Full-automatic feeding machine

An unwinding machine, fully automatic technology, applied in metal sawing equipment, tool manufacturing of sawing machine equipment, metal processing equipment, etc. Achieve the effect of low equipment cost, small footprint and low maintenance cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

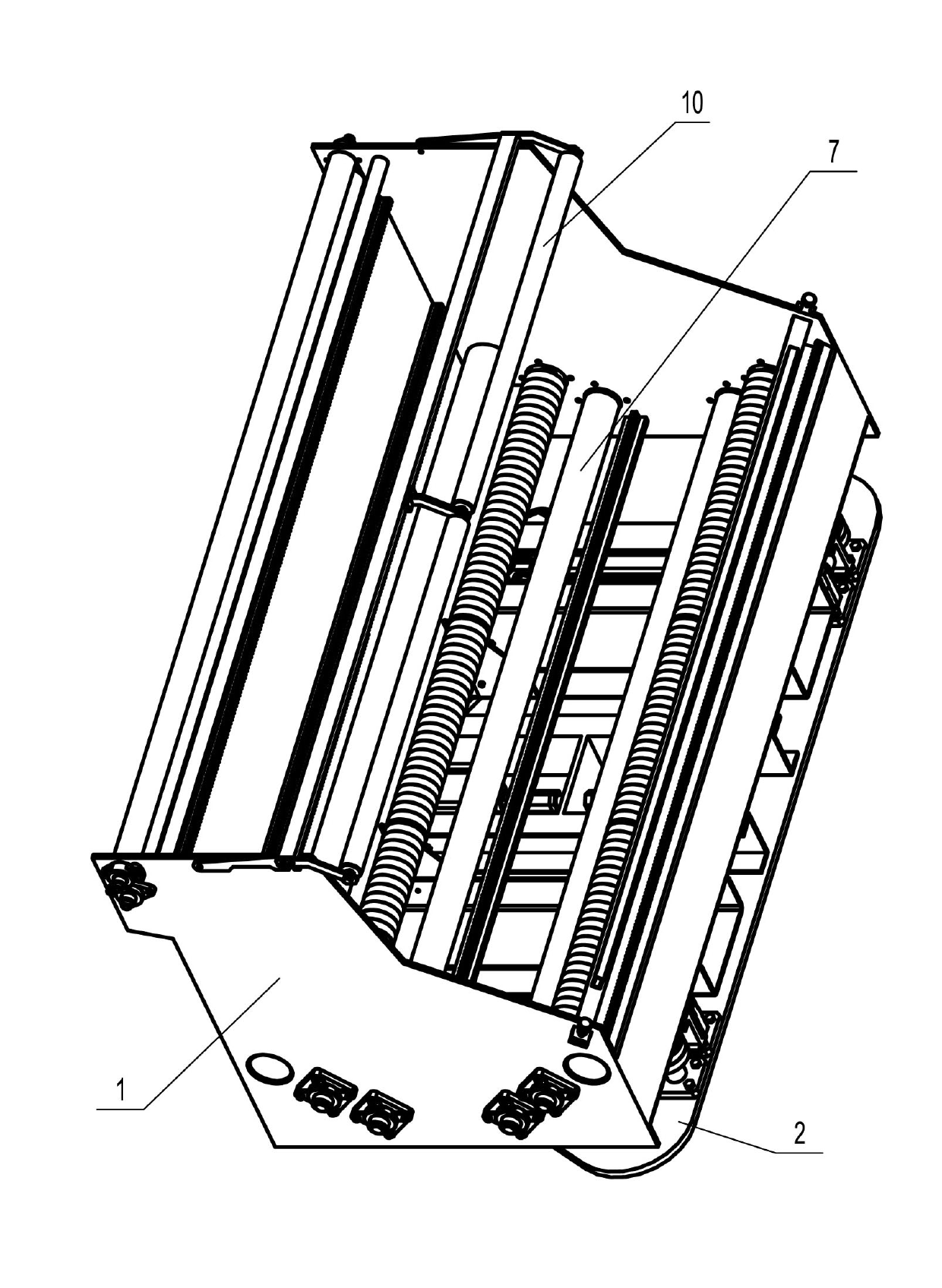

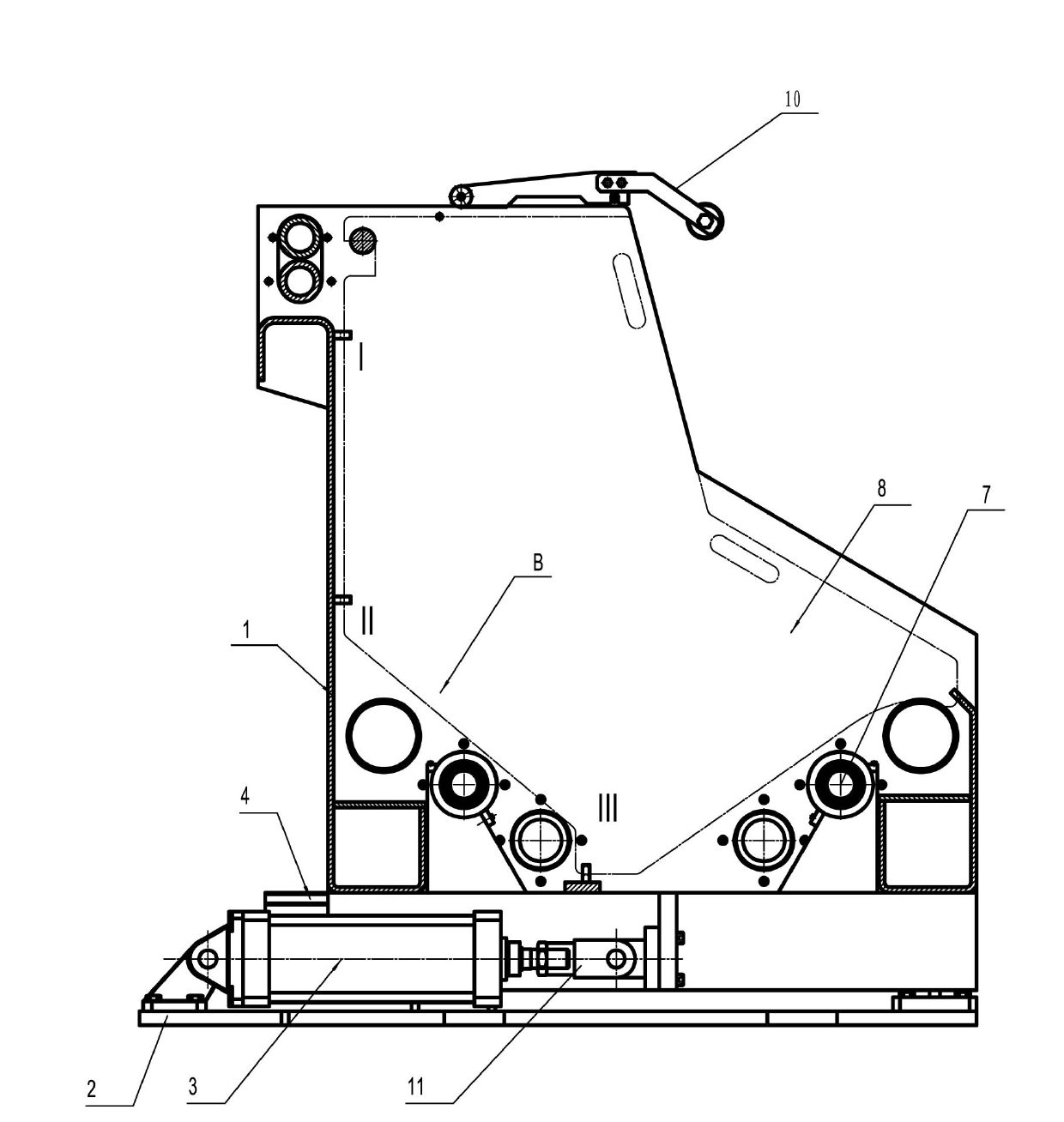

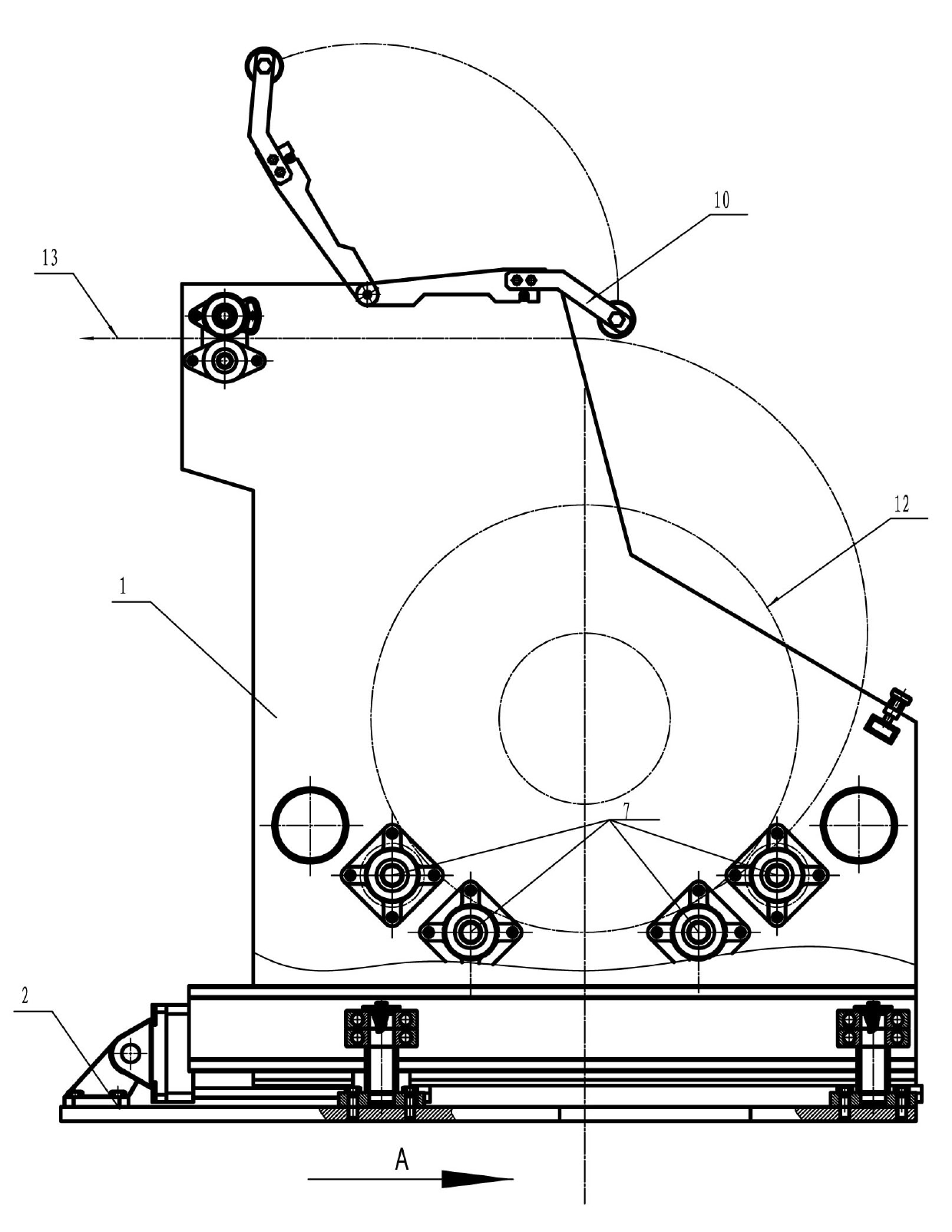

[0031] A fully automatic feeding machine, such as figure 1 and 2 As shown, it includes a frame 2, a cylinder 3 fixed on the frame 2, and a discharge support 1 connected to the cylinder through a joint 11; one side of the cylinder 3 is provided with an electromagnetic reversing valve for controlling the intake and exhaust of the cylinder 3. A supporting and limiting mechanism is also provided between the discharging bracket 1 and the frame 2 to make the discharging bracket 1 move linearly relative to the frame 2 in the direction A of cylinder advancement. Such as image 3 As shown, the structure of the support limit mechanism is that four support bearings 5 mounted on the frame 2 for supporting the guide rail 4 are arranged below the guide rail 4 fixedly connected to the bottom end of the discharge bracket 1, and one side of the guide rail 4 There are four limit bearings 6 installed on the frame 2 to prevent the guide rail 4 from moving left and right.

[0032] The upper e...

Embodiment 2

[0038] A fully automatic feeding machine, comprising a frame 2, a reciprocating propulsion mechanism mounted on the frame 2, a discharging bracket 1 connected to one end of the reciprocating propulsion mechanism, and a gap between the discharging bracket 1 and the frame 2 A supporting and limiting mechanism is provided to make the discharging bracket 1 move linearly relative to the frame 2 in the advancing direction A of the reciprocating advancing mechanism. Such as Figure 6 As shown, the structure of the reciprocating propulsion mechanism is a crank linkage mechanism installed at the output end of the motor, and one end of the crank linkage mechanism is connected to the discharge bracket 1 through a joint 11 . Such as image 3 As shown, the structure of the support limit mechanism is that four support bearings 5 mounted on the frame 2 for supporting the guide rail 4 are arranged below the guide rail 4 fixedly connected to the bottom end of the discharge bracket 1, and on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com