High-precision tip pipe rolling machine

A tube coiling machine, high-precision technology, applied in application, fishing, fishing rods, etc., can solve the problems of rod body coiling, coiling distortion is not dense, rod body coiling distortion and looseness, etc., to achieve tight and seamless coiling Twisting, ensuring rolling effect, optimizing the effect of pressing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing, the present invention is further described:

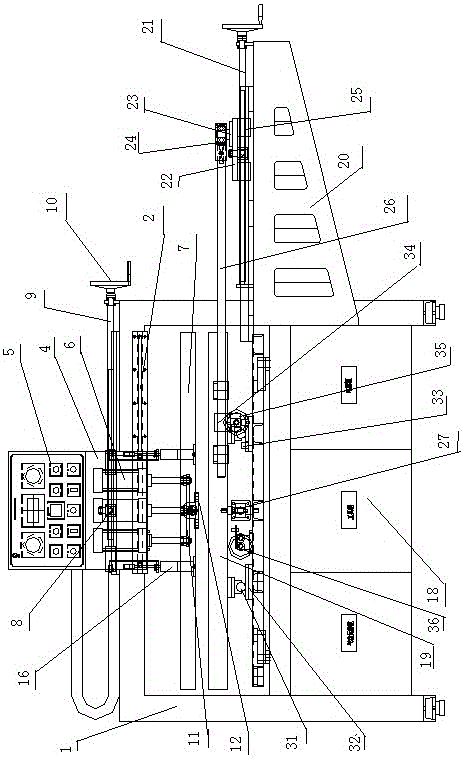

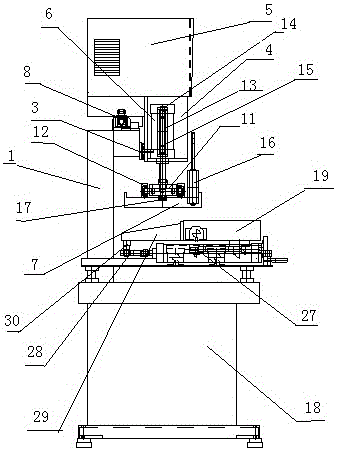

[0020]As shown in the accompanying drawings, a high-precision tip coiling machine is provided with a machine base 18 on which an upper working plate 7 and a lower working plate 19 are arranged. Composed of a rotary rolling mechanism with a lower working plate, the two sides of the machine base 18 in the pressing mechanism are respectively connected with the two side arms of the gantry-type main beam 1, and the front of the cross-arm of the gantry-type main beam 1 There are moving guide rails 2 on the side and upper side, the moving guide rail 2 on the front side of the cross arm of the gantry type main beam 1 is connected with the cylinder positioning box 4 through the guide block 3, and the upper end of the gantry type main beam 1 cross arm is provided with electrical control Box 5, the front end of the electrical control box 5 is connected to the upper end of the cylinder pos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com