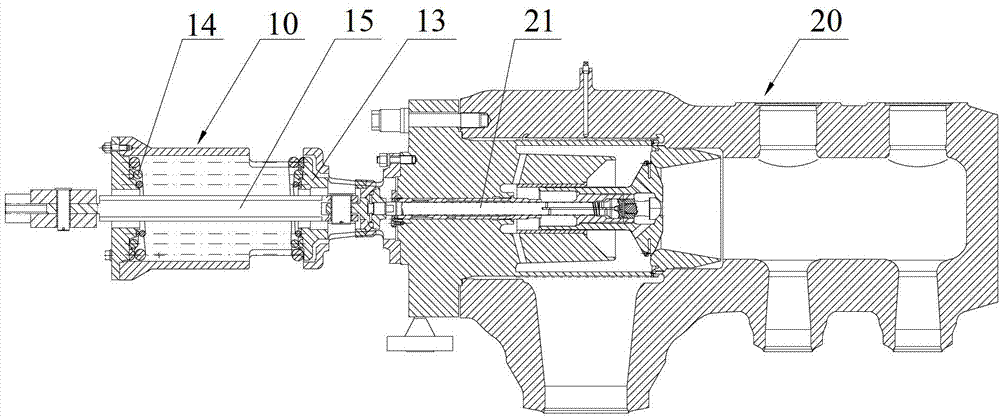

High-pressure main throttle valve apparatus of steam turbine

A main steam valve and steam turbine technology, applied in mechanical equipment, engine components, machines/engines, etc., can solve the problems of easy bending of the valve stem, large closing resistance of the main steam valve, and long closing time, so as to avoid closing time Effect of too long, reduced closing resistance, reduced possibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

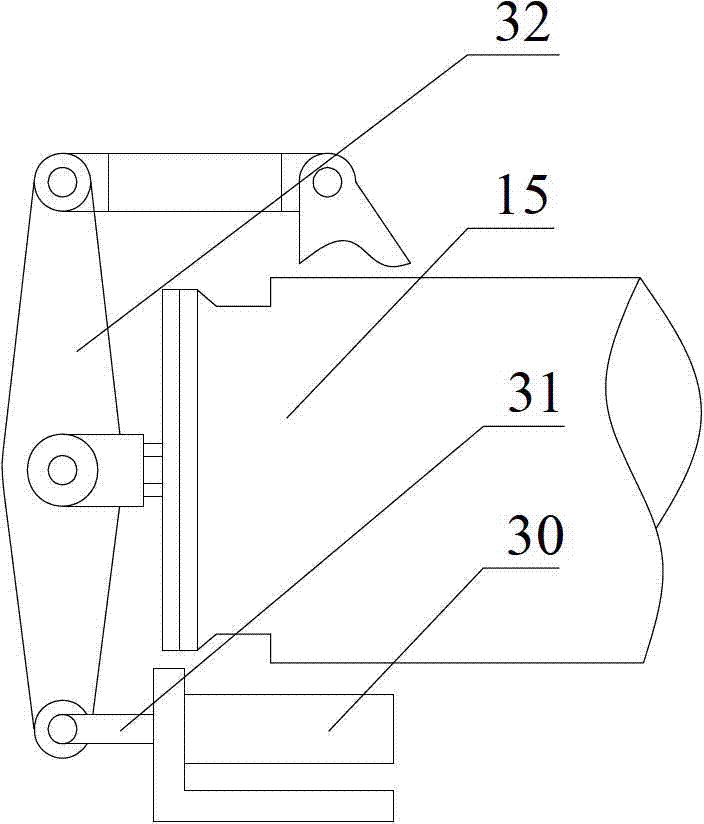

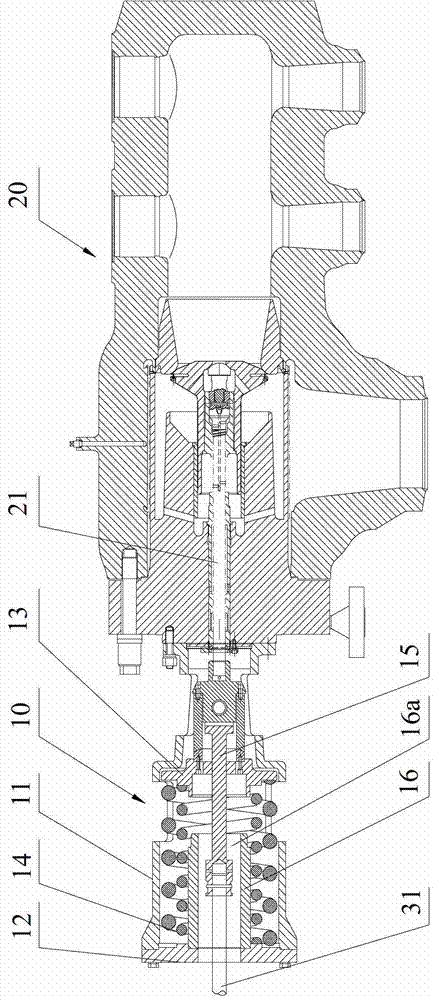

[0041] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

[0042] In the present invention, in the case of no contrary description, the used orientation words such as "inner and outer" usually refer to the center line of the housing of the spring mechanism, which is relatively close to the center line of the housing. "inner" and "outer" which is relatively far away from the center line of the shell.

[0043] As mentioned above, the existing main valve device often has the problem of too long closing time during emergency shutdown. After inspection and verification, it is found that the main reason for the long closing time of the main steam valve is that the valve stem 21 of the main steam valve 20 bears the gravity of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com