Milling tool for end surface of pipe material

A face milling cutter and face milling technology, which is applied in milling cutters, manufacturing tools, milling machine equipment, etc., can solve the problems of poor quality, low efficiency of heat exchange tube flat tube head, etc., achieve low cost, reduce uneven processing surface, The effect of improving the processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

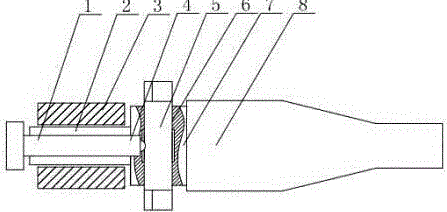

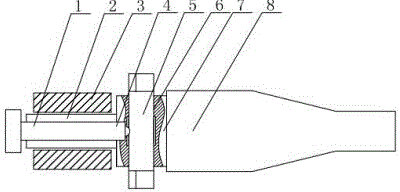

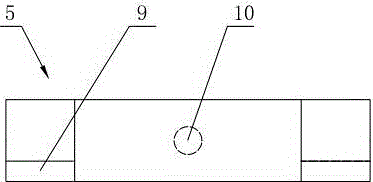

[0021] like figure 1 and figure 2 As shown, the pipe material end milling cutter of the present invention is improved based on the existing conventional tool holder. The rear part of the tool holder is a tool handle 8, and the front part is a tool clamping end 7 with a smaller diameter The anti-shake end 2 and the middle part of the tool clamping end 7 have a square hole 6 for installing the tool 5. The size of the square hole 6 depends on the size of the tool 5. The clearance on one side is 0.1mm~0.2mm, which is convenient for the disassembly of the tool 5. pretend; see image 3 and Figure 4 , the cutting tool 5 has a cuboid structure, and its two ends are respectively provided with symmetrical cutting heads 9, and the center of the cutting tool 5 is provided with a concave circular groove 10; The outer peripheral surface of 3 fits with the inner wall gap of the tube material to be processed, and the anti-shake ring 3 can be made of wear-resistant polytetrafluoroethylene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com