Double-station measuring cup metering device

A metering device, double-station technology, applied in the direction of packaging, transportation and packaging, packaging item types, etc., to achieve the effect of improving accurate control, accurate rotation angle, and improving precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

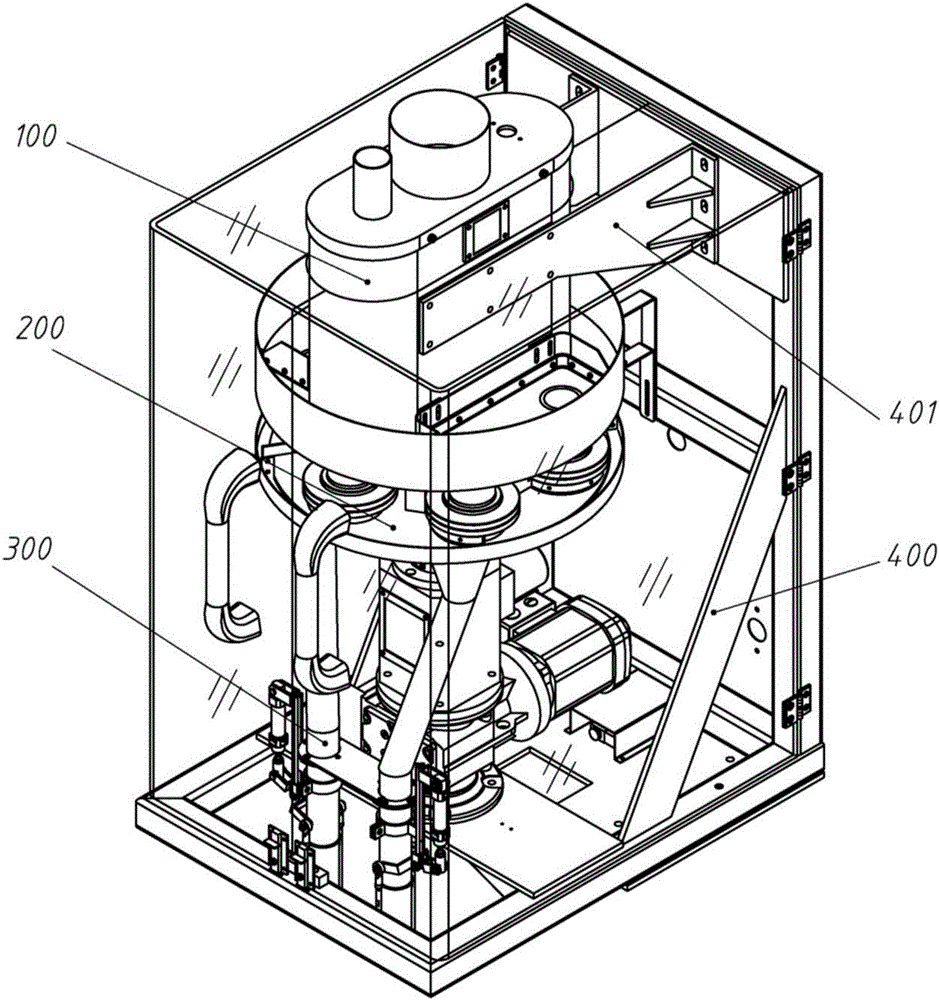

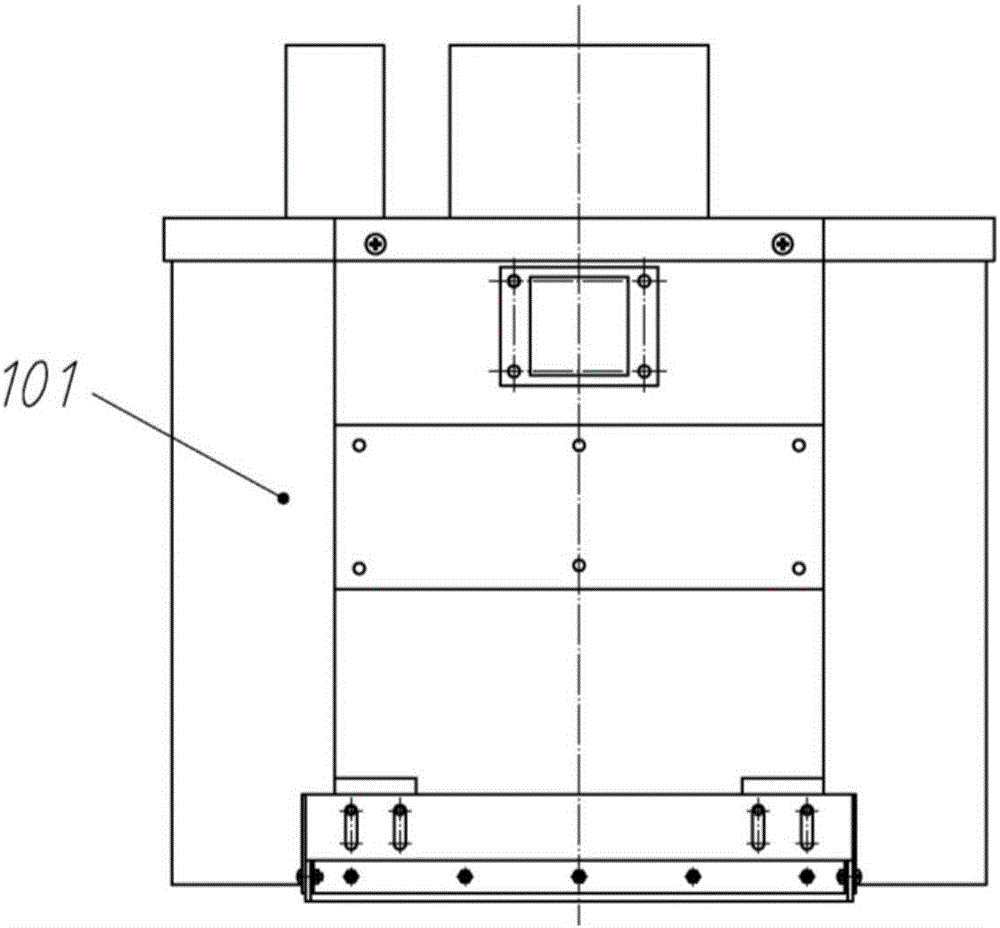

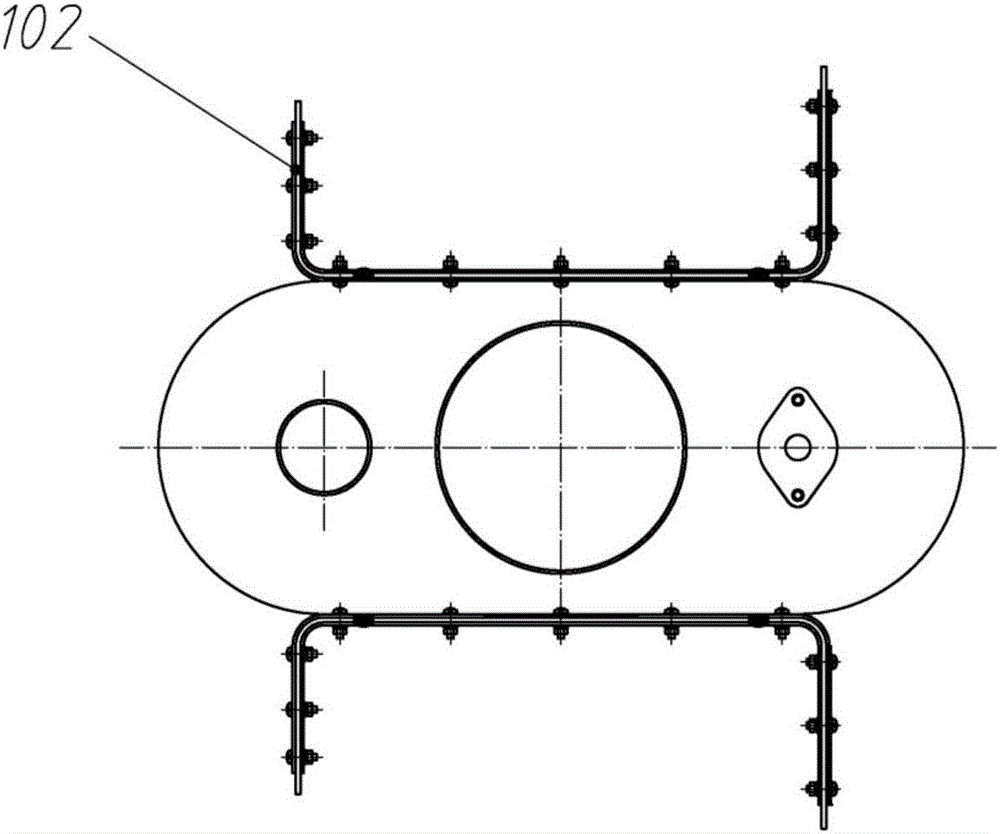

[0035] refer to Figure 1 to Figure 10 As shown, a double-station measuring cup metering device in an embodiment provided by the present invention is characterized in that it includes a bin assembly 100, a metering cup assembly 200, a feeding tube assembly and a bracket assembly, the bin assembly 100, the metering The cup assembly 200 and the feeding pipe assembly are sequentially arranged on the bracket assembly from top to bottom, the output end of the bin assembly 100 is connected to the input end of the metering cup assembly 200, and the output end of the measuring cup assembly 200 is connected to the input end of the feeding pipe assembly. End connection, the output end of the feeding tube assembly is docked with the packaging and sealing link of the packaging machine;

[0036] Wherein, the metering cup assembly 200 is provided with two feeding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com