Patents

Literature

79results about How to "Less chance of bending" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

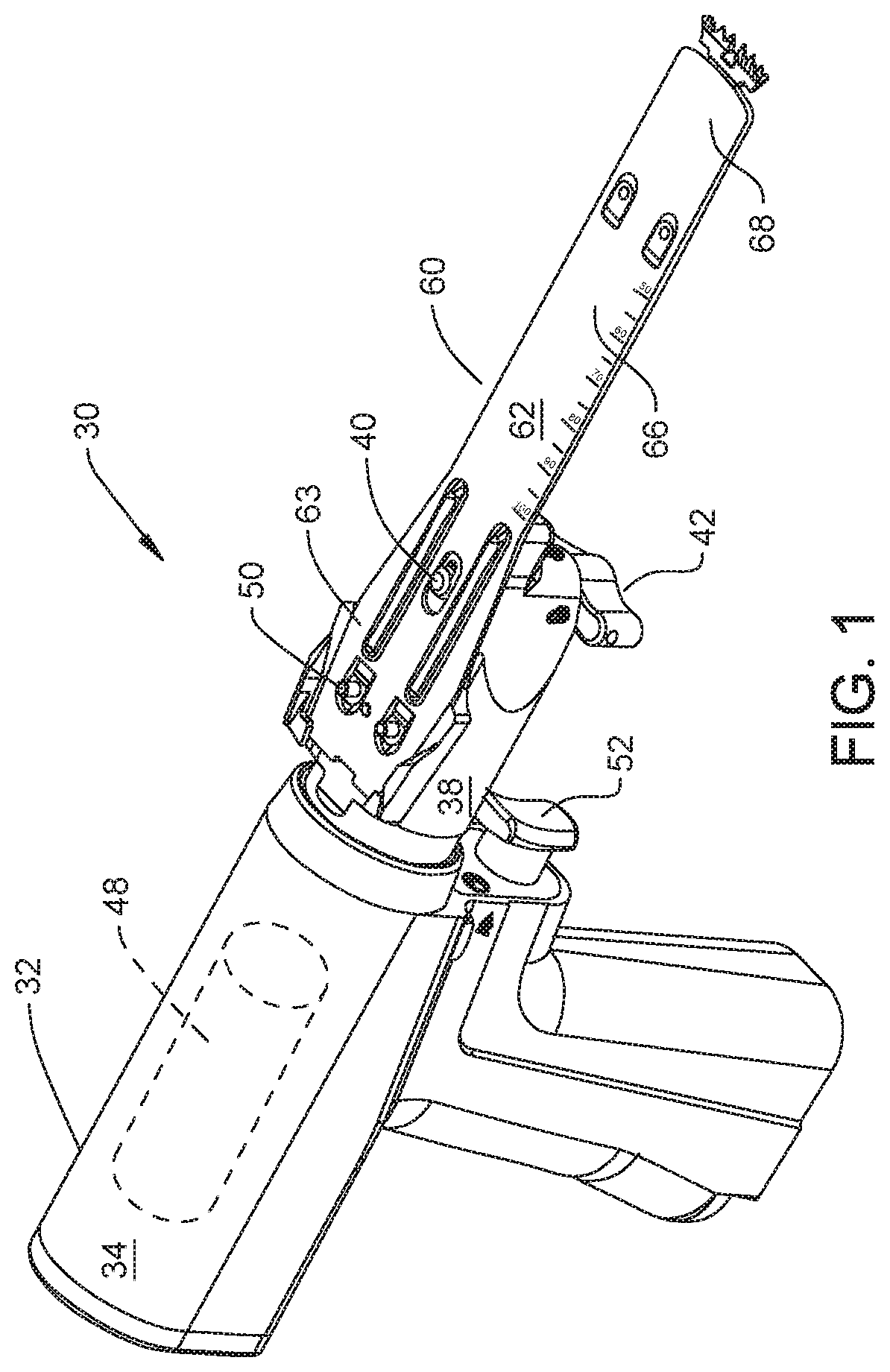

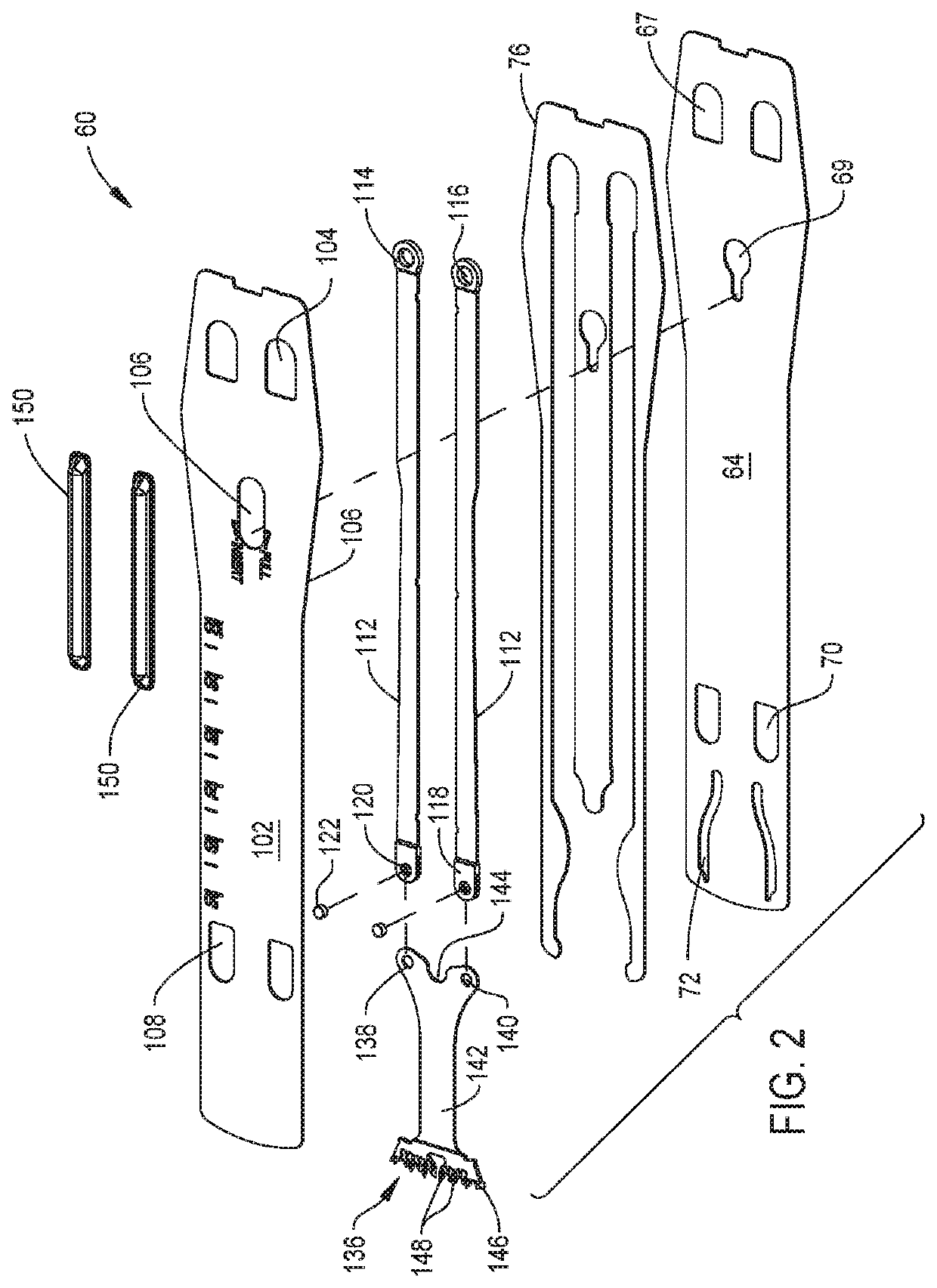

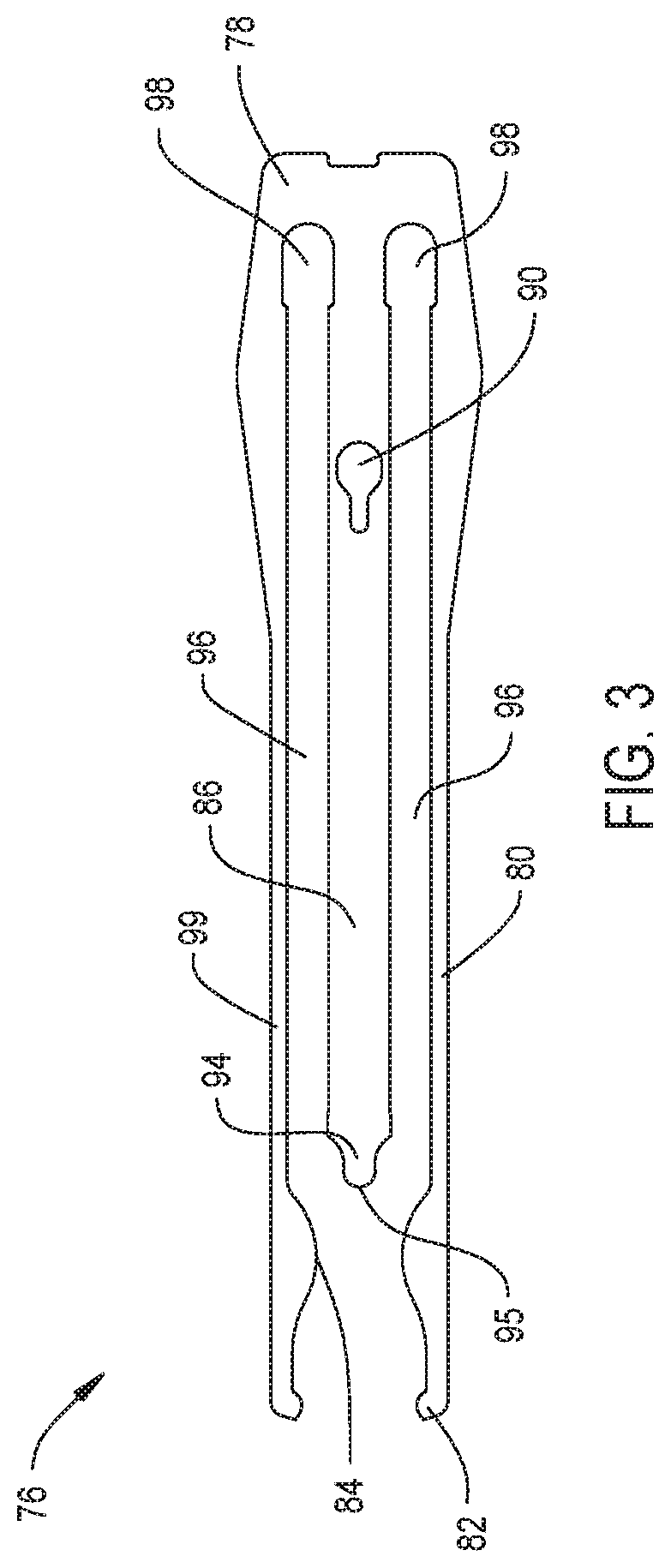

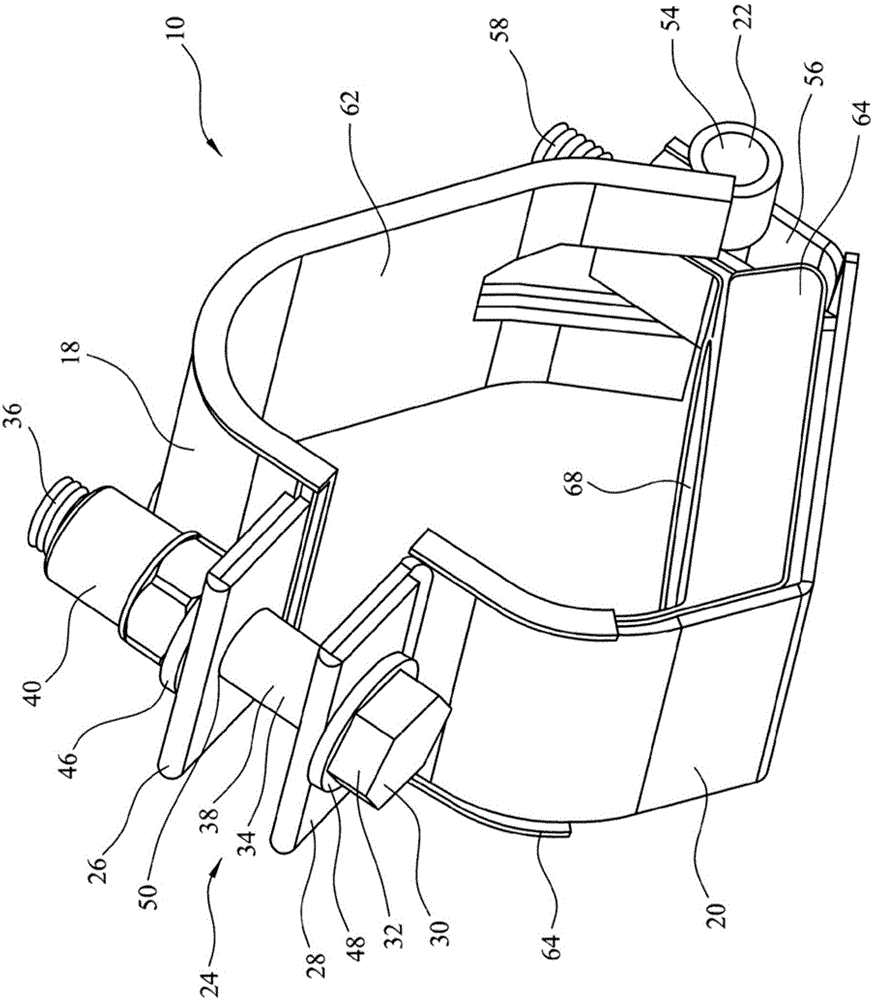

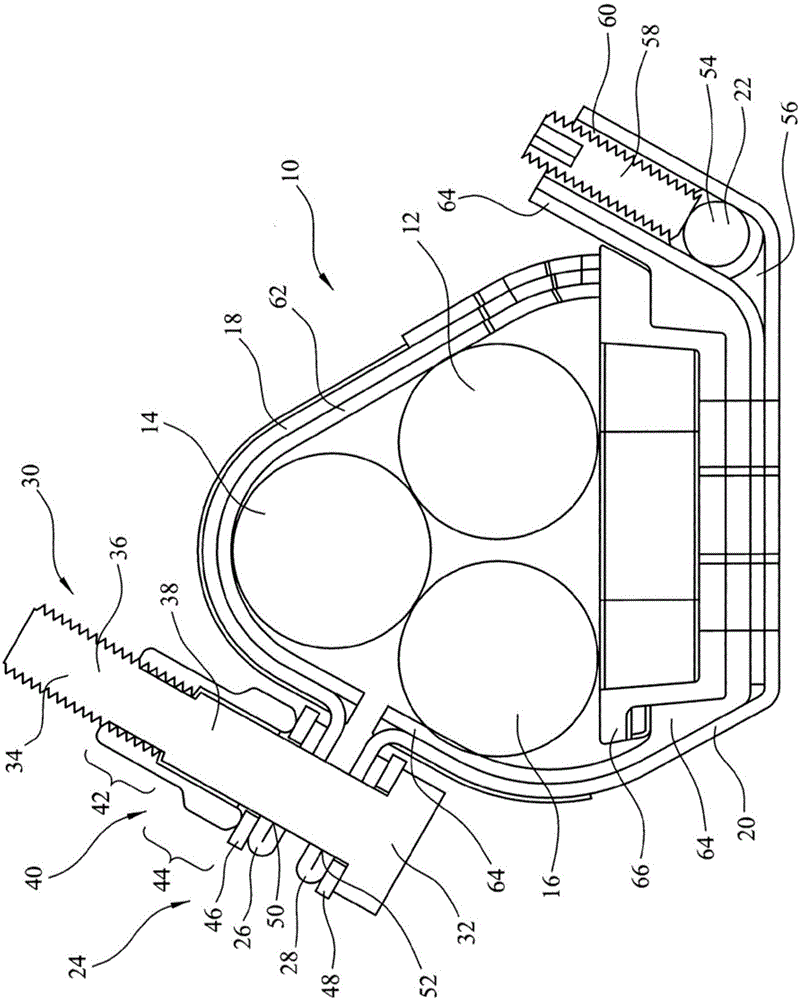

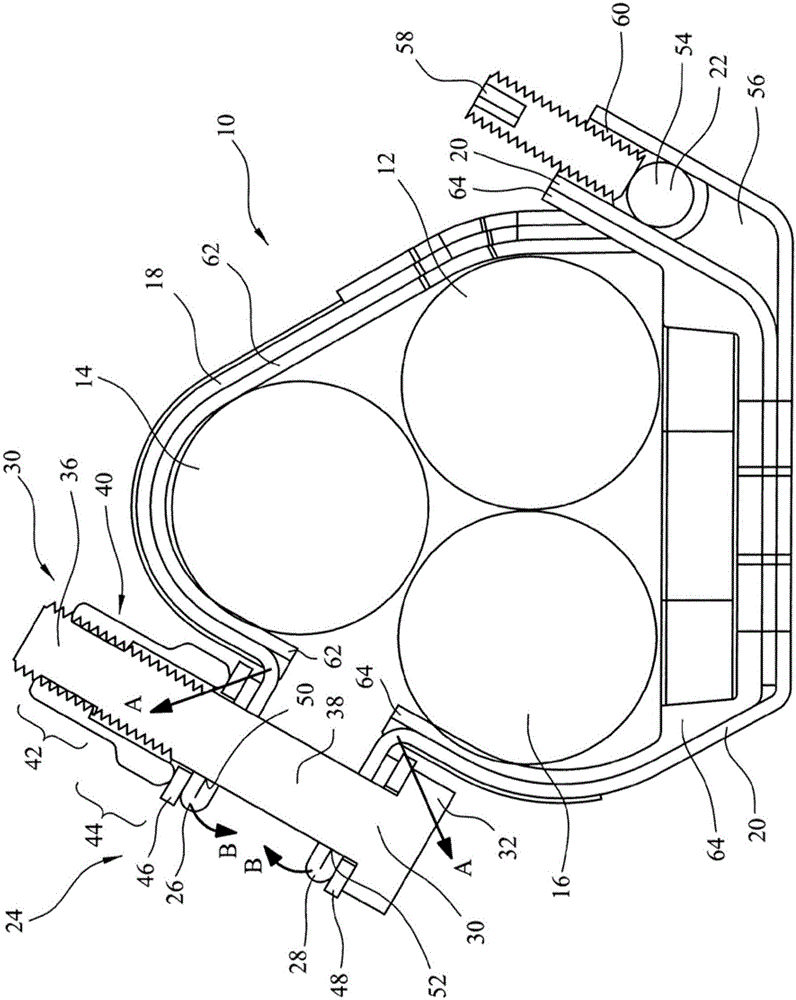

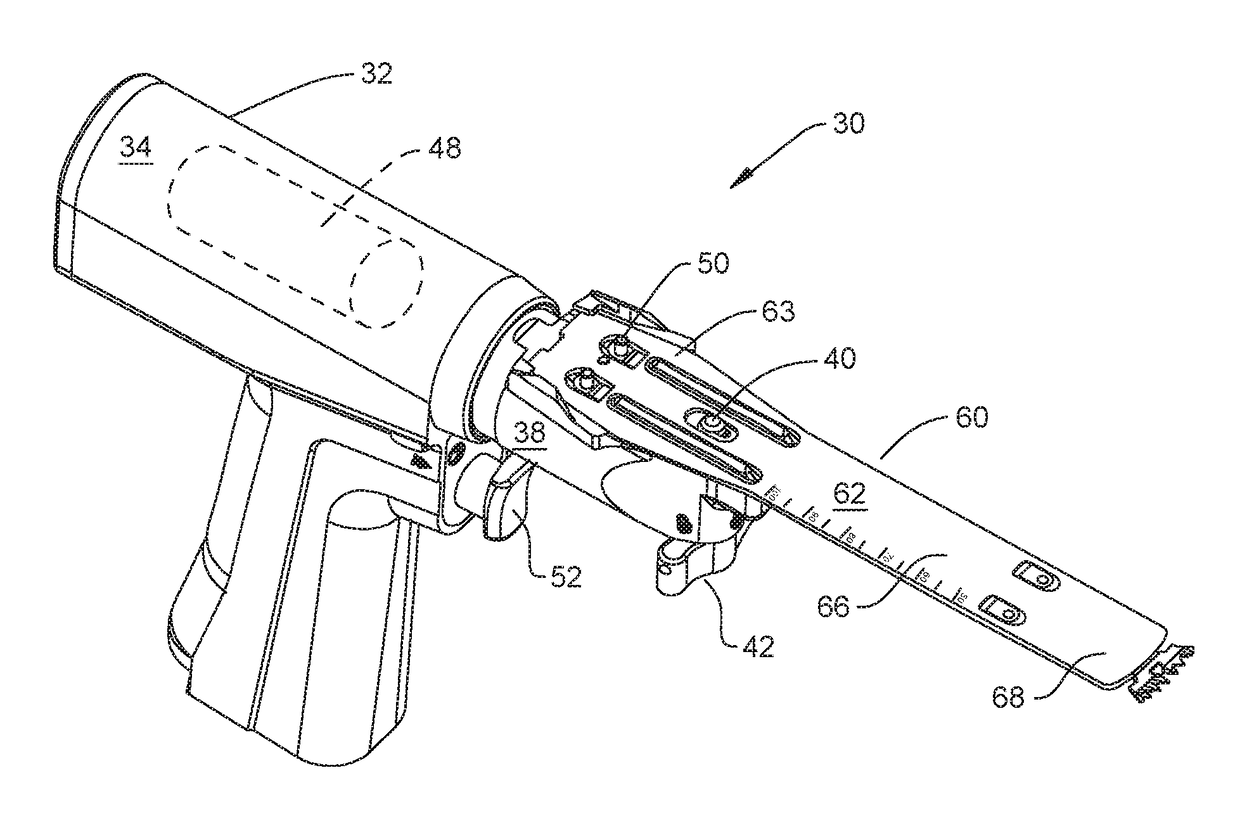

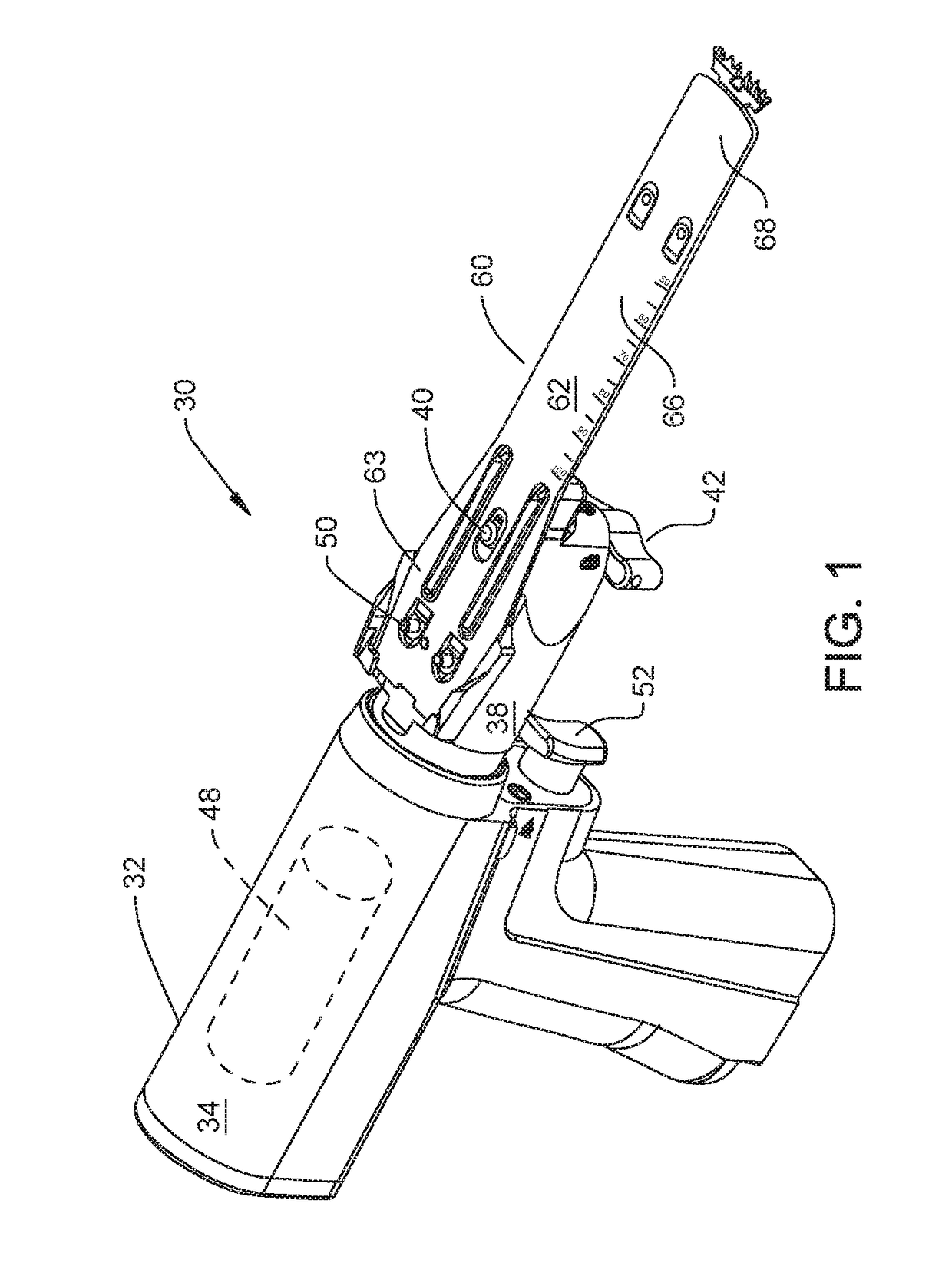

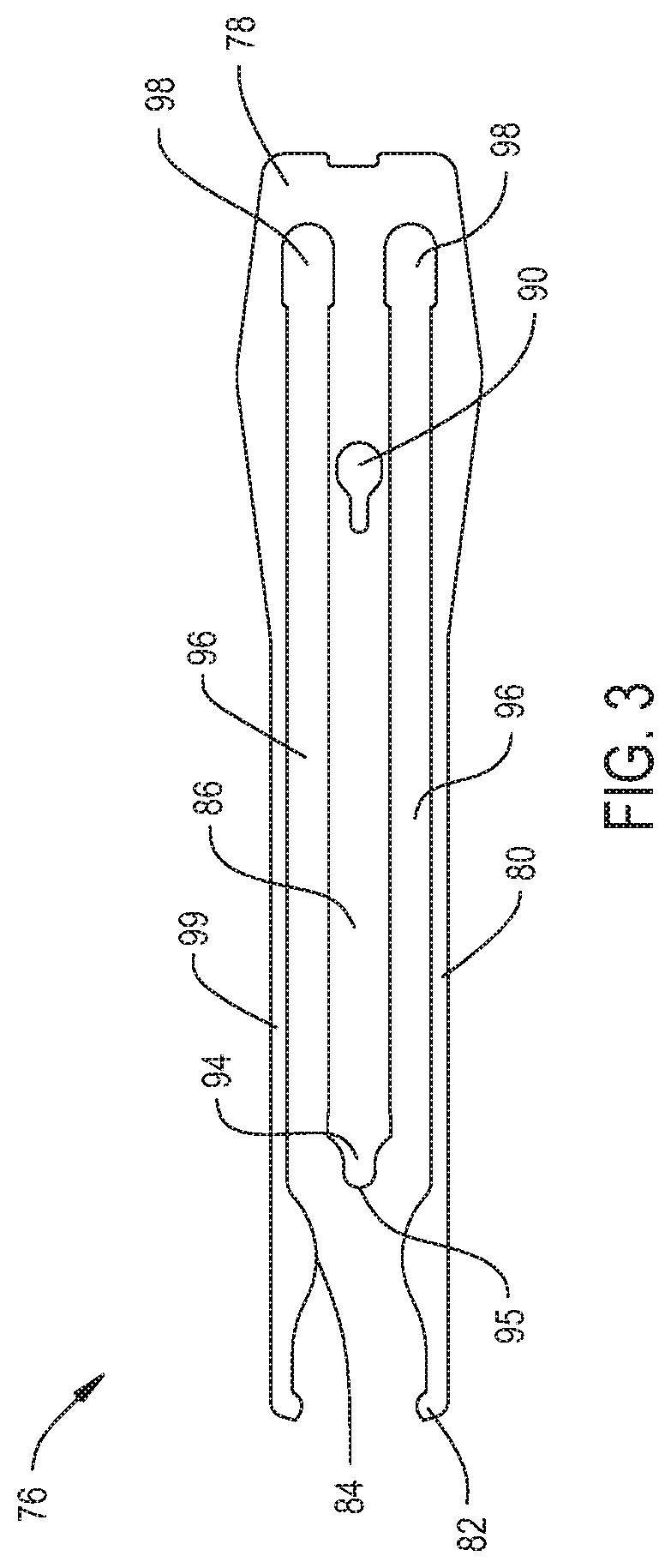

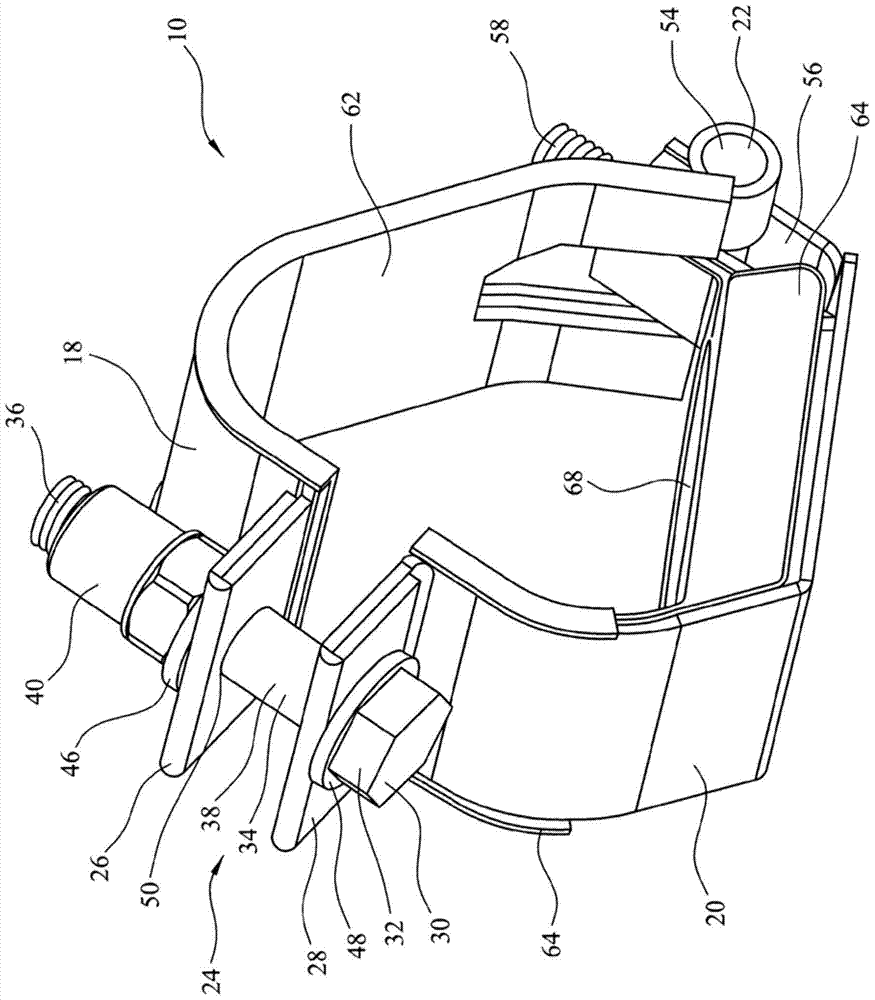

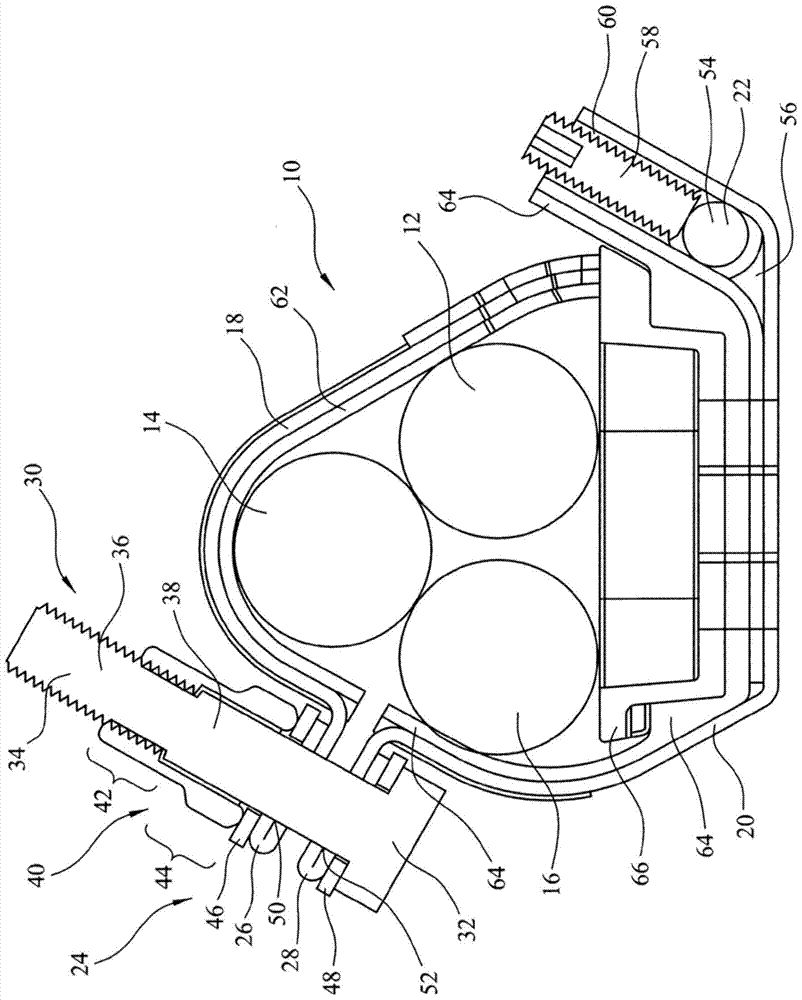

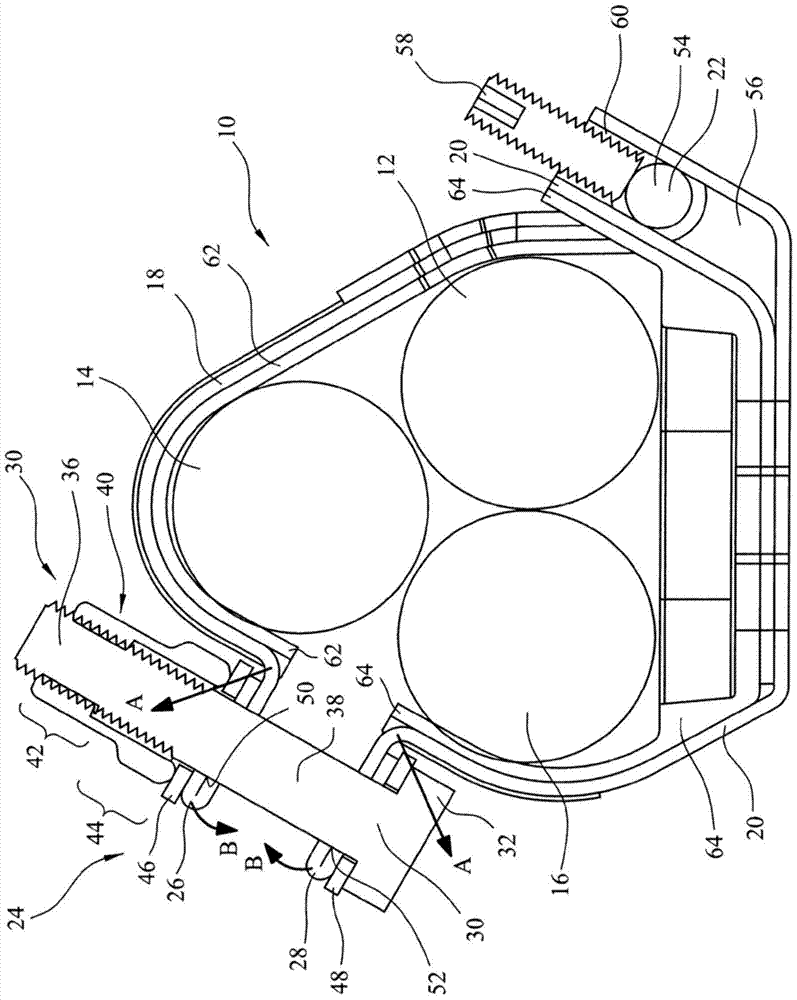

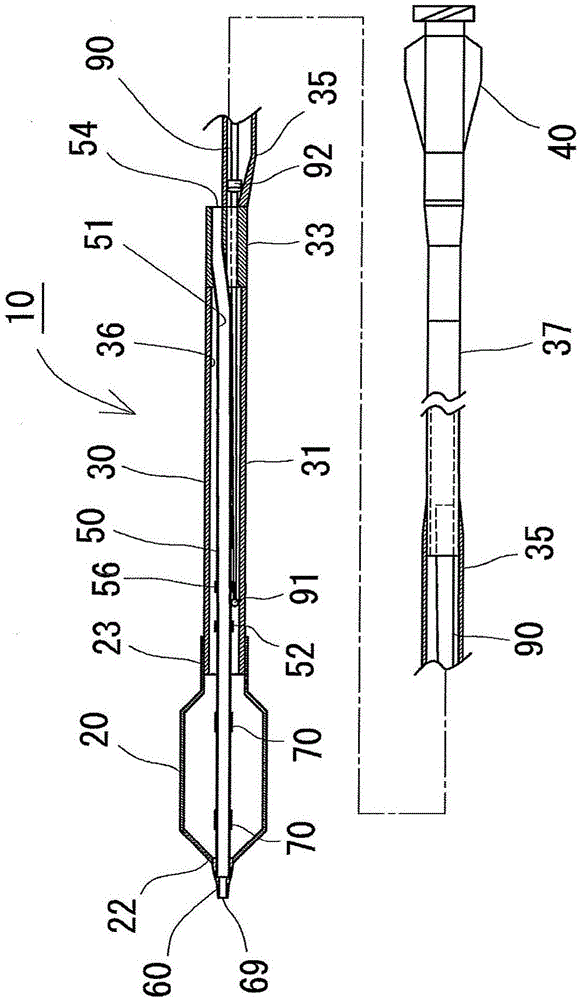

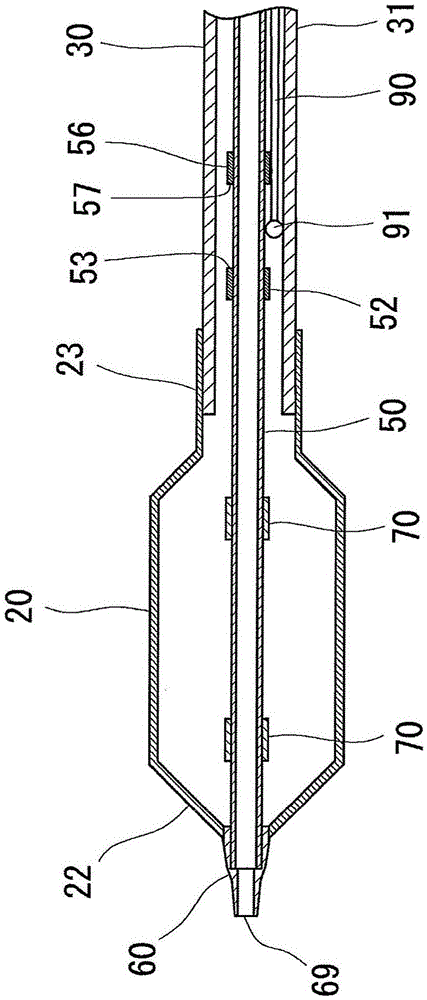

Surgical sagittal blade cartridge with a reinforced guide bar

ActiveUS10687823B2Less chance of bendingMetal sawing devicesMetal sawing toolsPhysical medicine and rehabilitationTine

A surgical sagittal saw cartridge that includes a guide bar formed form an inner plate and opposed outer plates, the inner plate having a head. The cartridge has a blade that is disposed against the head of the inner plate. The inner plate is formed to have an inner tine and two opposed outer tines. The inner tine is formed to define the head against which the blade is disposed. The outer tines extend forward of the inner tine so as to define a space between the outer tines in which the blade is seated.

Owner:STRYKER EURO OPERATIONS HLDG LLC

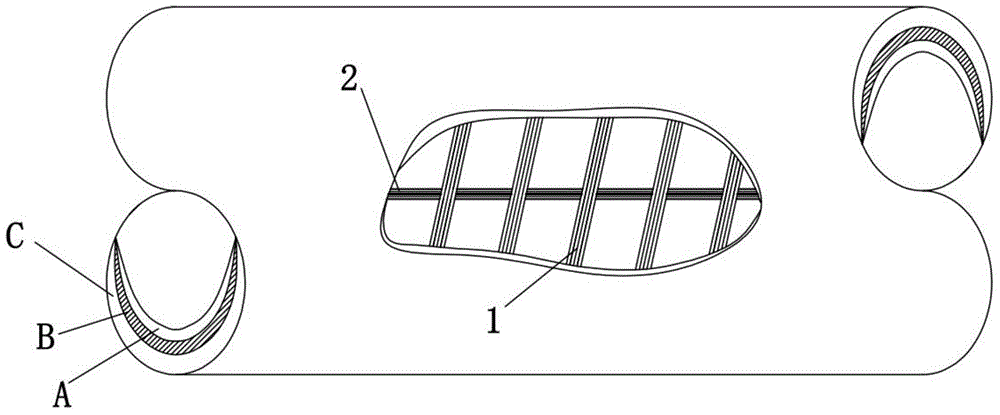

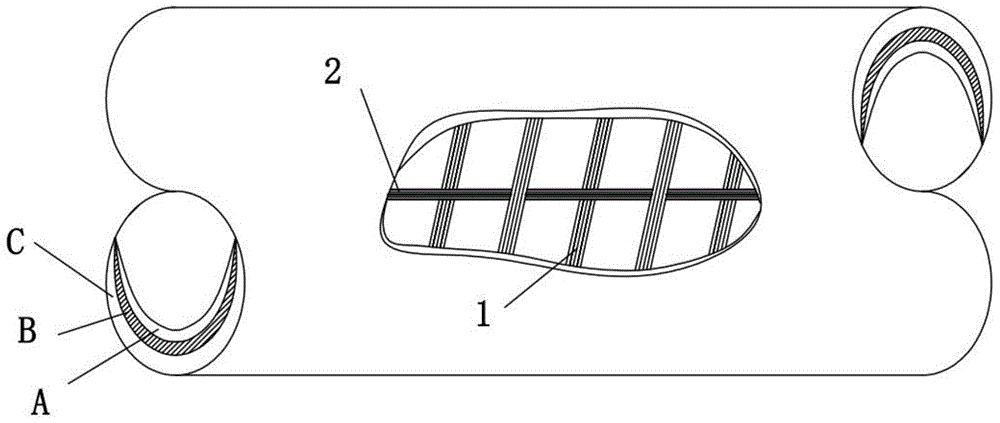

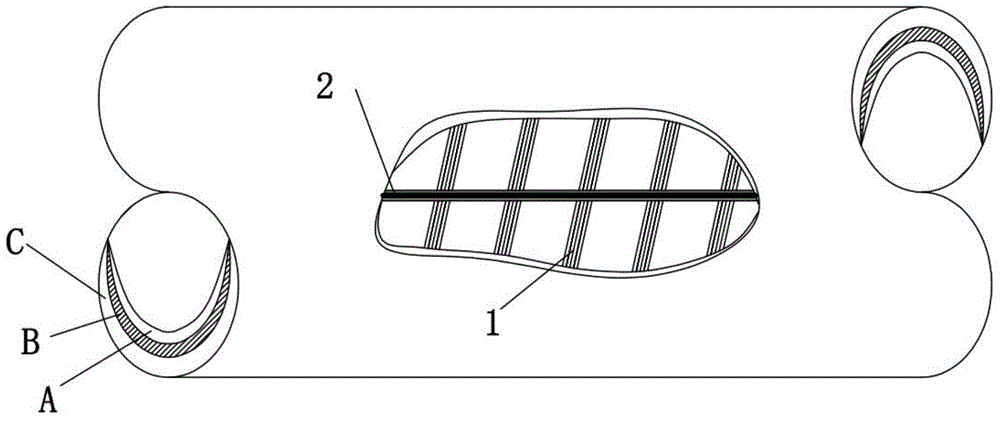

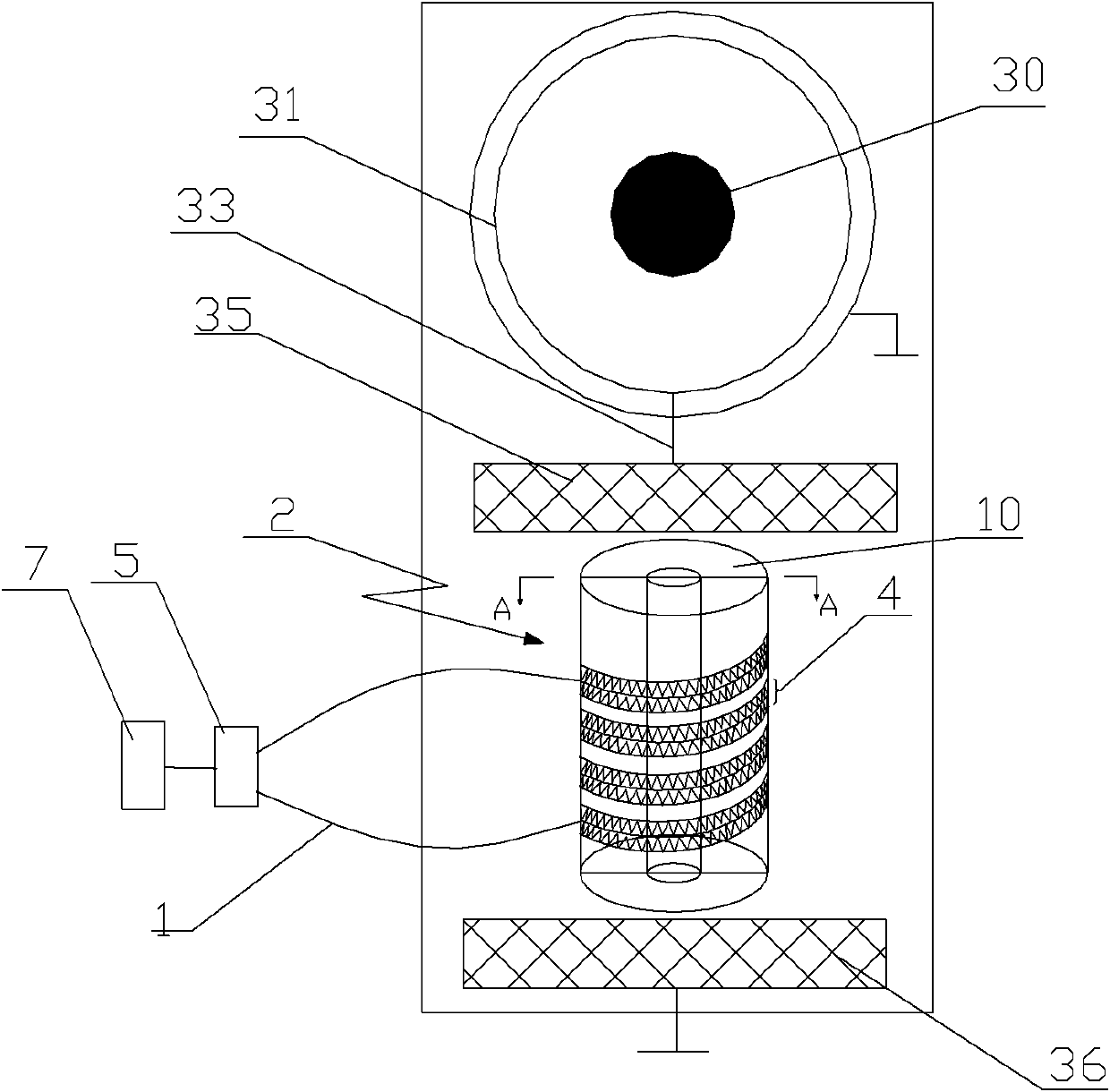

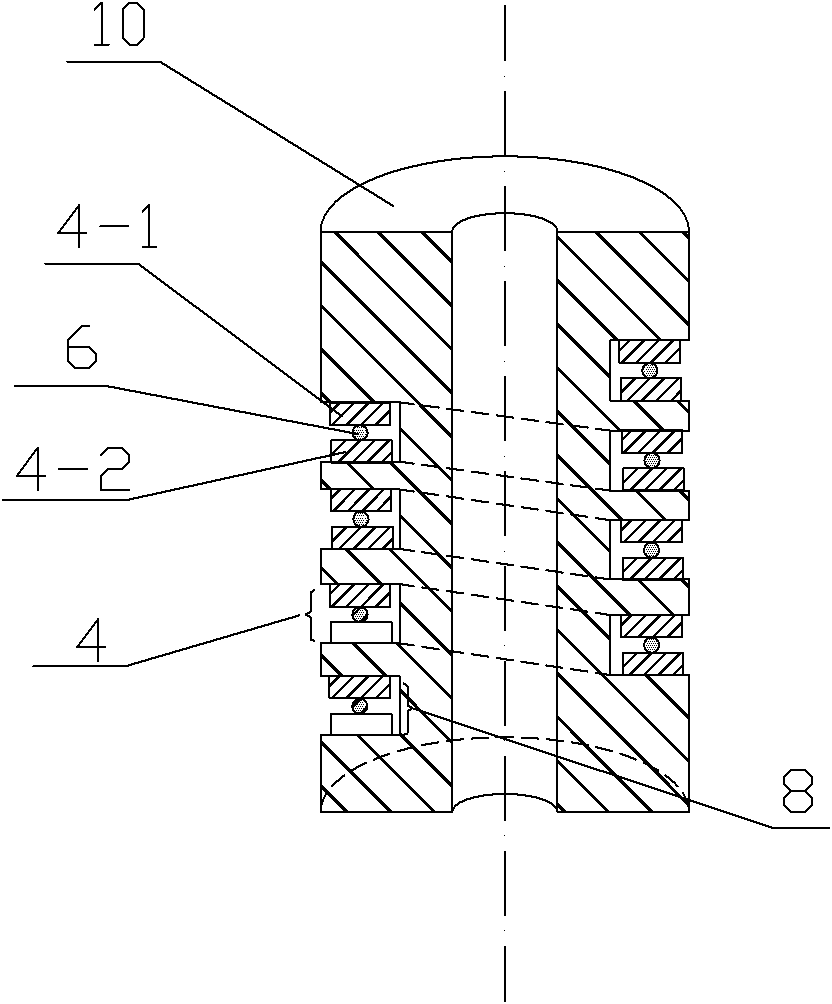

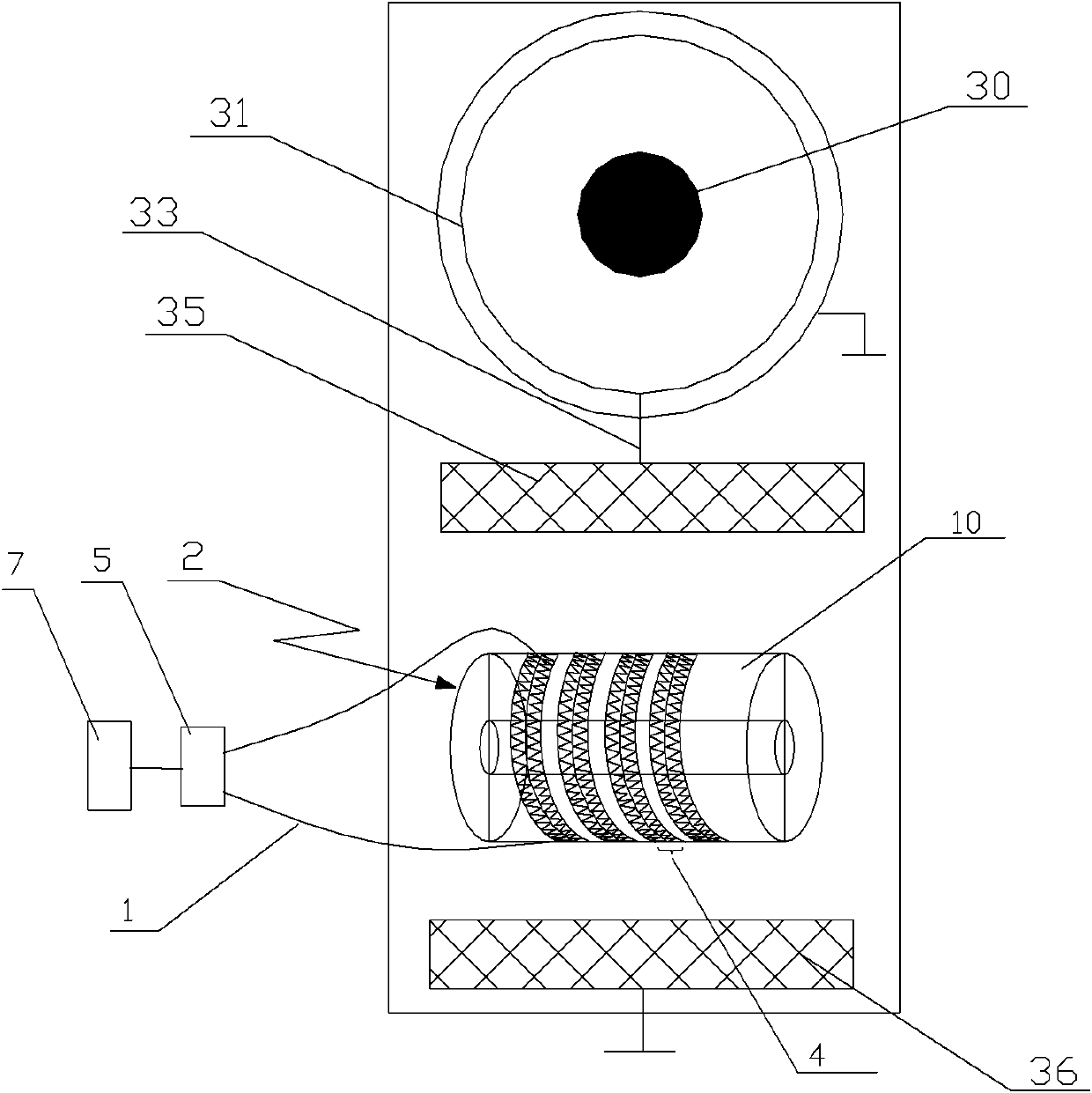

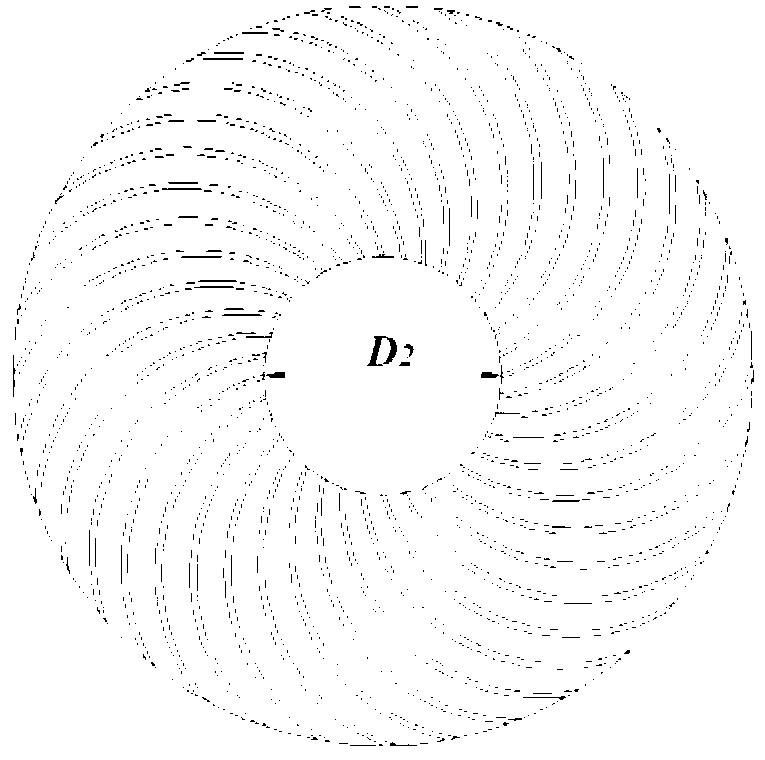

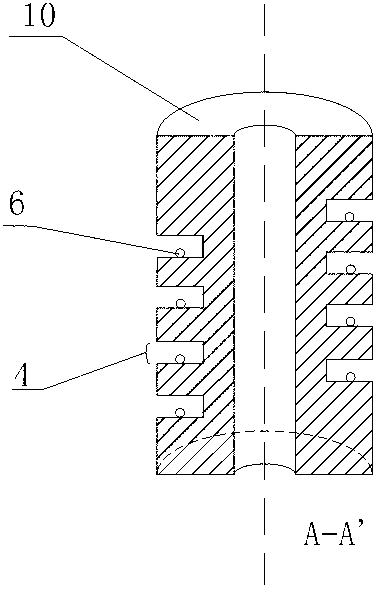

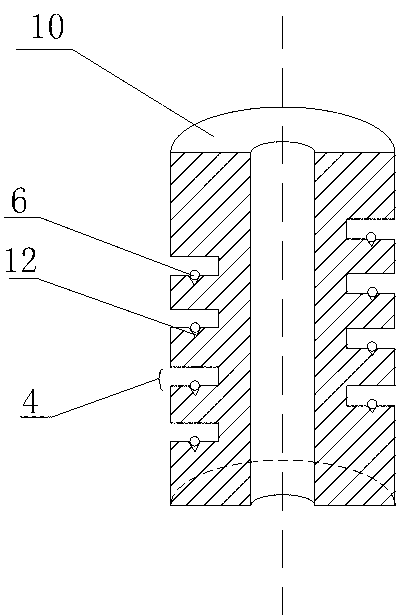

Reinforced compound sheathing canal, preparation method and application thereof

InactiveCN105105894AReduce surgical riskPrevent extensionStentsSurgeryTransport systemInvasive treatments

The invention discloses a reinforced compound sheathing canal, a preparation method and application thereof. The reinforced compound sheathing canal sequentially comprises an inner layer, a reinforced layer and an outer layer from interior to exterior, wherein the reinforced layer comprises axial reinforcing elements and a spiral reinforcing element, the spiral reinforcing element is a single spiral element or is formed by combining two or more spiral elements, the axial reinforcing elements are disposed on the inner side or outer side of the spiral element, or are inserted between the spiral elements, and various axial reinforcing elements are uniformly arranged in the circumference direction of the sheathing canal. The reinforced compound sheathing canal provided by the invention has the advantages of thin wall, high axial strength, high radial strength, high torque transitivity and the like, can be applied to a transport system for transporting medical device implants needed in a minimally invasive treatment and can reduce the outer diameter of the transport system, so that the medical device implants are easy to arrive at lesion positions, damage to the blood vessel of a patient is reduced, and sufficient technical support is provided for reliable, successful and safe transport and implantation of the medical device implants by the transport system.

Owner:NINGBO LINSTANT POLYMER MATERIALS CO LTD

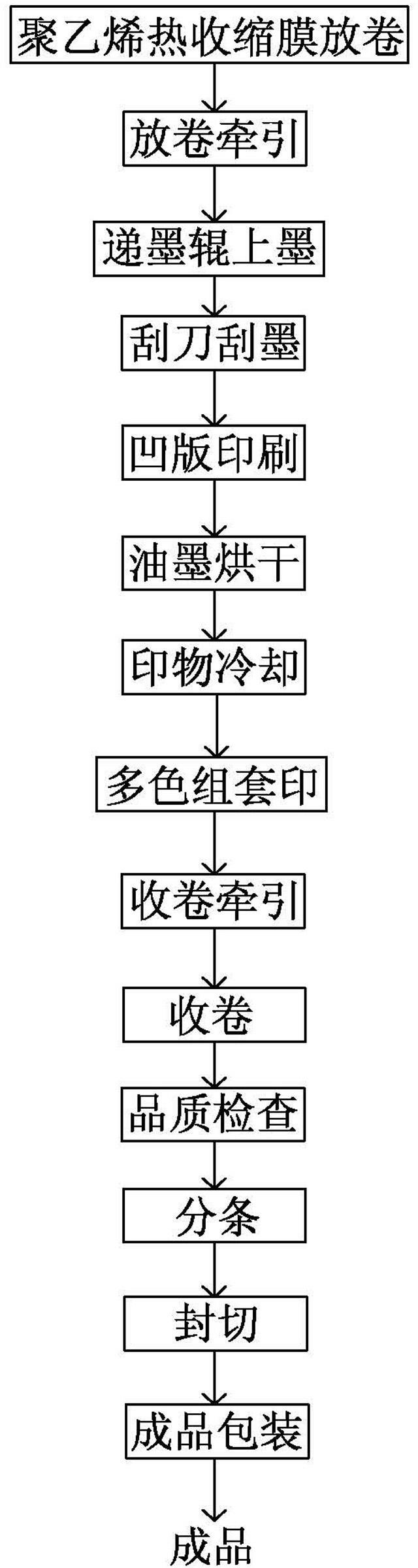

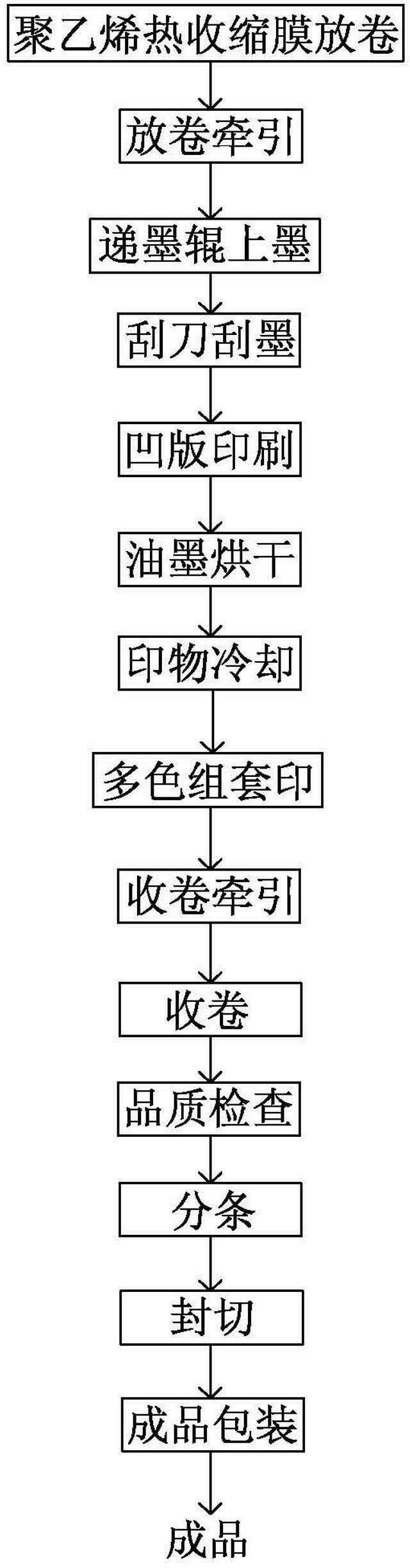

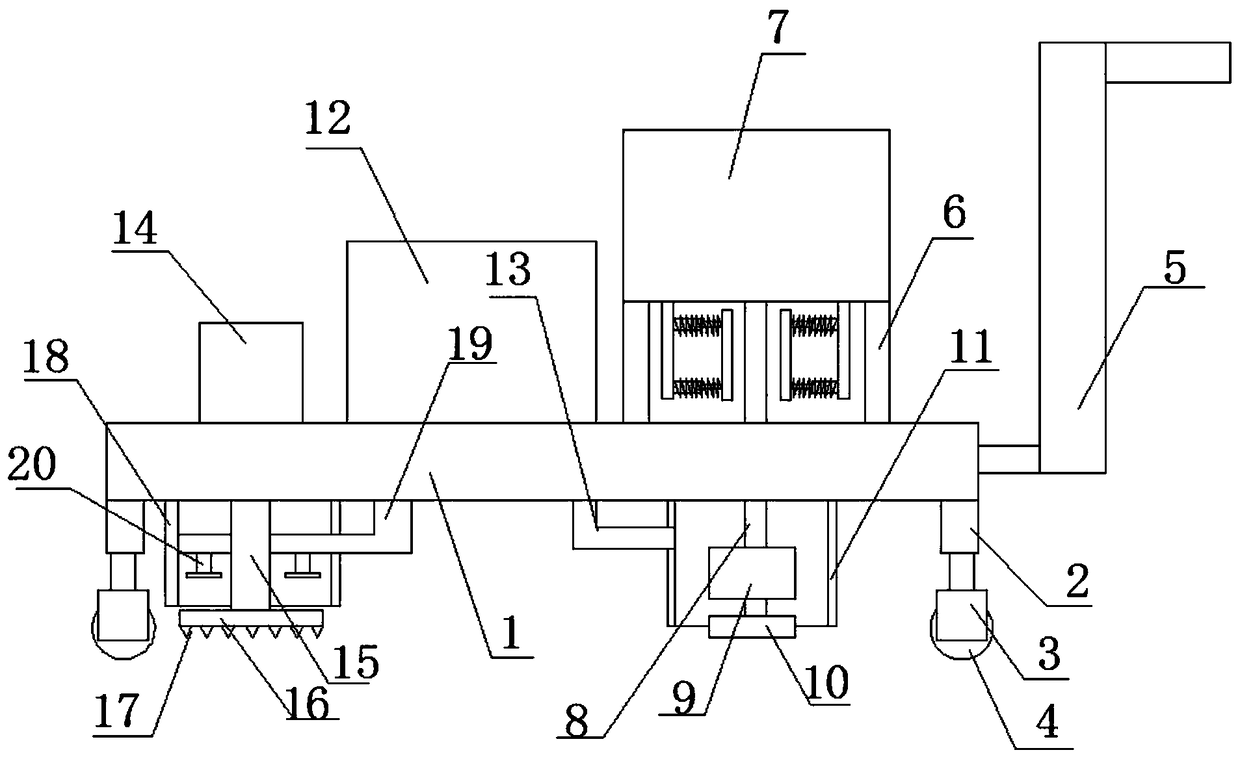

Polyethylene heat shrinkable film gravure printing process

InactiveCN102602177AIncrease temperatureIncrease air volumeRotary intaglio printing pressOther printing apparatusEngineeringElectrical and Electronics engineering

The invention relates to a polyethylene heat shrinkable film gravure printing process which comprises the following steps of: (1) unwinding a polyethylene heat shrinkable film; (2) carrying out unwinding drawing; (3) carrying out inking by a drop roller; (4) scraping ink by a scraper; (5) carrying out gravure printing; (6) drying ink; (7) cooling a printed object; (8) carrying out multiple color class overprinting, wherein the steps (3), (4), (5), (6) and (7) are sequentially repeated; (9) carrying out winding drawing; (10) winding; (11) checking the quality; (12) stripping; (13) sealing and cutting; and (14) carrying out finished product packaging to obtain a finished product, wherein when the step (6) is implemented, the ink printed on the surface of the polyethylene heat shrinkable film is dried by modes of feeding hot blast by an air blower and circulating the hot blast by a drying box and related equipment comprises an air energy heating device, the air blower, an external heating box, a suction fan and the drying box with an effect of an air chipper. The polyethylene heat shrinkable film gravure printing process is used for carrying out gravure printing on the polyethylene heat shrinkable film.

Owner:ZHENGXIN PACKAGING CO LTD DONGGUAN

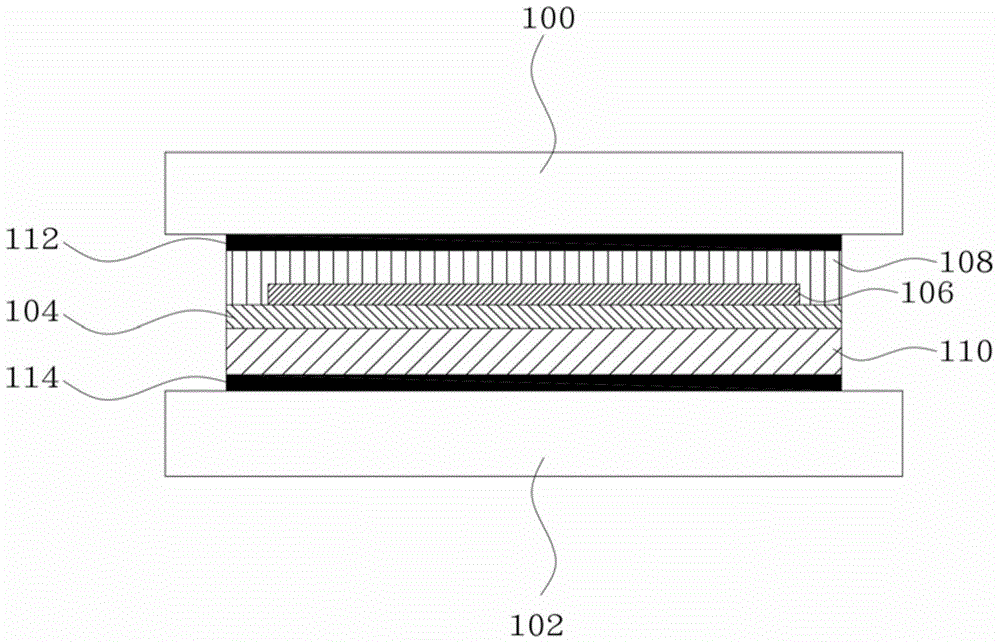

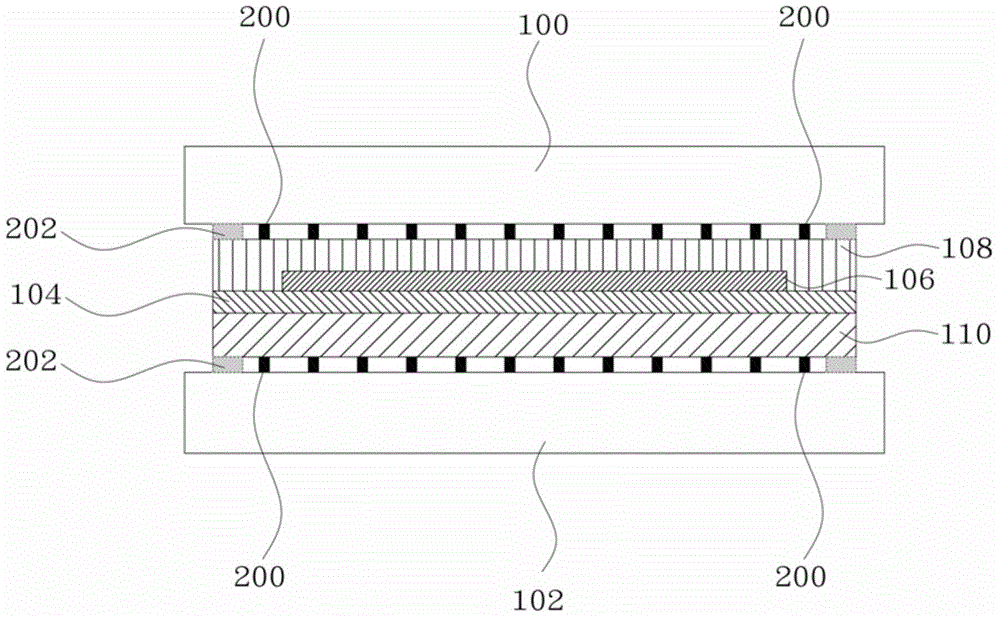

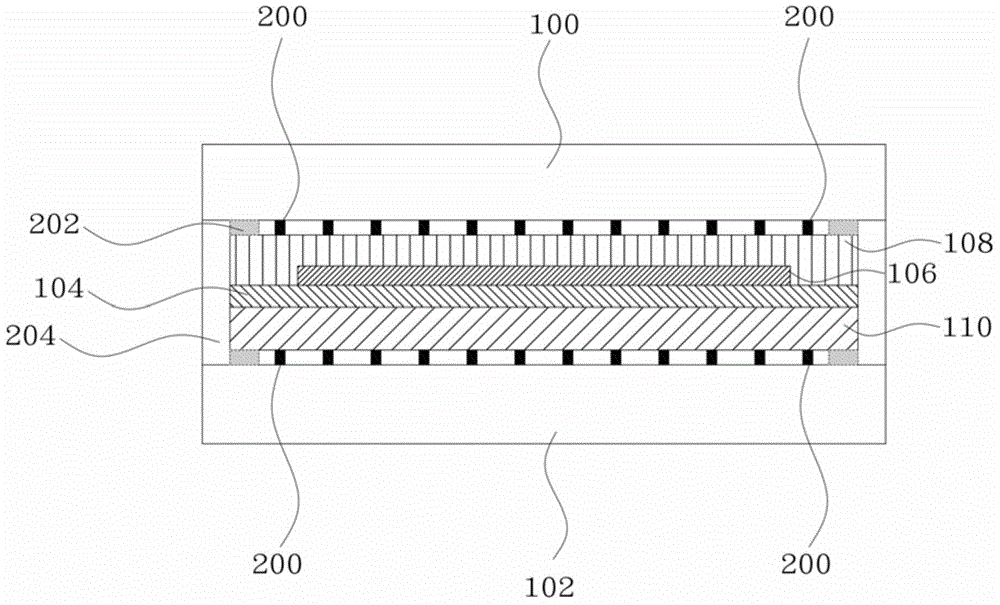

OLED panel packaging structure and OLED display

InactiveCN104868060ALess chance of bendingSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringSurface plate

The invention provides an OLED panel packaging structure and an OLED display; the packaging structure comprises the following elements: a first protection glass arranged above an OLED panel; a second protection glass arranged below the OLED panel; a plurality of spacers scattered between the first protection glass and a first protection layer, and between the second protection glass and a second protection layer, wherein an air gap is arranged between adjacent spacers; a first bonding layer respectively between the first protection layer and the first protection glass, and between the second protection layer and the second protection glass, wherein the height of the first bonding layer is equal to that of the spacers. Compared with the prior art, the structure uses the spacers between the protection glasses and corresponding protection layers of the OLED panel to divide stress distribution of the two, so upper and lower cover plate glasses are not fully attached to the OLED panel, and the structure can be protected by the cover plate glasses with a small bending curvature.

Owner:AU OPTRONICS CORP

Flexible glass article having a low bending curvature and method of making the same

PendingCN108147680AAvoid problemsLess chance of bendingDigital data processing detailsPretreated surfacesEngineeringFlexible display

The invention discloses a flexible glass article, a flexible display device comprising the flexible glass article, a method for manufacturing the flexible glass article, and a method for adjusting aneffective bending radius of the glass article which bears a bending stress. The flexible glass articles having modified bending radii and methods of making same provide an ultra-low bending curvature,while still retaining a thin profile and other favorable characteristics of glass.

Owner:SAMSUNG DISPLAY CO LTD

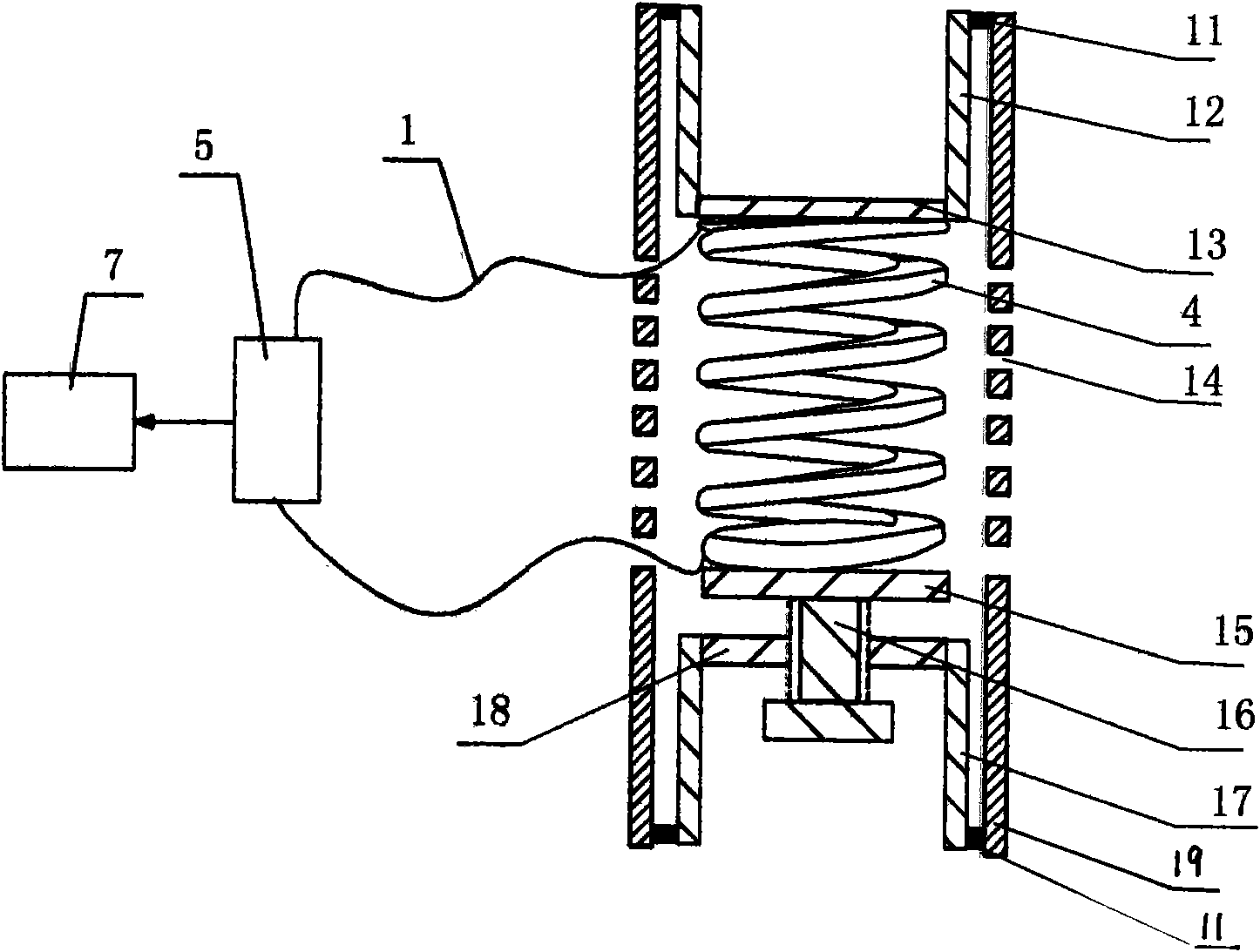

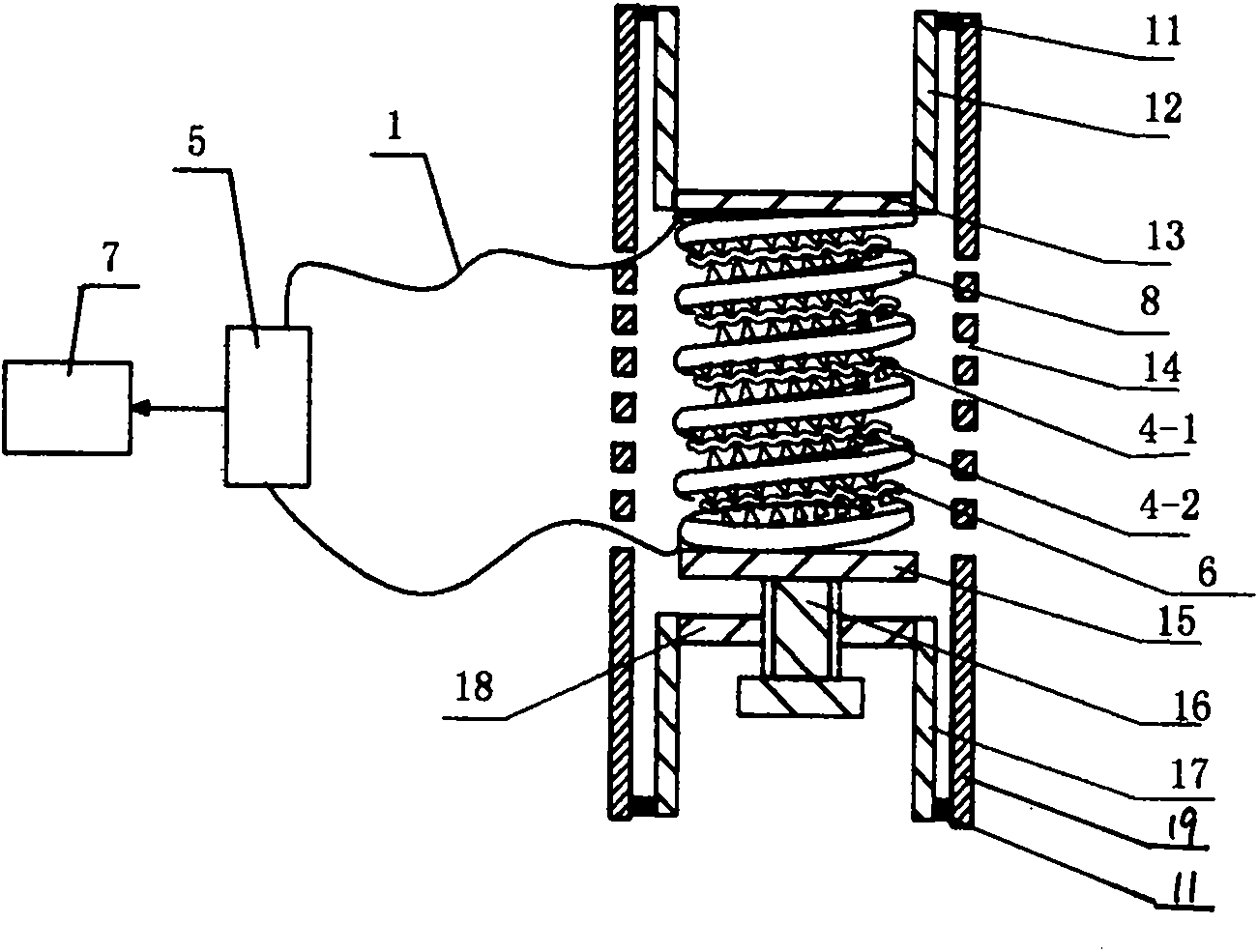

Fiber pressure sensing device based on C-shaped spring tube

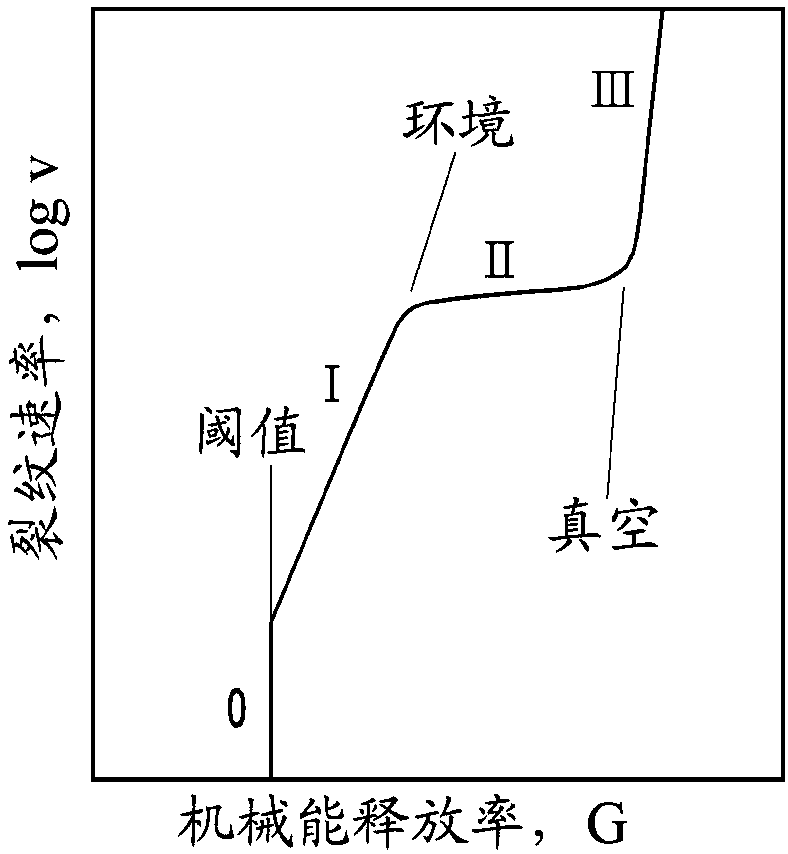

InactiveCN101922989AIncrease effective lengthReduce bending curvatureFluid pressure measurement using elastically-deformable gaugesFluid pressure measurement by optical meansEffective lengthFiber

The invention discloses a fiber pressure sensing device based on a C-shaped spring tube. A multi-layer microbend element containing a signal fiber is installed on the C-shaped spring tube. When the pressure to be measured is applied to the C-shaped spring tube, the C-shaped spring tube has the tendency of rounding and extending, and the extending displacement of the C-shaped spring tube causes the compression of the multi-layer microbend element so that the bending curvature of the signal fiber contained in the multi-layer microbend element is changed, thus the power of optical signals transmitted in the signal fiber is obviously changed, and the purpose of measuring the magnitude of the pressure is achieved by utilizing a testing instrument for detection. Because the multi-layer microbend element is adopted, the effective length of the signal fiber is extended, and the bending curvature of the signal fiber is reduced, thereby improving the accuracy of the device and greatly prolonging the service life of the signal fiber simultaneously, so that the device of the invention has wide application prospects.

Owner:XIAN JINHE OPTICAL TECH

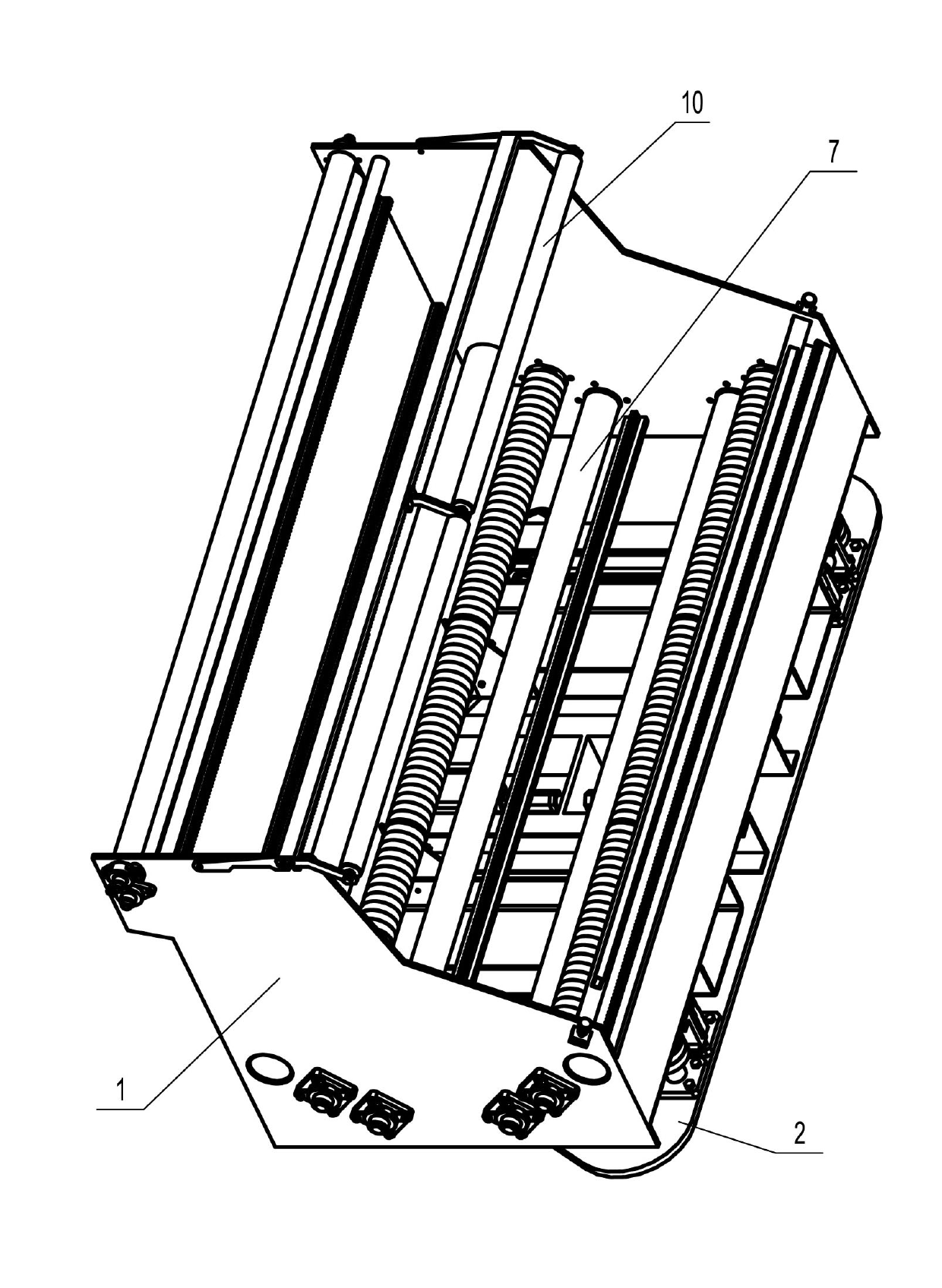

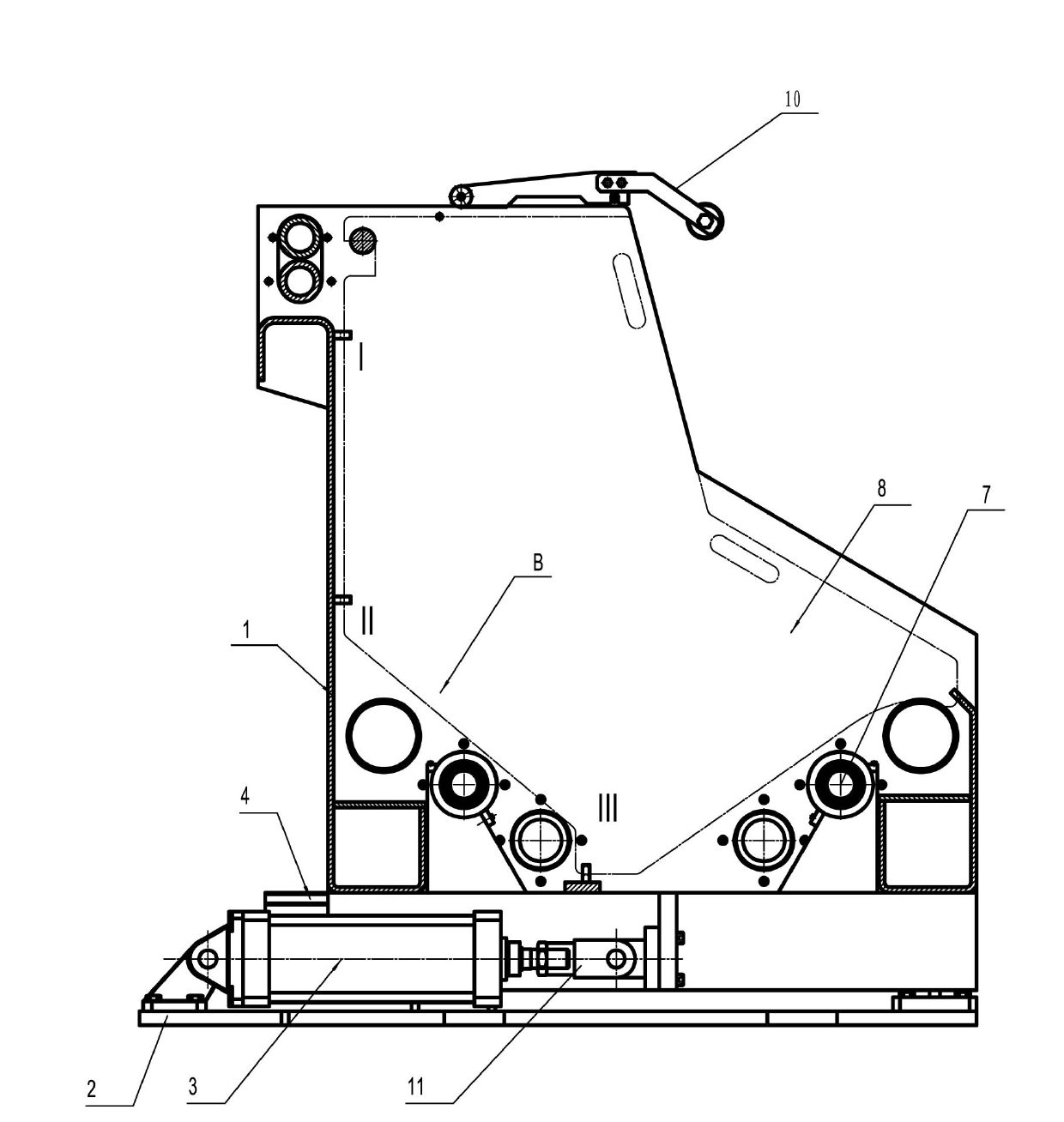

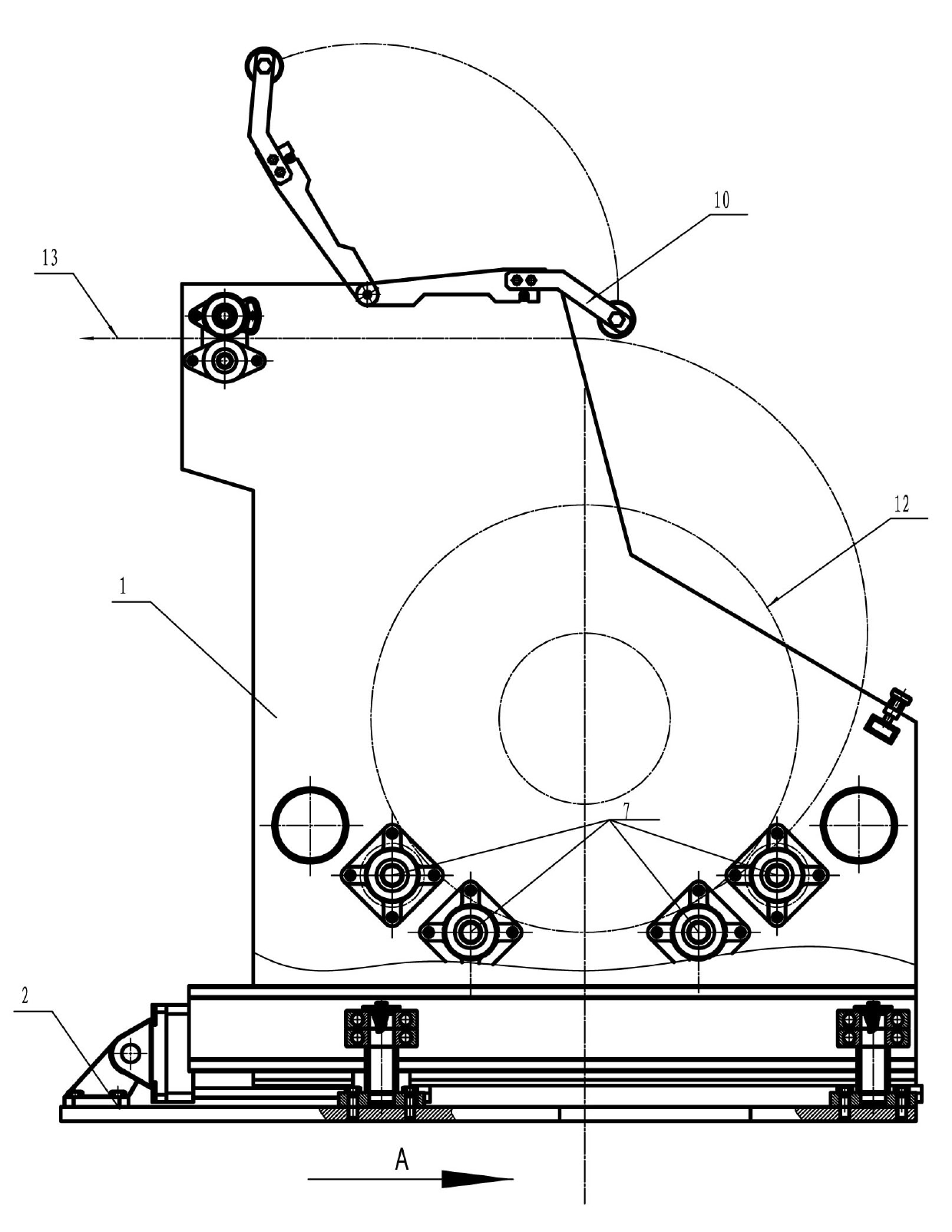

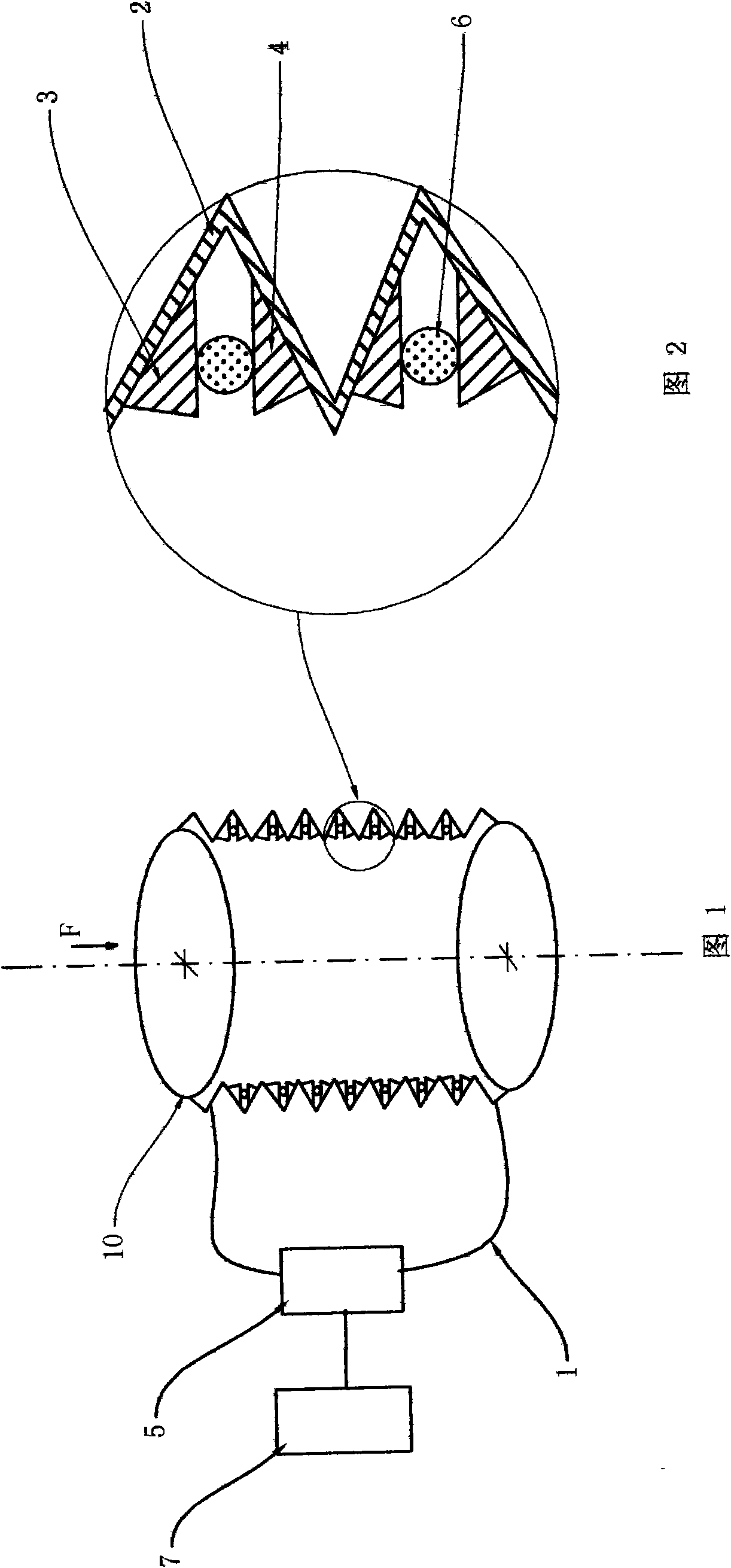

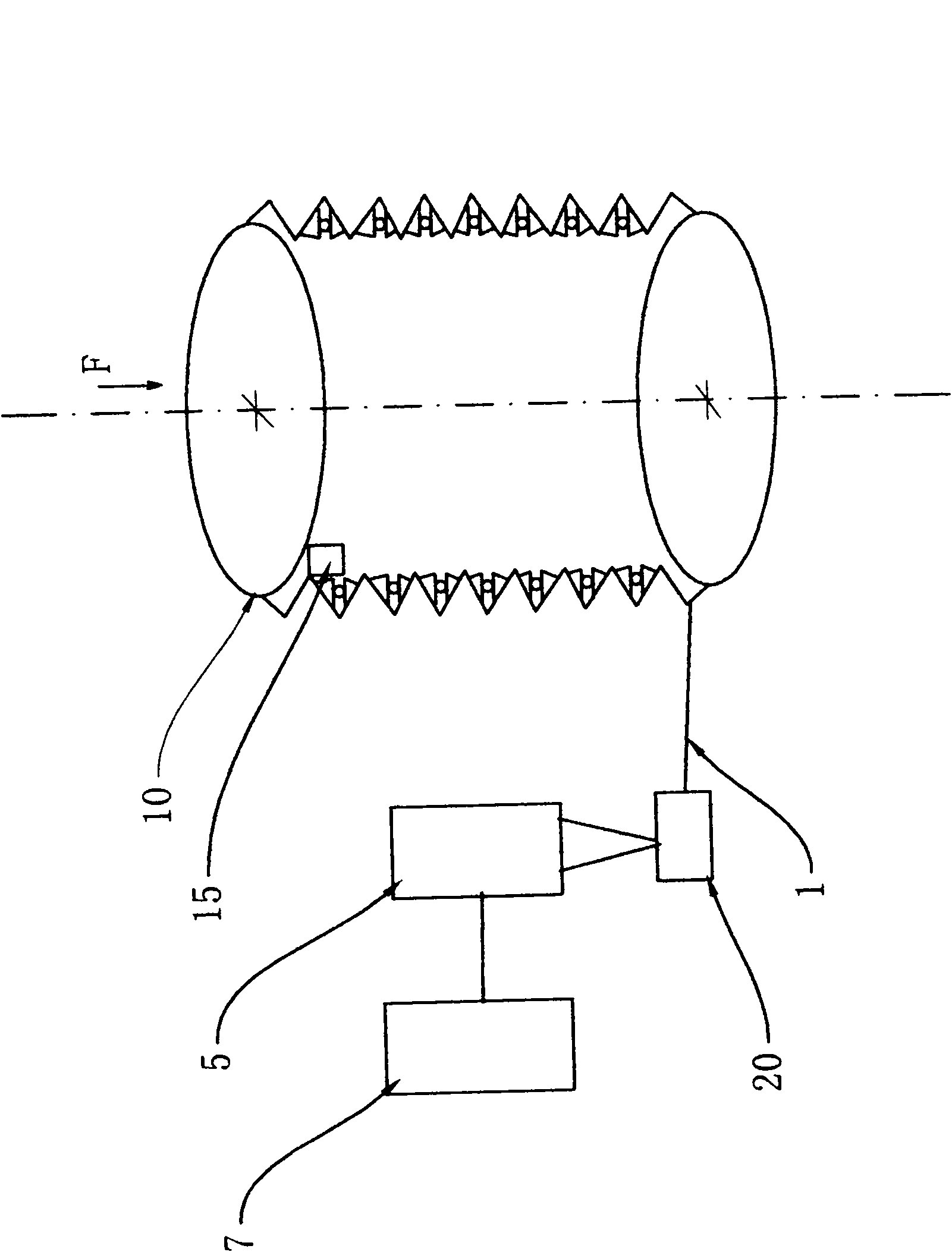

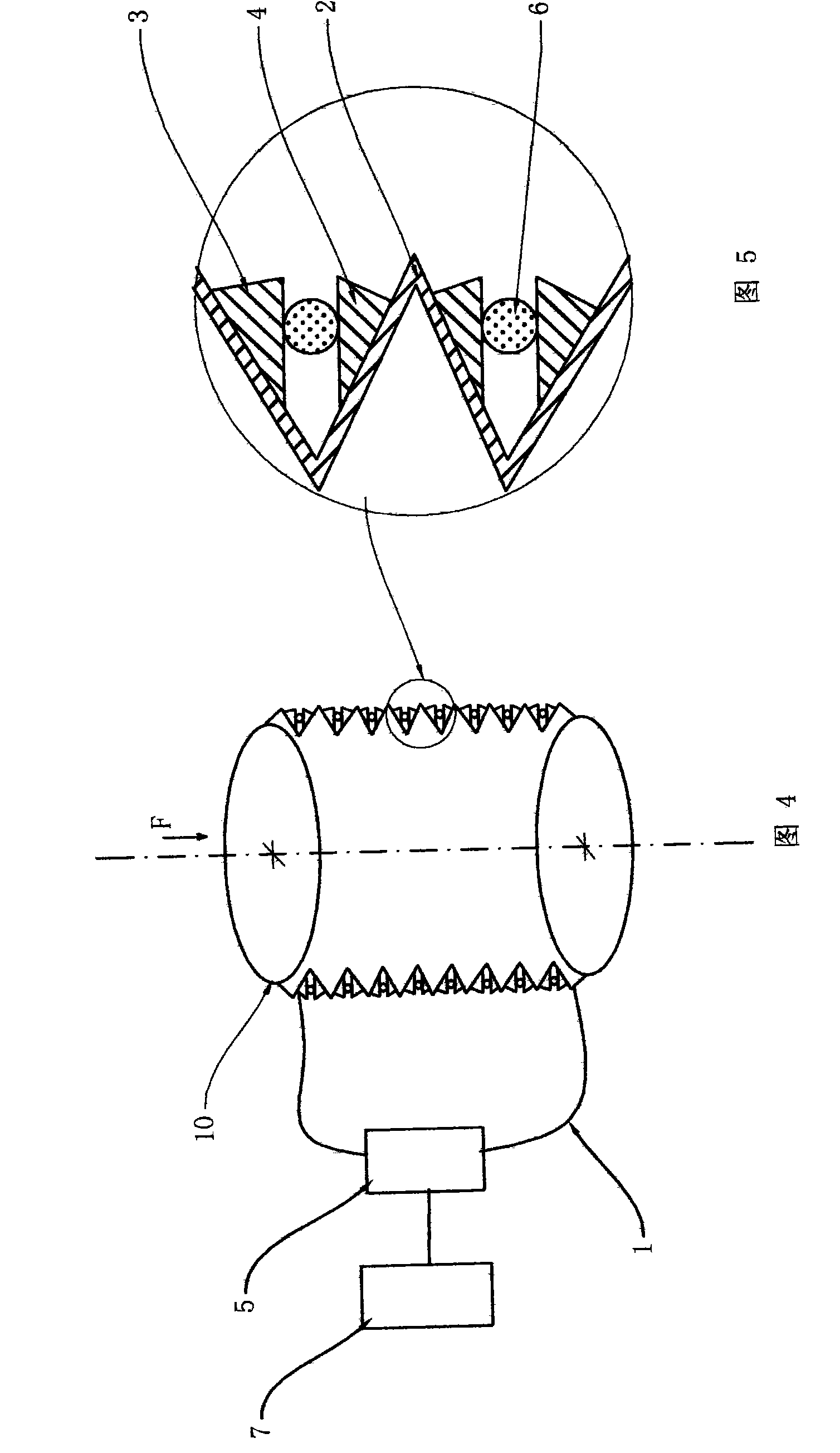

Section steel straightening device and method

The invention discloses a section steel straightening device, which comprises a straightening roll system, wherein the straightening roll system is arranged on a body; an output end of the straightening roll system is also provided with a rolling and straightening roll system; the rolling and straightening roll system comprises at least one pair of upper and lower rolling and straightening rolls and at least one pair of left and right rolling and straightening rolls; the upper and lower rolling and straightening rolls are symmetrically arranged on the upper and lower sides of a pass steel wire and a roll gap I for passing through section steel is formed between the two rolls; and the left and right rolling and straightening rolls are symmetrically arranged on the left and right sides of the pass steel wire and a roll gap II for passing through the section steel is formed between the two rolls. According to the section steel straightening device and a section steel straightening method, lateral bending of straightened section steel can be effectively improved, and the length of a straightening blind zone of a main bend of the section steel is reduced, so that the section size of the section steel is better, the flatness is higher, the residual stress is smaller, and particularly height difference existing in rail level of the straightening blind zone and a straightening zone can be effectively reduced and the yield of a steel rail is increased when the steel rail is straightened.

Owner:CISDI ENG CO LTD

Cable retaining apparatus

ActiveCN105075042ALess chance of bendingReduce distancePipe supportsElectrical apparatusEngineeringScrew thread

A cable retaining apparatus, or trefoil cleat, for retaining three cable high voltage cables is disclosed. Two halves of the cleat are hinged together and between them engage the three cables. There is also a clamping portion for pulling the two halves together which includes a clamping member at the non-hinged end of each half. Both clamping members have holes through them and one hole has an internal thread. There is also a bolt that extends through the non-threaded hole and into the threaded hole. The bolt has a non-threaded portion that extends at least between the clamping members when the cleat is in use.

Owner:CMP PRODS

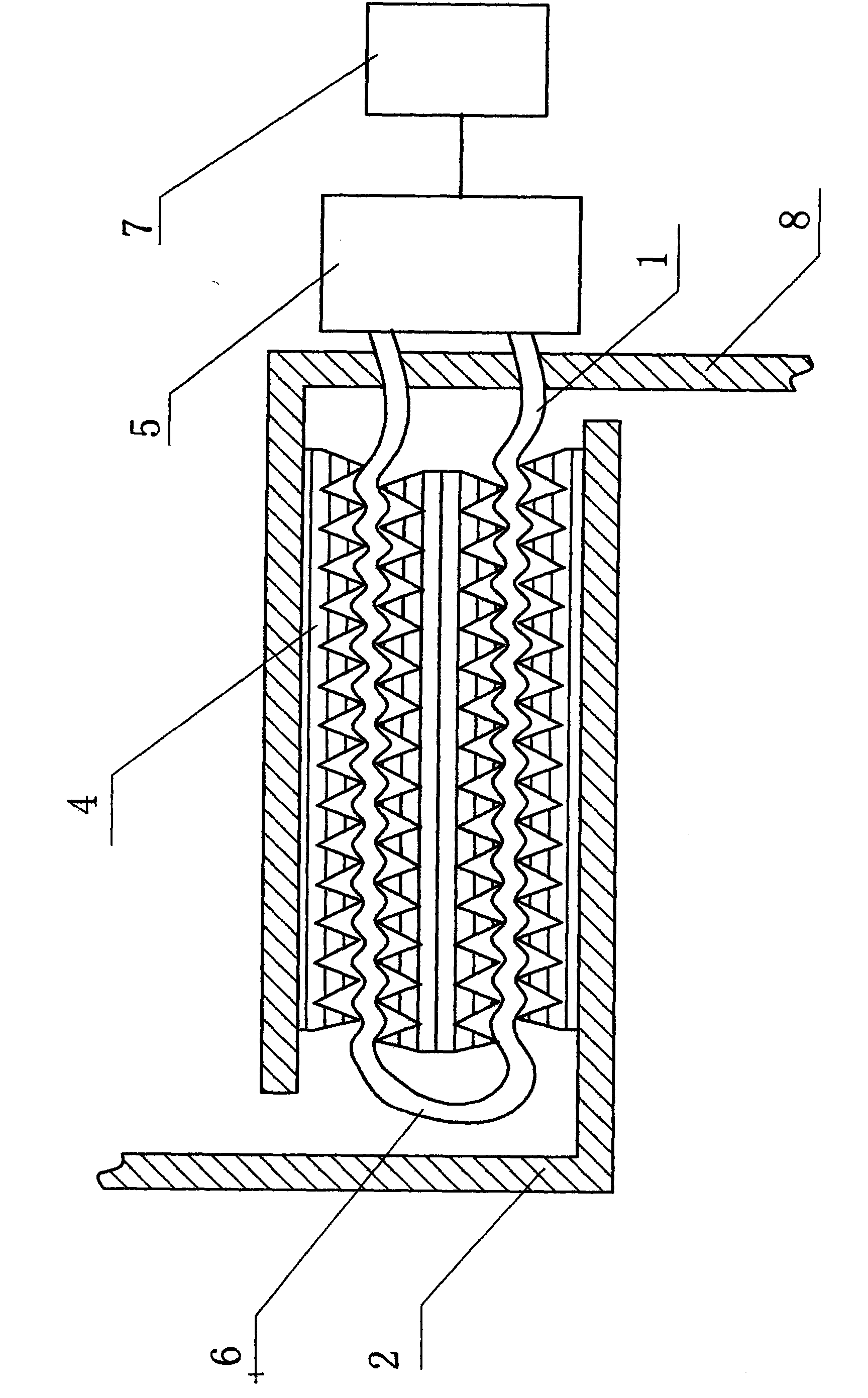

Universal pressure sensing device based on optical fiber microbending loss

InactiveCN102374913ALess chance of bendingIncrease effective lengthForce measurement by measuring optical property variationFluid pressure measurement by optical meansPressure senseEffective length

The invention discloses a universal pressure sensing device based on an optical fiber microbending loss, which comprises a cylindrical cavity, wherein one end of the cylindrical cavity is closed by a substrate, and the other end of the cylindrical cavity is fixedly provided with a corrugated piece; and a multi-layer microbending element containing a signal optical fiber is fixedly arranged between the substrate and the corrugated piece. When the tested pressure acts on the corrugated piece, the corrugated piece deforms and transfers the force to the multi-layer microbending element to allow the multi-layer microbending element to be compressed, so that the bending curvature of the signal optical fiber contained in the multi-layer slightly bent element changes, and thus the power of optical signals transmitted in the signal optical fiber is obviously changed, and the pressure is tested by the detection of a testing unit. The multi-layer microbending loss element is adopted, so that the effective length of the signal optical fiber is lengthened, the bending curvature of the signal optical fiber is reduced, and thus the precision of the device is improved, the service life of the signal optical fiber is substantially prolonged simultaneously, and the device has broad application prospects.

Owner:XIAN JINHE OPTICAL TECH

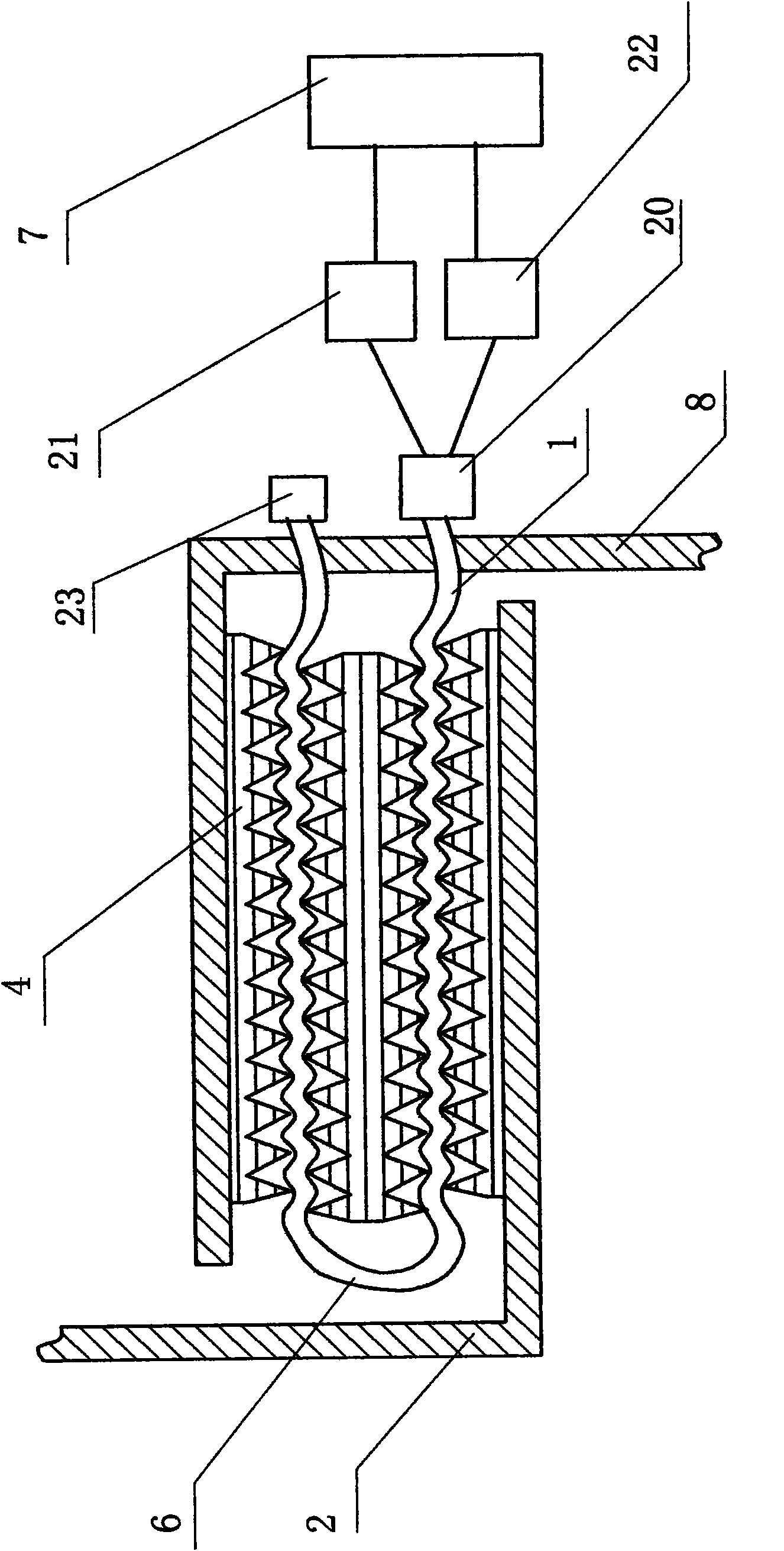

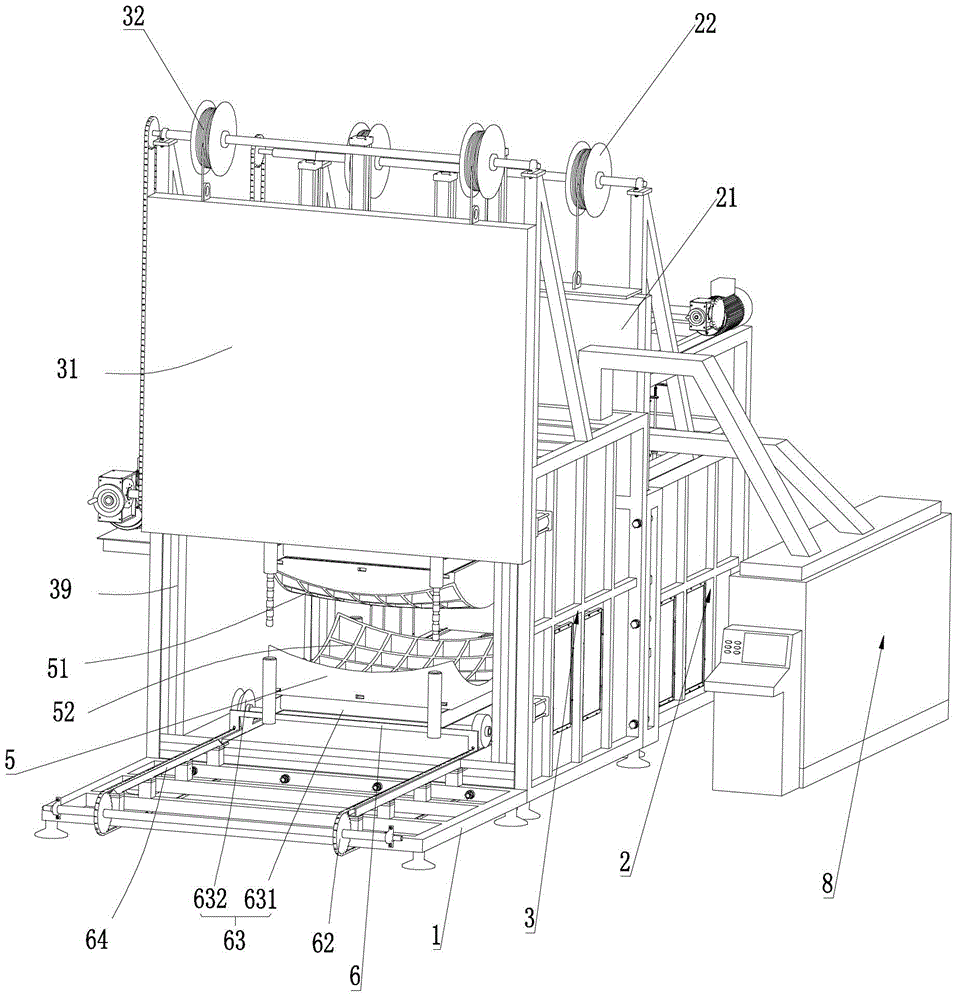

Compression molding device and process of multi-curved-surface inorganic glass

ActiveCN102745885AGuaranteed curvature accuracyGuaranteed bending temperatureGlass reforming apparatusInternal temperatureTemperature control

The invention relates to a compression molding device and process of multi curved surface inorganic glass. The compression molding device comprises a heating box, a molding box and a heating device, wherein the heating box and the molding box are arranged adjacently and are isolated by an inner door; the molding box is internally provided with a molding mold and a mold carrier; the mold carrier can move forwards and backwards between the molding box and the heating box; the molding mold comprises a female mold arranged on the mold carrier, a male mold movably arranged on the molding box, and a male mold driving device which is used for driving the male mode to stamp relative to the female mold; the compression molding device further comprises a control box; the control box is internally provided with a molding control module which is used for controlling the molding mold to do molding action, a mold moving control mold which is used for controlling the movement and the positioning of the mold carrier, and a temperature control module which is used for controlling the internal temperature of the molding box and the heating box. The compression molding device is applicable for multi curved surface molding of inorganic glass; the curvature precision of the multi curved surface inorganic glass after being molded can be improved; and moreover a proper bending temperature of the inorganic glass and the optical property and the quality of the surface of the glass after being bent and transformed can be ensured.

Owner:SHENZHEN SANXIN JMT GLASS

Optical fiber type non-invasive pipeline pressure sensor

InactiveCN101900617ASimple structureReasonable designForce measurement by measuring optical property variationFluid pressure measurement by optical meansFailure rateInternal pressure

The invention discloses an optical fiber type non-invasive pipeline pressure sensor, which comprises a curve type shell wound on the pipeline to be tested, a plurality of A-side deformation teeth and a plurality of B-side deformation teeth, wherein the A-side deformation teeth and B-side deformation teeth are distributed on opposite two sides in the curve type shell in staggered arrangement and are arranged on both sides of a signal optical fiber correspondingly. The prolonged optical fiber of the signal optical fiber is connected with a test unit. When the inner pressure of the pipeline increases or decreases, the circumference of the pipeline is to increase or decrease so that the distance between the deformation teeth on opposite sides within the curve type shell winding on the pipeline is to change, thereby changing the curvature of the signal optical fiber clamped between the deformation teeth on opposite sides. The test unit acquires the change of the inner pressure of the pipeline by detecting the change of the inner transmission optical signal power of the signal optical fiber. The device has the advantages of high precision, low failure rate and wide application prospect.

Owner:XIAN JINHE OPTICAL TECH

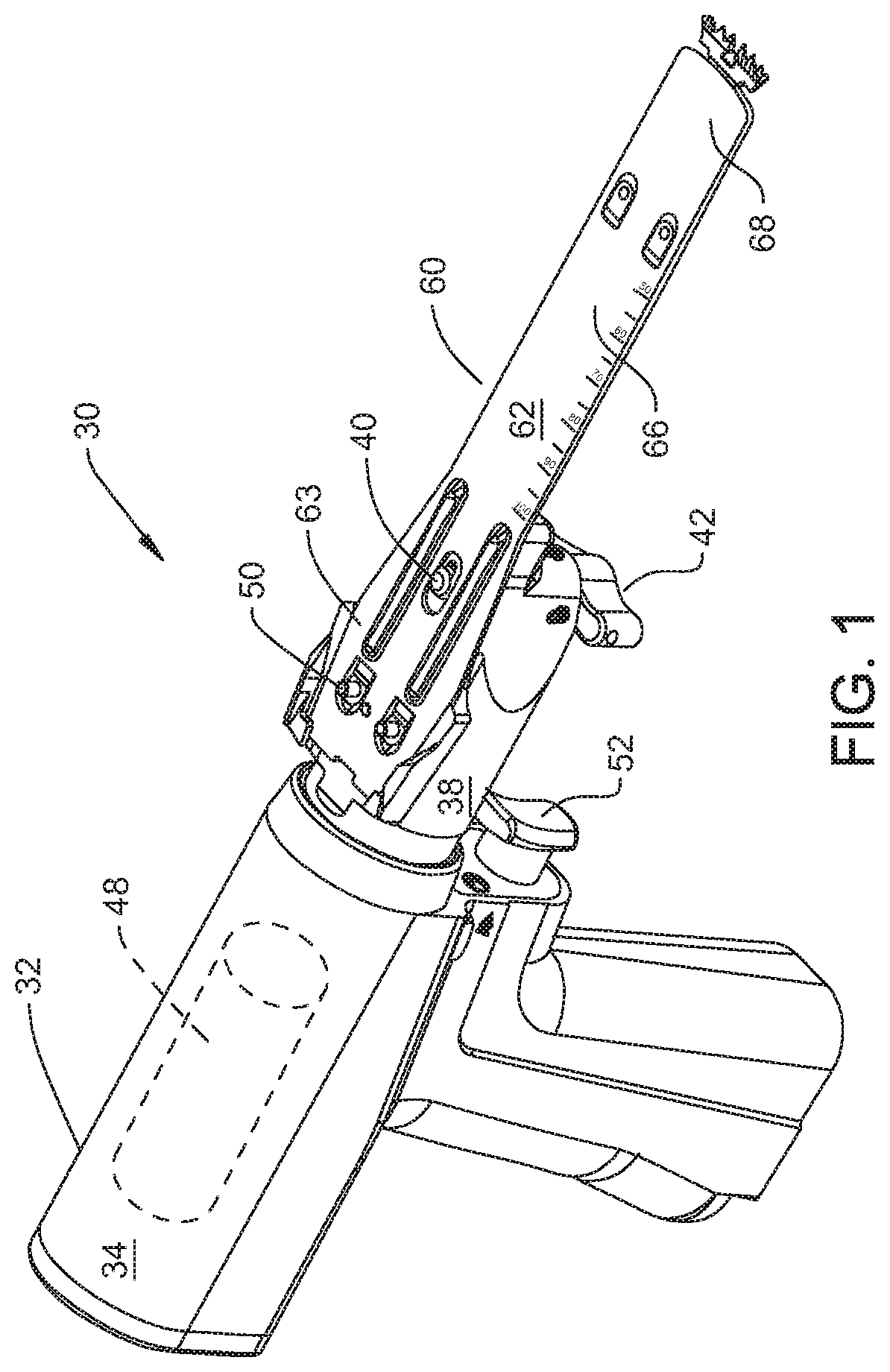

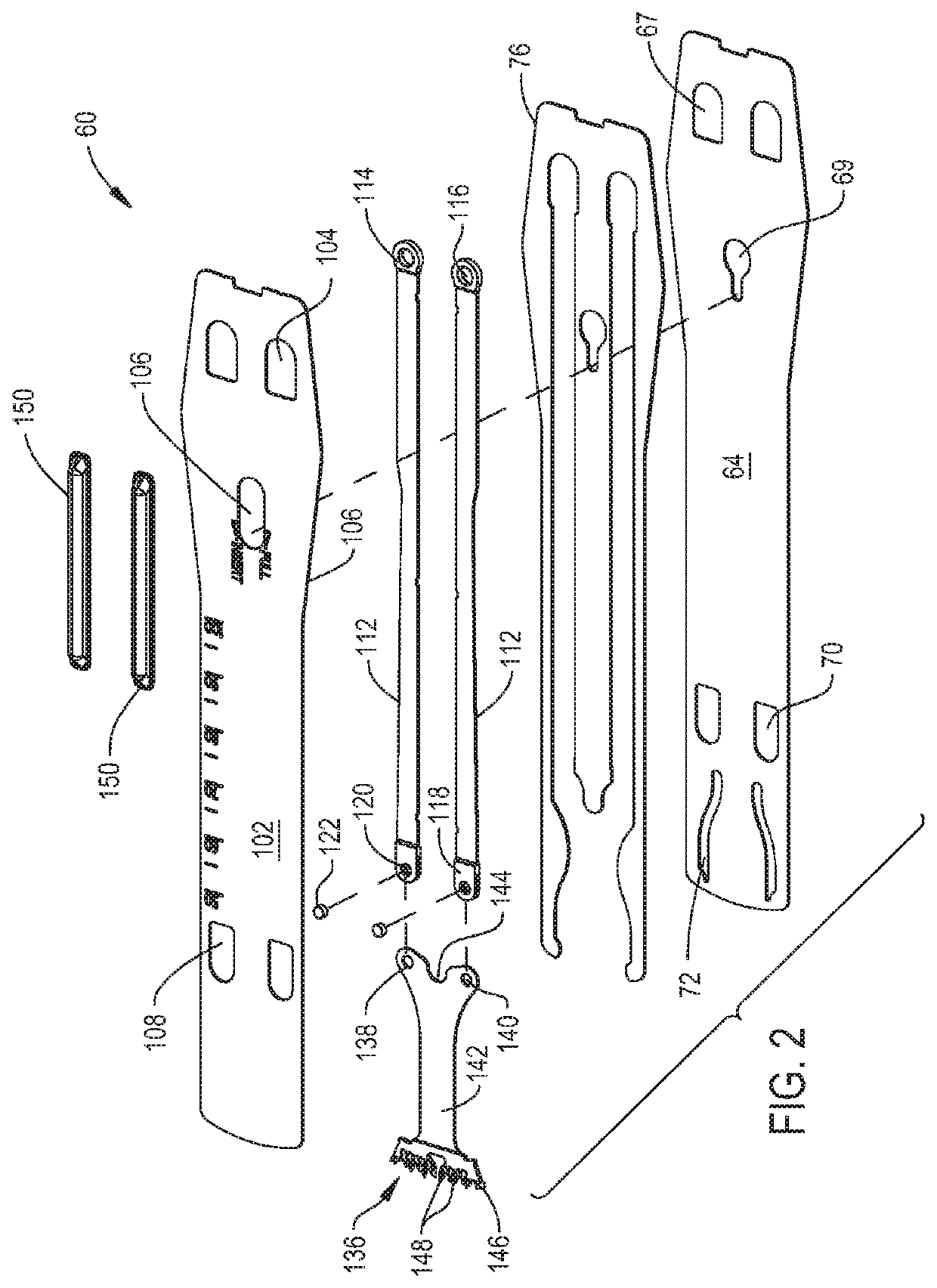

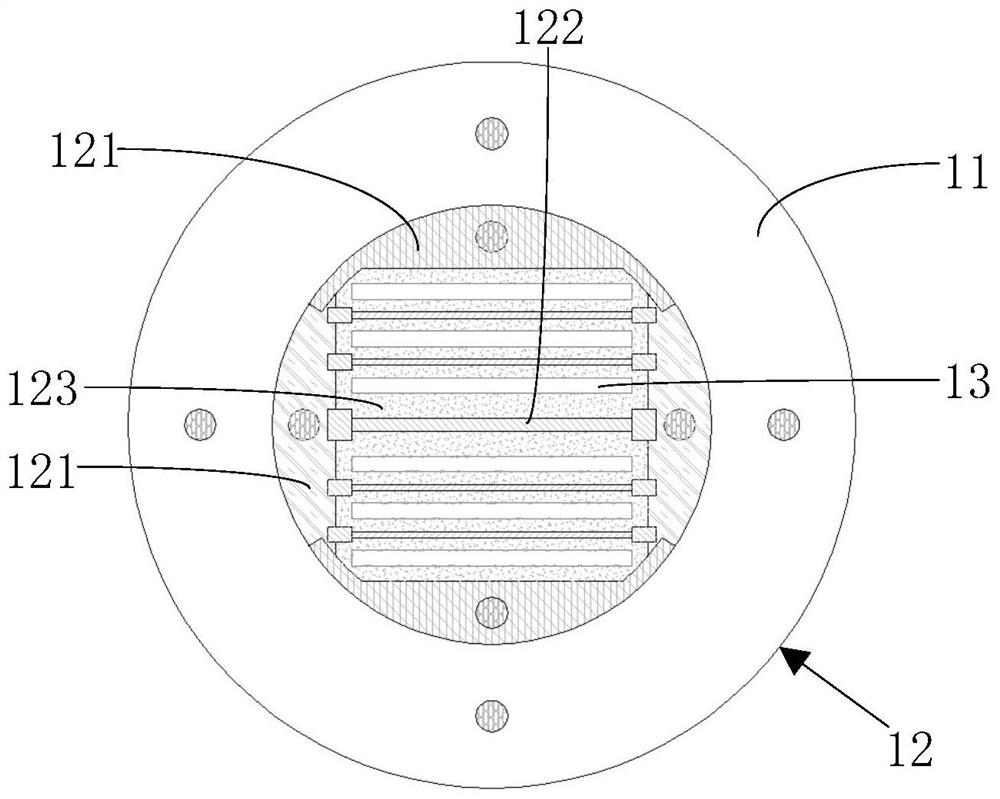

Surgical sagittal blade cartridge with a reinforced guide bar

ActiveUS20180064448A1Less chance of bendingMetal sawing devicesMetal sawing toolsEngineeringMechanical engineering

A surgical sagittal saw cartridge that includes a guide bar formed form an inner plate and opposed outer plates, the inner plate having a head. The cartridge has a blade that is disposed against the head of the inner plate. The inner plate is formed to have an inner tine and two opposed outer tines. The inner tine is formed to define the head against which the blade is disposed. The outer tines extend forward of the inner tine so as to define a space between the outer tines in which the blade is seated.

Owner:STRYKER EURO OPERATIONS HLDG LLC

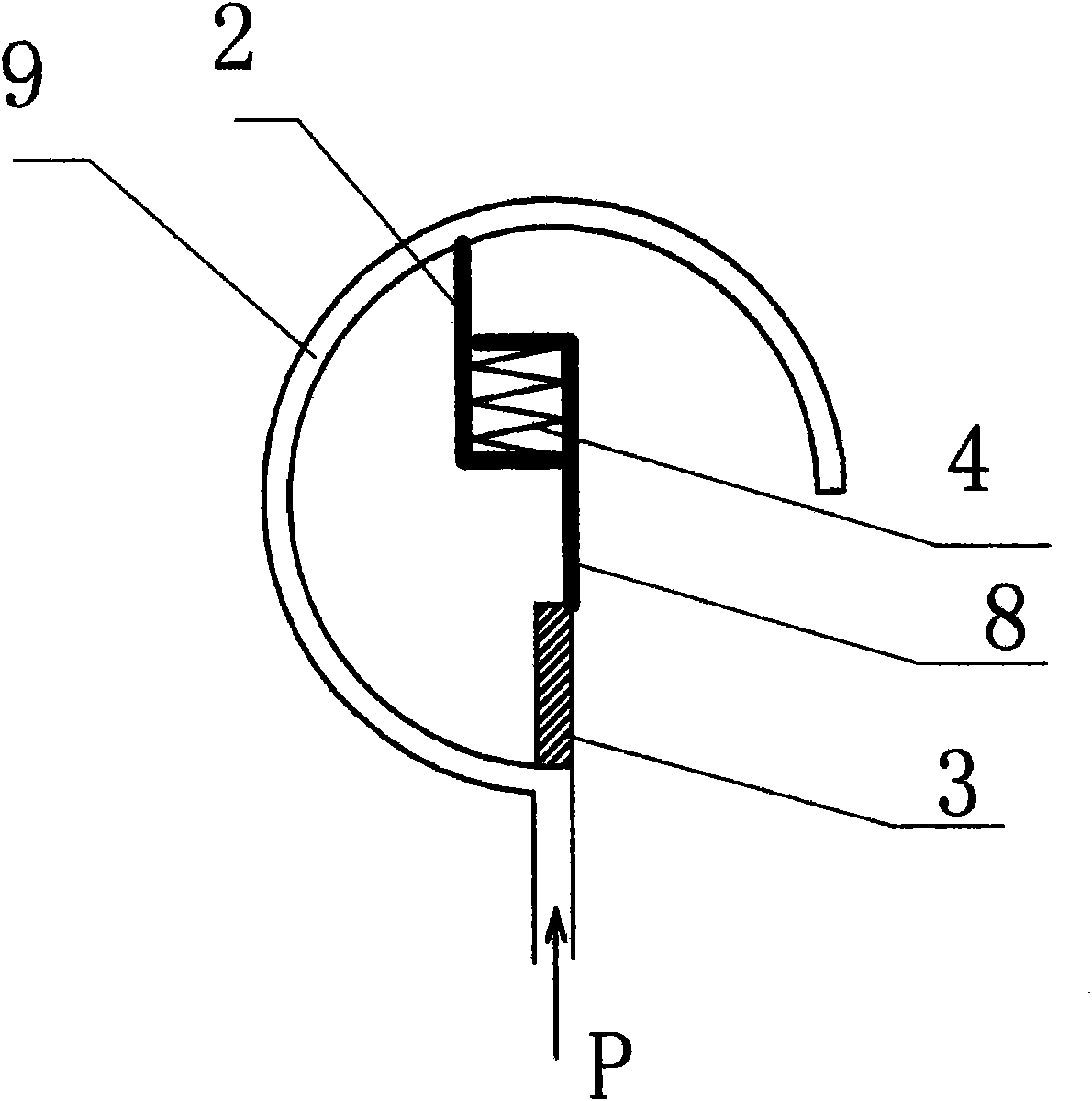

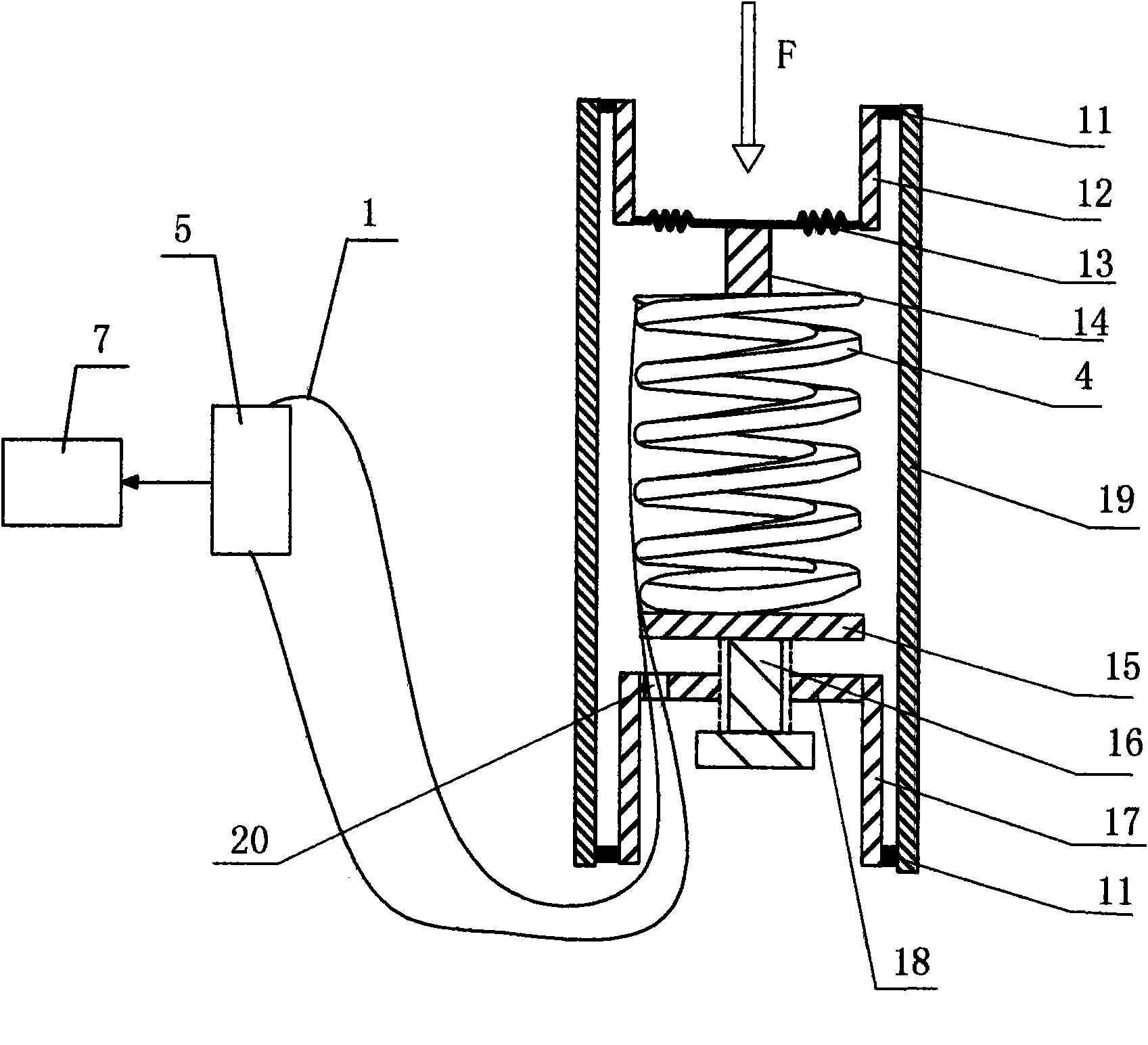

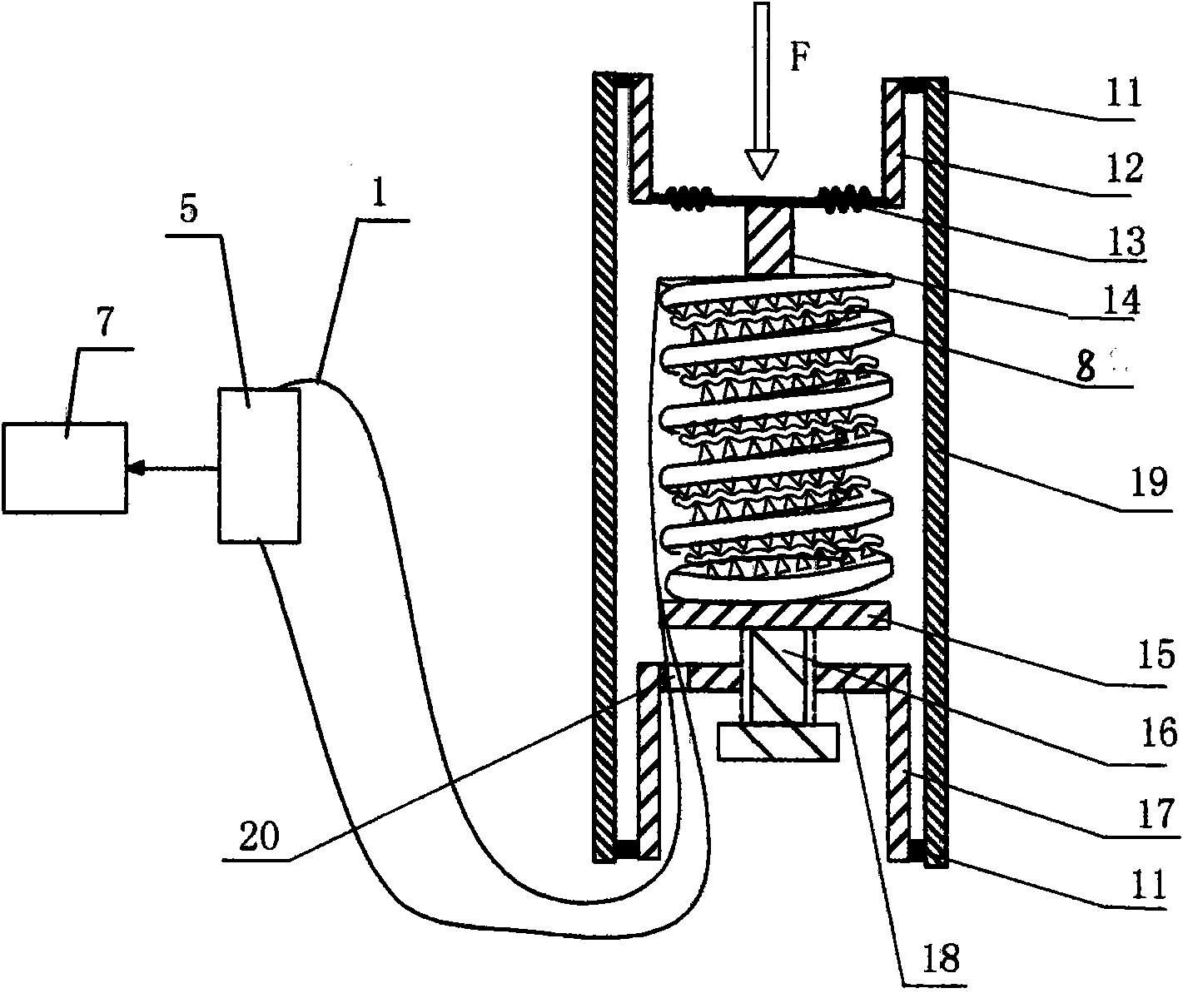

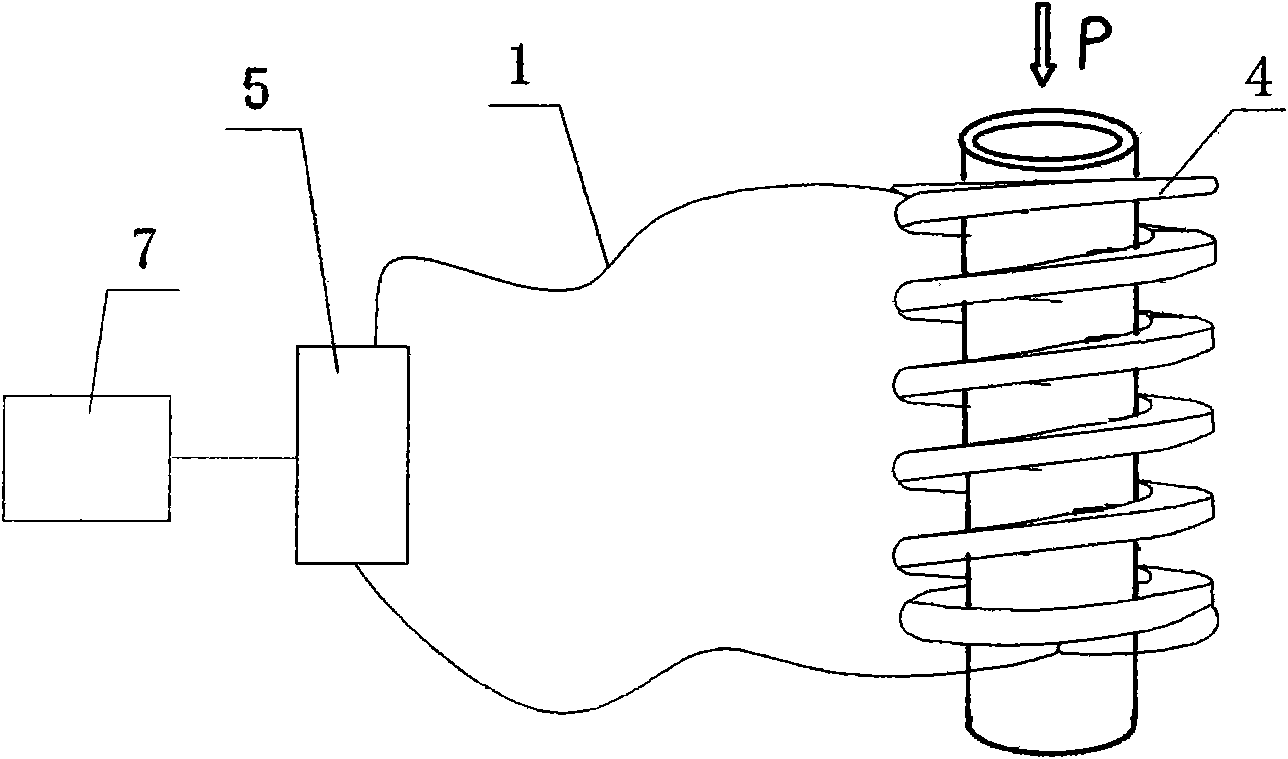

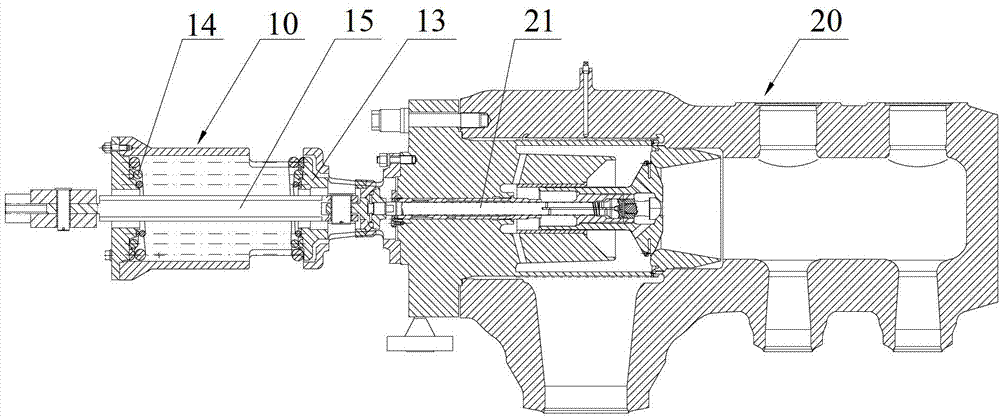

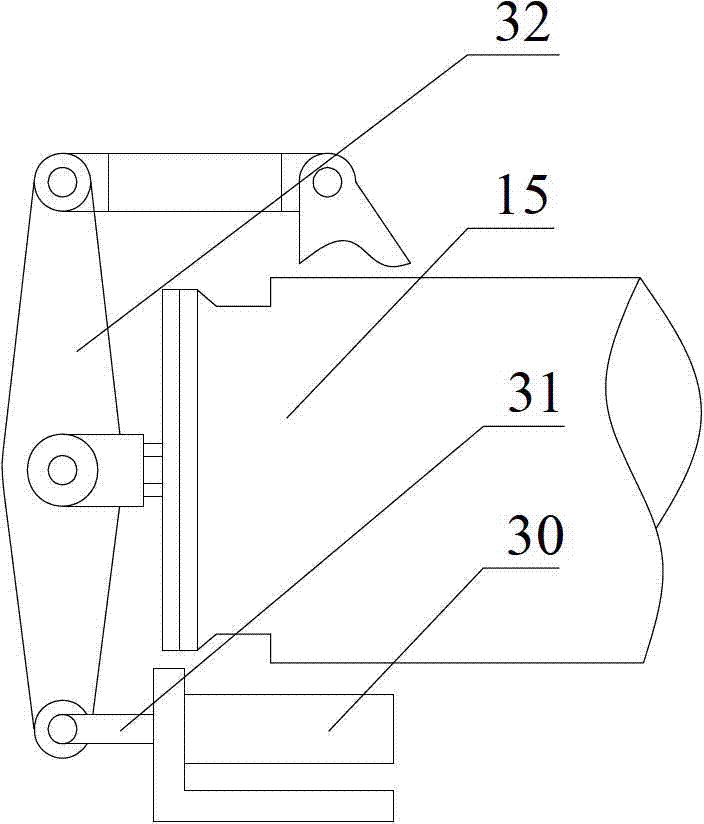

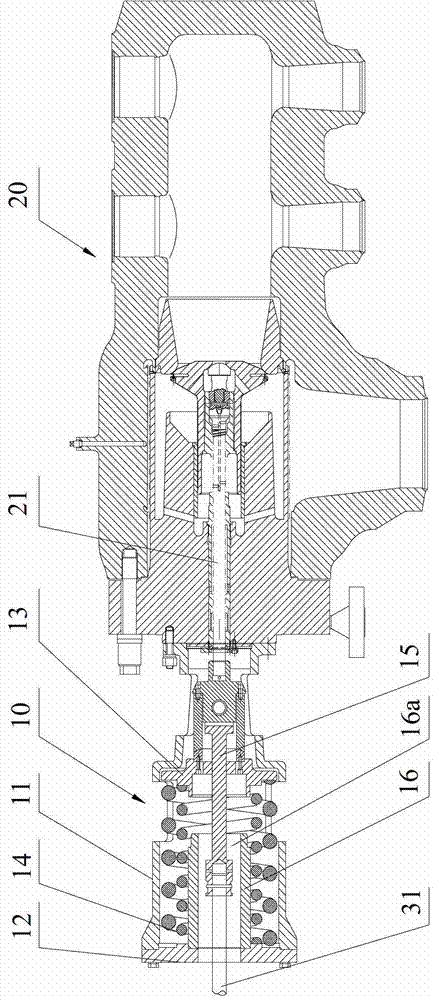

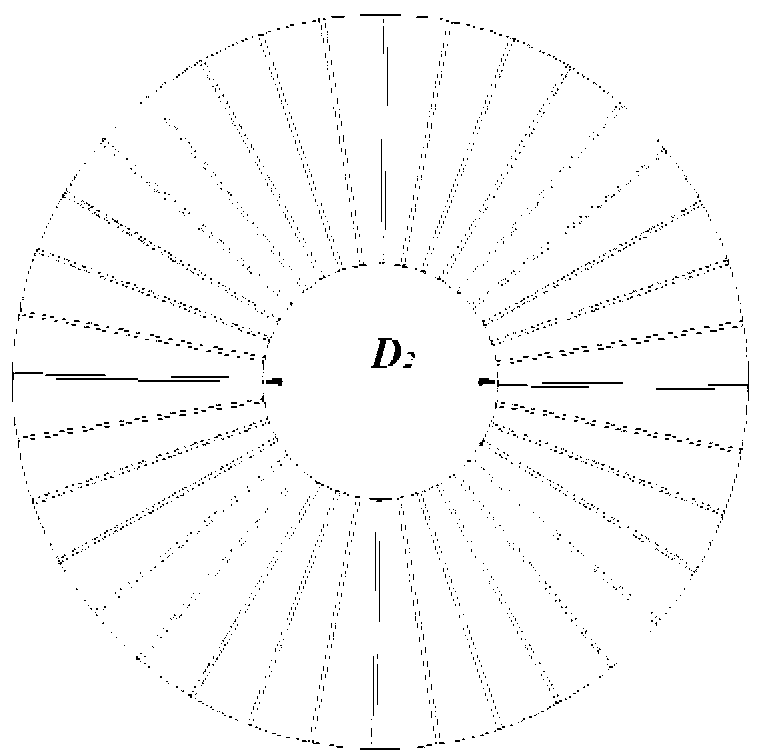

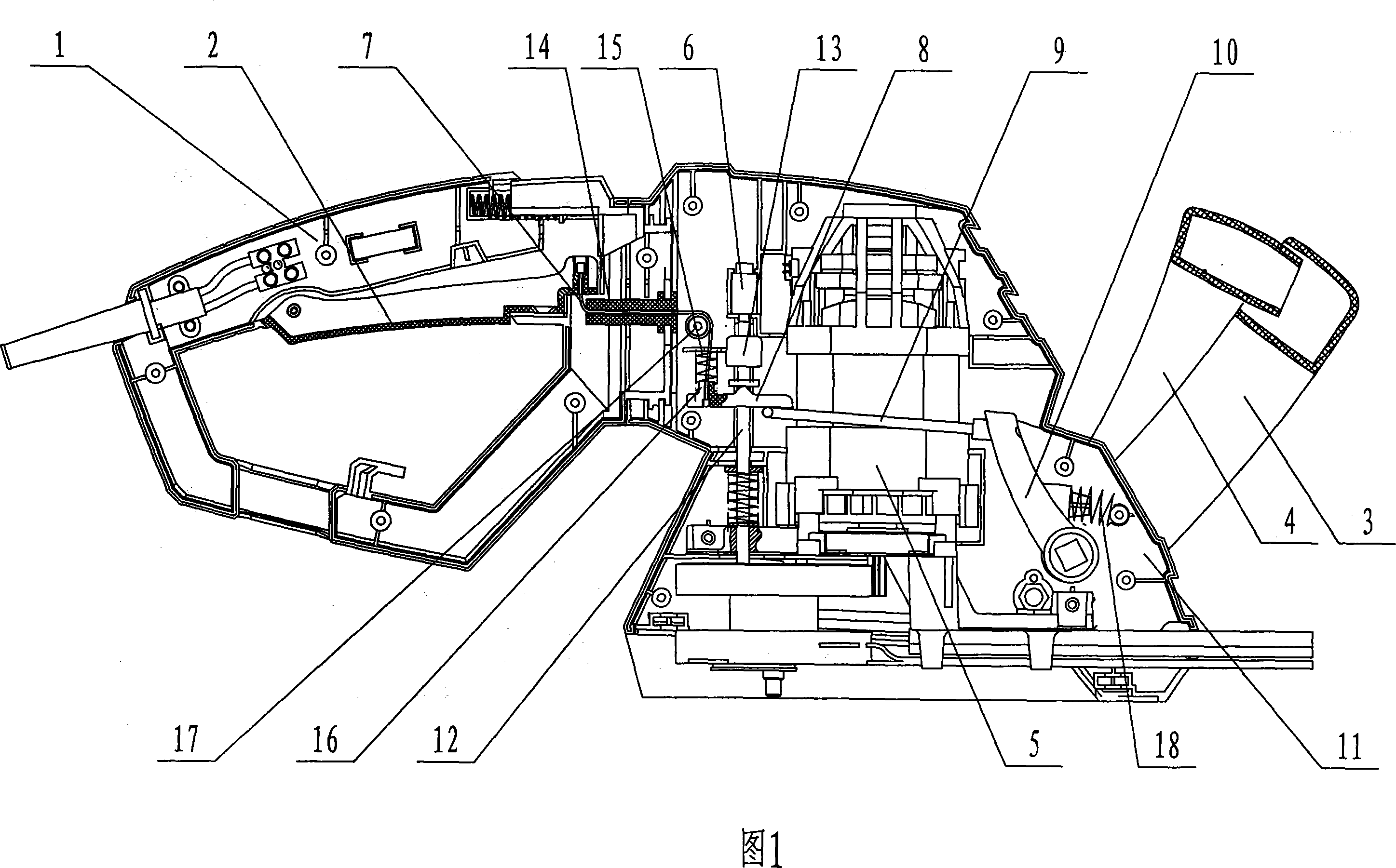

High-pressure main throttle valve apparatus of steam turbine

ActiveCN102865109AReduce lateral forceLess bendingMachines/enginesEngine componentsEngineeringHigh pressure

The invention discloses a high-pressure main throttle valve apparatus of a steam turbine. The high-pressure main throttle valve apparatus comprises a main throttle valve (20) and a spring mechanism (10), wherein the spring mechanism (10) comprises a housing (11), a spring seat (13), a spring (14) and a guide rod (15), wherein the housing (11) is fixed on a main stop valve (11), an end cover (12) is arranged on one end of the spring, the spring seat (13) is movably mounted in the housing along the axial direction, two ends of the spring (14) are respectively mounted on the end cover and the spring seat and respectively apply an elastic force onto the end cover and the spring seat, the guide rod (15) is connected with a valve rod (21) of the main stop valve in the housing, a guide cylinder (16) is fixed in the housing, the spring is sleeved on the guide cylinder (16), the guide rod can move in a hollow cavity (16a) of the guide cylinder, and the spring seat is supported on the guide cylinder (16) when the main stop valve is opened. According to the high-pressure main throttle valve apparatus of the steam turbine, the gravities of the spring seat and the spring are borne by the guide cylinder, the gravity borne by the valve rod is reduced, and the problem that closing time of the main stop valve is too long is avoided.

Owner:CHINA SHENHUA ENERGY CO LTD +2

Optical fiber sensing device based on functional material

InactiveCN102374872ASimple structureReasonable designConverting sensor output opticallyEffective lengthEngineering

The invention discloses an optical fiber sensing device based on a functional material, which comprises a multi-ring slightly bent element for clamping a signal optical fiber, wherein at least one part of the multi-ring slightly bent element is made by the functional material, i.e., all or part of deformed teeth, or all or part of regions in which the deformed teeth are fixed is made by the functional material, and the functional material varies with the change of physical quantities to be tested. The distance between the deformed teeth in the multi-ring slightly bent element is changed when the physical quantities to be tested change, so that the bending curvature of the signal optical fiber clamped between the deformed teeth is changed, and thus the power of an optical signal transmitted in the signal optical fiber is obviously changed, and the change size of the physical quantities to be tested is tested by the detection of a testing unit. The multi-ring slightly bent element is adopted, so that the effective length of the signal optical fiber is lengthened, the bending curvature of the signal optical fiber is reduced, and thus the precision is improved, the service life is prolonged, and the device has broad application prospects.

Owner:XIAN JINHE OPTICAL TECH

Novel high voltage optical fiber sensing device

InactiveCN102565499ARegular length extensionHigh precisionCurrent/voltage measurementVoltage/current isolationEngineeringHigh pressure

The invention discloses a novel high voltage optical fiber sensing device, which comprises an electrode I, a ground potential electrode and at least one optical fiber sensitive unit which is located between the electrode I and the ground potential electrode, wherein a high-voltage bus loads the high voltage of the high-voltage bus on the optical fiber sensitive unit through the electrode I and the ground potential electrode; the optical fiber sensitive unit comprises a cylinder; at least one curved groove is distributed on the side face of the cylinder; A-sided deformation teeth and B-sided deformation teeth are distributed on the two opposite surfaces in the groove and correspond to each other in a staggered way; a signal optical fiber is clamped between the A-sided deformation teeth and the B-sided deformation teeth and is connected with an optical cable; the optical cable is connected with a testing unit; and the testing unit is connected with a processing unit. According to the novel high voltage optical fiber sensing device, subtle deformation can be detected by greatly increasing the number of the deformation teeth and greatly increasing the length of the signal optical fiber.

Owner:XIAN JINHE OPTICAL TECH

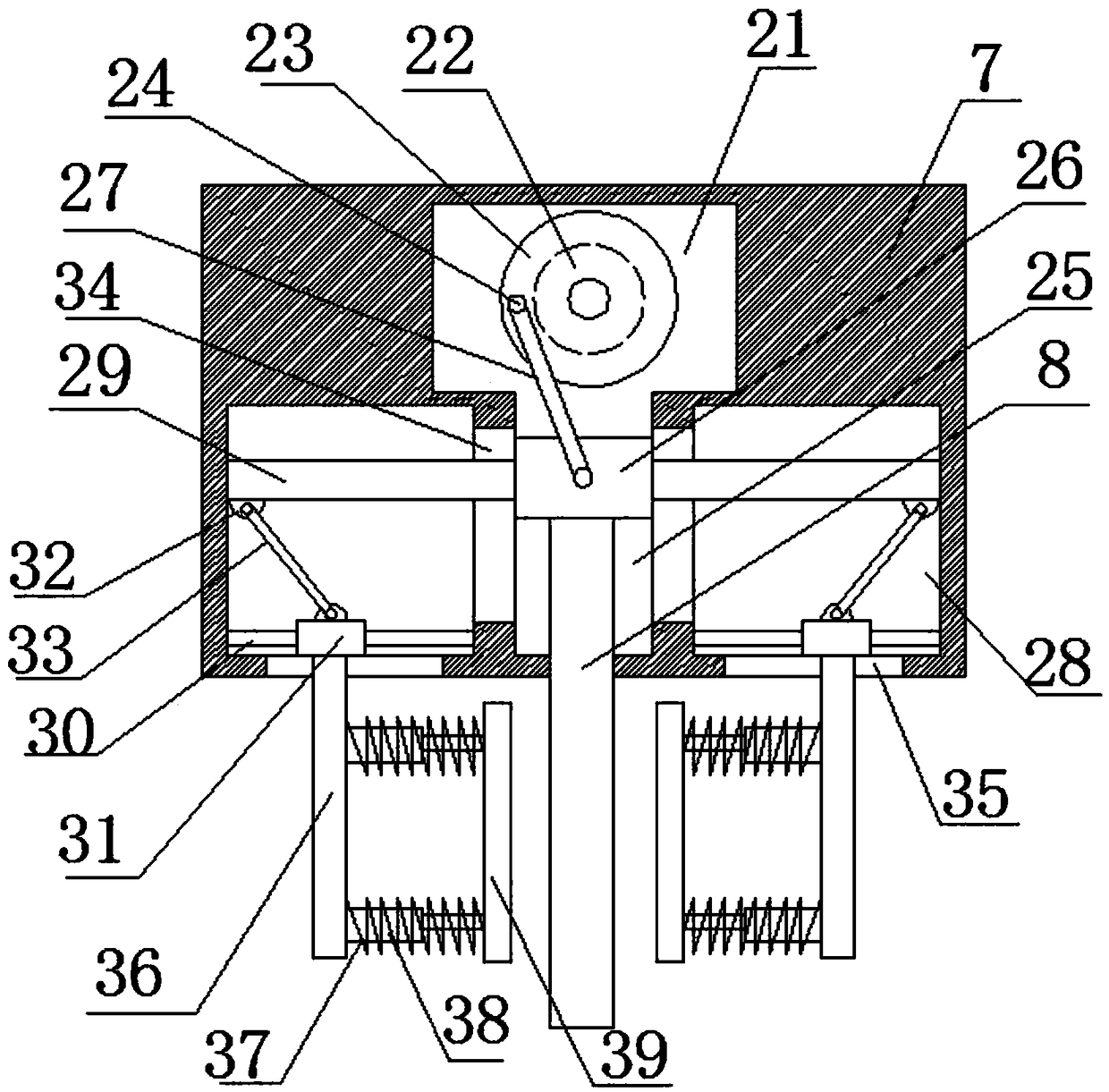

Rammer compactor with high stability for building construction

InactiveCN109137875AWill not increase the burdenWon't shakeSoil preservationBuilding constructionChassis

The invention discloses a rammer compactor with high stability for building construction. The rammer compactor comprises a base frame, wherein slide ways are arranged at the lower end of a motor cavity, sliding blocks are arranged in the slide ways, and drive cavities are formed at the position, located on the two sides of the slide ways, of the interior of a machine body. Vertical sliding groovesare formed between the drive cavities and the slide ways, and lifting rods extending to the drive cavities through the vertical sliding grooves symmetrically arranged on the left and right sides of asliding block. Sliding rods are arranged on the lower portions of the drive cavities, moving seats are slidably connected with the sliding rods, and connecting seats are arranged on the upper sides of the moving seats and the left ends of the front sides of the drive rods. Two connecting seats are connected with each other through a drive rod, and transverse sliding grooves are formed in the lower ends of the drive cavities. The lower ends of the moving seats abut against the drive cavities, and supporting plates extending out of the drive cavities through the transverse sliding grooves are connected to the lower ends of the moving seats. Telescopic rods are arranged on the inner sides of the supporting plates, limiting plates are arranged at the inner ends of the telescopic rods, and buffer springs are arranged on the outer sides of the telescopic rods. The rammer compactor with high stability for the building construction has simple structure, convenient use, good tamping effect, long service life and high practicability.

Owner:湖北金丰建筑工程有限公司

Surgical Sagittal Blade Cartridge With A Reinforced Guide Bar

ActiveUS20200315632A1Less chance of bendingMetal sawing devicesMetal sawing toolsPhysical medicine and rehabilitationTine

A surgical sagittal saw cartridge that includes a guide bar formed from an inner plate and opposed outer plates, the inner plate defining a head. The cartridge has a blade that is disposed against the head of the inner plate. The inner plate may comprise an inner tine and / or two opposed outer tines. The inner tine may be formed to define the head against which the blade is disposed. The outer tines extend distally so as to define a space between the outer tines in which the blade is seated.

Owner:STRYKER EURO OPERATIONS HLDG LLC

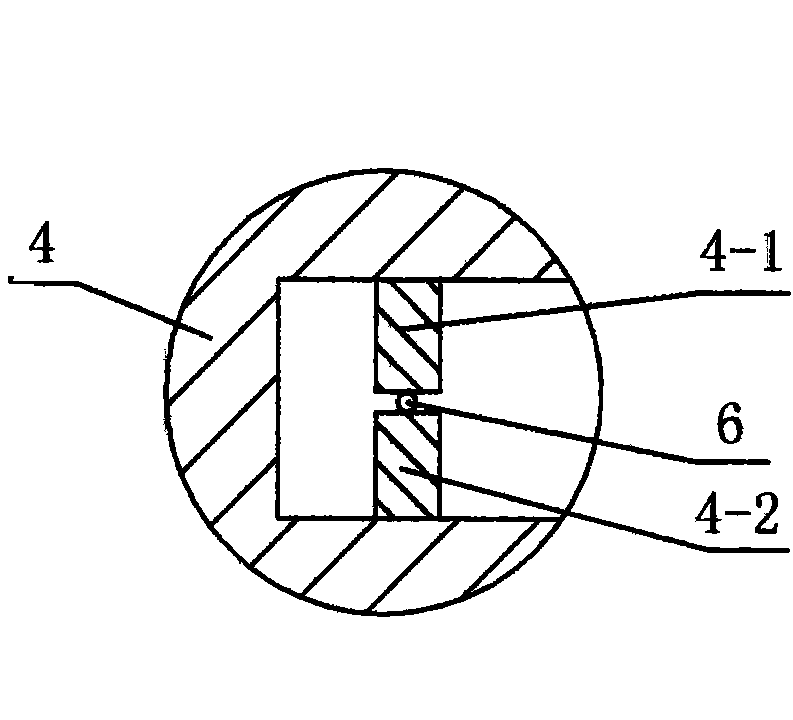

Mechanical-damping-type yarn tensioner without skimming wear

The invention relates to a mechanical-damping-type yarn tensioner without skimming wear. The tensioner is characterized in that a pair of large-diameter tension plates is used, and tension adjustment is achieved through the facts that a flaky spring is pushed and pressed towards a rotor through a tension adjustment screw, the rotor is rubbed to produce damping force, the damping force is adjusted through adjustment of push force of the tension adjustment screw, the damping force is transferred to yarns through the tension plates due to the fact that the pair of the large-diameter tension plates and the rotor are fixedly assembled together, and accordingly the yarn tension adjustment is achieved. Due to the pure mechanical type adjustment mode, relative sliding between the yarns and parts providing the damping force does not exist, the yarn bending radius is large, the yarn bending curvature is small, and the yarn tensioner is suitable for glass fiber and rock fiber which are not bending-resistant and friction-resistant, simple, practical, reliable, high in quality and low in price.

Owner:窦其勇

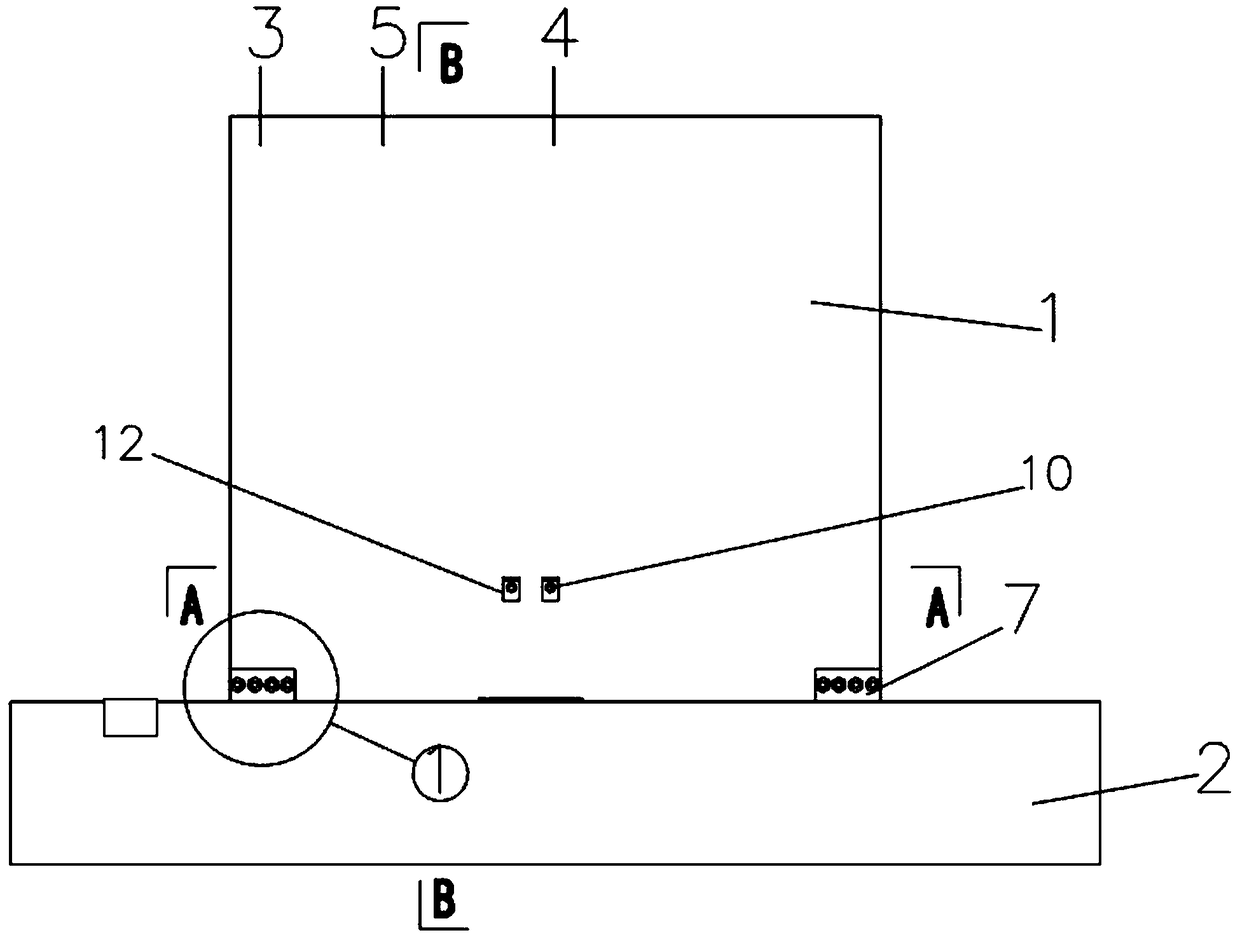

Self-resetting fabricated shear wall structure connecting device

The invention provides a self-resetting fabricated shear wall structure connecting device. The connecting device comprises a prefabricated shear wall and a foundation shear wall, and the prefabricatedshear wall is internally provided with a steel reinforcement cage and a plurality of longitudinal bars. The connecting device is characterized in that the prefabricated shear wall comprises an end confined region, a middle confined region and a distributing reinforcement region, wherein the middle confined region is located in the middle of a wall body of the prefabricated shear wall, the end confined region is located at both ends of the wall body of the prefabricated shear wall, and the distributing reinforcement region is located between the end confined region and the middle confined region; the purpose is to apply energy-dissipation earthquake-reduction to the fabricated structure, according to the connecting mode, the energy dissipation capacity of the shear wall structure is improved, the shear wall has self-resetting capacity under lateral loads, the seismic demand of the whole structure can be reduced, and the seismic performance of the main structure is improved; and at thesame time, the connecting device has the characteristic of easy industrial production and is more efficient and quicker, and the problems of inconvenience and pollution of energy consumption caused byon-site wet working are avoided.

Owner:CHINA MCC17 GRP

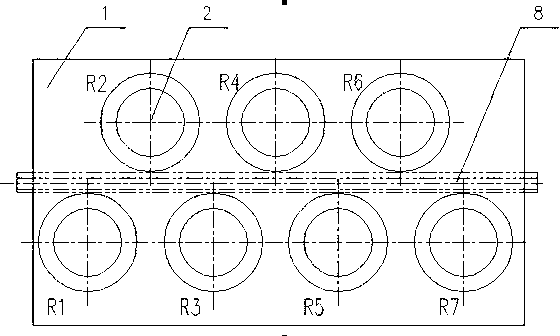

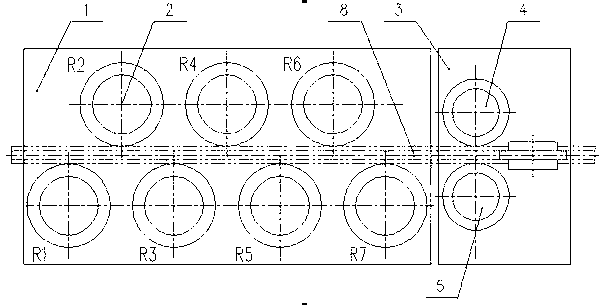

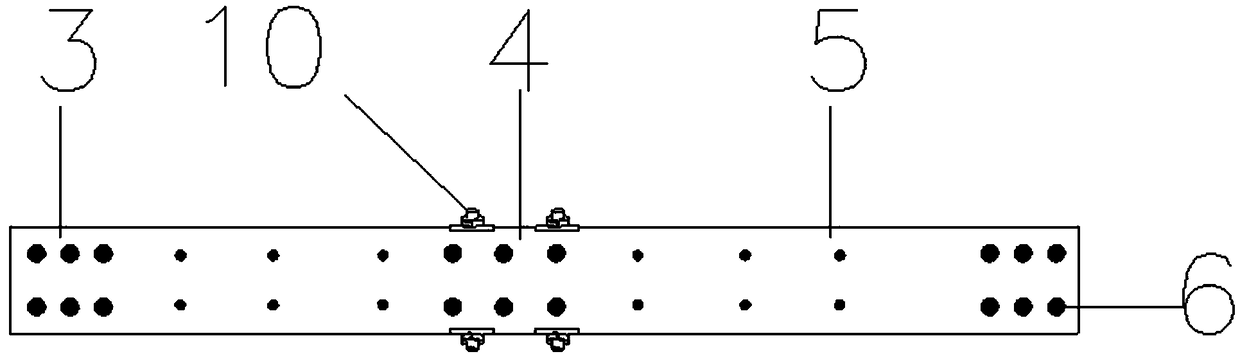

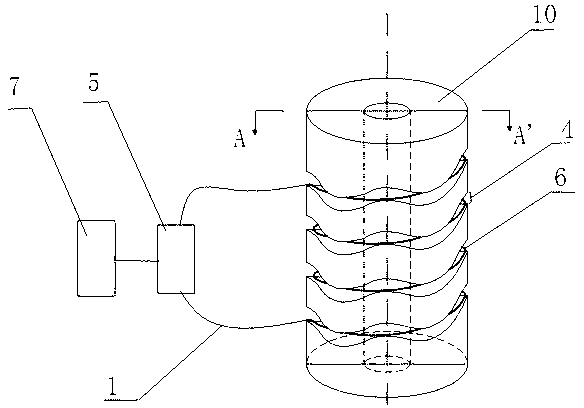

Air-injection vortex-spinning groove-shaped self-twist hollow spindle

InactiveCN103305980AImprove cohesionReduce the ratioContinuous wound-up machinesOpen-end spinning machinesFiberYarn

The invention relates to an air-injection vortex-spinning groove-shaped self-twist hollow spindle which comprises a fiber inlet (1), a yarn forming channel (2), a circumferential step groove (4), conical top plane arc grooves (5) and conical top wall face spiral grooves (3), wherein square groove bodies on a conical top plane of the hollow spindle are arc; included angles between the conical top wall face grooves and a horizontal direction are 20-40 degrees; the circumferential groove is step-shaped; and the quantity of steps is 1-3. According to the spindle, positive pressure bonded between a fiber at a free end and a wall face of the hollow spindle in a spinning process can be increased, and a friction force between the fiber and the wall face is increased, so that the twisting possibility of the fiber is improved, a cohesive force between the fibers in a yarn is increased, and the strength of the yarn is improved finally; in addition, the loss of the fibers can be reduced; and a use ratio of the fibers can be increased.

Owner:DONGHUA UNIV

Hot rolled plate shape improving method

InactiveCN107695096AAvoid defectsLow costWork treatment devicesMetal rolling arrangementsSlow coolingHot rolled

The invention belongs to the technical field of hot continuously rolled plate and strip production and particularly relates to a technique for solving the problem of cambers of hot rolled plates. In order to solve the technical problem, a hot rolled plate shape improving method is provided and includes that a coiled steel billet is put into a slow cooling pit for slow cooling within 60min. By adoption of the slow cooling pit for production of hot rolled steel coils, cambers are smaller than 2.0mm / 10m in use. By adoption of the method, probability of camber occurrence in a utilization process of steel plates is greatly reduced.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

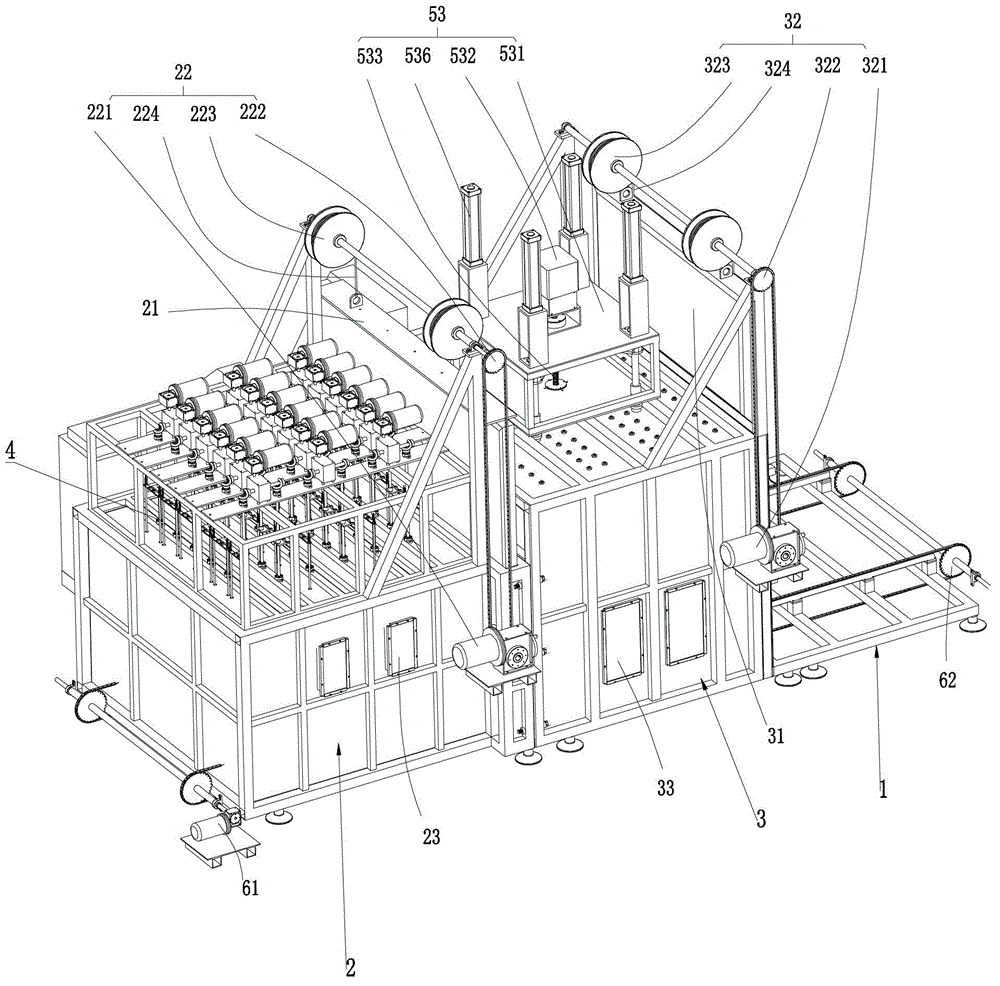

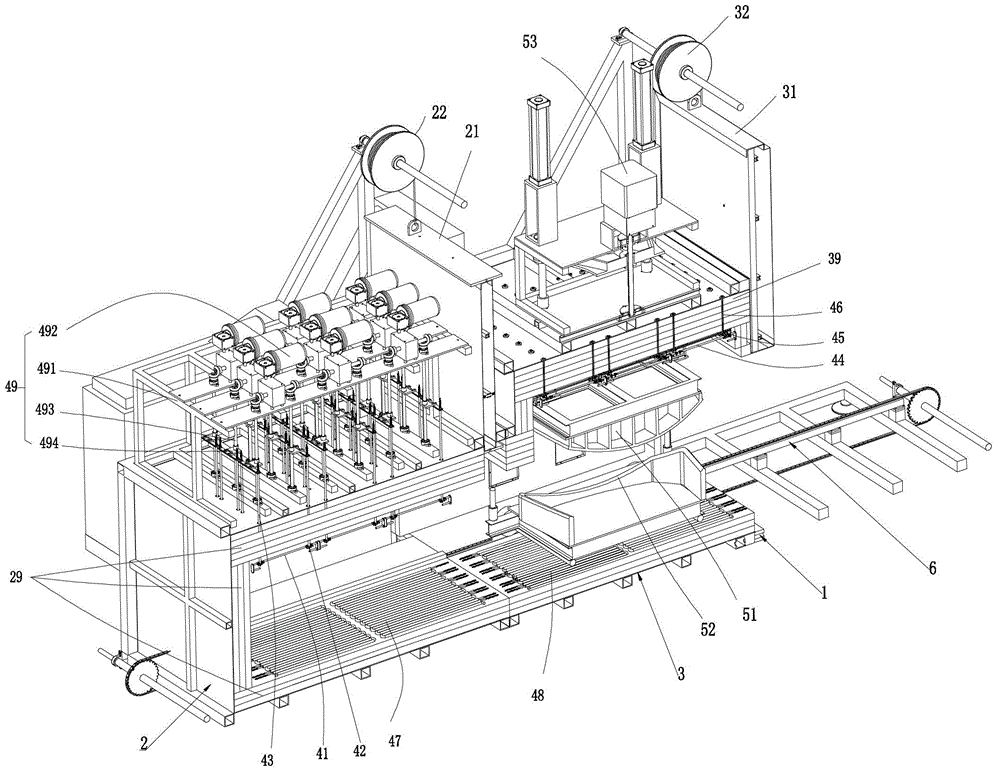

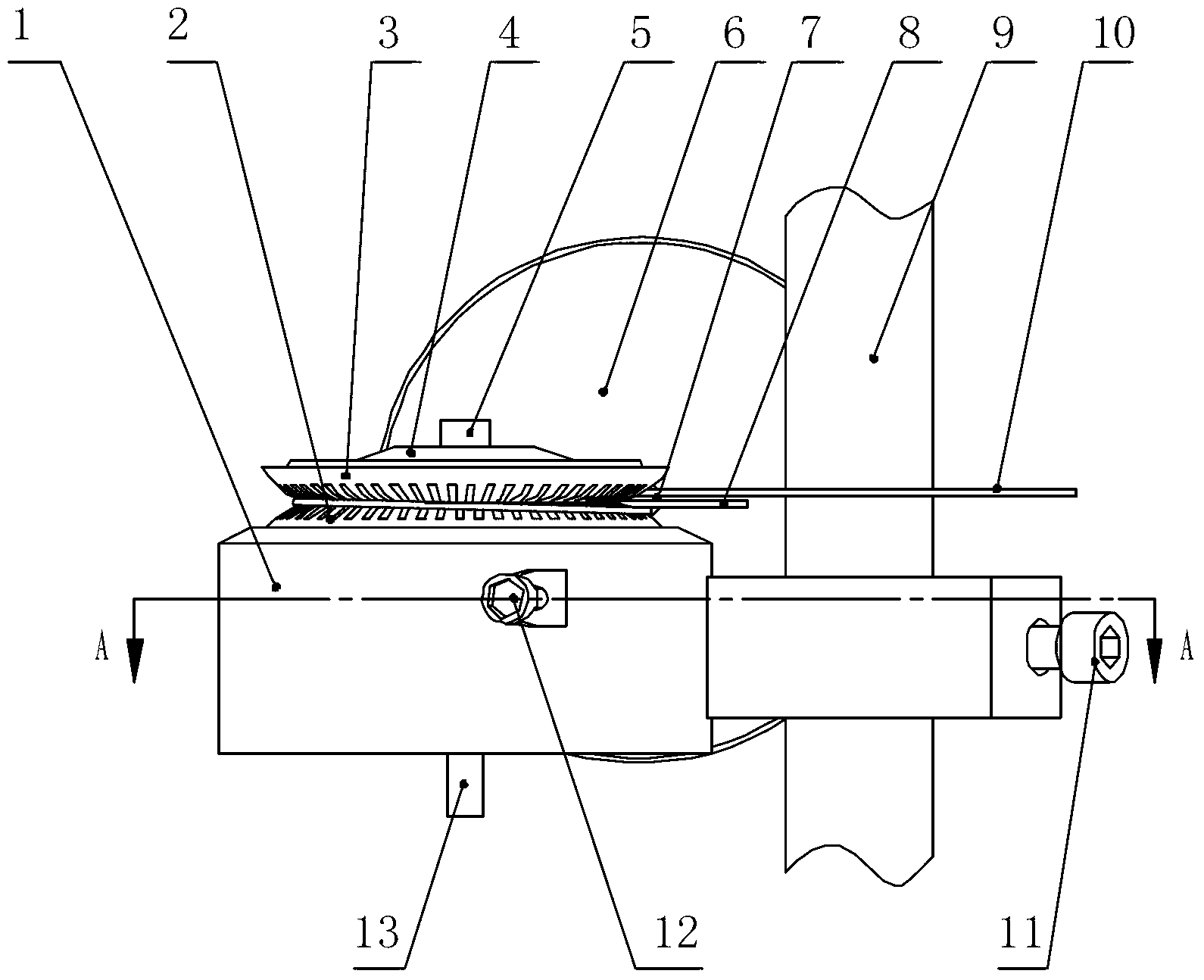

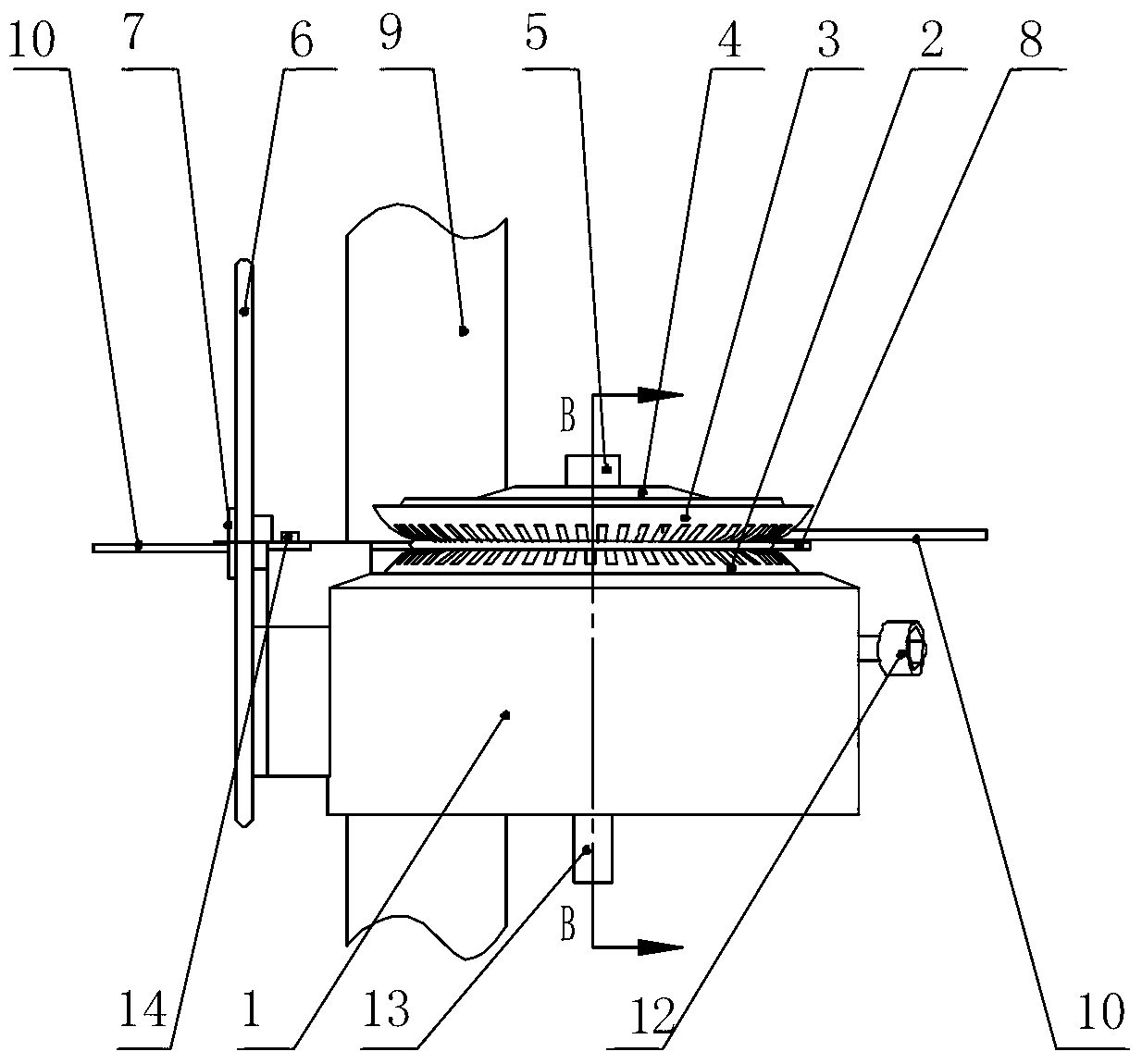

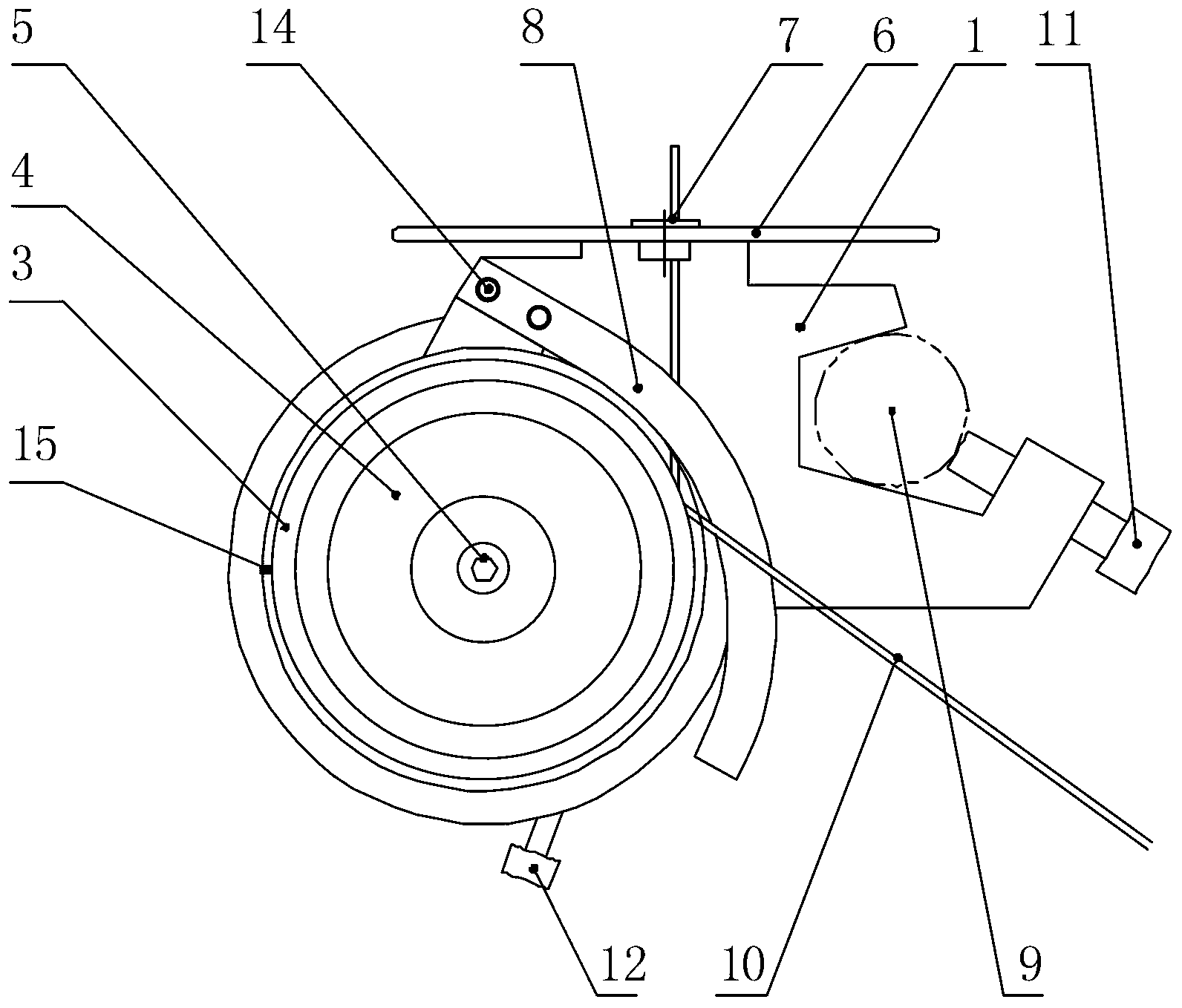

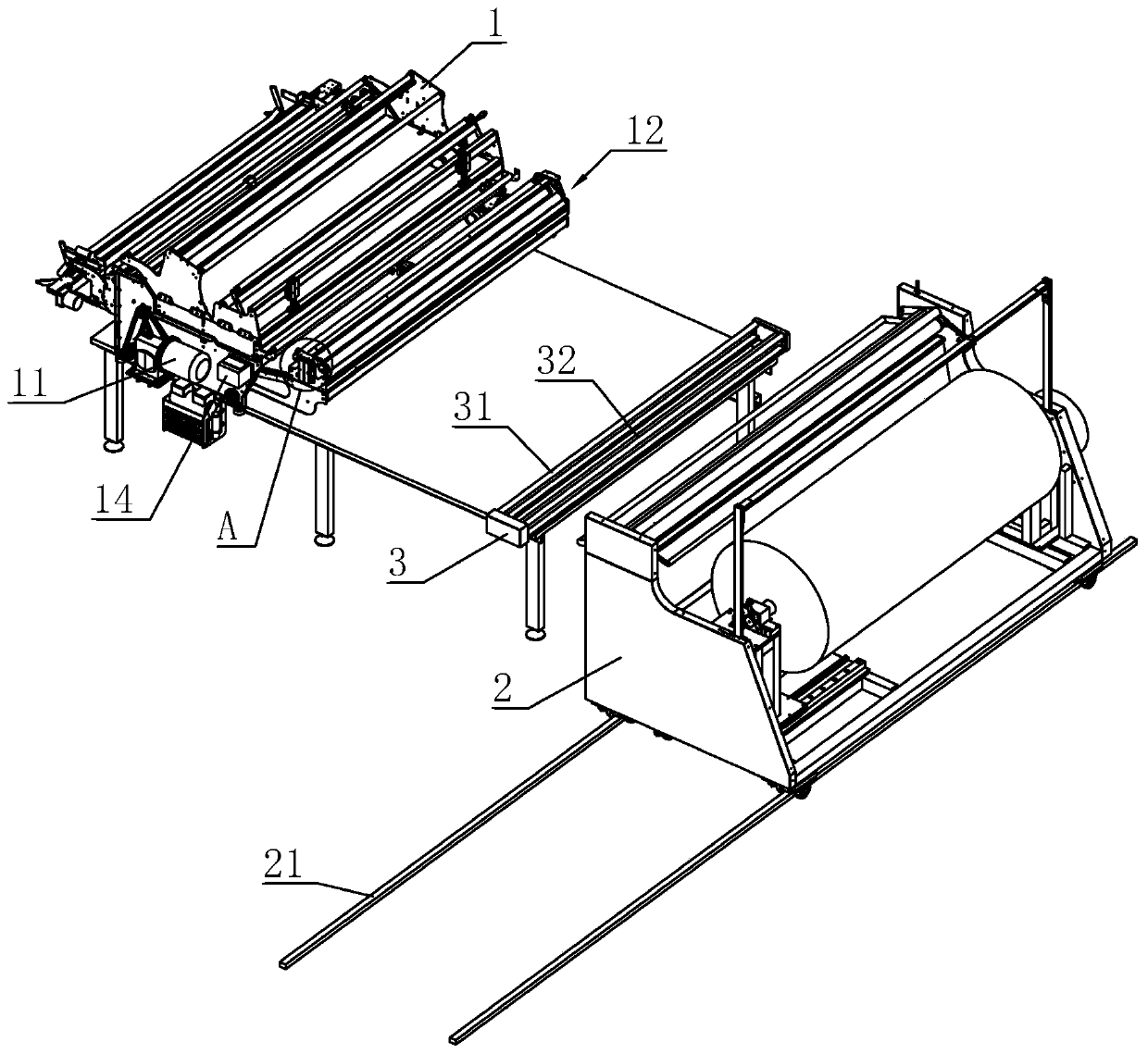

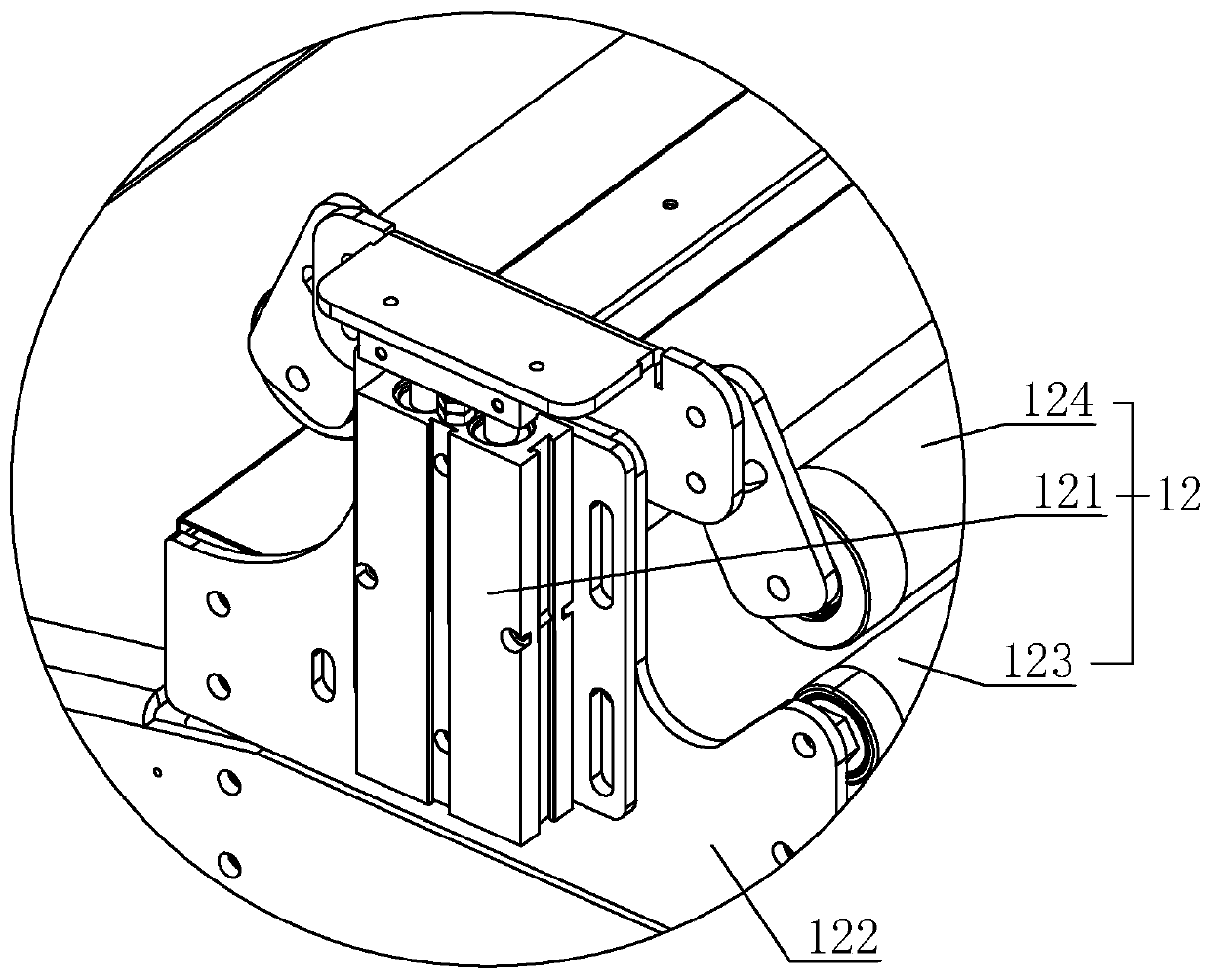

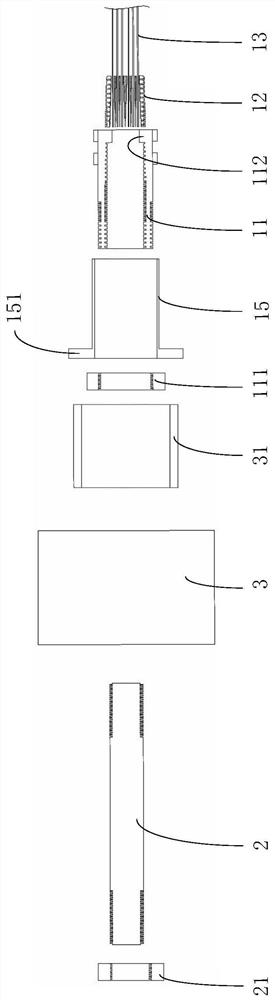

Full-automatic feeding machine

ActiveCN101905357AImprove milling qualityReduce labor intensityMetal sawing tool makingEngineeringLinear motion

The invention discloses a full-automatic feeding machine for feeding band saw plates, comprising a stand, a reciprocating feed mechanism installed on the stand and a feeding support connected with one end of the reciprocating feed mechanism, wherein a supporting limit mechanism ensuring the feeding support to do linear motion relative to the stand in the feed direction A of the reciprocating feed mechanism is arranged between the feeding support and the stand. The machine realizes full-automatic feeding, dispenses with manual attendance and management, reduces the labor intensity of workers, improves the production efficiency, reduces the bend probability during composite feeding, improves the milling teeth quality, is safe and reliable, occupies less space and is low in equipment set cost and maintenance cost. Besides, the selection space of the specifications of the composites is larger during gear milling, and the number of the composite plates to be processed each time can be flexibly selected and is more than the number of the plates to be processed each time in the original feeding mechanisms.

Owner:BICHAMP CUTTING TECH HUNAN

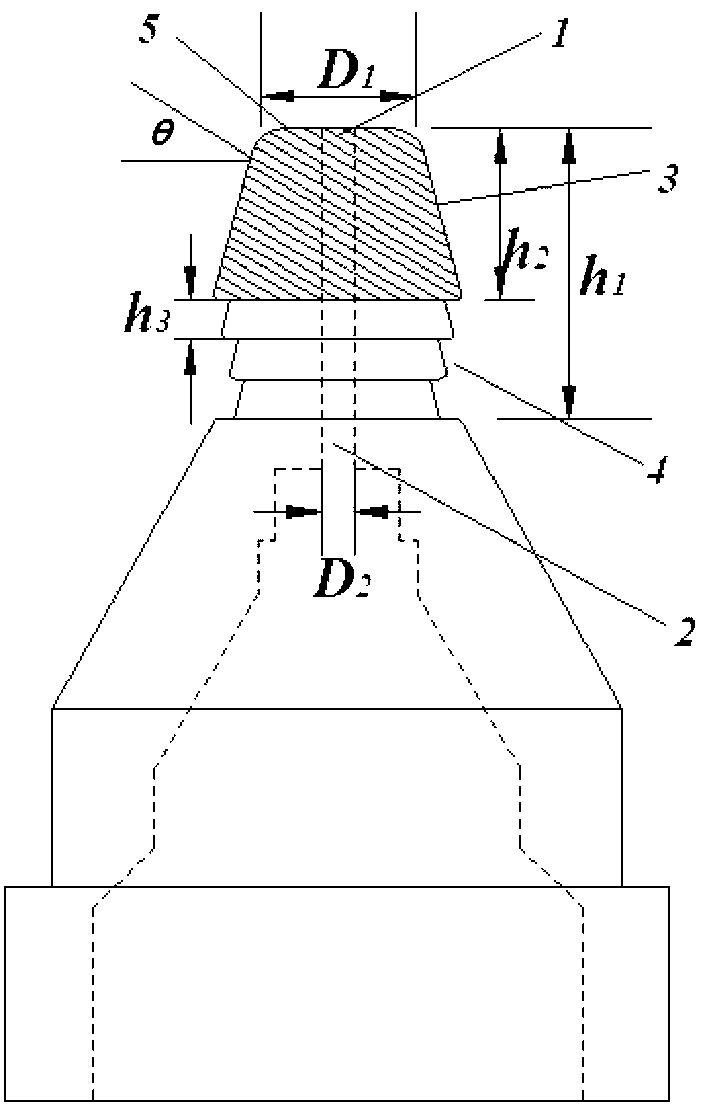

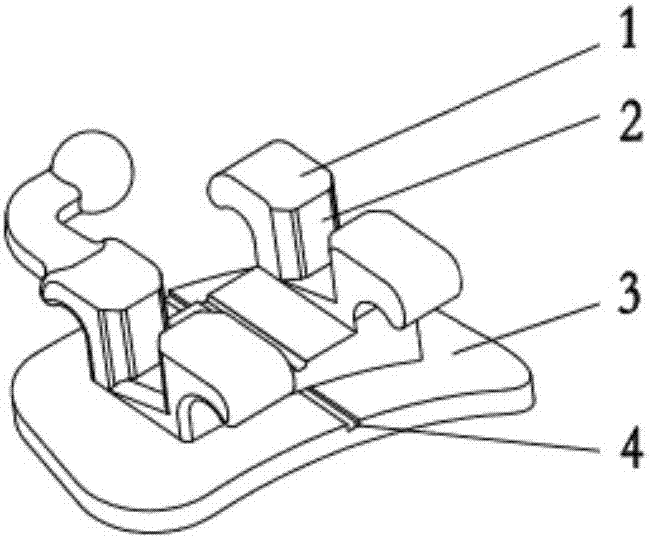

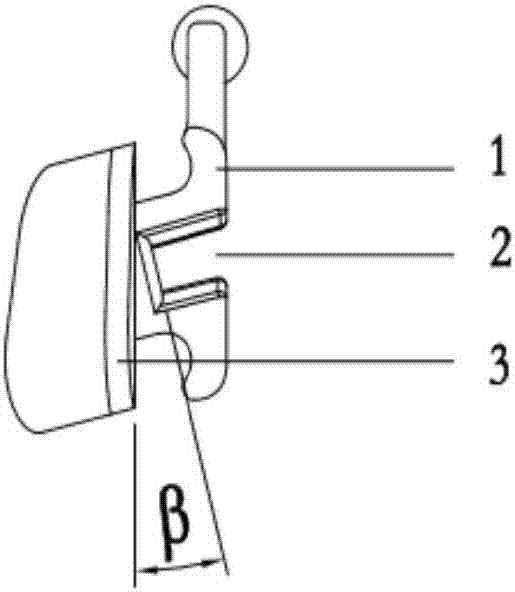

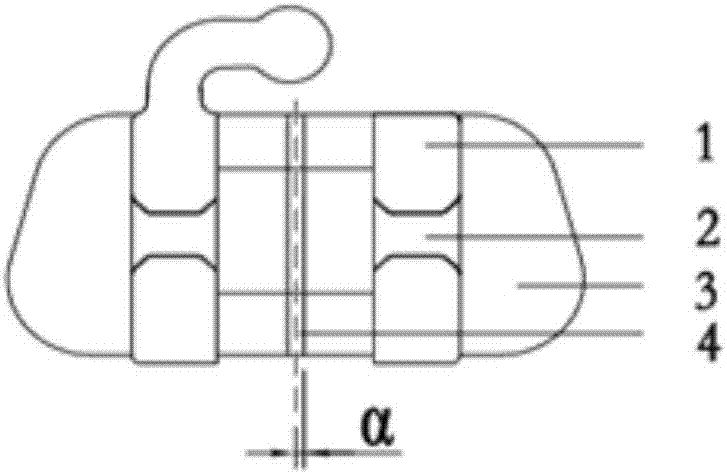

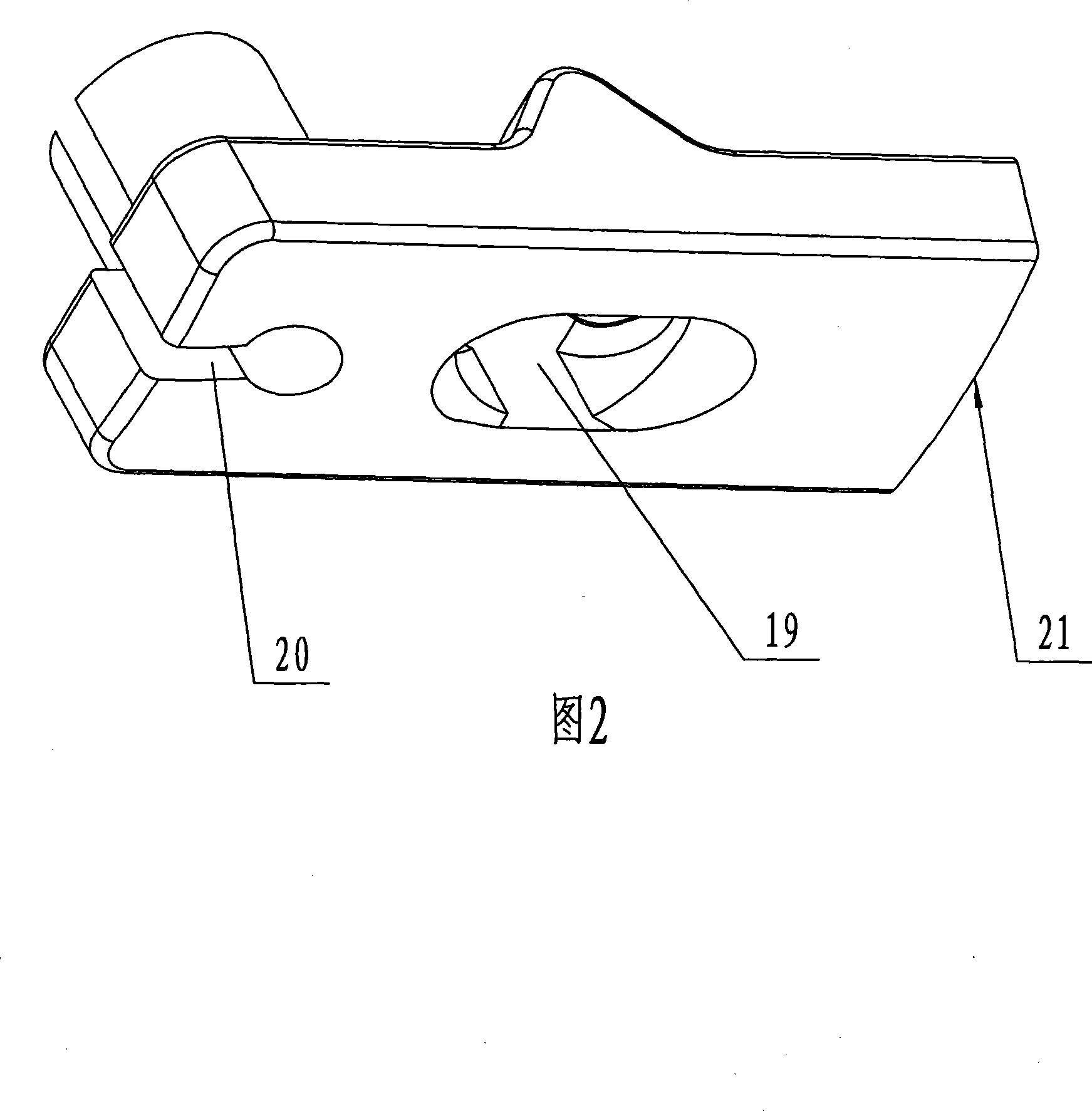

Wx series bracket and buccal tube

InactiveCN107280784AReduce or avoid rotationReduce the chance of bendingBracketsEngineeringTooth position

The invention discloses dentistry appliance used for orthodontic treatment of first molar and second molar, specifically a wx series bracket and buccal tube. The wx series bracket comprises bracket bottom plate; a slot, bracket wings and a position slot are arranged on the bracket bottom plate in sequence; according to different tooth position and molar morphology, the bracket has three offset angles with different angles, namely theta1, theta2 and theta3, wherein, theta1 is 4 to 10 degree, theta2 is -5 to -3 degree and theta3 is 0 degree; wx series buccal tubes comprises a buccal tube bottom plate, a tube body of the buccal tube and a slot of the buccal tube are arranged on the buccal tube bottom plate, a towing hook is arranged on the tube body of the buccal tube. According to different tooth position and molar morphology, the buccal tube has three offset angles with different angles, namely theta'1, theta'2 and theta'3, wherein, theta'1 is 4 to 10 degree, theta'2 is -5 to -3 degree and theta'3 is 0 degree. The wx series bracket and buccal tube is suitable for more different types of orthodontic patient, molar rotation is effectively reduced or avoided and a better occluding relation is built.

Owner:DALIAN UNIVERSITY

Corrugated pipe-based optical fiber stress sensing device

InactiveCN102338676AIncrease the effective bending lengthReduce bending curvatureForce measurement by measuring optical property variationEngineeringStress sensing

The invention discloses a corrugated pipe-based optical fiber stress sensing device. An A-side deformation tooth and a B-side deformation tooth which correspond to each other in a staggering manner are respectively arranged on two opposite surfaces at the sunk place of a corrugated pipe wall, and a signal optical fiber is clamped between two deformation teeth. When a corrugated pipe expands and deforms under stress, a distance between the A-side deformation tooth and the B-side deformation tooth on the corrugated pipe wall changes, so that a bending curvature of the signal optical fiber clamped between the two deformation teeth changes, and bending loss of the signal optical fiber changes, the change degree of the bending loss of the signal optical fiber can be obtained through a test unit, and the stress size of the corrugated pipe can be calculated. The corrugated pipe and an optical fiber micro-bending structure are organically combined to form an intelligent device with many advantages of high precision, soundness and durability, strong adaptability and convenience and flexibility for use. The corrugated pipe-based optical fiber stress sensing device has broad application prospect.

Owner:XIAN JINHE OPTICAL TECH

Cable clamping device

ActiveCN105075042BLess chance of bendingReduce distancePipe supportsElectrical apparatusScrew threadThreaded rod

Owner:CMP PRODS

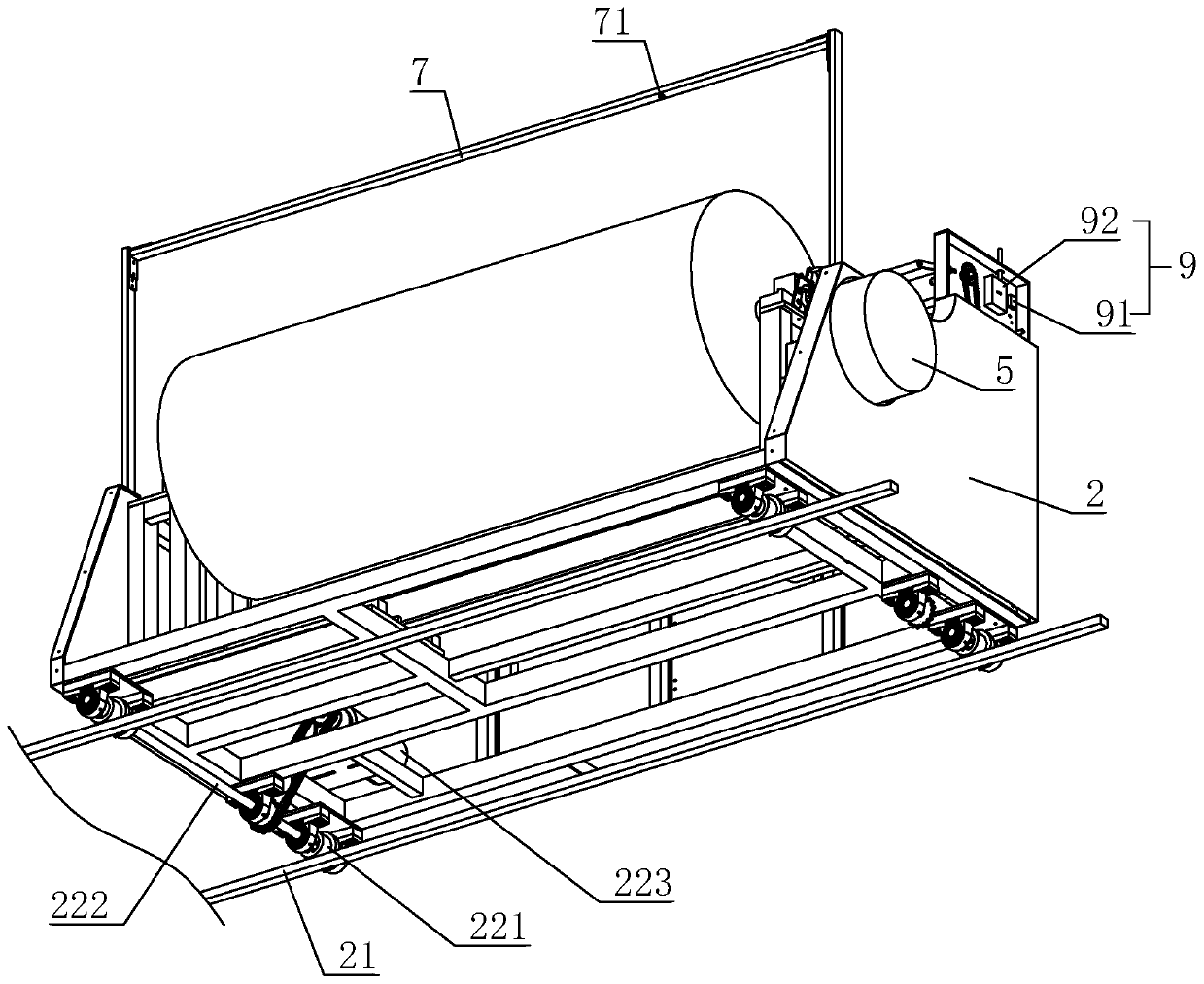

Cloth feeding structure of spreading machine

PendingCN109928243AReduce scrap rateThe unwinding margin is reducedWebs handlingWrinkle skinMagnetic powder

The invention relates to a cloth feeding structure of a spreading machine, and relates to the technical field of cloth paving equipment. The cloth feeding structure of the spreading machine comprisesa rack moving on a cloth paving platform through wheels, and a cloth feeding frame arranged on one side of the length direction of the cloth paving platform, wherein a cloth paving motor connected with the wheels is arranged on the rack; a cloth clamping assembly electrically connected with the cloth paving motor is arranged on the rack; an inflatable roller is rotatably arranged at one end, far away from the rack, of the cloth feeding frame; a magnetic powder brake connected with the inflatable roller and electrically connected with the cloth paving motor is further arranged on the cloth feeding frame; and a fabric roll is fixedly arranged on the inflatable roller in a sleeving way. According to the cloth feeding structure of the spreading machine provided by the invention, through arranging the inflatable roller and the magnetic powder brake, the fabric roll is at a suspension state and keeps a certain strained state during the conveying process, and the unwinding allowance can be greatly reduced, so that the probability of the occurrence of wrinkles and folds can be greatly reduced, the scrap rate of the fabric is reduced, and the cost is reduced.

Owner:浙江精力玛智能机械有限公司

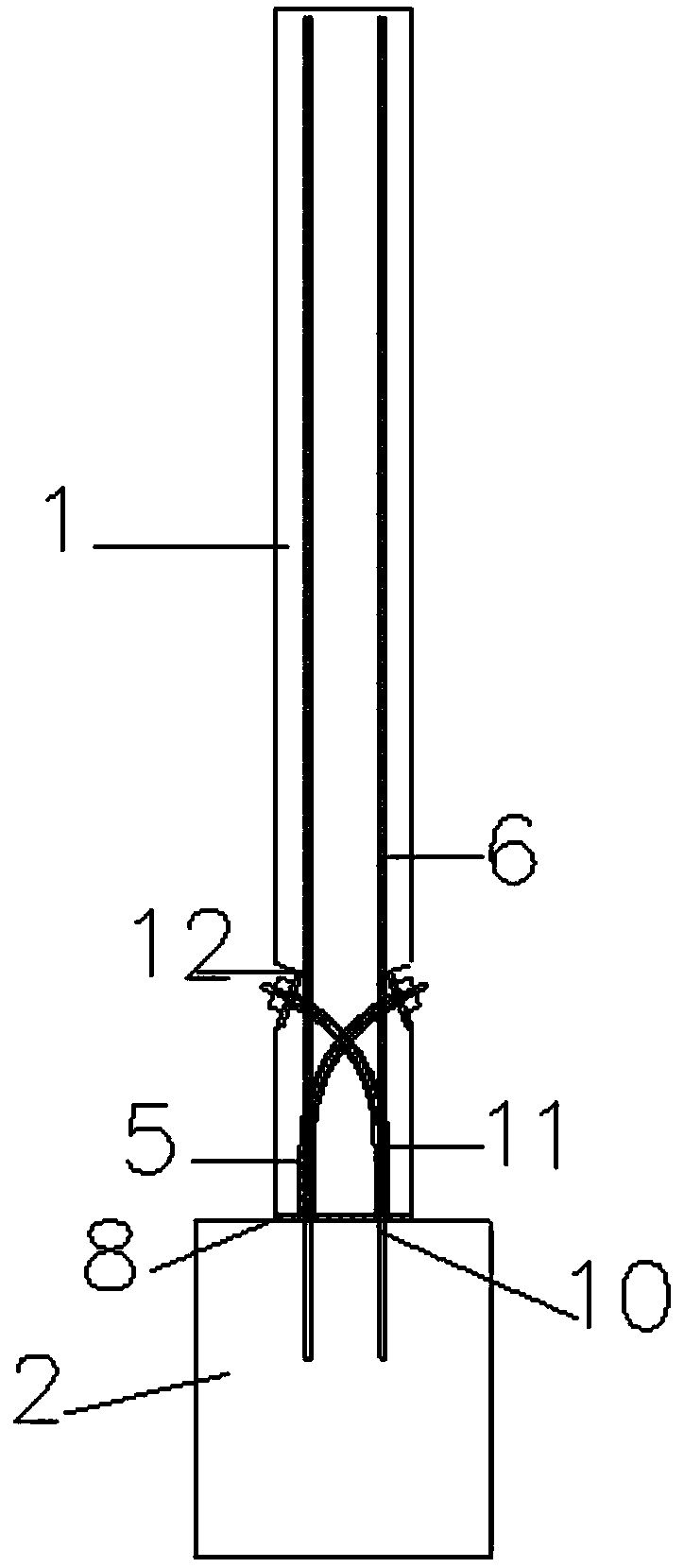

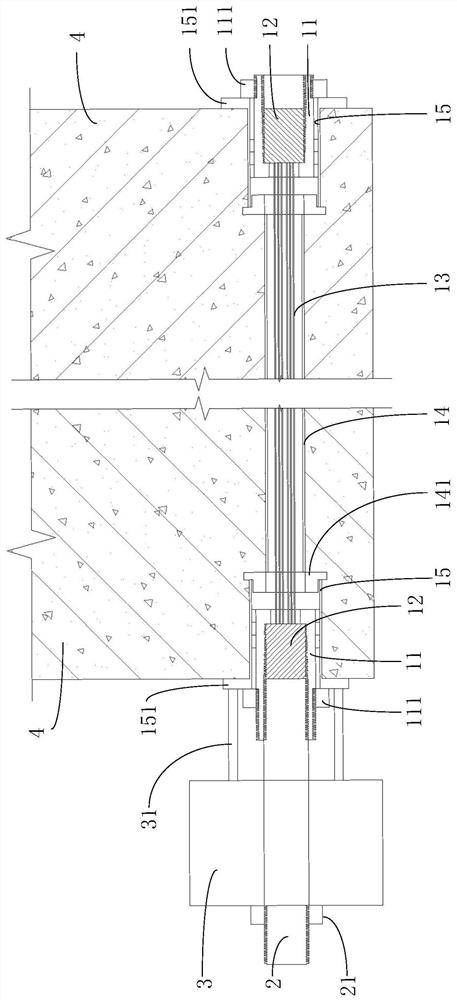

Tensioning and anchoring system of carbon fiber plate bundle and tensioning method thereof

The invention discloses a tensioning and anchoring system of a carbon fiber plate bundle and a tensioning method thereof, the system comprises a prestressed plate bundle, the prestressed plate bundle comprises two anchoring sleeves, two anchoring plugs and a plurality of carbon fiber plates, the plurality of carbon fiber plates are sleeved with pre-buried casing pipes, a plurality of inserting piece holes which are arranged side by side in the same direction are formed in the anchoring plugs, the ends of the multiple carbon fiber plates extend out of the embedded sleeve and are inserted into the multiple insertion piece holes correspondingly, the anchoring insertion head is contained in the first end of the anchoring sleeve, and the second end of the anchoring sleeve is adjustably sleeved with a limiting lantern ring; a supporting insertion rod, wherein the first end of the supporting insertion rod is detachably inserted into the second end of the anchoring sleeve, and a supporting lantern ring is installed at the second end of the supporting insertion rod; and a pushing device which is provided with a first end and a second end which is propped against the supporting lantern ring. The problems that after an existing carbon fiber rib bundle is installed, the carbon fiber rib bundle cannot be straightly placed, and the performance of the carbon fiber rib bundle is affected due to bending are solved.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

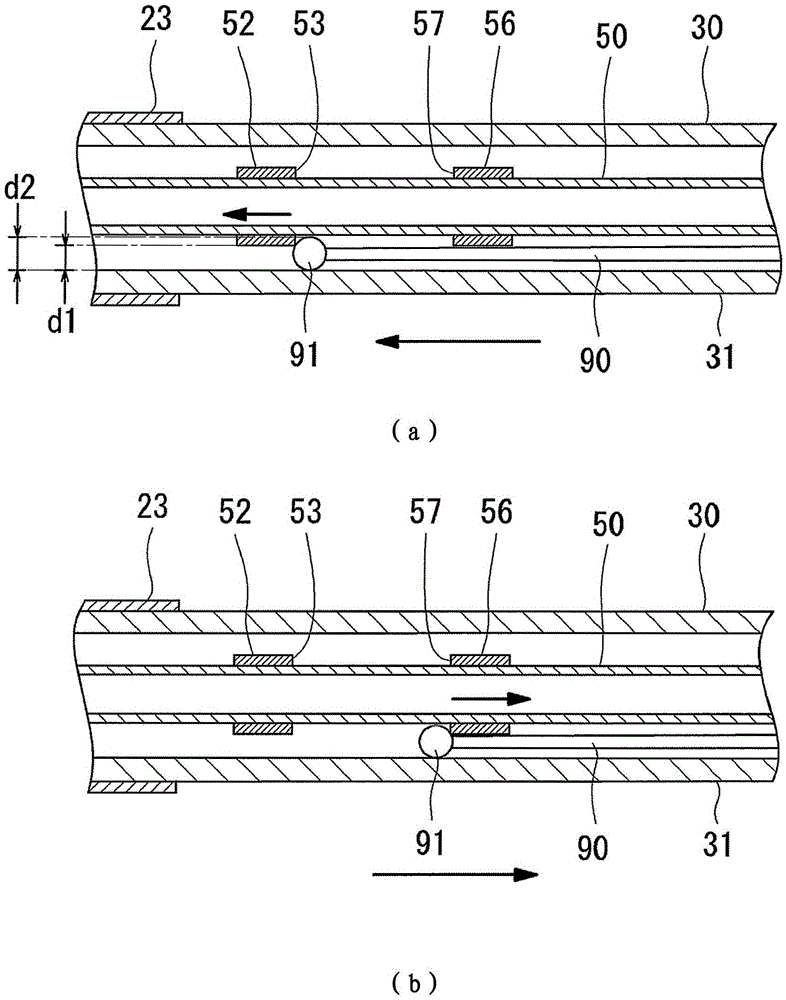

Balloon catheter

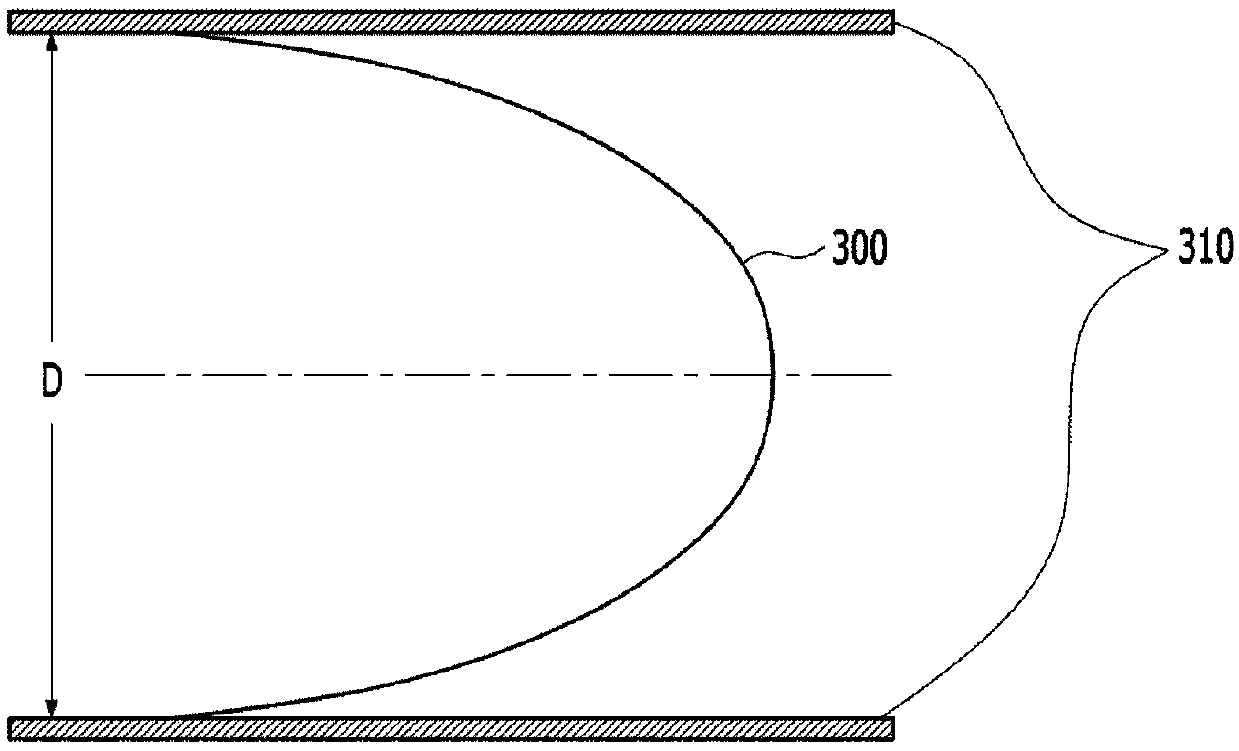

ActiveCN106075701ALess chance of bendingEasy to operateBalloon catheterSurgeryBalloon catheterBiomedical engineering

Provided is a balloon catheter which can pass smoothly through the inside of a curved blood vessel, and can provide an improved kink resistance of a reinforcement member. A distal step 53 and a proximal step 57 are provided at an inner shaft 50, and a bulged portion 91 provided at the distal end of a core wire 90 is configured to be capable of moving in the axial direction between the distal step 53 and the proximal step 57. This can allow smooth passage through the inside of the curved blood vessel and improve the kink resistance of the core wire 90.

Owner:ASAHI INTECC CO LTD

Pruning machine

ActiveCN101226415AShorten the lengthLess bendingCuttersCutting implementsThermal deformationEngineering

The invention discloses a pruning machine, wherein a steel wire shaft (7), an upright rod (12), a switch top block (13), a main button (2), a lifting plate (8) and an inching switch (6) are arranged at the left of a motor component (5), a draw plate (10) and a sub button (4) are arranged at the right of the motor component (5), two ends of the steel wire shaft (7) are respectively connected with the right end of the main button (2) and the left end of the lifting plate (8), a rigid metal rod (9) is connected between the right end of the lifting plate (8) and the upper end of the draw plate (10), the lower ends of the draw plate (10) and the sub button (3) are hinged with a shell (11), the lifting plate (8) is sliding sheathed on the upright rod (12) sheathed by the switch top block (13), and the inching switch (6) is above the switch top block (13). The invention has the advantages that the invention can turn on and off motor with small force and can prevent thermal deformation of driving mediums caused by the heat radiation of motor.

Owner:NINGBO ENERGY POWER TOOLS

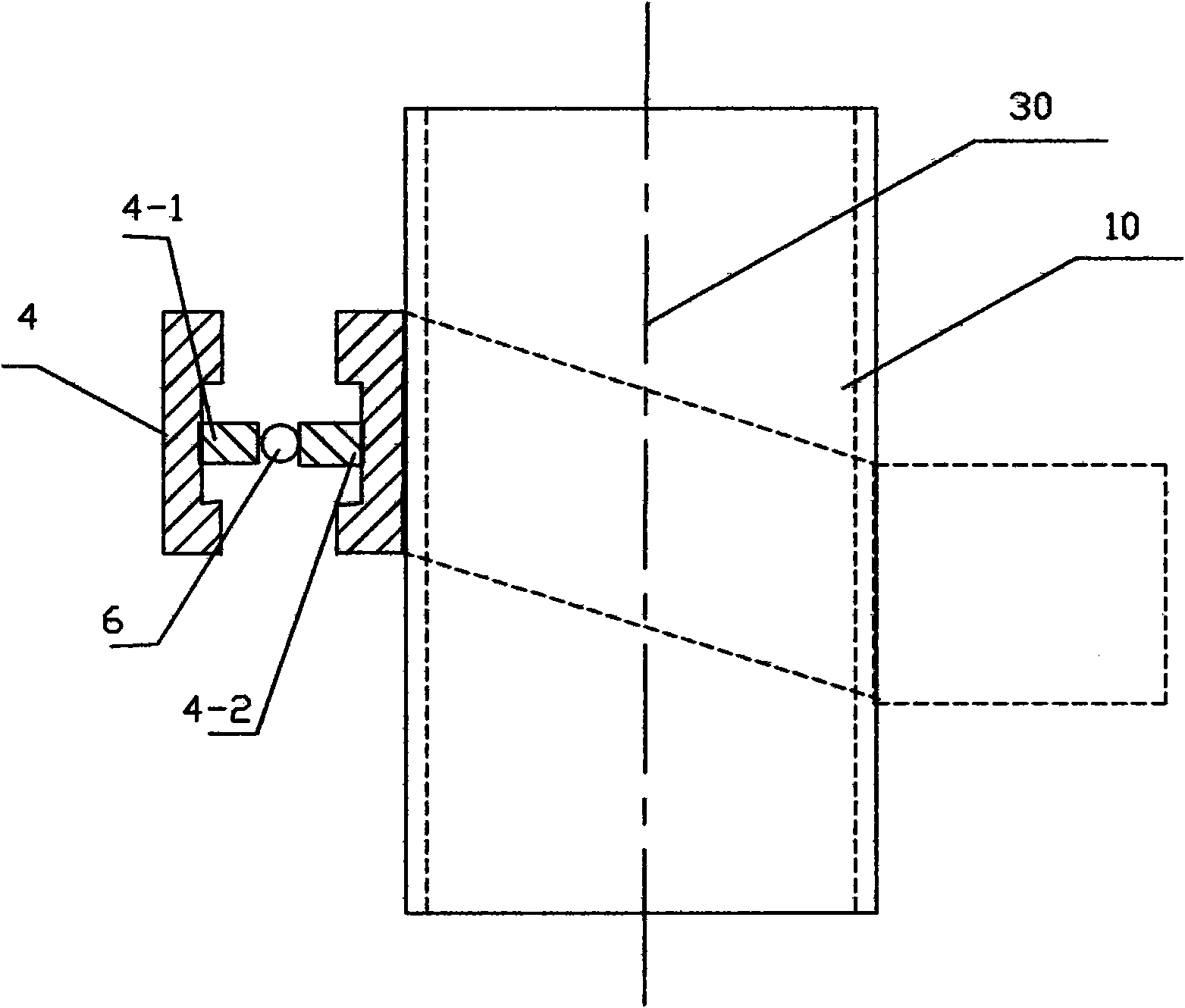

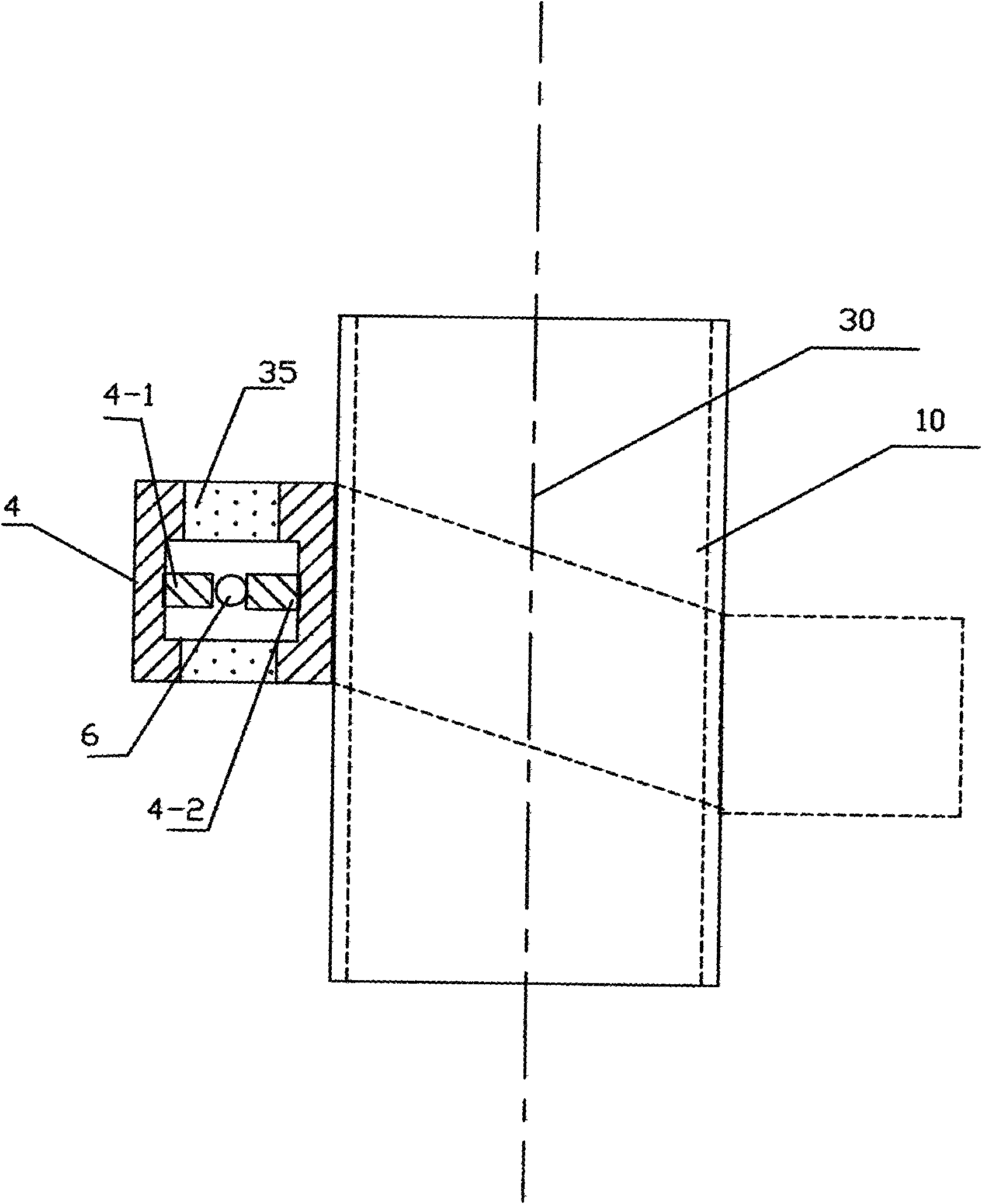

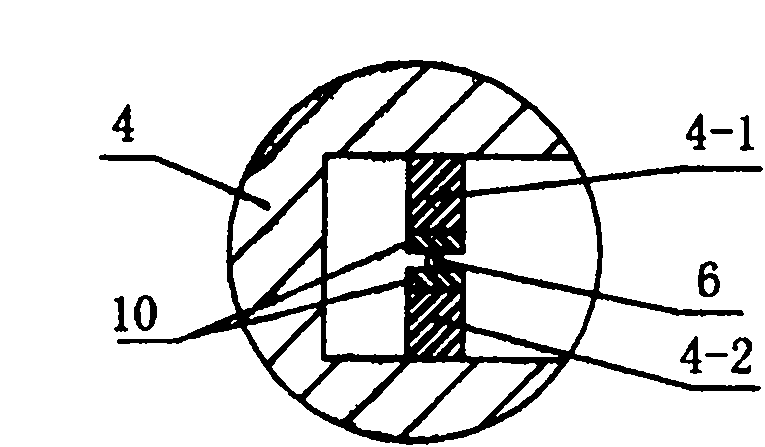

Optical fiber sensing device waveform grooves and cylinder body

InactiveCN102829901ASimple structureReasonable designForce measurement by measuring optical property variationEngineeringBend loss

The invention discloses an optical fiber sensing device with waveform grooves and a cylinder body, wherein the waveform grooves (4) are distributed on the cylinder body (10); wave crests and wave troughs which are staggered and corresponded to each other are arranged on two opposite planes of the waveform grooves (4); and a first signal optical fiber (6) is arranged between wave crests on two opposite planes of the waveform grooves (4). When the cylinder body (10) is deformed under stress, the distance between wave crests at two opposite sides inside the waveform grooves (4) on the cylinder body (10) is changed, then a bending curvature of the first optical fiber (6) arranged between the wave crests is changed, so that the bending loss of the first optical fiber (6) is changed; the stress on the cylinder body (10) can be calculated through a testing unit (5) and a processing unit (7); and a novel sensing device is formed through the organic combination of the cylinder body (10) and the micro-bending waveform grooves (4).

Owner:XIAN JINHE OPTICAL TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com