Patents

Literature

68results about How to "Improve accurate control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

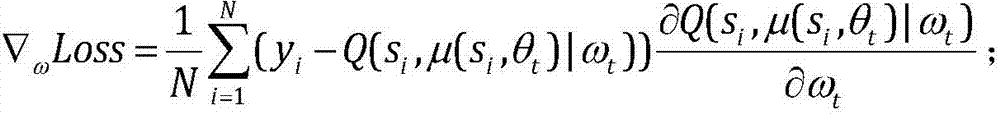

Method and system for controlling underwater robot locus based on deep reinforcement learning

ActiveCN107102644AAvoid control problems with low trajectory tracking accuracyEasy to operateAdaptive controlAltitude or depth controlControl systemSimulation

The present invention discloses a method and system for controlling an underwater robot locus based on deep reinforcement learning. The system comprises a learning phase and an application phase. In the learning phase, a simulator simulates the running process of an underwater robot and collects the data of the simulated running underwater robot, the data comprises the state of each moment and the target state of the next moment corresponding to each moment, and the learning is performed aiming at a decision neural network, an auxiliary decision neural network, an evaluation neural network and an auxiliary evaluation neural network through the data. In the application phase, the state o the underwater robot at the current moment and the target state of the underwater robot at the next moment are obtained and input to the decision neural network obtained through the final learning in the learning phase, and the decision neural network is configured to calculate the propulsive force required by the underwater robot at the current moment. The method and system for controlling underwater robot locus based on the deep reinforcement learning can realize accurate control of the underwater motion track.

Owner:SOUTH CHINA NORMAL UNIVERSITY

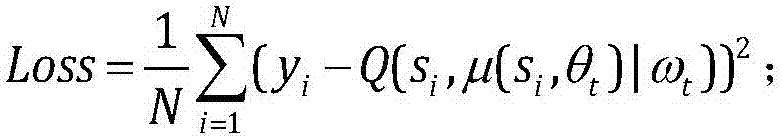

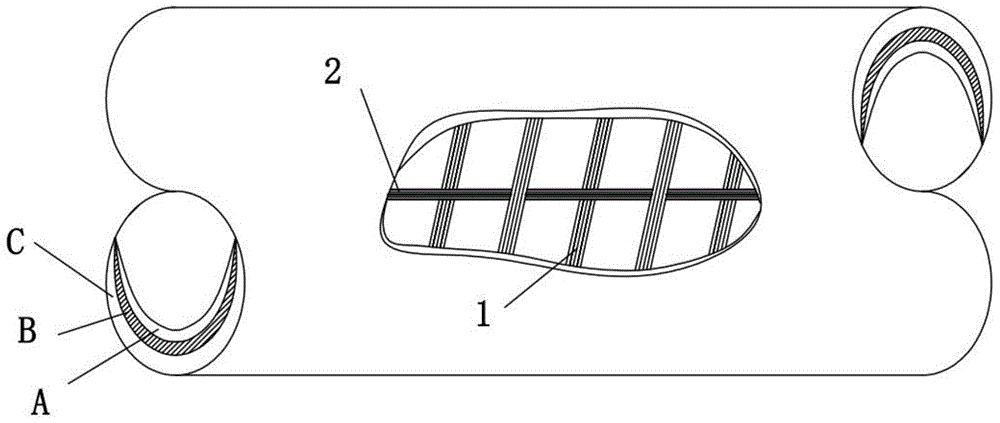

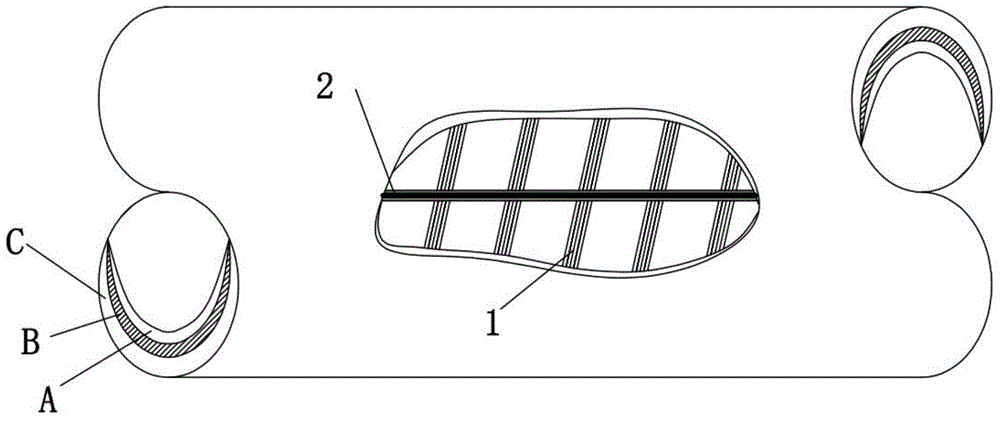

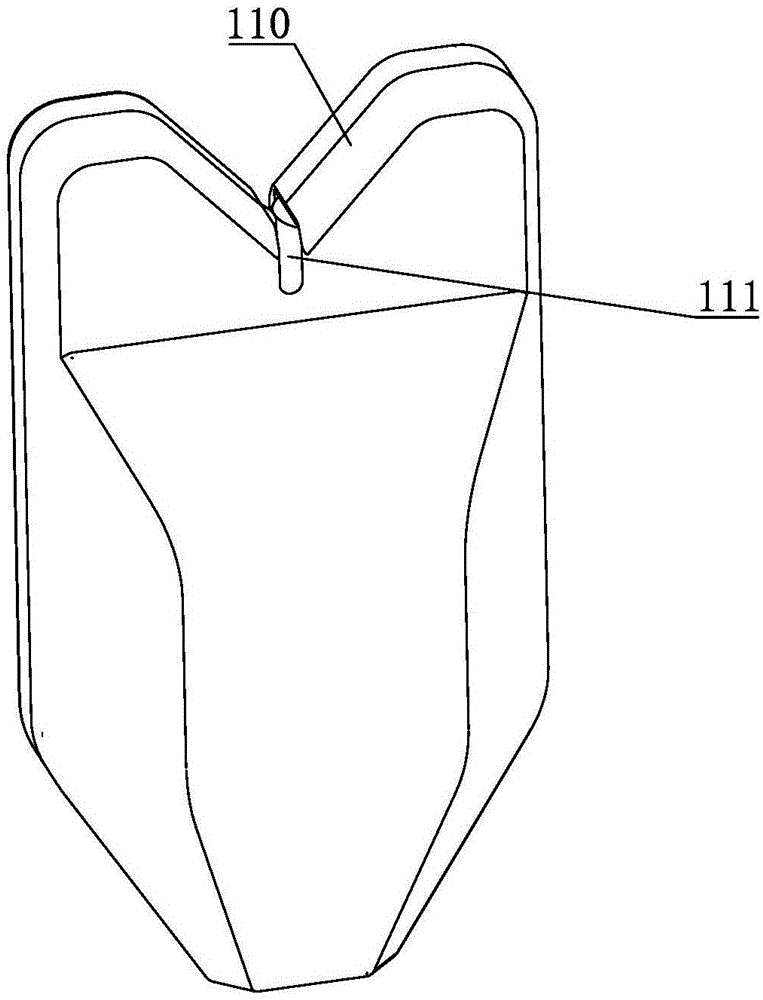

Reinforced compound sheathing canal, preparation method and application thereof

InactiveCN105105894AReduce surgical riskPrevent extensionStentsSurgeryTransport systemInvasive treatments

The invention discloses a reinforced compound sheathing canal, a preparation method and application thereof. The reinforced compound sheathing canal sequentially comprises an inner layer, a reinforced layer and an outer layer from interior to exterior, wherein the reinforced layer comprises axial reinforcing elements and a spiral reinforcing element, the spiral reinforcing element is a single spiral element or is formed by combining two or more spiral elements, the axial reinforcing elements are disposed on the inner side or outer side of the spiral element, or are inserted between the spiral elements, and various axial reinforcing elements are uniformly arranged in the circumference direction of the sheathing canal. The reinforced compound sheathing canal provided by the invention has the advantages of thin wall, high axial strength, high radial strength, high torque transitivity and the like, can be applied to a transport system for transporting medical device implants needed in a minimally invasive treatment and can reduce the outer diameter of the transport system, so that the medical device implants are easy to arrive at lesion positions, damage to the blood vessel of a patient is reduced, and sufficient technical support is provided for reliable, successful and safe transport and implantation of the medical device implants by the transport system.

Owner:NINGBO LINSTANT POLYMER MATERIALS CO LTD

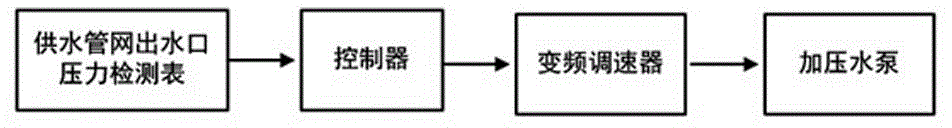

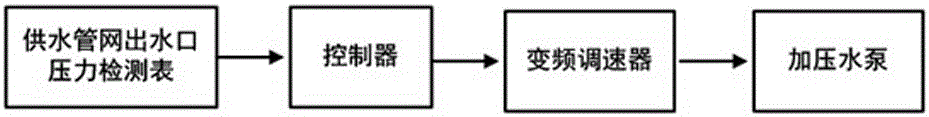

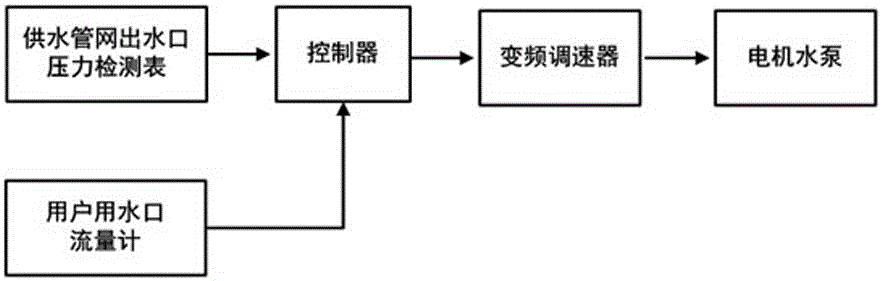

Secondary water supply equipment control method and system based on model

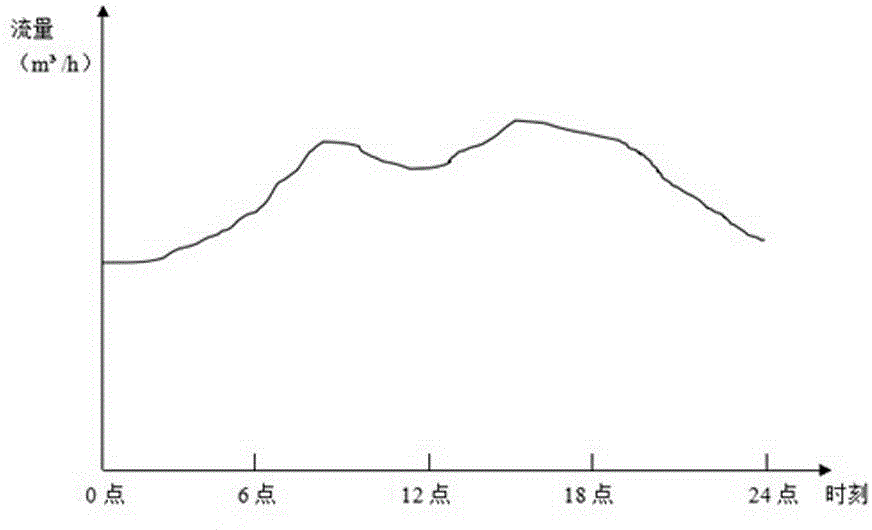

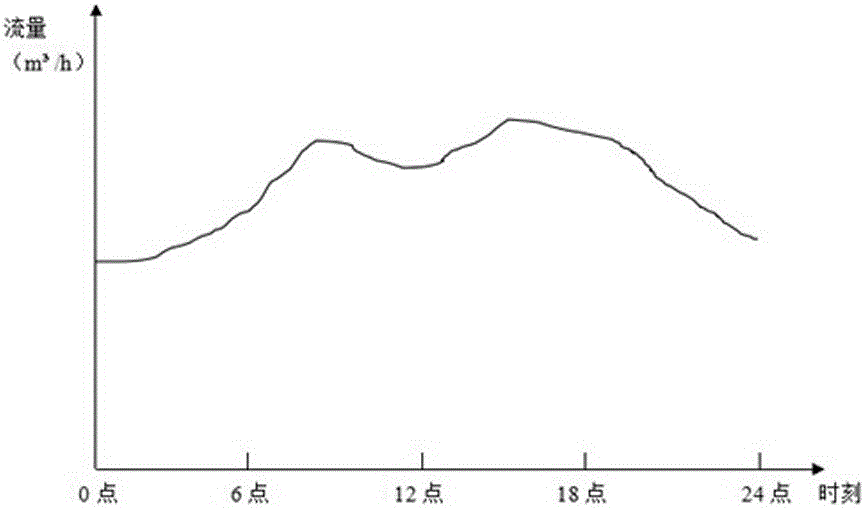

InactiveCN104153424AImprove water experiencePrevent overpressureService pipe systemsWater mainsWater useStream flow

The invention provides a secondary water supply equipment control method and system based on a model. The secondary water supply equipment control system comprises a water supply pipe network water outlet pressure detection meter, a controller, a variable-frequency governor and a pressurization water pump, wherein the water supply pipe network water outlet pressure detection meter, the controller, the variable-frequency governor and the pressurization water pump are electrically connected in sequence. The secondary water supply equipment control system further comprises a user water consumption port flow meter. The output end of the user water consumption port flow meter is electrically connected with the input end of the controller. The user water consumption port flow meter accurately calculates the water consumption quantity of a user water outlet and inputs flow data into the controller. The controller builds a water supply model according to the flow data and corresponding time, controls frequency changes of the variable-frequency governor according to the flow value at each time point in the model, and then controls the rotation speed of the pressurization water pump. The secondary water supply equipment control system realizes high-accuracy control and a higher response speed in the secondary water supply equipment control process by modeling the water supply data, saves water and electricity, better avoids overpressure of a water supply pipe network, guarantees the safety of the water supply pipe network and provides better water consumption experience for a user on the water consumption side.

Owner:青岛沈源水务科技有限公司

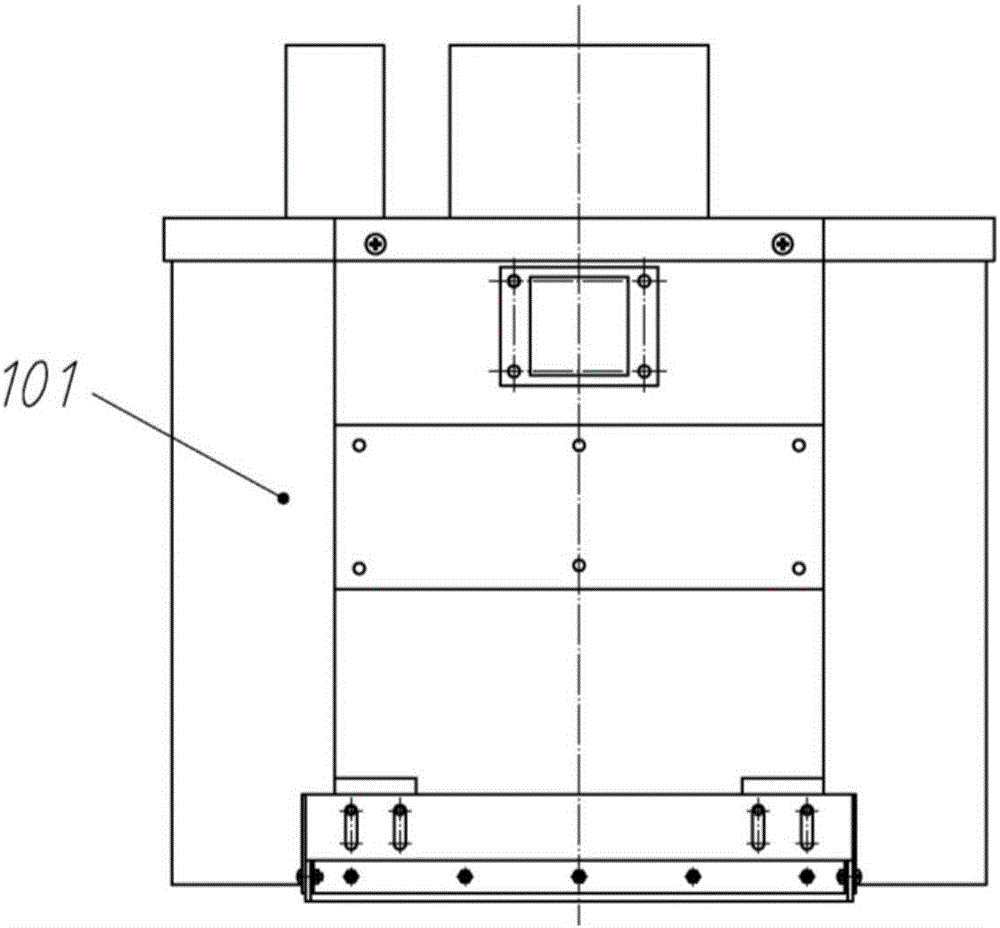

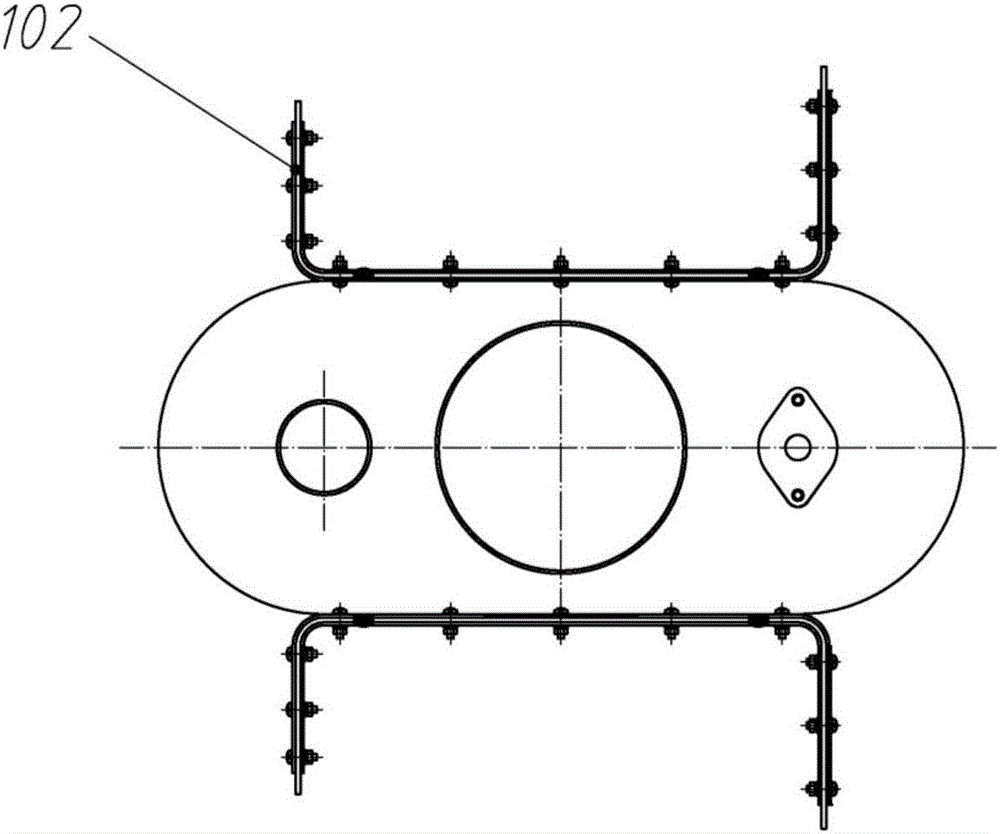

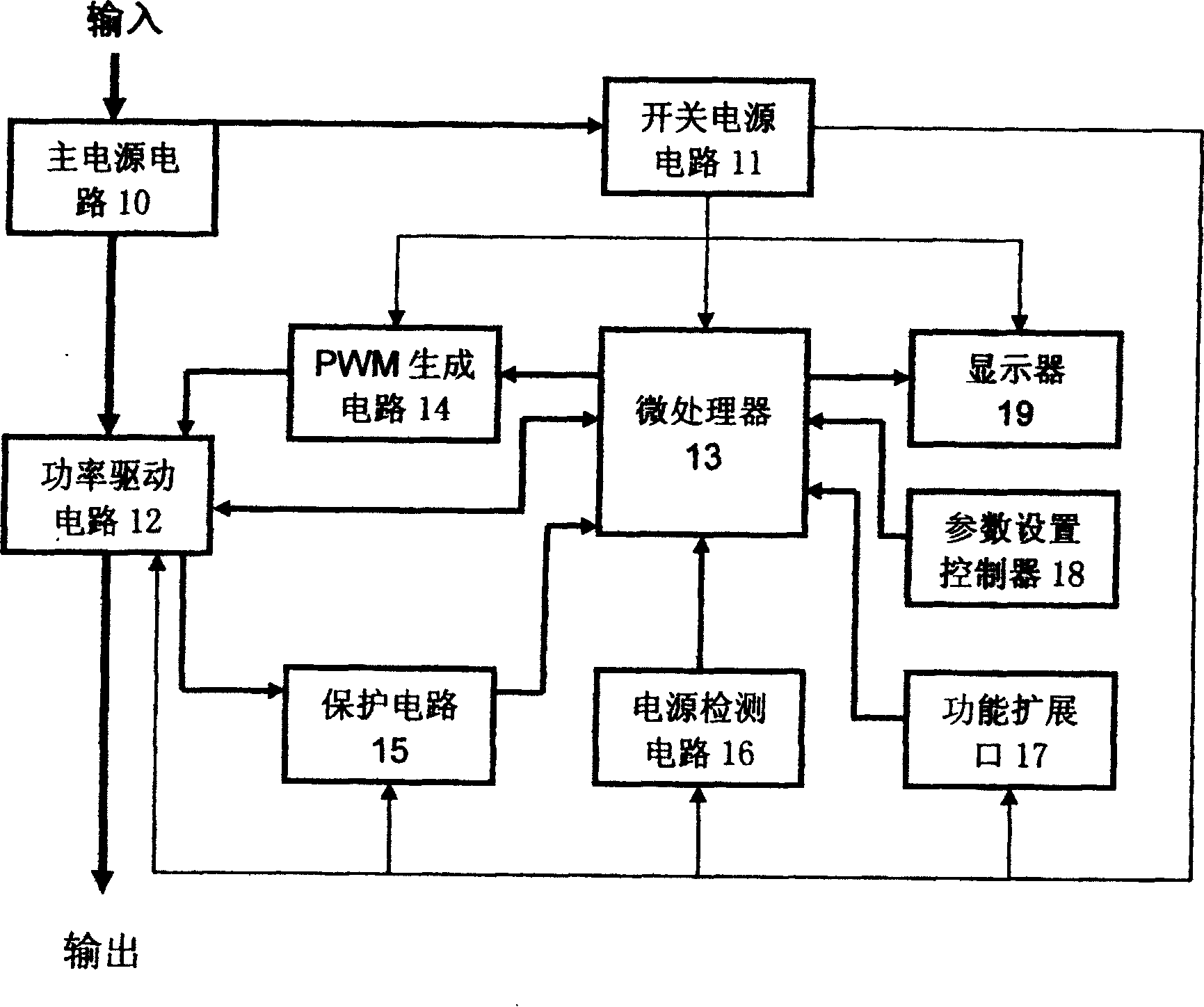

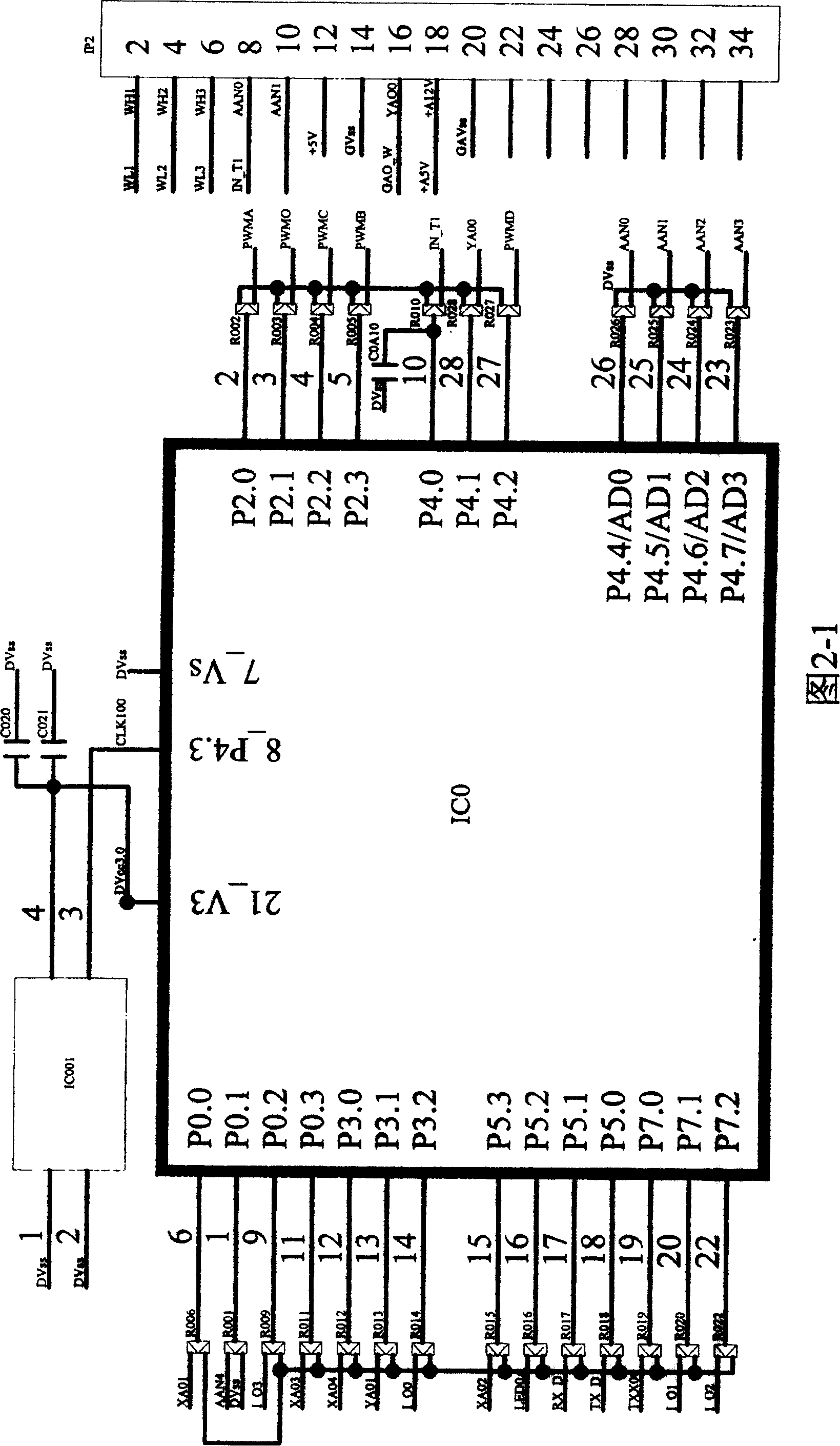

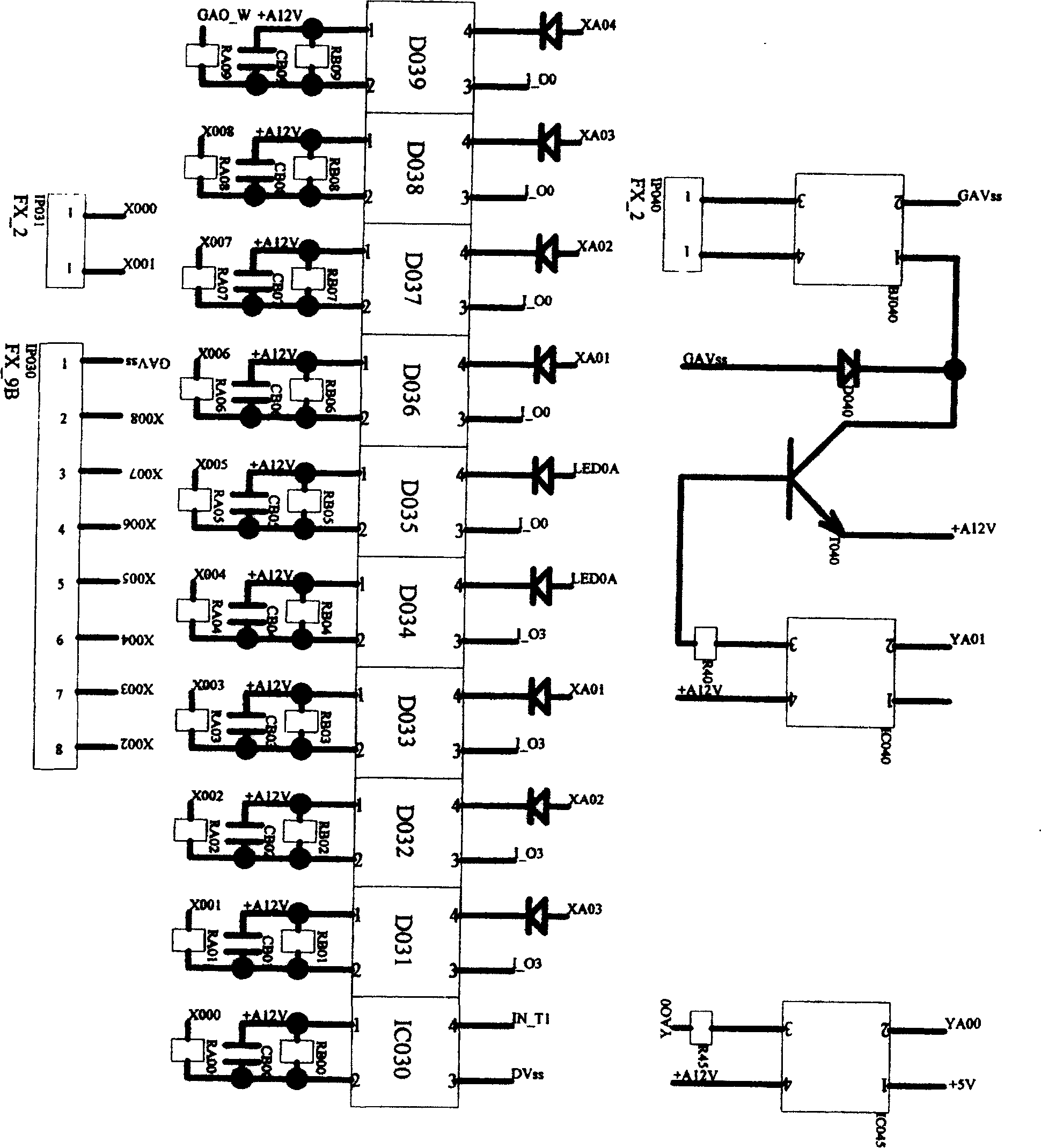

Motor intelligent power-saving protector

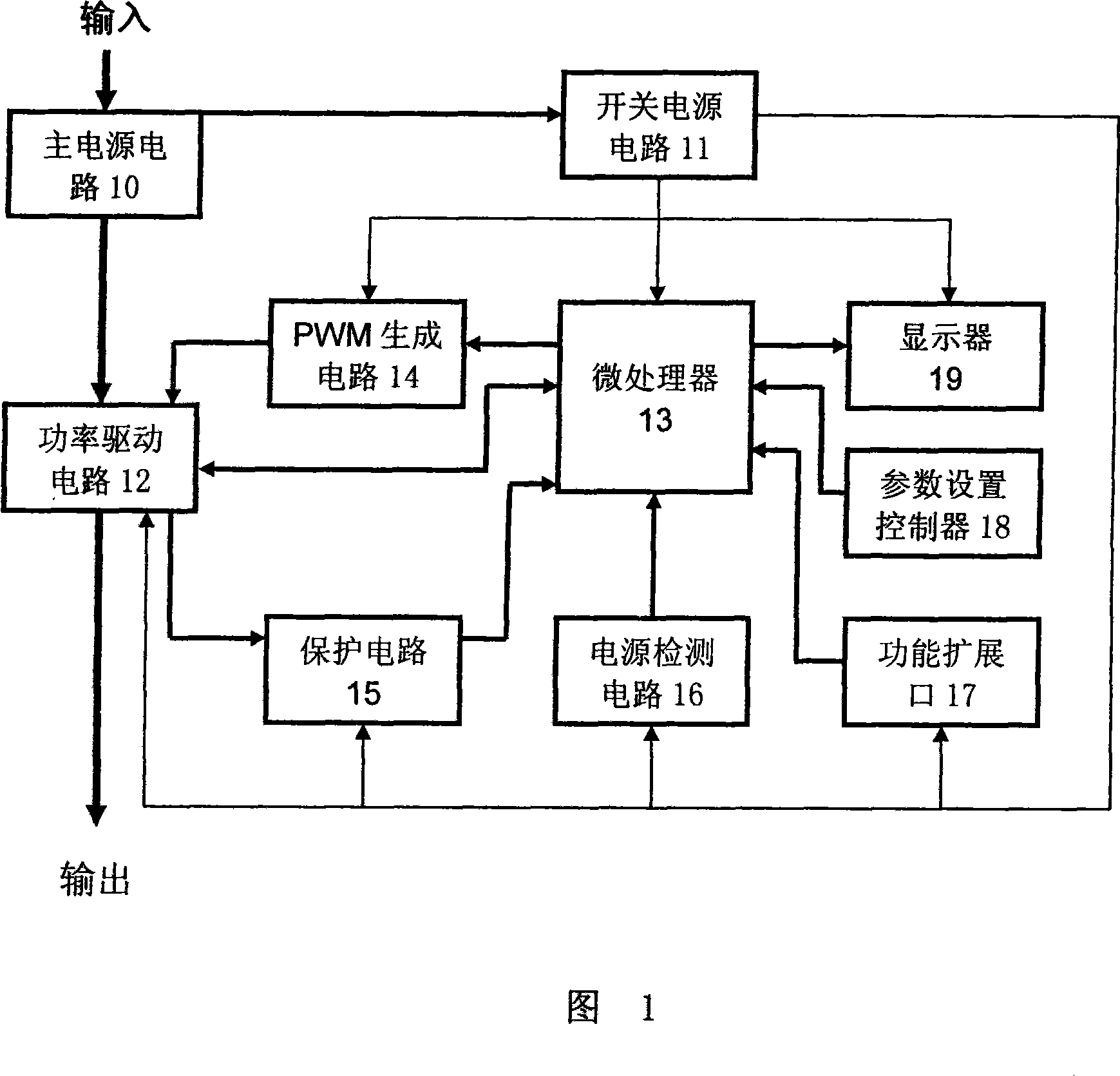

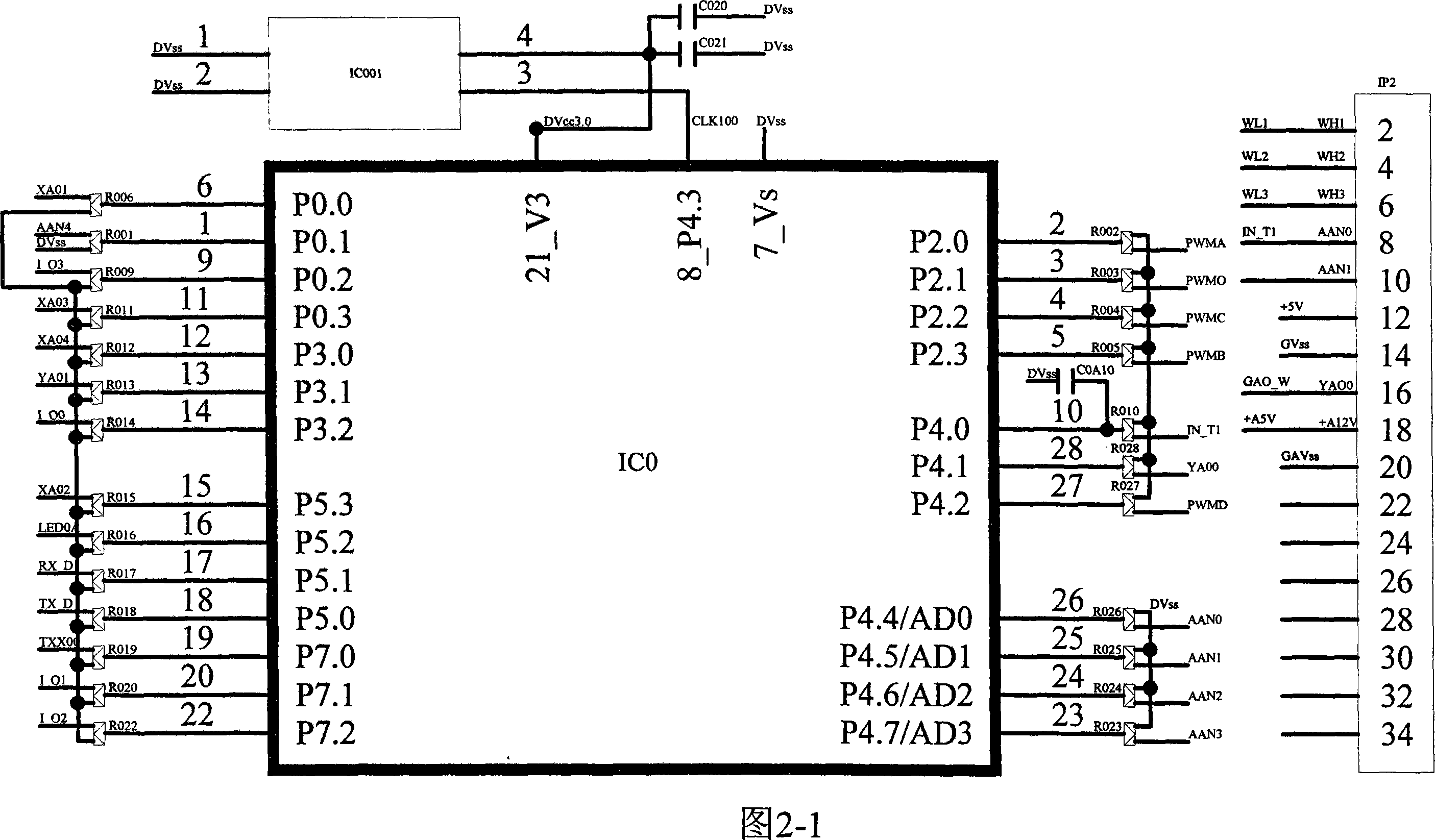

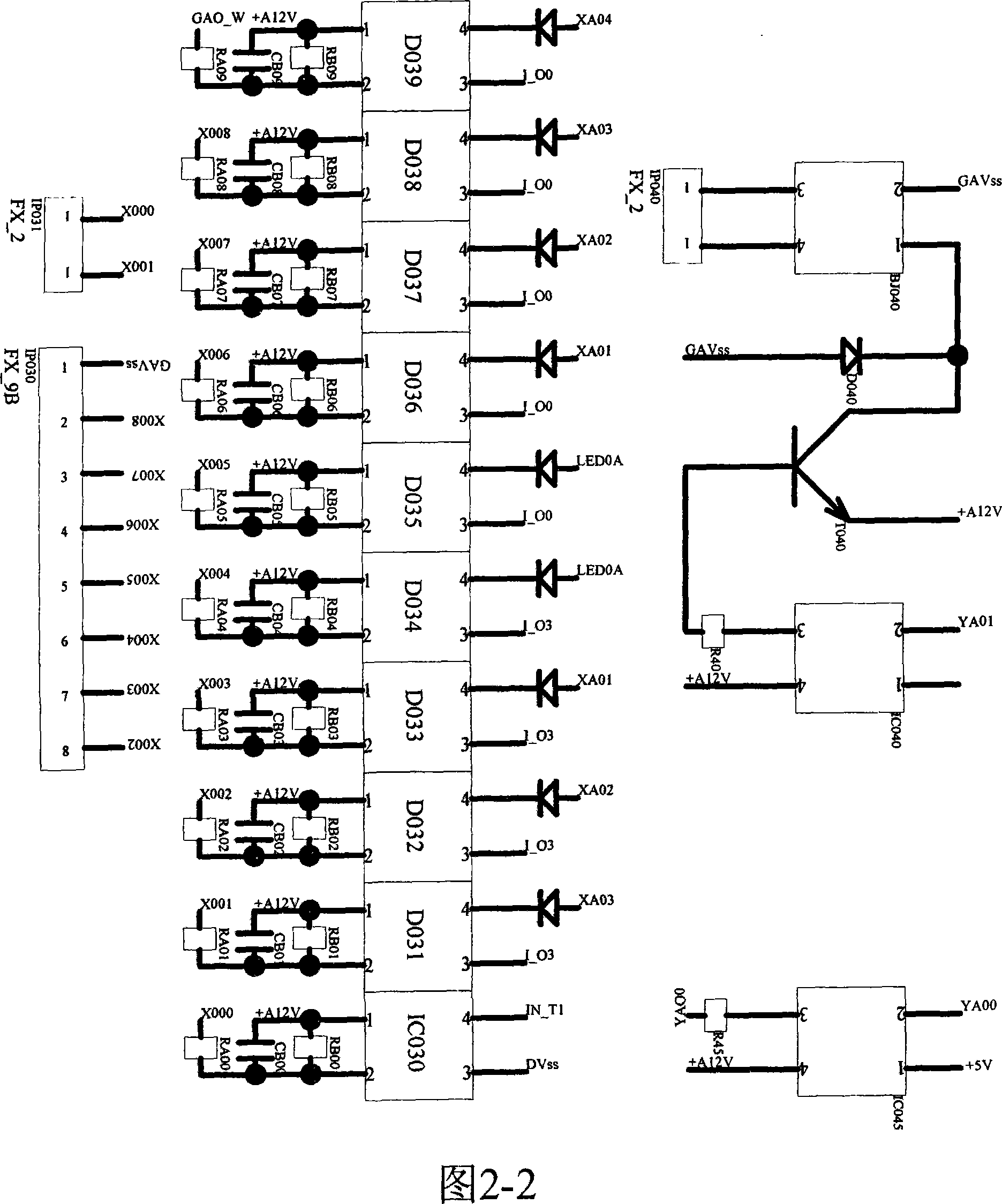

InactiveCN101060304AImprove precise controlAvoid Control Parameter MismatchesMotor control for low load efficiencyComputer controlPower savingPower circuits

The disclosed intelligent power-saving protective device for motor comprises: a primary power circuit with output end connected with the input of following two circuits, a switch power circuit with output end connected with input end of all following members, a power drive circuit with input end connected with the PWM generating circuit and microprocessor and the switch power, a microprocessor with input end connected all of the power drive circuit, protective circuit, the power detection, the parameter controller and the switch power circuit; a PWM generating circuit, a protective circuit, a power detection circuit, a function extension interface, a parameter setting controller, and a display. This invention is convenient and reliable.

Owner:湖南巨汇科技发展有限公司

Production apparatus and extrusion technology of novel clad pipe

The invention relates to a production apparatus and an extrusion technology of a novel clad pipe. The production apparatus comprises an extrusion production line apparatus for production of an inner layer and an external layer of an enhanced clad pipe, winders for winding and preheating a long fiber strip, a center locating frame for controlling a fibrous strip winding to cause tilt of an inner pipe, and a heating box for heating the inner pipe wound with the fibrous strip. According to the invention, two winders are configured between an inner pipe extrusion line and an external layer extrusion cladding die head and used alternately; when a fibrous strip on one winder is using up, the other winder is initiated rapidly to ensure continuous and stabilized production of the enhanced clad pipe. In the invention, a winding packaging technology is upgraded and reconstructed to combine with a cladding double-layer extrusion technology. A foreign complex technology requiring a special windercan be substituted to raise operation convenience, promote generalization of the technology and fill domestic technical blank of continuous fiber winding enhanced clad pipe. Therefore, the technologyof the invention is suitable for industrialized popularization.

Owner:LINHAI WEIXING NEW BUILDING MATERIALS CO LTD

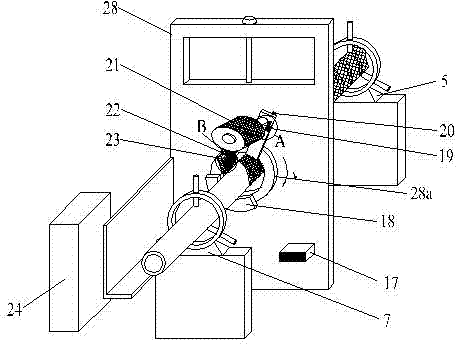

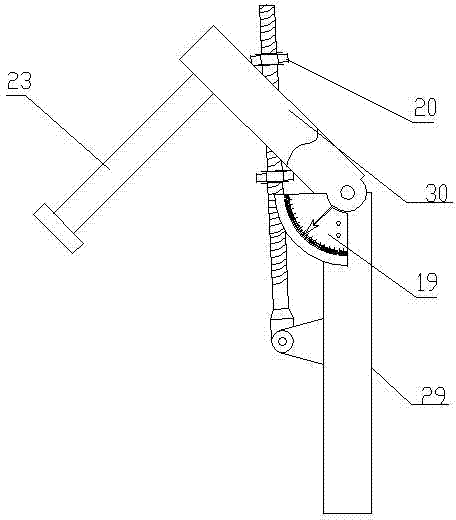

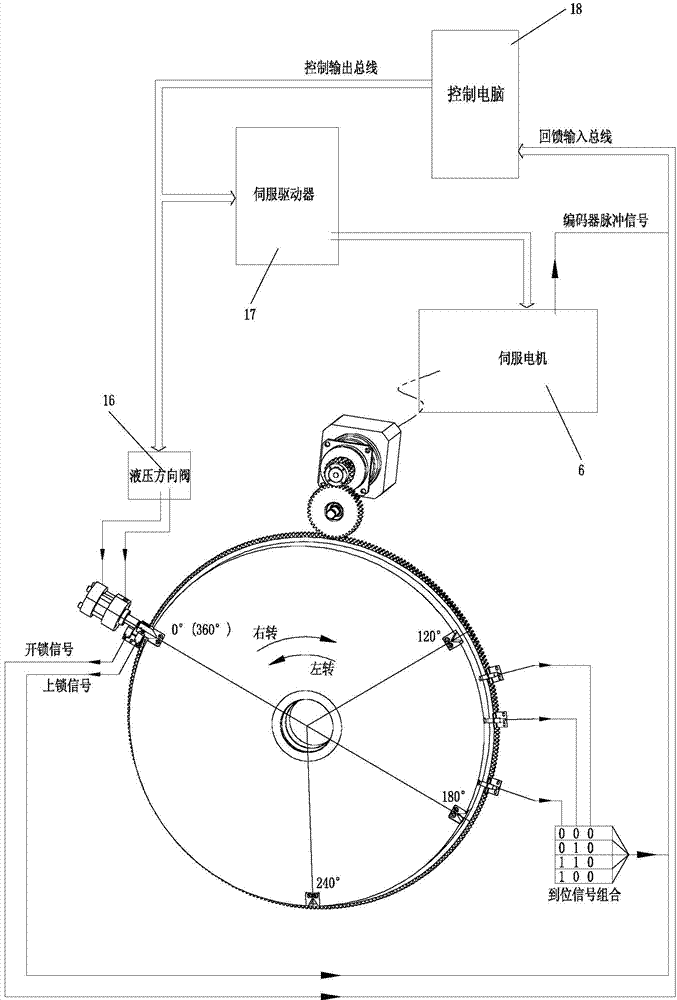

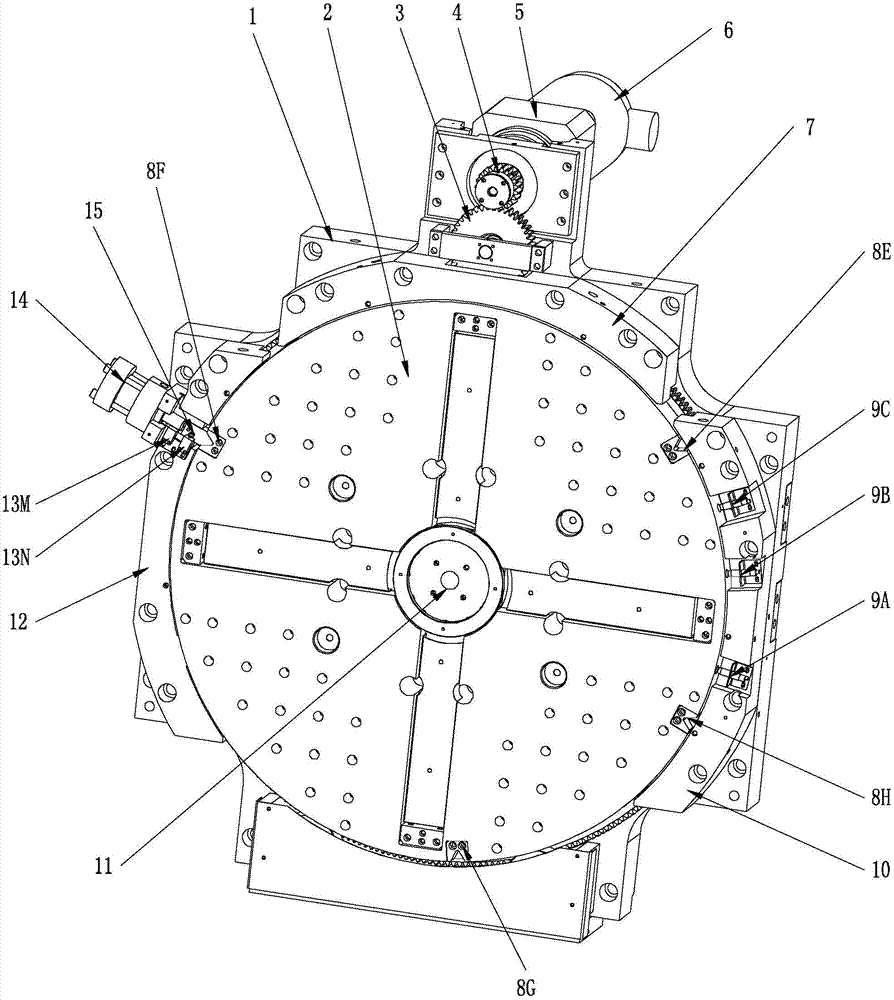

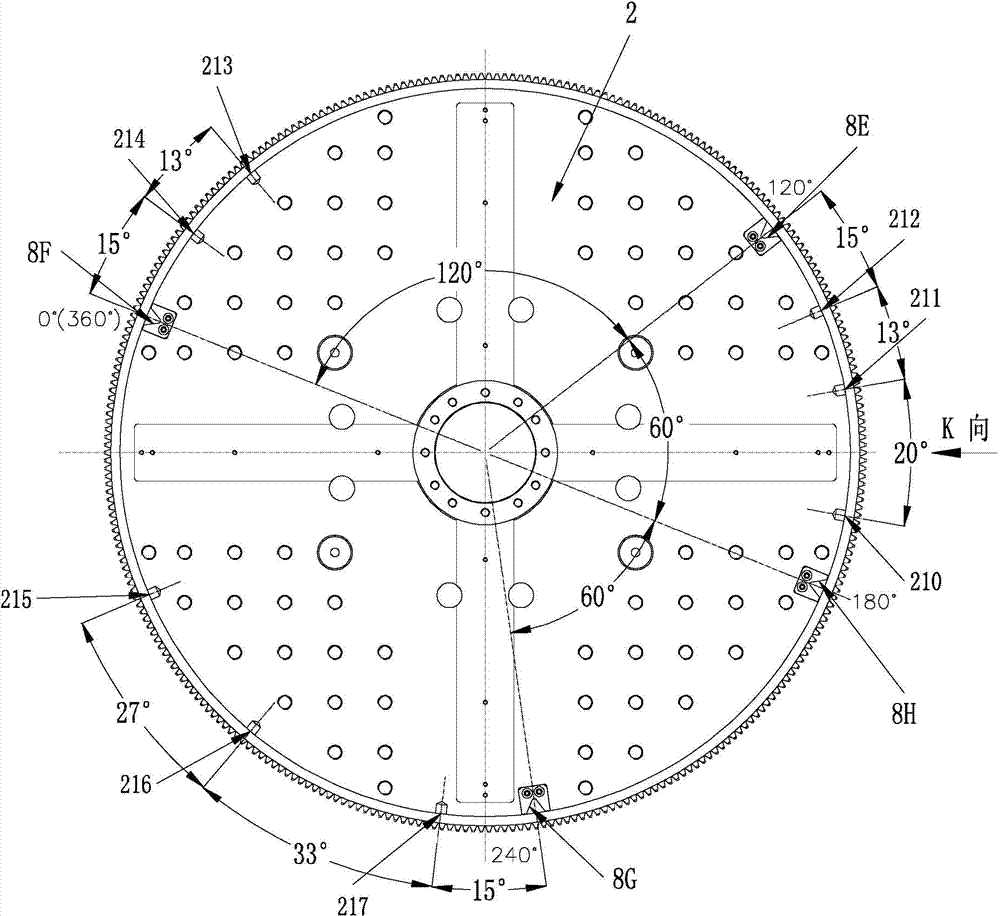

Servo-power four-station rotary plate mechanism

The invention relates to a servo-power four-station rotary plate mechanism applied to the field of multiple material injection molding machines. The servo-power four-station rotary plate mechanism mainly comprises a bottom plate, a rotary plate which can rotate around a rotary shaft component on the center of the bottom plate, a servo motor which is used for driving the rotary plate to rotate through engaged transmission of a gear set, a positioning insertion pin component which is arranged at the peripheral side of the rotary plate, and the like. 120-180 indexing patterns of the mechanism can realize rotary indexing modes of 0-180-0(360), 0-120-240-0(360), 0-120-180-240-0(360); the 90-180 indexing patterns of the mechanism can realize rotary indexing modes of 0-180-0(360), 0-90-180-0(360), 0-90-180-270-0(360). The mechanism is quick in rotation, stable in starting and stopping, precise in indexing, and various in multi-station multi-mode using choices.

Owner:DONGHUA MACHINERY

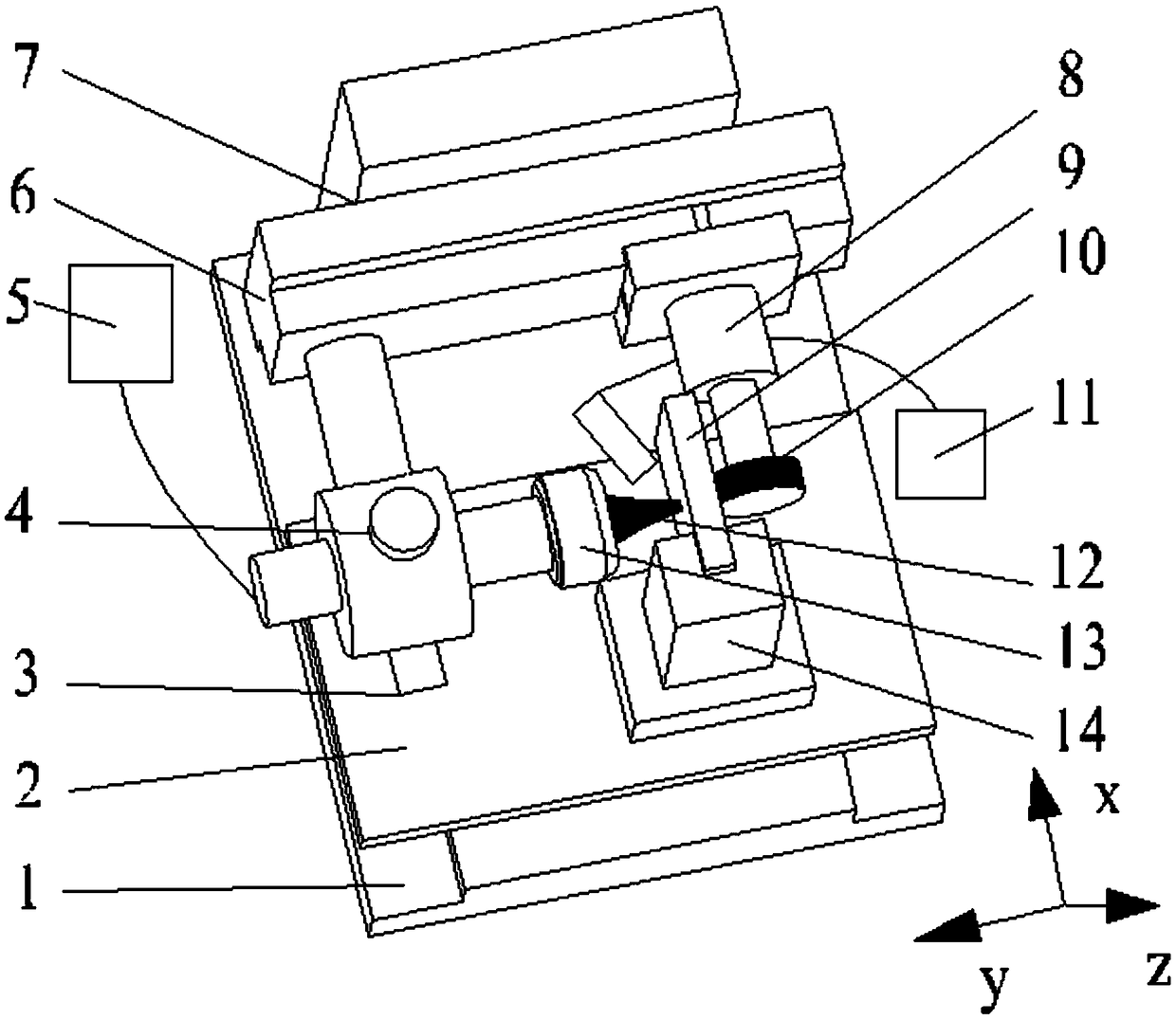

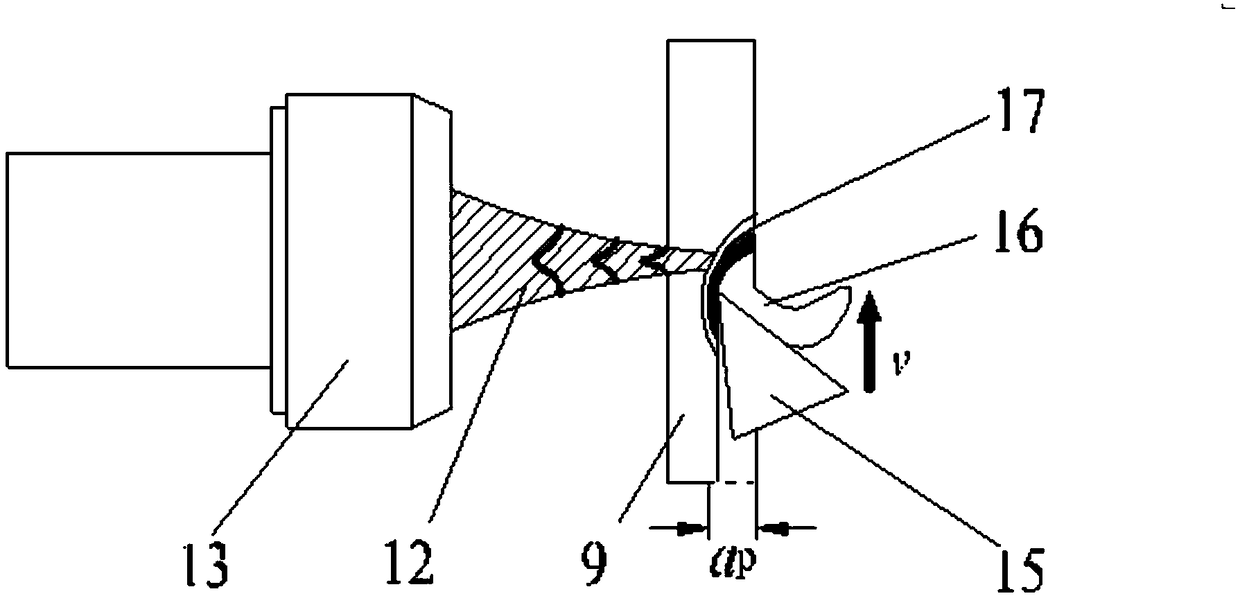

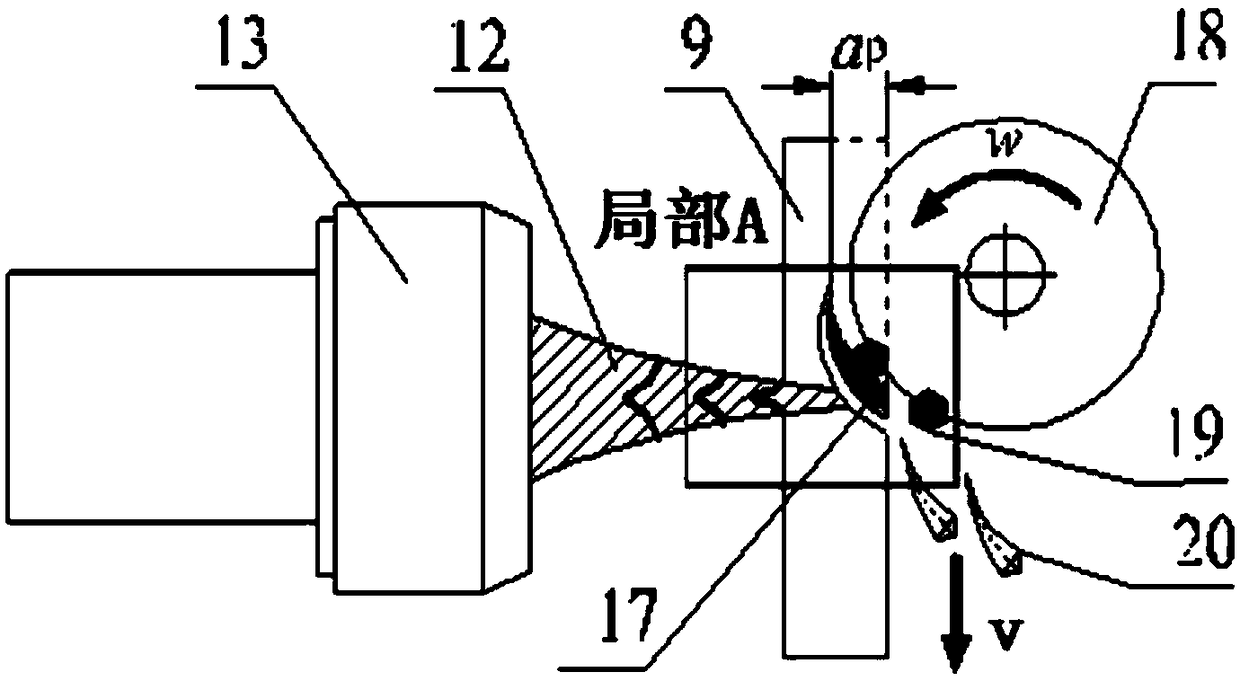

Device and technology for laser auxiliary cutting and grinding machining of transparent hard and bristle material

The invention discloses a device and technology for laser auxiliary cutting and grinding machining of a transparent hard and bristle material. A laser head and a cutting and grinding tool are locatedon the two sides of a transparent workpiece correspondingly, and the cutting and grinding tool is fixed to a rotating shaft. The laser head and the rotating shaft are fixed to the z-direction linear axis through a fixing plate. The transparent workpiece is fixed to the linear shaft x through a clamp and moves in the x direction of the linear axis x. The transparent workpiece, the laser head and the cutting and grinding tool are controlled through the z-direction linear axis along the displacement in the z direction. Lasers are emitted to the other side of the workpiece from the transparent workpiece, and it is ensured that the other side of the transparent material obtains the heating temperature in the laser beam defocusing amount range so that the material can be softened. The device andtechnology for laser auxiliary cutting and grinding machining of the transparent hard and bristle material has the beneficial effects that tool abrasion is reduced, and the surface quality of the workpiece is improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

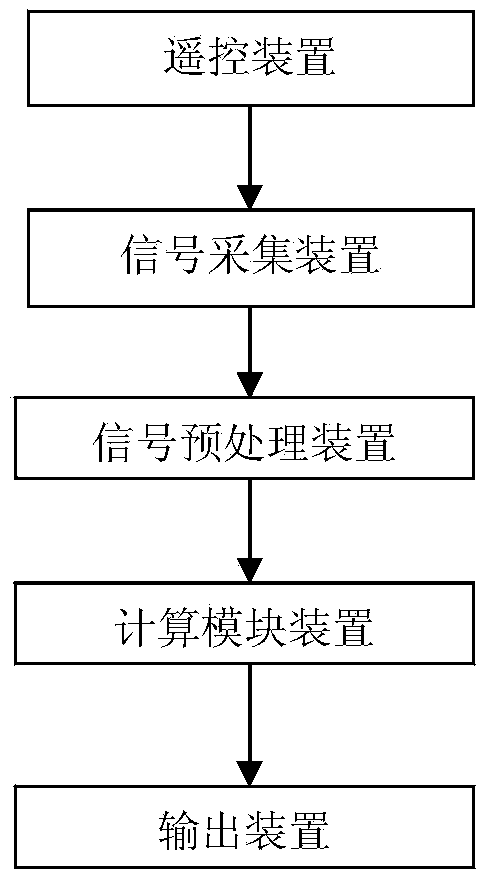

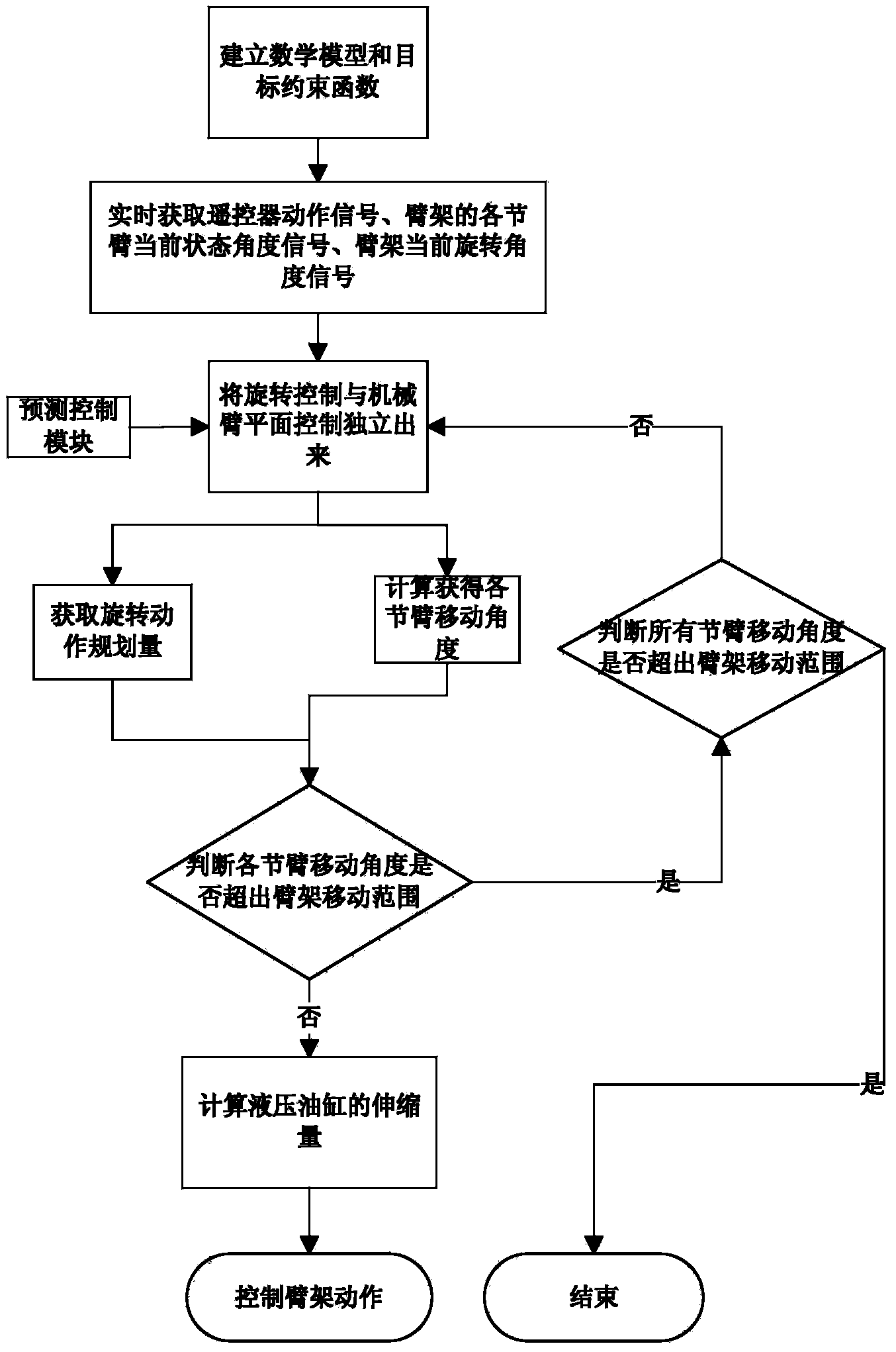

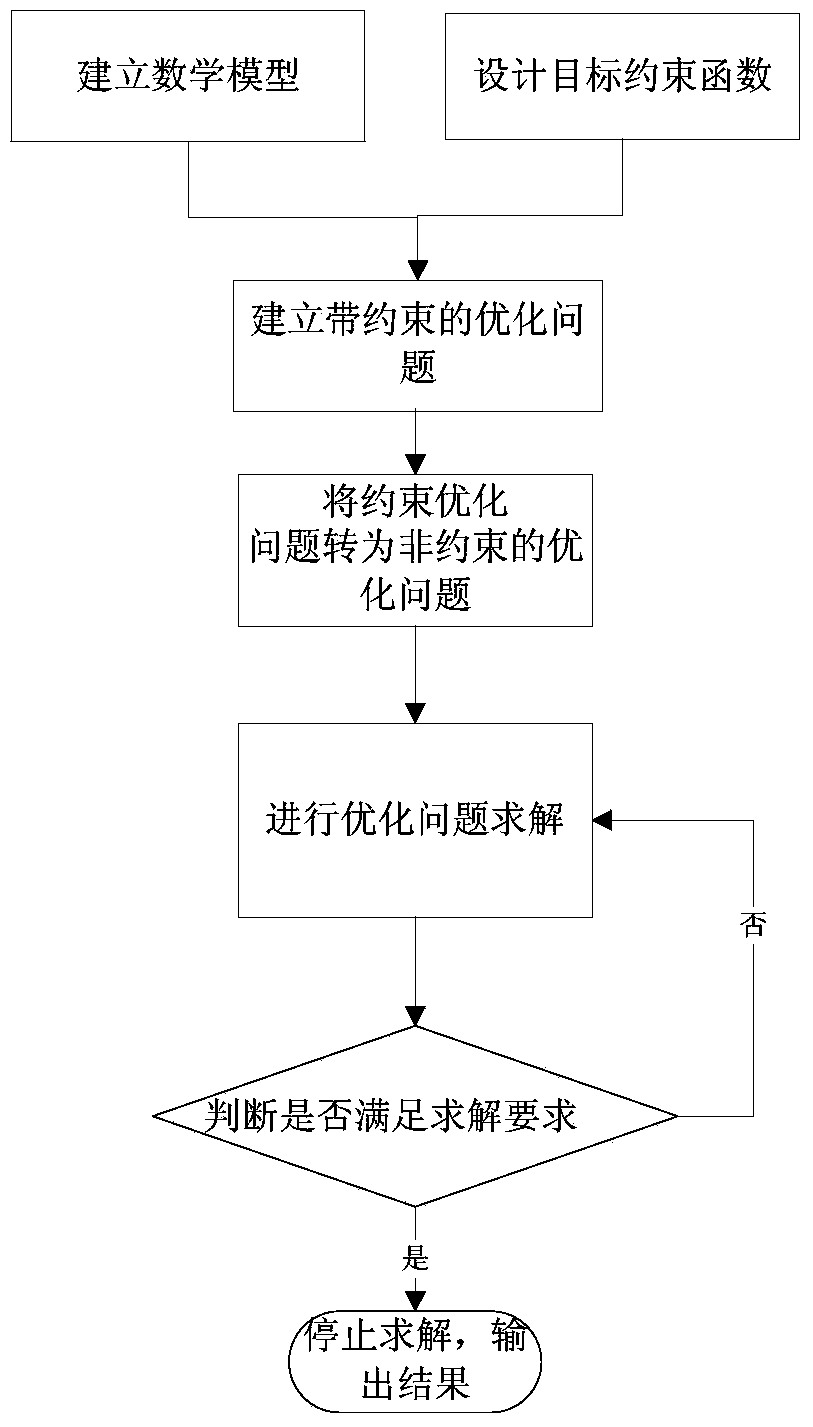

Concrete pump truck and cantilever crane control method and device

ActiveCN103806667AImprove continuityImprove motion stabilityBuilding material handlingEngineeringCantilever

The invention discloses a cantilever crane control method. The cantilever crane control method comprises the following steps: step 1, a mathematical model is established according to the current position of a cantilever crane to the next target position, and a target constraint function is established based on the principles of minimum movement amount and movement stability of each arm; step 2, an actuating signal of a remote controller, a current state angle signal of each arm and a current rotation angle signal of the cantilever crane are obtained; step 3, the movement angle of each arm and the target rotation angle of the cantilever crane are obtained through calculation; step 4, whether the movement range of the cantilever crane is exceeded is judged; step 5, the movement of the cantilever crane is stopped if the movement range of the cantilever crane is exceeded, and the cantilever crane is controlled to move if otherwise. The invention further provides a concrete pump truck and a cantilever crane control device. By means of the cantilever crane control method, the cantilever crane is small in movement amount, good in stability and continuity, high in accuracy and wide in operating range.

Owner:SANY AUTOMOBILE MFG CO LTD

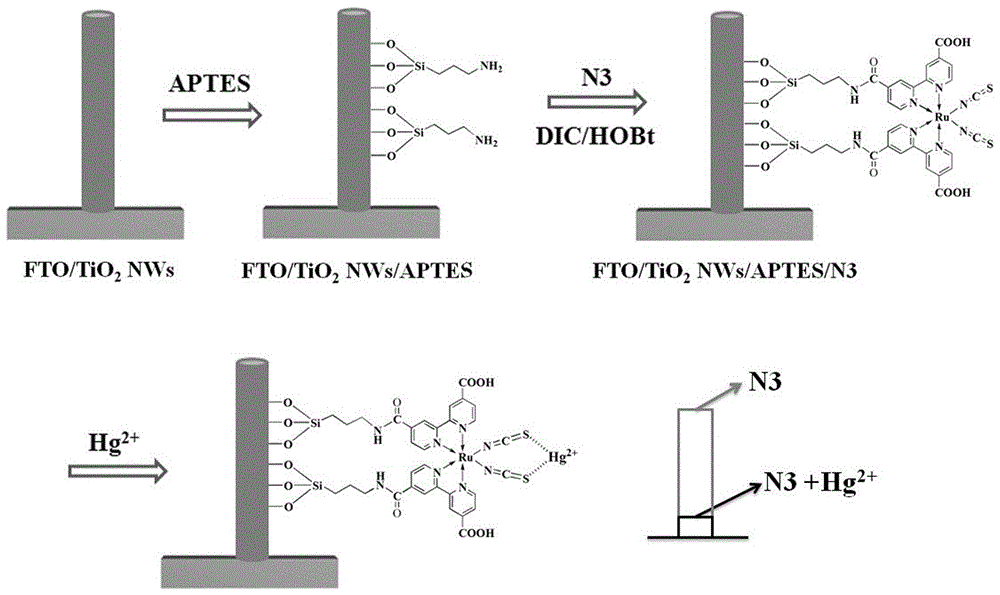

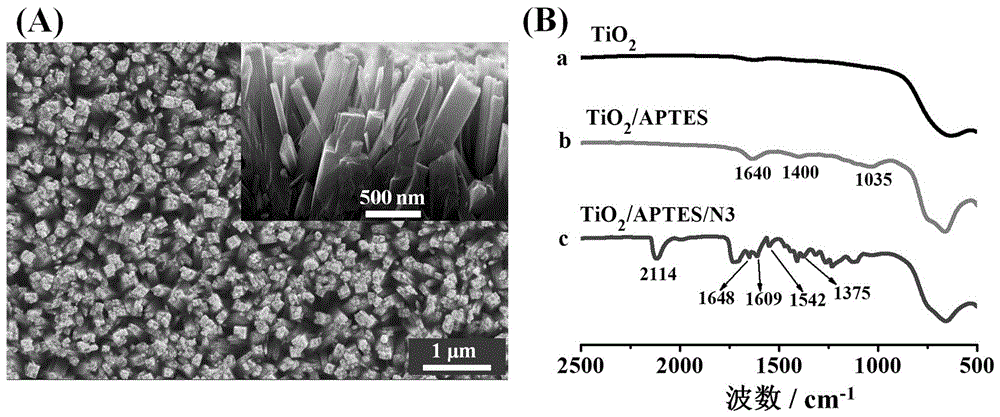

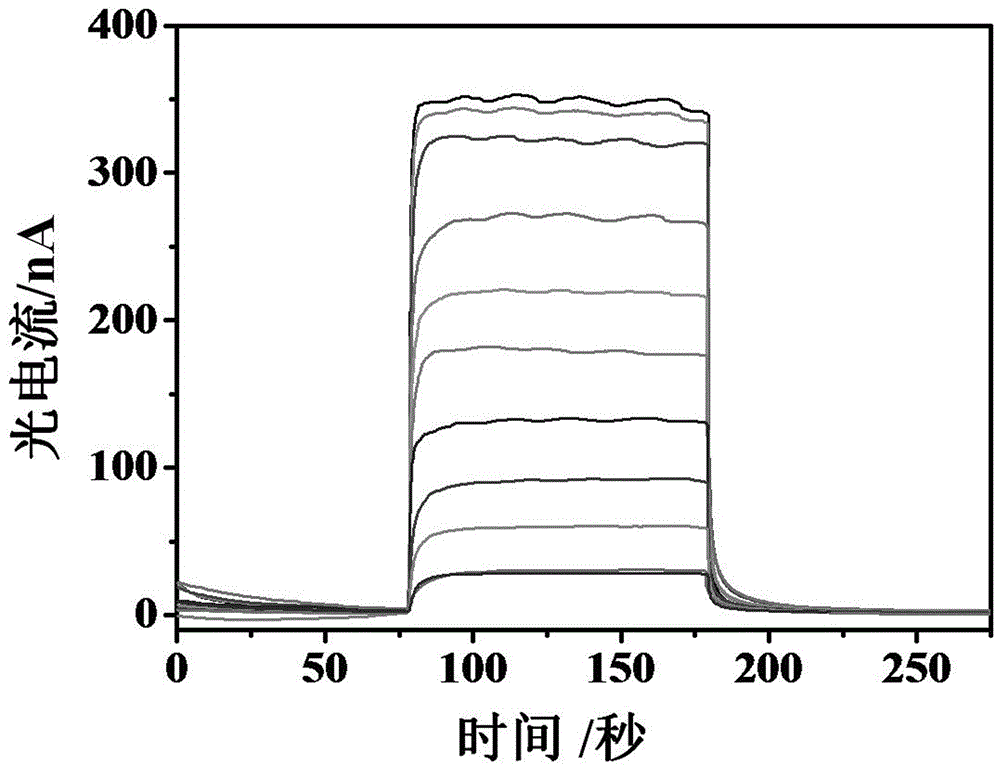

Mercury ion photo-electrochemical sensor working electrode and manufacturing method and application thereof

ActiveCN105784806AGood specificity recognitionHigh selectivityMaterial electrochemical variablesIonEnvironmental chemistry

The invention discloses a mercury ion photo-electrochemical sensor working electrode and a manufacturing method and an application thereof, and belongs to the technical field of chemical analysis detection. The manufacturing method of the photo-electrochemical sensor working electrode comprises the following steps: performing hydro-thermal synthesis on titanium dioxide nanowires on FTO conductive glass to form amination titanium dioxide nanowires; coupling photosensitive molecules with the amination titanium dioxide nanowires through chemical bonding to obtain the working electrode. The sensor working electrode has the advantages of high selectivity and high sensitivity to mercury ions, the response speed is high, the response range is 0.5nmol.L<-1>-50mumol.L<-1>, and the detection limit is up to 0.15nmol.L<-1>. Accurate control on mercury ion recognition by a mercury ion photo-electrochemical sensor is enhanced, a stable photosensitive dye molecular structure contributes to keeping of sensor stability, and the working electrode has a good development prospect.

Owner:SHANGQIU NORMAL UNIVERSITY

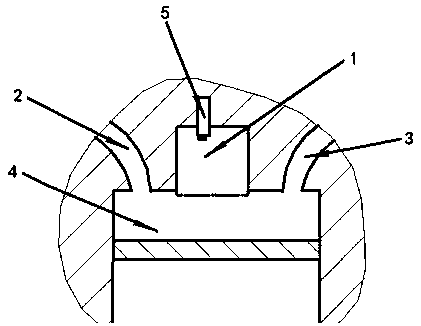

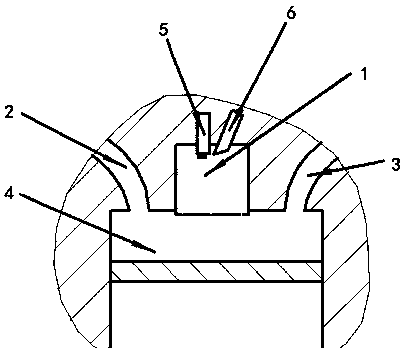

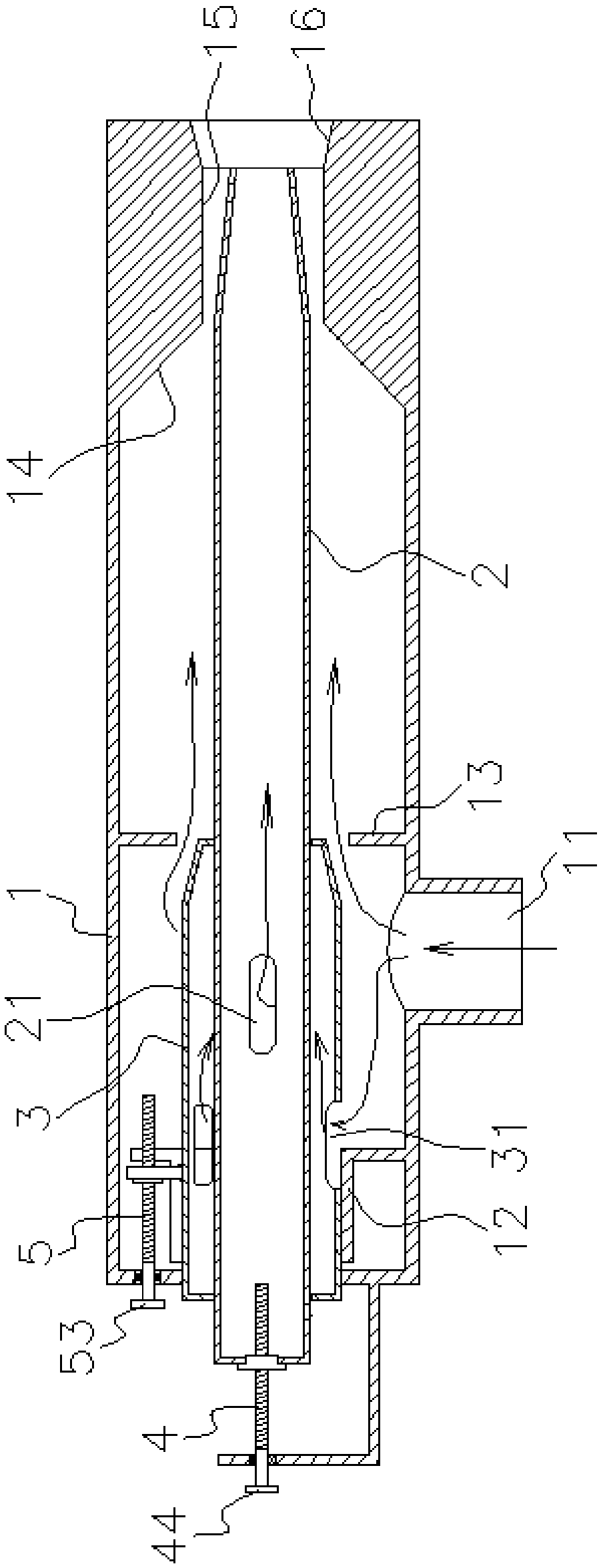

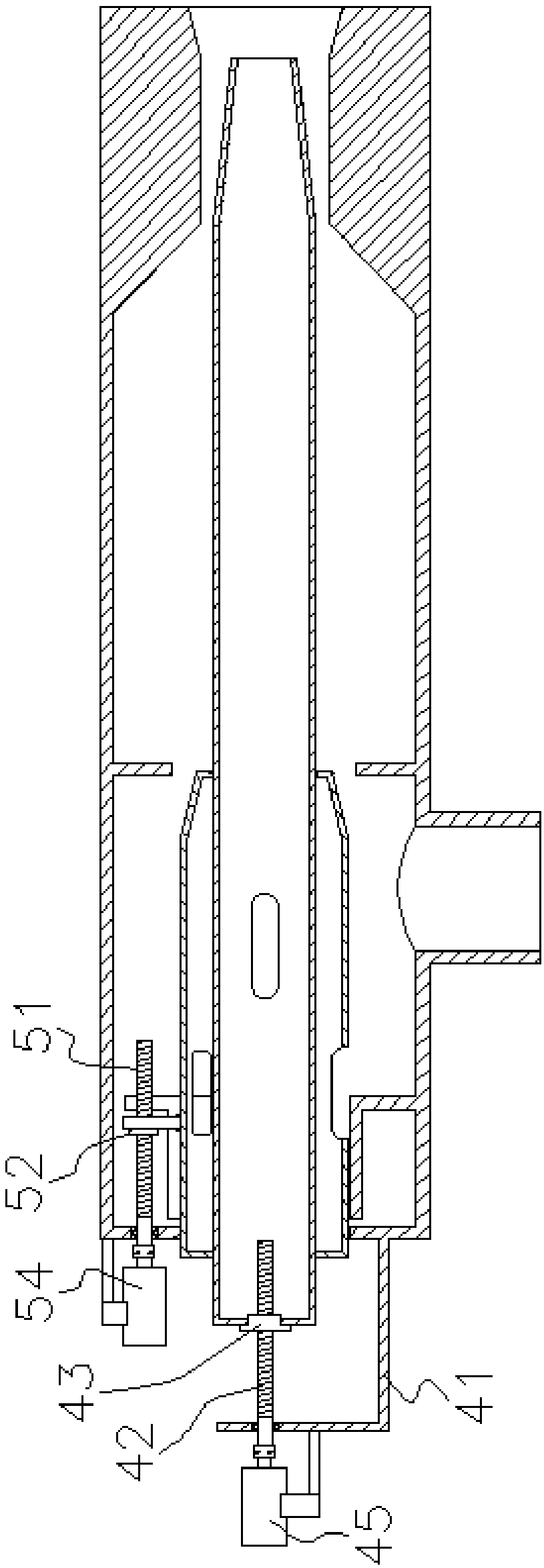

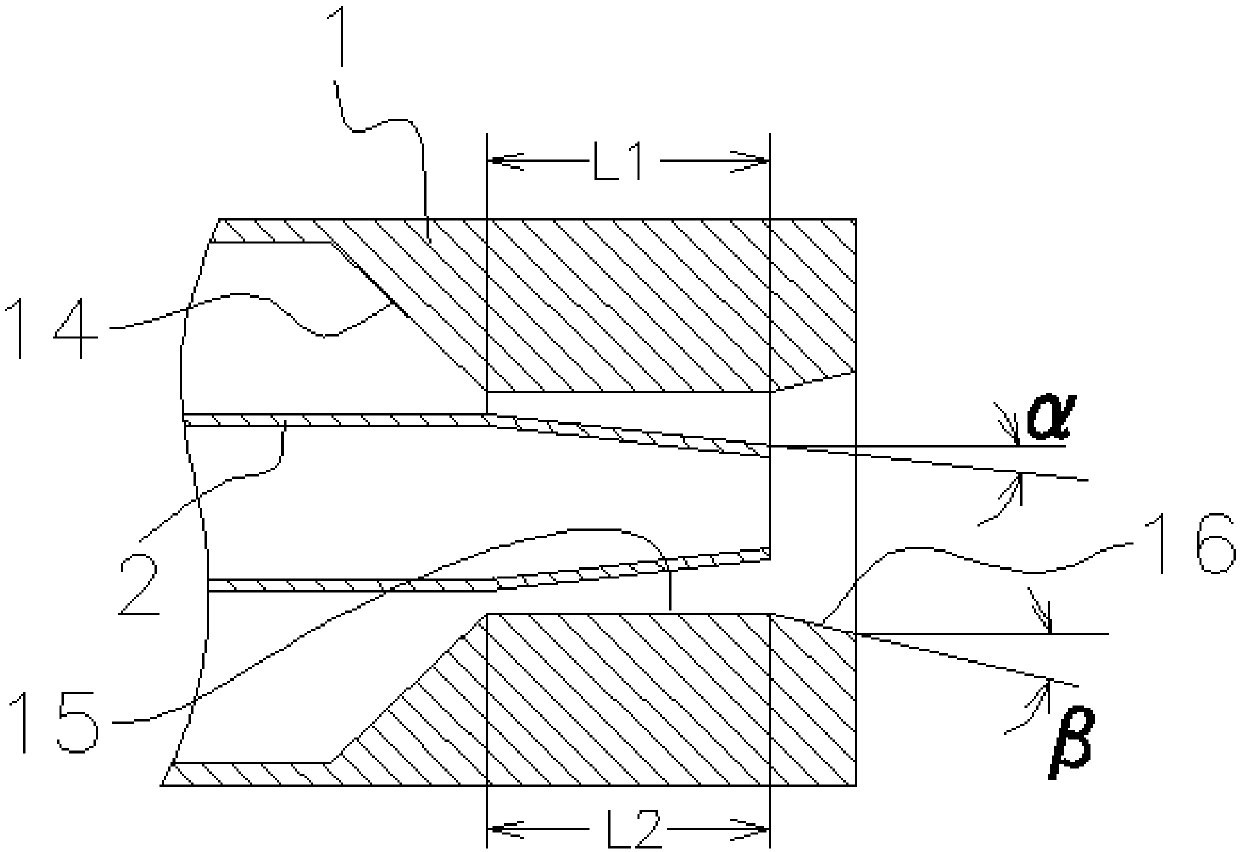

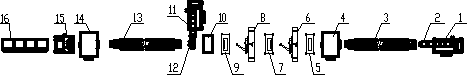

Precombustion system with gas-carried nozzle, internal combustion engine and precombustion control method

PendingCN110953059ASimple structureAchieve hybridElectrical controlInternal combustion piston enginesControl systemProcess engineering

The invention discloses a precombustion system with a gas-carried nozzle. The system comprises a precombustion chamber, a gas-carried nozzle mechanism, an ignition mechanism and a control mechanism; through arrangement of the gas-carried nozzle mechanism, the fuel and air mixing can be realized, and mixed gas is sprayed into the precombustion chamber to solve the problems of waste gas emission andfuel and air supply; and a precombustion chamber intake way and related structures have no need to be added in the precombustion chamber to greatly simplify the structure of the precombustion chamber. The invention provides the precombustion system with the gas-carried nozzle; and through arrangement of the control system, the control of the fuel mixing quantity, the compressed air mixing quantity, the mixed gas spraying time and the spraying lasting period in the gas-carried nozzle mechanism can be realized, and residual waste gas in the precombustion chamber can be eliminated, so that the stability and the precise control of ignition and combustion are improved, high efficiency from idle speed to highest rotating speed and from low load to full load is achieved, and the internal combustion engine works in the combustion process with high performance and low emission.

Owner:天津轩云科技有限公司

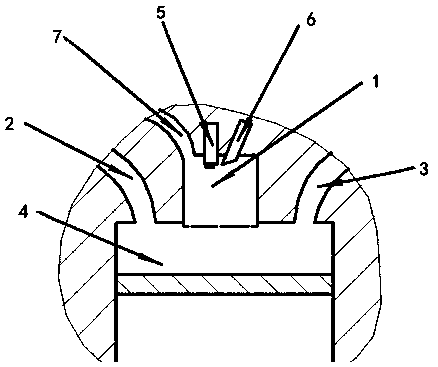

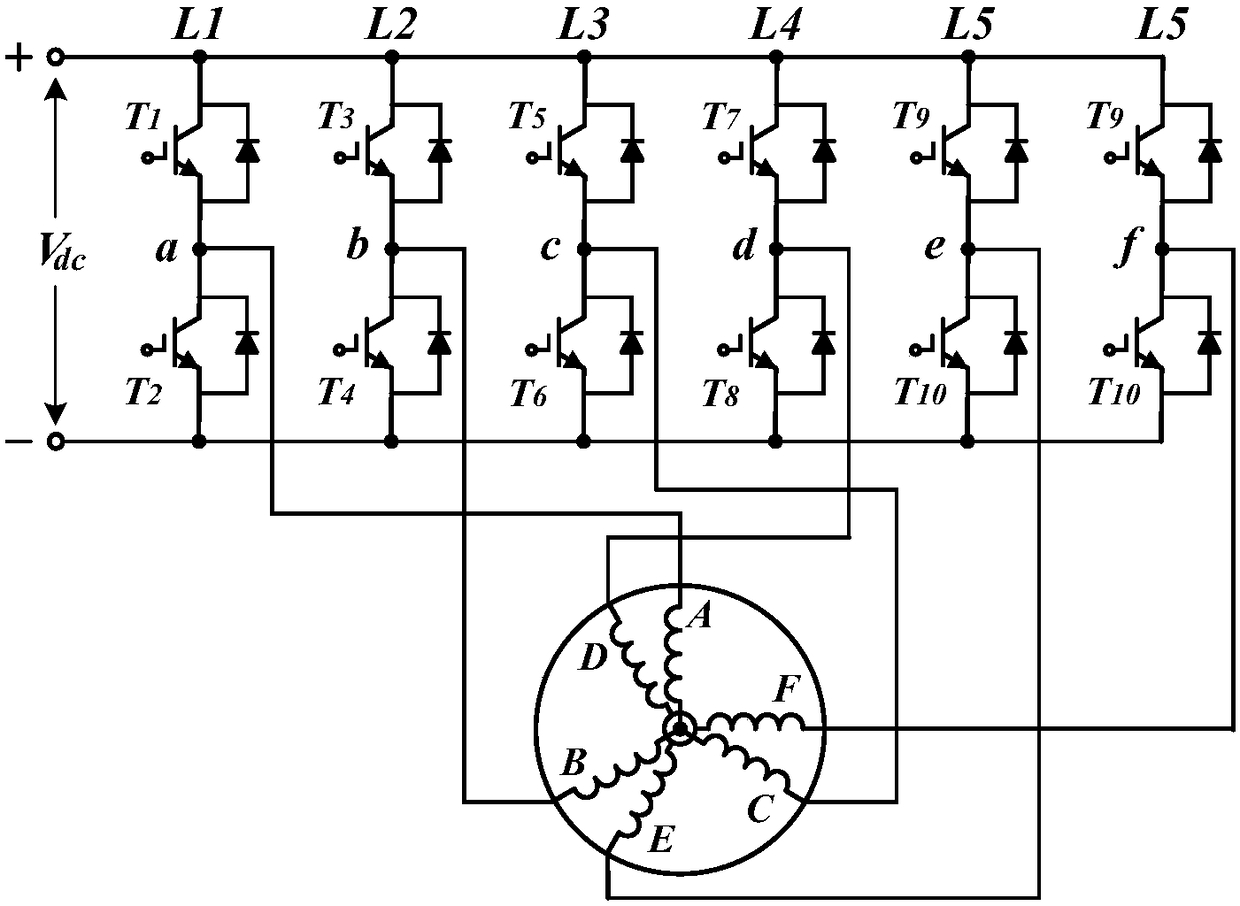

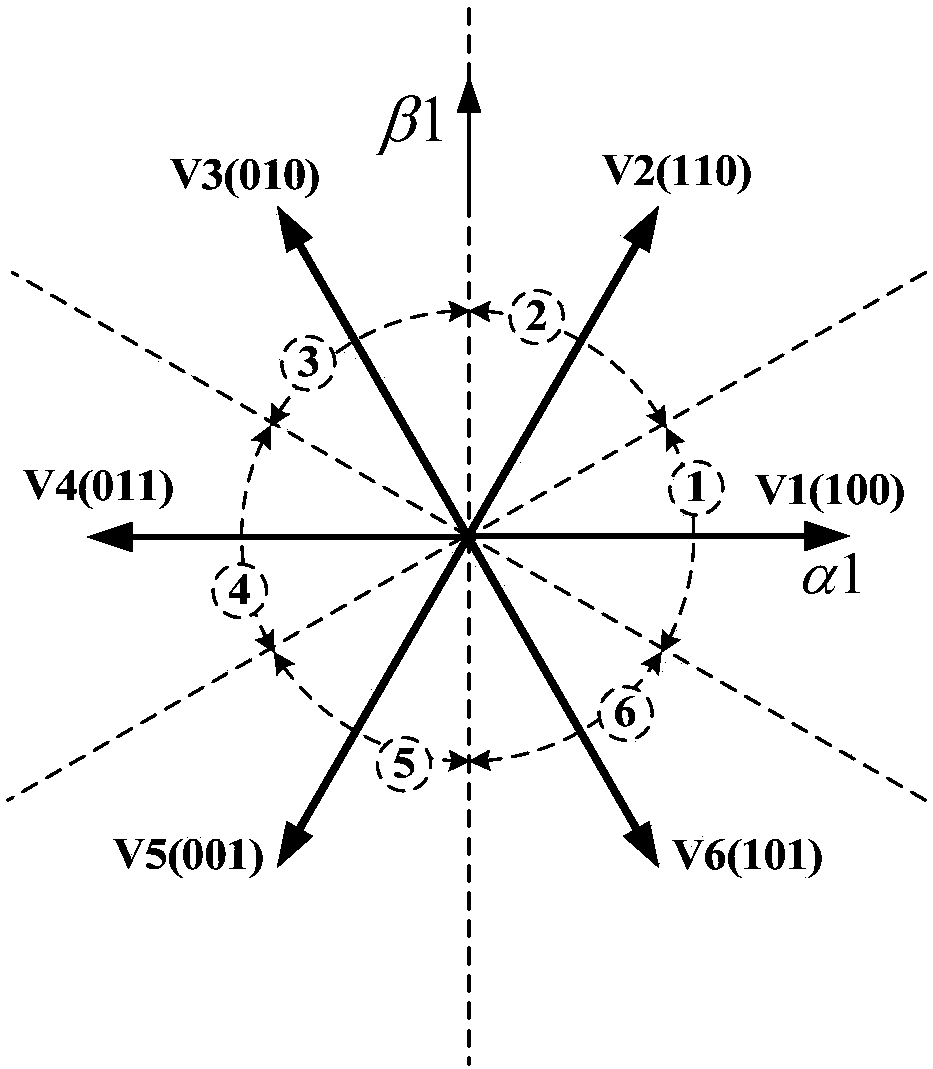

Direct torque control system and method of six-phase motor

ActiveCN108574442AControl speedFast switching speedElectronic commutation motor controlAC motor controlPower inverterControl system

The invention discloses a direct torque control system and method of a six-phase motor. The direct torque control system is connected with a six-arm inverter and a six-phase double-Y-winding motor, middle points of six arms of the six-arm inverter are connected with six phases of winding terminals of the six-phase double-Y-winding motor correspondingly, each inverter arm of the six-arm inverter isformed by connecting two power switch tubes in series, a connecting point of the two power switch tubes in each inverter arm is the middle point of the corresponding arm, the two ends of the serial-connected power tubes are connected with anode and cathode of a DC power supply respectively, the former three inverter arms in the six-arm inverter form a first inverter, the latter three in the sameform a second inverter, and the direct torque control system obtains switch triggering signals of the first and second inverters to realize direct torque control for the six-phase double-Y-winding motor. According to the control system and method, calculation steps are simplified, the calculation difficulty is reduced, and control of high precision and rapid response is realized.

Owner:CHANGAN UNIV

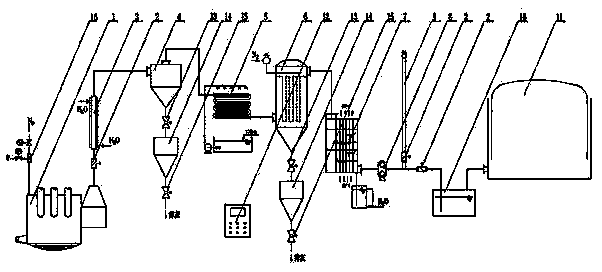

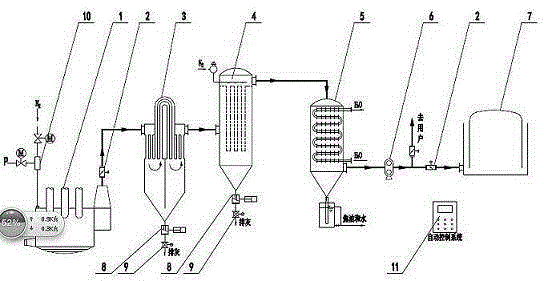

Closed ferroalloy furnace coal gas dry method purification and recovery system

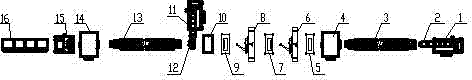

ActiveCN103528388ASmall footprintImprove purification efficiencyIncreasing energy efficiencyGas purification by non-gaseous materials condensationEvaporative coolerAutomatic control

The invention relates to a closed ferroalloy furnace coal gas dry method purification and recovery system. A closed ferroalloy electric furnace 1 is sequentially connected with a water-cooling flue 3, a spark catcher 4, a surface evaporation cooler 5, a bag filter 6, a condensation drainer 7, a coal gas fan 8, a torch burner 9, a coal gas water seal 10 and a coal gas cabinet 11 through metal pipelines, the connecting pipeline of the ferroalloy electric furnace 1 and the water-cooling flue 3, the connecting pipeline of the coal gas fan 8 and the torch burner 9 and the connecting pipeline of the torch burner 9 and the coal gas water seal 10 are respectively provided with a switching valve 2, an upper ash discharging valve 13, a middle ash tank 14 and a lower ash discharging valve 15 are sequentially installed below the spark catcher 4 and the bag filter 6 respectively, a furnace pressure measuring device 16 is installed on a furnace cover of the closed ferroalloy electric furnace 1, and an automatic control system 12 is connected with the mentioned equipment and a valve through signal lines. According to the closed ferroalloy furnace coal gas dry method purification and recovery system, coal gas purification efficiency and quality are improved, water pollution and sludge problems caused by a wet method purifying process are avoided, sewage treatment investment and operating expense are saved, corrosion, blocking, freezing and the other problems existing in the wet method process are avoided, and maintenance workloads are reduced.

Owner:中钢集团天澄环保科技股份有限公司 +1

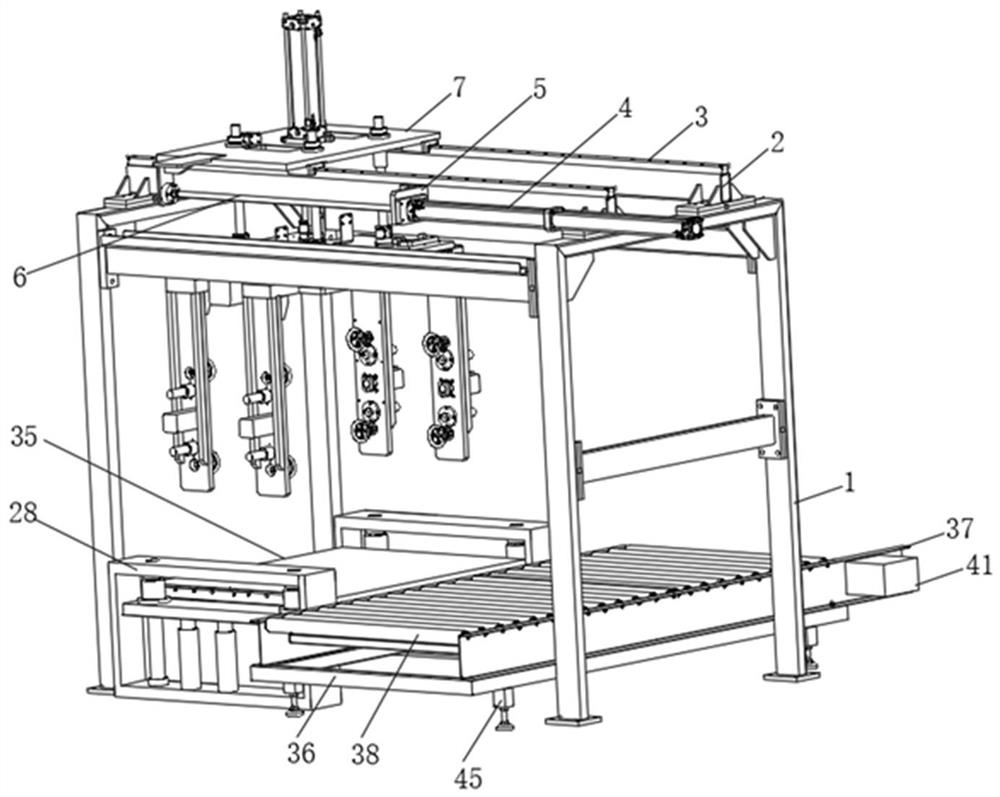

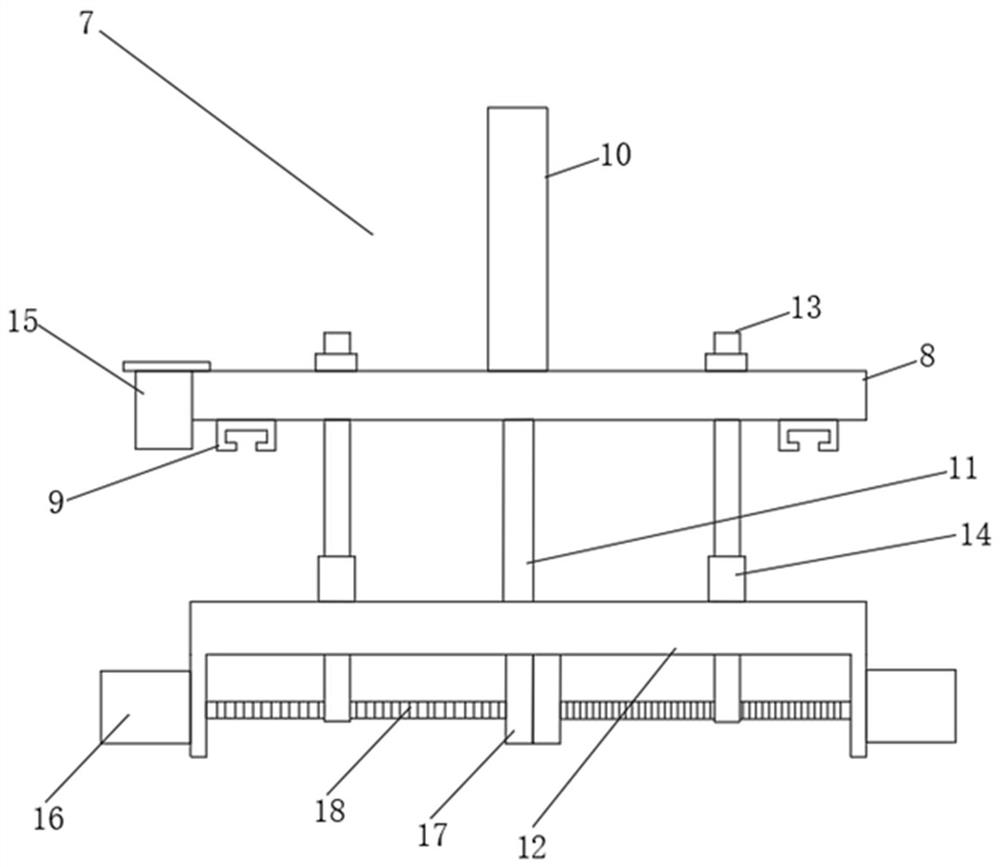

Wooden cabinet transfer equipment

PendingCN112141873AEasy to moveReduce the adverse effects of inertiaConveyorsBase supporting structuresElectric machineryEngineering

The invention relates to the technical field of transfer equipment, in particular to wooden cabinet transfer equipment. The wooden cabinet transfer equipment comprises a support frame, a moving assembly, a lifting plate, a clamping assembly and a lifting assembly. Lead screws are driven by corresponding first motors to rotate, a nut moves on the lead screws, a connecting plate is driven by the nutto move in the direction of the lead screws, so as to drive two clamping plates to move, the clamping plates at two ends of the lifting plate are driven by the two first motors to correspondingly move, so as to clamp a wooden cabinet, and the two first motors are used for driving, so that accurate control for clamping operation of the wooden cabinet is increased, control for the clamping force can be improved, the wooden cabinet is clamped more firmly by the wooden cabinet transfer equipment, the safety of subsequent transfer operation is improved, and the wooden cabinet can be prevented frombeing extruded and damaged in the operation process.

Owner:萧县八宝畜禽养殖农民专业合作社

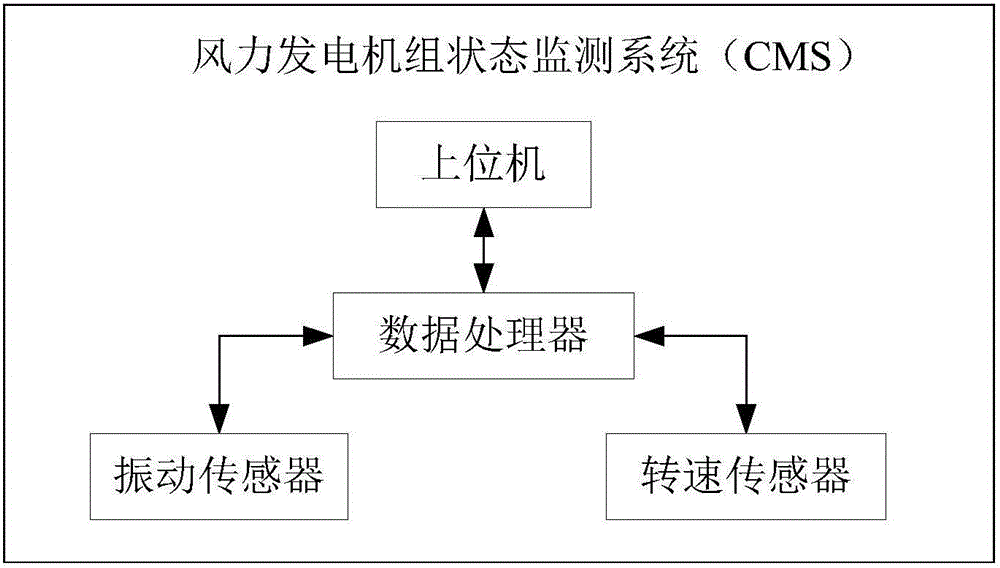

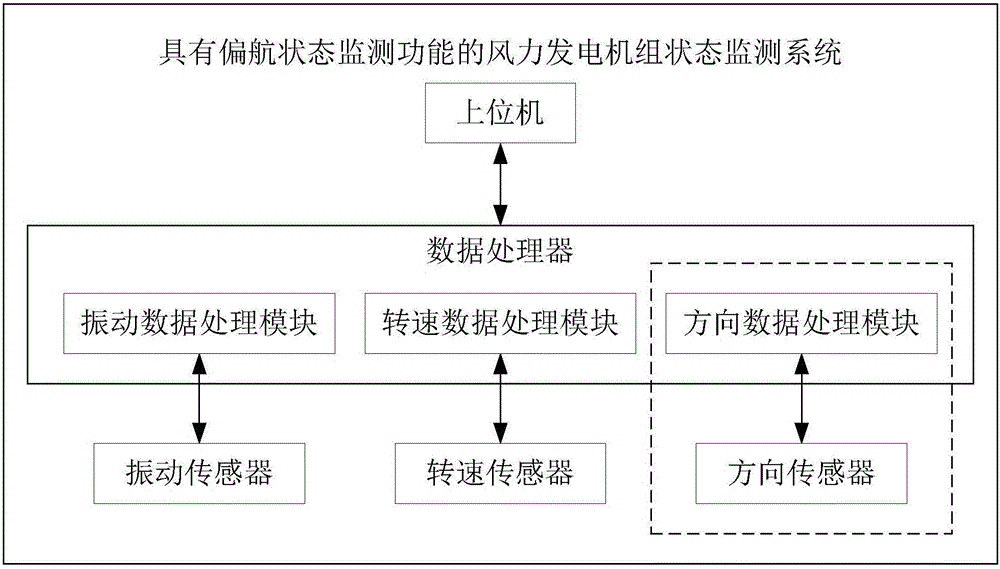

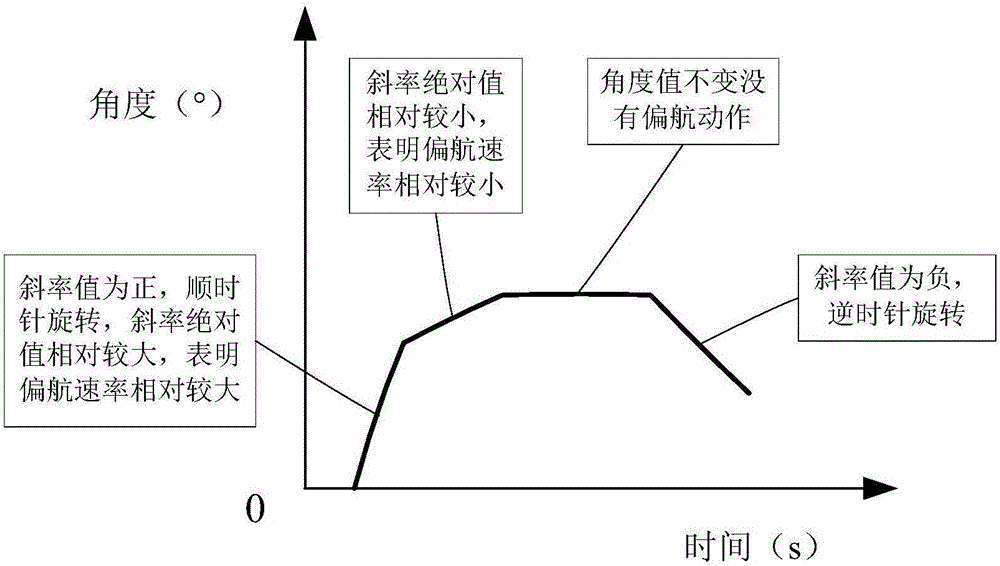

Wind turbine generator set state monitoring system having yawing state monitoring function and wind turbine generator set state monitoring method thereof

ActiveCN106338307AImprove accurate controlImprove accuracyMeasurement devicesData synchronizationElectricity

The invention discloses a wind turbine generator set state monitoring system having a yawing state monitoring function and a wind turbine generator set state monitoring method thereof. According to the scheme, the yawing direction monitoring function is additionally arranged in the wind turbine generator set state monitoring system so that real-time monitoring of the wind turbine generator set yawing state can be realized. The generator set yawing state synchronized with the vibration data often needs to be referred in fault diagnosis of the wind turbine generator set according to the vibration data so as to judge whether the fault is associated with yawing of the generator set. The effective basis can be provided for fault diagnosis of the wind turbine generator set through real-time monitoring of the wind turbine generator set yawing state so that the diagnosis accuracy can be enhanced.

Owner:北京能高普康测控技术有限公司

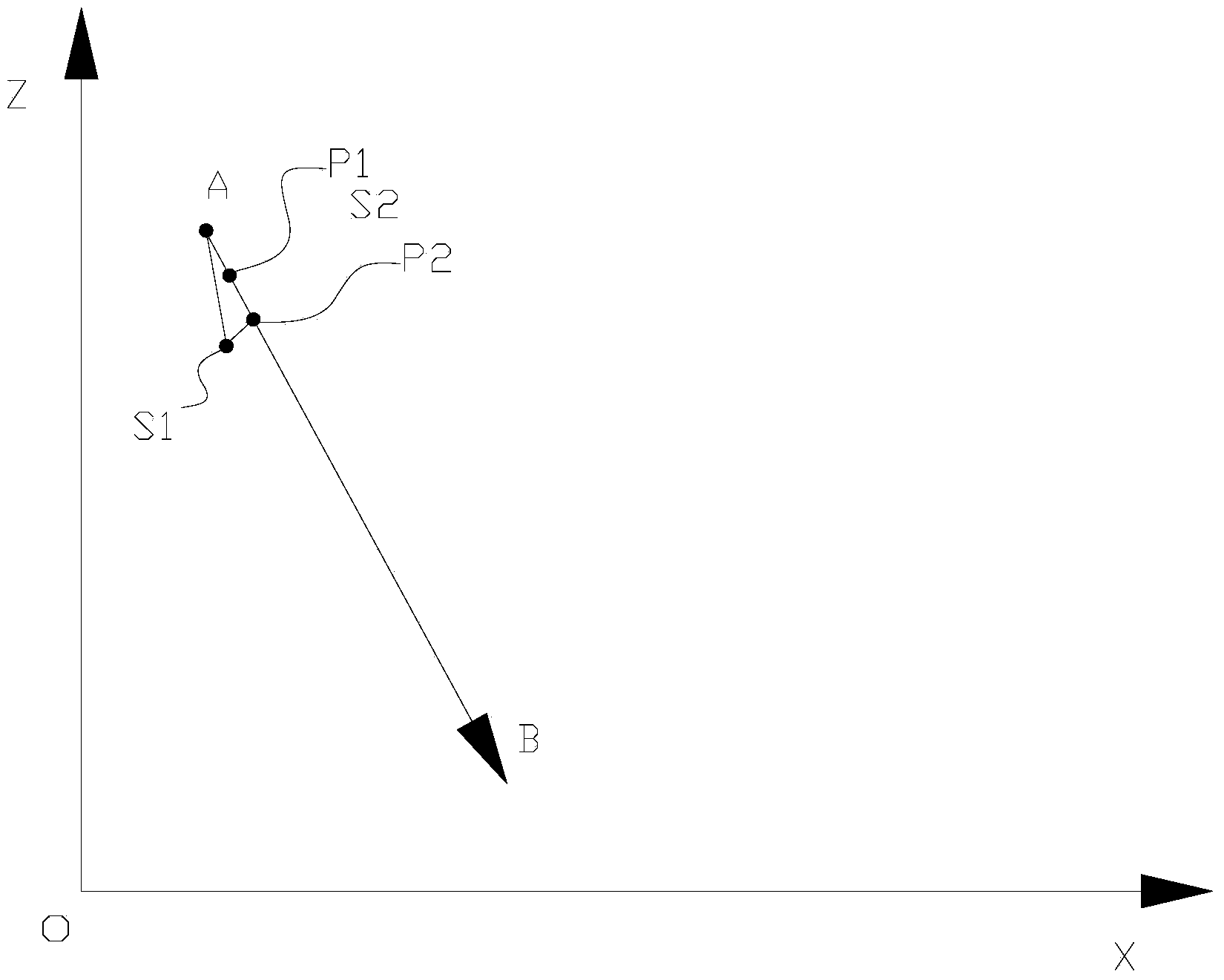

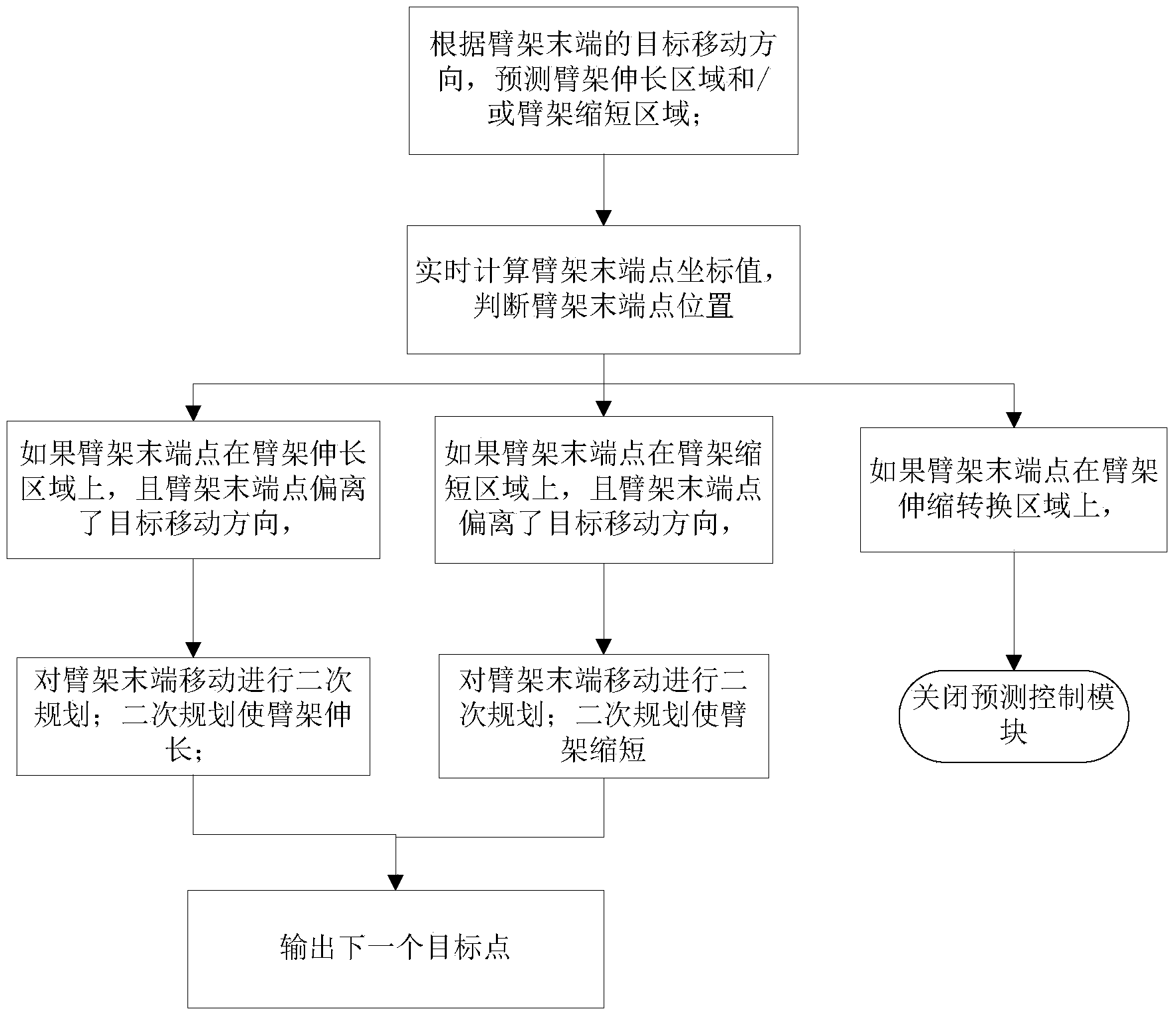

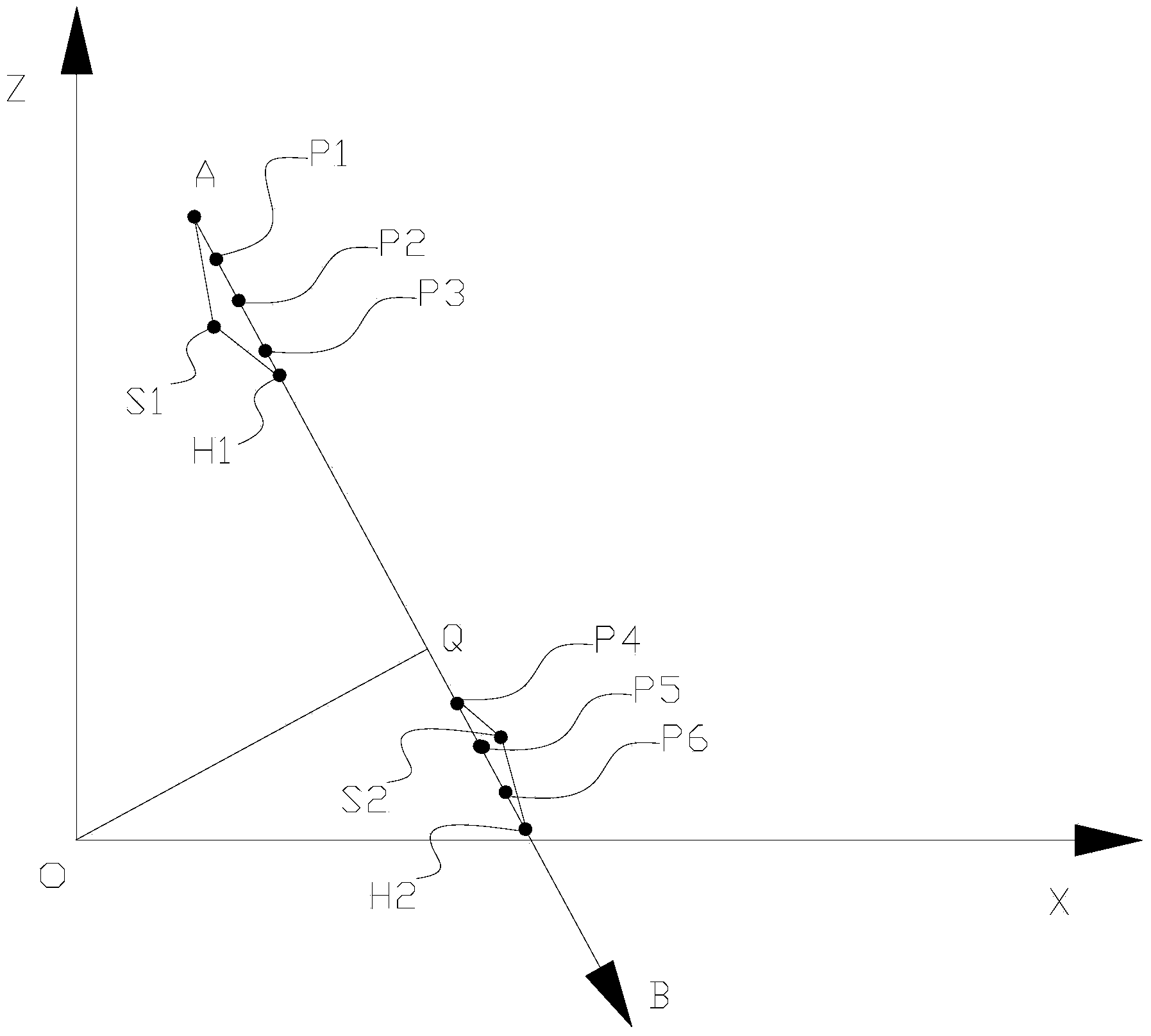

Concrete pump truck and cantilever crane control method

The invention discloses a cantilever crane control method. The cantilever crane control method comprises the steps that an actuating signal of a remote controller, a current state angle signal of each arm and a rotation angle signal of a cantilever crane are obtained in real time; the movement of the tail end of the cantilever crane is planned. The cantilever crane control method further comprises the step of prediction control. According to the prediction control, according to the target moving direction of the tail end of the cantilever crane, the coordinate value of the tail end point of the cantilever crane is calculated, if the tail end point of the cantilever crane deviates from the target moving direction, the tail end of the cantilever crane is planned for the second time, and a next target point is output through secondary planning. The invention further provides a concrete pump truck. According to the cantilever crane control method, due to the fact that the tail end of the cantilever crane is planned for the second time under the condition that the tail end of the cantilever crane deviates from the target moving direction, the cantilever crane is no longer controlled to move according to an originally planned scheme, it is guaranteed that the tail end point of the cantilever crane always moves towards the target point, the possibility that the cantilever crane stretches and contracts repeatedly and alternately is lowered, and the tail end of the cantilever crane is made to move stably.

Owner:SANY AUTOMOBILE MFG CO LTD

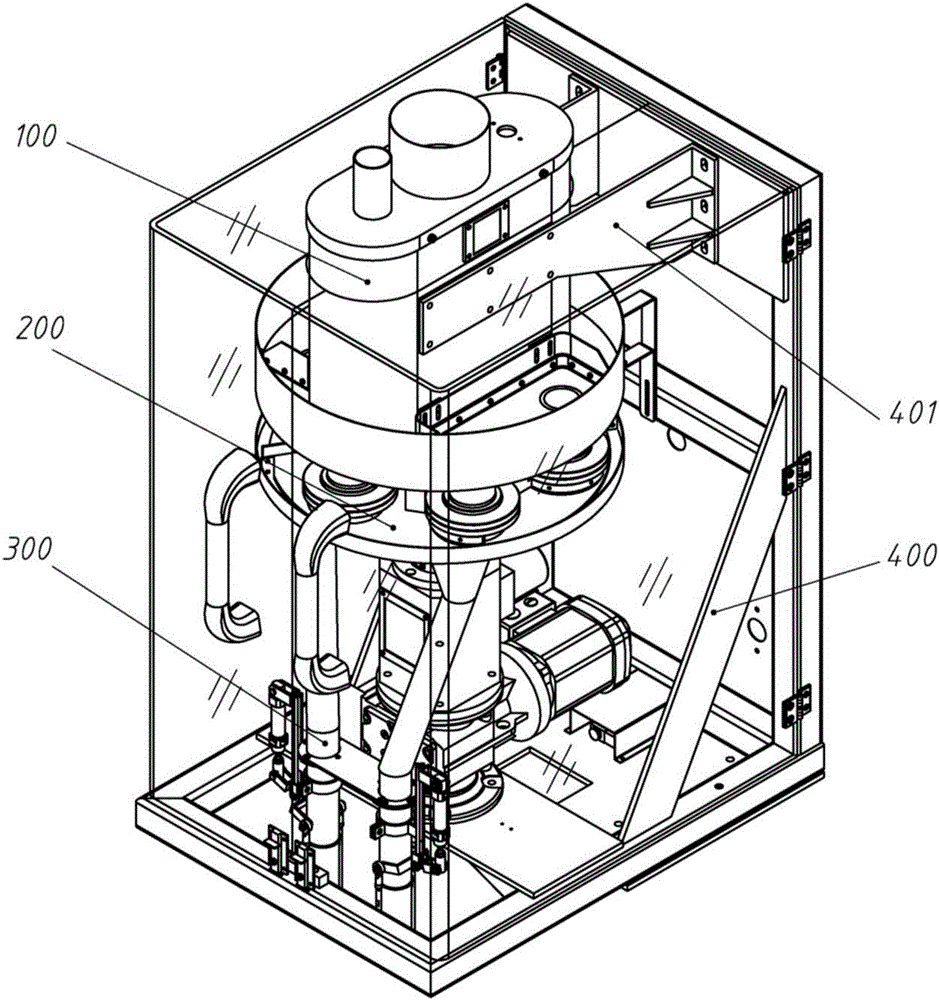

Double-station measuring cup metering device

The invention discloses a double-station measuring cup metering device. The double-station measuring cup metering device comprises a bin assembly, a measuring cup assembly, a discharge tube assembly and a supporting frame assembly, wherein the bin assembly, the measuring cup assembly and the discharge tube assembly are sequentially arranged on the supporting frame assembly from top to bottom; the output end of the storage bin assembly is in butt-jointed with the input end of the measuring cup assembly; the output end of the measuring cup assembly is connected with the input end of the discharge tube assembly; two discharge openings are formed in the measuring cup assembly; the discharge tube assembly comprises two discharge tubes; upper ends of the two discharge tubes are respectively butt-jointed with the two discharge openings of the measuring cup assembly in the; and a pneumatic gate valve is arranged at the lower end of each of the discharge tubes. Through the adoption of the double-station measuring cup metering device, the packaging speed is increased by one time, and accurate control of the discharge time is effectively improved, so that the packaging efficiency is improved by adopting the same manufacture cost.

Owner:WUHAN RENTIAN PACKAGING TECH

Motor intelligent power-saving protector

InactiveCN100409563CImprove accurate controlGood conditionMotor control for low load efficiencyComputer controlDisplay deviceEngineering

The disclosed intelligent power-saving protective device for motor comprises: a primary power circuit with output end connected with the input of following two circuits, a switch power circuit with output end connected with input end of all following members, a power drive circuit with input end connected with the PWM generating circuit and microprocessor and the switch power, a microprocessor with input end connected all of the power drive circuit, protective circuit, the power detection, the parameter controller and the switch power circuit; a PWM generating circuit, a protective circuit, a power detection circuit, a function extension interface, a parameter setting controller, and a display. This invention is convenient and reliable.

Owner:湖南巨汇科技发展有限公司

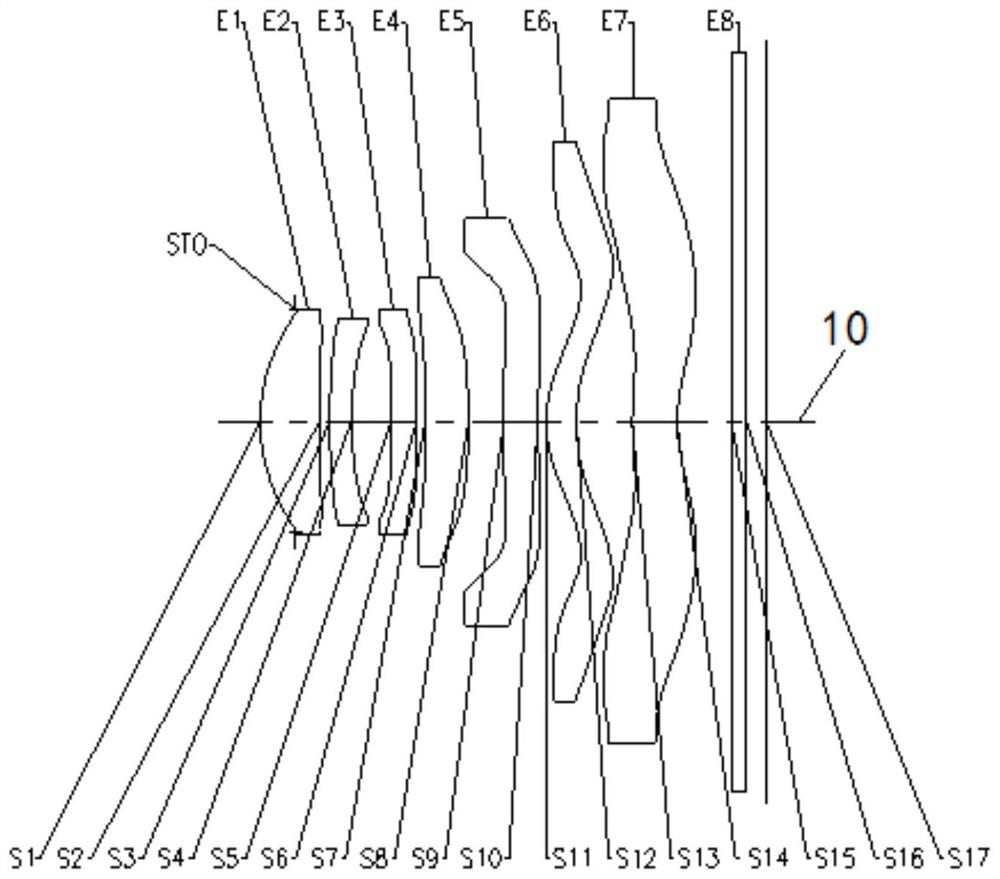

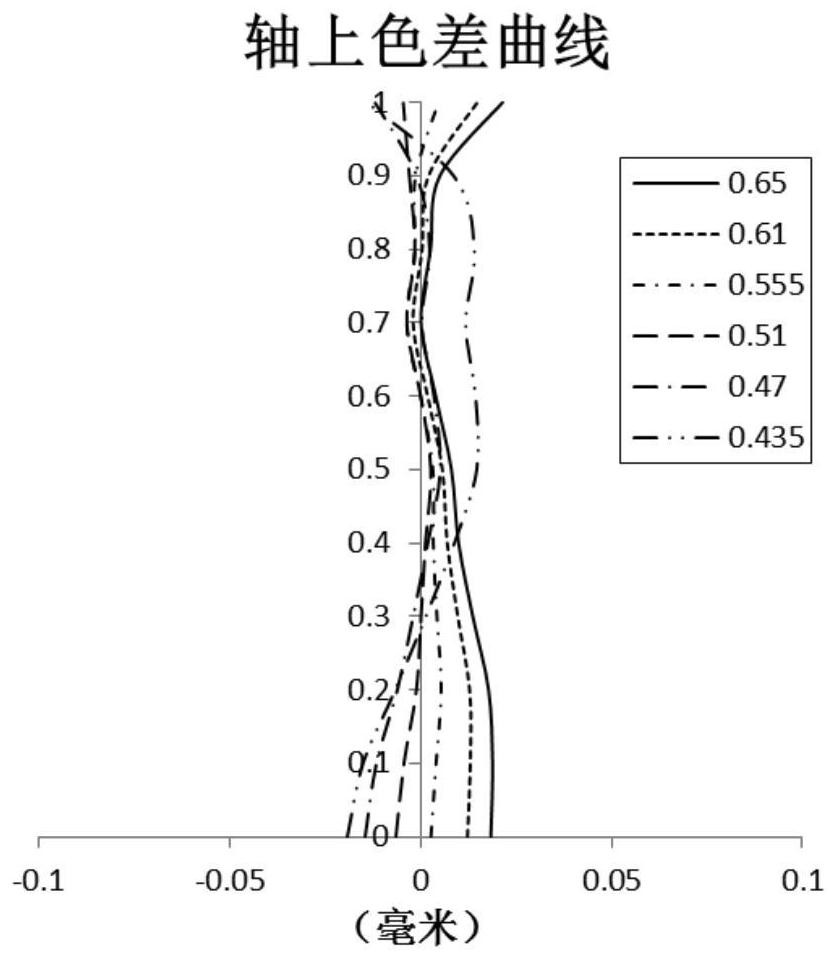

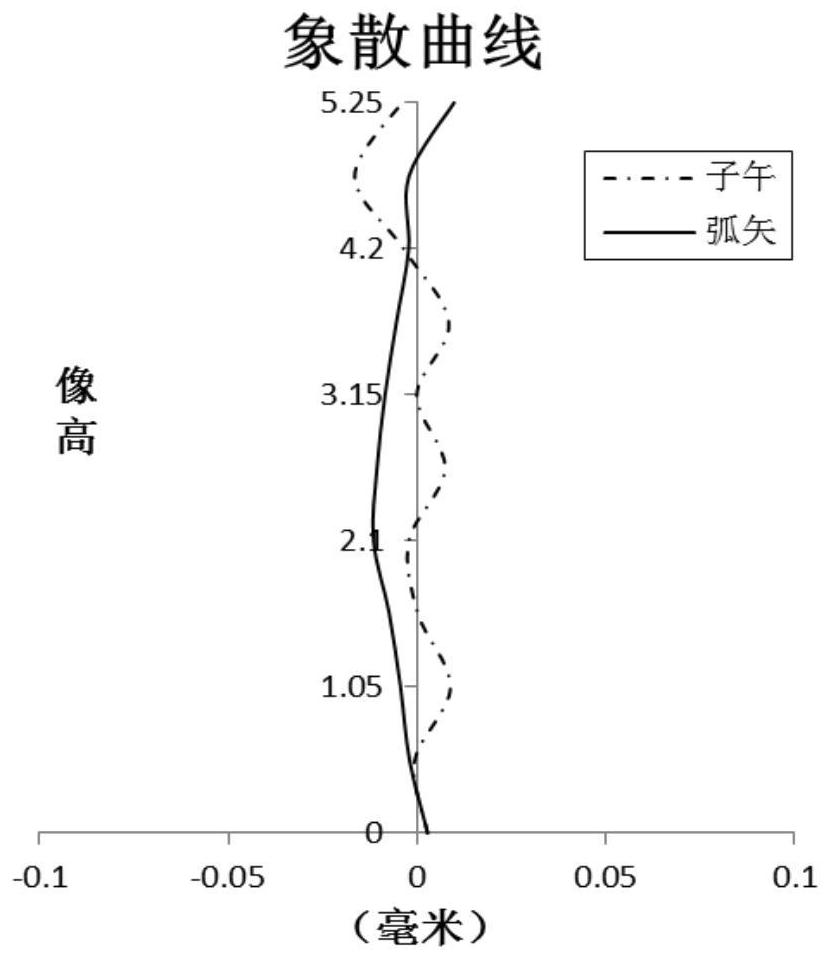

Optical imaging lens

PendingCN112034599AHigh image qualityImprove image qualityOptical elementsOphthalmologyImaging quality

The invention provides an optical imaging lens. The optical imaging lens sequentially comprises a first lens having positive focal power, a second lens having focal power, a third lens having focal power, a fourth lens having focal power, a fifth lens having focal power, a sixth lens having positive focal power and a seventh lens having focal power that are arranged from the object side to the image side along the optical axis of the optical imaging lens. The effective focal length f of the optical imaging lens and the maximum half-field angle Semi-FOV of the optical imaging lens meet the condition that f * tan (Semi-FOV) is greater than or equal to 5.0 mm; the curvature radius R11 of the object side surface of the sixth lens, the curvature radius R12 of the image side surface of the sixthlens and the effective focal length f of the optical imaging lens satisfy the following conditions: f / R11 + f / R12 is larger than 5.0 and is less than 7.0; the curvature radius R13 of the object sideface of the seventh lens, the curvature radius R14 of the image side face of the seventh lens and the effective focal length f7 of the seventh lens meet the condition that f7 / (R13-R14) is smaller thanor equal to -2.0. According to the invention, the problem of unstable imaging quality of an optical imaging lens in the prior art is solved.

Owner:ZHEJIANG SUNNY OPTICAL CO LTD

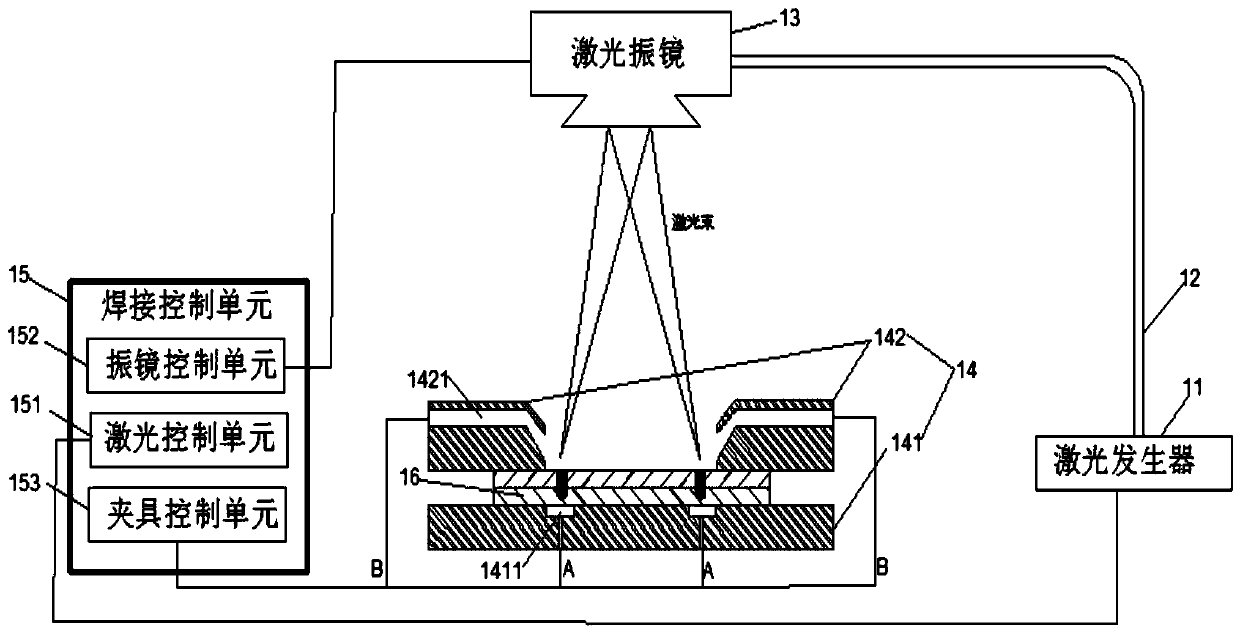

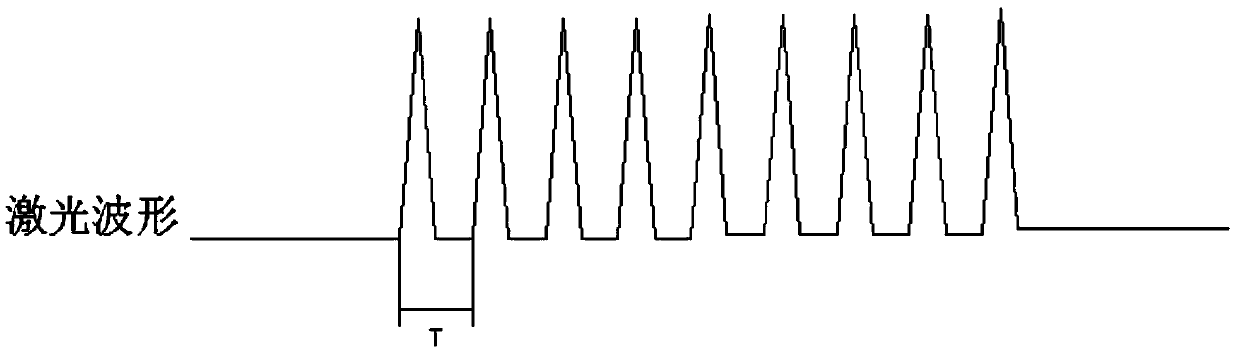

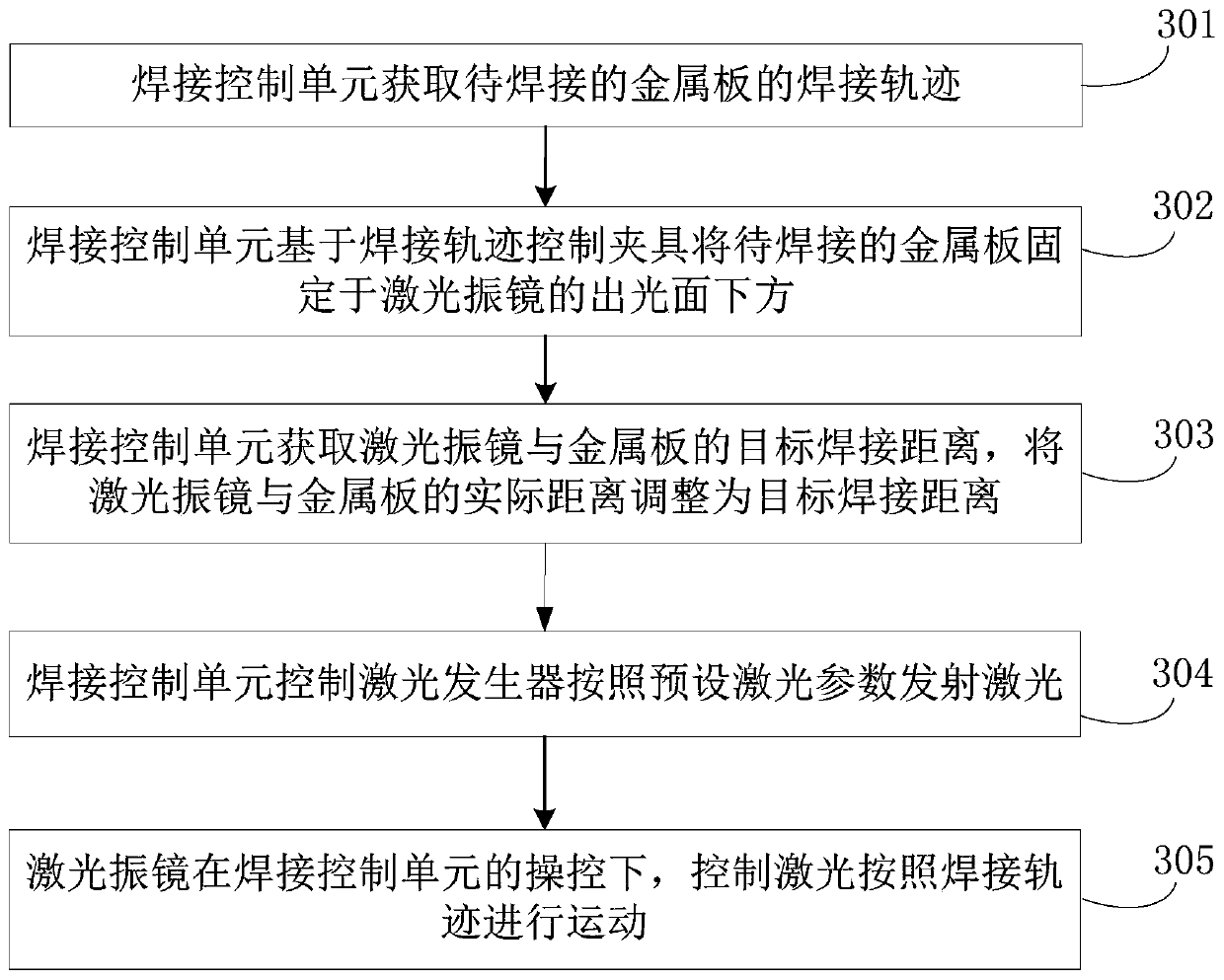

Laser welding system and method of metal plate

InactiveCN110142507ARealize high frequency and high speed weldingReduce weld sizeLaser beam welding apparatusGalvanometerPenetration depth

The invention discloses a laser welding system and method for a metal plate. The method comprises the following steps that a welding track of a to-be-welded metal plate can be obtained through a welding control unit; then the to-be-welded metal plate is fixed below a light emitting surface of a laser galvanometer by a control clamp based on the welding track; the target welding distance between the laser galvanometer and the metal plate is obtained, the actual distance between the laser galvanometer and the metal plate is adjusted to be the target welding distance; a laser generator is controlled to emit laser according to a preset laser parameter; and the laser is controlled by the laser galvanometer to move according to the welding track. According to the laser welding system and method,the laser is a nanosecond-level laser, high-frequency and high-speed welding of the metal plate can be realized, and high-frequency and high-speed welding can effectively reduce the weld joint size of the metal plate and improve the accurate control of the penetration depth.

Owner:HANS LASER TECH IND GRP CO LTD

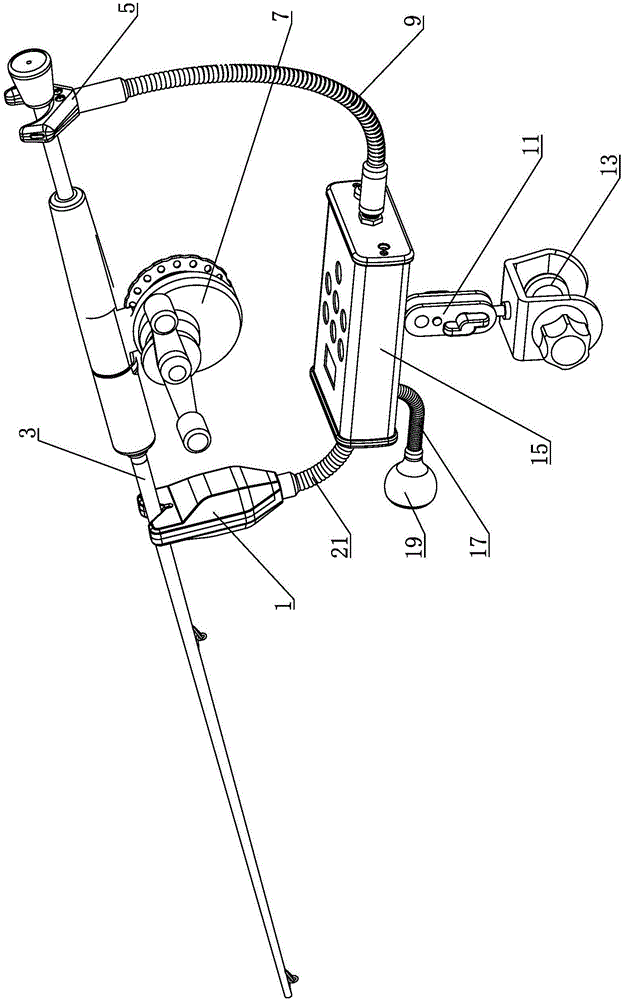

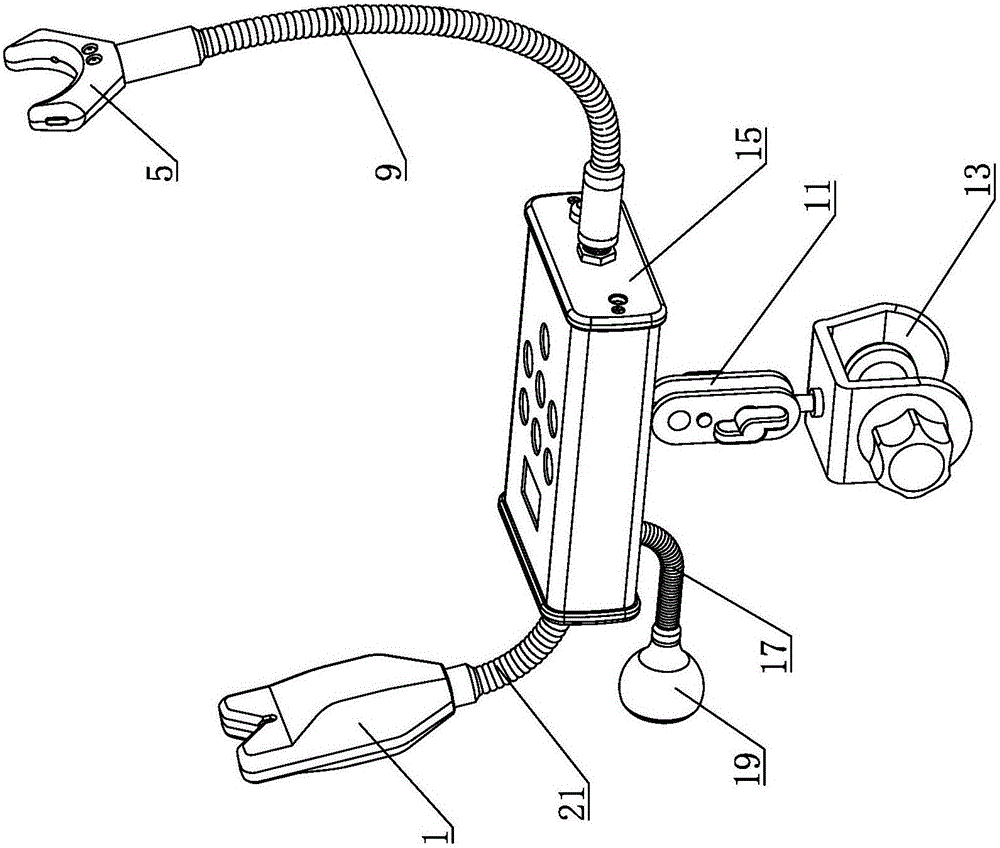

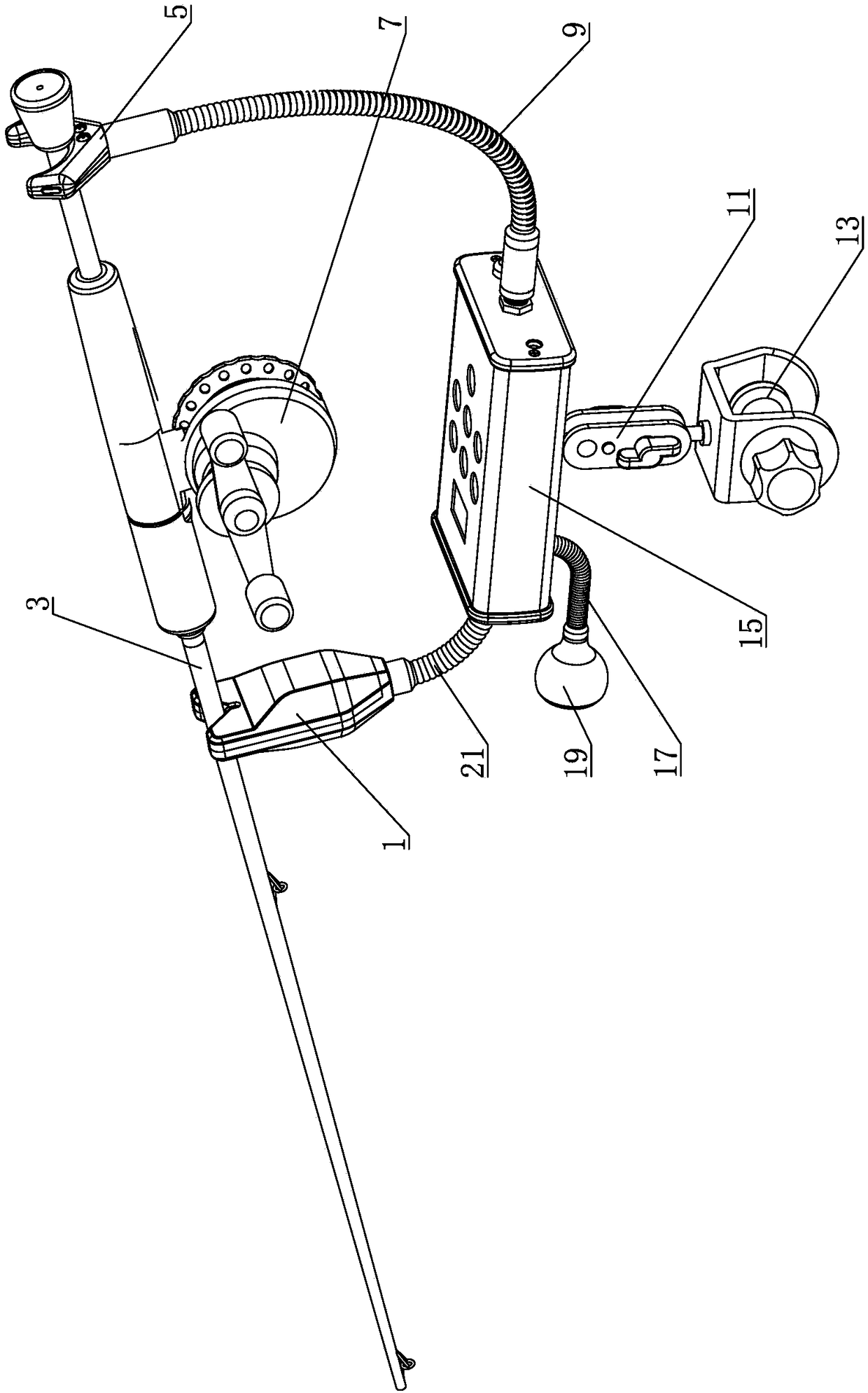

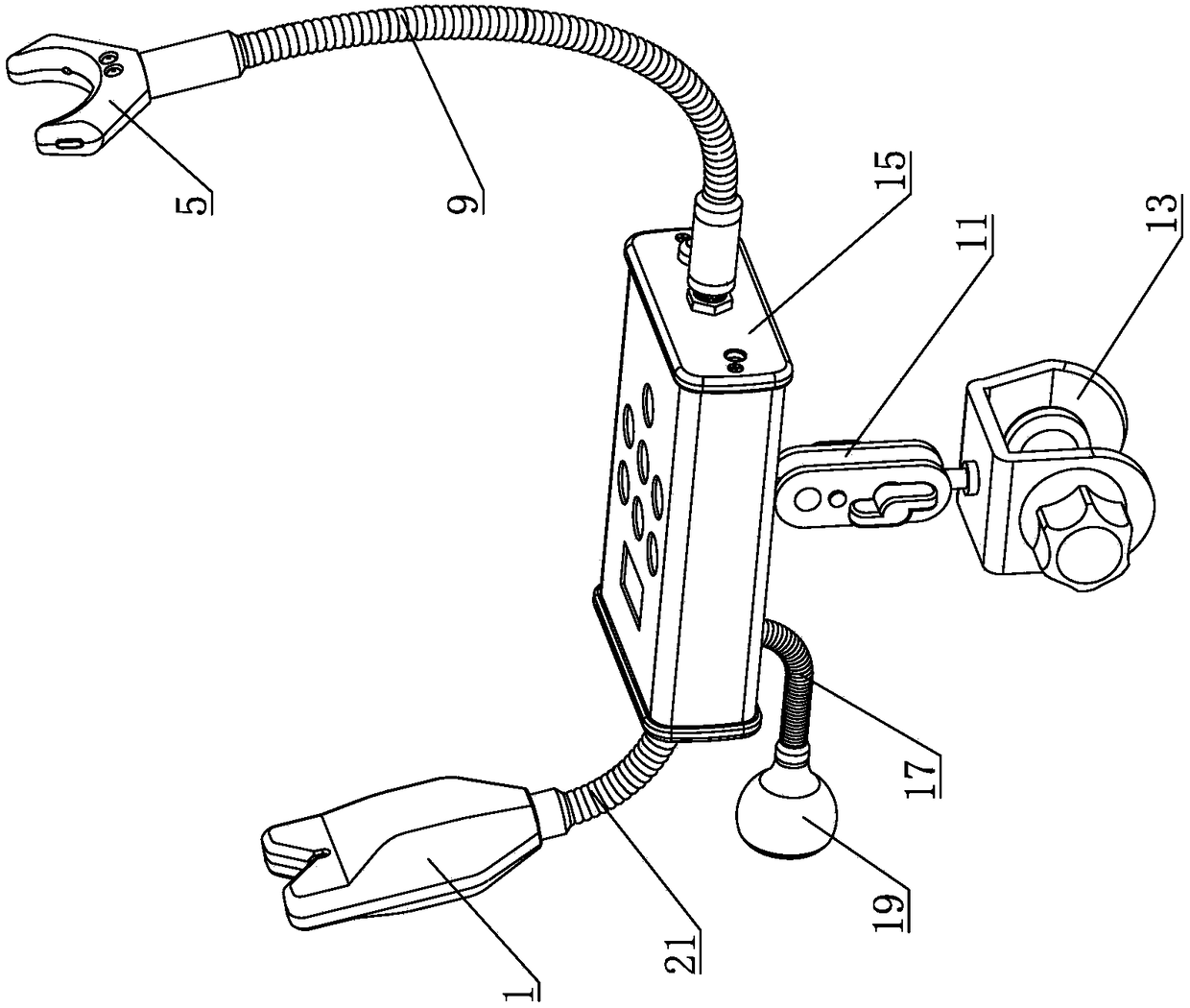

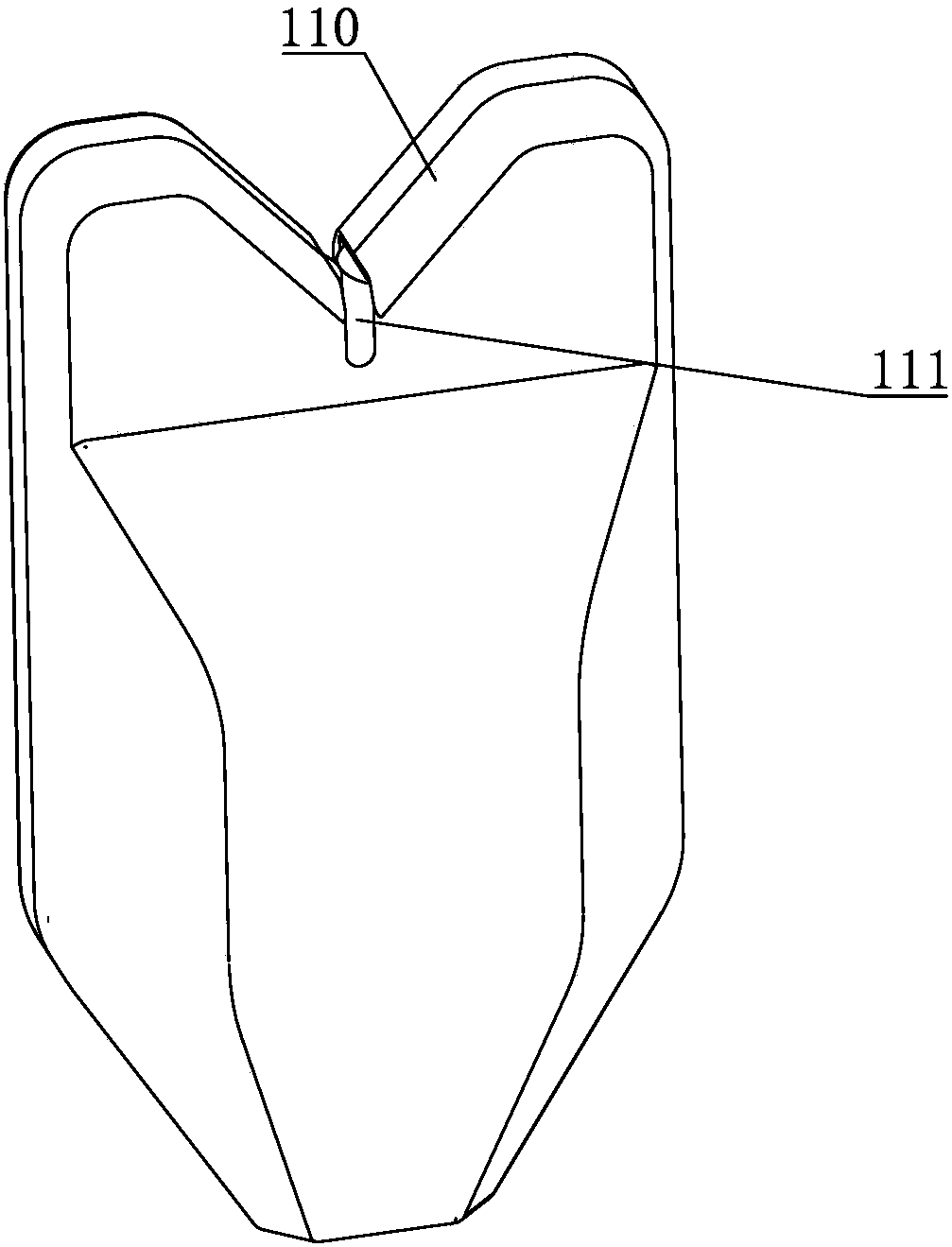

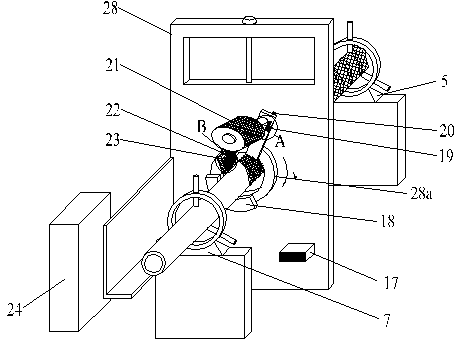

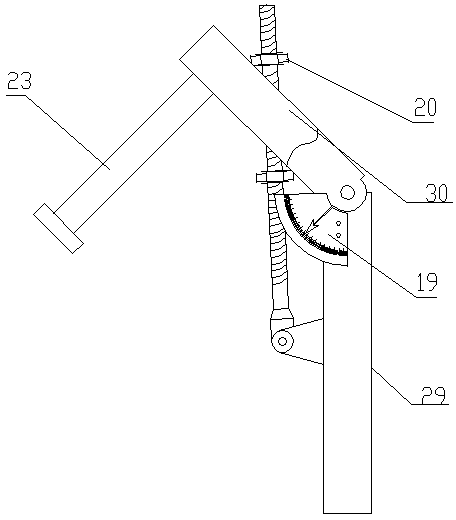

Multifunctional automatic fish-searching raft fishing pole-supporting device and raft fishing pole-supporting device front bracket structure

InactiveCN105918274ASolve the problem of tangling into the raft reelReduce weightReelsOther angling devicesDisplay deviceOrbit

The invention relates to a multifunctional automatic fish-searching raft fishing pole-supporting device and a raft fishing pole-supporting device front bracket structure. The device and the structure are used for helping a person raft fishing to reduce the manually holding time of a fishing pole and for reducing the dependence of fishing line casting and retracting on human effort. The device comprises a front bracket, a back bracket, a support, and a control display device. The control display device has a housing. The front bracket is connected with the housing through a front bracket tube, and the back bracket is connected with the housing through a back bracket tube. A fishing line gap is formed in the pole supporting face of the front bracket. A stepper motor, a gear, a gear shaft, a main pressure rubber line wheel and an auxiliary pressure rubber line wheel are arranged in the inner cavity of the front bracket. The main pressure rubber line wheel is fixed on one end of the gear shaft, and the gear is fixed on the other end of the gear shaft. The stepper motor is engaged with the gear through an output shaft gear. The auxiliary pressure rubber line wheel is arranged on a frame performing linear orbit movements. The frame is pressed by a spring with one end pressed against the front bracket body, in the direction along a linear orbit. With the device and the structure provided by the invention, a line outlet speed is stable, the weight of raft fishing sinkers is reduced, and the capacity of accurate control over line outlet length is improved.

Owner:南平市佳创机电科技有限公司

Closed submerged arc furnace coal gas dry-process purifying and recycling system

ActiveCN104089492APrecise control of working pressureRealize safe productionGas purification by non-gaseous materials condensationGas dust removalAutomatic controlSludge

The invention relates to a closed submerged arc furnace coal gas dry-process purifying and recycling system which comprises a closed submerged arc furnace 1, an air natural cooler 3, a bag filter 4, a water-cooled type condensation drainer 5, a coal gas draught fan 6, a coal gas cabinet 7 and an automatic control system 11. The closed submerged arc furnace 1, the air natural cooler 3, the bag filter 4, the water-cooled type condensation drainer 5, the coal gas draught fan 6 and the coal gas cabinet 7 are sequentially connected through carbon steel pipes. The connecting pipeline between the closed submerged arc furnace 1 and the air natural cooler 3 and the connecting pipeline between the coal gas draught fan 6 and the coal gas cabinet 7 are provided with switching valves 2. A furnace cover of the closed submerged arc furnace 1 is provided with a furnace pressure measuring device 10. The automatic control system 11 is connected with the devices and the valves through signal lines. The dust content of coal gas purified through the system is smaller than 10 mg / m<3>, and investment and running energy consumption are low; the water content of the recycled coal gas is low, and the heating value is high; no waste water problem or sludge problem exists, and no corrosion, blockage, freeze or other running faults exist; furnace pressure is controlled accurately, and running is safely and reliably conducted in place; occupied area is small, and technical transformation is facilitated.

Owner:中钢集团天澄环保科技股份有限公司 +2

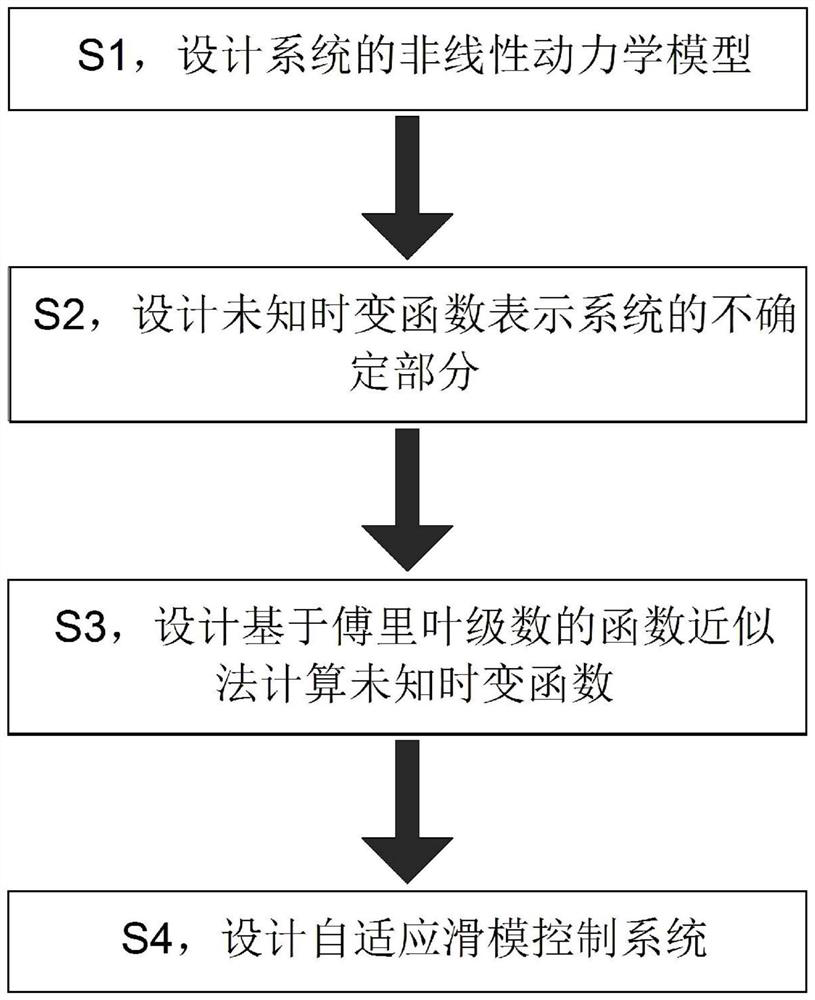

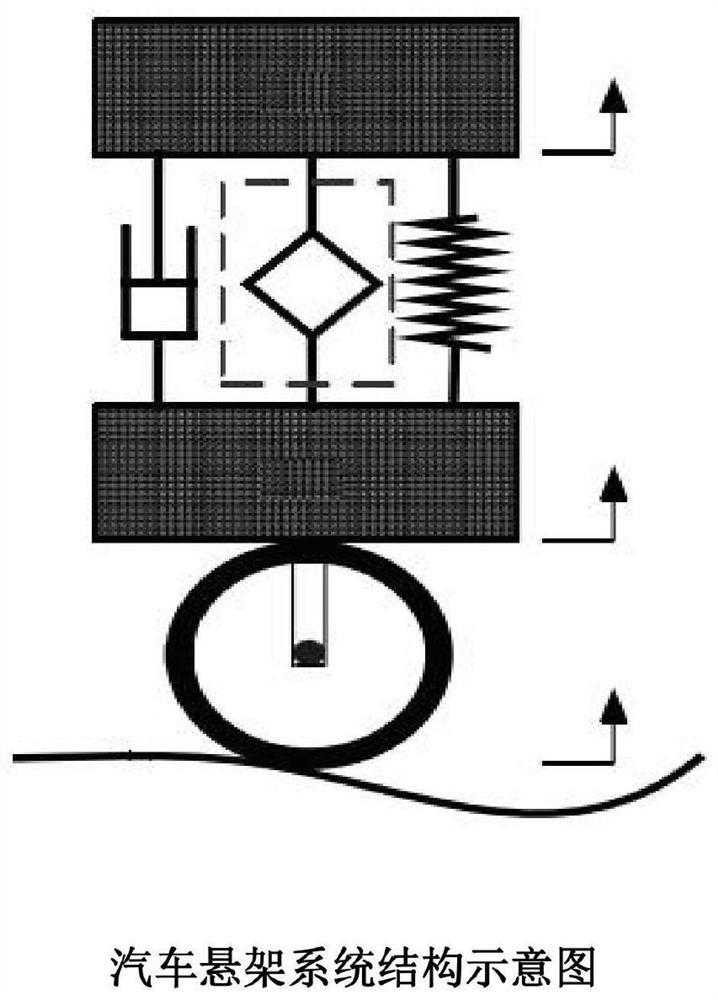

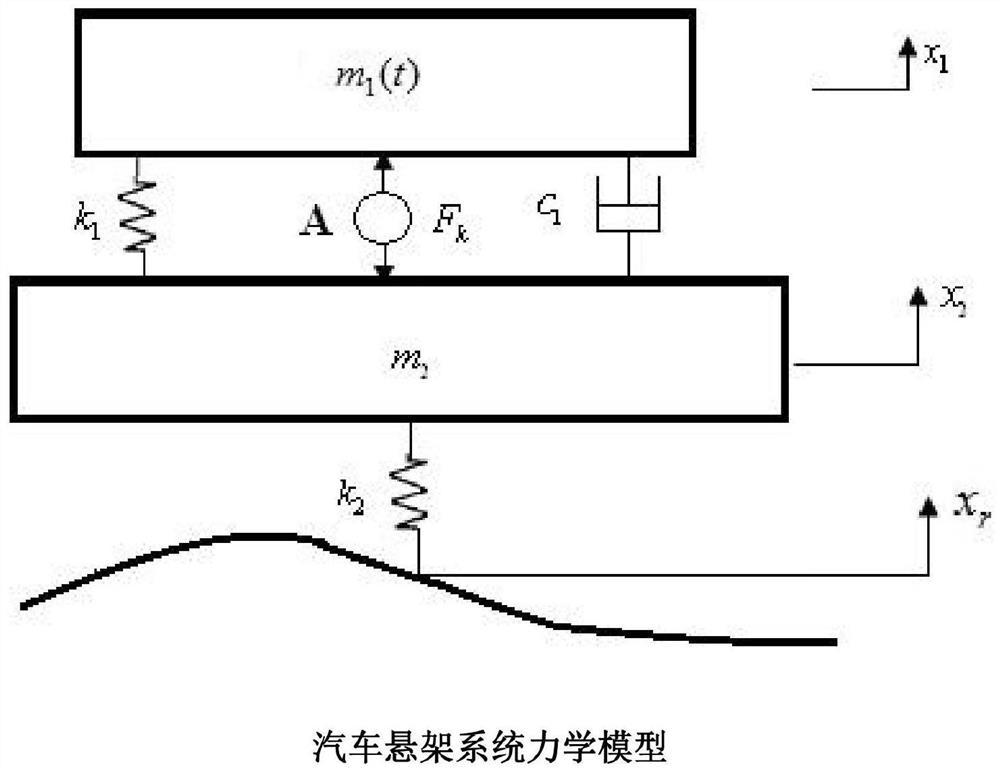

Self-adaptive control method for automobile active suspension

PendingCN113879062AIn line with the actual stateImprove accurate controlGeometric CADSustainable transportationSliding mode controlSelf adaptive

The invention discloses a self-adaptive control method for an automobile active suspension, and belongs to the technical field of automobile engineering. The invention discloses a self-adaptive control method for an automobile active suspension. The self-adaptive control method comprises the following steps: S1, designing a nonlinear dynamic model of a system; S2, designing an unknown time-varying function to represent an uncertain part of the system; S3, designing a Fourier series-based function approximation method to estimate an unknown time-varying system function; and S4, designing a self-adaptive sliding mode control system. According to the method, the uncertain part of the system is estimated on line, the control force is calculated on line through the self-adaptive sliding mode controller, the influence of load and system parameter time varying can be better overcome, and compared with traditional PID control, the vibration reduction control performance of the system is greatly improved.

Owner:NANYANG NORMAL UNIV

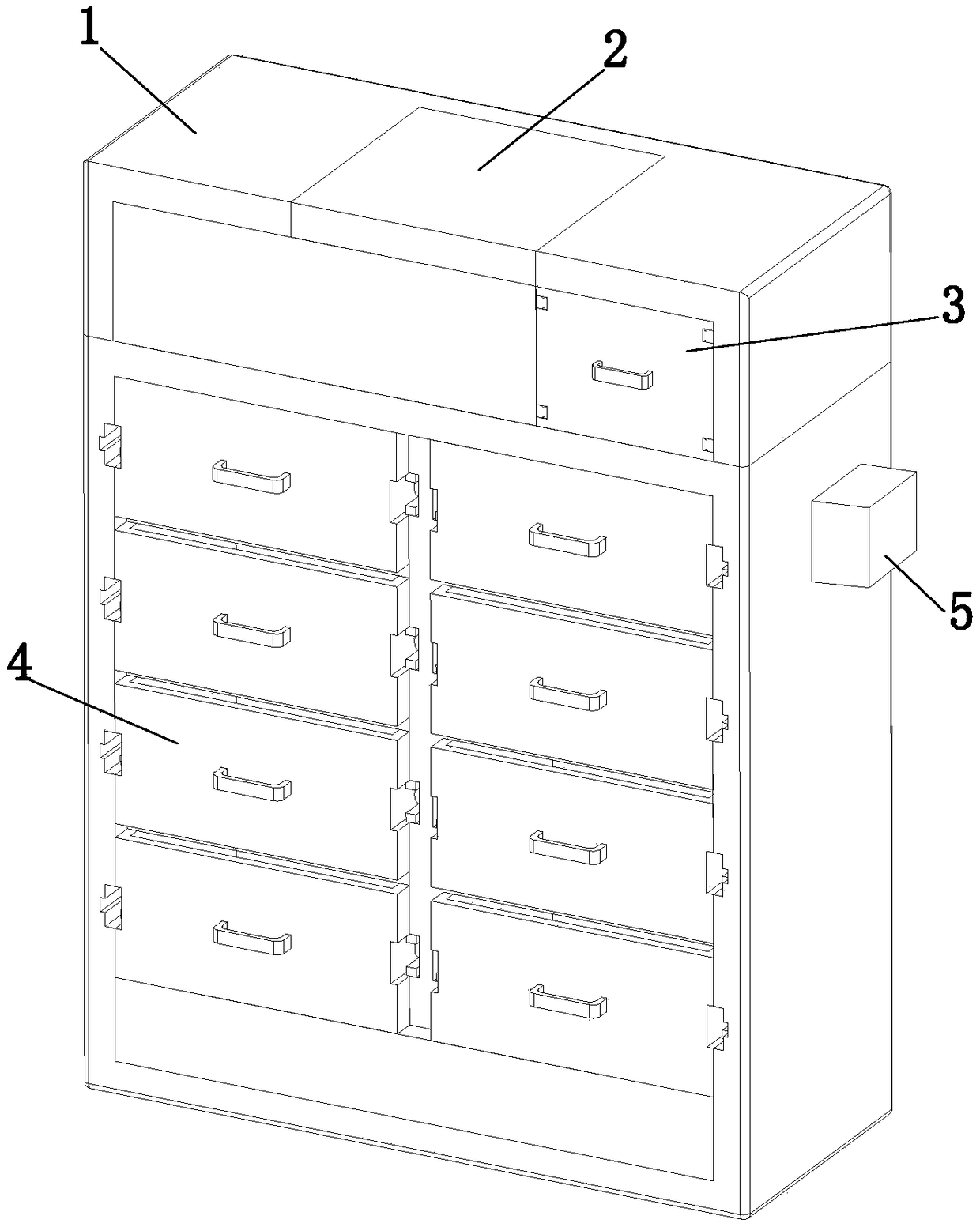

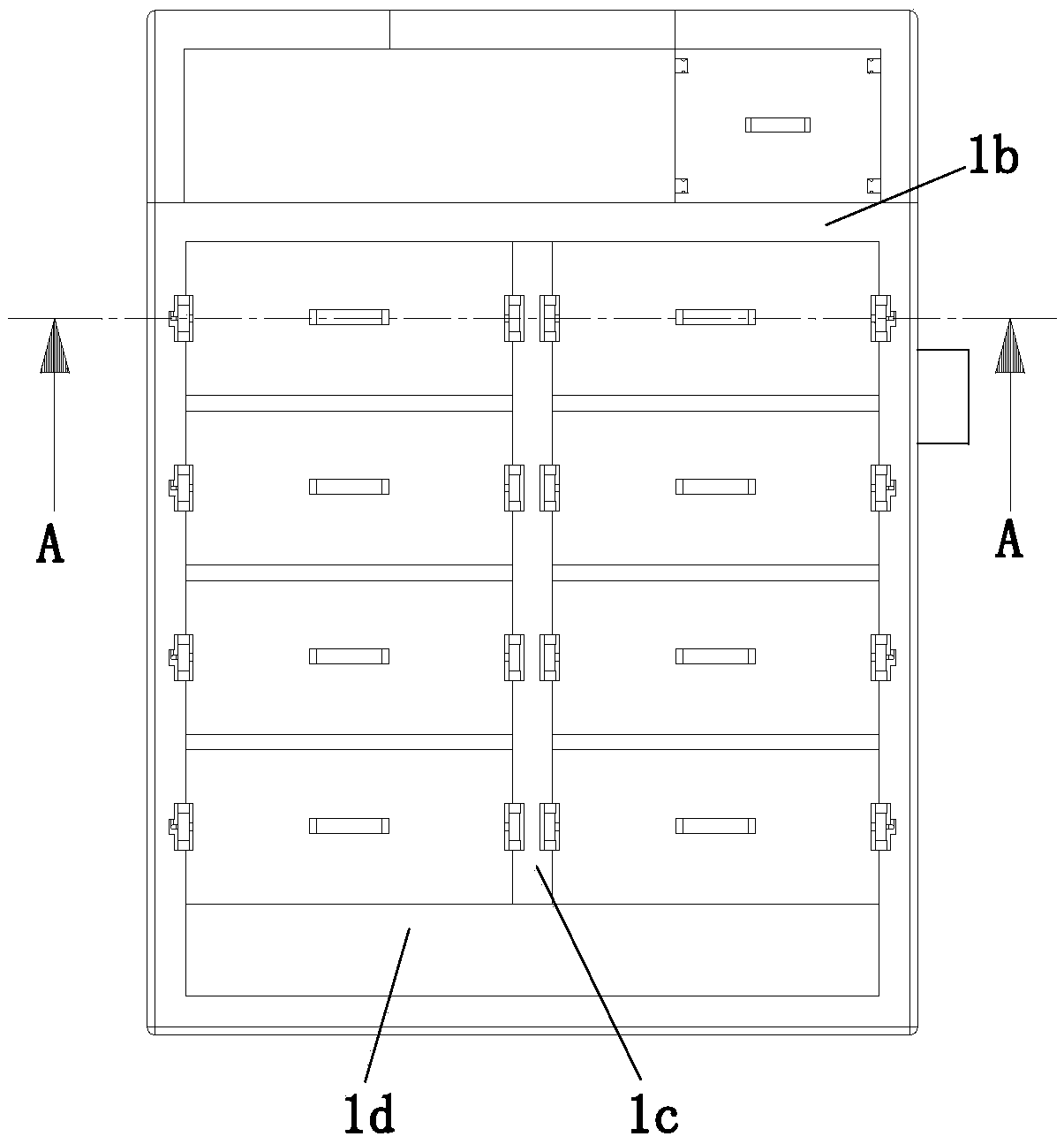

Intelligent household locker

InactiveCN108851632AIncrease storage areaIncrease profitVariable dimension cabinetsDrawersEngineeringMechanical engineering

The invention relates to the field of smart homes, in particular to an intelligent household locker. The intelligent household locker comprises a loading cabinet body, a load jacking device, a top storage device and a plurality of load positioning devices, wherein the front of the loading cabinet body is provided with a first containing cavity with an outward open port, the first containing cavityis internally provided with a partition plate arranged in a horizontal state, the load jacking device comprises a moving loading part and a jacking driving part, the top storage device comprises a driving stretching part and a stretching loading part, each load positioning device comprises a containing cabinet, a moving guiding part and a containing driving part, the side wall of the loading cabinet body is provided with a controller, and the containing driving part, the driving stretching part and the jacking driving part are all electrically connected with the controller. The intelligent household locker has the advantages that the storage area of the whole loading storage cabinet is increased, and the utilization rate of the loading storage cabinet is increased; the manpower output isreduced, and the accurate control of the storage cabinets is improved.

Owner:TAIZHOU DINGTUO IND DESIGN CO LTD

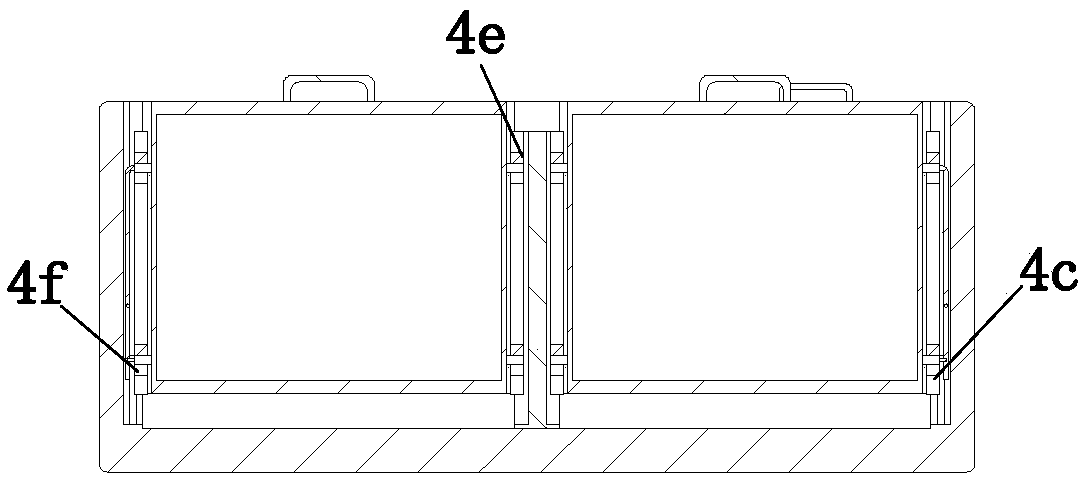

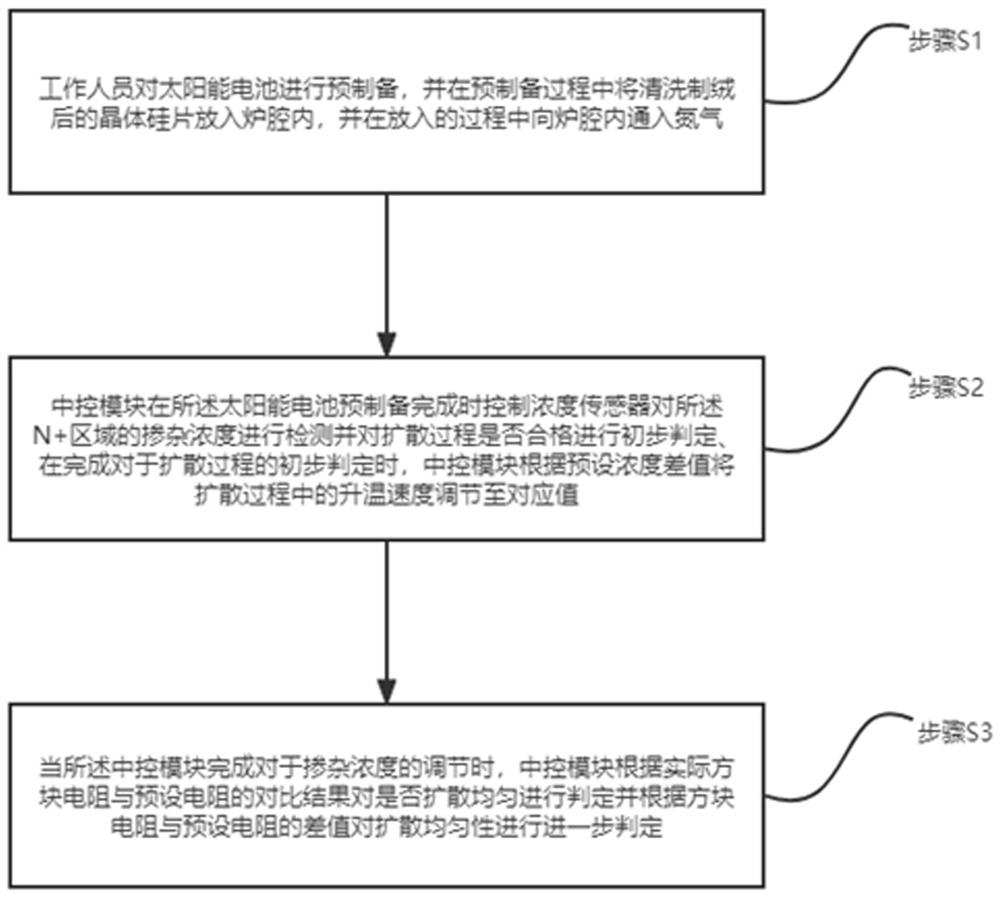

Diffusion process for reducing doping concentration of N + region of solar cell

ActiveCN114678449AReduce doping concentrationImprove work efficiencySemiconductor/solid-state device testing/measurementFinal product manufacturePhysical chemistrySolar battery

The invention relates to the technical field of solar cells, in particular to a diffusion process for reducing the doping concentration of an N + region of a solar cell, which comprises the following steps of: S1, prefabricating the solar cell by a worker, and putting a cleaned and textured crystal silicon wafer into a furnace chamber in the prefabrication process; s2, a central control module controls a concentration sensor to detect the doping concentration of the N + region and preliminarily judge whether the diffusion process is qualified or not when preparation of the solar cell is completed, and the temperature rise speed in the diffusion process is adjusted to a corresponding value according to a preset concentration difference value; and S3, when the central control module completes adjustment of the doping concentration, the central control module judges whether diffusion is uniform or not according to a comparison result of the actual square resistance and the preset resistance and further judges the diffusion uniformity according to a difference value of the square resistance and the preset resistance. According to the invention, the doping concentration in the diffusion process is reduced, and the diffusion uniformity is accurately controlled.

Owner:一道新能源科技股份有限公司

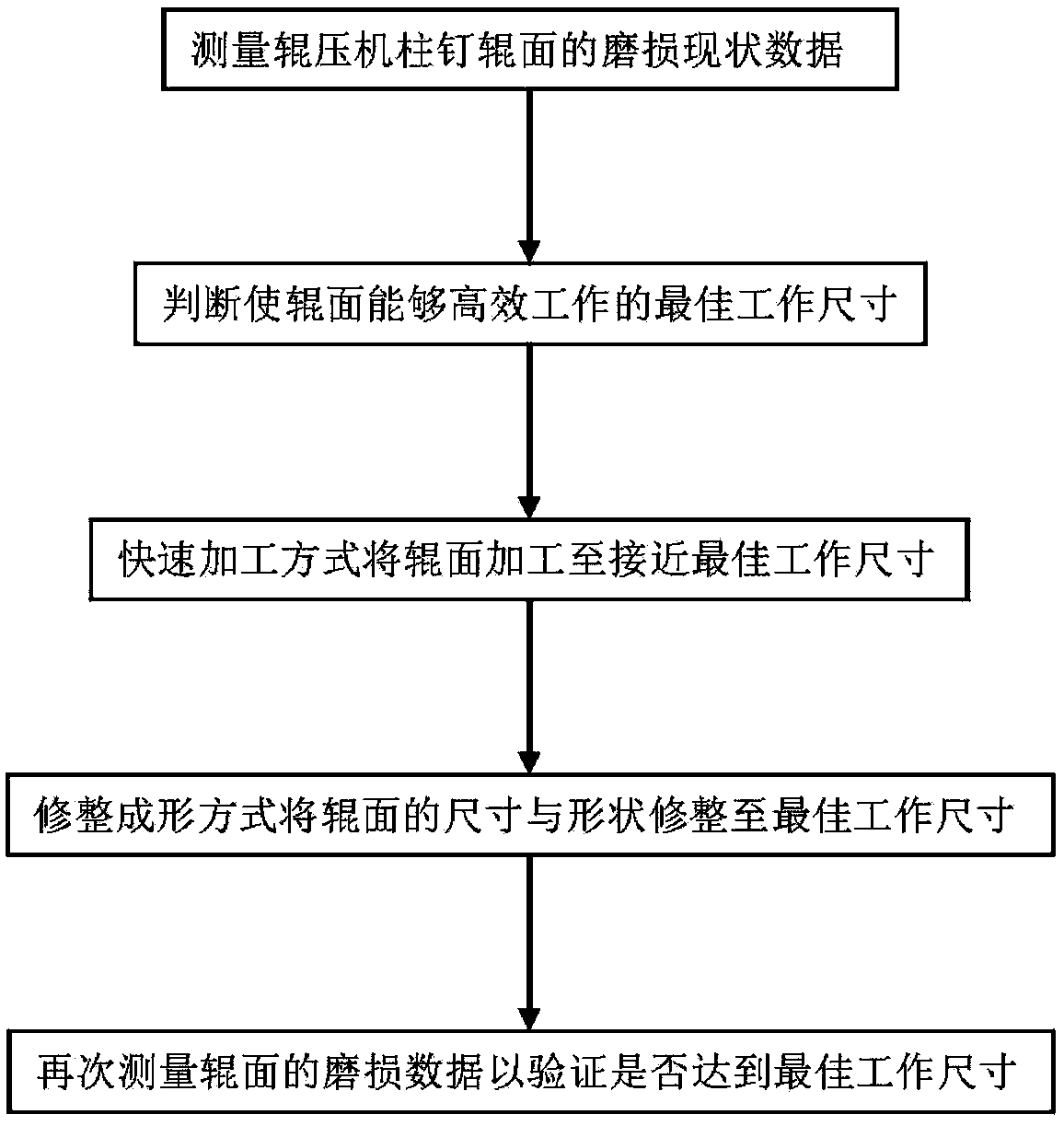

Abrasion homogenizing method for pin roller surface

ActiveCN107900606AReduce processing timeImprove accurate controlGrain treatmentsWorkloadRapid tooling

The invention provides an abrasion homogenizing method for a pin roller surface. The method comprises steps as follows: (1) abrasion data are measured as follows: current abrasion situation data of the roller surface are calculated; (2) the homogenizing quantity is calculated as follows: according to the current abrasion situation data and the optimal working size, the total homogenizing quantityrequired to be homogenized is calculated; (3) quick machining is performed as follows: according to the total homogenizing quantity, the roller surface is machined to be close to the optimal working size through quick machining, and partial to-be-homogenized part is reserved; (4) trimming machining is performed as follows: the to-be-homogenized part reserved in the step (3) is trimmed to the optimal working size through trimming forming; (5) the abrasion data are verified as follows: the abrasion data are measured so as to verify whether the optimal working size is realized. With the method, the processing time for abrasion homogenization of the pin roller surface can be shortened, accurate control on the roller surface size and shape can be enhanced, and meanwhile, the use amount of grinding pieces and the change workload can be reduced; and the problem of abrasion inconsistency of the pin roller surface in the roller width direction is solved, and the working efficiency of a roller press is improved.

Owner:CNBM HEFEI POWDER TECH EQUIP CO LTD

Multi-functional automatic fish search raft and fishing rack and the front bracket structure of the raft fishing rack

InactiveCN105918274BSolve the problem of tangling into the raft reelReduce weightReelsOther angling devicesDisplay deviceEngineering

The invention relates to a multifunctional automatic fish-searching raft fishing pole-supporting device and a raft fishing pole-supporting device front bracket structure. The device and the structure are used for helping a person raft fishing to reduce the manually holding time of a fishing pole and for reducing the dependence of fishing line casting and retracting on human effort. The device comprises a front bracket, a back bracket, a support, and a control display device. The control display device has a housing. The front bracket is connected with the housing through a front bracket tube, and the back bracket is connected with the housing through a back bracket tube. A fishing line gap is formed in the pole supporting face of the front bracket. A stepper motor, a gear, a gear shaft, a main pressure rubber line wheel and an auxiliary pressure rubber line wheel are arranged in the inner cavity of the front bracket. The main pressure rubber line wheel is fixed on one end of the gear shaft, and the gear is fixed on the other end of the gear shaft. The stepper motor is engaged with the gear through an output shaft gear. The auxiliary pressure rubber line wheel is arranged on a frame performing linear orbit movements. The frame is pressed by a spring with one end pressed against the front bracket body, in the direction along a linear orbit. With the device and the structure provided by the invention, a line outlet speed is stable, the weight of raft fishing sinkers is reduced, and the capacity of accurate control over line outlet length is improved.

Owner:南平市佳创机电科技有限公司

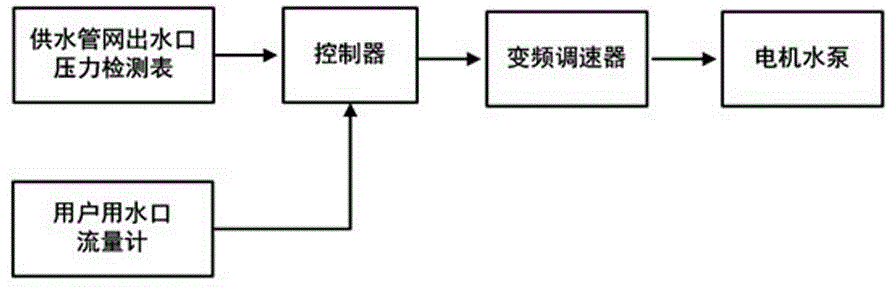

A Model-Based Control Method for Secondary Water Supply Equipment and Its Control System

InactiveCN104153424BImprove water experiencePrevent overpressureService pipe systemsWater mainsWater useControl system

The invention provides a secondary water supply equipment control method and system based on a model. The secondary water supply equipment control system comprises a water supply pipe network water outlet pressure detection meter, a controller, a variable-frequency governor and a pressurization water pump, wherein the water supply pipe network water outlet pressure detection meter, the controller, the variable-frequency governor and the pressurization water pump are electrically connected in sequence. The secondary water supply equipment control system further comprises a user water consumption port flow meter. The output end of the user water consumption port flow meter is electrically connected with the input end of the controller. The user water consumption port flow meter accurately calculates the water consumption quantity of a user water outlet and inputs flow data into the controller. The controller builds a water supply model according to the flow data and corresponding time, controls frequency changes of the variable-frequency governor according to the flow value at each time point in the model, and then controls the rotation speed of the pressurization water pump. The secondary water supply equipment control system realizes high-accuracy control and a higher response speed in the secondary water supply equipment control process by modeling the water supply data, saves water and electricity, better avoids overpressure of a water supply pipe network, guarantees the safety of the water supply pipe network and provides better water consumption experience for a user on the water consumption side.

Owner:青岛沈源水务科技有限公司

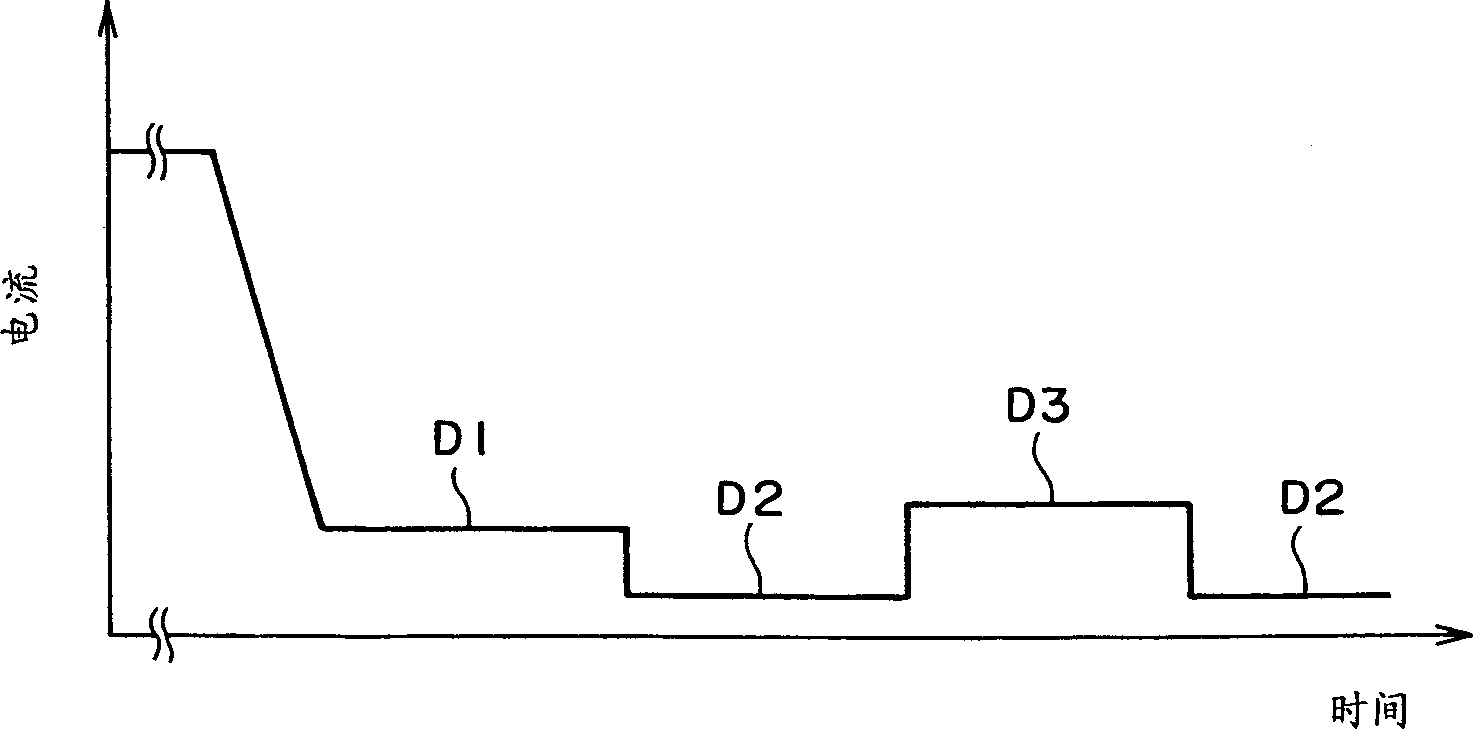

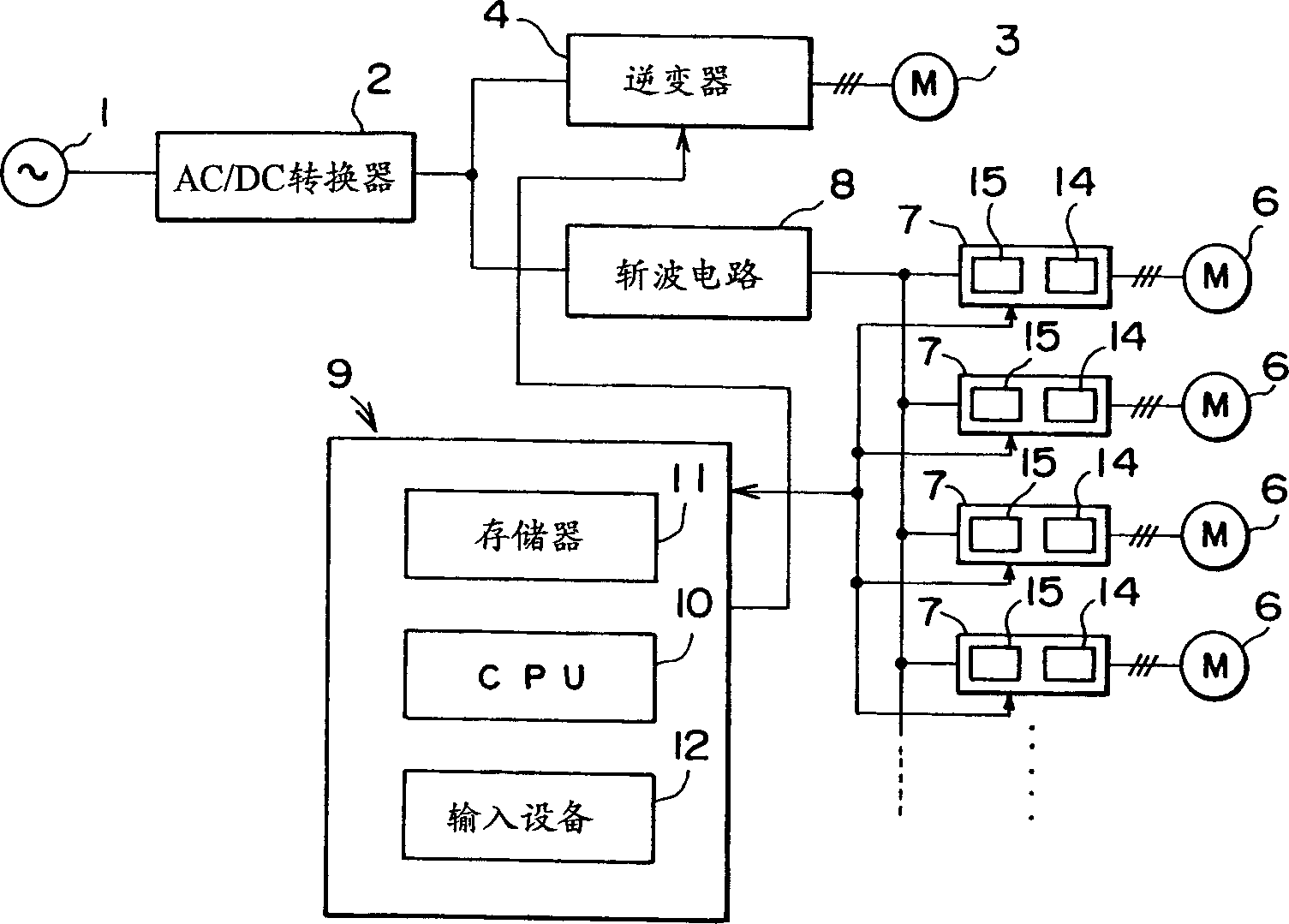

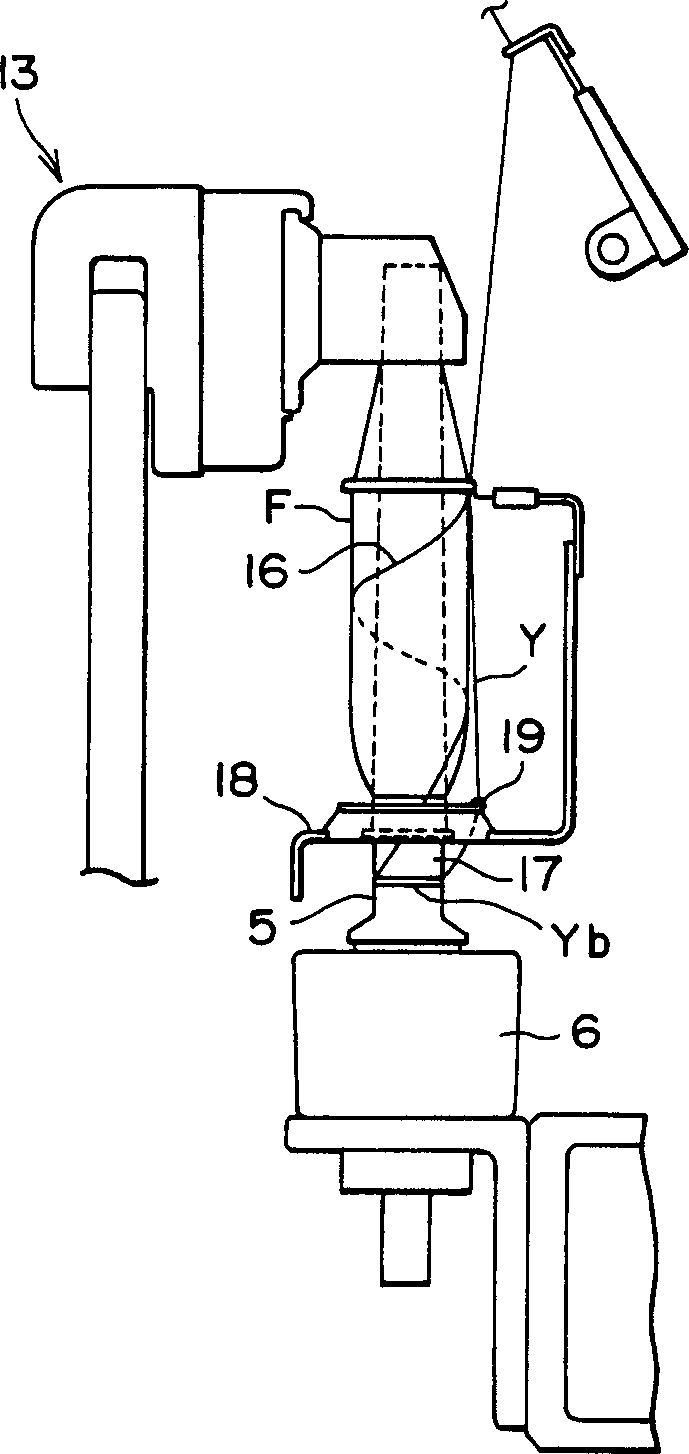

Method of controlling single spindle driving motor of spinning machine

InactiveCN1343802AImprove accurate controlHigh torqueContinuous wound-up machinesElectronic commutatorsBobbinElectric machinery

In a spinning machine for independently driving each spindle (5) by an individual motor (6), a synchronization motor is used as the motor and is controlled through an inverter (14). At least when a bobbin is pulled out after a doffing stop, each of the motors is supplied with a direct current (D3), and a holding force for holding the spindle in a stop state is increased.

Owner:TOYOTA IND CORP

Low-NOx gas burner and flame adjusting method thereof

PendingCN110513680AChange export sizeControl spray lengthFuel supply regulationGaseous fuel burnerOuter coreGas burner

The invention provides a low-NOx gas burner. The low-NOx gas burner comprises a main pipe body, an inner core pipe and an outer core pipe. Under the condition that the gas inflow amount is constant, afirst position adjusting mechanism is used for changing the gap between the head of the inner core pipe and the main pipe body, in other words, a total outlet of the burner is changed, thus, the flowrate is changed, and the jetting length of jet flames is controlled; under the condition that the flow rate is constant, a second position adjusting mechanism is used for changing the amounts of gasentering the inner core pipe and an inner cavity of the main pipe body separately, and then the positions of hot spots in the jet flames are adjusted; and the jet flames at proper lengths can be rapidly adjusted, lower NOx emission is generated, meanwhile, the positions where the hot spots in the jet flames are released can be conveniently adjusted, and the flame stability and the jet permeabilityare improved.

Owner:ANDERSON THERMAL SOLUTION SUZHOU CO LTD

Production apparatus and extrusion technology of novel clad pipe

ActiveCN102225622BHigh control precisionContinuous and stable productionProcess engineeringFilament winding

The invention relates to a production apparatus and an extrusion technology of a novel clad pipe. The production apparatus comprises an extrusion production line apparatus for production of an inner layer and an external layer of an enhanced clad pipe, winders for winding and preheating a long fiber strip, a center locating frame for controlling a fibrous strip winding to cause tilt of an inner pipe, and a heating box for heating the inner pipe wound with the fibrous strip. According to the invention, two winders are configured between an inner pipe extrusion line and an external layer extrusion cladding die head and used alternately; when a fibrous strip on one winder is using up, the other winder is initiated rapidly to ensure continuous and stabilized production of the enhanced clad pipe. In the invention, a winding packaging technology is upgraded and reconstructed to combine with a cladding double-layer extrusion technology. A foreign complex technology requiring a special windercan be substituted to raise operation convenience, promote generalization of the technology and fill domestic technical blank of continuous fiber winding enhanced clad pipe. Therefore, the technologyof the invention is suitable for industrialized popularization.

Owner:LINHAI WEIXING NEW BUILDING MATERIALS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com