whole calendering process can be lightened, the quality of rubber products is improved, and the service life is prolonged.

Owner:HAINAN ZHONG XIANG TECH CO LTD +2

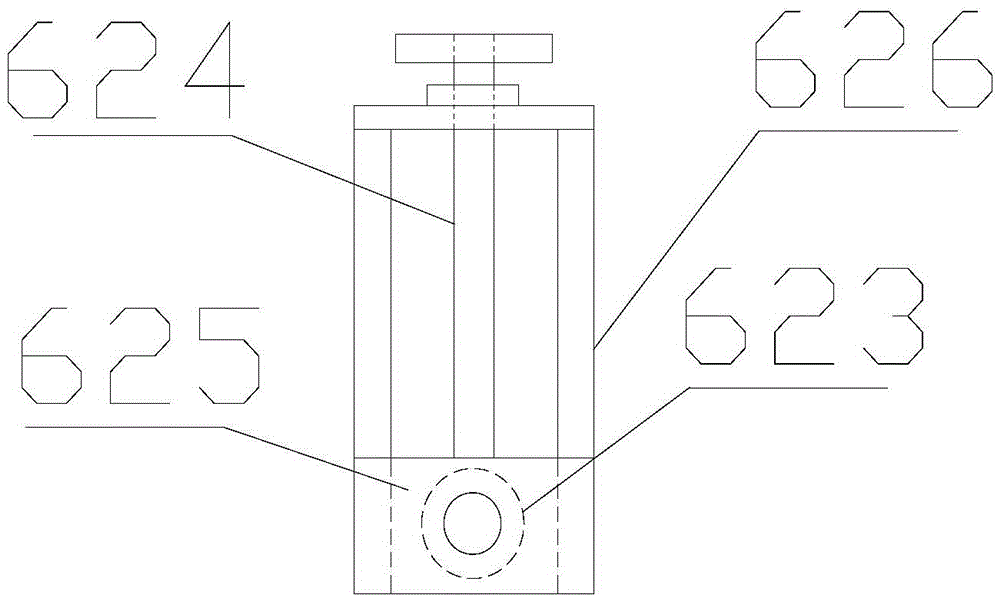

Industrial hazardous waste incineration line pretreatment crushing device

PendingCN114210401AImprove crushing efficiencyGuaranteed sharpness and service lifeIncinerator apparatusGrain treatmentsEnvironmental geologyMechanical engineering

The invention discloses an industrial hazardous waste incineration line pretreatment crushing device which comprises a crushing cabinet in a rectangular vertical cabinet shape. The crushing assembly comprises rotating shafts, grinding wheels, mounting frames and cutters, the two rotating shafts are symmetrically and rotatably mounted on the two sides of the interior of the crushing cabinet body, the grinding wheels are fixedly connected to the rotating shafts, the two mounting frames are symmetrically and fixedly connected to the interior of the crushing cabinet body and located below the grinding wheels, and the cutters are rotatably arranged in the mounting frames; and the extrusion assembly comprises a fixing frame, a driving machine, air cylinders and a pressing block, a strip-shaped opening is formed in the upper side of the crushing cabinet body, the driving machine is installed in the fixing frame through an adjusting assembly, and the multiple air cylinders are fixedly connected to the lower portion of the driving machine. During use, pressure can be applied to hazardous wastes which cannot be effectively crushed, so that the condition of blockage in the whole crushing process is avoided, and the crushing efficiency of the hazardous wastes is improved.

Owner:绍兴艾笛薇机械设备有限公司

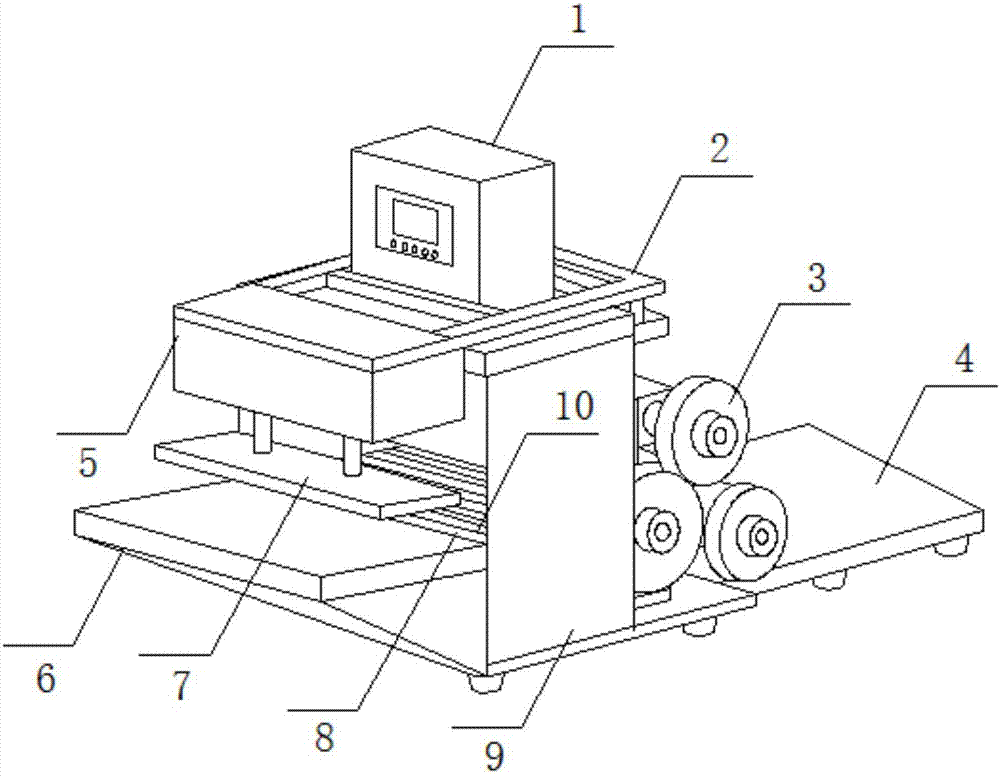

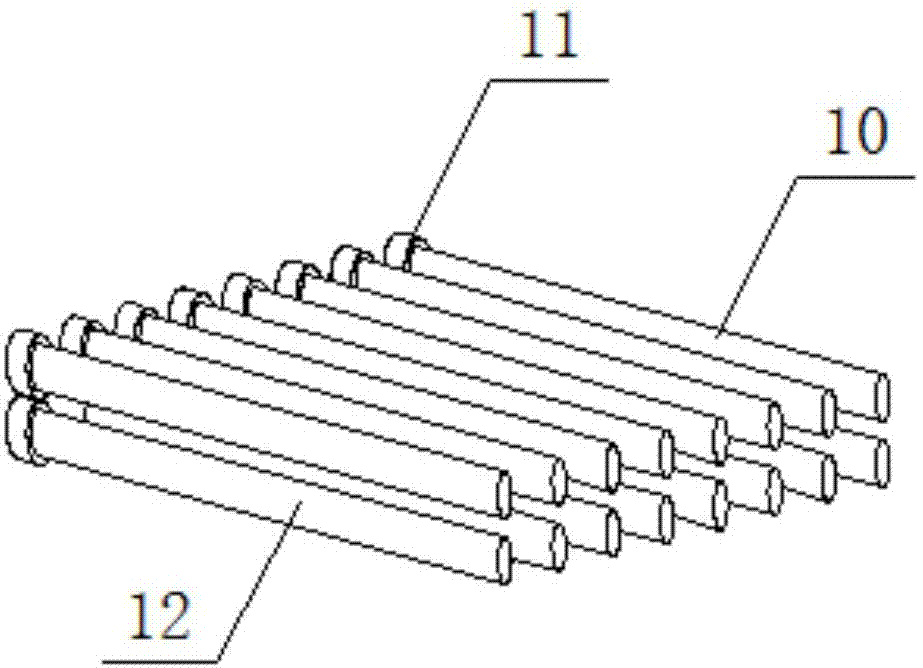

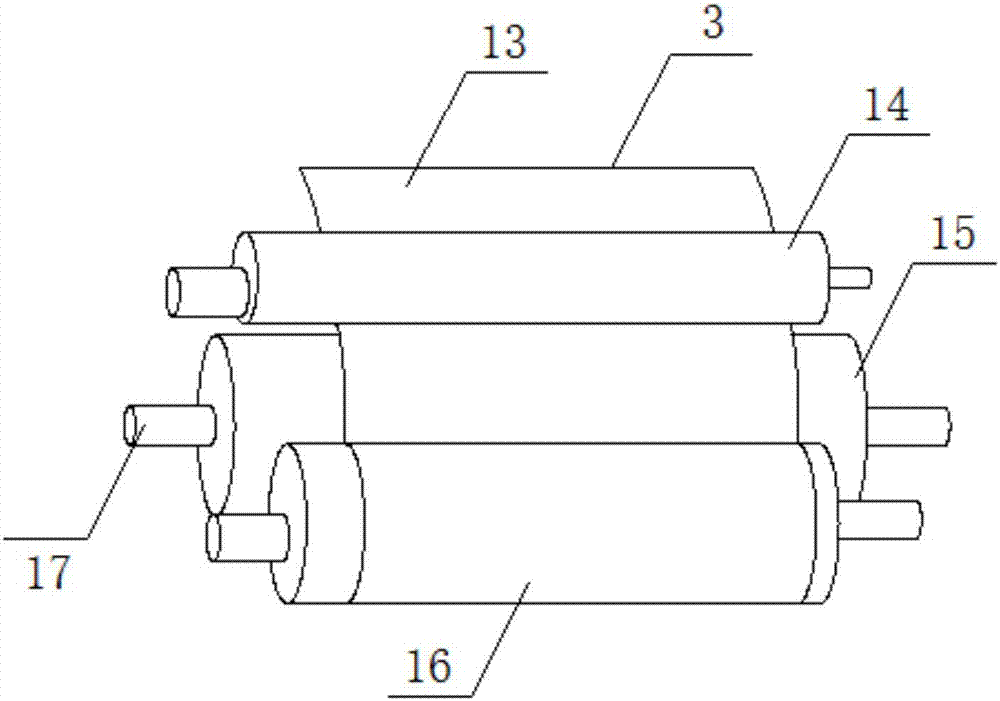

Preliminary calendering device used for automobile plate

The invention discloses a preliminary calendering device used for an automobile plate. The preliminary calendering device used for the automobile plate comprises a control cabinet, a support, a calendering device body, a bottom plate, a pressing box, an operation table, a telescopic pressing plate, an inner groove, a case, an inner roller combination, rotating discs, polishing wheels, the plate, a lower pressing roller, a calendering roller, a winding roller and rotating rods. The preliminary calendering device used for the automobile plate has the beneficial effects that the inner roller combination is mounted inside the inner groove and used for calendering and polishing the plate; the operation table is arranged on one side of the inner groove, the telescopic pressing plate is mounted above the operation table so that the plate can be preliminarily calendered by the telescopic pressing plate before entering the inner groove, it is guaranteed that the thickness and the flatness of the plate reach the standard preliminarily, and accordingly the plate can enter the inner roller combination to be polished and secondarily calendered; and by mounting the calendering device on the other side of the inner groove, the plate subjected to two times of calendering treatment through the telescopic pressing plate and the inner roller combination is conveyed to the calendering device body to be subjected to final calendering-winding treatment, and thus the calendering effect of the plate is guaranteed.

Owner:无锡贺邦汽车配件有限公司

Calendering device for PVC plastic floor

ActiveCN113370445AIncrease spacingImprove convenienceStructural engineeringManufacturing engineering

The invention discloses a calendering device for a PVC plastic floor, which comprises a bottom plate, a calendering bin is installed in the middle of the top of the bottom plate, sliding grooves are symmetrically arranged at the two ends of the two sides of the top of the bottom plate, sliding blocks are arranged in the sliding grooves, a processing bin is jointly installed at the tops of the two sets of sliding blocks on one side, the tops of the two sets of sliding blocks on the other side are jointly provided with a drying oven, and a preheating bin is installed on the top of the drying oven. Through cooperative use of the processing bin, the calendering bin, the drying oven, a two-way electric air cylinder, the sliding blocks and the sliding grooves, the two-way electric air cylinder is used for pushing the processing bin and the drying oven to be gradually away from the calendering bin, and the distance between the processing bin and the calendering bin and the distance between the drying oven and the calendering bin are increased, the head end of the PVC raw material plate can conveniently and manually penetrate through the space between a hollow mirror surface roller and a first mirror surface roller, the space between five sets of pressing rollers and the space between two sets of cutting rollers in sequence by an operator, so that the using convenience of the device is improved, and application and popularization are facilitated.

Owner:深圳市华塑万诚塑胶材料有限公司

Rolling equipment for fluff fabric

ActiveCN106835589AMaintain constant pressureGuaranteed rolling effectTextile shapingMechanical engineering

Owner:浙江小布点服饰有限公司

An improved roll-forming device for a non-woven fabric dyeing production line

The invention discloses an improved coiling device for a non-woven fabric dying production line. The improved coiling device comprises a motor, a speed changer, a frame body, a first drive roller, a second drive roller, a coiling shaft, guiding grooves, baffles, bolts, chains, a first gear, a second gear, a third gear and a misalignment-prevention mechanism. The first drive roller, the second drive roller and the misalignment-prevention mechanism are installed on the frame body. The front end of a shaft of the first drive roller is provided with the first gear, and the rear end of the shaft of the first drive roller is provided with the second gear. The front end of a shaft of the second drive roller is provided with the third gear. The speed changer is in transmission connection with the second gear through the corresponding chain, and the first gear is in transmission connection with the third gear through the corresponding chain. The front portion and the rear portion of the frame body are provided with the guiding grooves, and the two ends of the coiling shaft are connected with the guiding grooves in a sliding mode. The baffles are arranged on the guiding grooves, and the bolts are arranged on the baffles. Compared with the prior art, the coiling effect and the overall attractiveness are guaranteed, slippage in transmission can also be avoided, and the transmission rate is guaranteed.

Owner:FENGJIE DONGYANG BUILDING MATERIALS CO LTD

A solid waste treatment system with a pretreatment process

The invention belongs to the technical field of solid waste treatment, and specifically relates to a solid waste treatment system with a pretreatment process, which includes a treatment box, a primary crushing assembly and a crushing roller. A sealing plate, a primary crushing assembly is arranged above the rotating sealing plate, and an electro-hydraulic telescopic rod is connected between the lower end of the rotating sealing plate and the processing box; the present invention realizes the crushing of the elastic arc by setting the crushing knife as a combined type. The fixed waste between the curved surface on the plate and the two sides of the triangular slider is crushed, thereby increasing the crushing effect on solid waste; by setting the triangular slider to slide and install in the chute on the sealing plate, On the one hand, it prevents the problem of excessive wear caused by excessive impact force after the single elastic arc plate is stressed; on the other hand, it realizes that the solid waste is evenly spread on the two crushing rollers, thereby reducing the possibility of the crushing motor being burned out. Thereby improving the service life of the crushing motor.

Owner:山东同其数字技术有限公司

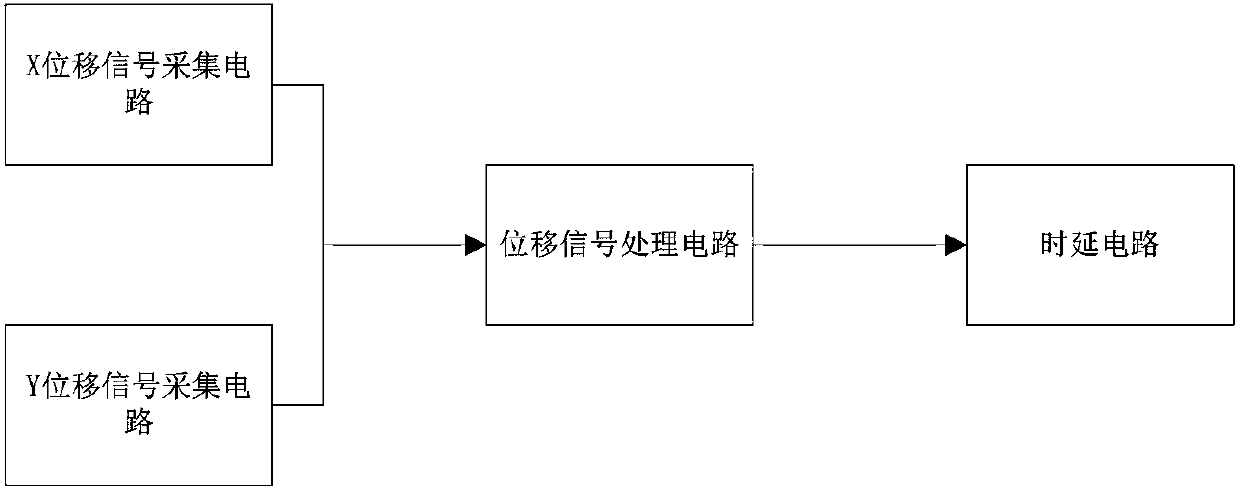

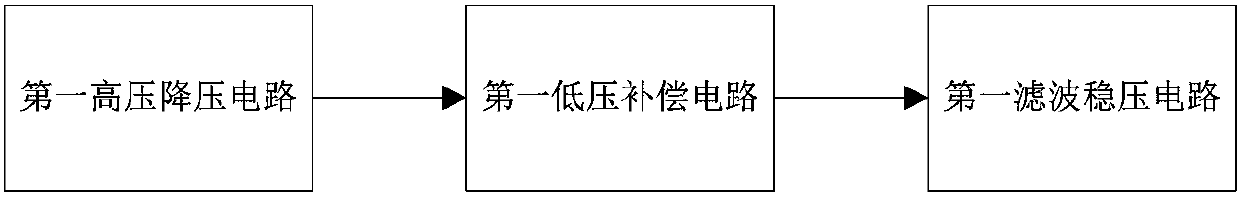

Roller deflection signal processing device for pvc calender

The invention discloses a PVC (polyvinyl chloride) calender roller deflection signal processing device which comprises an X displacement signal acquisition circuit, a Y displacement signal acquisition circuit, a displacement signal processing circuit and a time delay circuit. Transverse and longitudinal displacement signals of PVC calender rollers can be acquired by laser sensors X1 and Y1 in the X displacement signal acquisition circuit and the Y displacement signal acquisition circuit, amplitude can be adjusted by a high-voltage step-down circuit and a low-voltage compensation circuit, then the transverse and longitudinal displacement signals can be filtered by an LC circuit, and voltages of the transverse and longitudinal displacement signals can be stabilized by a voltage stabilizer tube to be in the ranges of +5 V and +10 V. The PVC calender roller deflection signal processing device has the advantages that the shortcoming of nonlinear errors due to external disturbance can be overcome, the measurement accuracy can be improved, reliable on or off of MOS (metal oxide semiconductor) tubes T1-T4 can be guaranteed by the amplitude, and the accuracy of control signals can be improved; only simple logic judgment is carried out on the availability of transverse and longitudinal displacement deviation signals by a NAND gate circuit with the MOS tubes T1-T4 in the displacement signal processing circuit, the time is delayed by 5 S, determined high or low level can be outputted to a controller, accordingly, the PVC calender roller deflection signal processing device is fast in response and high in efficiency, deflection can be timely discovered and controlled, calendering effects can be guaranteed, and the work efficiency can be improved.

Owner:PUYANG TAIPU ADHESIVE PROD

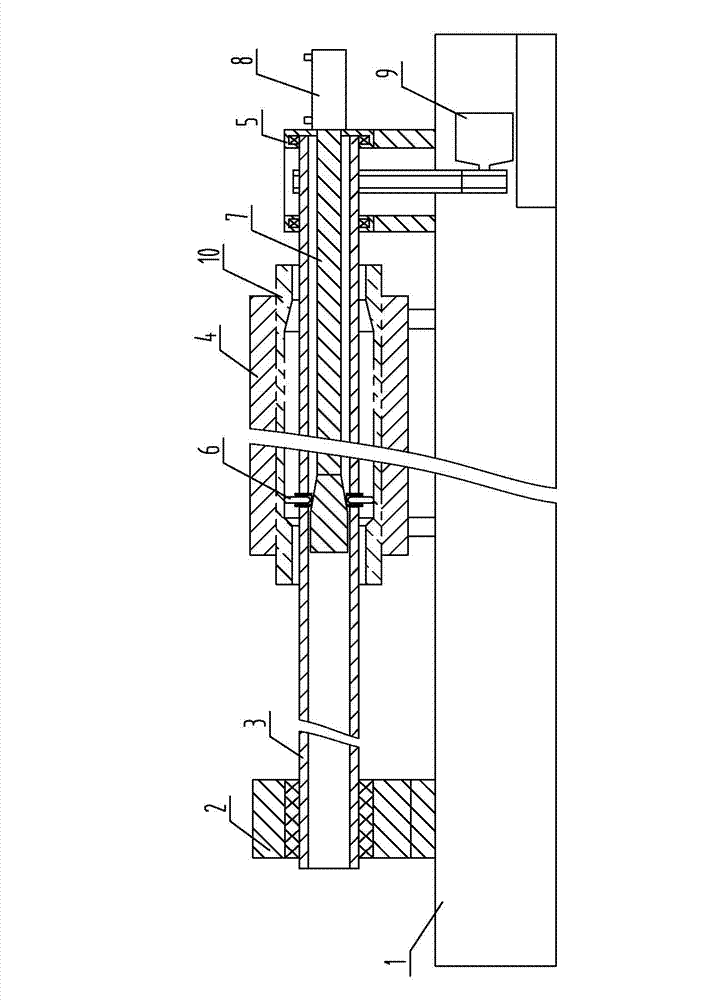

Apparatus for processing body of internally-thickened alumium alloy drill pipe

ActiveCN102814355AGuaranteed continuous transitionAvoid the disadvantages of uncontrollable deformationPipe fittingEngineering

The invention discloses an apparatus for processing a body of an internally-thickened alumium alloy drill pipe, belonging to the technical field of drilling equipment. The apparatus comprises an operation platform and is characterized in that a front support seat, an outer support pipe and a rear support seat are sequentially arranged on the operation platform back and forth; a pipe fitting is erected between the front and rear support seats, penetrates through the outer support pipe and is coaxial with the outer support pipe; a rolling head is mounted on the wall of the pipe fitting and connected with a control mechanism which enables the rolling head to move in the radial direction; the pipe fitting is driven by a motor to rotate in the front and rear support seats; and the outer support pipe is connected with a first servo power device which enables the outer support pipe to move back and forth along the operation platform. The processing apparatus is capable of clamping the equal-diameter alumium alloy pipe to be processed in the outer support pipe, the opening of the rolling head is controlled by the control mechanism, the rolling head rolls the inner wall of the body of the alumium alloy pipe, and simultaneously, the outer support tube drives the body of the alumium alloy pipe to move back and forth, so that the body of the alumium alloy pipe is formed through once rolling, the continuous transition of the sections with different wall thicknesses of the alumium alloy pipe is guaranteed, and simultaneously, the shortcoming of uncontrollable deformation caused by heading is overcome.

Owner:淄博斯壮铝业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com