Universal pressure sensing device based on optical fiber microbending loss

A sensing device, a general-purpose technology, applied in fluid pressure measurement using optical methods, measurement of force by measuring the change of optical properties of materials when they are stressed, etc. The practicality and promotion of sensors, the limitation of practical application and application scope, etc., achieve the effect of flexible use, simple structure, and extended effective length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

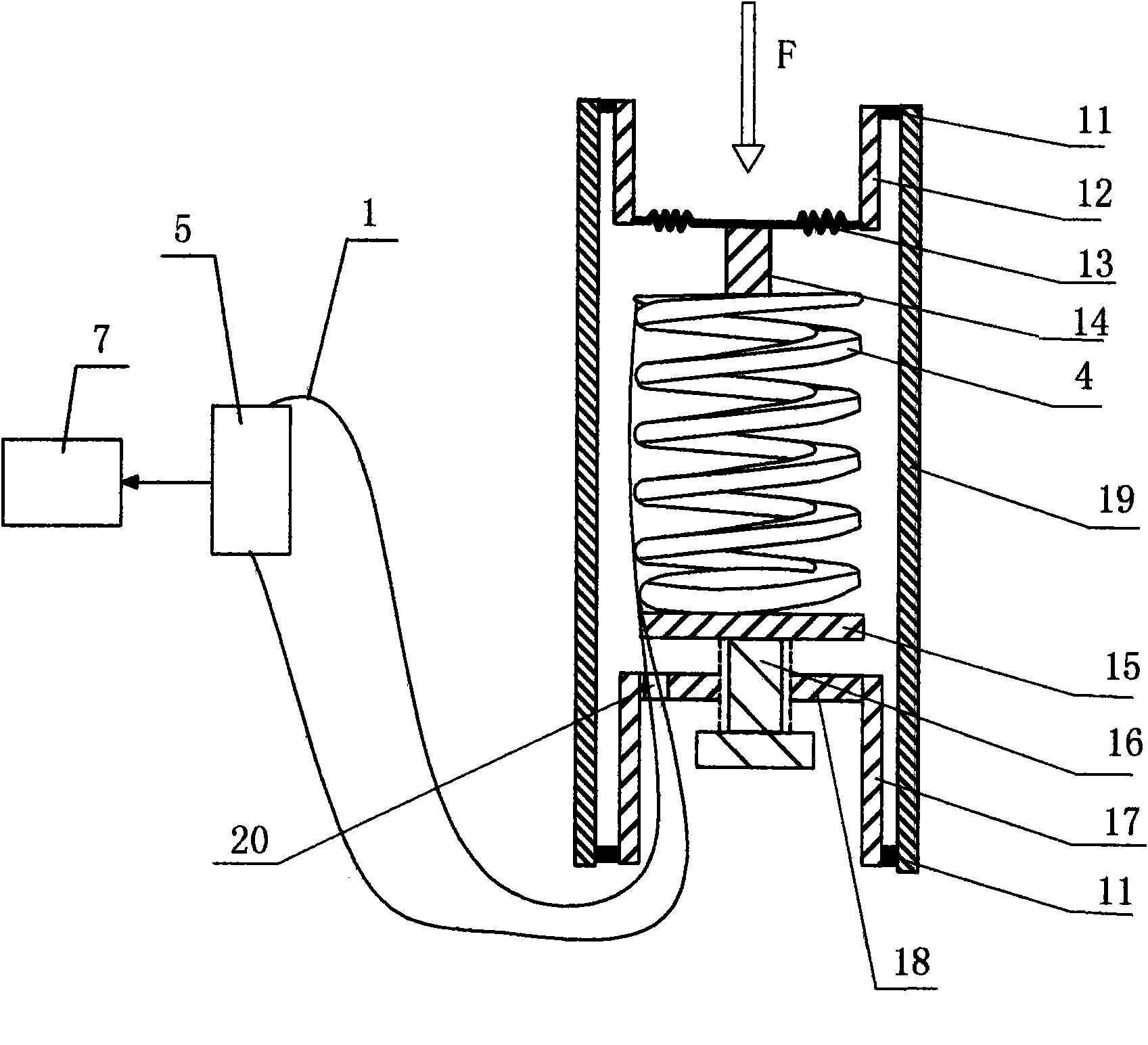

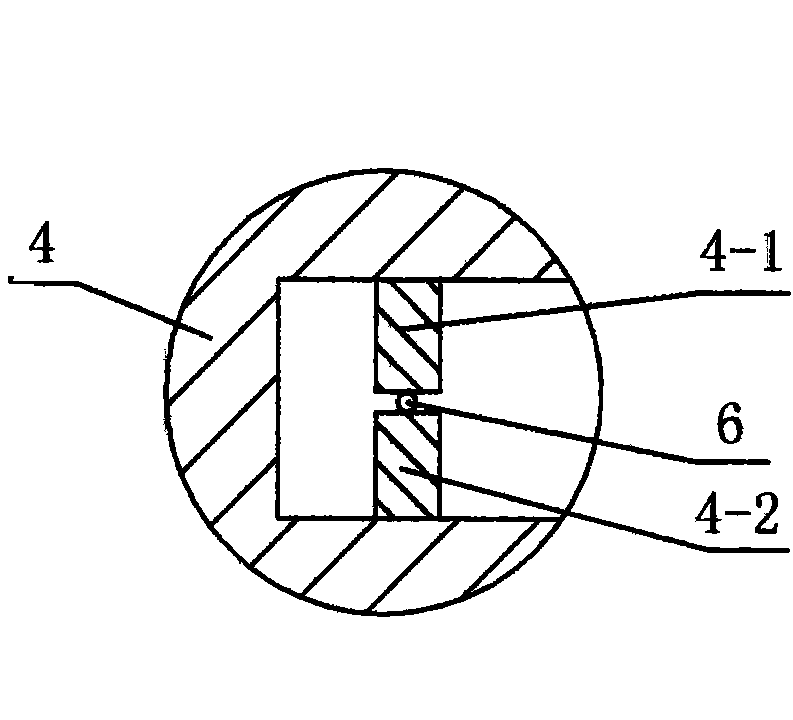

[0035] like figure 1 , figure 2 As shown, the present invention has a multi-layer microbending element composed of a curved housing 4 that includes a signal optical fiber 6, and the lower deforming teeth 4-1 and the upper deforming teeth 4-1 fixed in the curved housing 4 2. Corresponding to each other and clamping the signal fiber 6 between the two, the signal fiber 6 is connected to the test unit 5 through the extension fiber 1, and the test unit 5 is connected with the processing unit 7, and there are two layers of cavities outside the curved housing 4 , the upper edge and the lower edge of the inner wall of the cylindrical cavity 19 are respectively fixed with an inner cylindrical cavity A12 and an inner cylindrical cavity B17, and the lower end of the inner cylindrical cavity A12 is provided with a corrugated sheet 13, and the inner cylindrical cavity The upper end of the body B17 is provided with a base plate 18 . The corrugated sheet 13 transmits the received pressure...

Embodiment 2

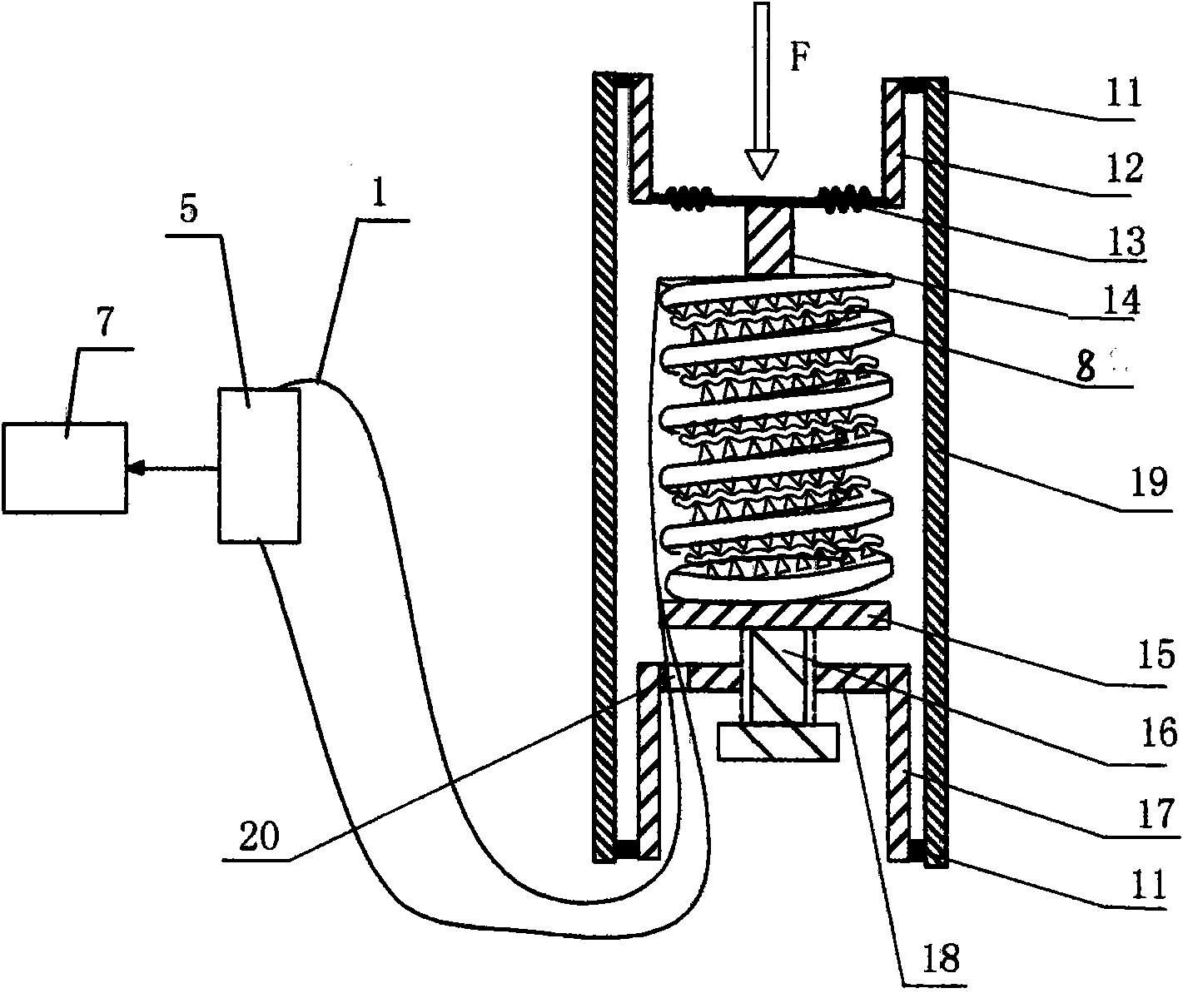

[0039] like image 3 , Figure 4 As shown, in this embodiment, the difference from Embodiment 1 is that the multi-turn micro-bending element is composed of a spring-shaped element with two adjacent coils of spring wire 8 that are interlaced with corresponding deformation teeth. A signal optical fiber 6 is clamped. In this embodiment, the structures, connections and working principles of other parts are the same as those in Embodiment 1.

Embodiment 3

[0041] like Figure 5 As shown, in this embodiment, the difference from Embodiment 1 is that an optical reflector 22 is arranged at one end of the signal fiber 6, the other end of the signal fiber 6 is connected to the extension fiber 1, and the extension fiber 1 is connected to a 1X2 optical branch Device 21, 2 terminals of 1X2 optical splitter 21 are connected to test unit 5, and this test unit 5 is made of stable light source and optical power meter, that is to say, 2 ends of 1X2 optical splitter 21 are respectively connected with stable light source and optical power meter, The testing unit 5 is connected with the processing unit 7, so that the optical signal transmitted in the signal fiber 6 can pass through the bending part of the signal fiber 6 twice, which further improves the accuracy and sensitivity of the detection device. In this embodiment, the structures, connections and working principles of other parts are the same as those in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com