Patents

Literature

74 results about "Volumetric measurement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

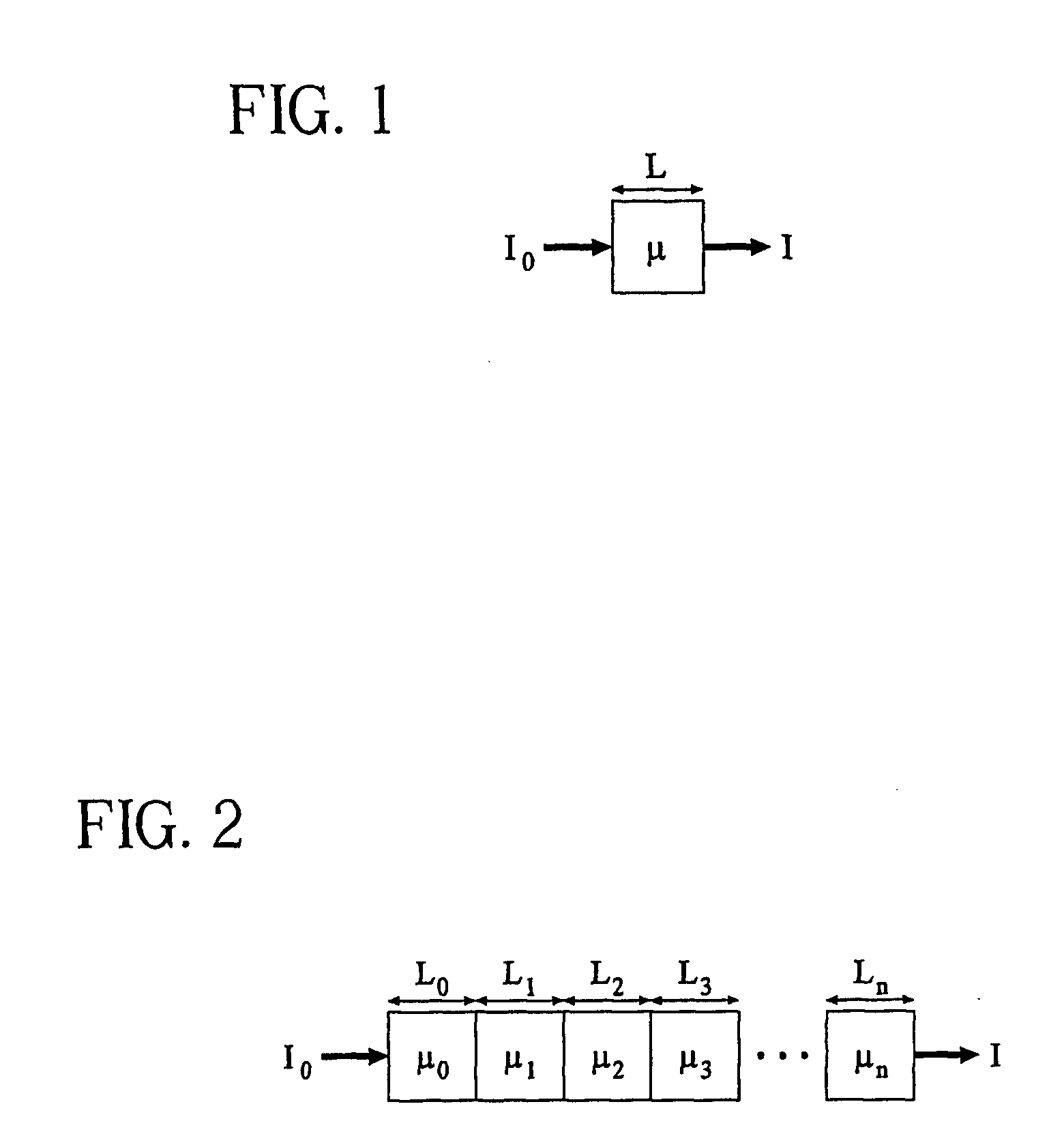

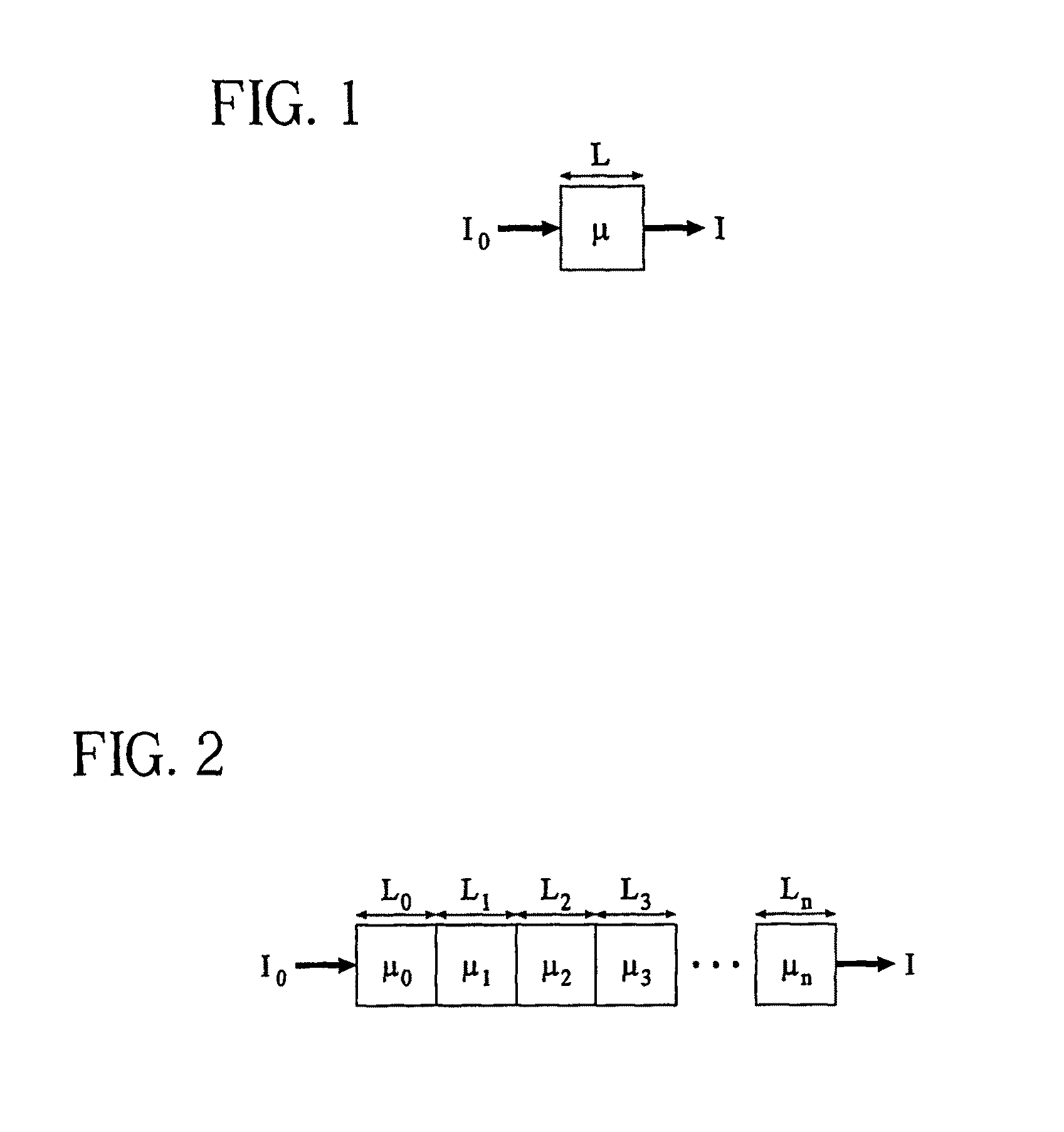

Volumetric Measurement If the amount of gas exiting a column or split vent is measured in units of volume, the flow rate is volumetric based. For example, measuring the volume of gas in milliliters (mL) per unit time in minutes will result in a volumetric flow rate in mL/min. Usually, flow rates are measured at ambient temperature and pressure.

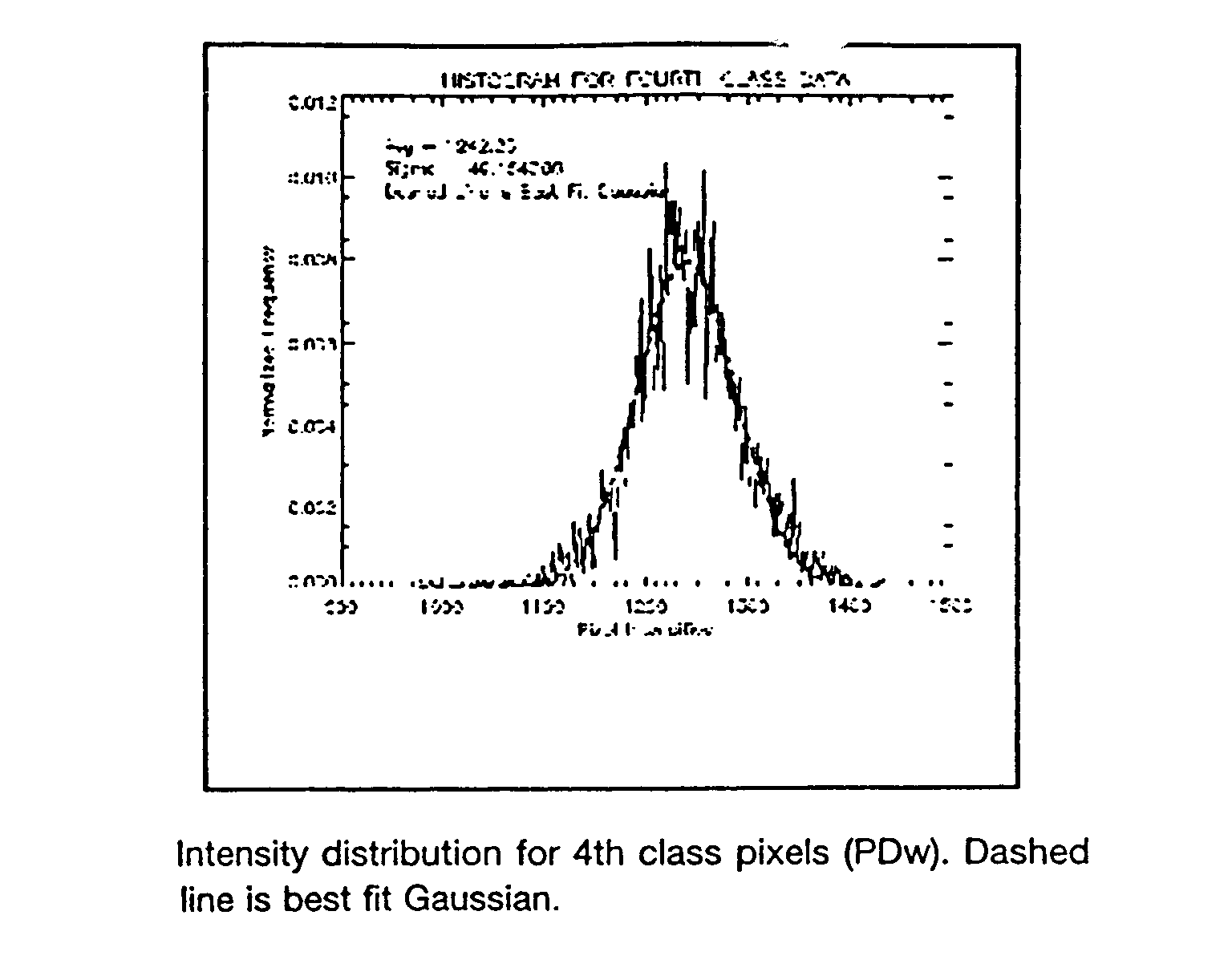

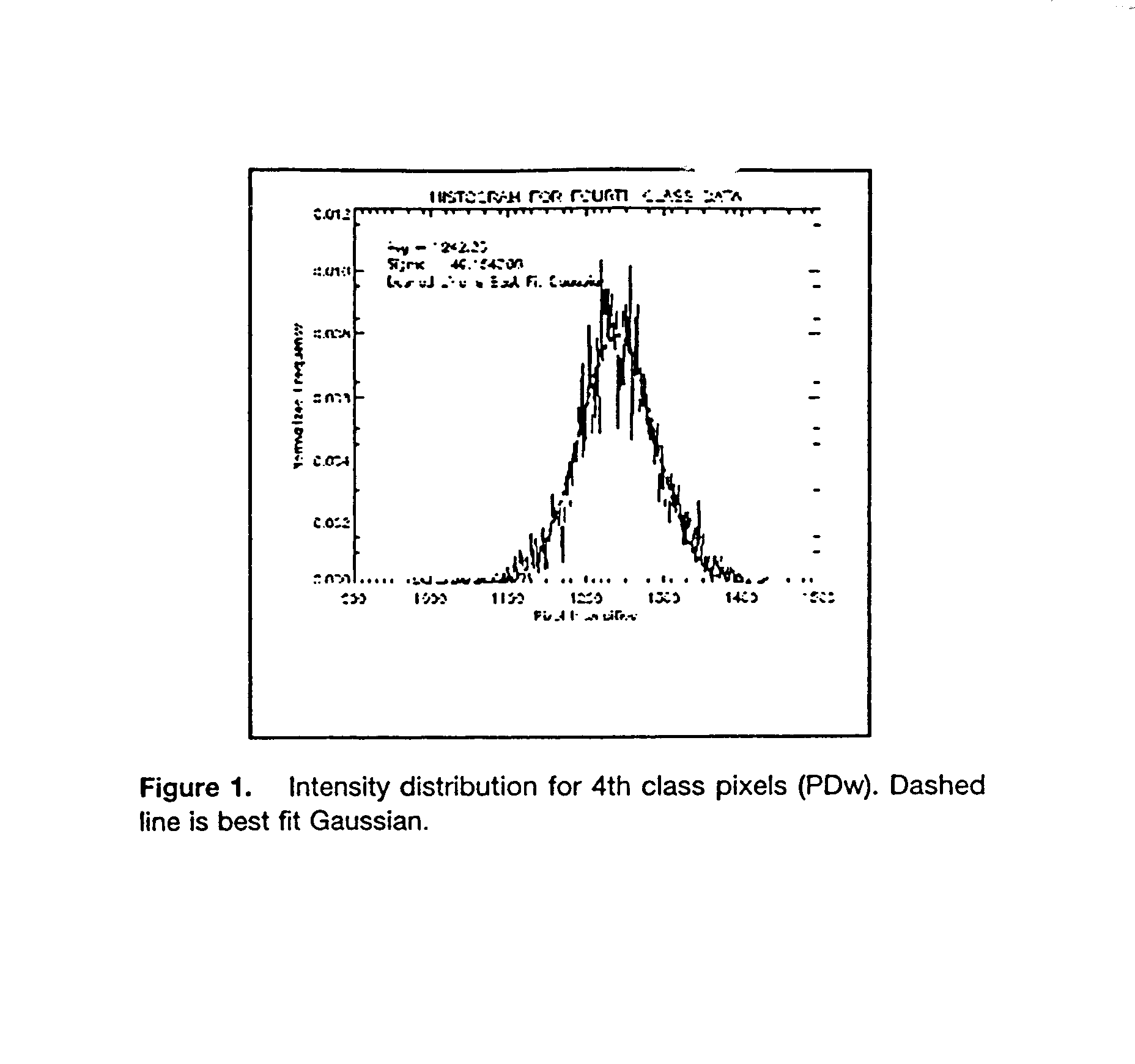

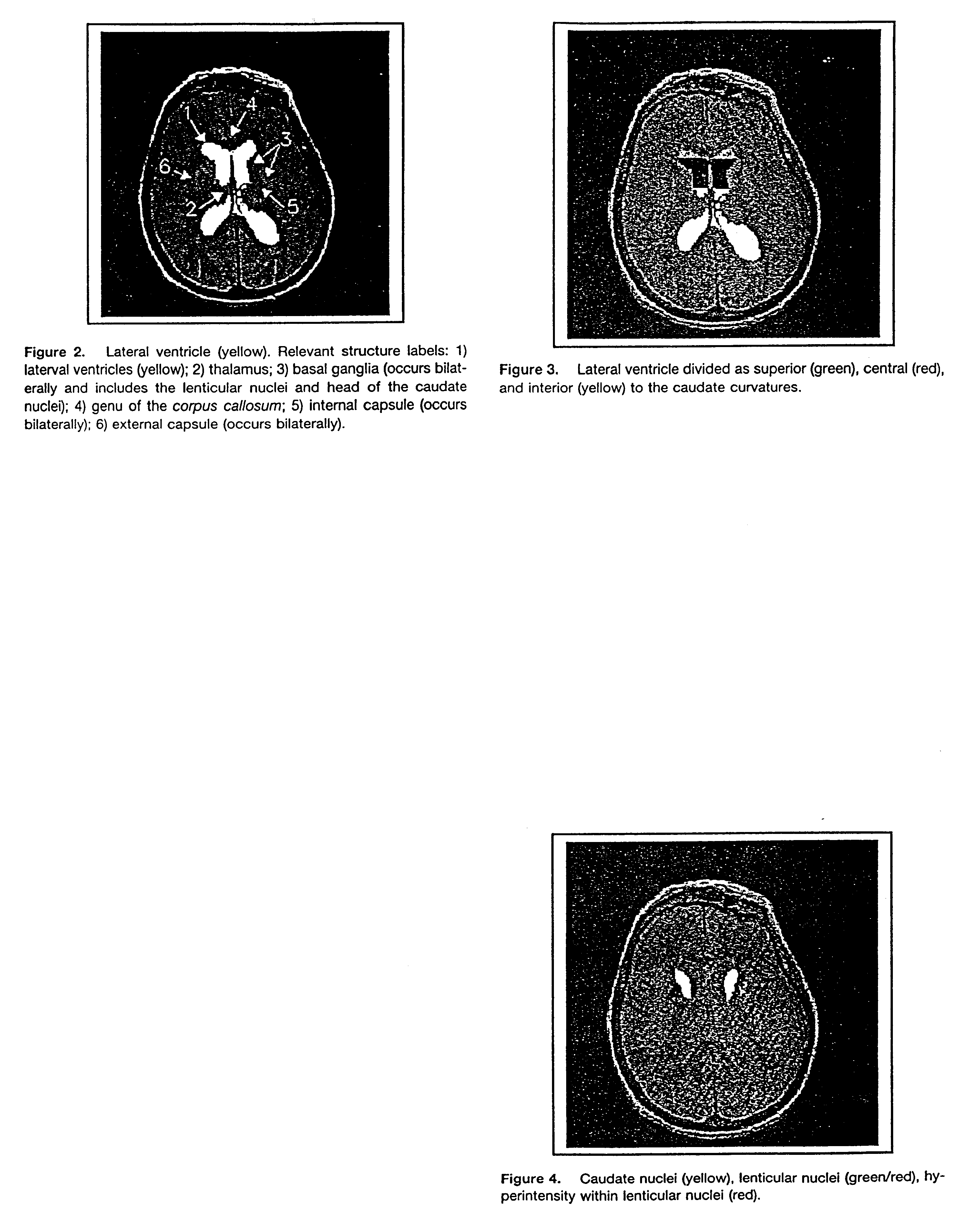

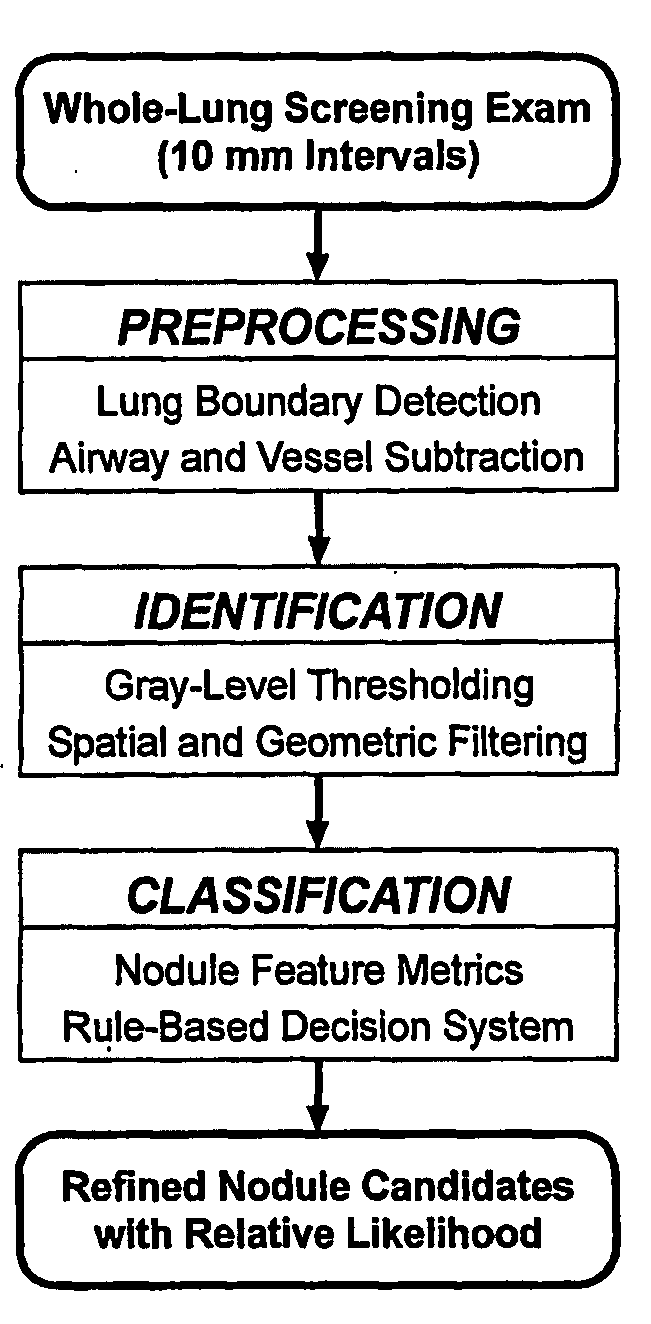

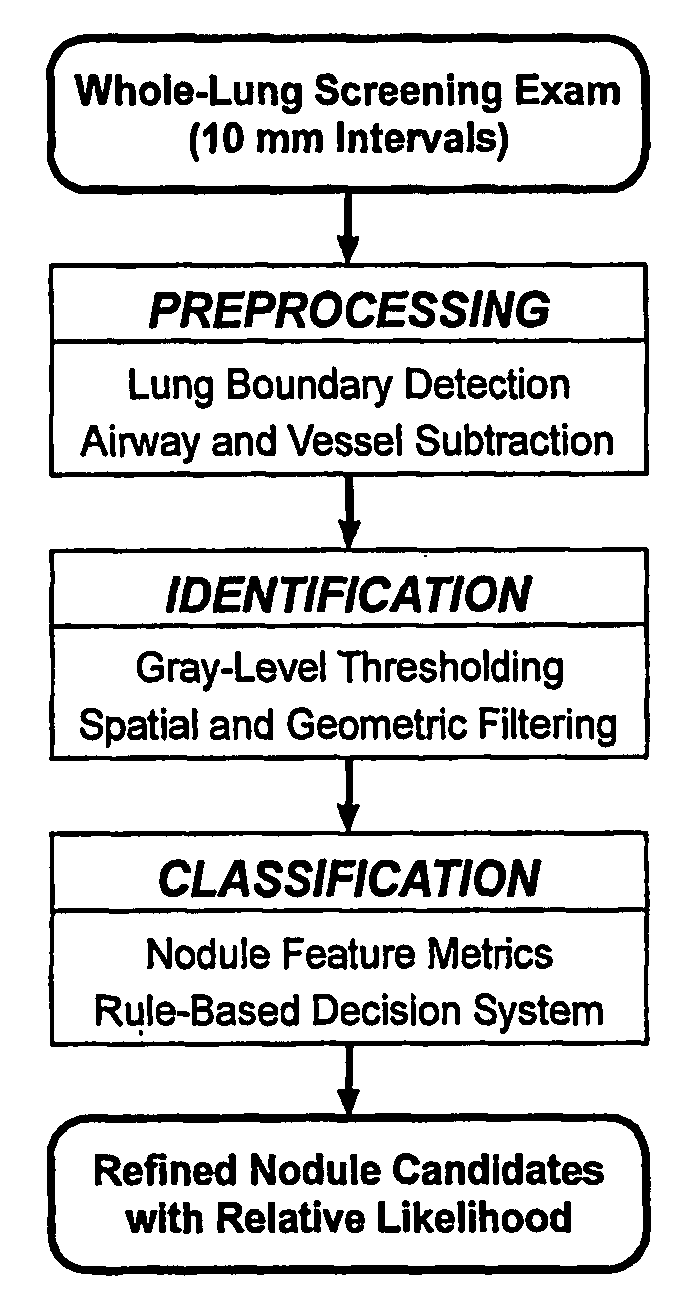

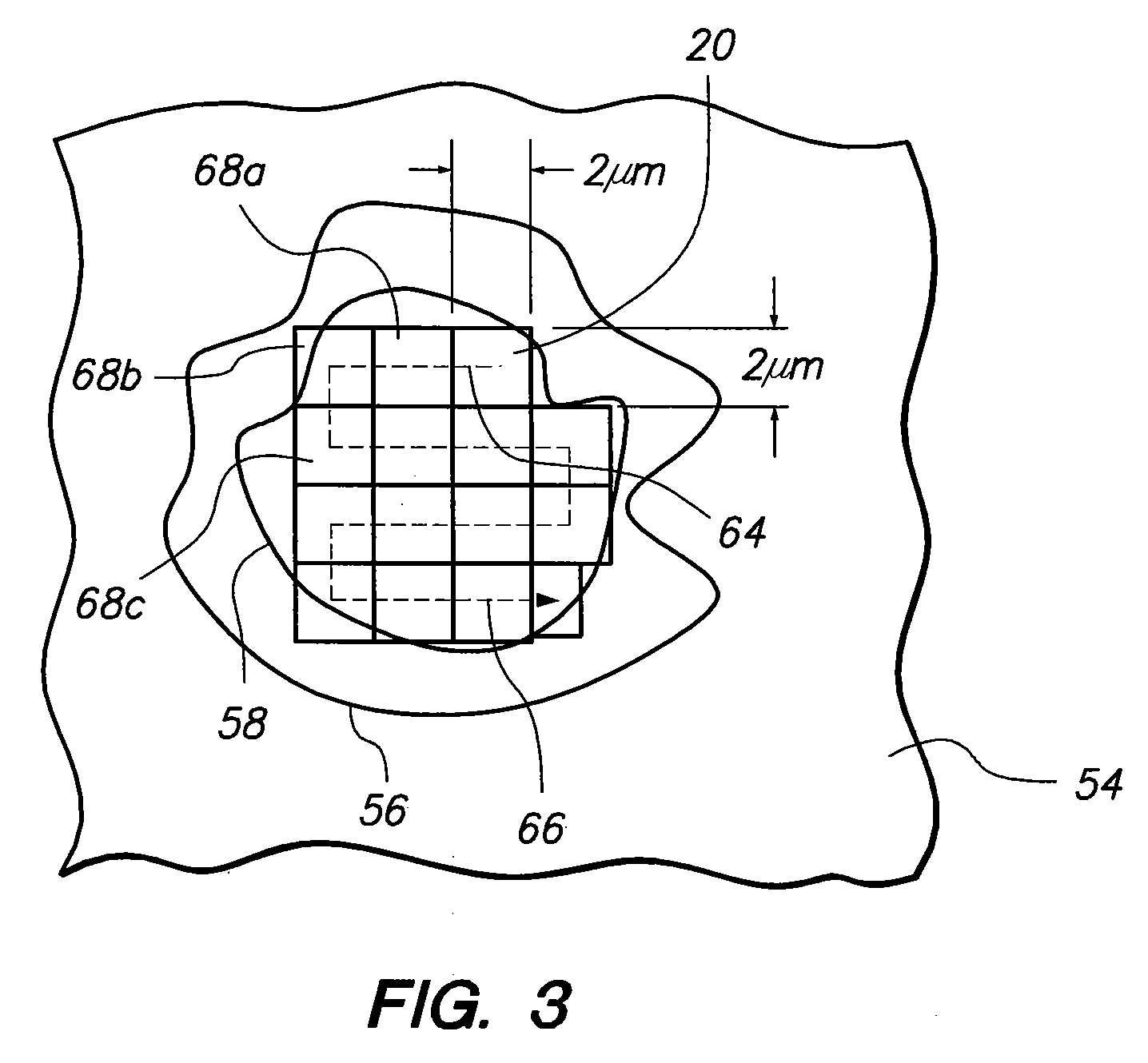

Method and system for knowledge guided hyperintensity detection and volumetric measurement

InactiveUS6430430B1High sensitivityHigh detectionImage enhancementImage analysisAnatomical structuresTissues types

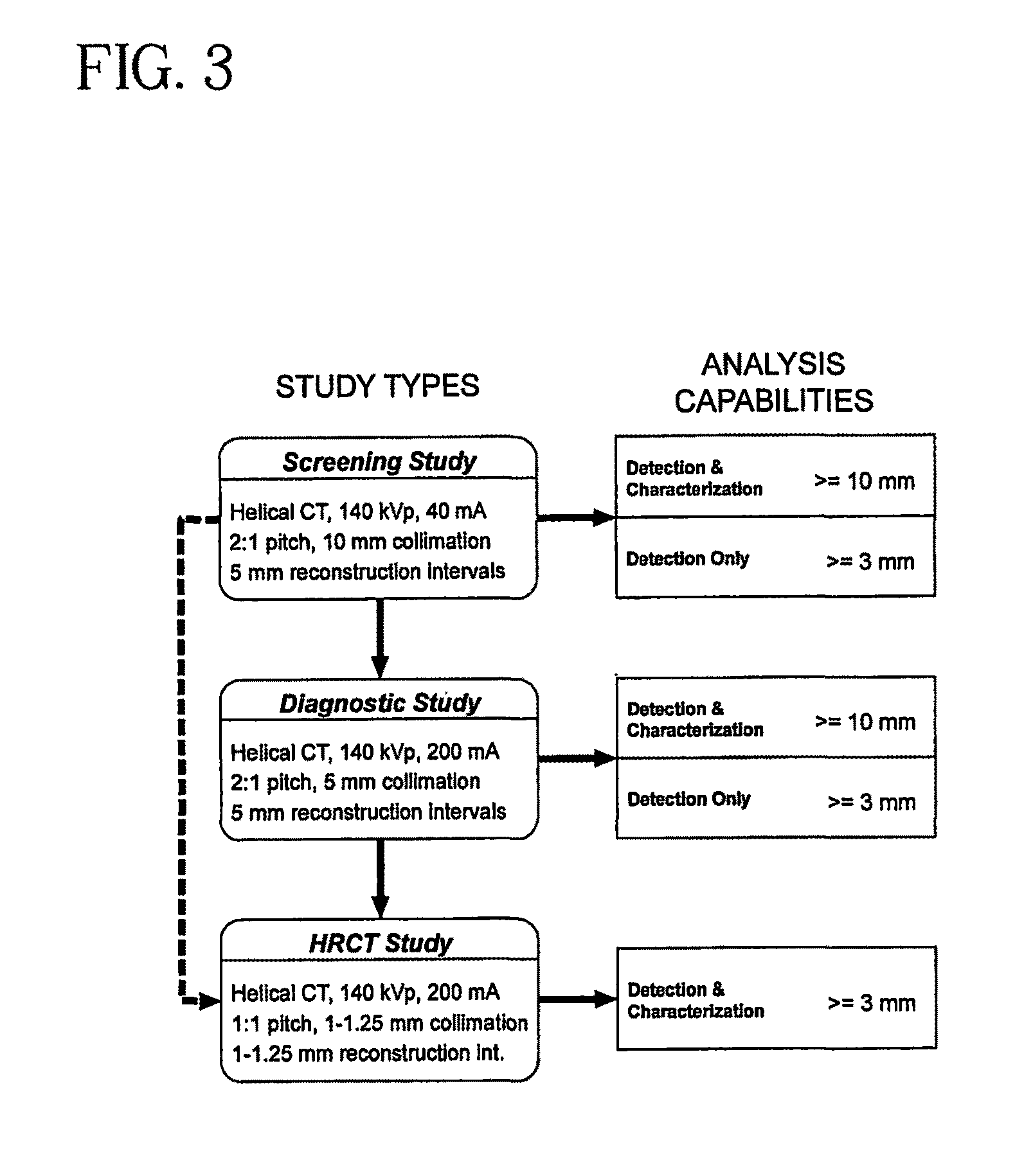

An automated method and / or system for identifying suspected lesions in a brain is provided. A processor (a) provides a magnetic resonance image (MRI) of a patient's head, including a plurality of slices of the patient's head, which MRI comprises a multispectral data set that can be displayed as an image of varying pixel intensities. The processor (b) identifies a brain area within each slice to provide a plurality of masked images of intracranial tissue. The processor (c) applies a segmentation technique to at least one of the masked images to classify the varying pixel intensities into separate groupings, which potentially correspond to different tissue types. The processor (d) refines the initial segmentation into the separate groupings of at least the first masked image obtained from step (c) using one or more knowledge rules that combine pixel intensities with spatial relationships of anatomical structures to locate one or more anatomical regions of the brain. The processor (e) identifies, if present, the one or more anatomical regions of the brain located in step (d) in other masked images obtained from step (c). The processor (f) further refines the resulting knowledge rule-refined images from steps (d) and (e) to locate suspected lesions in the brain.

Owner:UNIV OF SOUTH FLORIDA

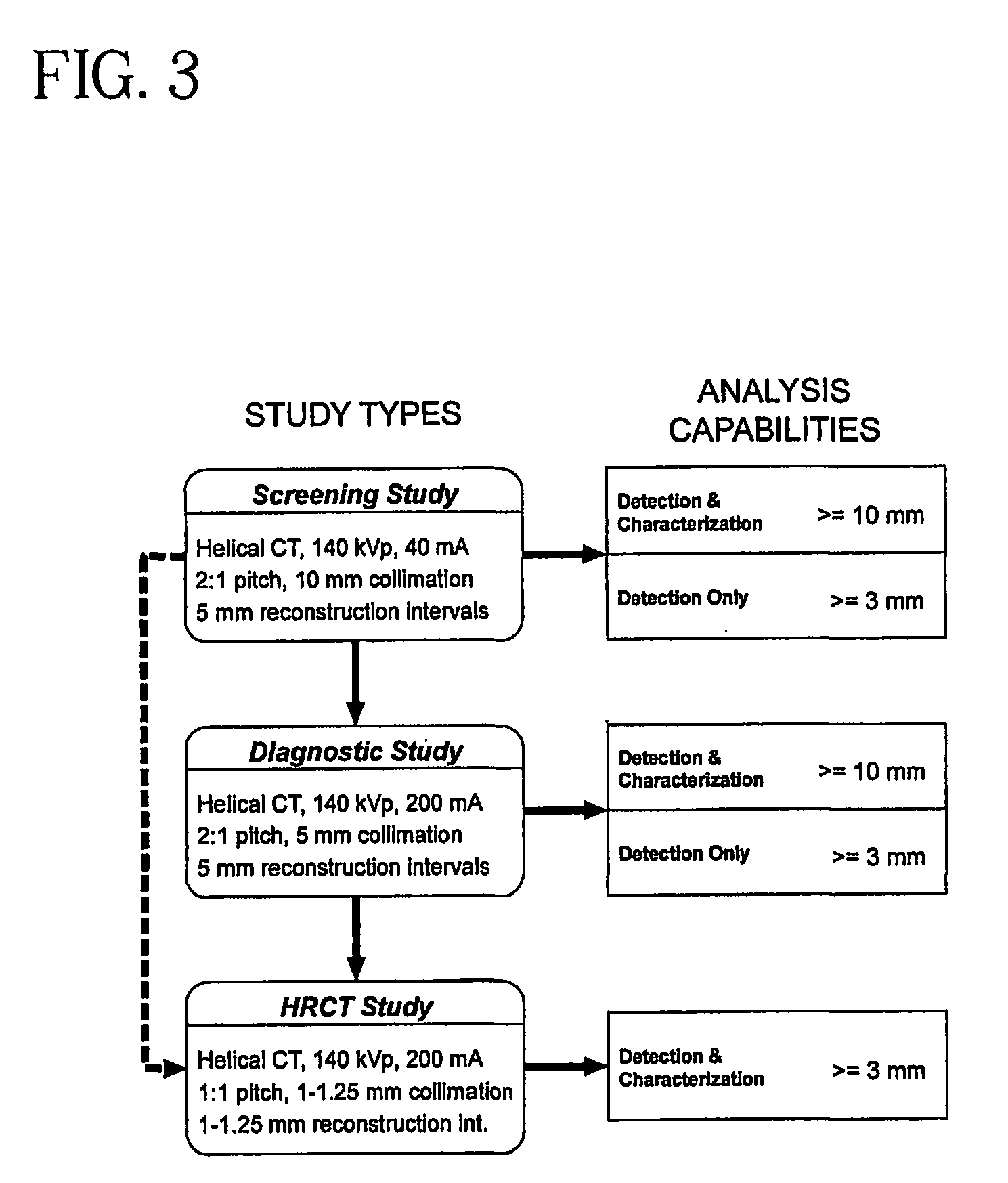

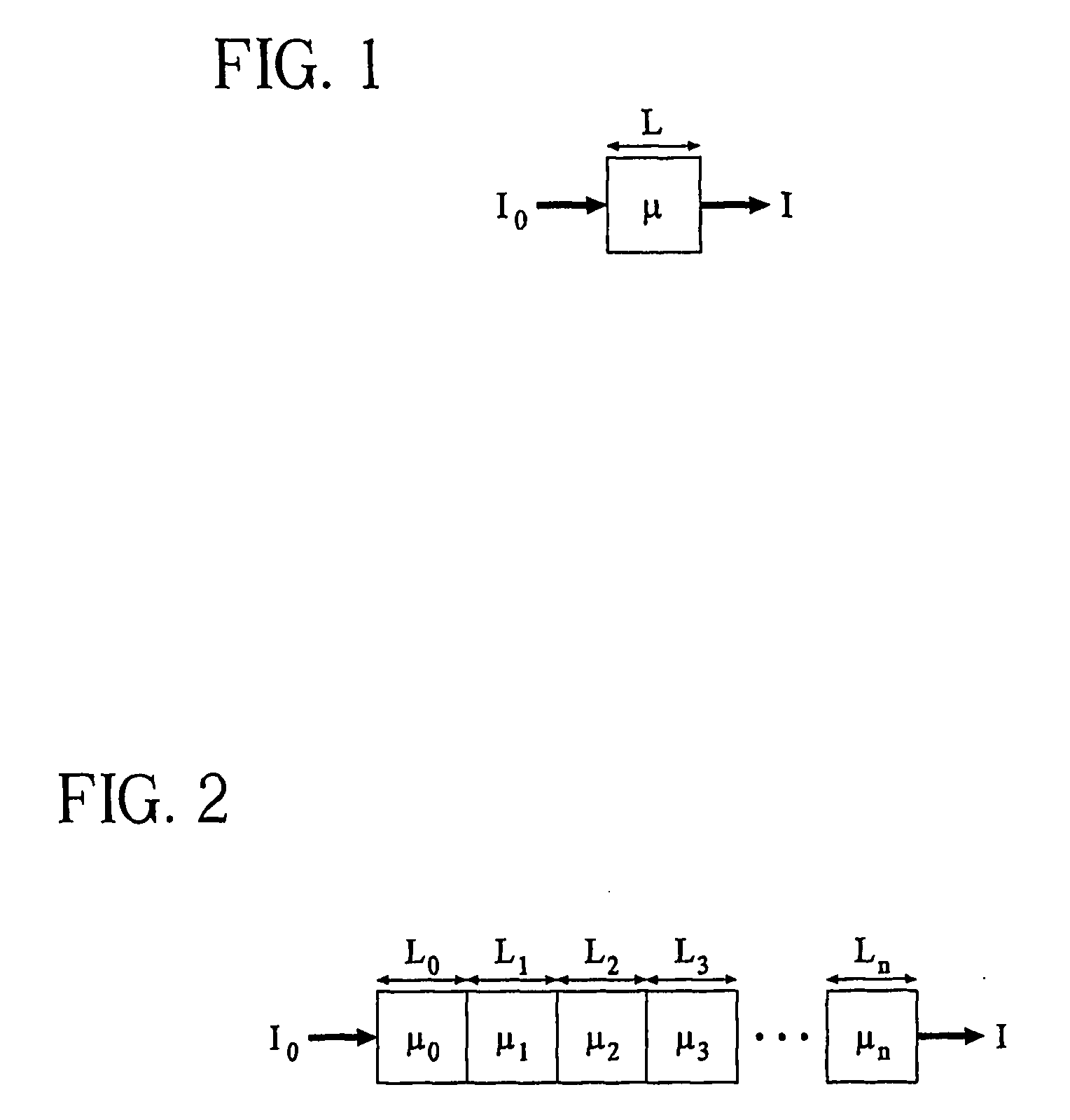

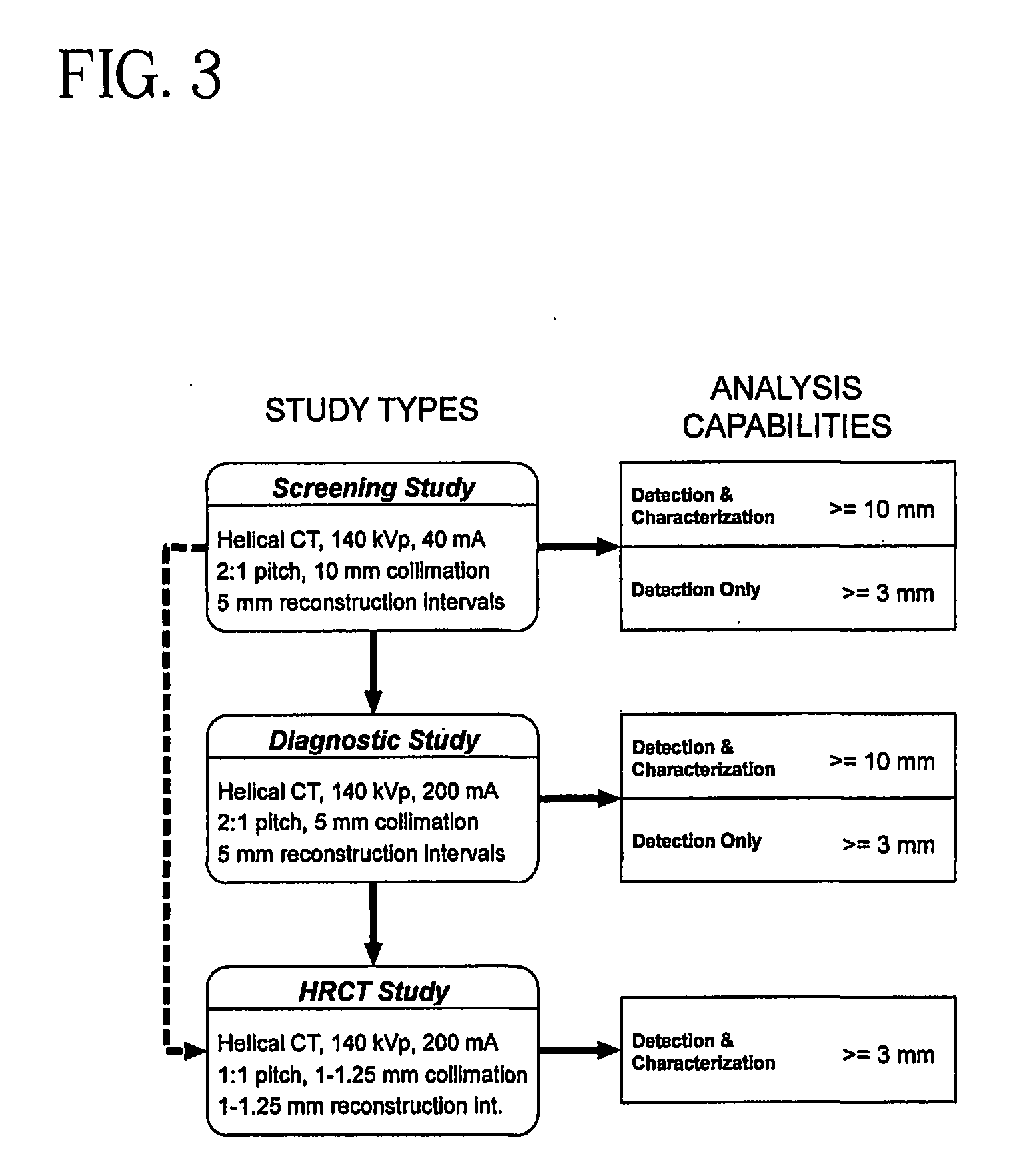

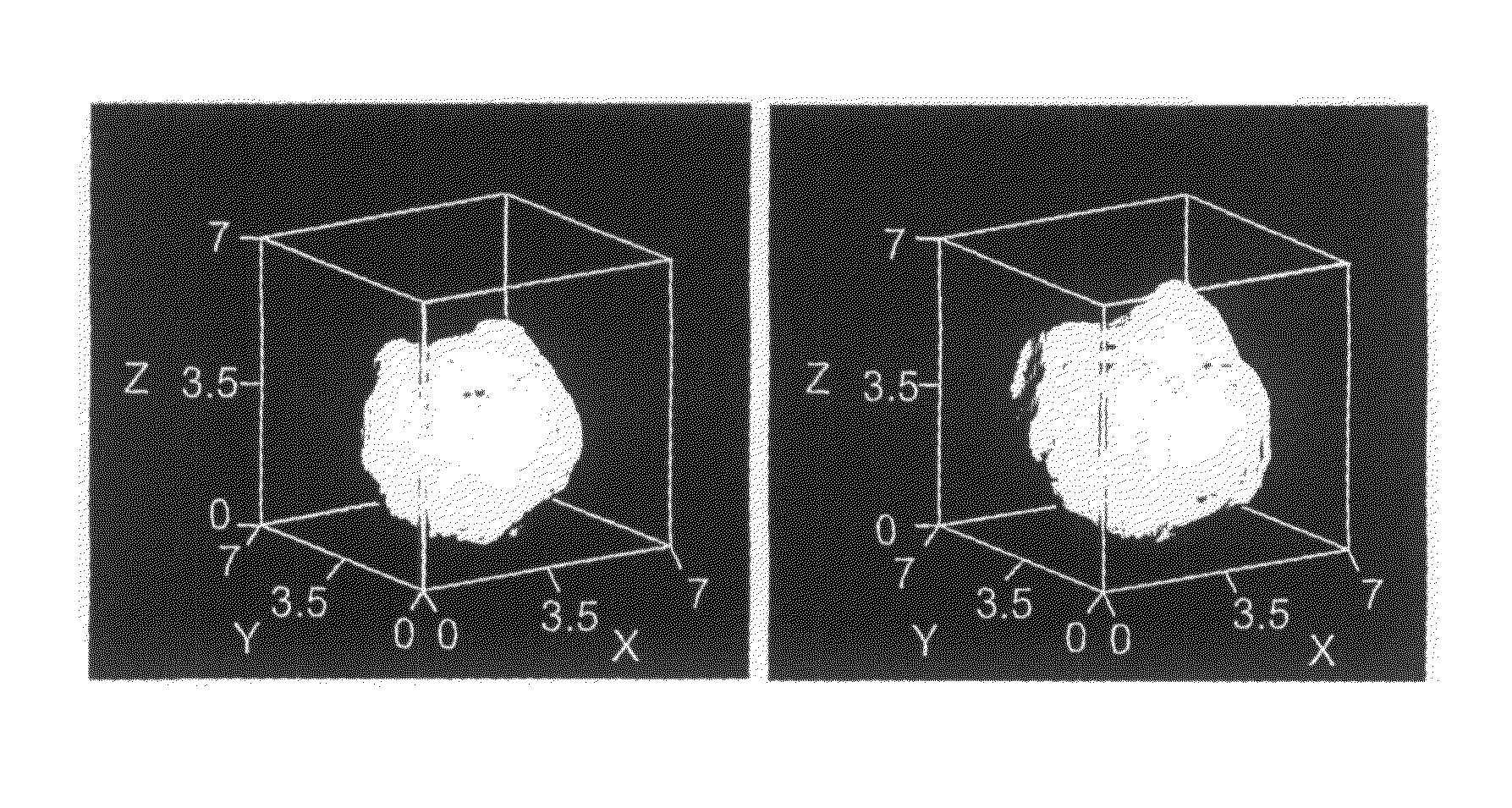

System and method for three-dimensional image rendering and analysis

InactiveUS20080205717A1Reduce decreaseReduce contributionImage enhancementReconstruction from projectionImaging analysis3d image

The present invention relates to methods and systems for conducting three-dimensional image analysis and diagnosis and possible treatment relating thereto. The invention includes methods of handling signals containing information (data) relating to three-dimensional representation of objects scanned by a scanning medium. The invention also includes methods of making and analyzing volumetric measurements and changes in volumetric measurements which can be used for the purpose of diagnosis and treatment.

Owner:CORNELL RES FOUNDATION INC

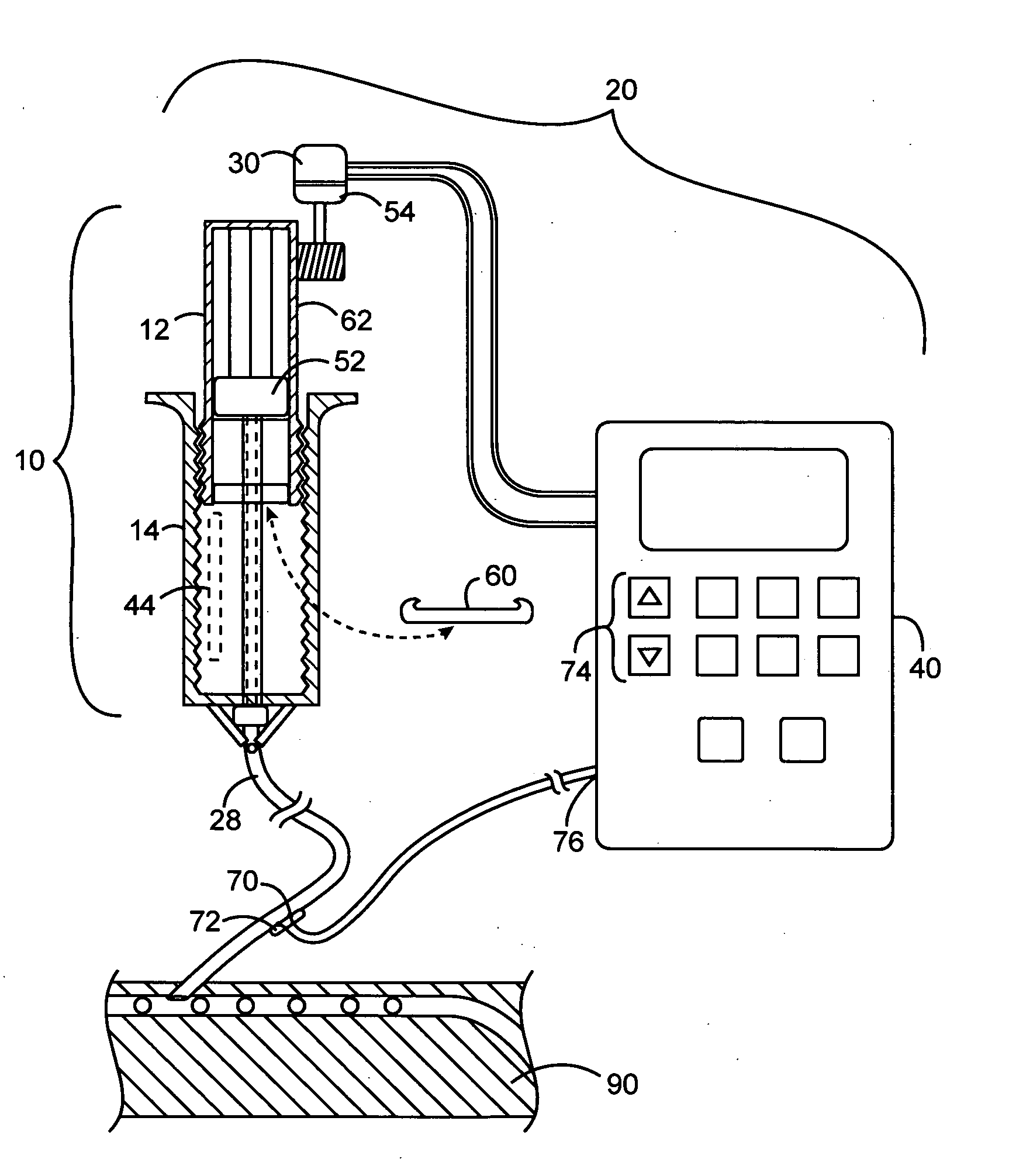

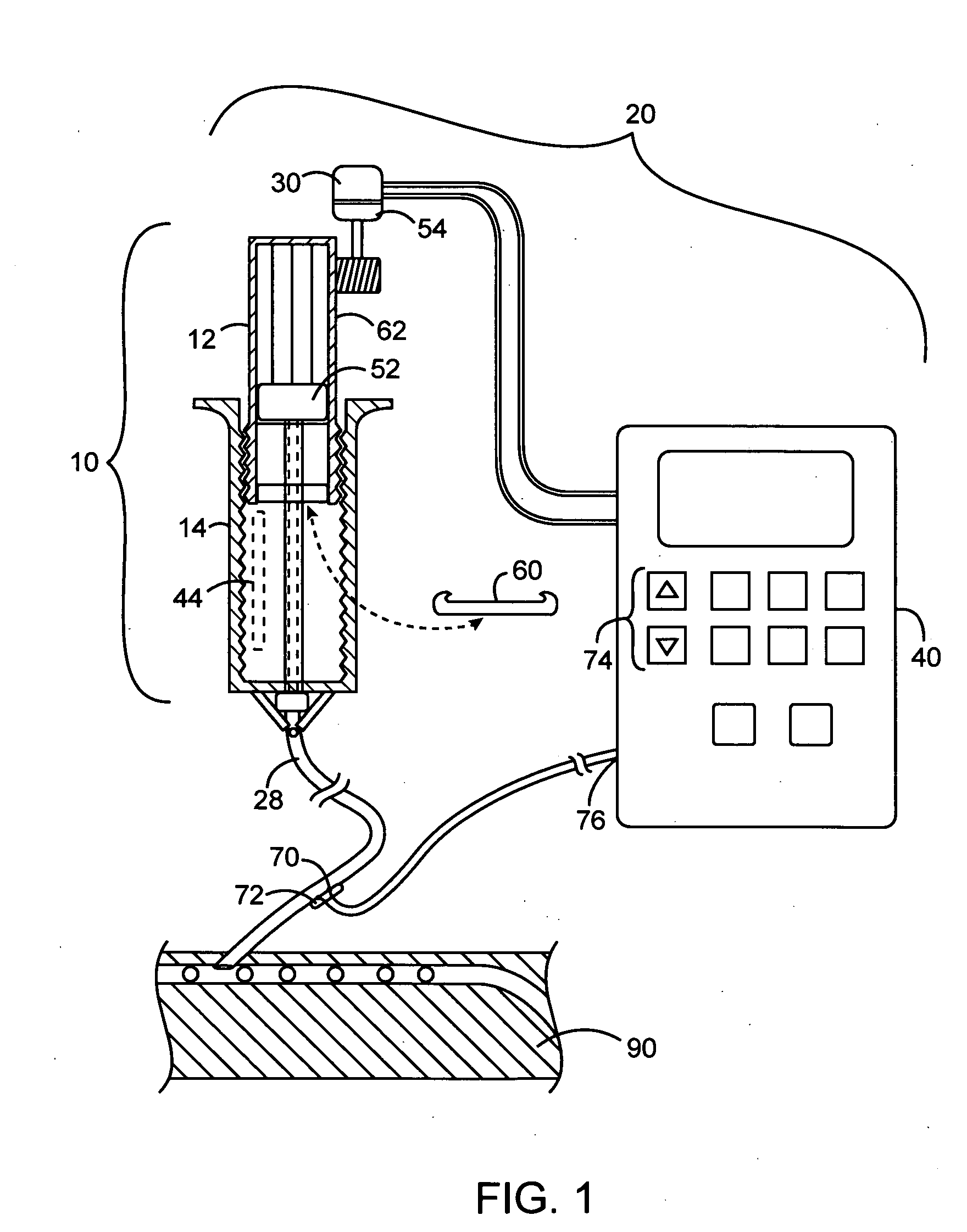

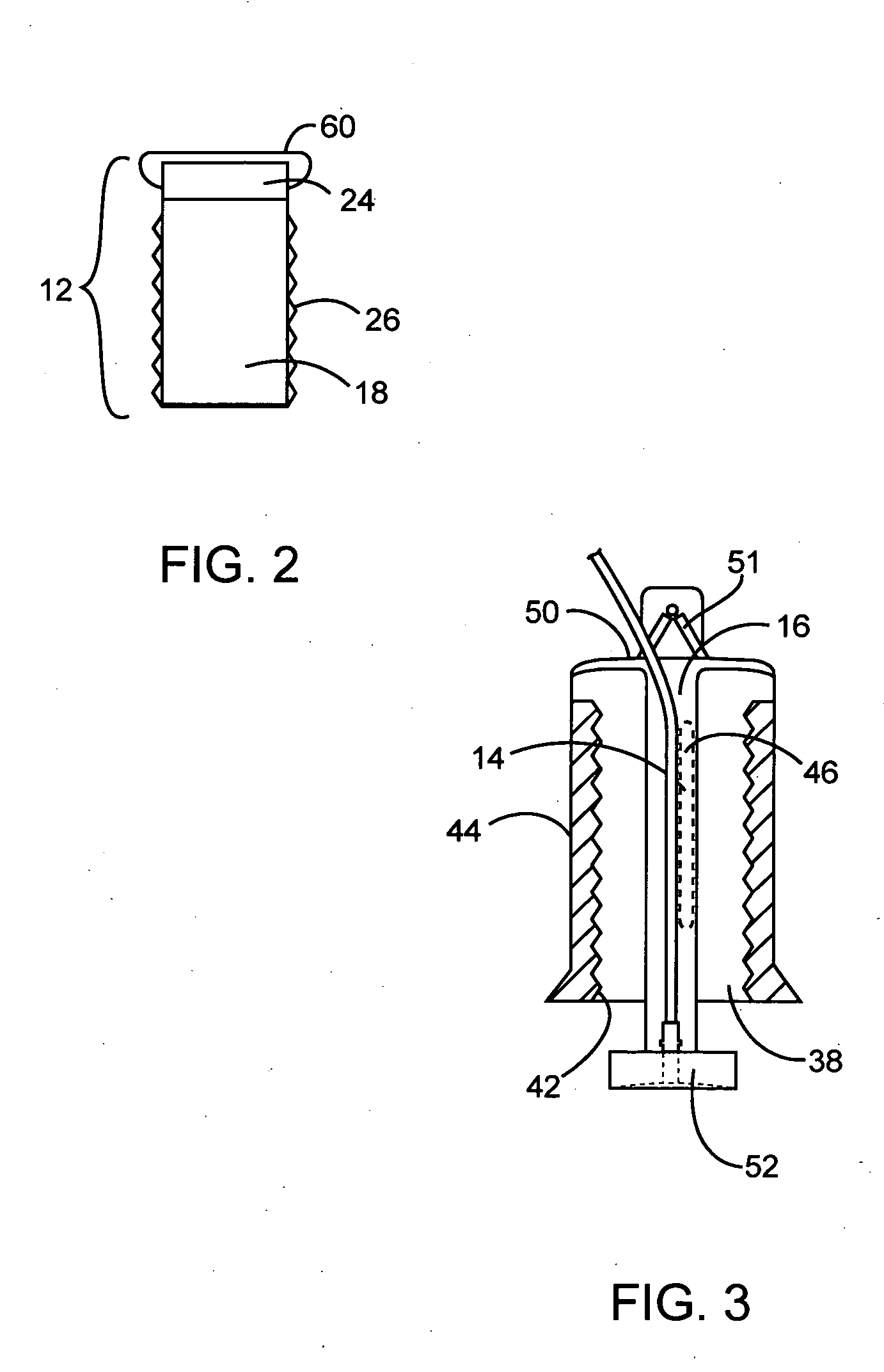

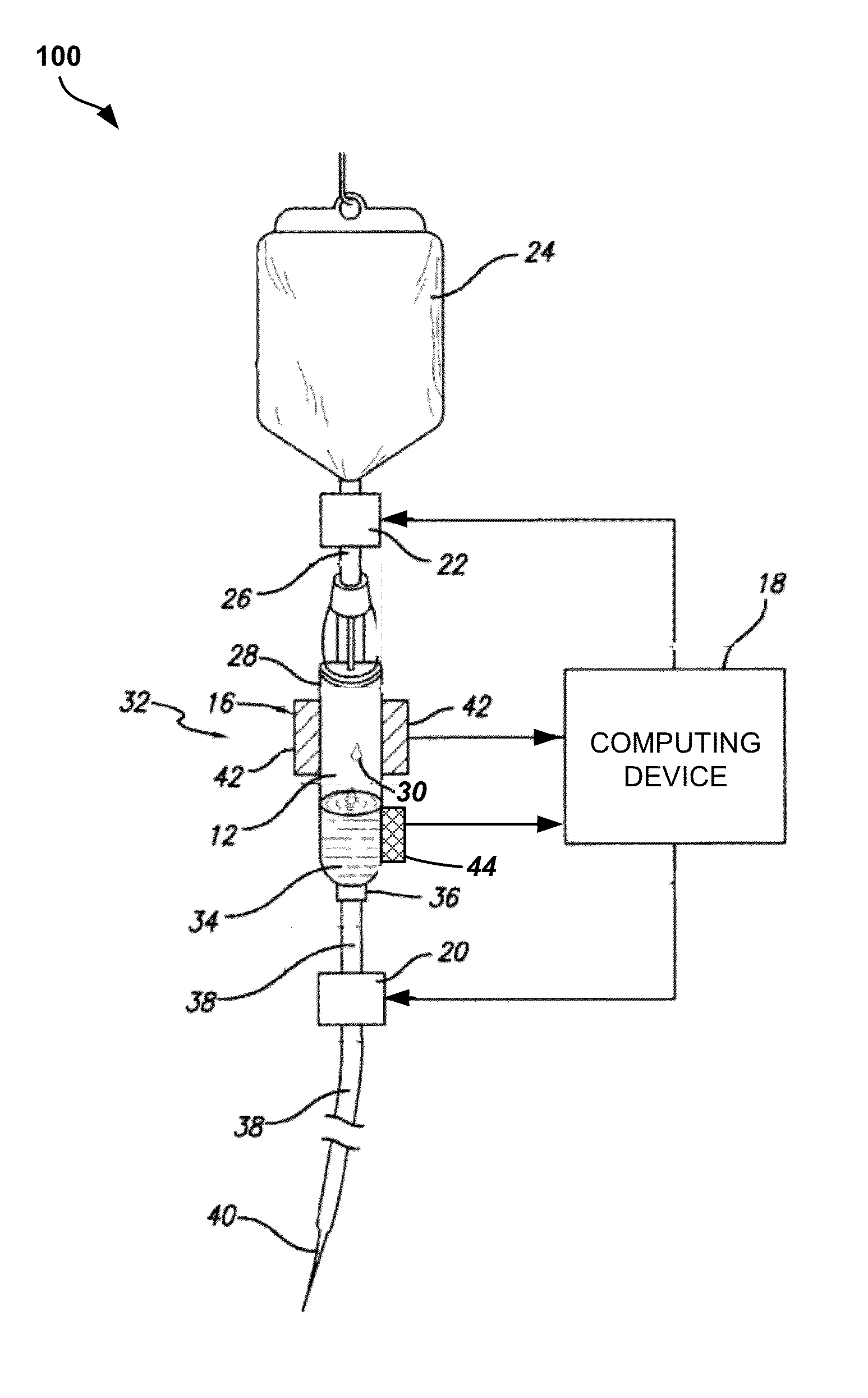

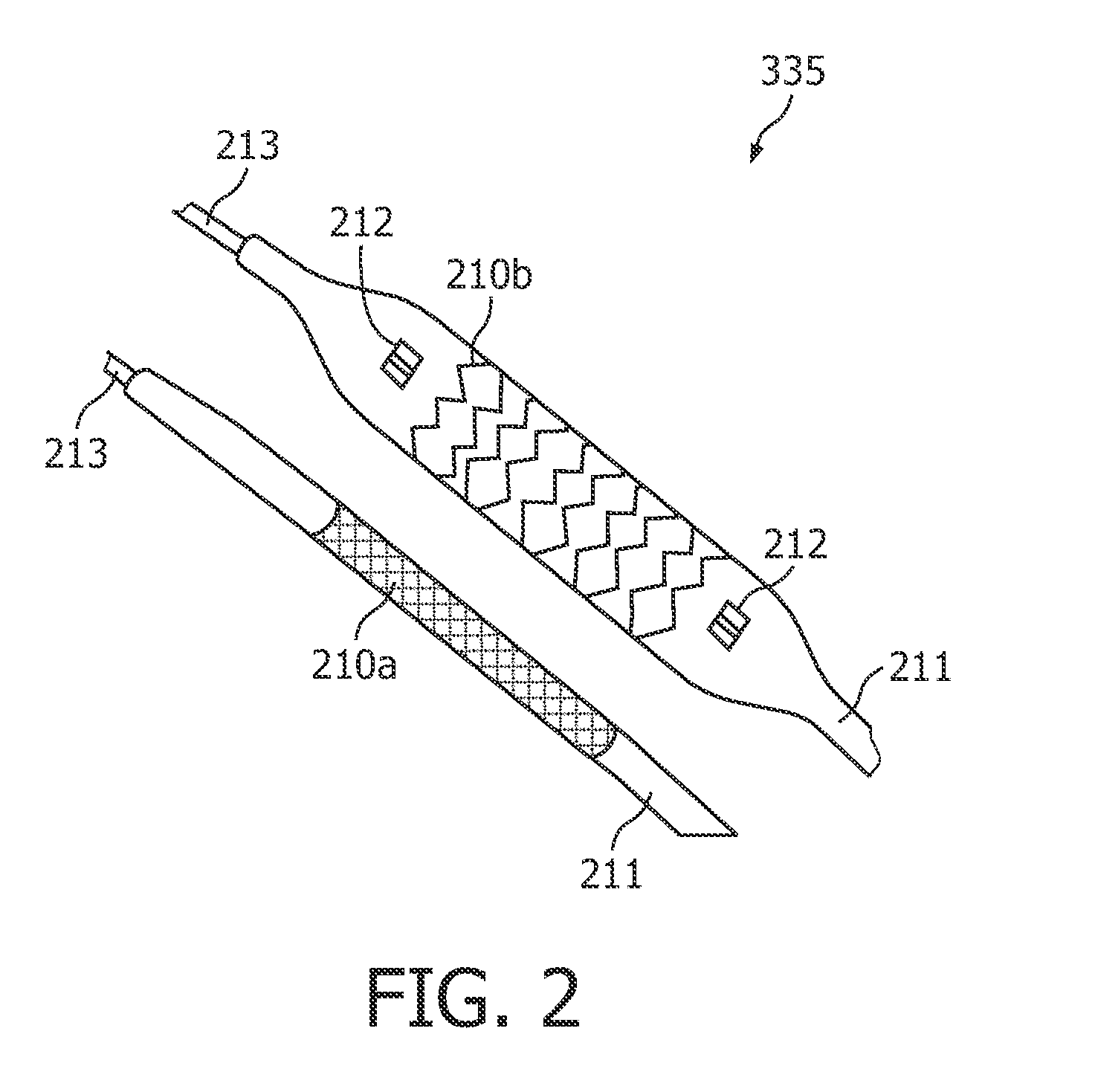

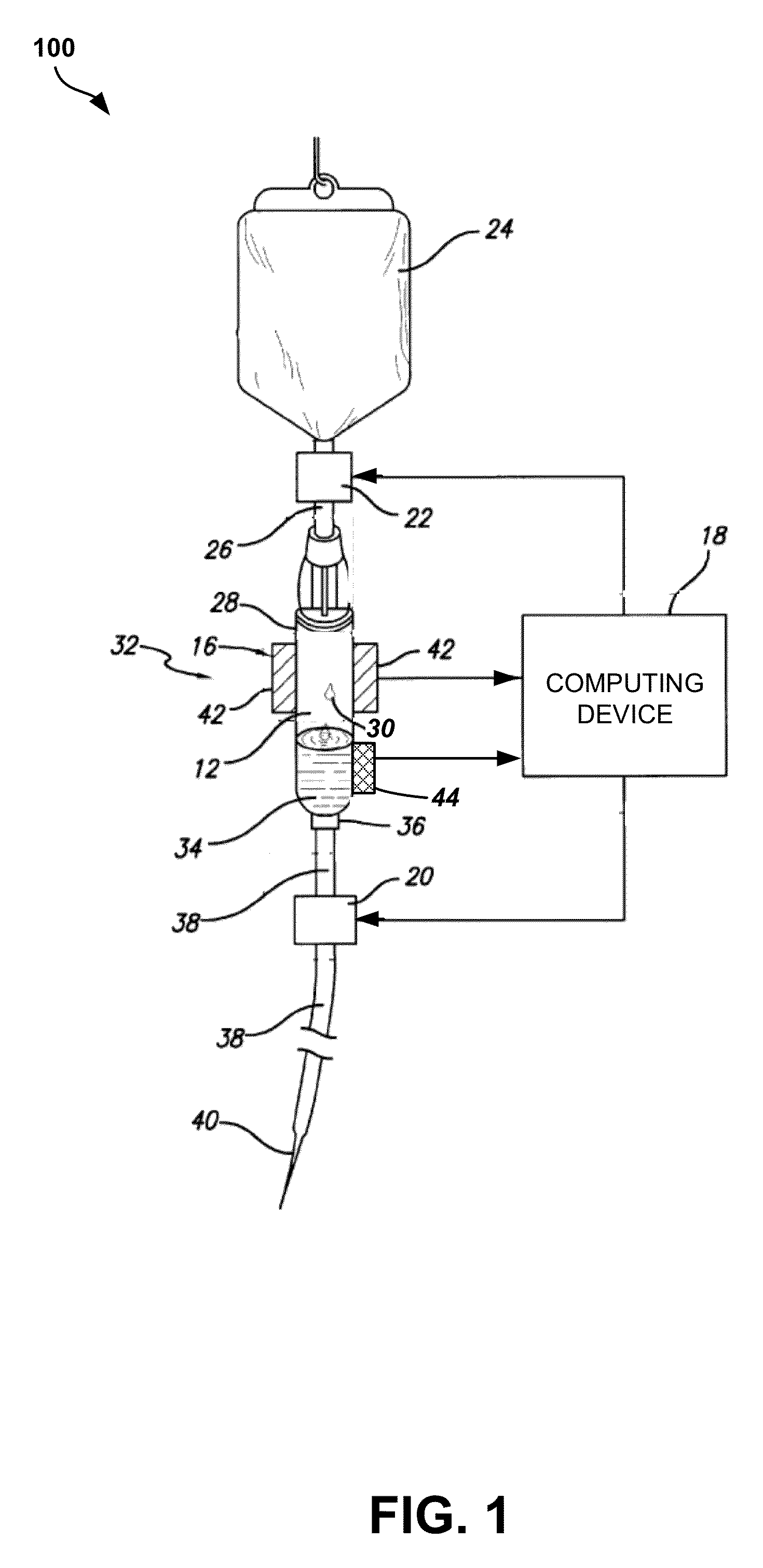

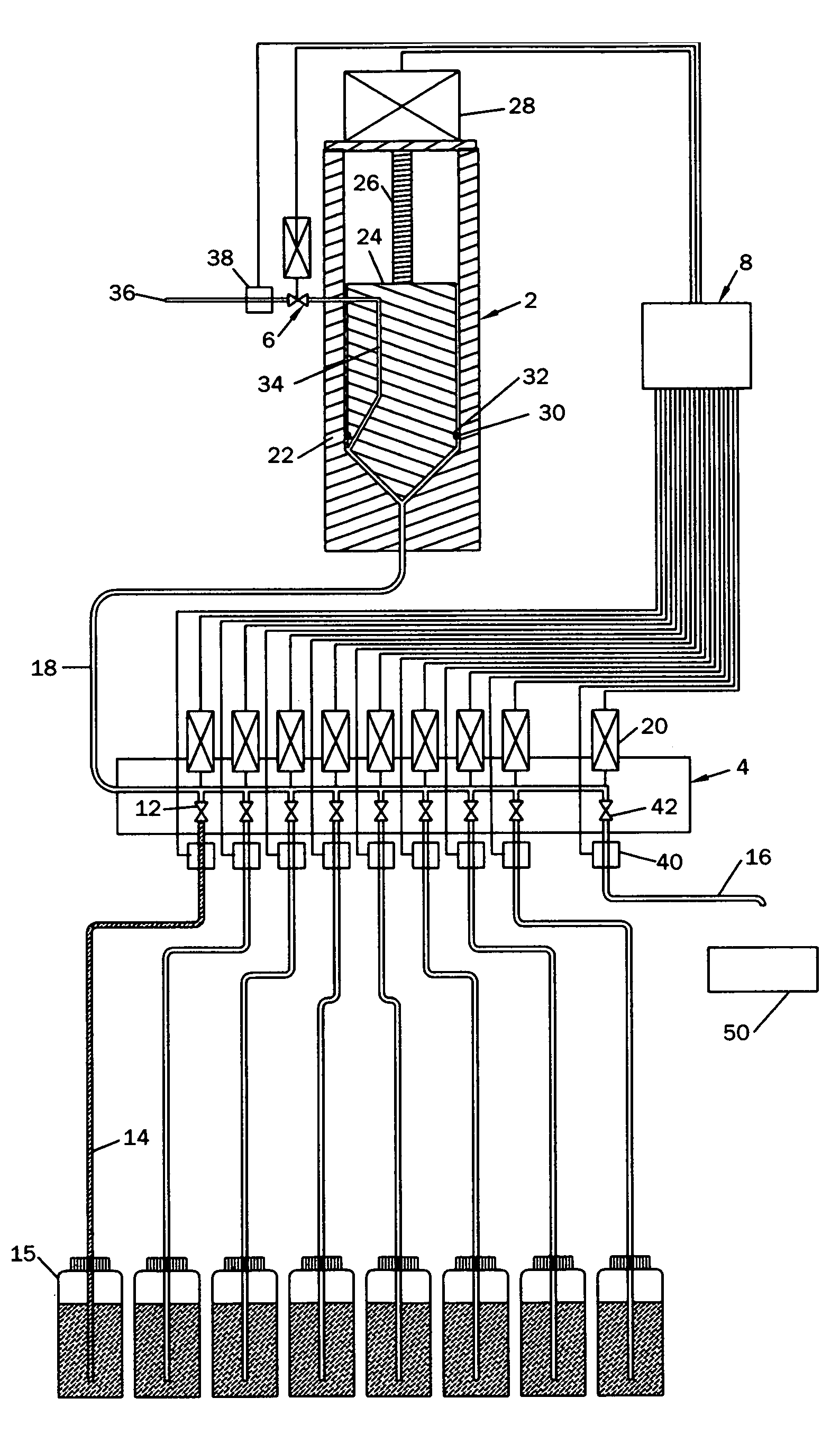

Quantitative chronological medical infusion device

InactiveUS20060079831A1Reduce riskReduced glucose levelMedical devicesIntravenous devicesLine sensorHigh rate

The present invention is a medical infusion and aspiration system delivering precisely timed and accurately calculated, adjusted pulsated delivery in high rates of flow delivering an effective profile of pulses tailored to provide momentary spikes of levels of freely available medicines based upon the uptake of the medicine and optimally on real time measurements of the medicine or response of the patient, termed Quantitative Chronological Delivery. The system comprises any pumping mechanism, and optimally a pumping mechanism, and a cassette or cartridge having a reservoir area where the plunger rotates as it advances in reference to the cartridge to provide additional accuracy and overcome the forces of inertia and slip-stick as well as eliminate backlash. Optimally, the systems incorporates an encoded area and an opening for connection to an infusion tube with an in-line sensor area where sampling probes are located. The infusion is adjusted in both amount and duration between pulses to provide quantitatively controlled, chronologically optimized infusion. A motor causes bi-directional pumping to allow for samples to be presented to the sensor area. The system accuracy allows for more concentrated medicines, as a sealed container can eliminate the need for diluting or withdrawing medicine to load a reservoir, and achieves extraordinary accuracy without error correcting software or expensive volumetric measurement and control systems.

Owner:BIONICA INT

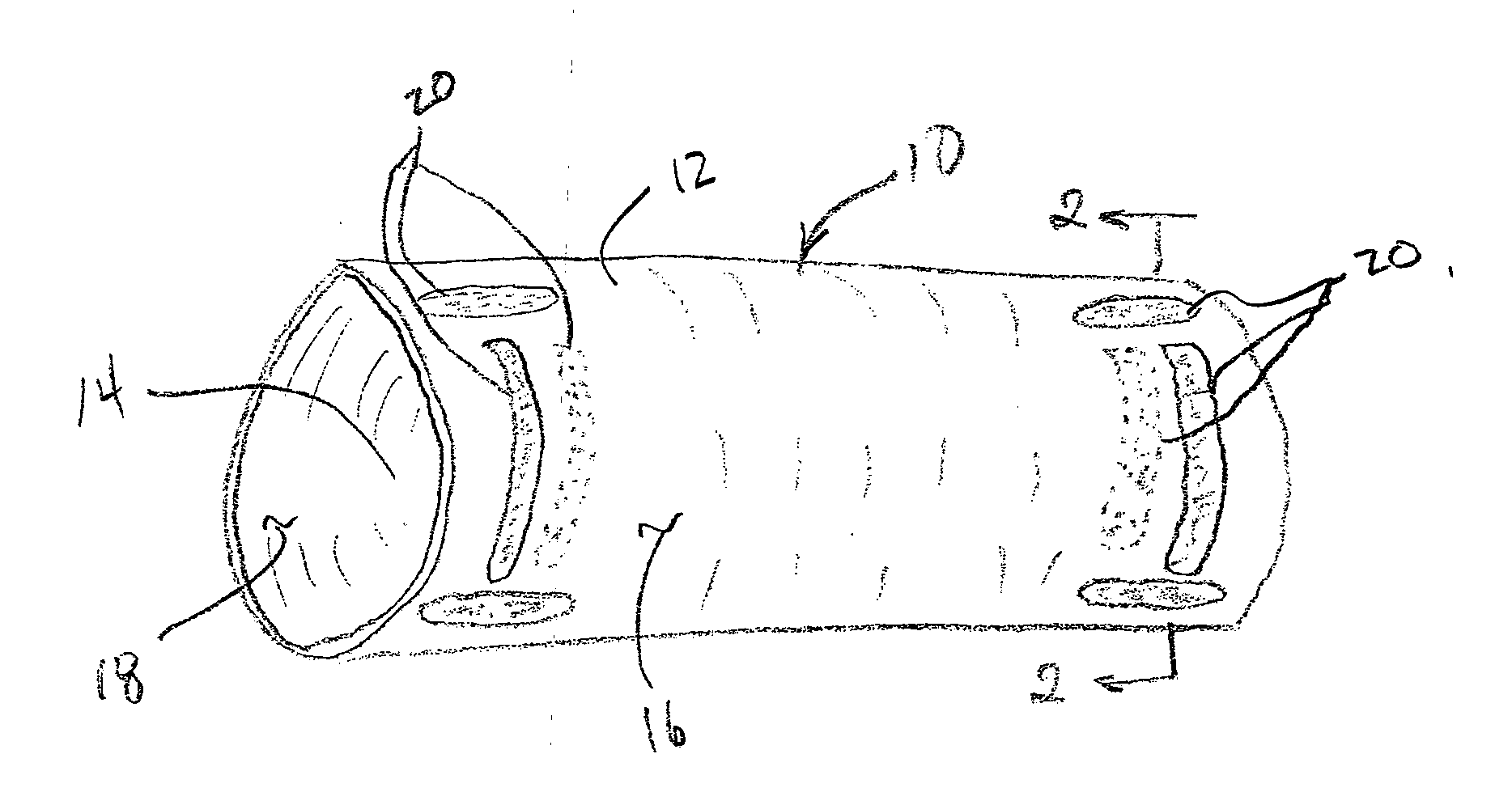

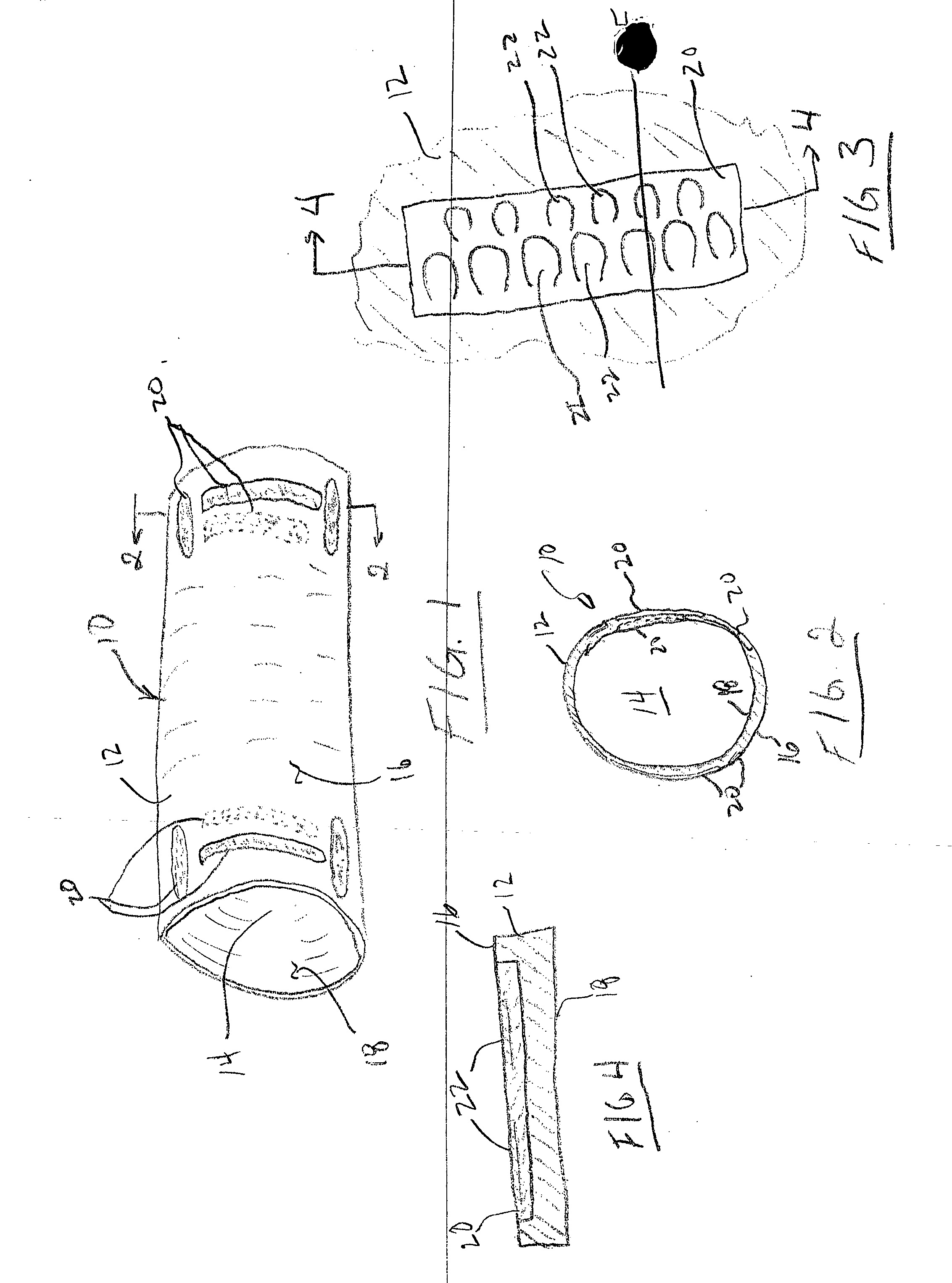

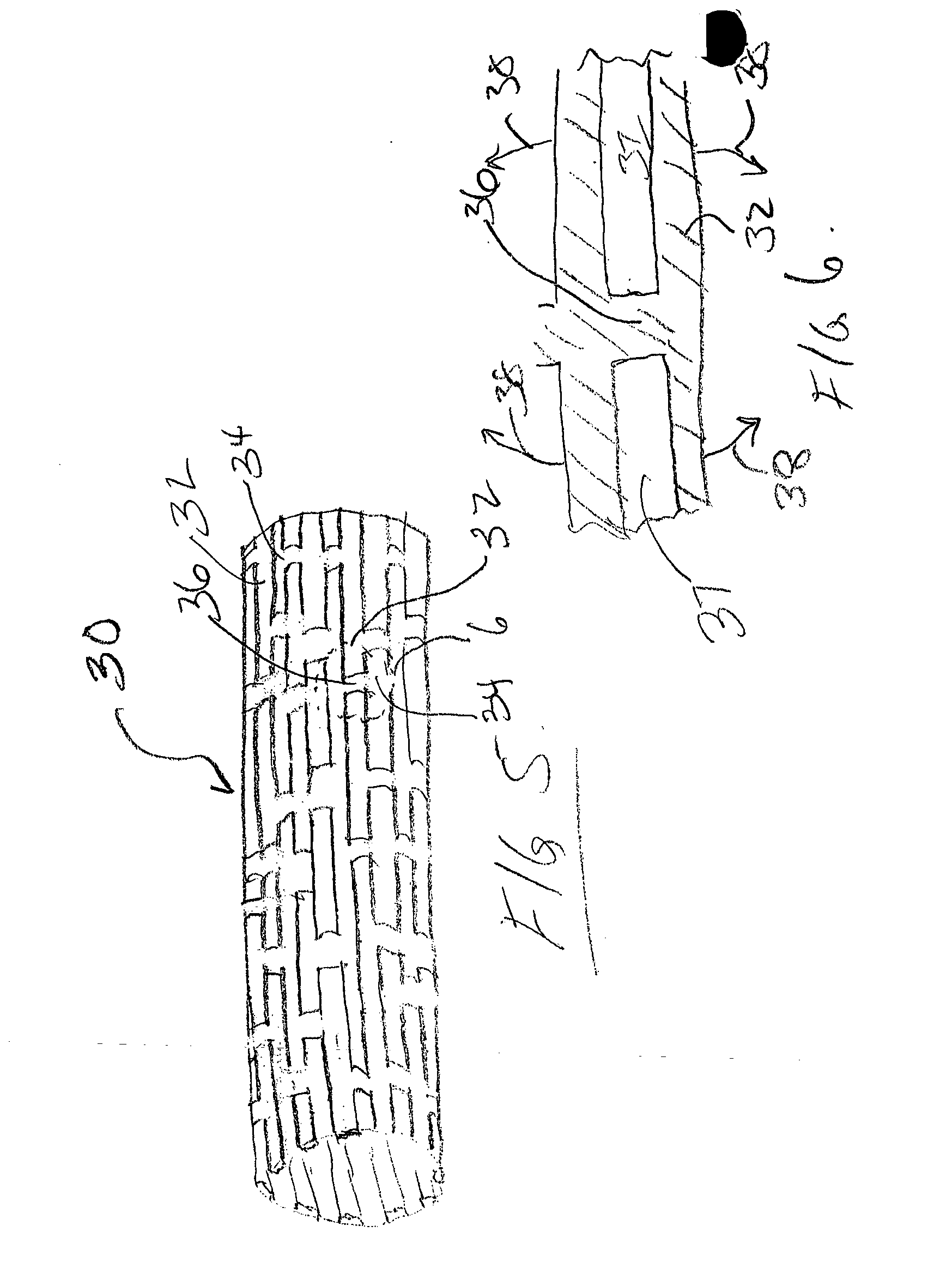

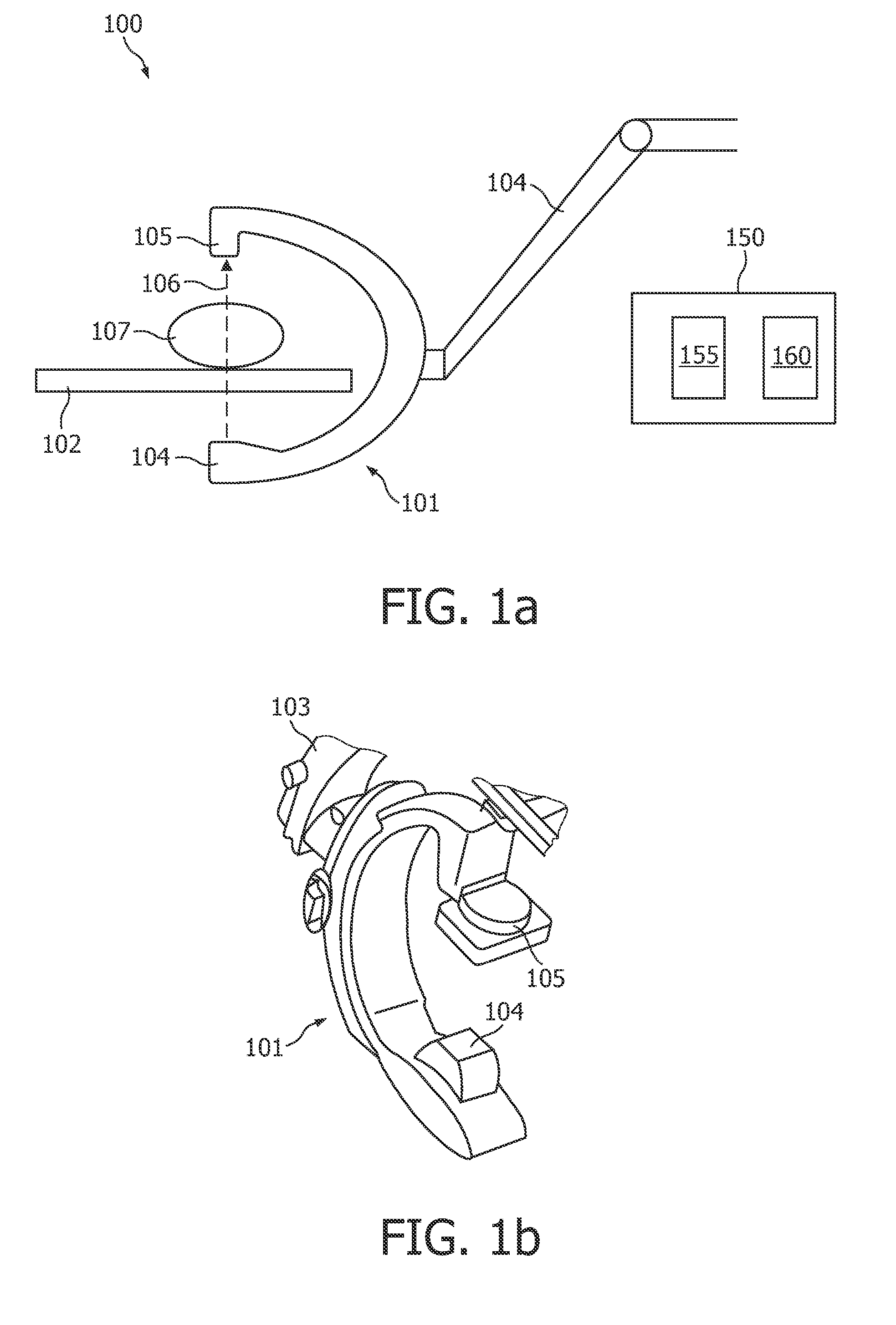

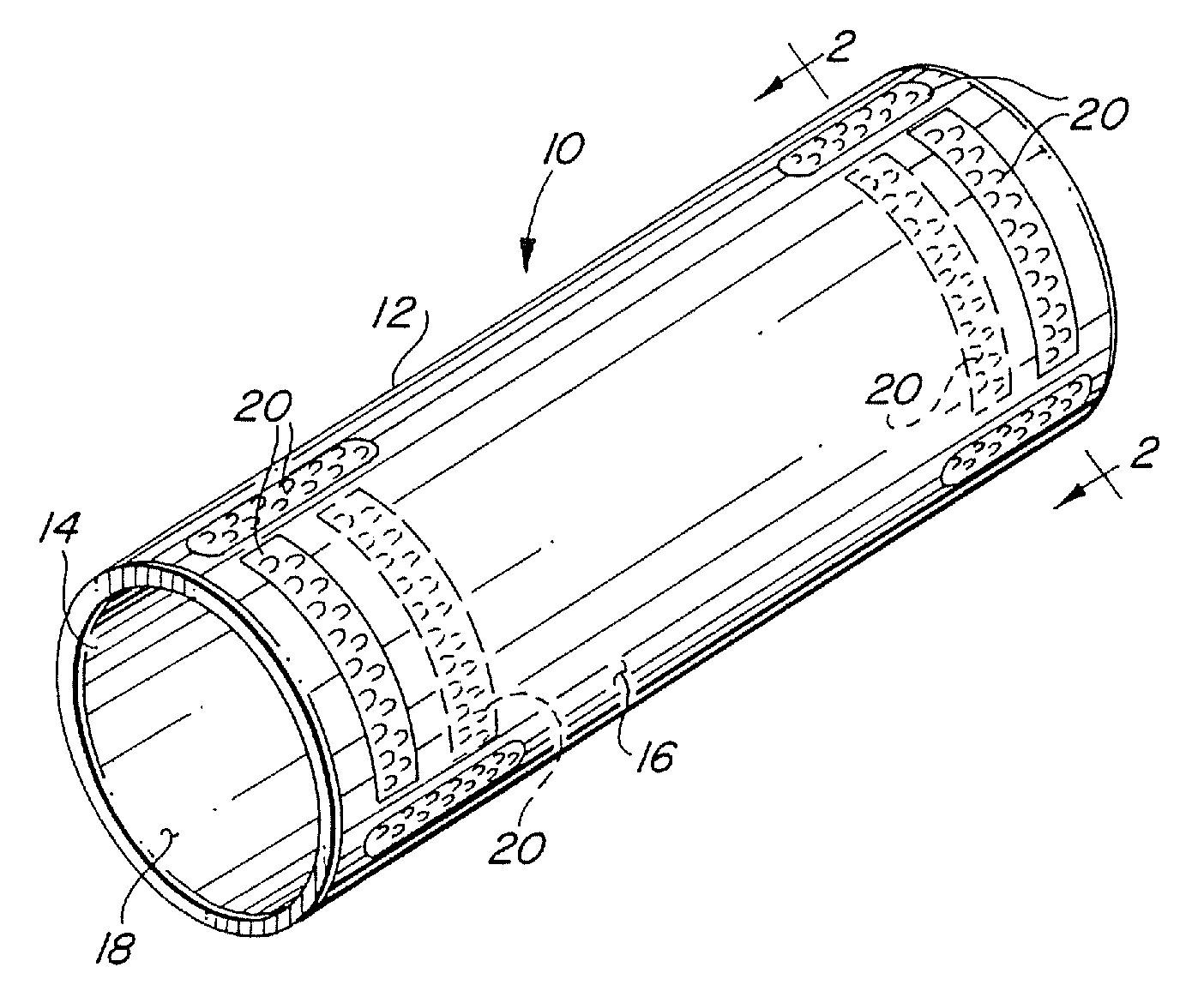

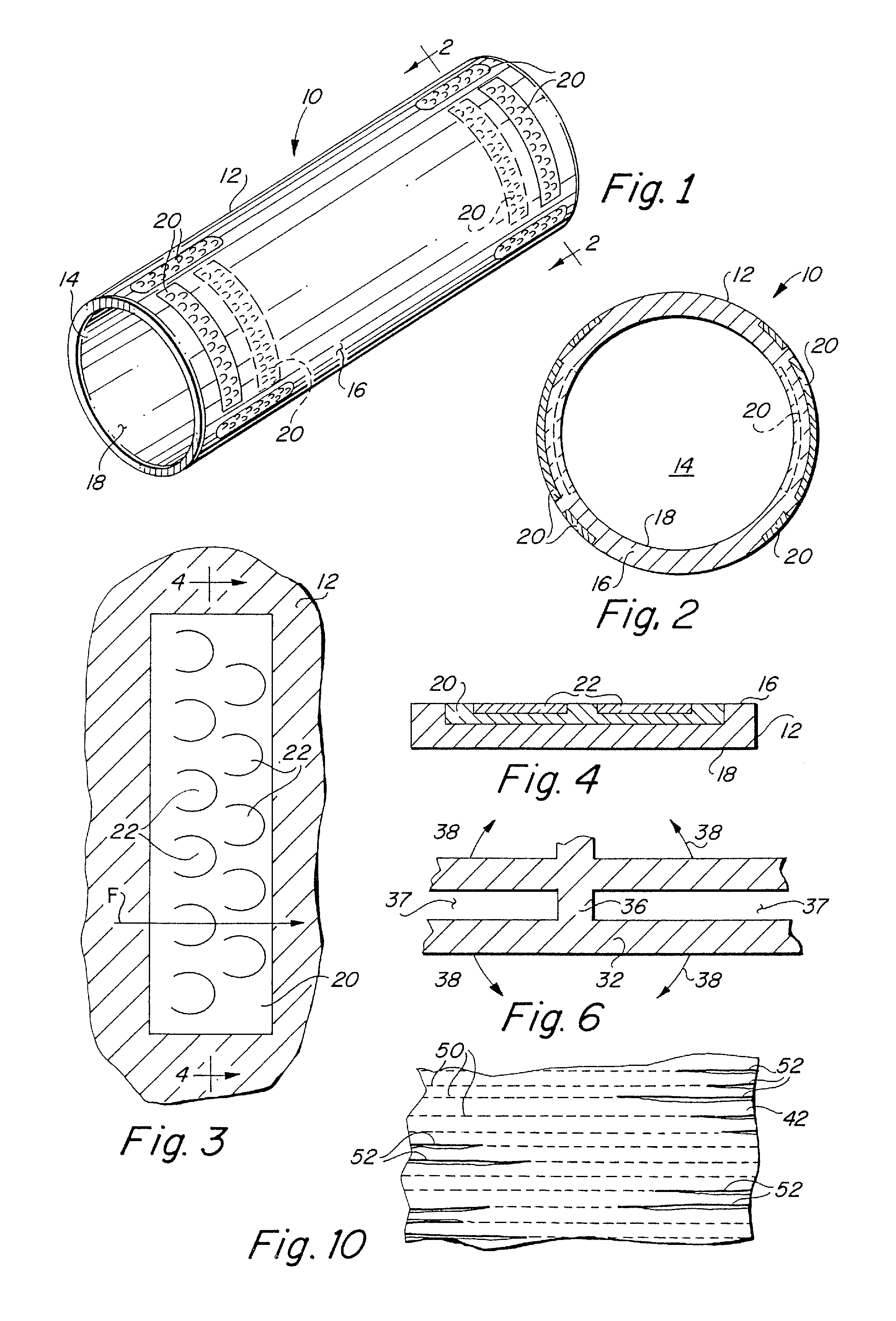

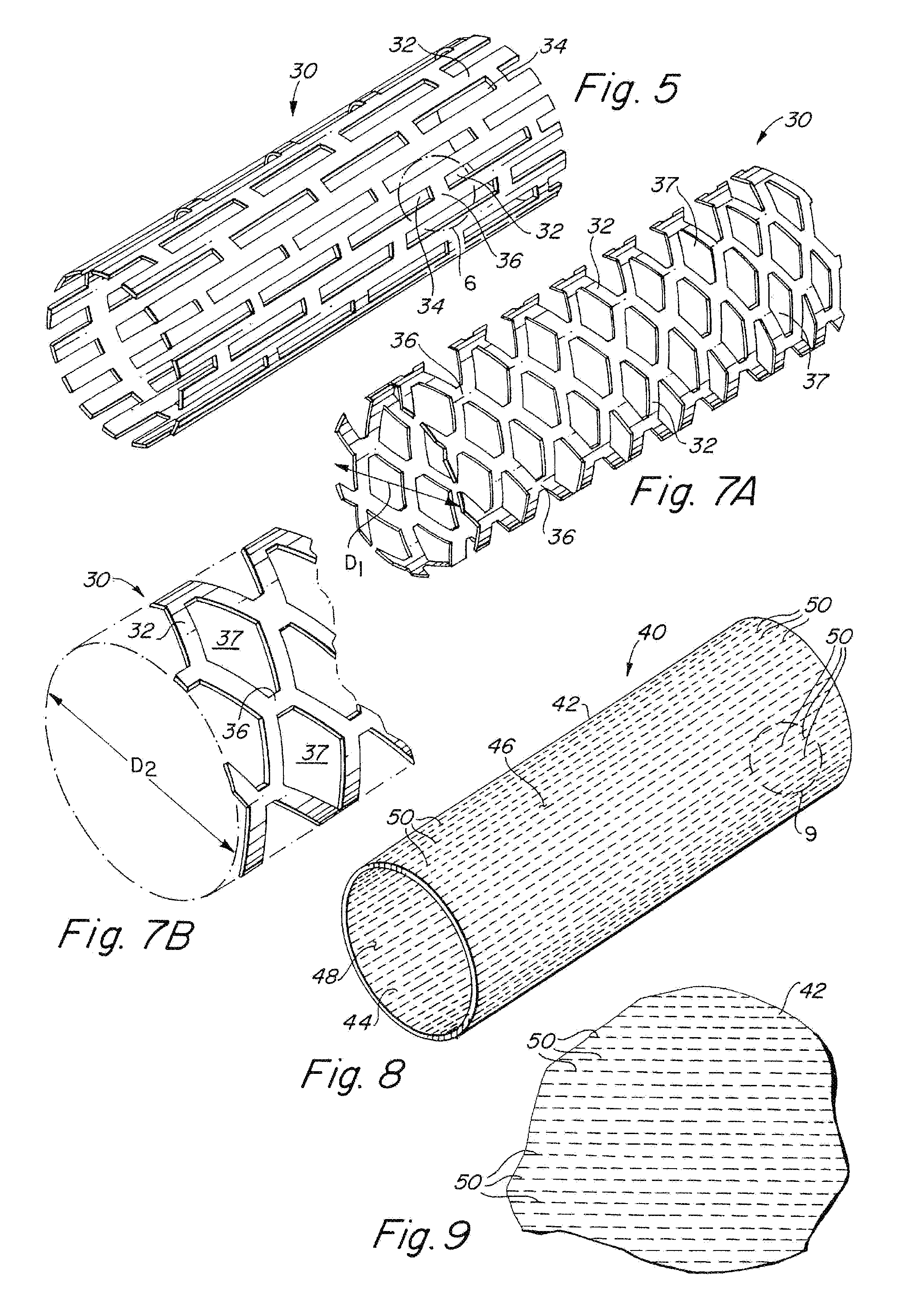

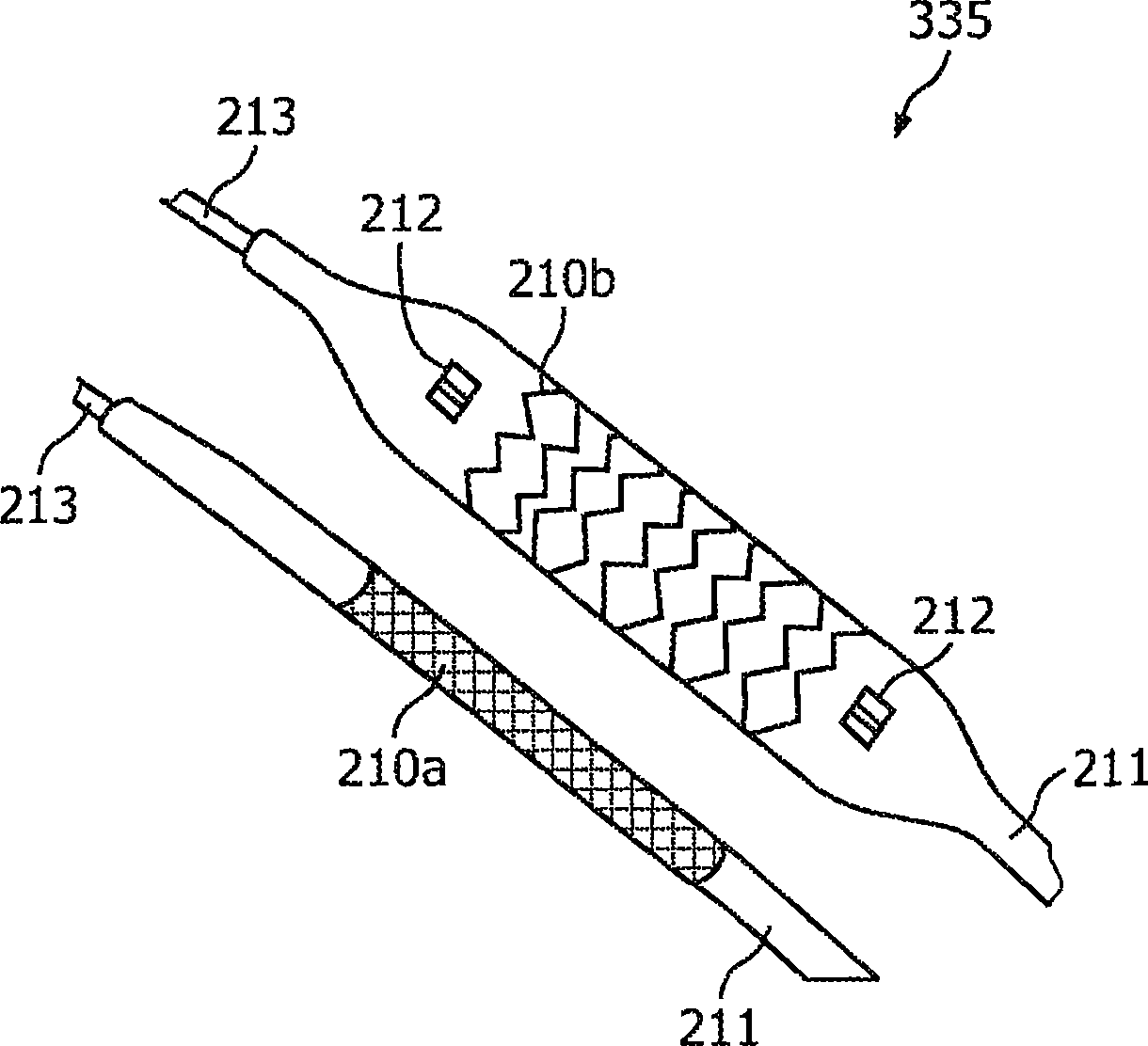

In VIVO sensor and method of making same

InactiveUS20060074479A1Easy to detectUltrasonic/sonic/infrasonic diagnosticsSurgeryIn vivoRadio frequency

Implantable in vivo sensors used to monitor physical, chemical or electrical parameters within a body. The in vivo sensors are integral with an implantable medical device and are responsive to externally or internally applied energy. Upon application of energy, the sensors undergo a phase change in at least part of the material of the device which is then detected external to the body by conventional techniques such as radiography, ultrasound imaging, magnetic resonance imaging, radio frequency imaging or the like. The in vivo sensors of the present invention may be employed to provide volumetric measurements, flow rate measurements, pressure measurements, electrical measurements, biochemical measurements, temperature, measurements, or measure the degree and type of deposits within the lumen of an endoluminal implant, such as a stent or other type of endoluminal conduit. The in vivo sensors may also be used therapeutically to modulate mechanical and / or physical properties of the endoluminal implant in response to the sensed or monitored parameter.

Owner:VACTRONIX SCI LLC

System and method for three-dimensional image rendering and analysis

ActiveUS20080002873A1Reduce contributionSimple structureImage enhancementReconstruction from projectionImaging analysis3d image

The present invention relates to methods and systems for conducting three-dimensional image analysis and diagnosis and possible treatment relating thereto. The invention includes methods of handling signals containing information (data) relating to three-dimensional representation of objects scanned by a scanning medium. The invention also includes methods of making and analyzing volumetric measurements and changes in volumetric measurements which can be used for the purpose of diagnosis and treatment.

Owner:YANKELEVITZ DAVID DR

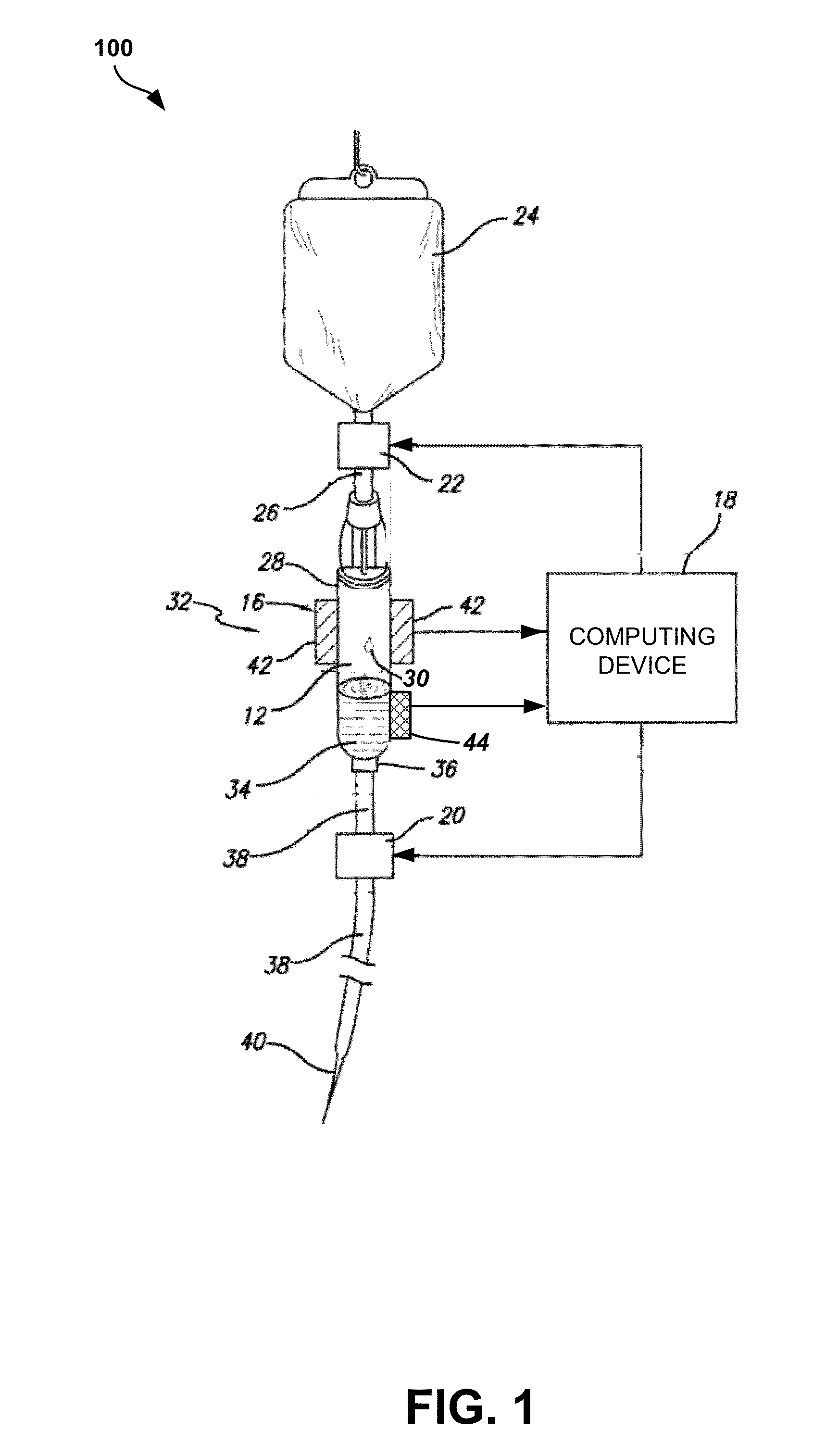

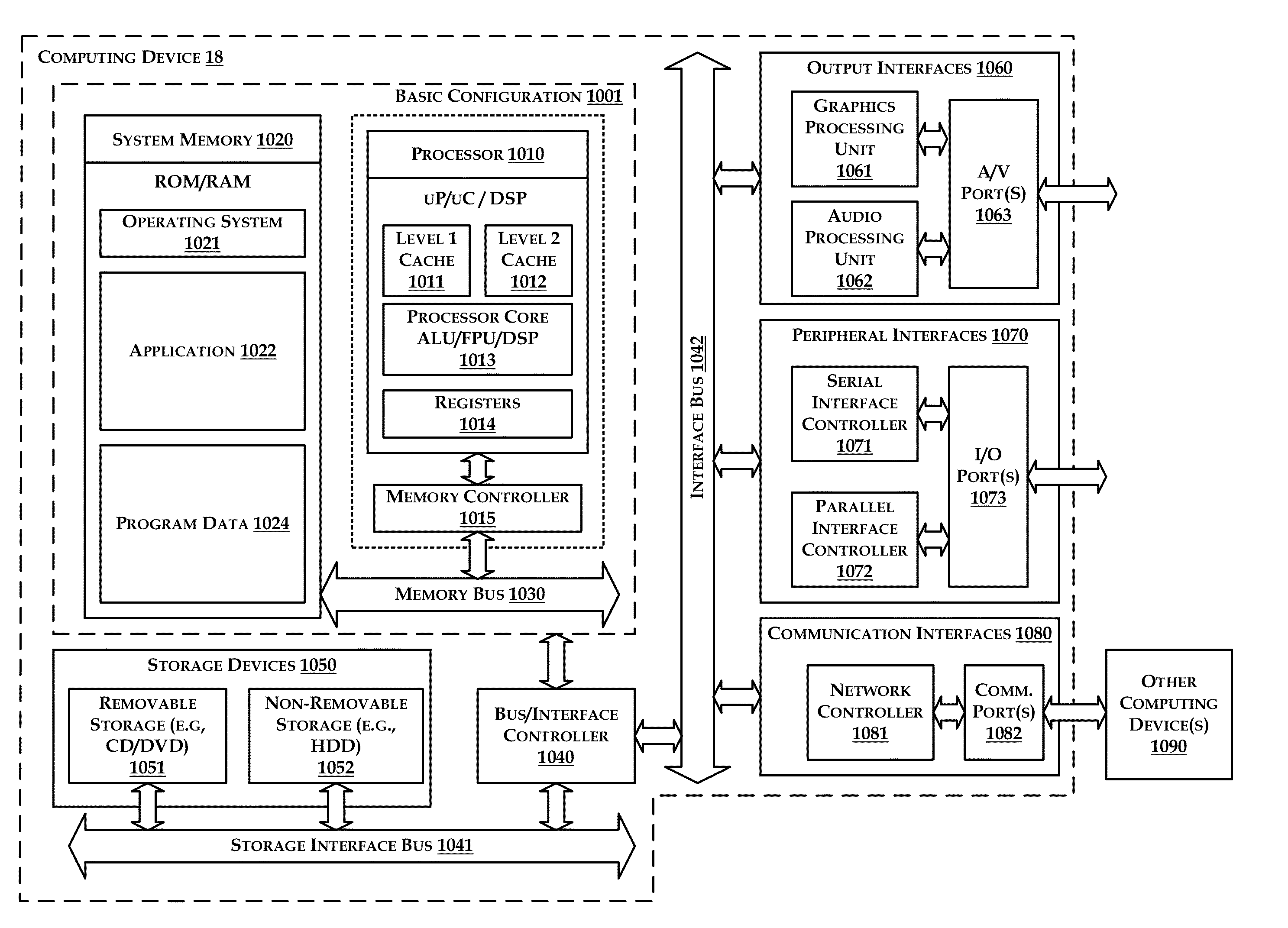

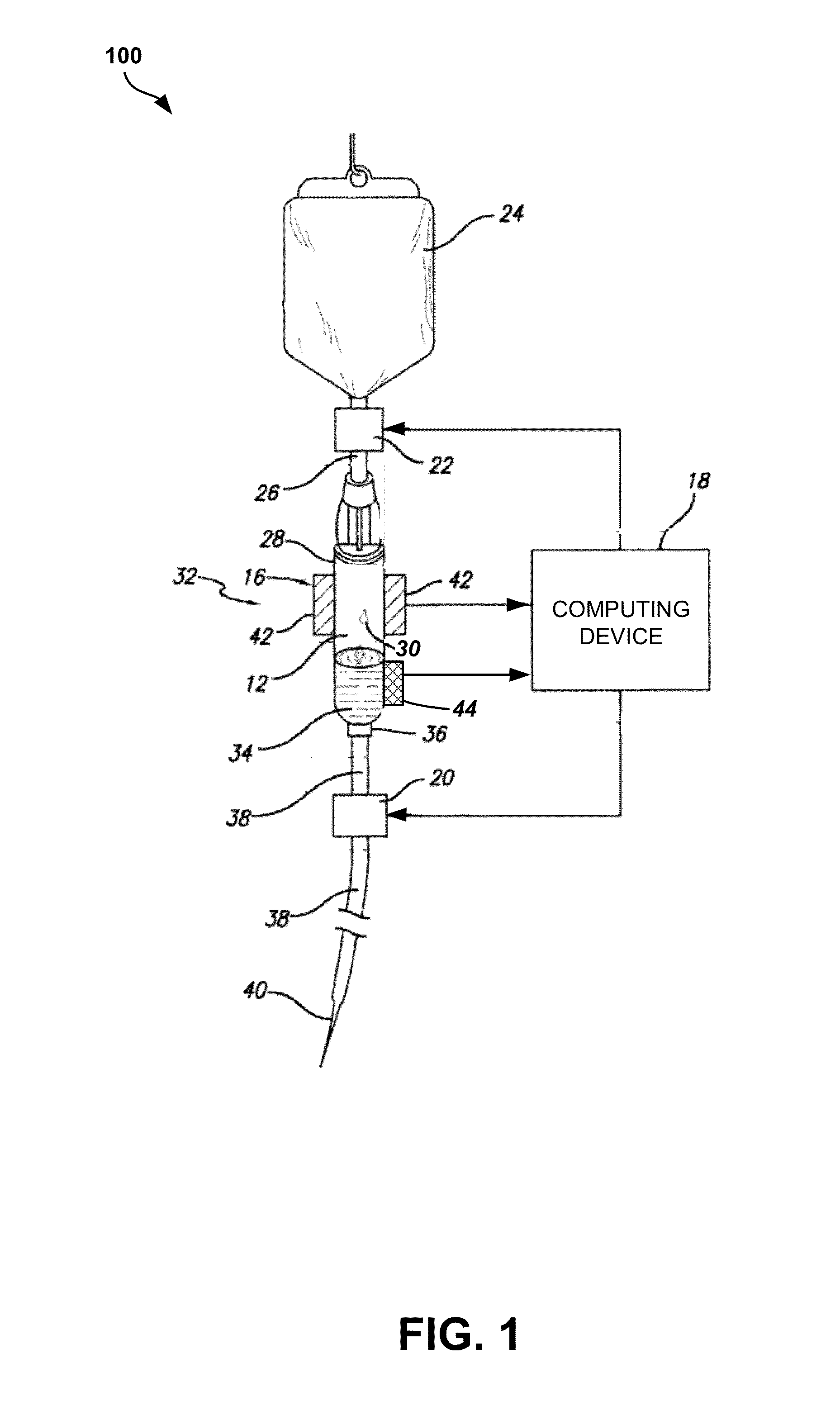

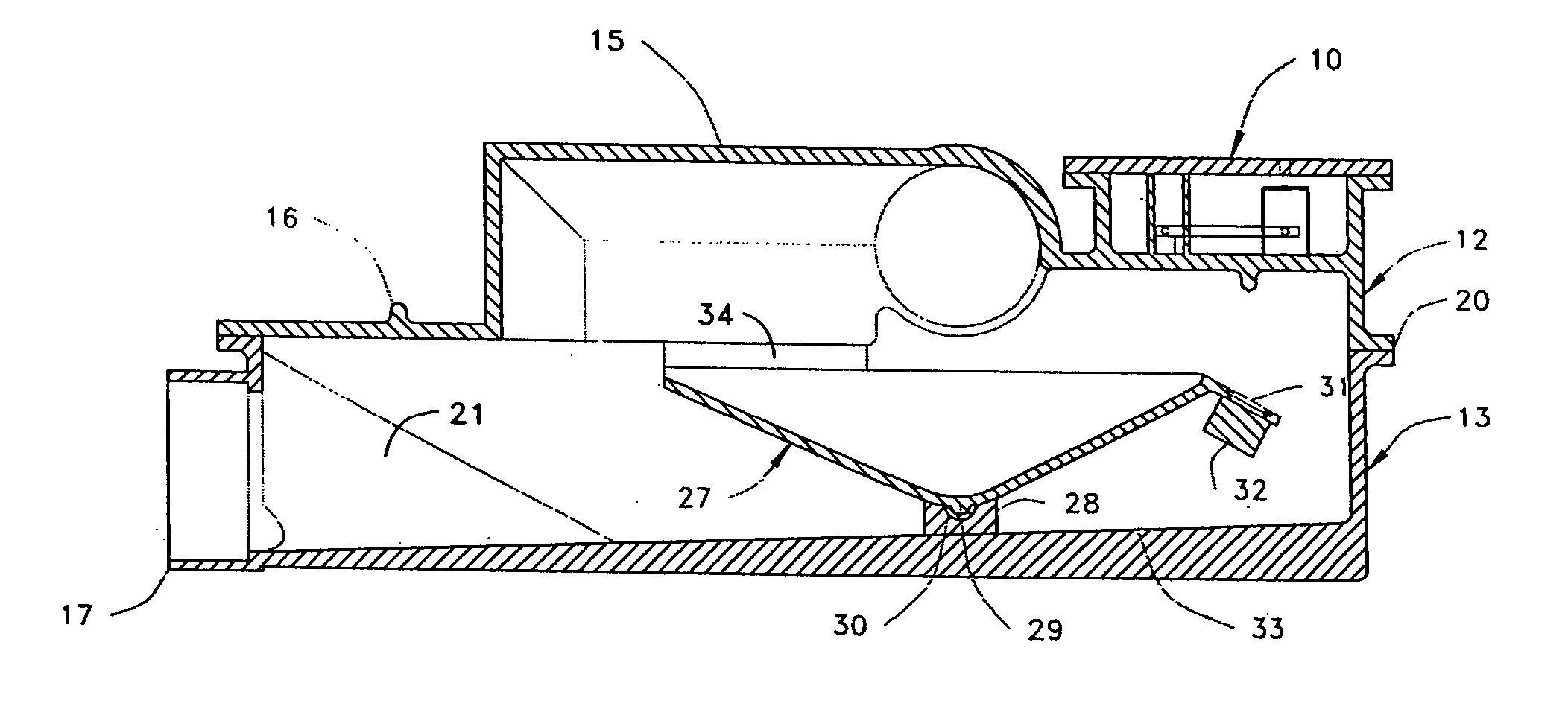

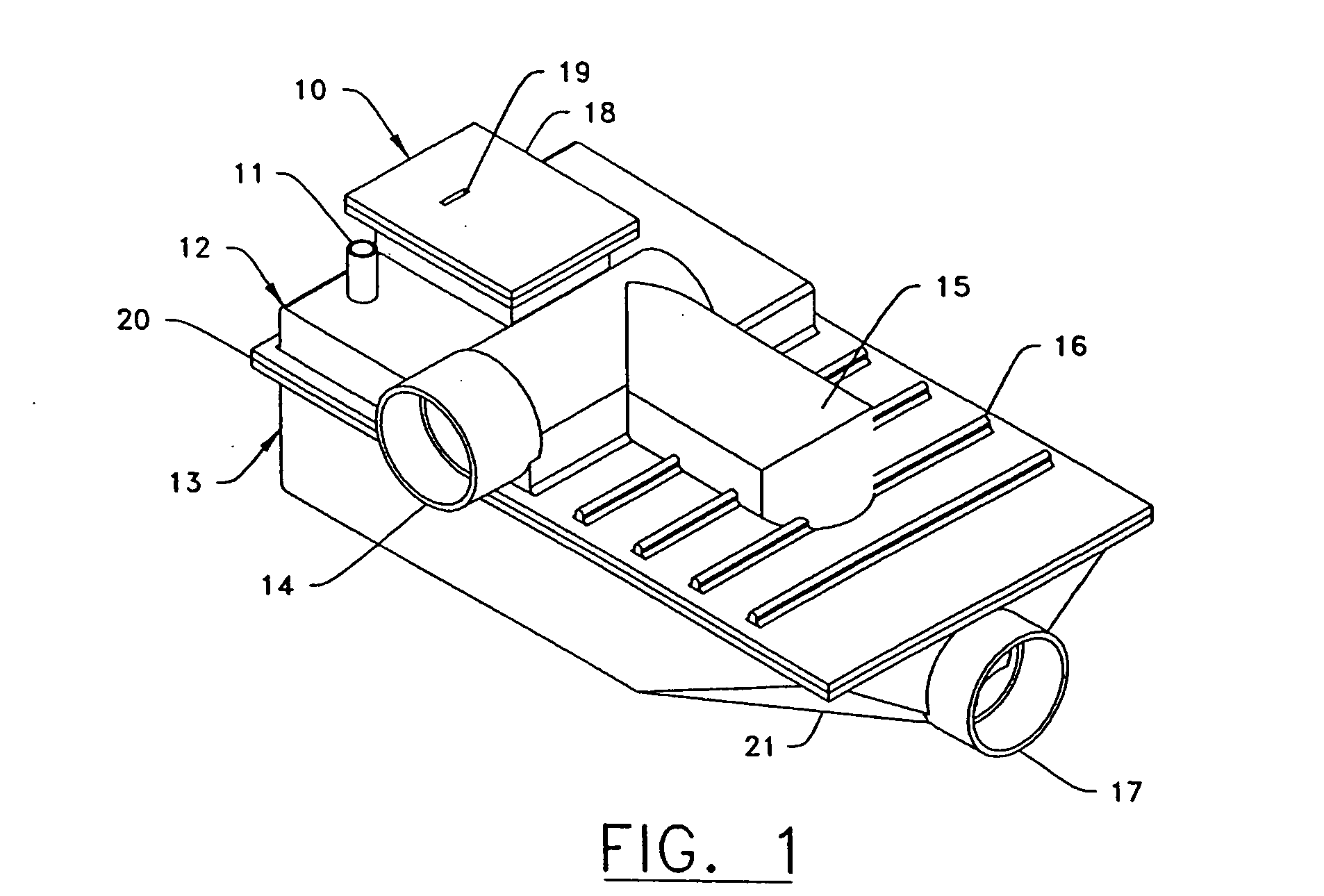

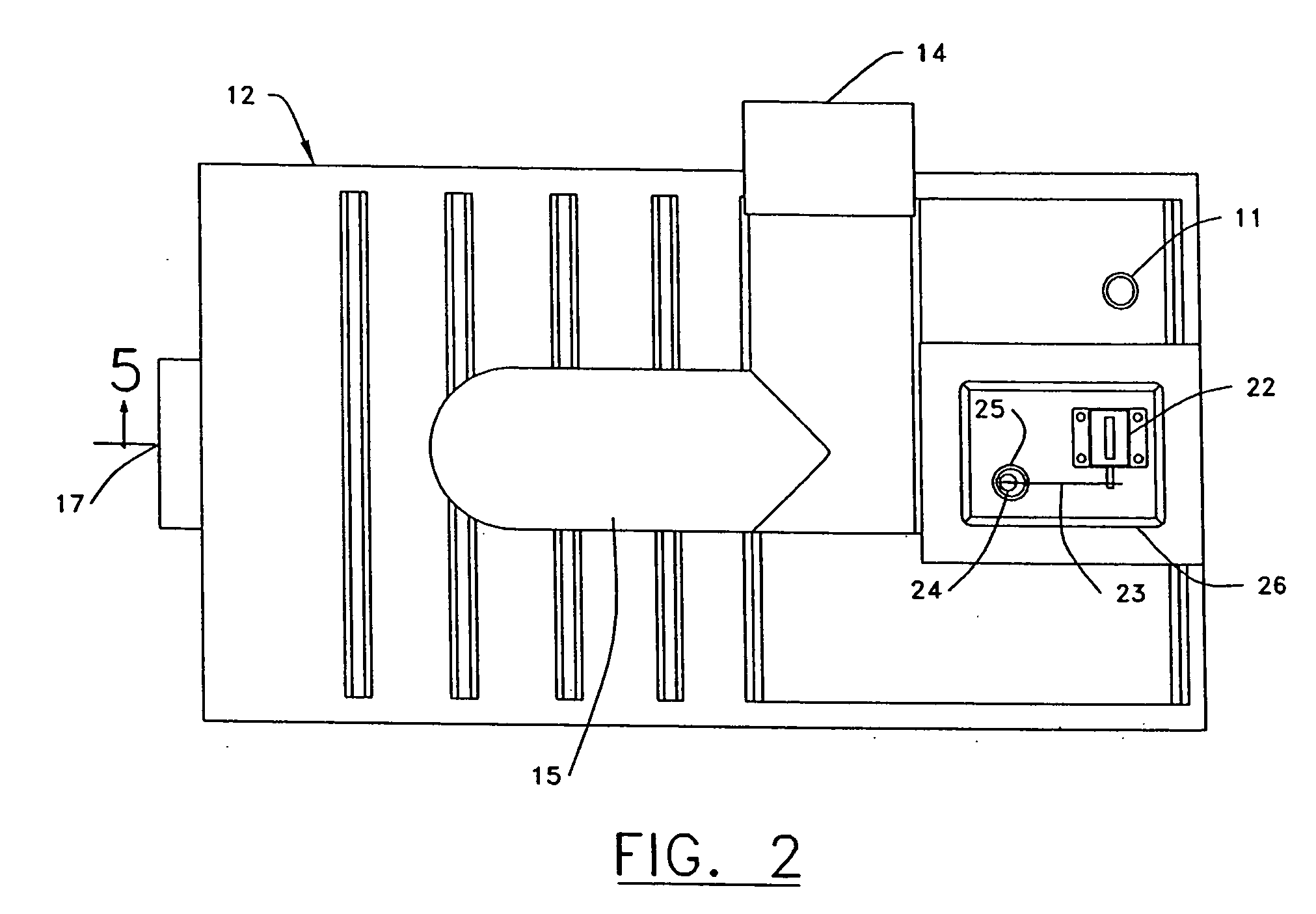

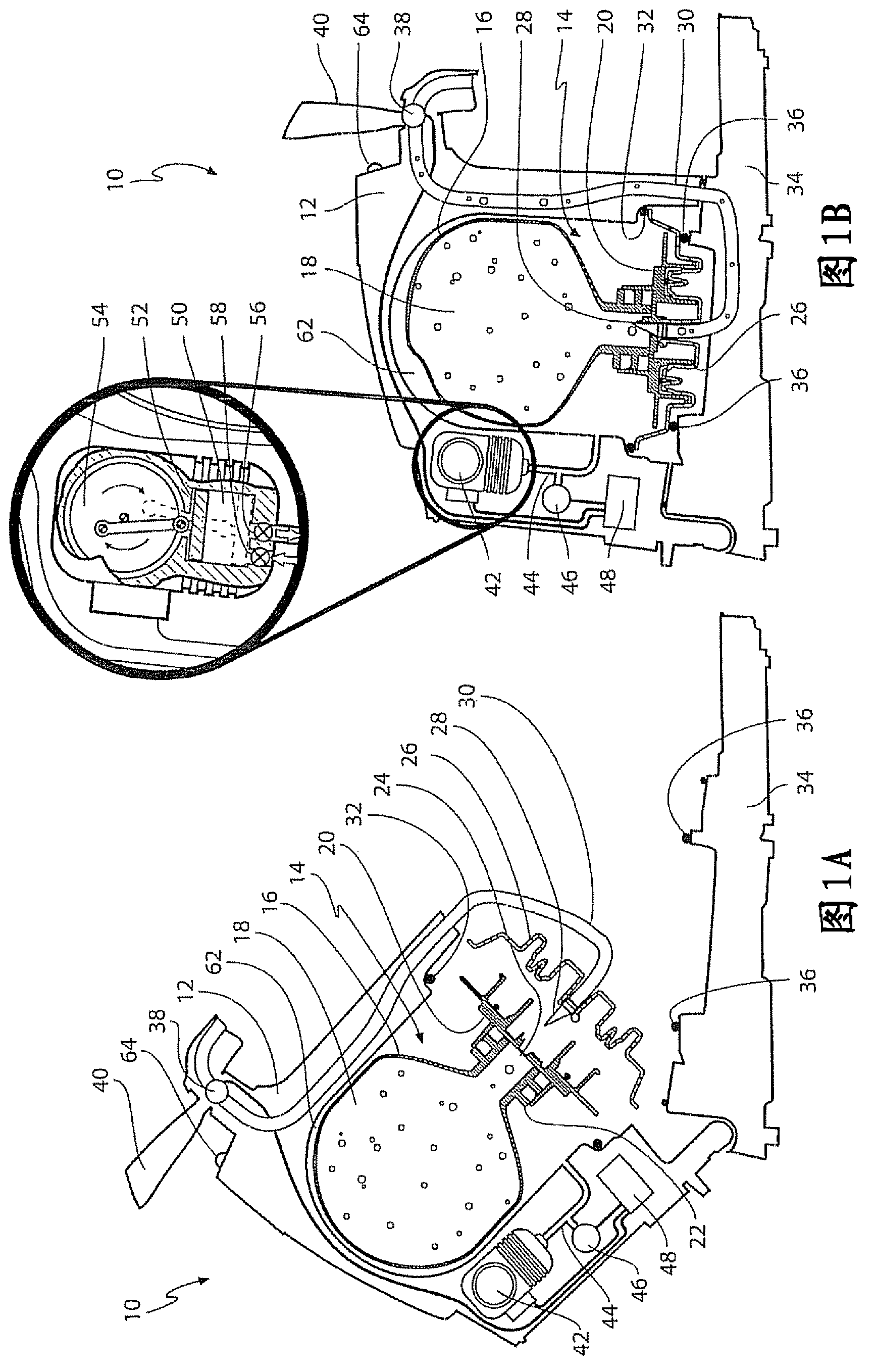

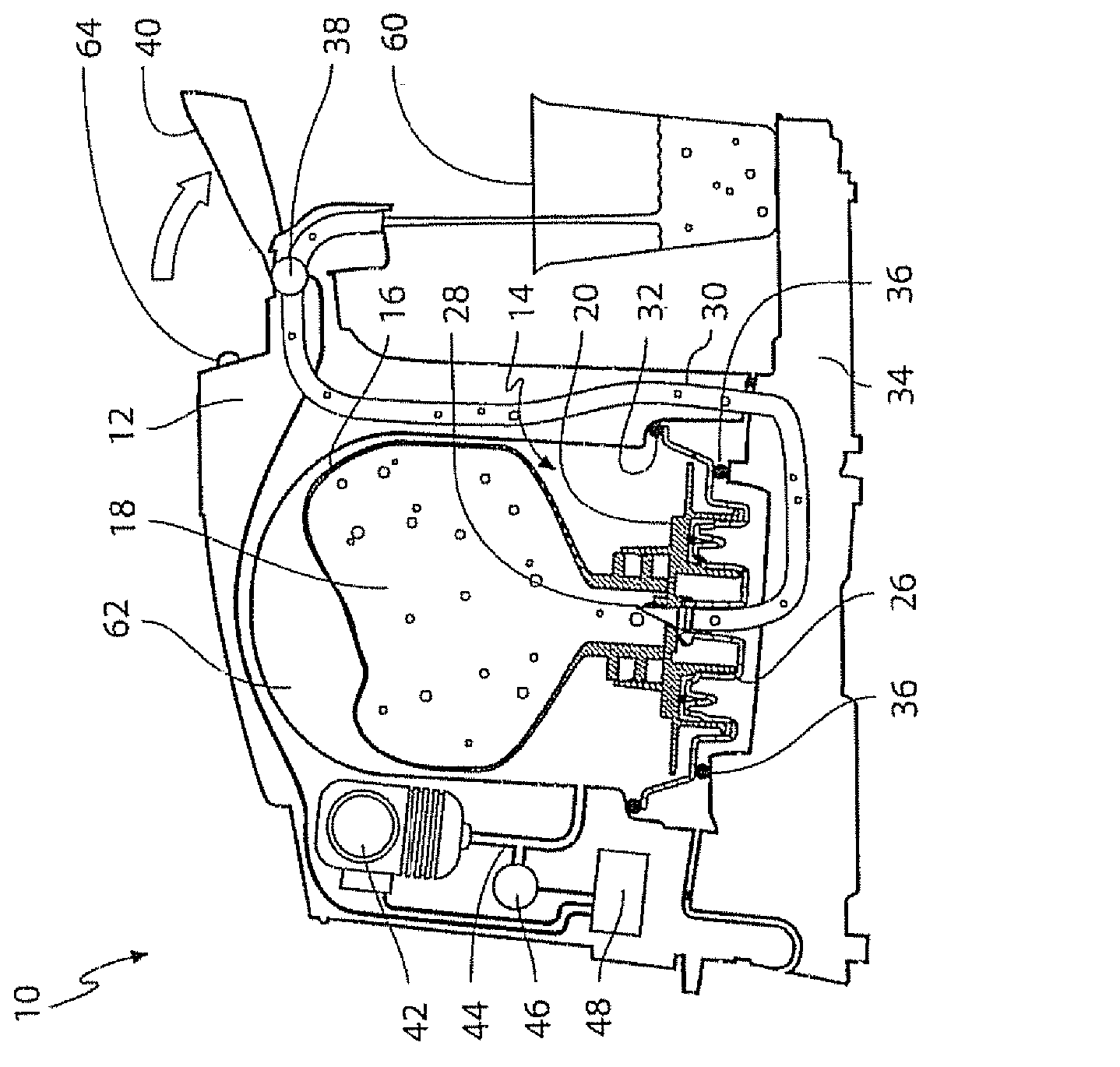

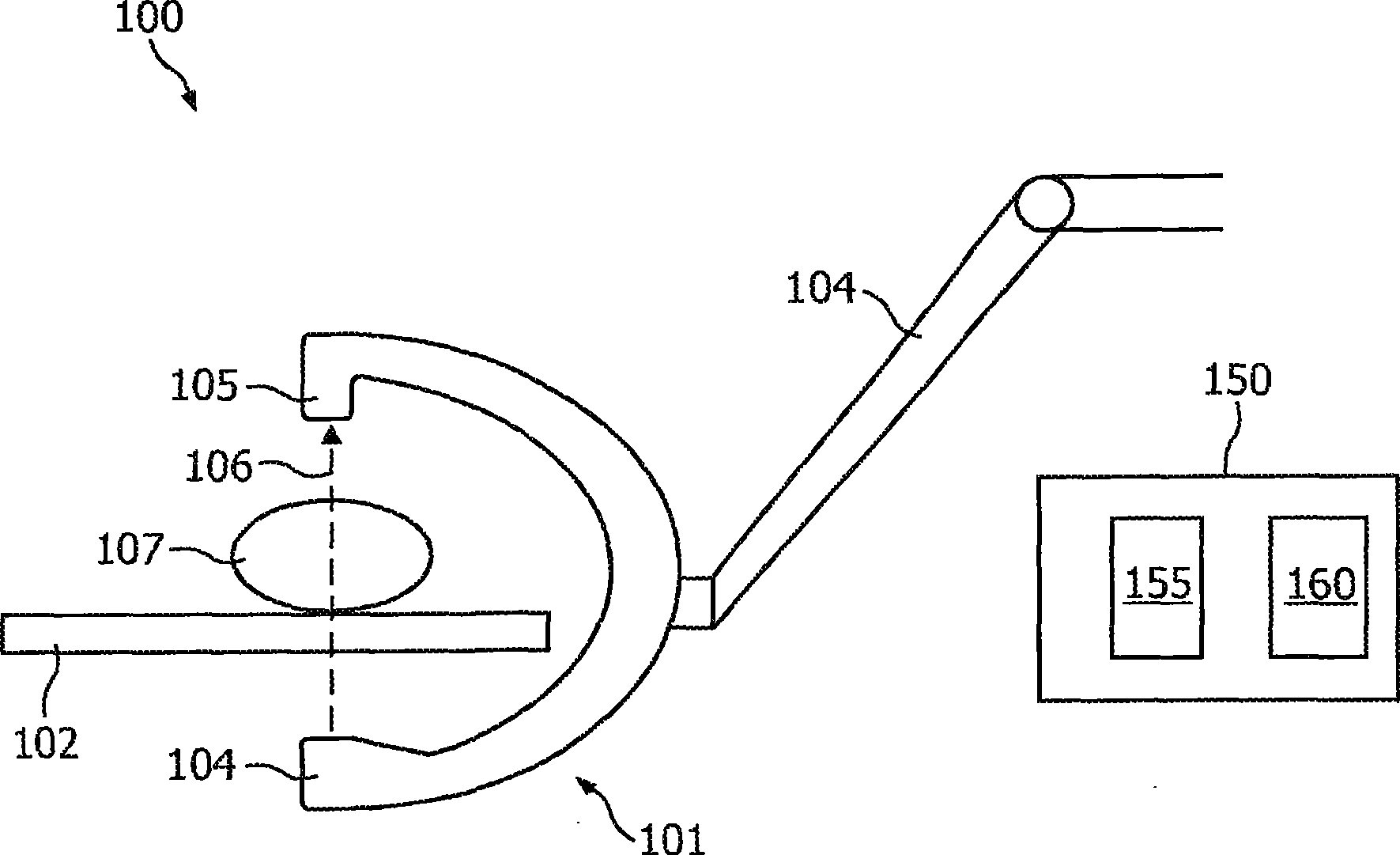

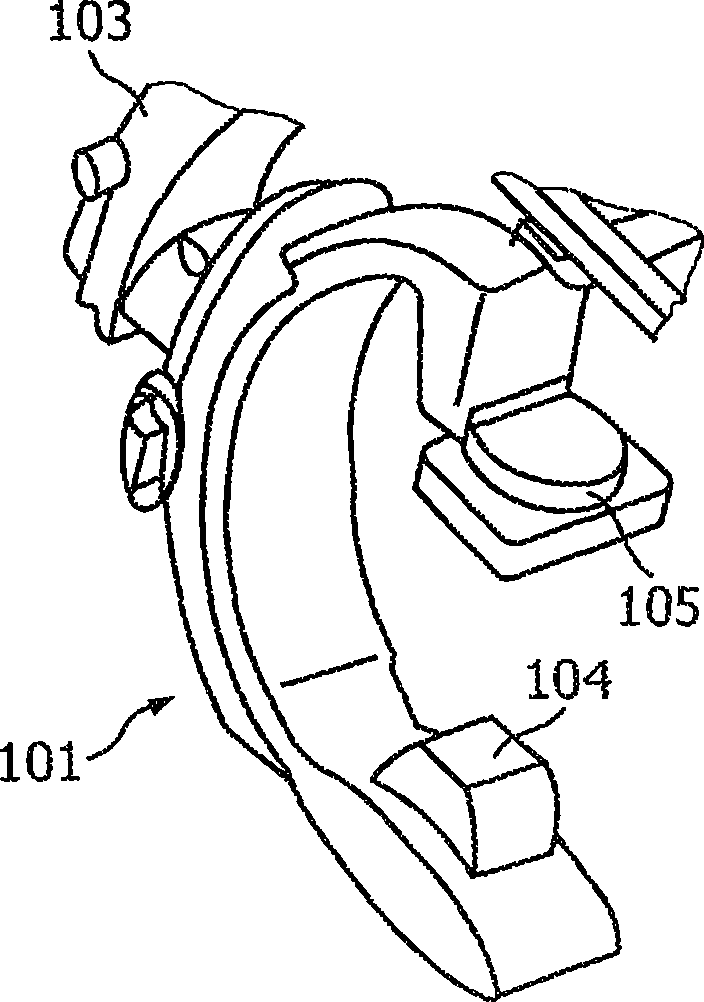

Intravenous Flow Rate Controller

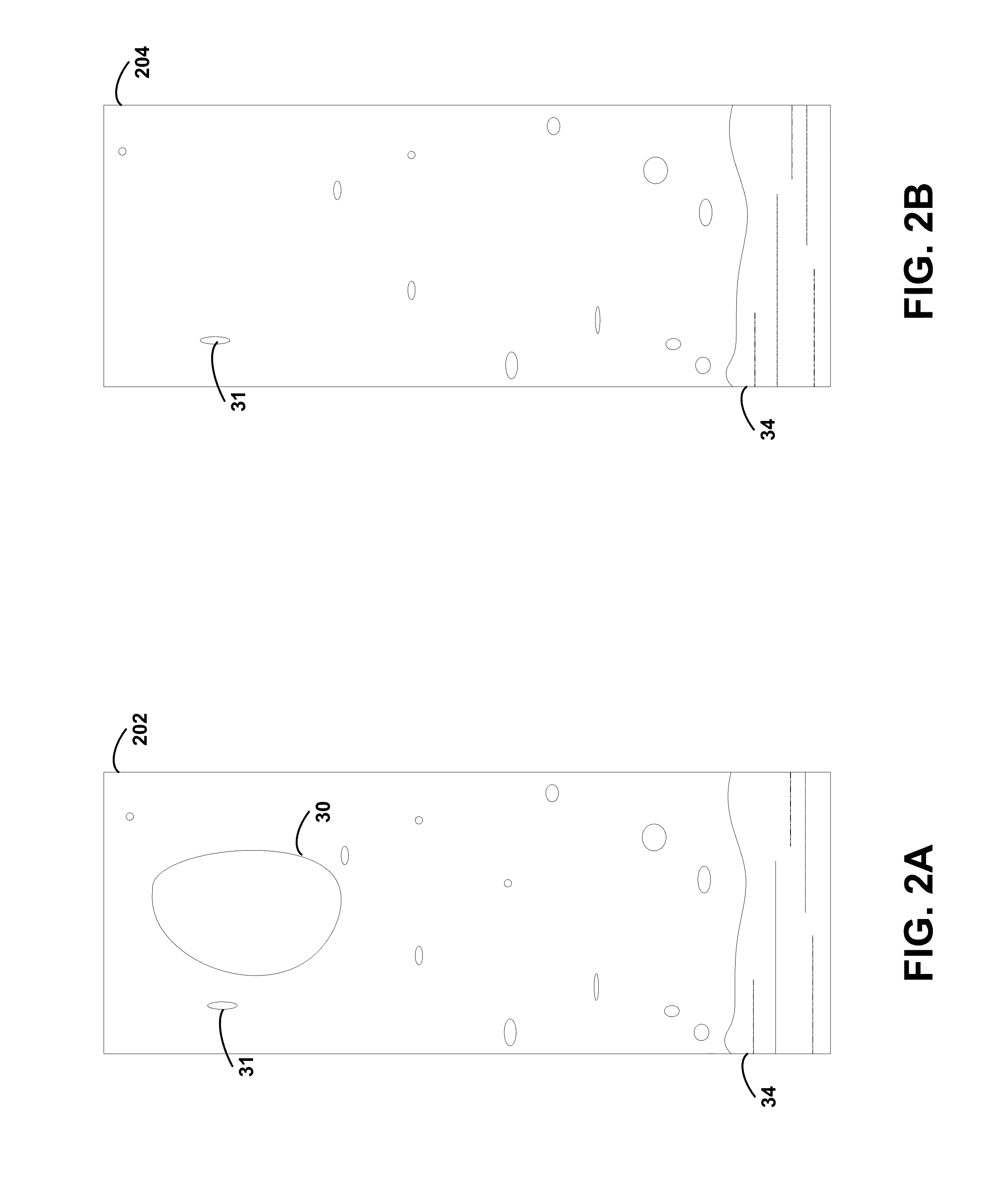

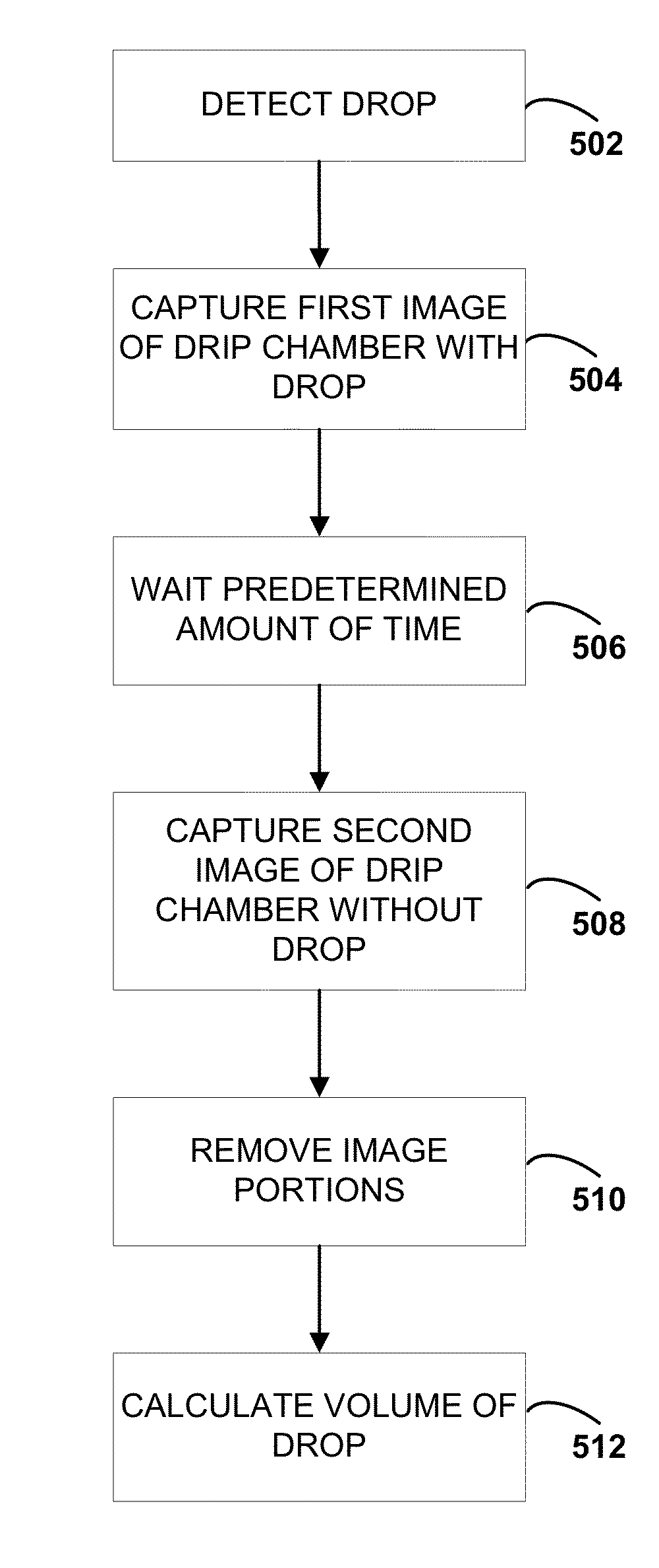

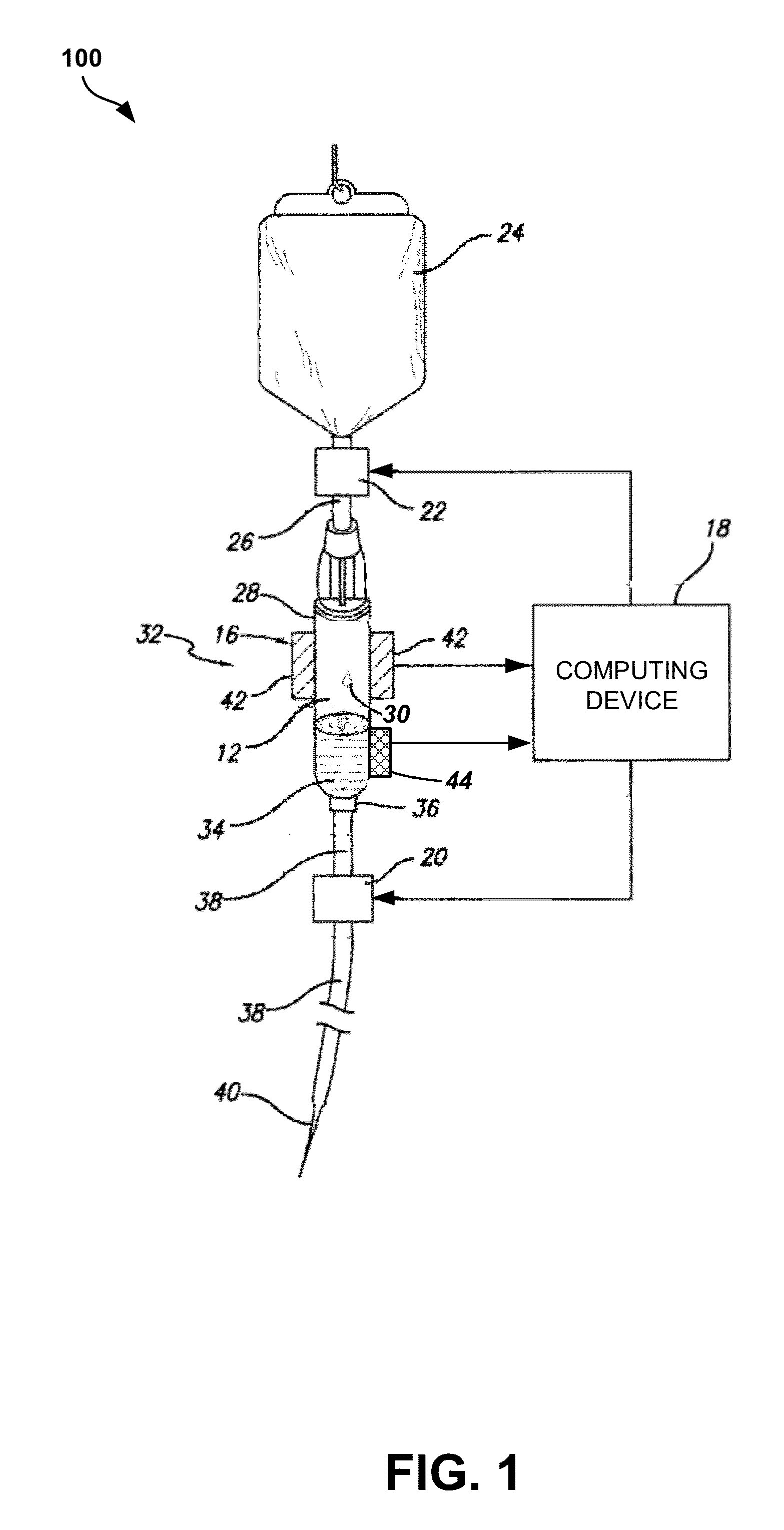

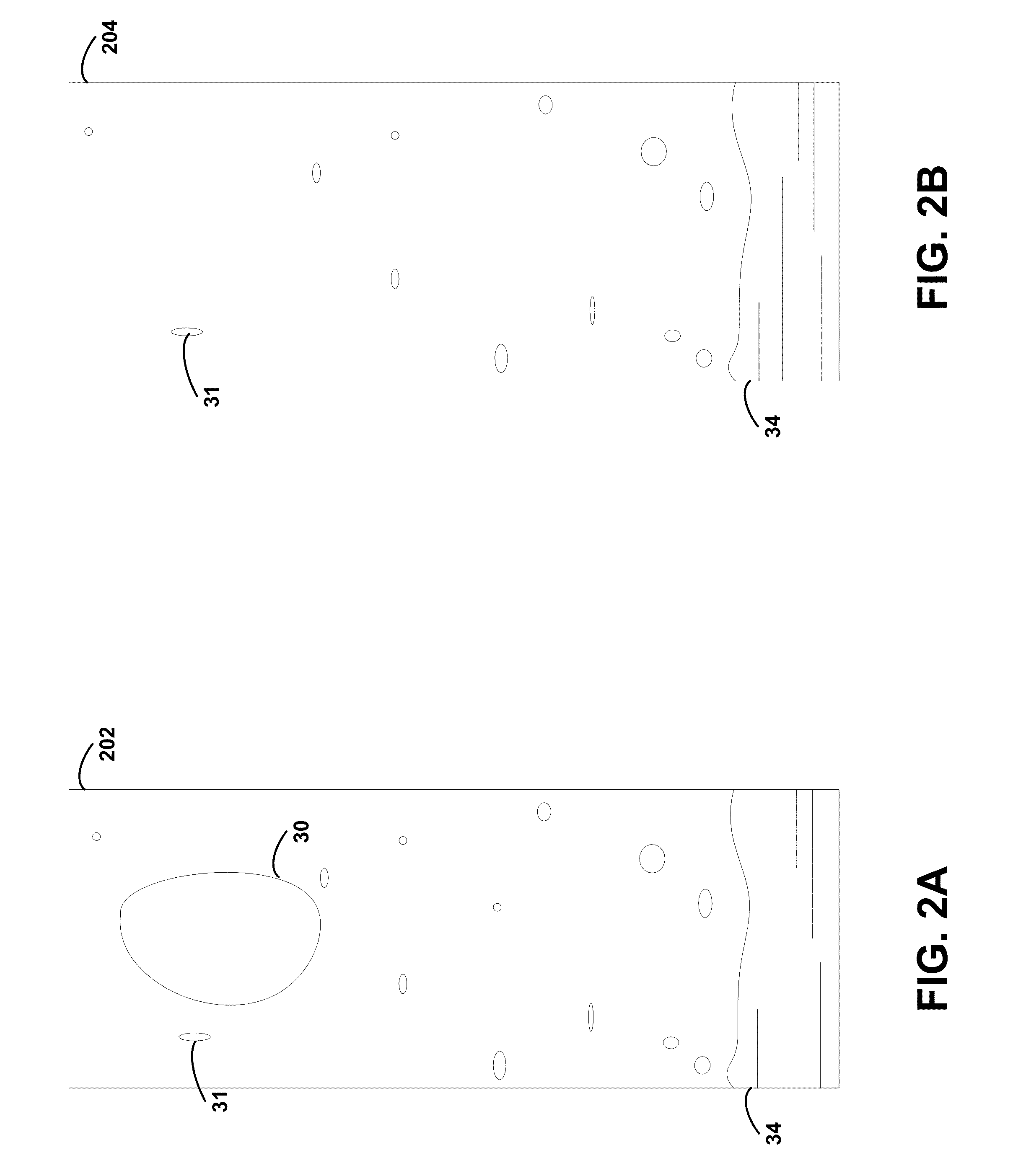

Tilting of a drip chamber from its vertical axis during fluid administration can have negative effects upon the accuracy of systems configured for drop counting and / or for volumetric measurement of individual drops passing through the drip chamber. To address these negative effects, in accordance with one embodiment of the present disclosure, a fluid delivery system engages in a fluid control process that comprises determining an error parameter, based at least in part on a tilt signal, generating an error condition, and either holding the fluid flow at the present rate or stopping the flow.

Owner:ICU MEDICAL INC

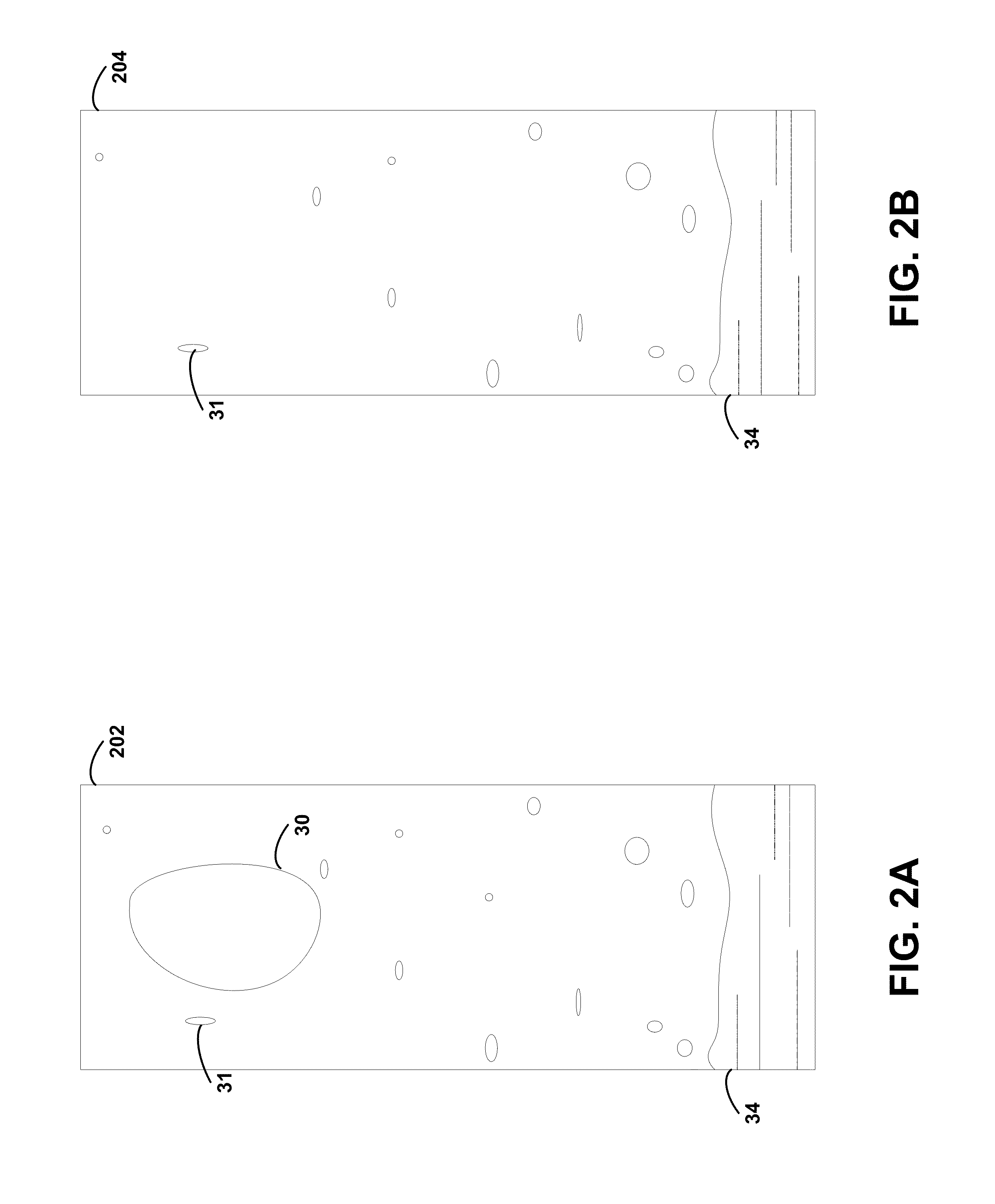

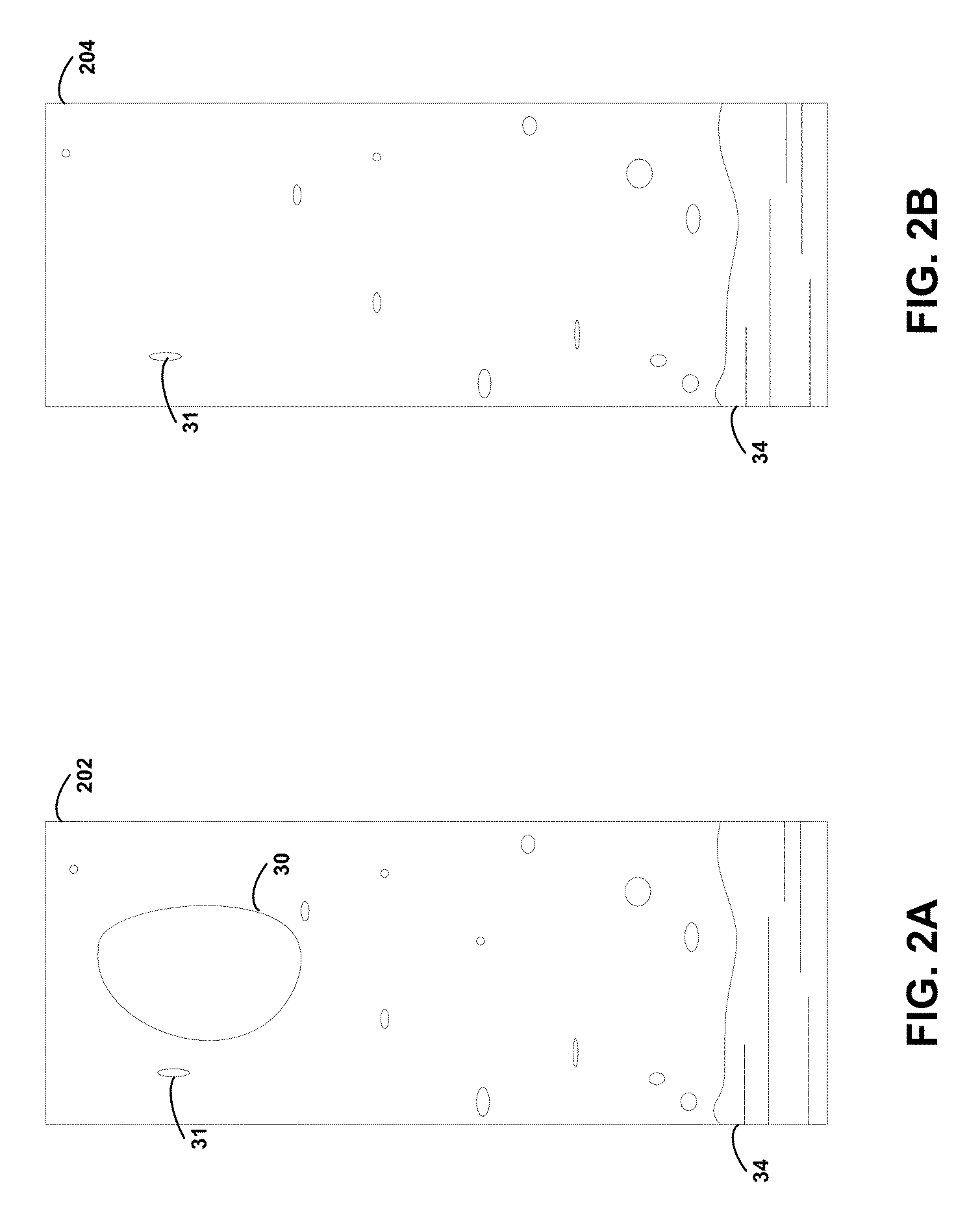

Intravenous Flow Rate Controller

Tilting of a drip chamber from its vertical axis during fluid administration can have negative effects upon the accuracy of systems configured for drop counting and / or for volumetric measurement of individual drops passing through the drip chamber. To address these negative effects, in accordance with one embodiment of the present disclosure, a fluid delivery system that measures the flow volume of a fluid delivery system is disclosed, which includes an imaging apparatus that captures a first image of a drip chamber while a drop is falling therein and a second image of the drip chamber with no drop. Portions of each image that are in substantially the same position in each image are subtracted.

Owner:ICU MEDICAL INC

Intravenous flow rate controller

Tilting of a drip chamber from its vertical axis during fluid administration can have negative effects upon the accuracy of systems configured for drop counting and / or for volumetric measurement of individual drops passing through the drip chamber. To address these negative effects, in accordance with one embodiment of the present disclosure, a fluid delivery system that measures the flow volume of a fluid delivery system is disclosed, which includes an imaging apparatus that captures a first image of a drip chamber while a drop is falling therein and a second image of the drip chamber with no drop. Portions of each image that are in substantially the same position in each image are subtracted.

Owner:ICU MEDICAL INC

Spatial characterization of a structure located within an object by identifying 2d representations of the structure within section planes

InactiveUS20100099979A1Clear visualizationPrecise quantitative comparisonImage enhancementImage analysisSection planeSonification

It is described a virtual pullback as a visualization and quantification tool that allows an interventional cardiologist to easily assess stent expansion. The virtual pullback visualizes the stent and / or the vessel lumen similar to an Intravascular Ultrasound (IVUS) pullback. The virtual pullback is performed in volumetric data along a reference line. The volumetric data can be a reconstruction of rotational 2D X-ray attenuation data. Planes perpendicular to the reference line are visualized as the position along the reference line changes. This view is for interventional cardiologists a very familiar view as they resemble IVUS data and may show a section plane through a vessel lumen or a stent. In these perpendicular section planes automatic measurements, such as minimum and maximum diameter, and cross sectional area of the stent can be calculated and displayed. Combining these 2D measurements allows also volumetric measurements to be calculated and displayed.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

Intravenous flow rate controller

Tilting of a drip chamber from its vertical axis during fluid administration can have negative effects upon the accuracy of systems configured for drop counting and / or for volumetric measurement of individual drops passing through the drip chamber. To address these negative effects, in accordance with one embodiment of the present disclosure, a fluid delivery system engages in a fluid control process that comprises determining an error parameter, based at least in part on a tilt signal, generating an error condition, and either holding the fluid flow at the present rate or stopping the flow.

Owner:ICU MEDICAL INC

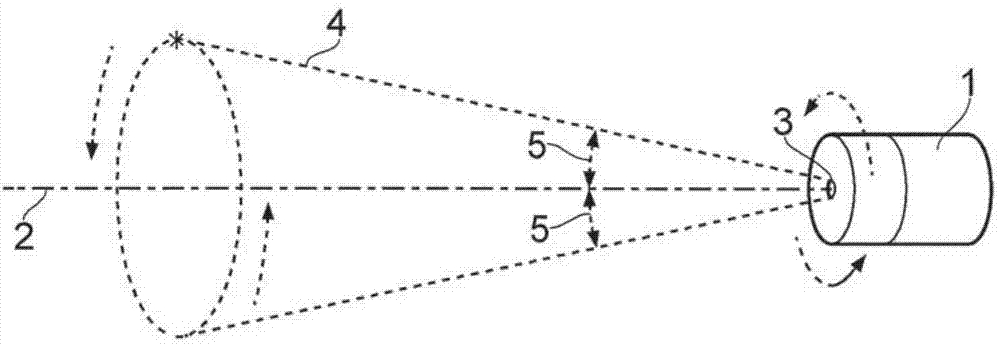

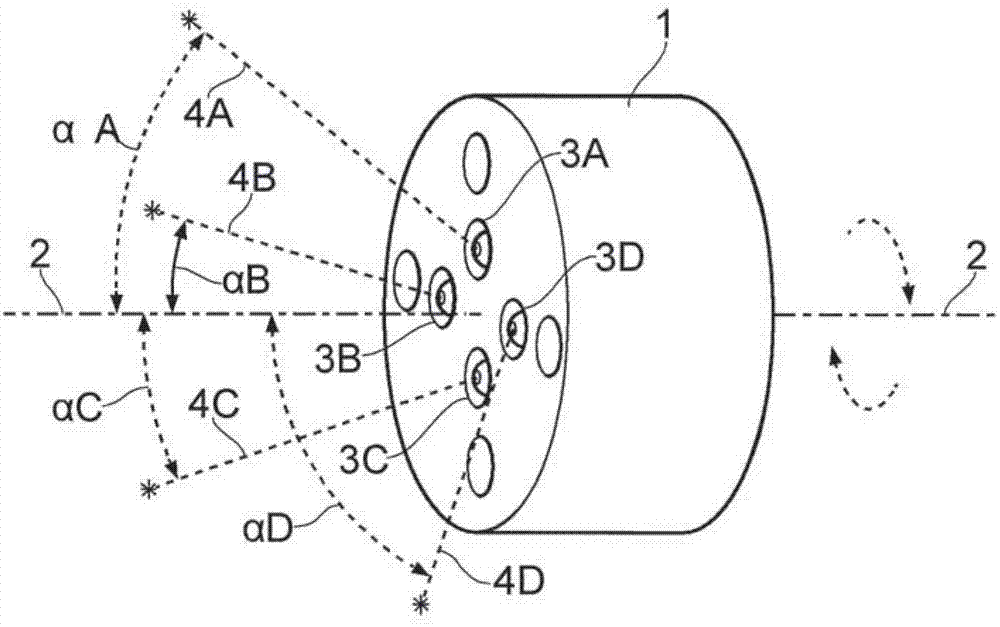

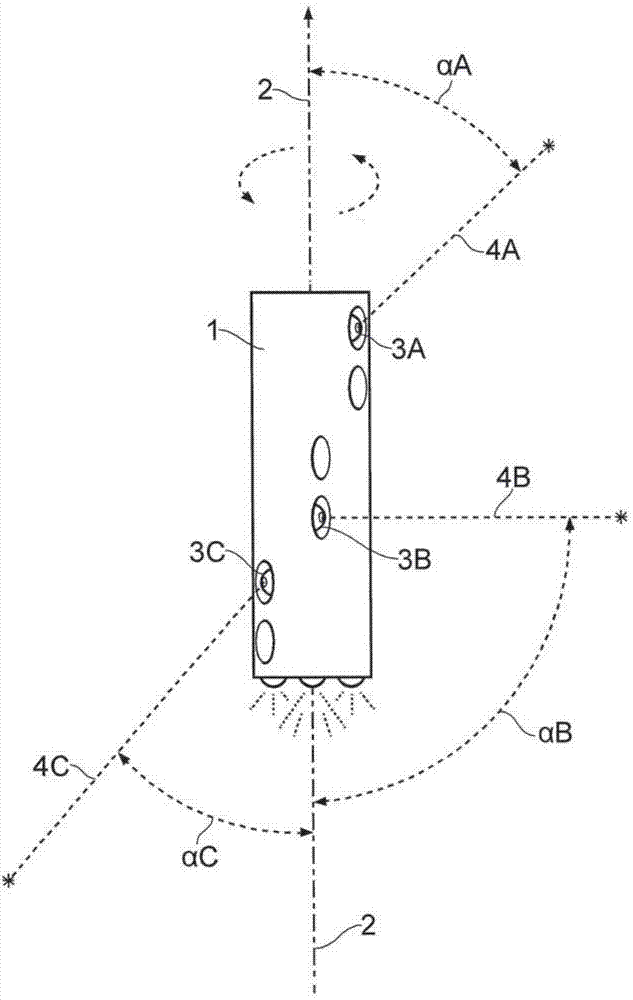

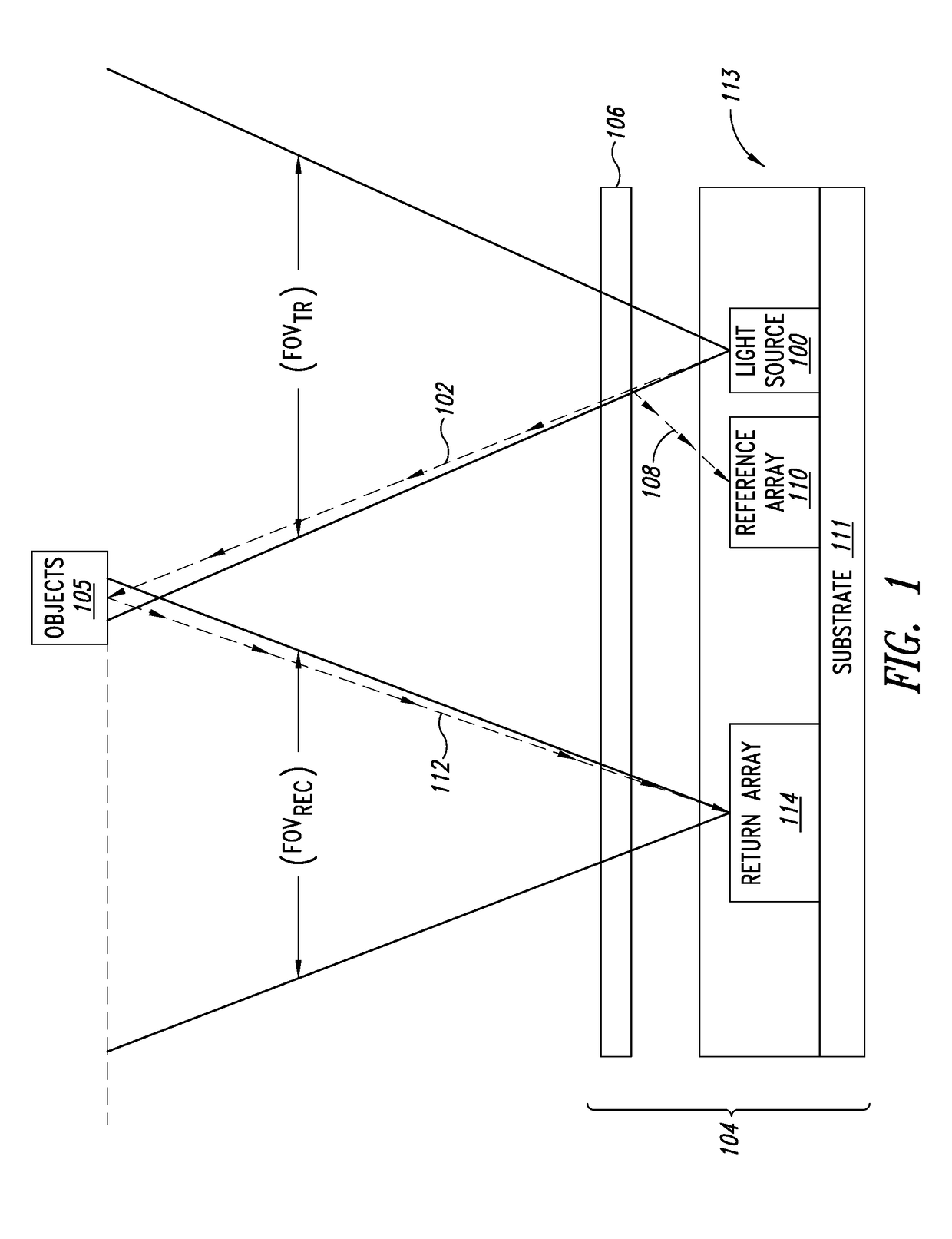

Laser scanning apparatus and method of use

InactiveCN102971657AReduce weightSimple designLighting support devicesPhotogrammetry/videogrammetryTerrainLaser scanning

A laser system comprises a housing and a laser. The laser can be positioned in the housing such that its laser beam is transmitted at an angle and its path forms a cone as the housing rotates. The laser device may also contain two or more lasers, the angle of each laser may be the same or different, and the angular position of each laser may be fixed or variable. The laser system may be stationary or mobile and used in a variety of methods to detect an object or topography and produce a three dimensional image. That information can be further used to provide maps, terrain data, volumetric measurements, landing guidance, obstacle avoidance warnings, mining profiles and other useful material.

Owner:RENISHAW PLC

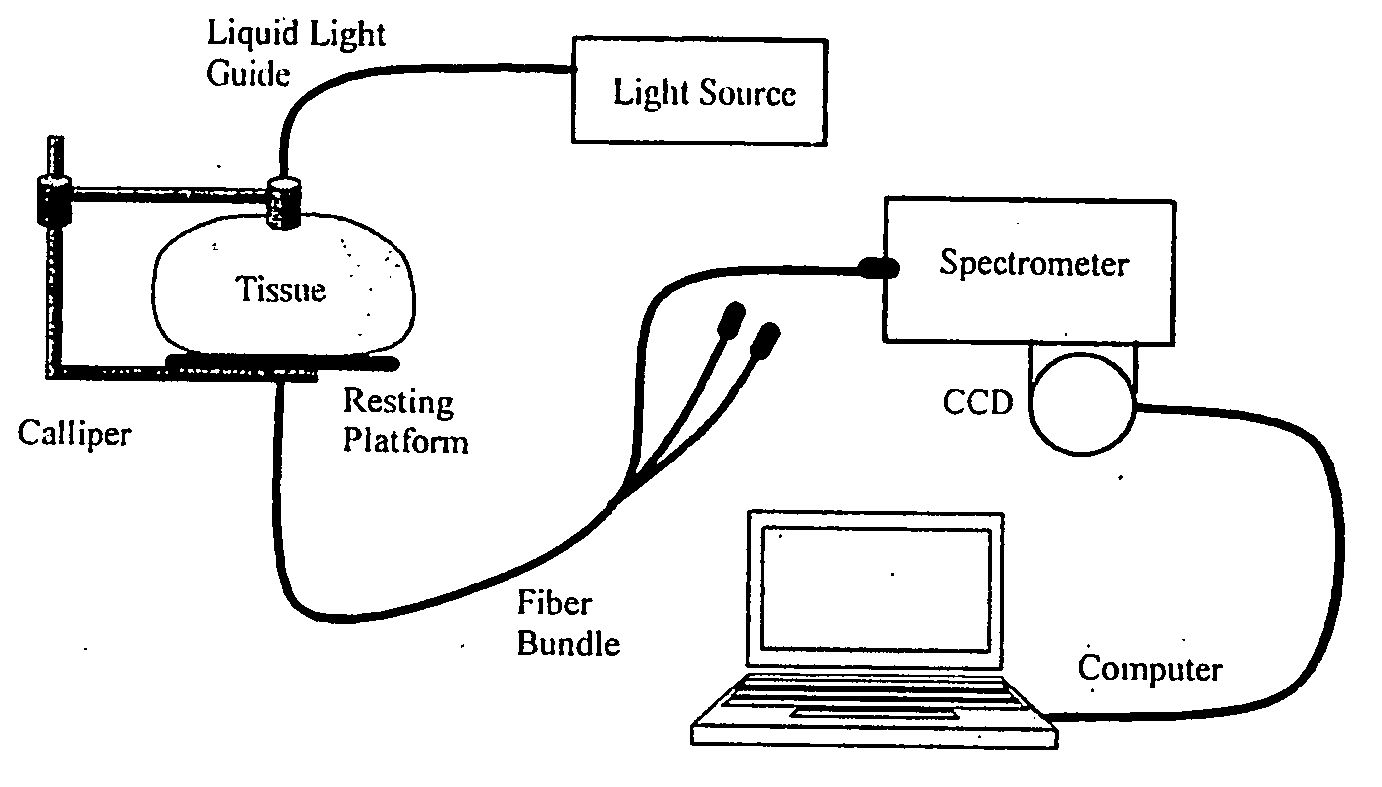

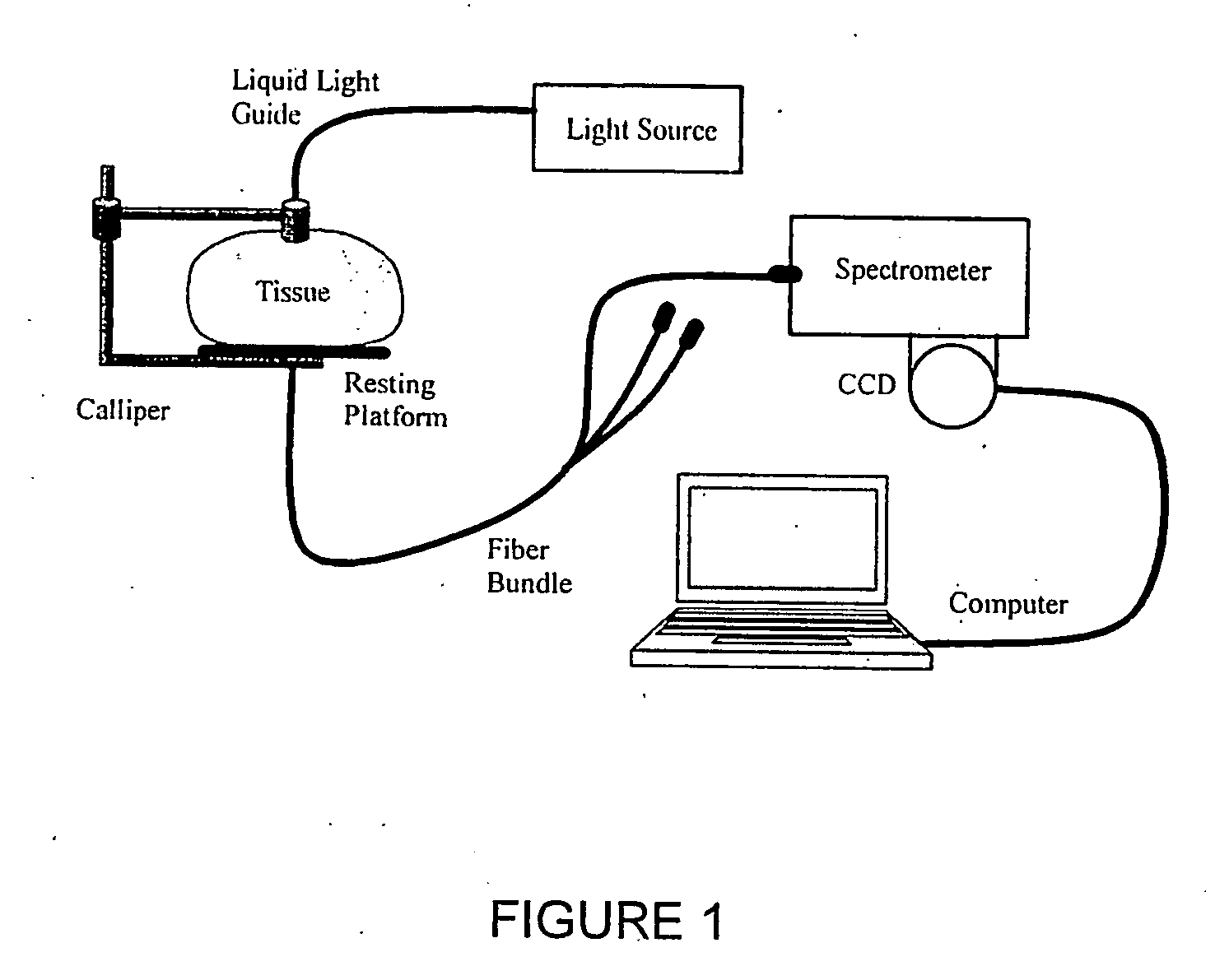

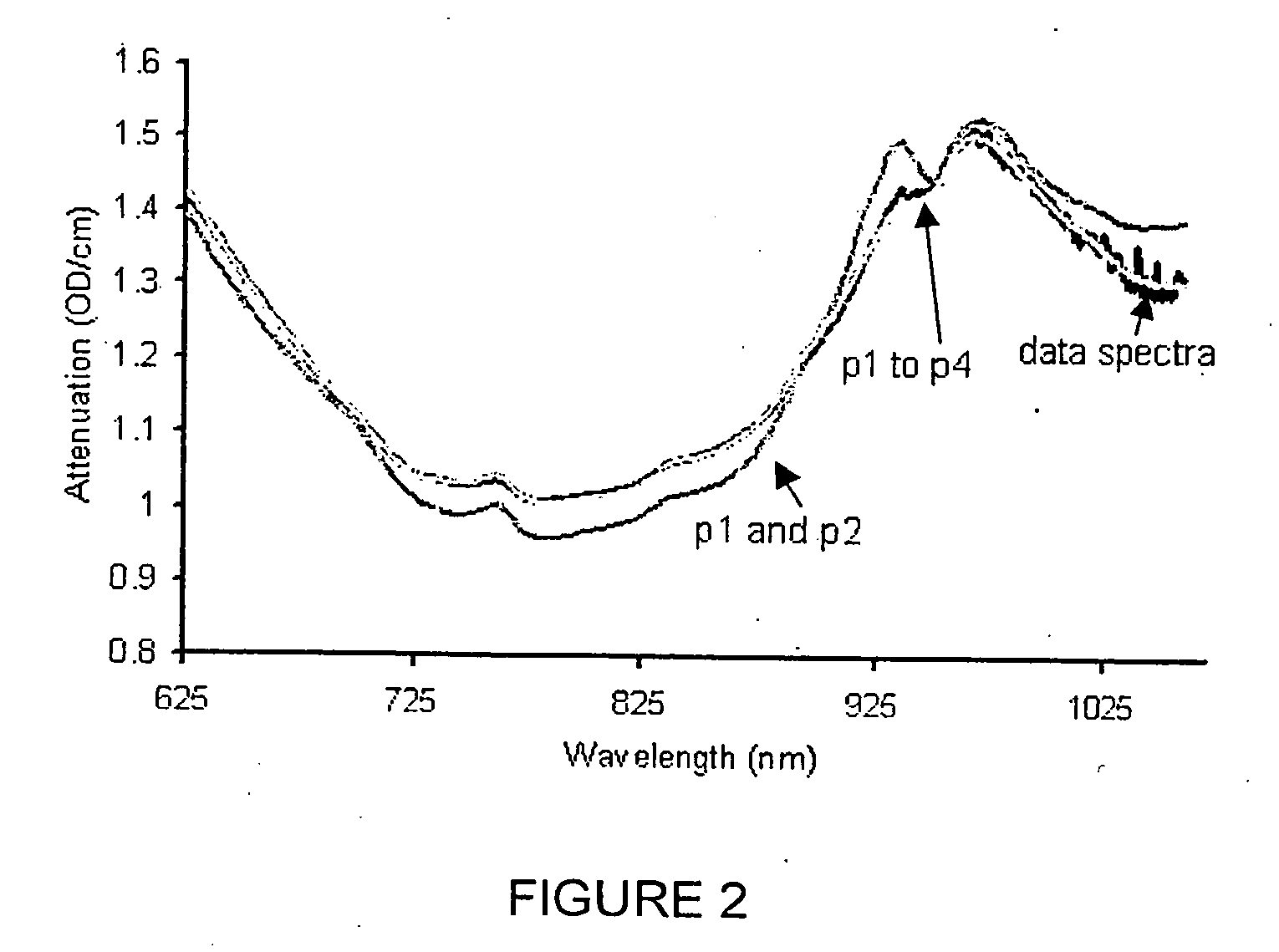

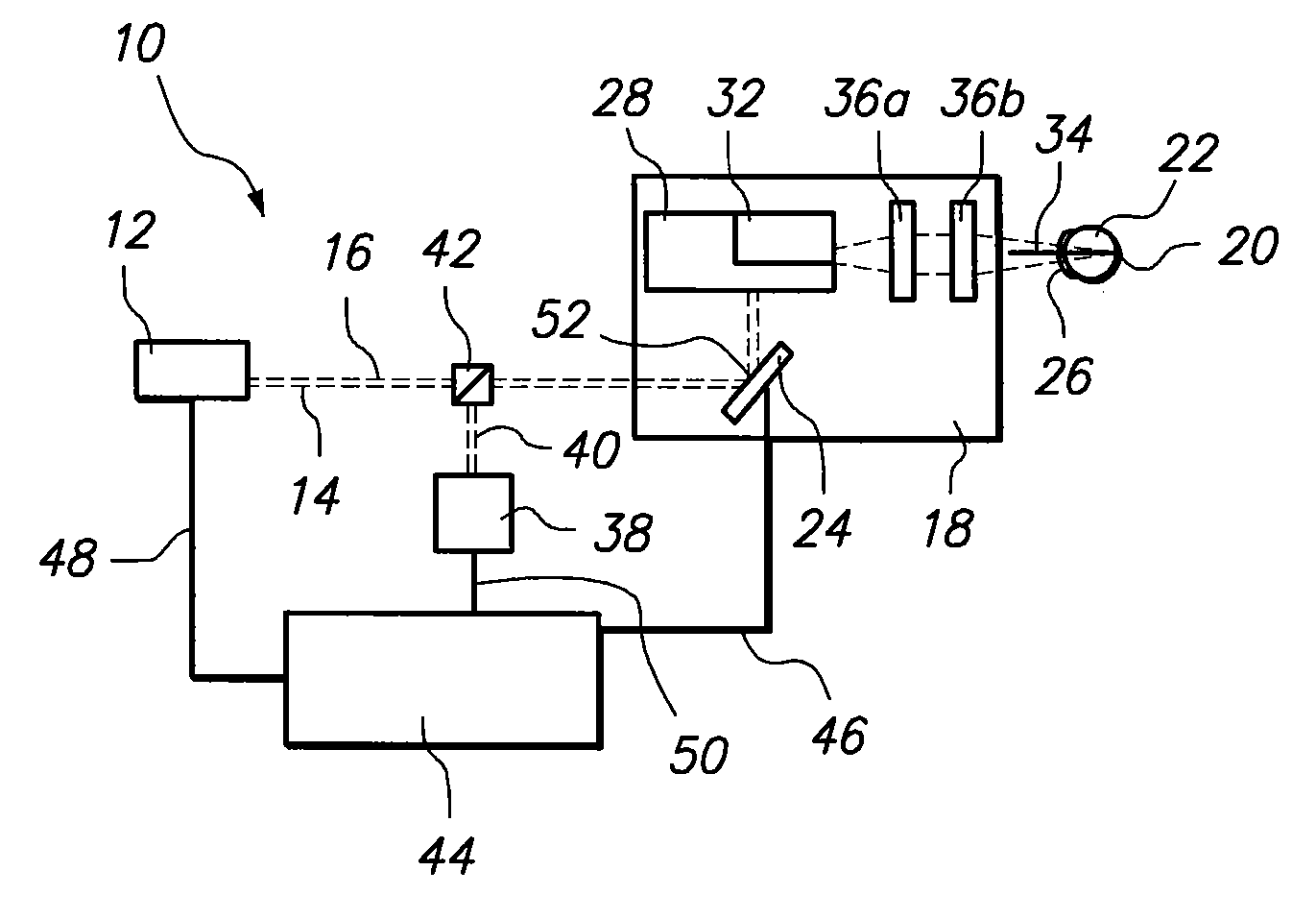

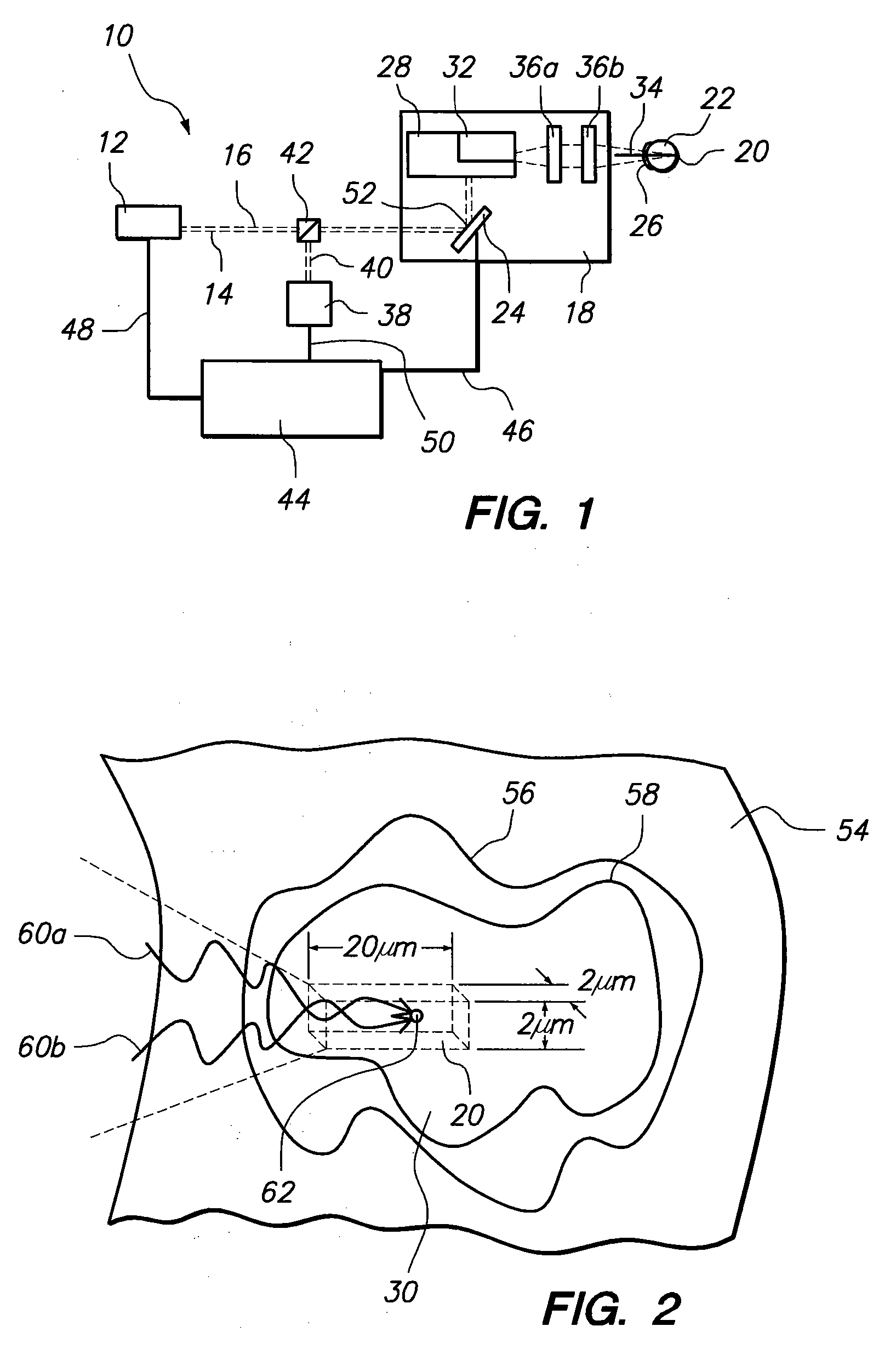

Optical transillumination and reflectance spectroscopy to quantify disease risk

InactiveUS20060173352A1Increased riskDiagnostic recording/measuringSensorsDisease riskNon-ionizing radiation

The present invention uses spectroscopic tissue volume measurements using non-ionizing radiation to detect pre-disease transformations in the tissue, which increase the risk for this disease in mammals. The method comprises illuminating a volume of selected tissue of a mammal with light having wavelengths covering a pre-selected spectral range, detecting light transmitted through, or reflected from, the volume of selected tissue, and obtaining a spectrum of the detected light. The spectrum of detected light is then represented by one or more basis spectral components, an error term, and an associated scalar coefficient for each of the basis spectral components. The associated scalar coefficient is calculated by minimizing the error term. The associated scalar coefficient of the each of the basis spectral components is correlated with a pre-selected property of the selected tissue known to be indicative of susceptibility of the tissue for the pre-selected disease to obtain the susceptibility for the mammal to developing the pre-selected disease.

Owner:UNIV HEALTH NETWORK

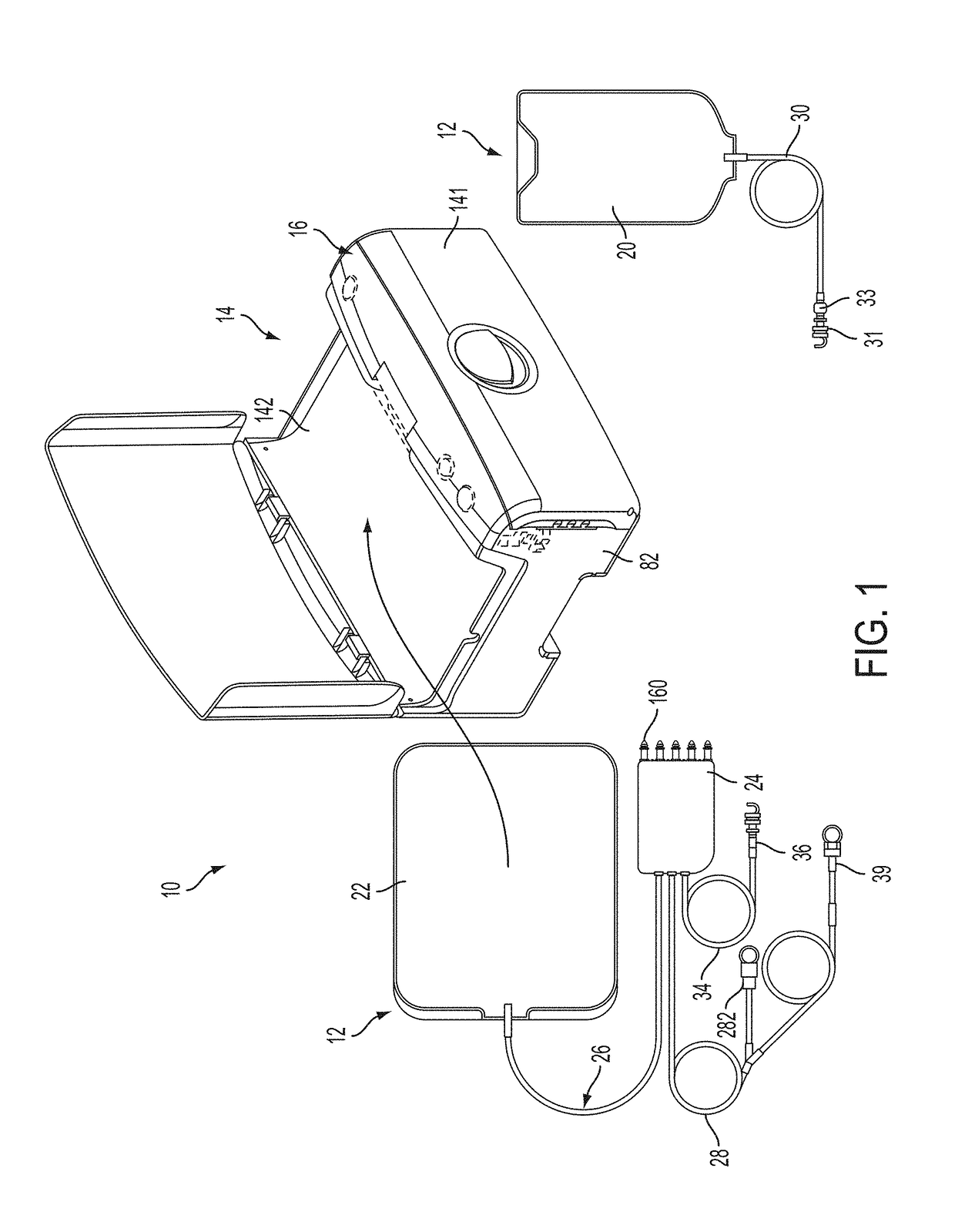

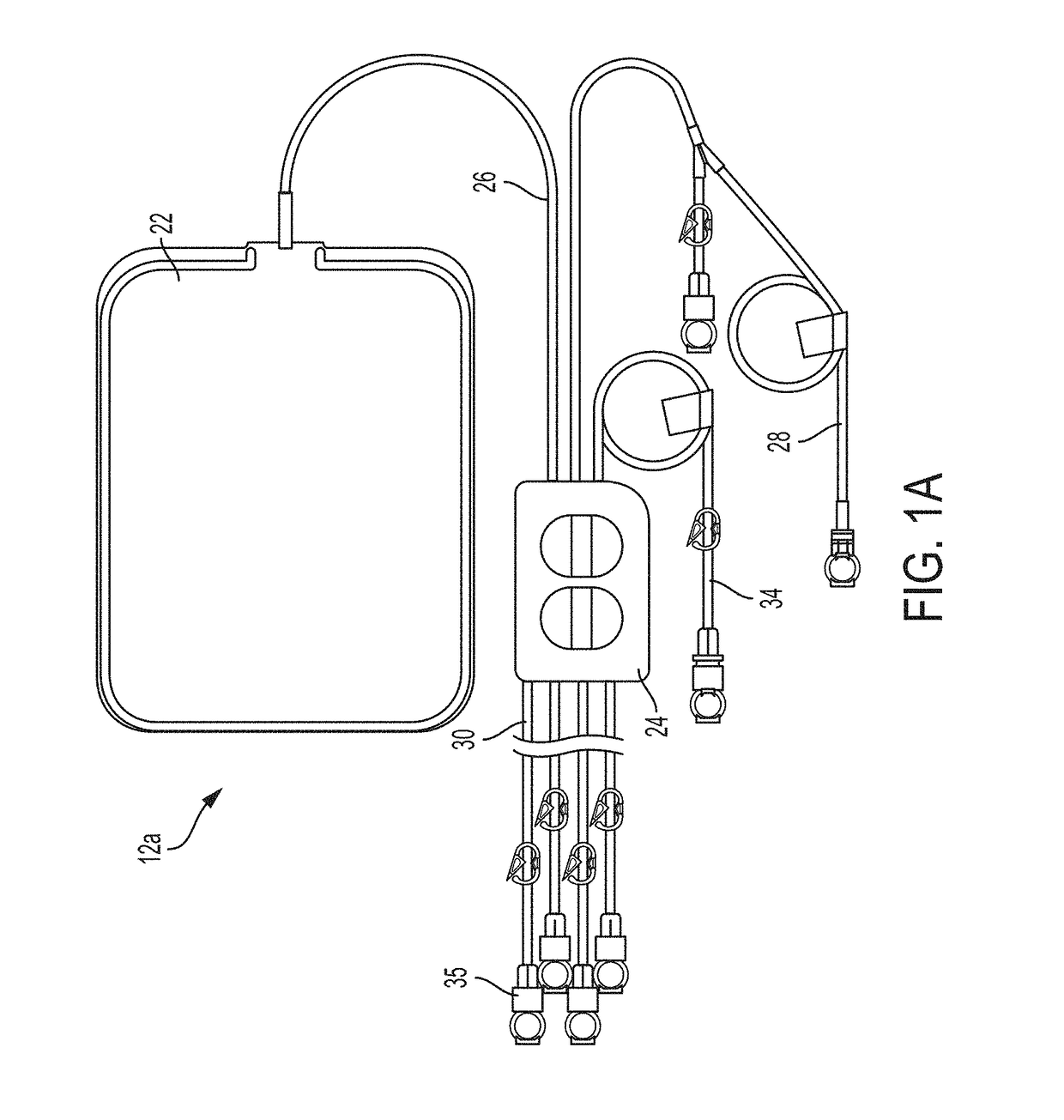

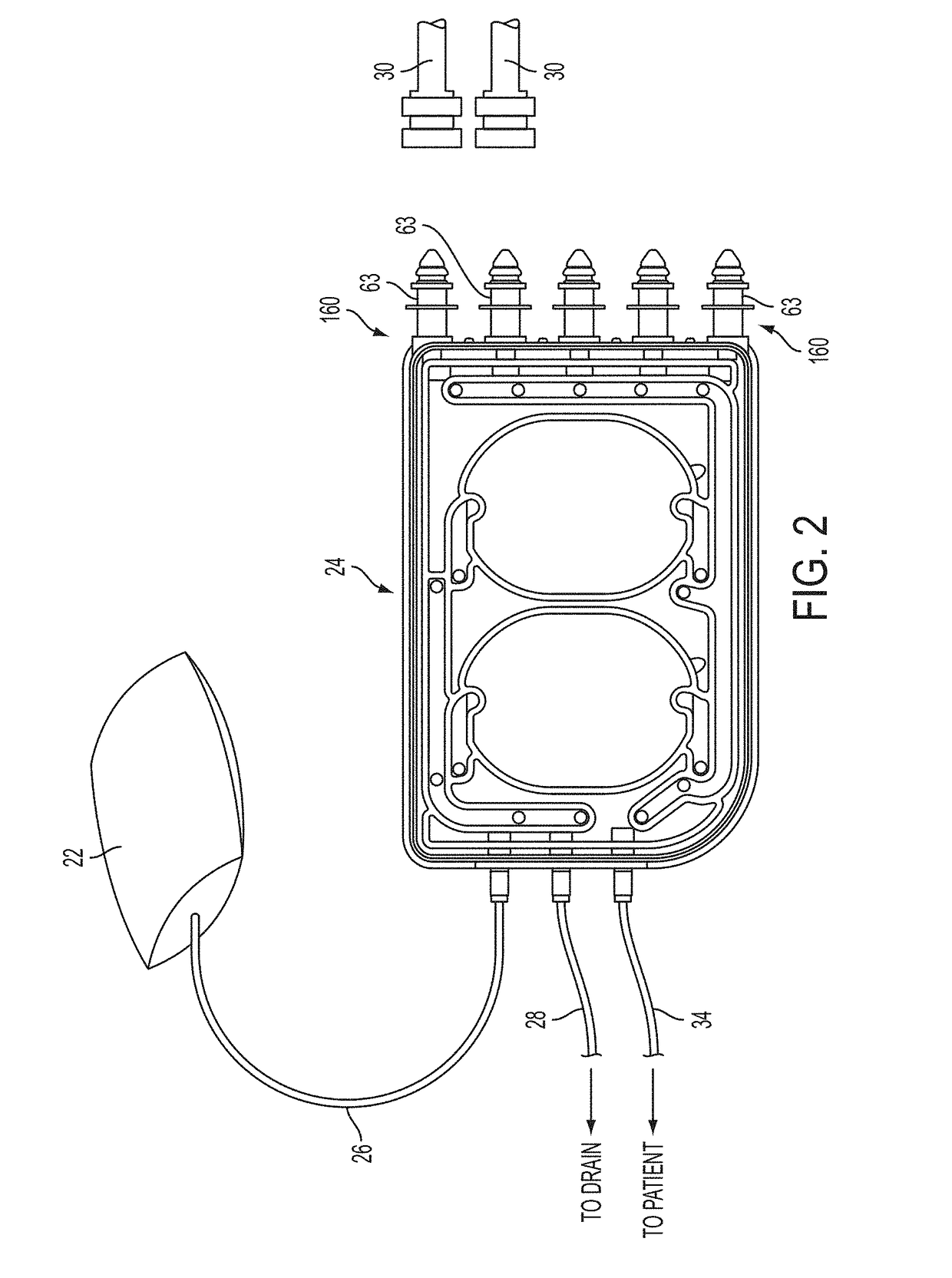

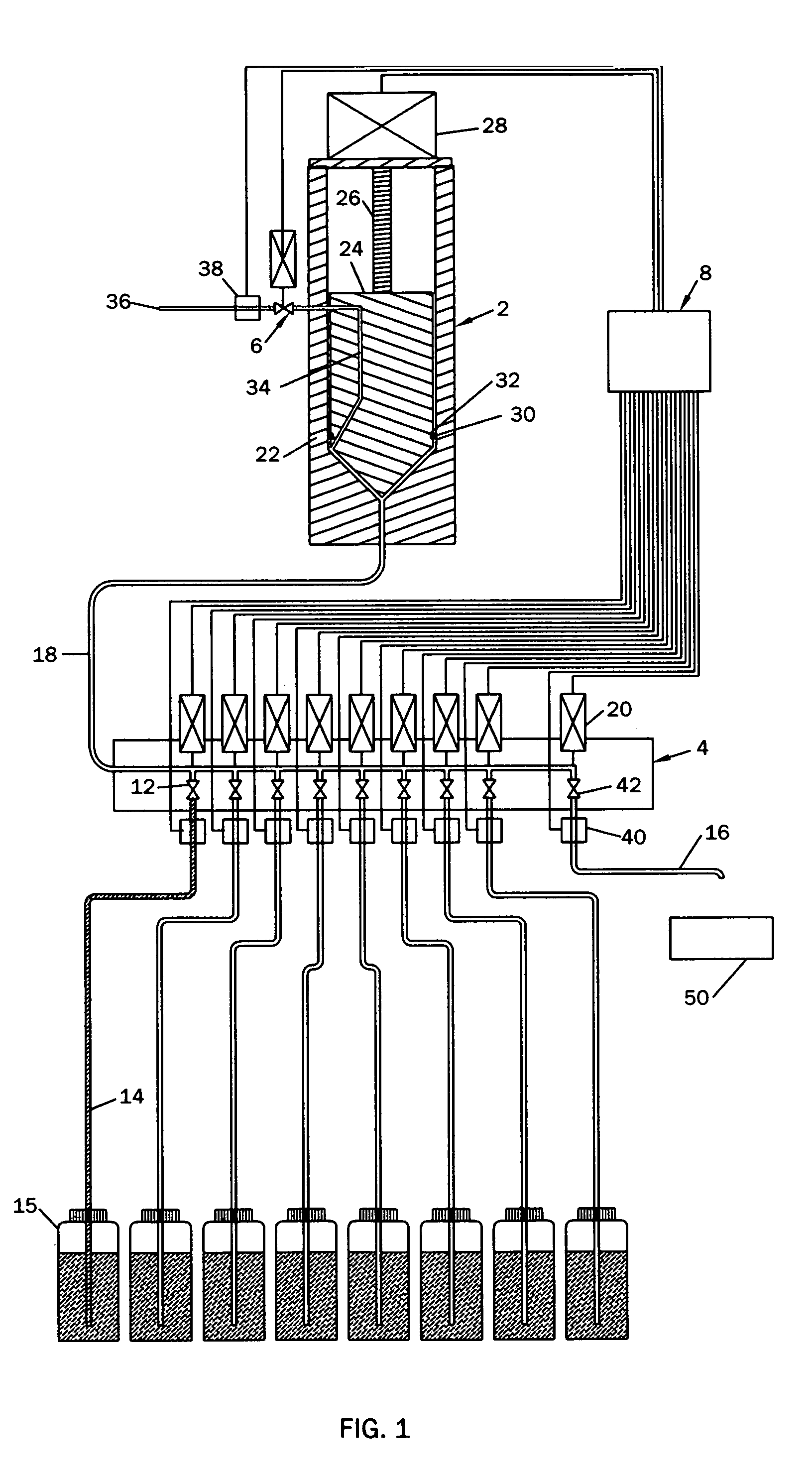

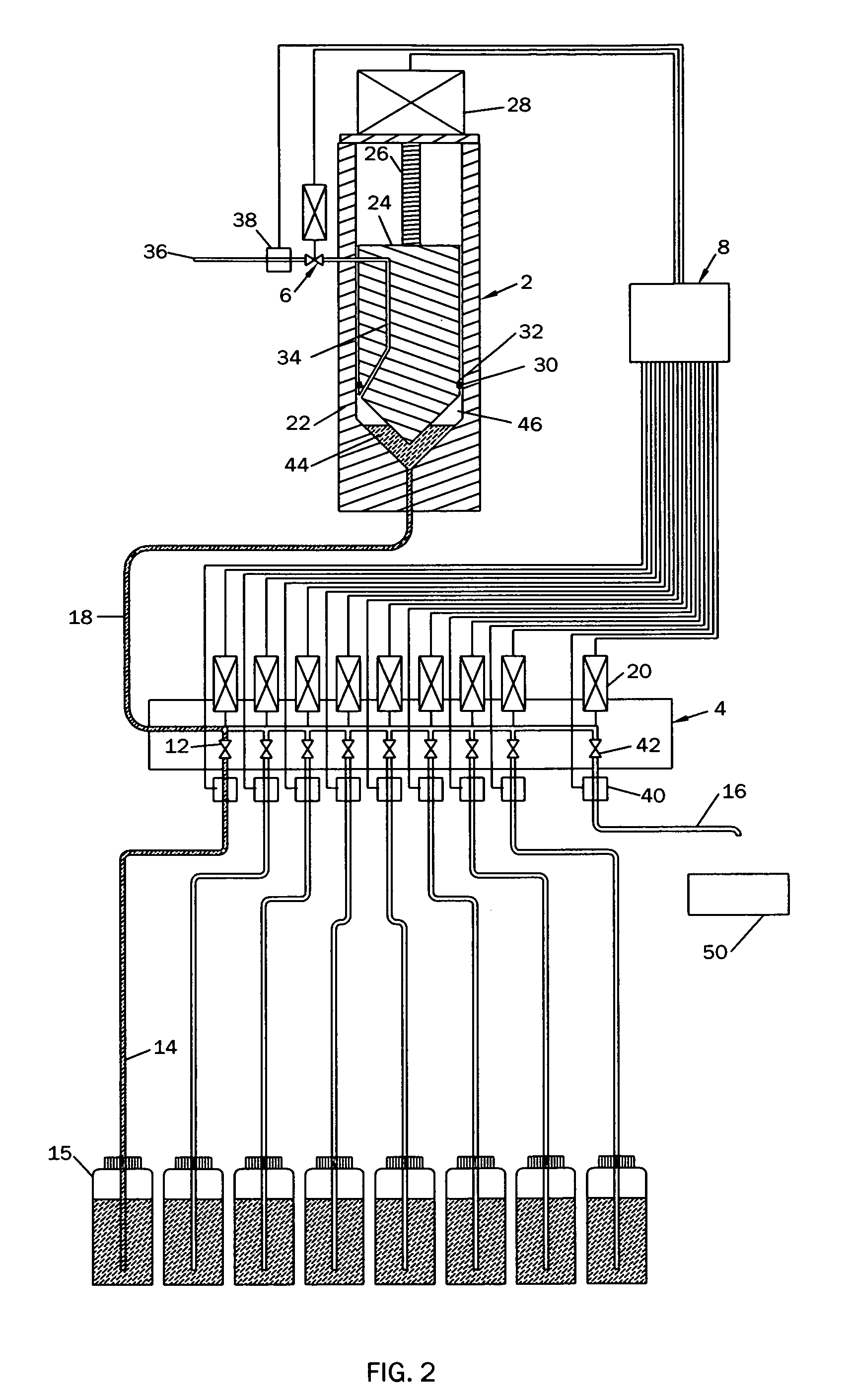

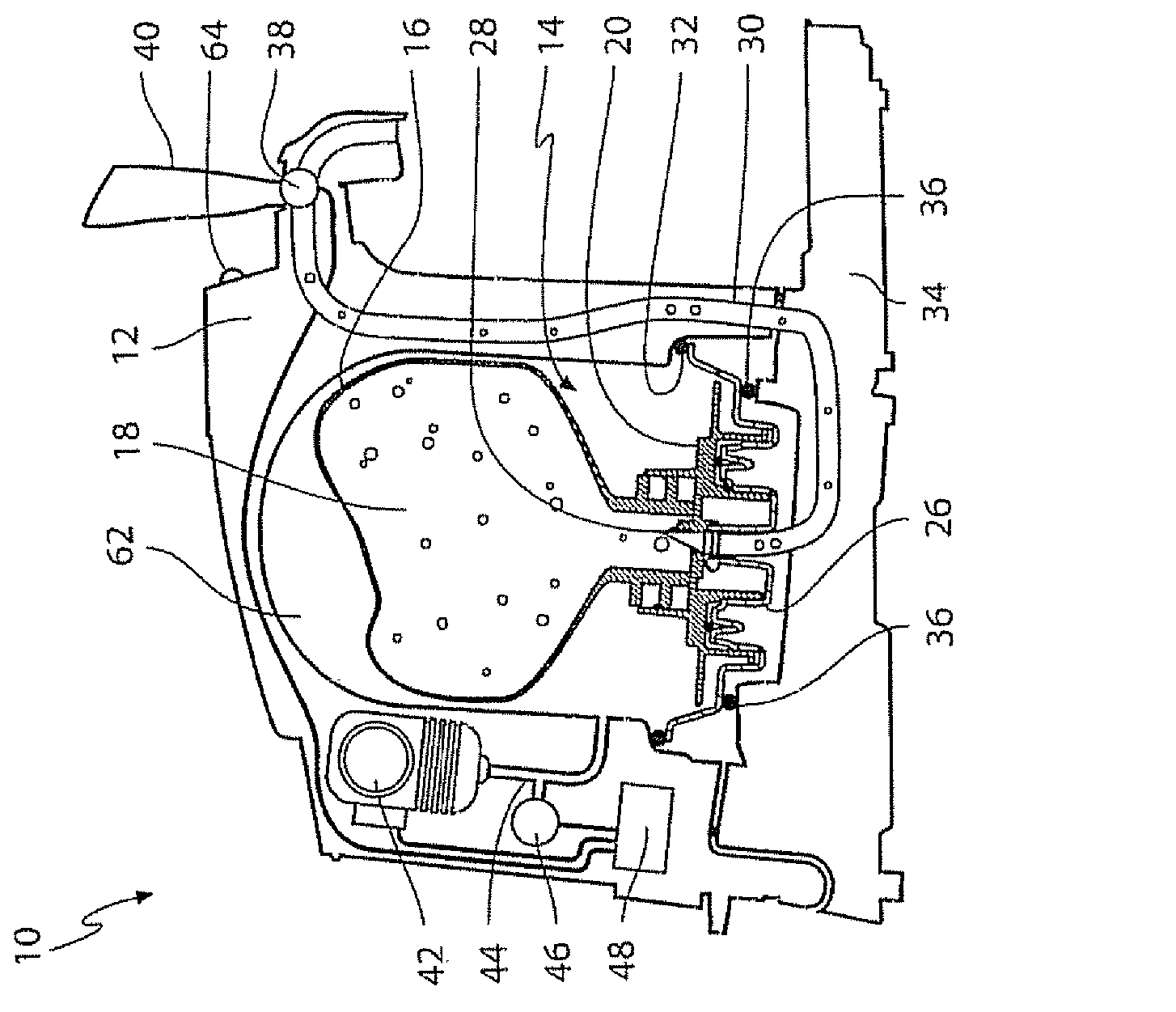

Medical treatment system and methods using a plurality of fluid lines

ActiveUS10201647B2Improve accuracyAvoid accumulationOther blood circulation devicesMedical devicesPeritoneal dialysisPolytropic process

Improvements in fluid volume measurement systems are disclosed for a pneumatically actuated diaphragm pump in general, and a peritoneal dialysis cycler using a pump cassette in particular. Pump fluid volume measurements are based on pressure measurements in a pump control chamber and a reference chamber in a two-chamber model, with different sections of the apparatus being modeled using a combination of adiabatic, isothermal and polytropic processes. Real time or instantaneous fluid flow measurements in a pump chamber of a diaphragm pump are also disclosed, in this case using a one-chamber ideal gas model and using a high speed processor to obtain and process pump control chamber pressures during fluid flow into or out of the pump chamber. Improved heater control circuitry is also disclosed, to provide added or redundant safety measures, or to reduce current leakage from a heater element during pulse width modulation control of the heater. Improvements are also disclosed in the application of negative pressure during a drain phase in peritoneal dialysis therapy, and to control the amount of intraperitoneal fluid accumulation during a therapy. Improvements in efficiency are also disclosed in the movement of fluid into and out of a two-pump cassette and heater bag of a peritoneal dialysis cycler, and in the synchronization of the operation of two or more pumps in a peritoneal dialysis cycler or other fluid handling devices using a multi-pump arrangement.

Owner:DEKA PROD LLP

System and method for three-dimensional image rendering and analysis

InactiveUS8045770B2Reduce contributionSimple structureImage enhancementReconstruction from projectionImaging analysisComputer graphics (images)

The present invention relates to methods and systems for conducting three-dimensional image analysis and diagnosis and possible treatment relating thereto. The invention includes methods of handling signals containing information (data) relating to three-dimensional representation of objects scanned by a scanning medium. The invention also includes methods of making and analyzing volumetric measurements and changes in volumetric measurements which can be used for the purpose of diagnosis and treatment.

Owner:CORNELL RES FOUNDATION INC

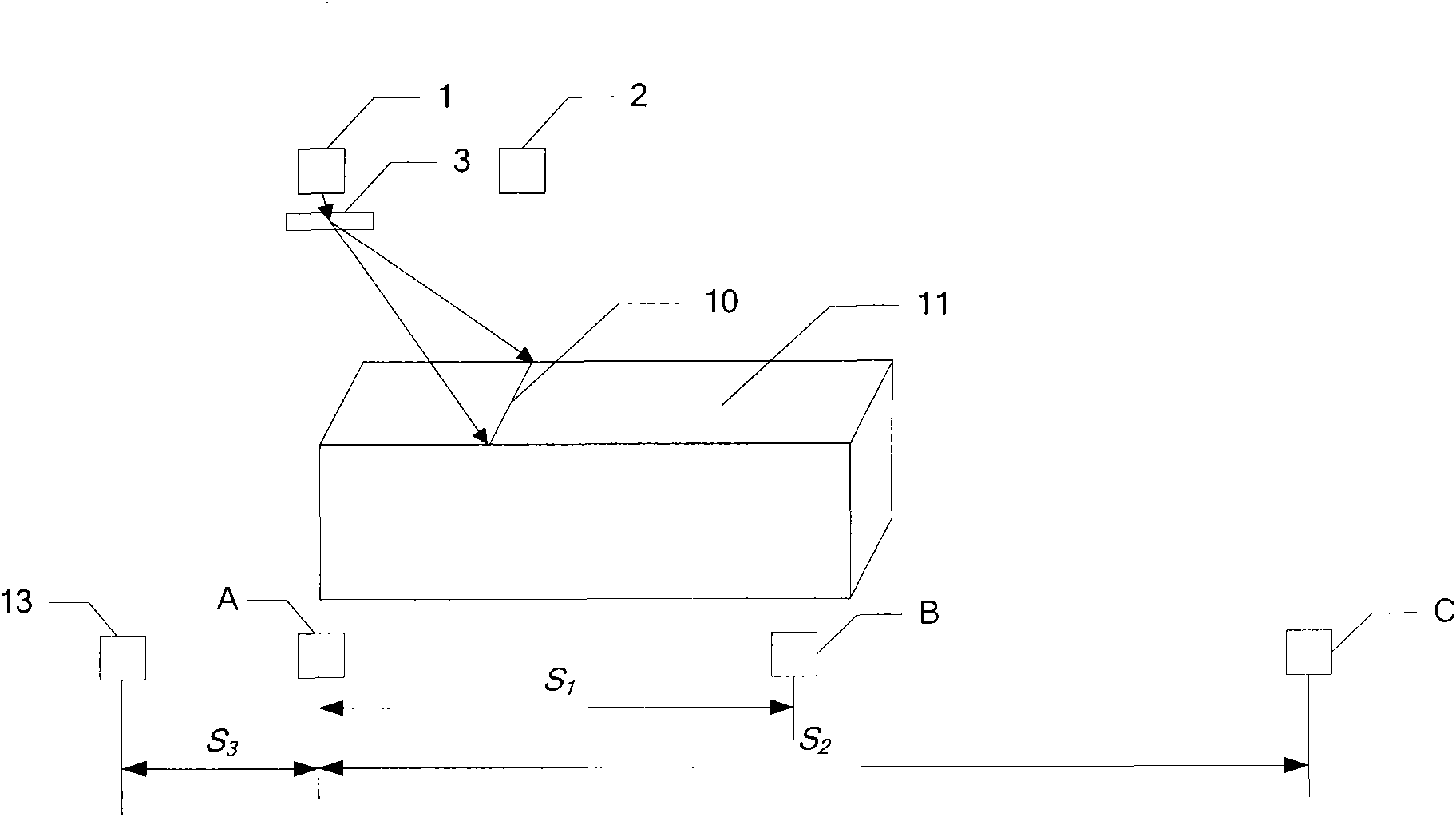

Truck volumetric measurement method based on laser triangulation

The invention discloses a truck volumetric measurement method based on laser triangulation, comprising the following steps: three measuring points are arranged in sequence along the vehicle travelling direction on a vehicle travelling channel; each measuring point is provided with a sensing device for sensing arrival and departure of the measured vehicle; a sensing device for acquiring car axle quantity of the measured vehicle is arranged at a set position in front of a first measuring point; the four sensing devices are used for acquiring length of the measured vehicle; a laser device and a video camera are arranged above the center line of the vehicle travelling channel; a cylindrical lens which causes laser beams to irradiate on a horizontal plane so as to form laser bars is additionally arranged in front of the laser device; length and position of the laser bars on vehicle roof, which are shoot by the camera video are used for acquiring width and height of the measured vehicle so as to work out volume of the measured vehicle. The method disclosed by the invention has advantages of practicability and reliability and can reduce costs for measuring the volume of trucks.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Device and method for the volumetric measurement and dispensing of liquids

InactiveUS7111757B1Allocation is accurateOpening closed containersBottle/container closureVolumetric Mass DensityBiomedical engineering

Devices and methods for accurate volumetric measurement and dispensing of any liquid, regardless of that liquid's density and vapor pressure, are disclosed. This invention employs devices and methods which are used to eliminate free volume from a variable volume chamber. A desired volume of liquid can be measured accurately within the volume range of the chamber. These devices and methods are suitable for volumetric measurement and dispensing of any liquid, regardless of density or vapor pressure.

Owner:OBRIEN THOMAS MATTHEW +1

Photodynamic therapy for treating age-related macular degeneration

Owner:HEIDELBERG ENG

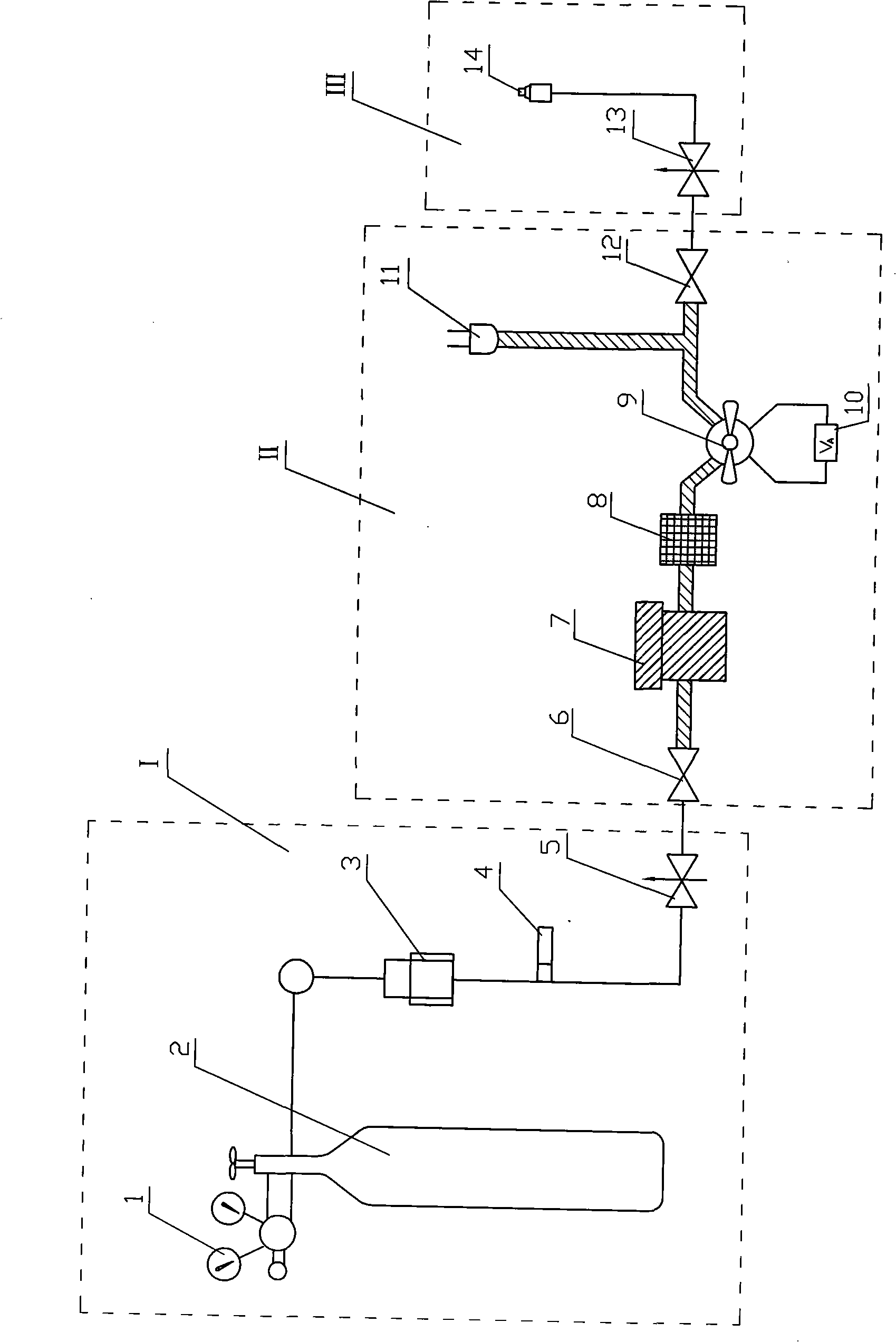

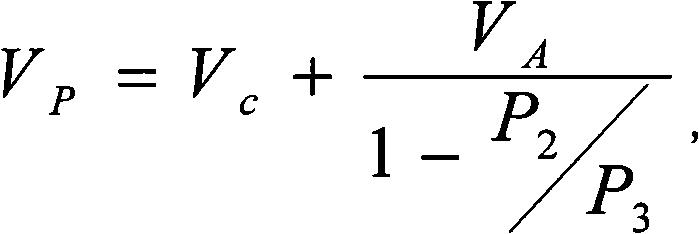

System and method for measuring true volume of gathered-state substances with gaps

InactiveCN101625234ASolid theoretical foundationHigh implementabilityUsing fluid meansEngineeringNitrogen gas

The invention provides a system and a method for measuring true volume of gathered-state substances with gaps. The system comprises a gas input part, a closed measurement part with a gas inlet switching valve and an exhaust switching valve, as well as an exhaust part, wherein a gas-flow input switching valve of the closed measurement part which is provided with a gas pressure measurement component and has the gas inlet switching valve and the exhaust switching valve is communicated with the gas input part, and the exhaust switching valve is communicated with the exhaust part. The method comprises the following steps: adopting helium or nitrogen as a measurement medium; putting a measured substance into a sample pool of a measurement system; filling the whole measurement system with the gas measurement medium; closing the exhaust switching valve and a standard volume access valve of the measurement system; filling the closed measurement part with the gas measurement medium till pressurization pressure P2 is measured when the pressure of the closed measurement part is higher than environmental pressure of 1.195 kg / cm<2>; connecting standard additional volume with the closed measurement part and then measuring the pressure P3 of the closed measurement part; and calculating the true volume of the measured substance through calculation formula. The measurement system and the method have the advantages of high measurement precision and use convenience.

Owner:柳州市圣诺科技有限公司 +1

Apparatus and methods for monitoring quantities of fluid in a container

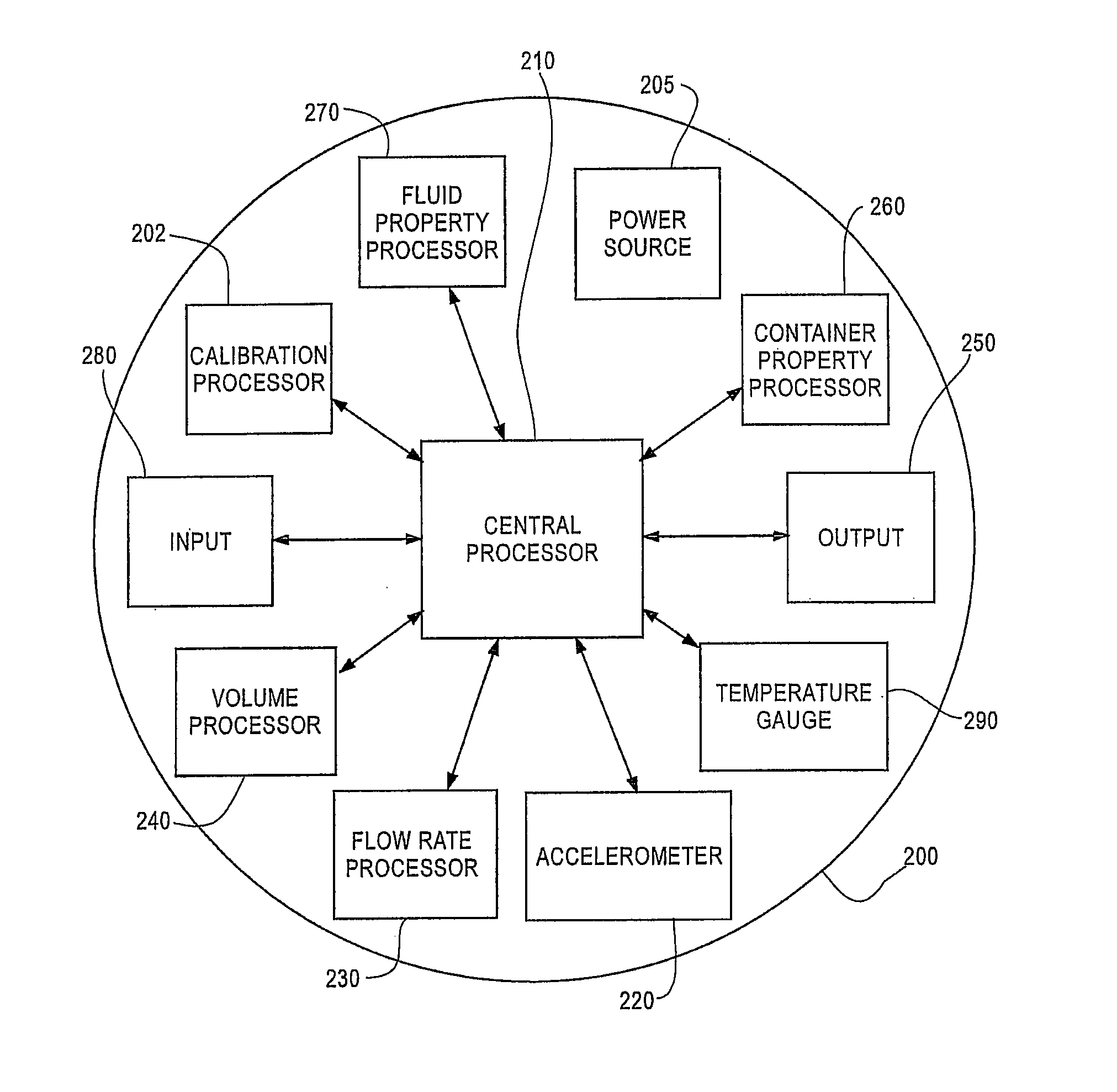

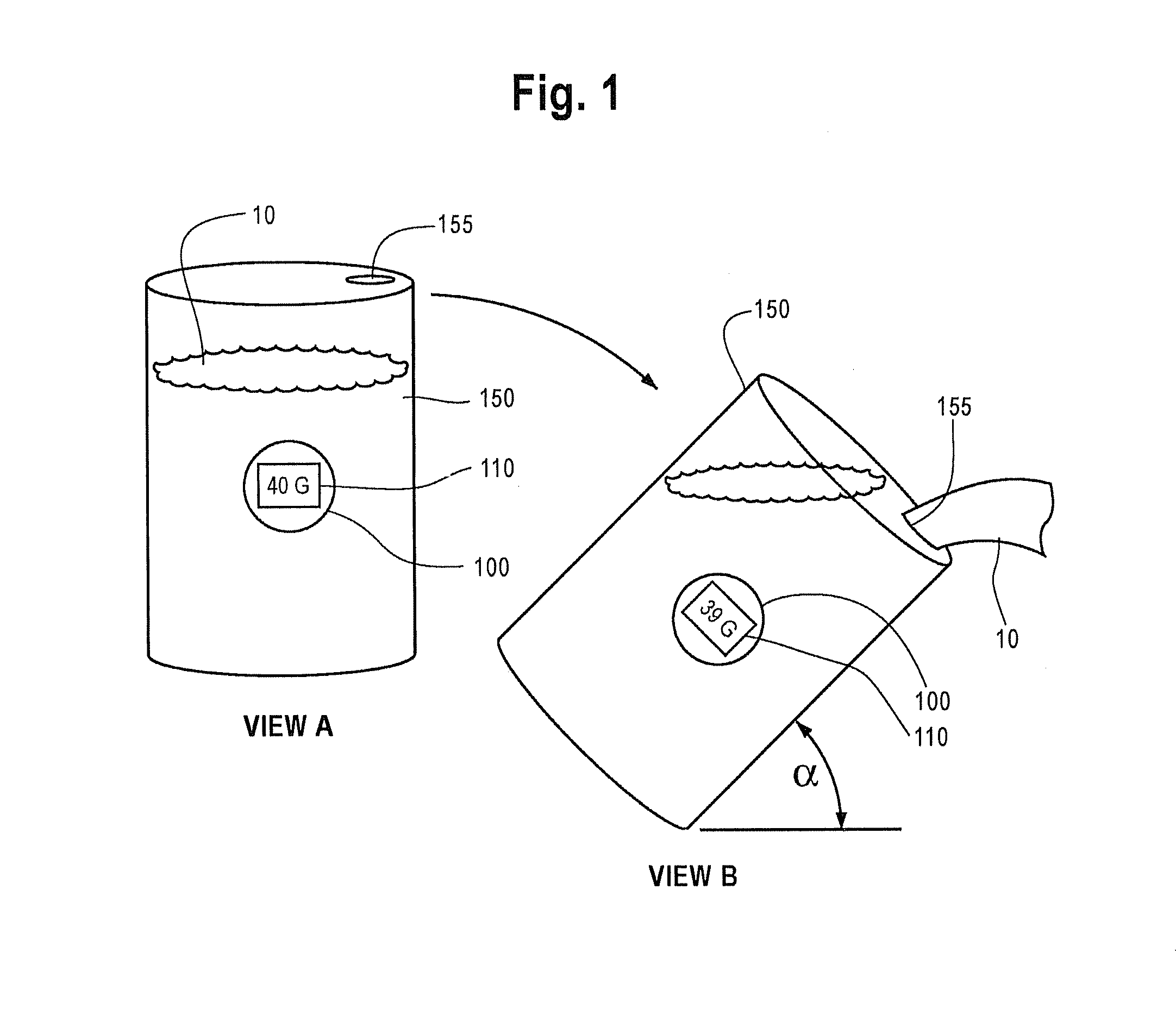

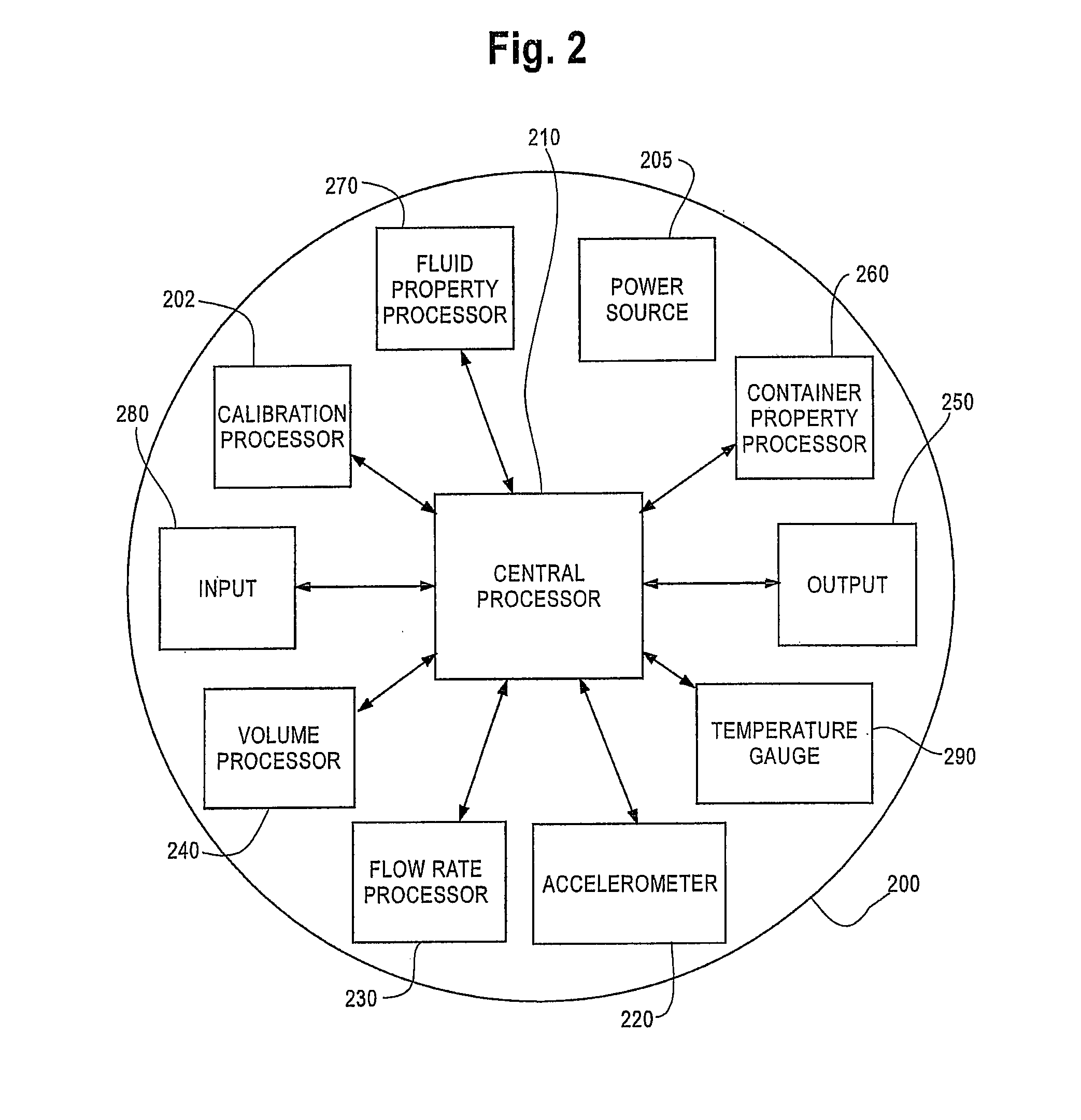

The present technology relates to a volumetric measurement device and various methods for operation of the device. The device comprises at least one accelerometer for detecting the angle of tilt / tip of a container. The device also comprises at least one fluid property processor capable of providing at least one fluidic property value of a fluid, a flow-rate processor capable of continuously calculating the present flow rate of the fluid when poured from the container, and a volume processor capable of continuously calculating the present volume of the fluid within the container. The flow-rate processor calculates the rate of flow of the fluid poured from the container based on the angle of tilt / tip of the apparatus, the at least one fluid property value, and the present volume of fluid within the container.

Owner:CEBULSKI DAVID W

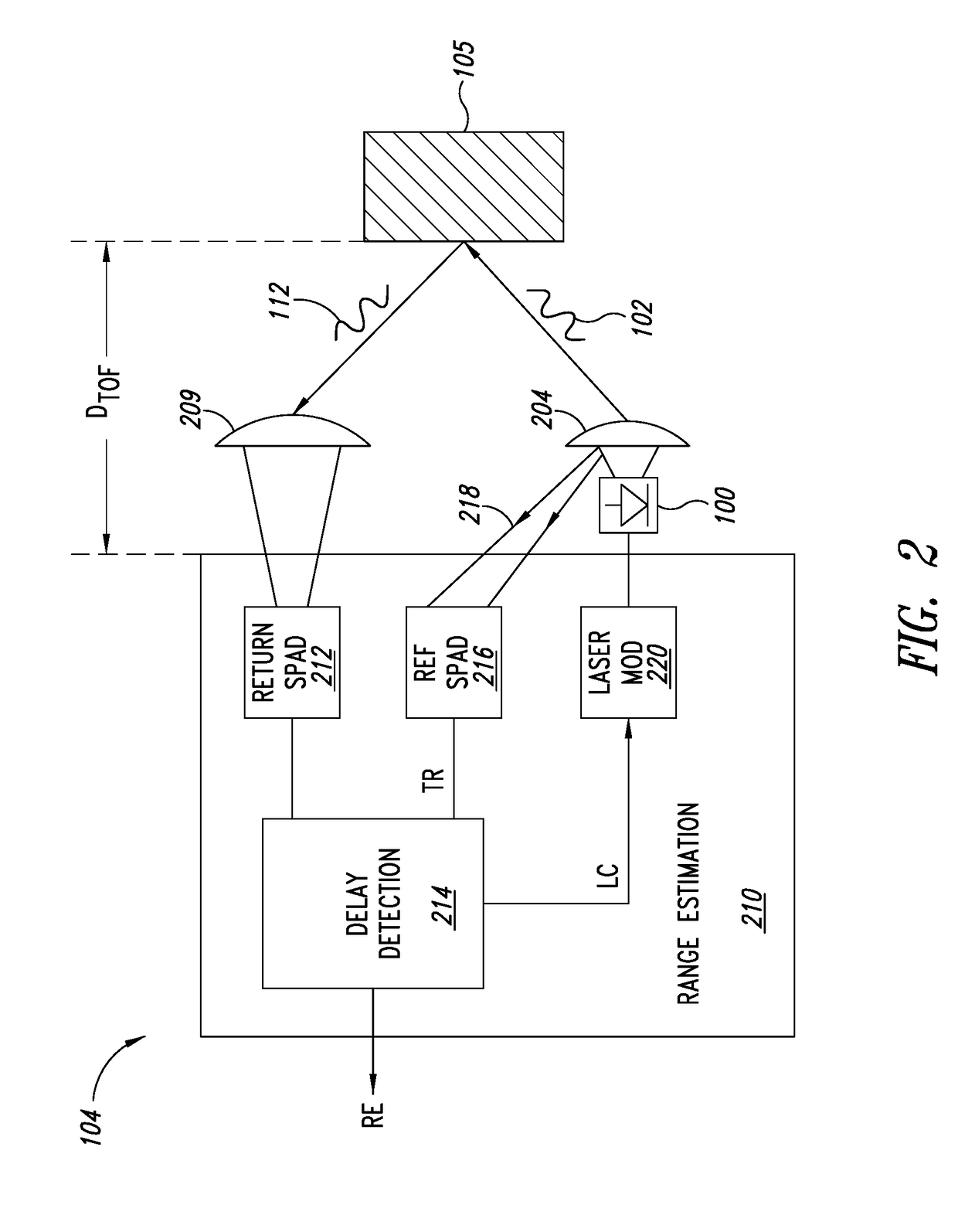

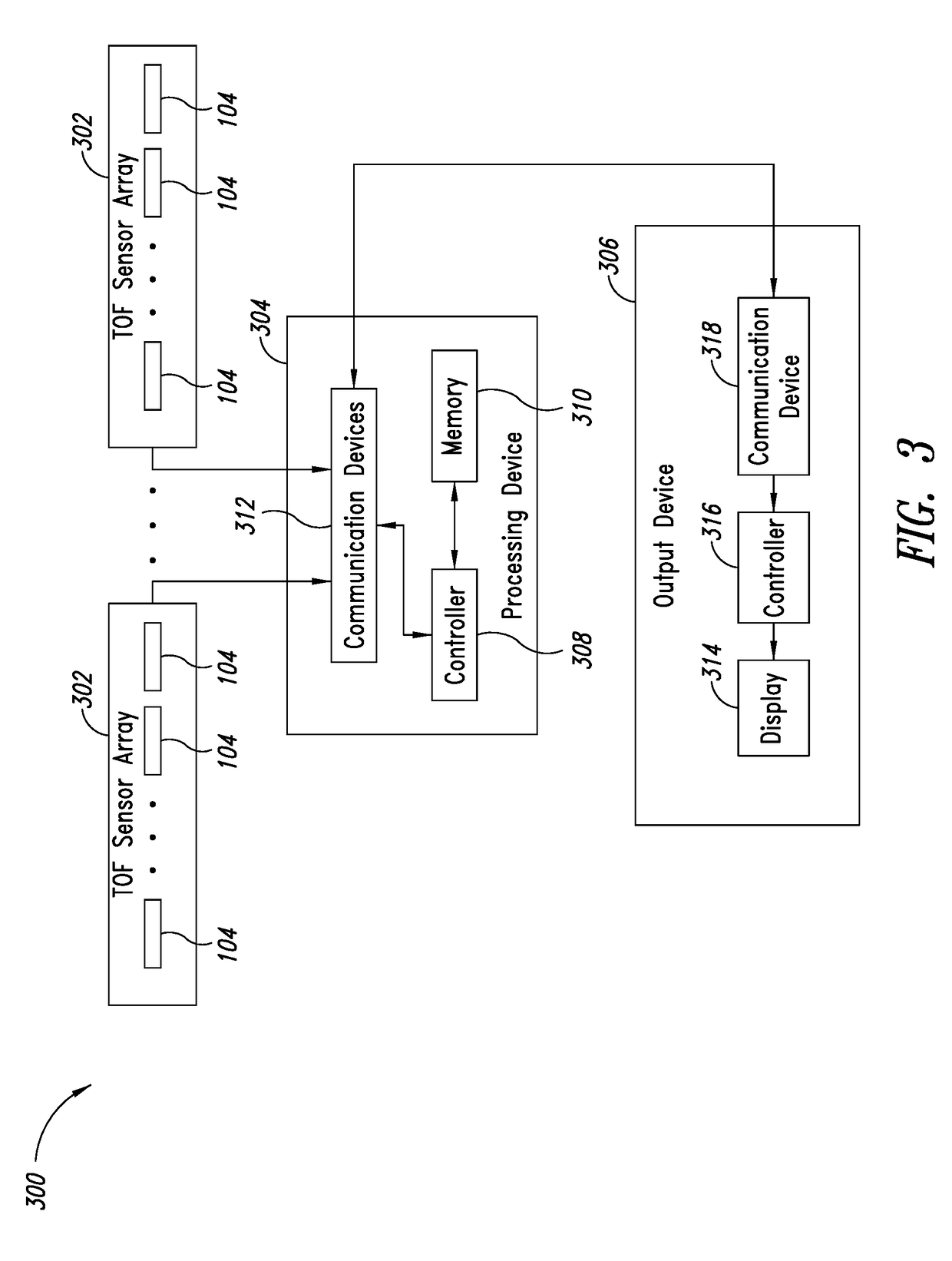

Three-dimensional time-of-flight sensors for a transportation system

ActiveUS20190033433A1Efficient packagingElectromagnetic wave reradiationSemiconductor devicesSensor arrayTime of flight sensor

A method and apparatus for determining space occupancy and performing volumetric measurement of a transportation system using a time-of-flight (TOF) sensor array are provided. In the method and apparatus, the TOF sensor array, which is mounted in a transportation system and includes a plurality of TOF sensors, outputs a plurality of distance measurements made by the plurality of TOF sensors, respectively. In the method and apparatus, a map of one or more objects positioned in the transportation system is generated based on the plurality of distance measurements. The map is output for display to a user by a display.

Owner:STMICROELECTRONICS SRL

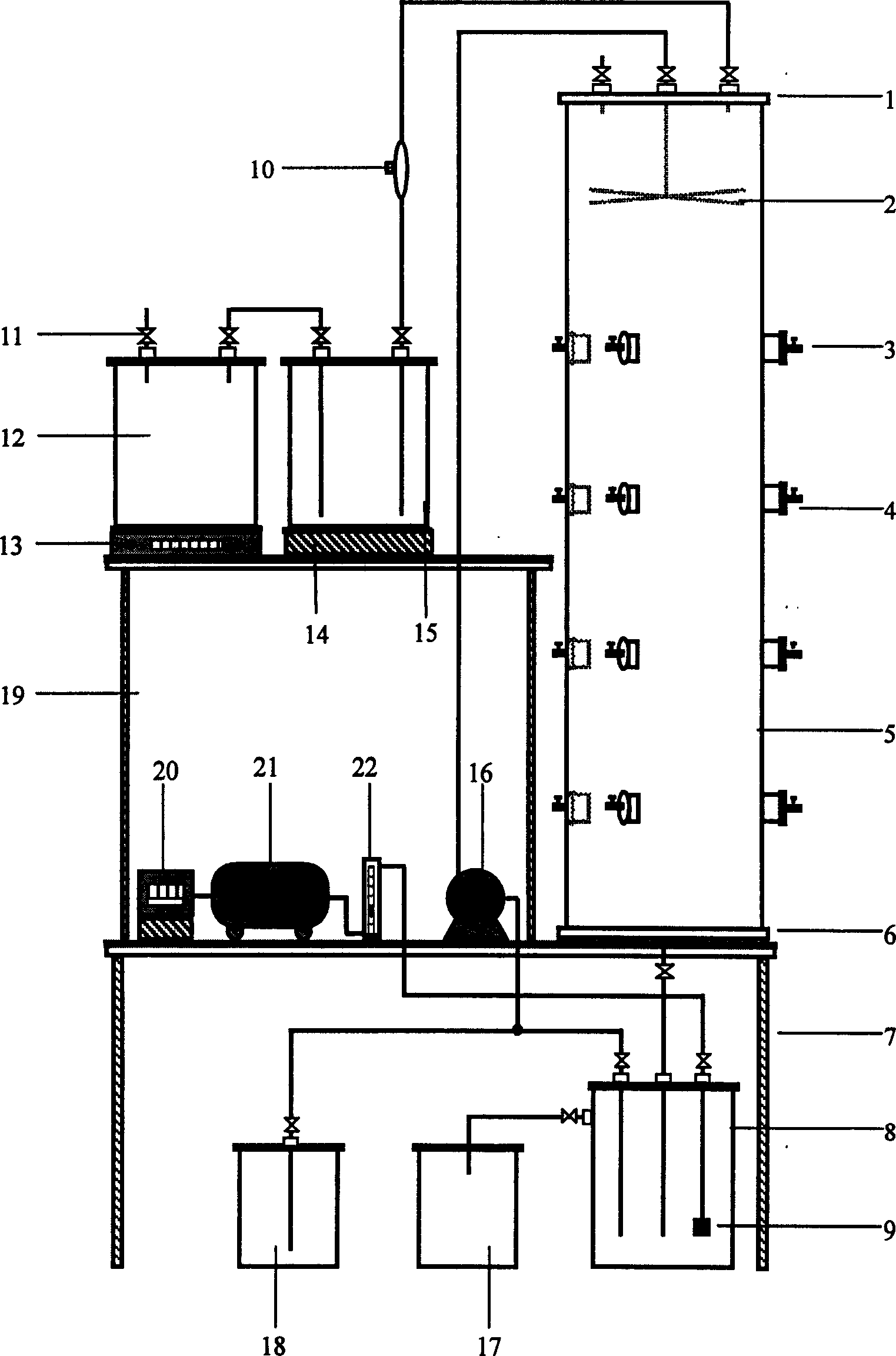

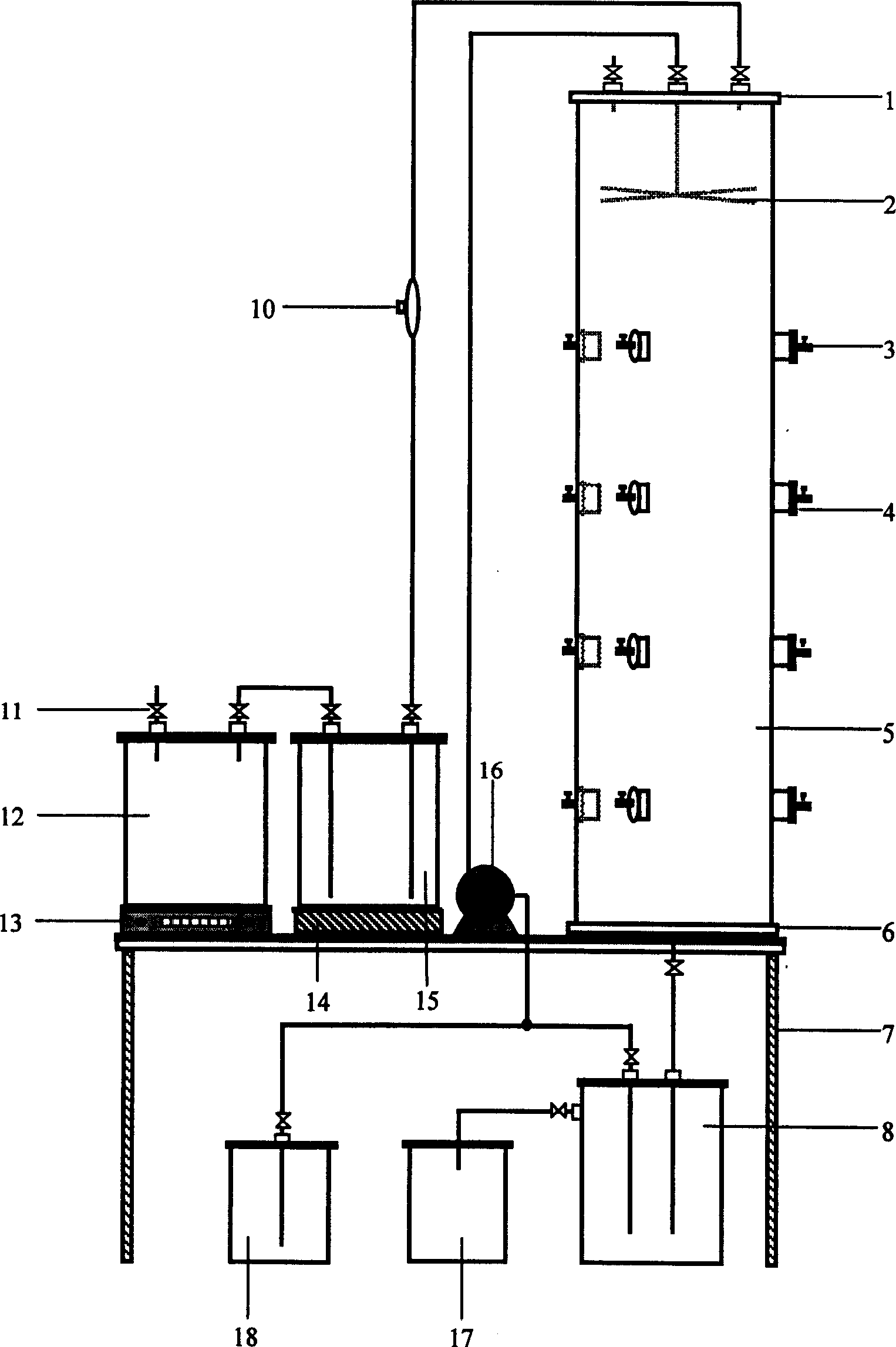

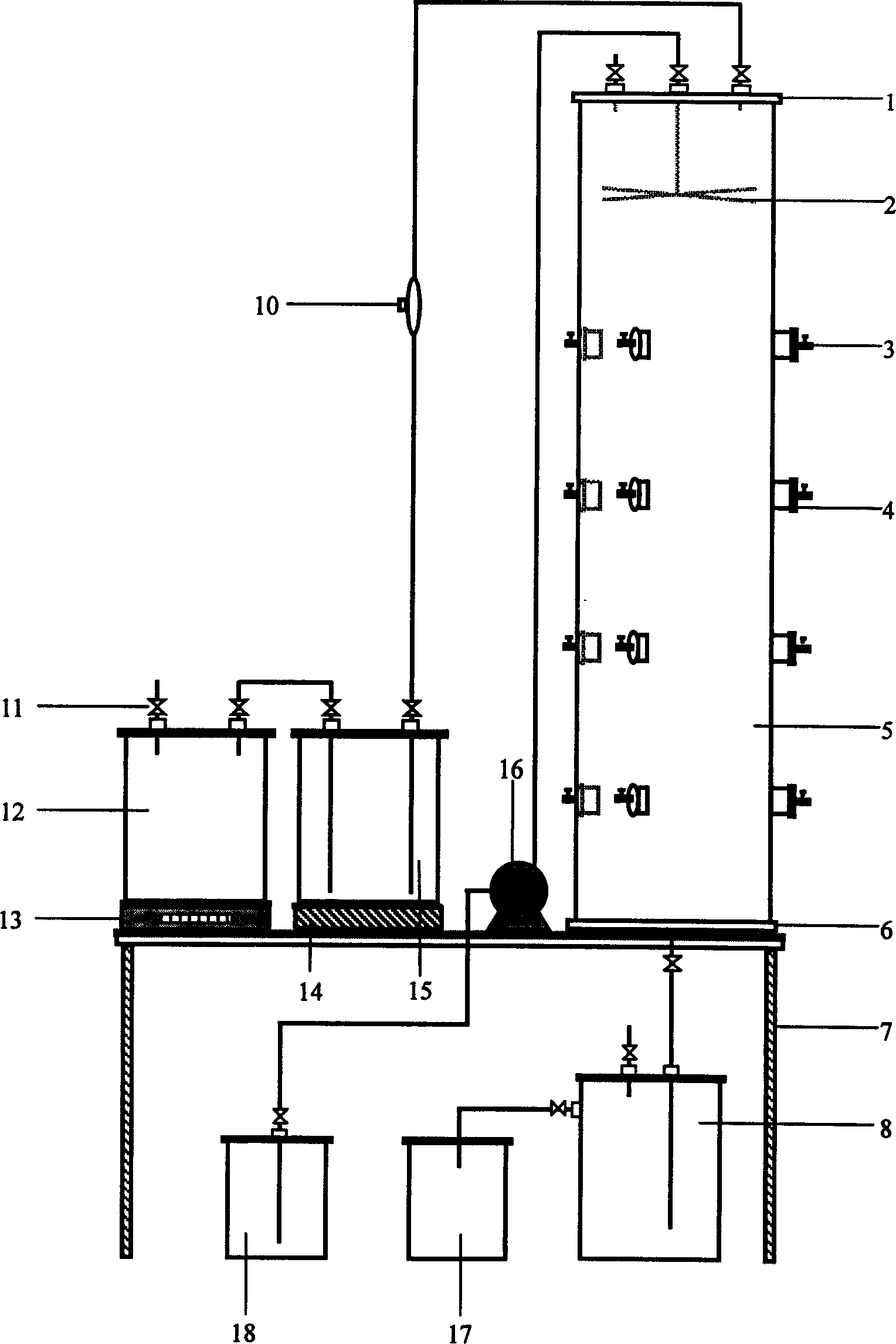

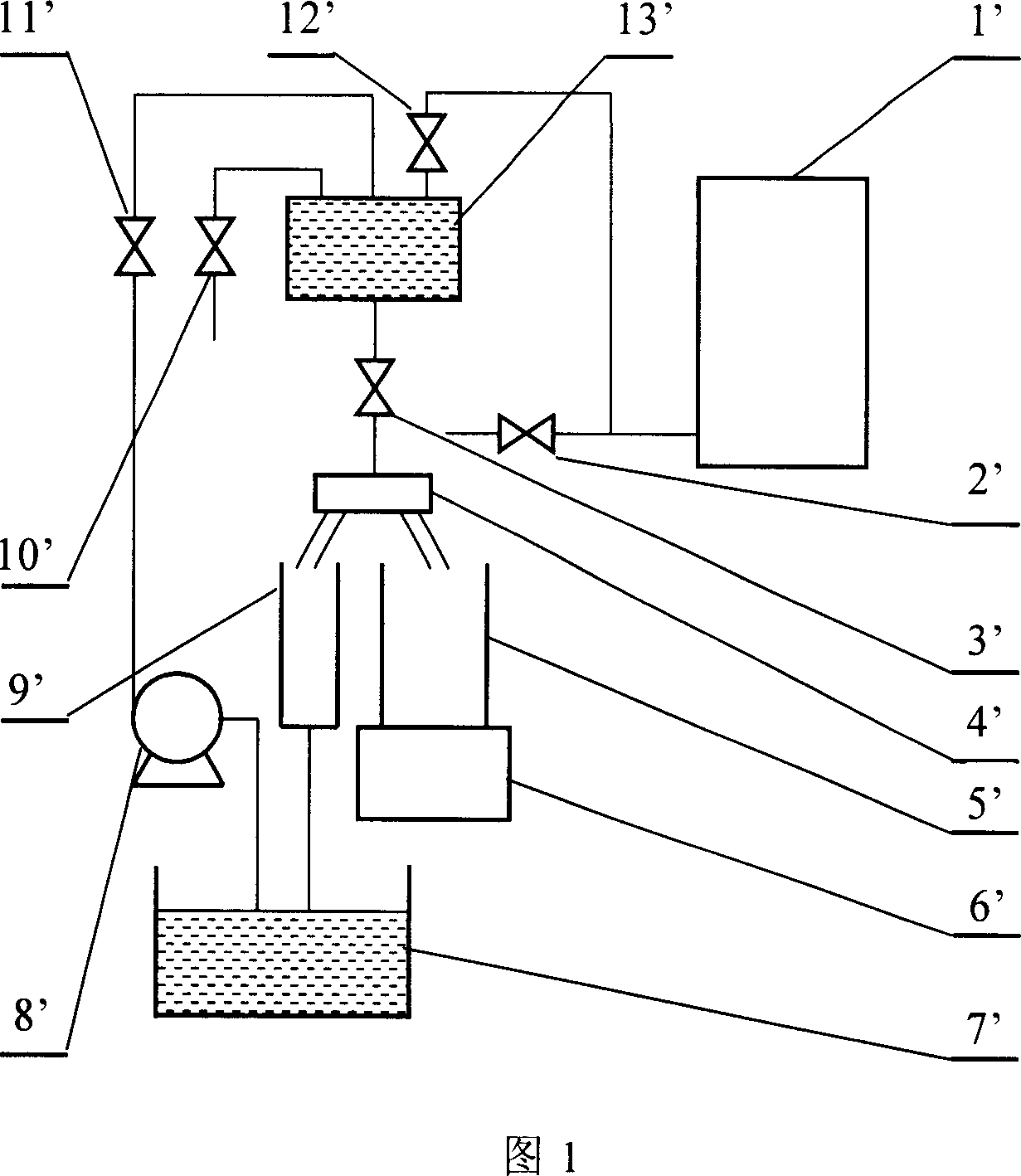

Multilayer sampling type life garbage ecological landfill reactor

InactiveCN1715860AAccurate volume measurementEasy to operateWithdrawing sample devicesPreparing sample for investigationPeristaltic pumpLitter

The ecological domestic garbage landfill reactor includes the first stainless steel frame with reactor, micro computerized time controller, aeration pump, glass rotor flow meter and precise peristaltic pump; the second stainless steel frame with exhaust liquid collecting bottle and gas collecting bottle; percolate regulating water tank, percolate collecting tank and simulating rainwater tank below the first frame. The micro computerized time controller is connected with the aeration pump, the glass rotor flow meter, the percolate regulating water tank, the precise peristaltic pump and the reactor; the percolate regulating water tank is connected to the reactor, percolate collecting tank and the imulating rainwater tank; and the reactor is connected to the sampling battle, the exhaust liquid collecting bottle, the gas collecting bottle and the control valve. The present invention can realize laminated sampling and instantaneous gas sampling in simple operation and high volumetric measurement precision.

Owner:吴伟祥 +2

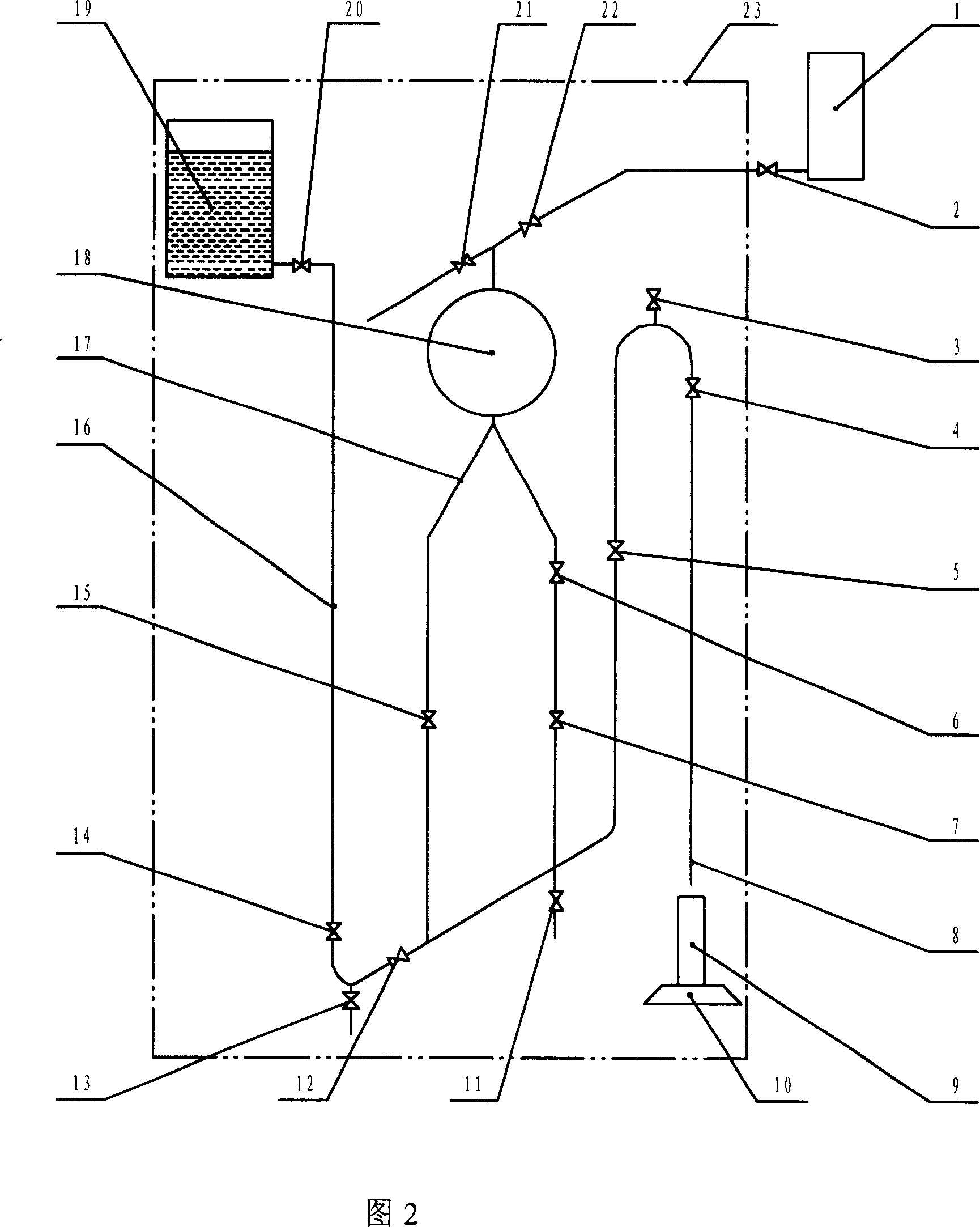

Liquid flow meter

InactiveUS20060254352A1Safer designVolume/mass flow measurementVolume measurementMechanical engineering

Owner:CITY METER

In vivo sensor and method of making same

InactiveUS8372139B2Easy to detectUltrasonic/sonic/infrasonic diagnosticsSurgeryIn vivoRadio frequency

Implantable in vivo sensors used to monitor physical, chemical or electrical parameters within a body. The in vivo sensors are integral with an implantable medical device and are responsive to externally or internally applied energy. Upon application of energy, the sensors undergo a phase change in at least part of the material of the device which is then detected external to the body by conventional techniques such as radiography, ultrasound imaging, magnetic resonance imaging, radio frequency imaging or the like. The in vivo sensors of the present invention may be employed to provide volumetric measurements, flow rate measurements, pressure measurements, electrical measurements, biochemical measurements, temperature, measurements, or measure the degree and type of deposits within the lumen of an endoluminal implant, such as a stent or other type of endoluminal conduit. The in vivo sensors may also be used therapeutically to modulate mechanical and / or physical properties of the endoluminal implant in response to the sensed or monitored parameter.

Owner:VACTRONIX SCI LLC

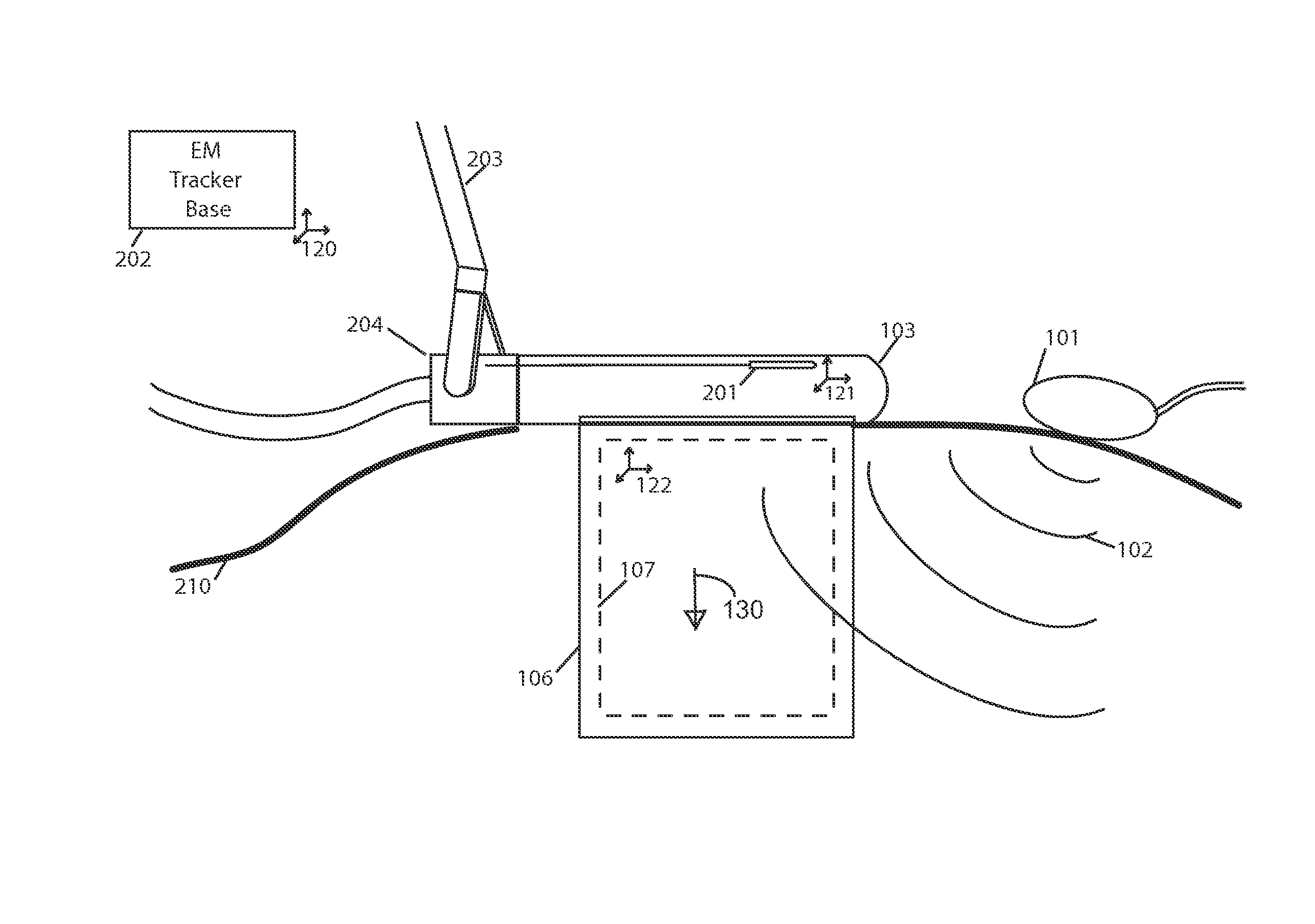

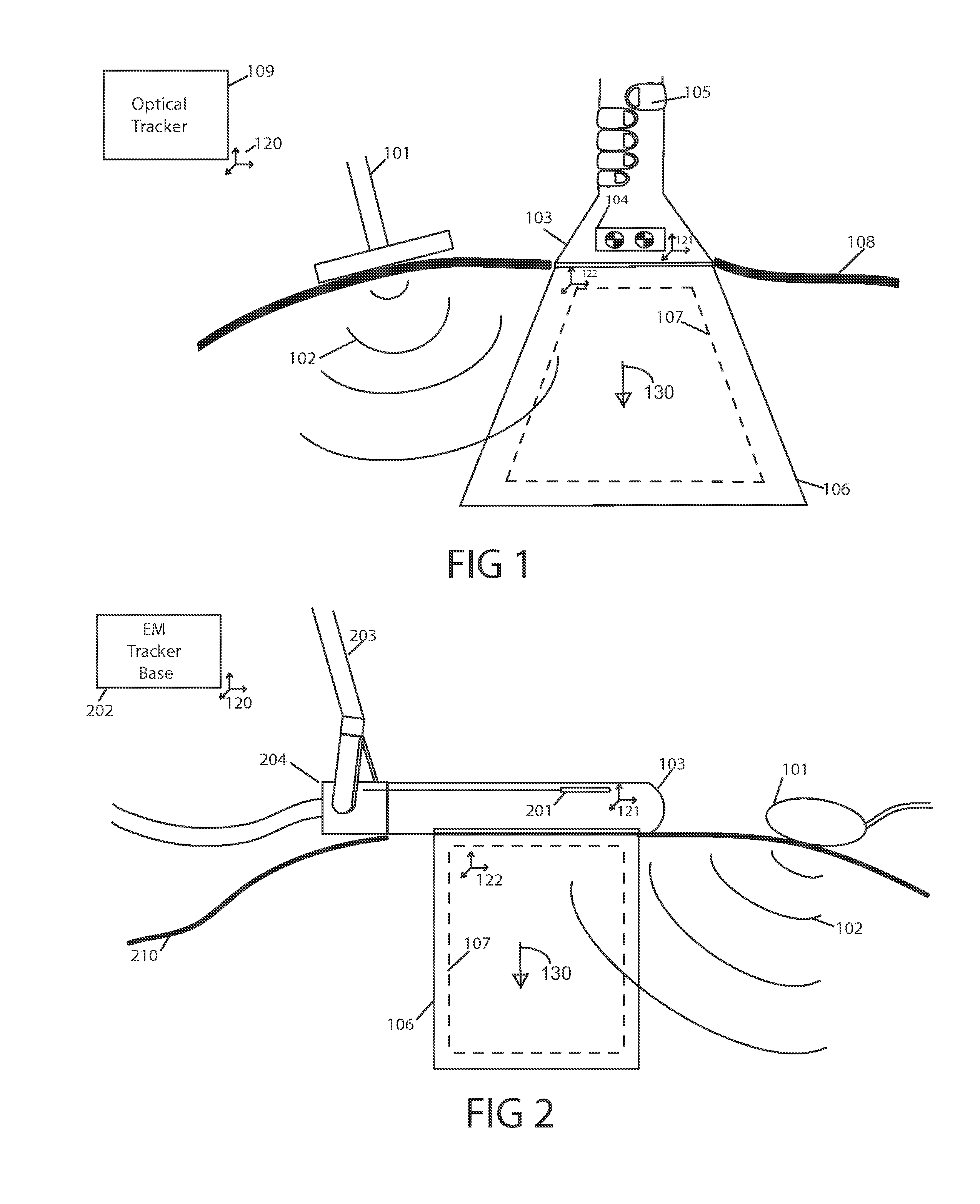

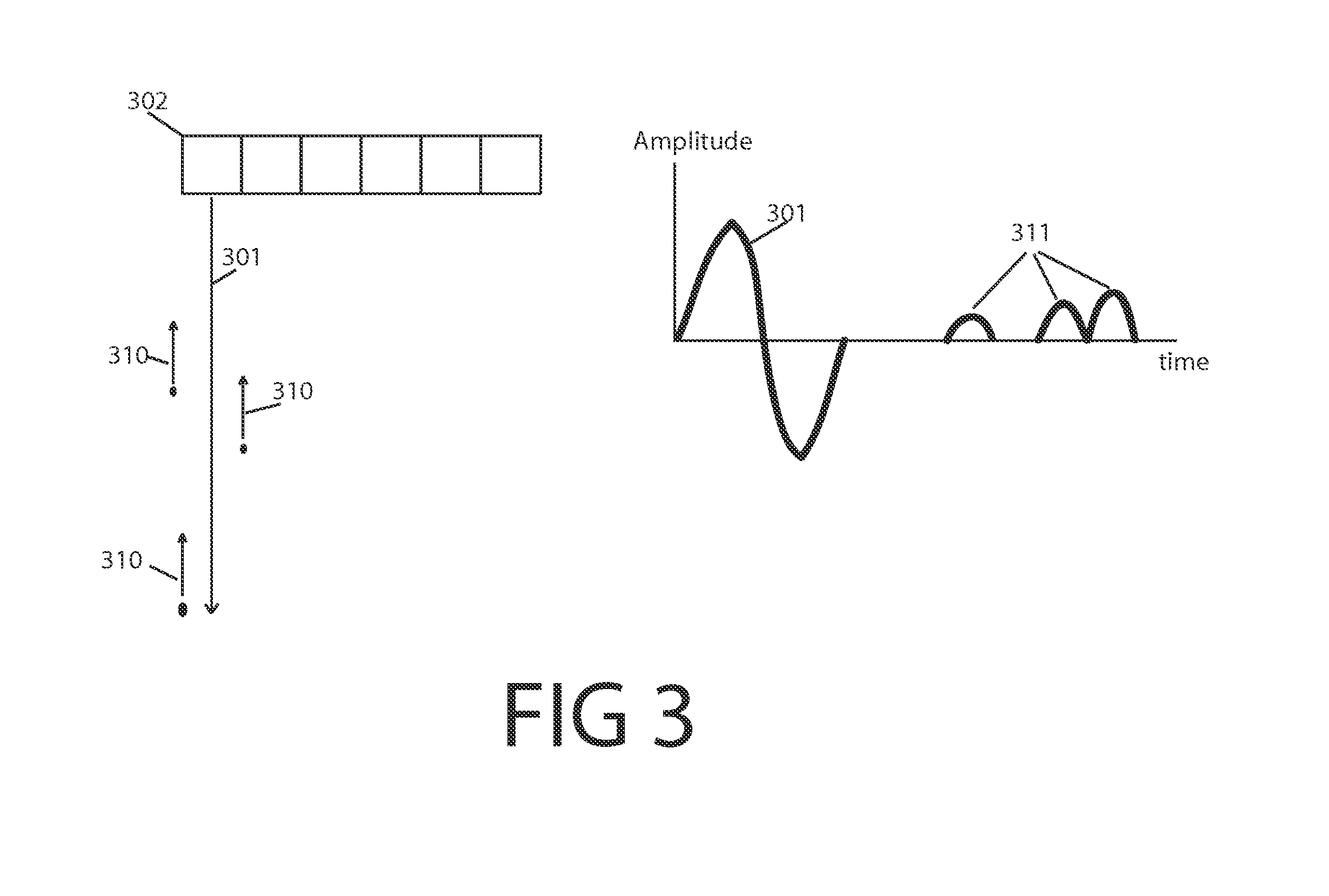

Quantitative Elastography with Tracked 2D Ultrasound Transducers

A method is described for acquiring 3D quantitative ultrasound elastography volumes. In one embodiment, the method comprises using a 2D ultrasound transducer to scan a volume of tissue through which shear waves are created using an external vibration source, the synchronized measurement of tissue motion within the plane of the ultrasound transducer with the measurement of the transducer location in space, the reconstruction of tissue displacements in time and space over a volume from this synchronized measurement, and the computation of one or several mechanical properties of tissue from this volumetric measurement of displacements. The tissue motion in the plane of the transducer may be measured at a high effective frame rate in the axial direction of the transducer, or in the axial and lateral directions of the transducer. The tissue displacements over the measured volume may be interpolated over a regular grid in order to make the computation of mechanical properties easier.

Owner:THE UNIV OF BRITISH COLUMBIA

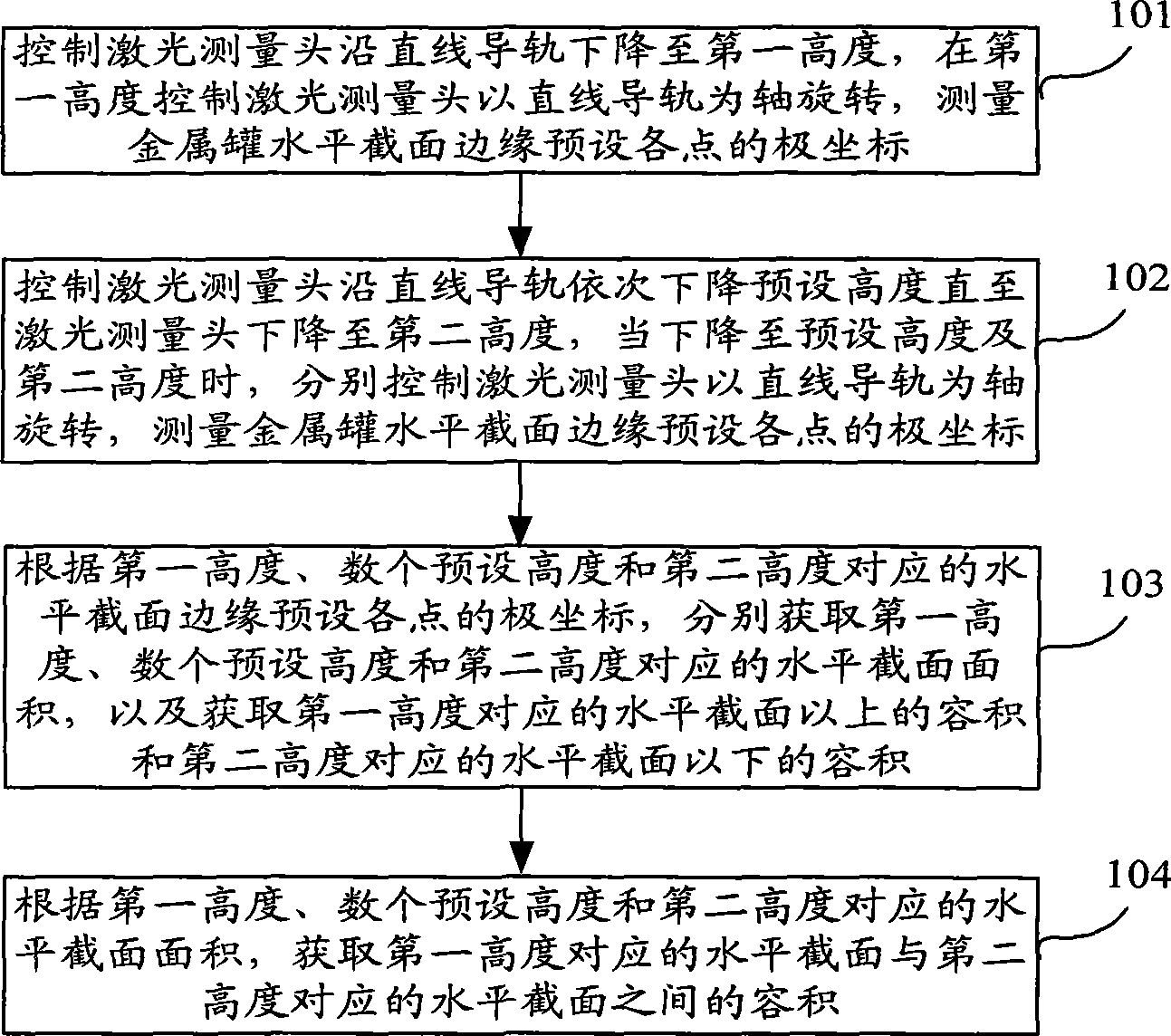

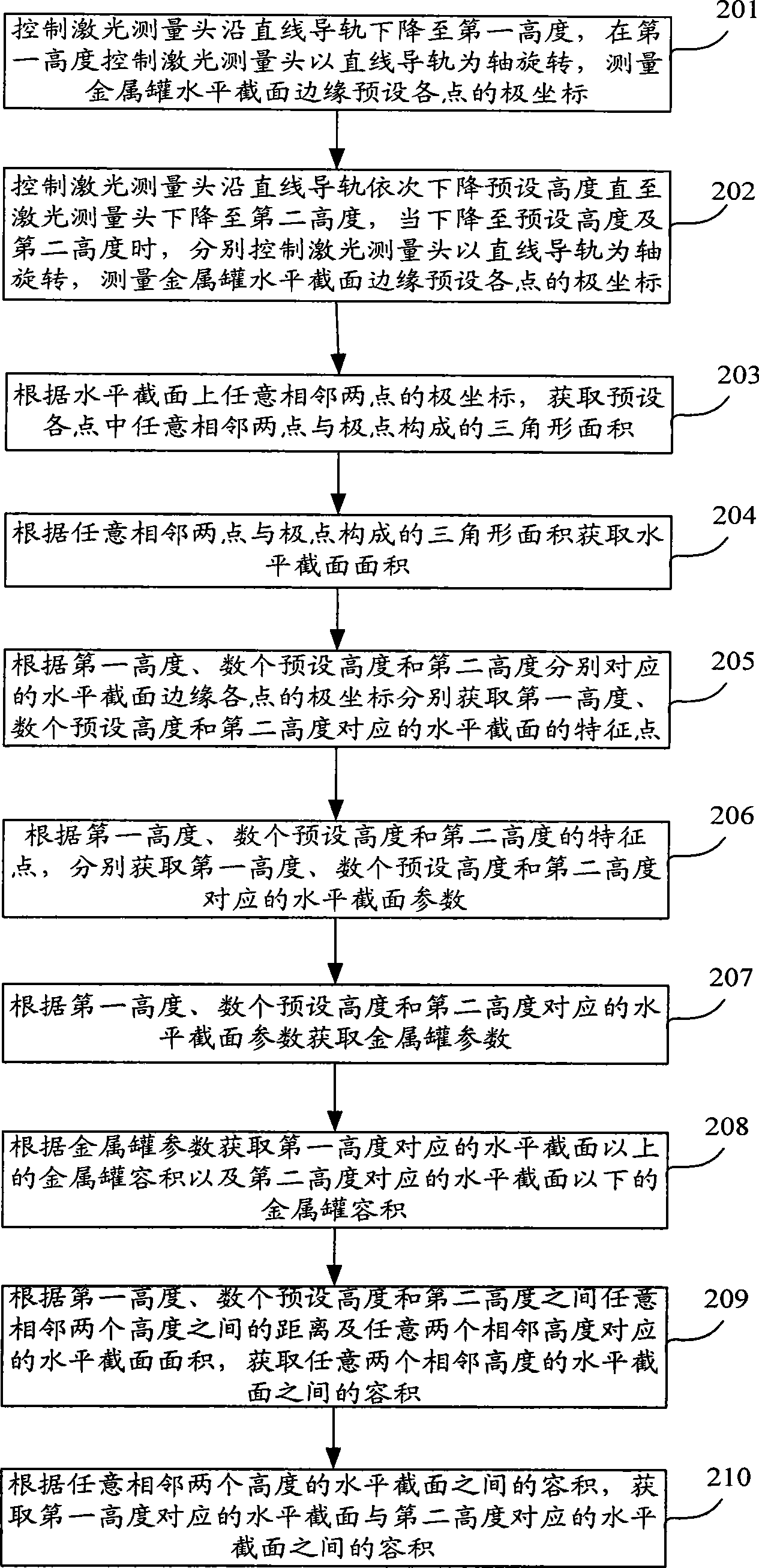

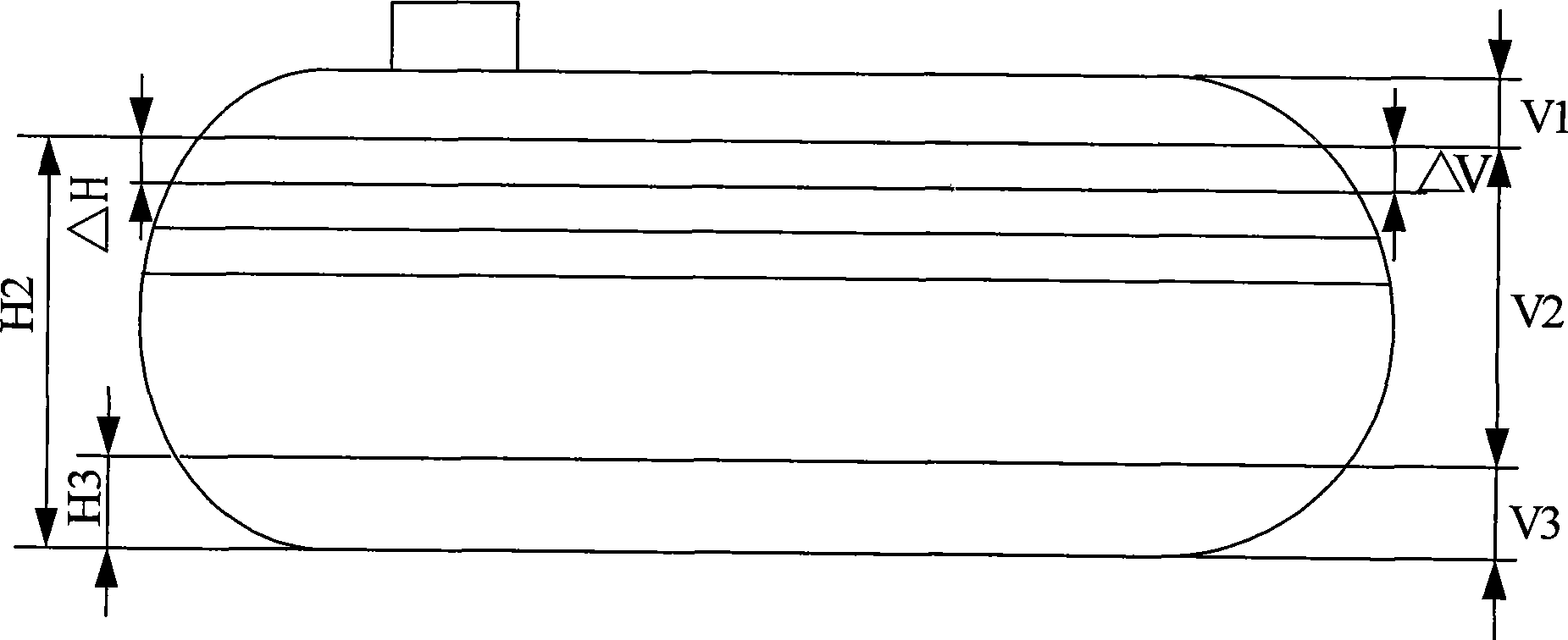

Volumetric measurement method and measurement device of horizontal metal can

The invention relates to a volumetric measurement method and a measurement device of a horizontal metal can. The method comprises the followings: laser measuring heads are controlled to be declined at a first height along a linear guide rail unit, the laser measuring heads rotates in a circle horizontally using the linear guide rail unit as a shaft at the first height, and the horizontal cross-section edge of the metal can is measured to preset the polar coordinates of each point; the laser measuring heads are controlled to be declined at a plurality of preset heights in turn till the laser measuring heads are declined at a second height, the laser measuring heads rotates in a circle horizontally using the linear guide rail unit as a shaft, and the horizontal cross-section edge of the metal can is measured to preset the polar coordinates of each point; the volume over the horizontal cross-section corresponding to the first height, the volume below the horizontal cross-section corresponding to the second height, and the volume between the horizontal cross-section corresponding to the first height and the horizontal cross-section corresponding to the second height are obtained according to the measured polar coordinates. The volumetric measurement method and measurement device of the horizontal metal can provided by the invention can automatically measure the volume of a horizontal metal can without a user, the measuring speed is quick, and the precision is high.

Owner:BEIJING INST OF OPTO-ELECTRONIC TECH +1

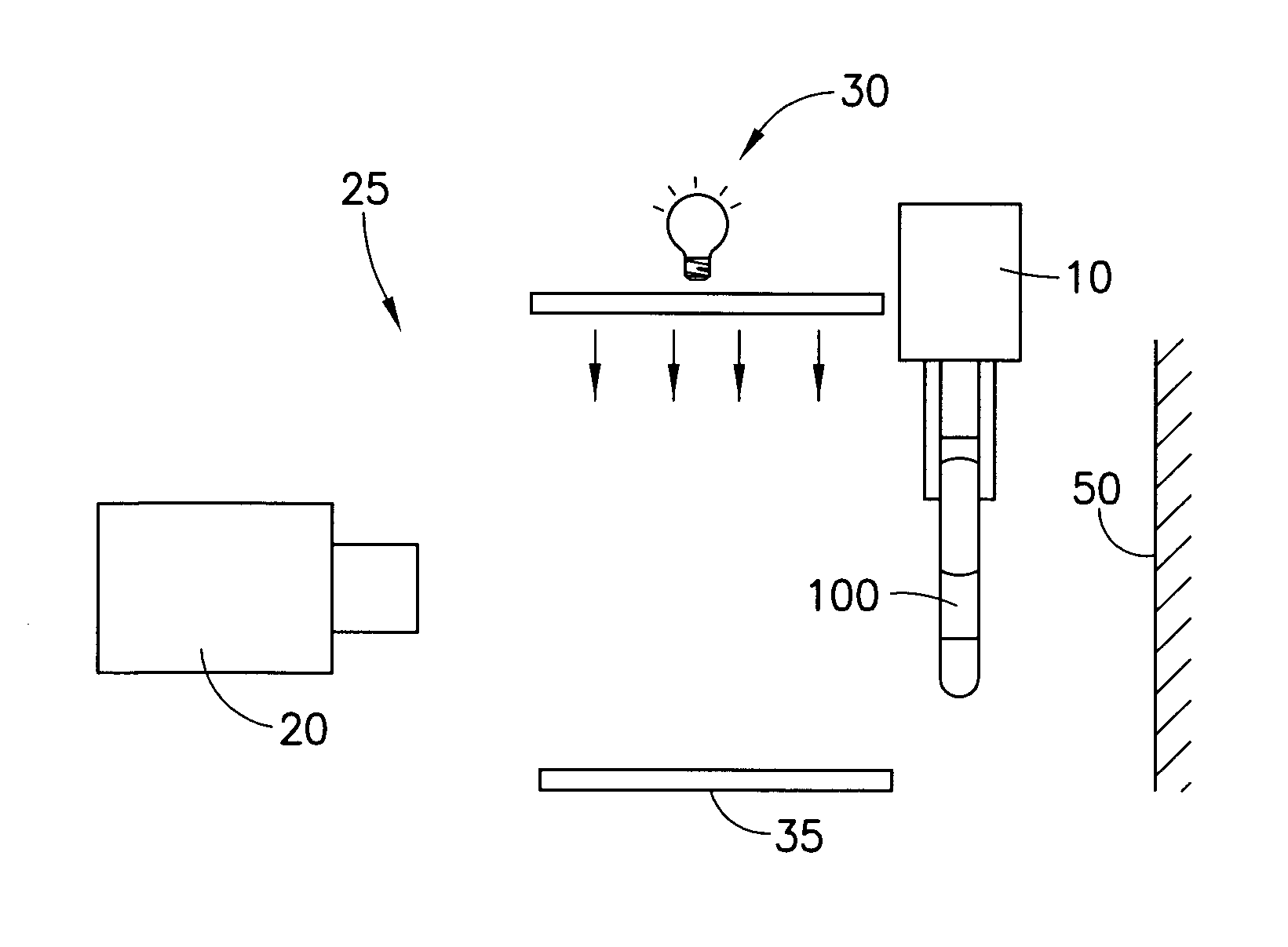

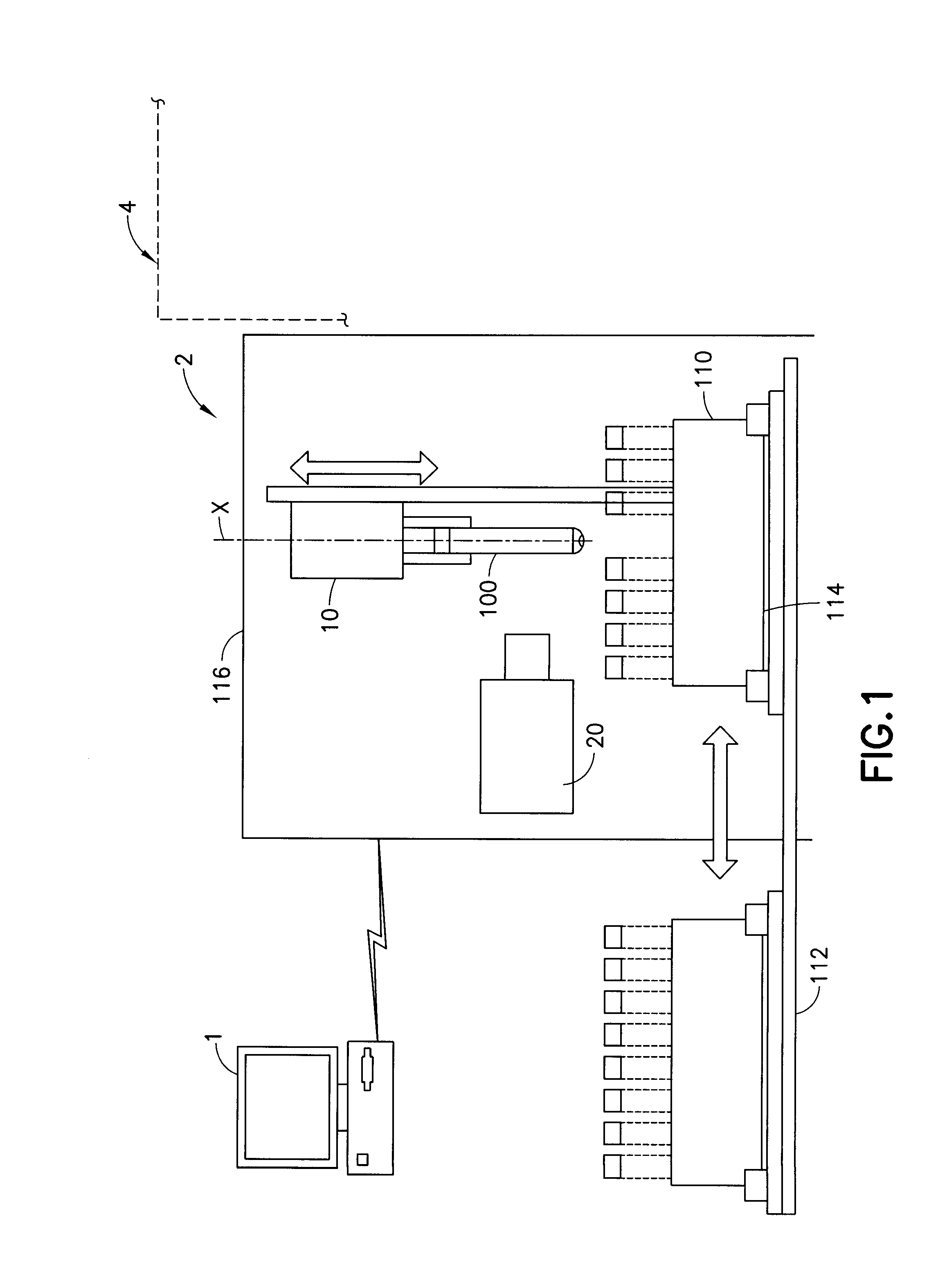

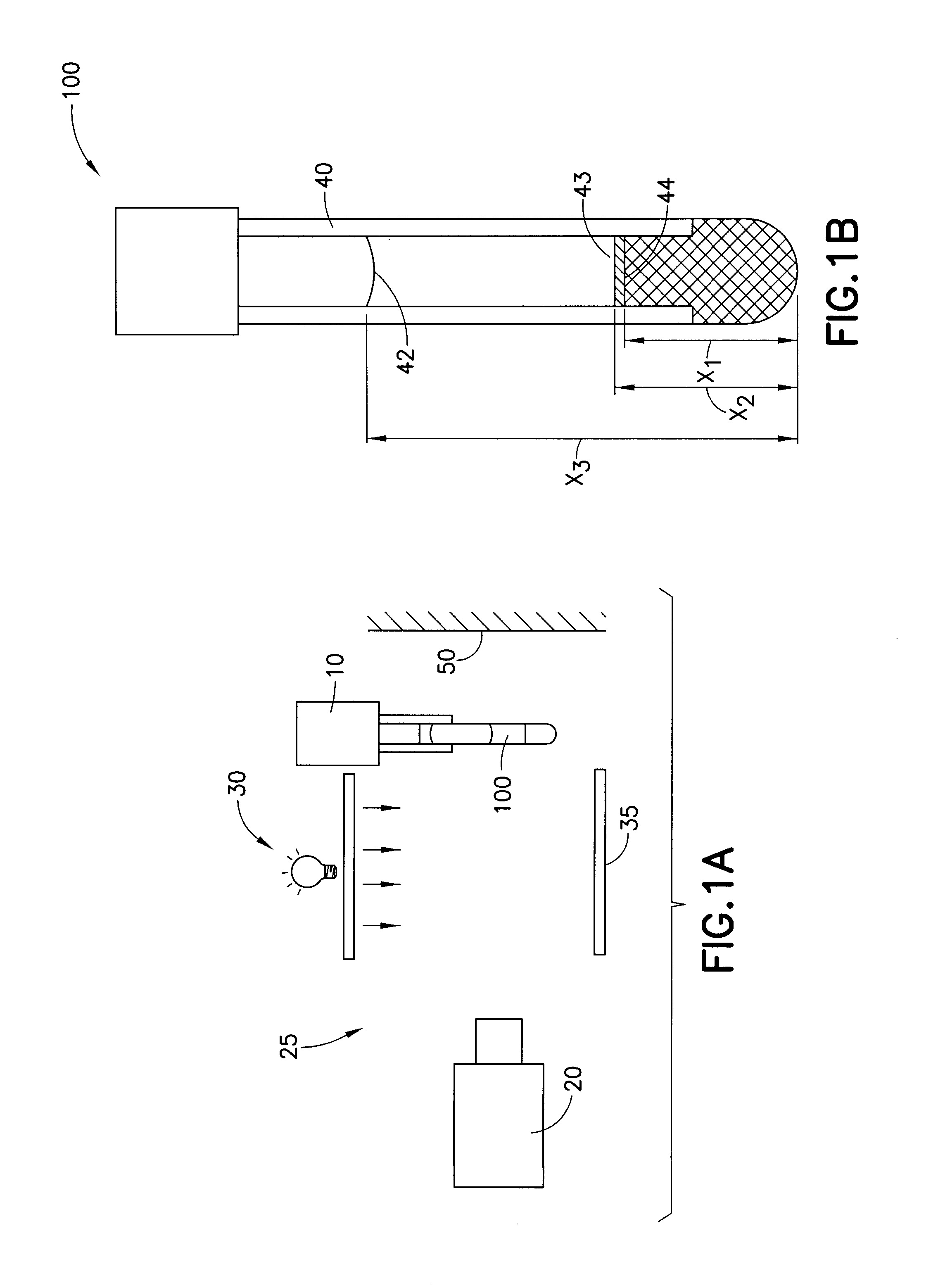

Volumetric measurement

ActiveUS20150062332A1Television system detailsColor television detailsVolumetric measurementLight source

A volumetric measurement system having an imaging device and a light source, where the light source is configured to illuminate the container and the sample regardless of a blockage or obstruction of the sample on at least part of the container.

Owner:BROOKS AUTOMATION INC

Correcting apparatus enhancing volume measuring accuracy of small size bell jar and correcting method thereof

ActiveCN1948930AAvoid disadvantages that reduce calibration accuracyPromote inconsistencyTesting/calibration apparatusDraining tubeGraduated cylinder

The invention relates to calibrating device used to increase mini-size bell jar volumetric measurement accuracy. It includes impounding container, four exhaust valves, eight glass cock valves, globe, electric-magnetic stop valve, silicone tube, tubule needle head type drainpipe, small caliber weighing cylinder. The glass pipeline is the main structure of the whole device. The calibrating method includes the following steps: connecting the pipeline as the calibrating device; complementing water and exhausting gas; adjusting their flow quantity; elevating the ball jar; finishing the calibrating by n is not less than 6 times. The invention realize super mini-size bell jar metering volume (minimum volume reaches 10ml) high accuracy calibrating, increase flow measurement accuracy of the micro gas flow calibrating device used super mini-size bell jar as main standard.

Owner:BEIJING AEROSPACE INST FOR METROLOGY & MEASUREMENT TECH

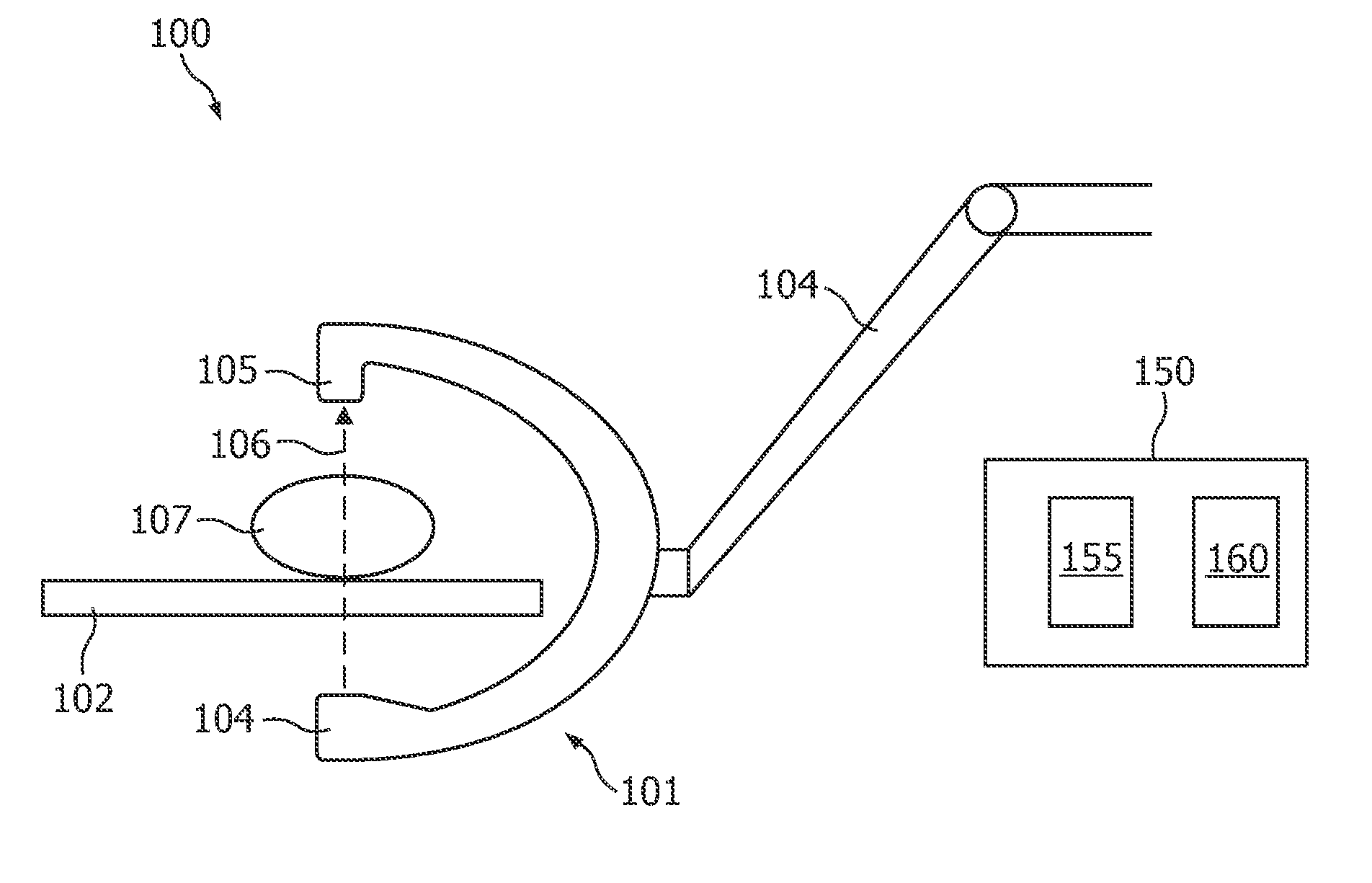

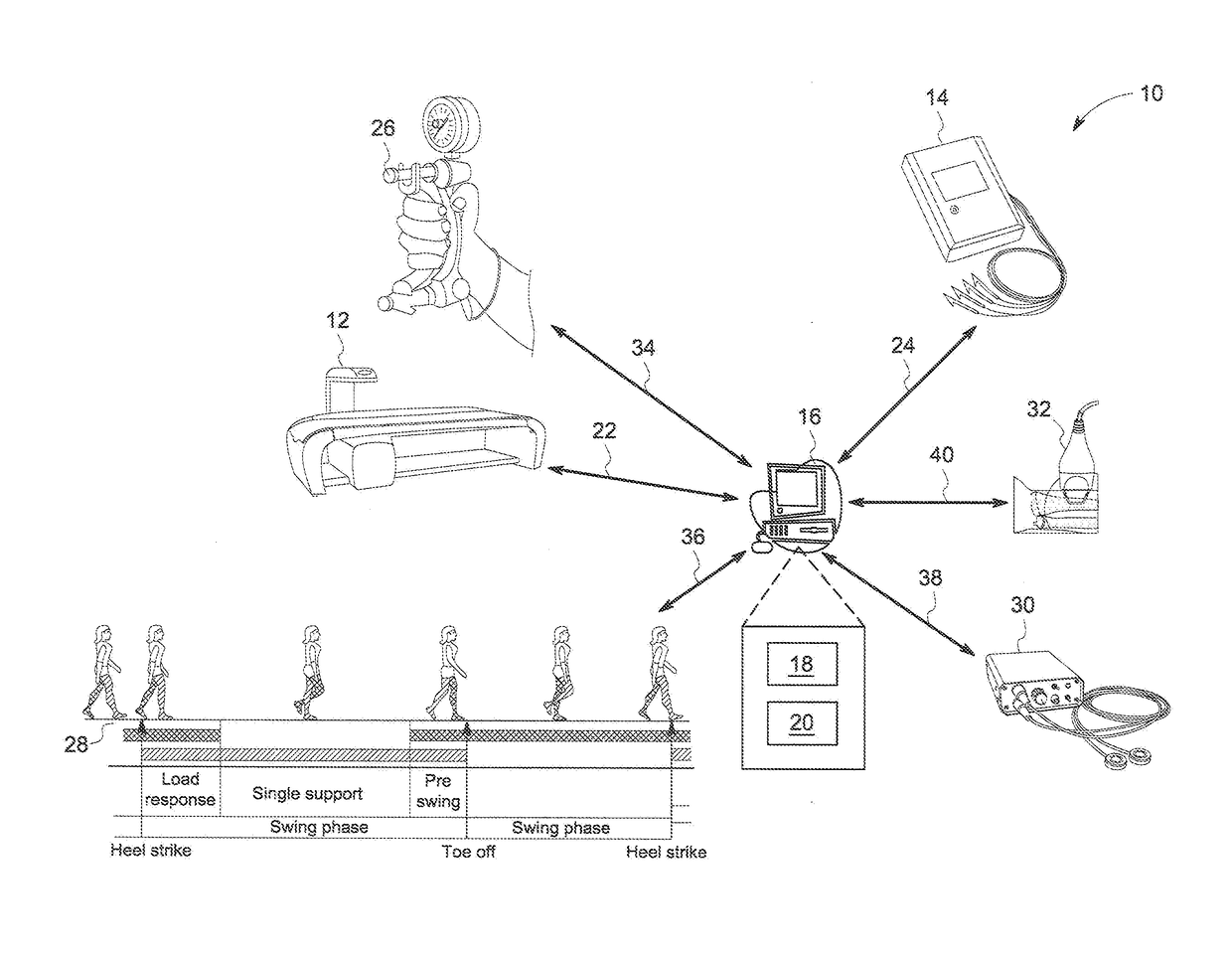

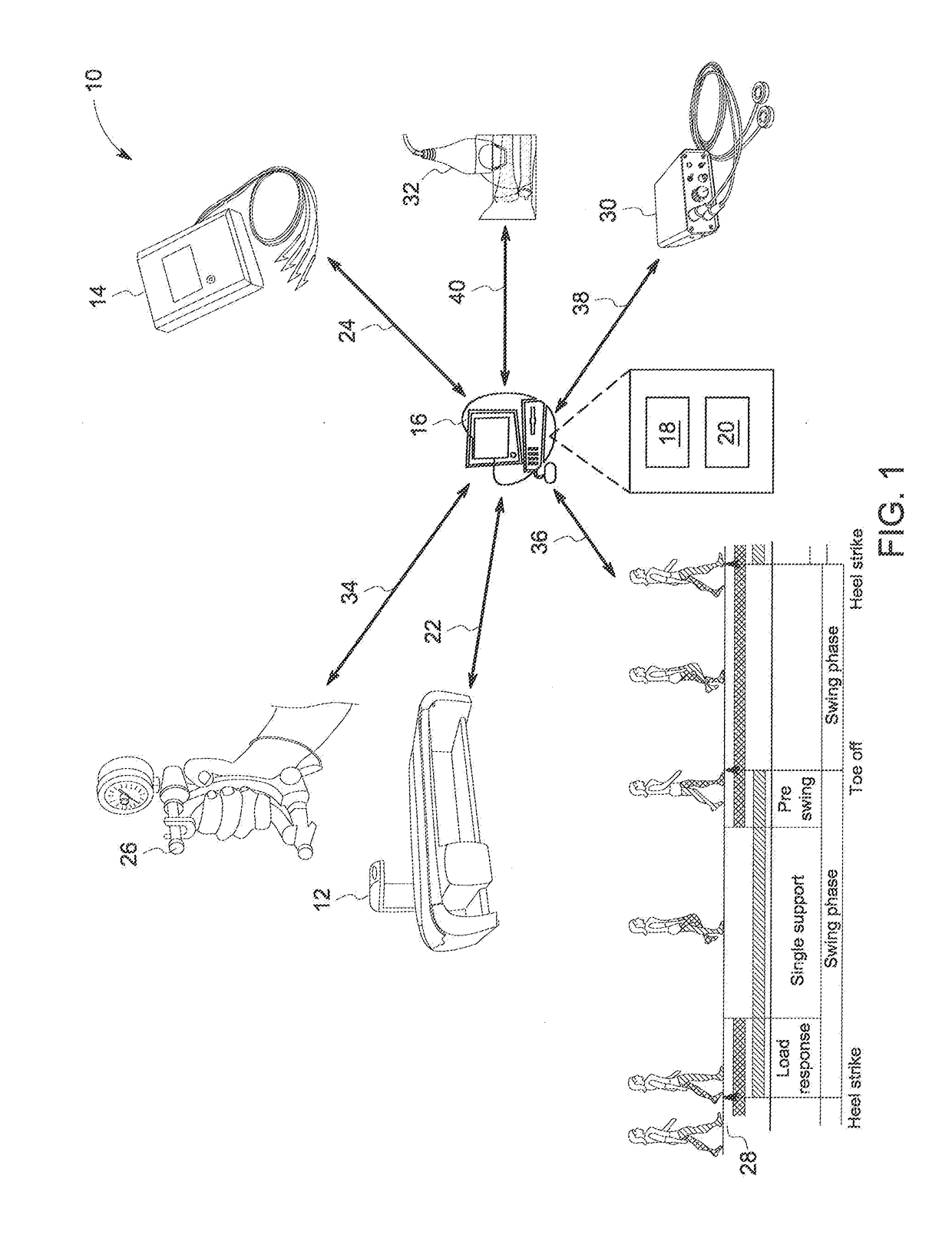

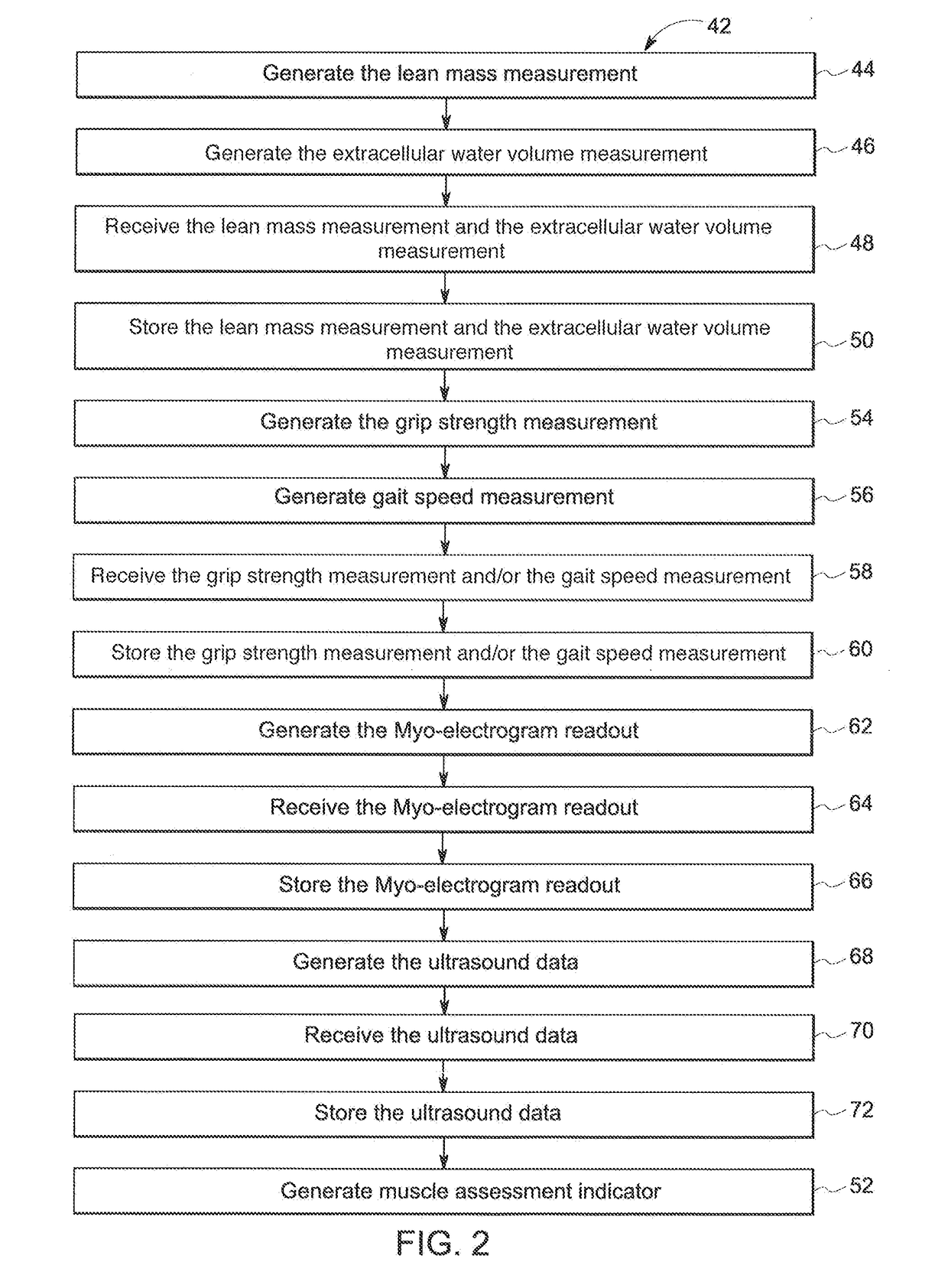

System and method for assessing muscle function of a patient

ActiveUS20180168530A1Health-index calculationRadiation diagnostic clinical applicationsBioelectrical impedance analysisMuscle functions

A system for assessing muscle function of a patient is provided. The system includes: a dual-energy X-ray absorptiometry device operative to scan the patient so as to generate a lean mass measurement; a bioelectrical impedance analysis device operative to scan the patient so as to generate an extracellular water volume measurement; and a controller that includes at least one processor and a memory device, the controller in electrical communication with the dual-energy X-ray absorptiometry device and the bioelectrical impedance device. The controller is adapted to: receive the lean mass measurement and the extracellular water volume measurement; store the lean mass measurement and the extracellular water volume measurement in the memory device; and generate a muscle assessment indicator of the patient based at least in part on the lean mass measurement and the extracellular water volume measurement stored in the memory device.

Owner:GENERAL ELECTRIC CO

Volumetric measurement of beverage

ActiveCN102985352ARelieve pressureVolume measurement and fluid deliveryContainer/cavity capacity measurementEngineeringHigh pressure

A method for determining a volume of beverage, preferably a carbonated beverage in a collapsible beverage container, comprises a beverage dispensing system including a pressure chamber with the collapsible container, the pressure chamber defining an inner volume equal to the sum of the volume of beverage and a residual gas volume. The method also comprises a pressurization system for supplying a volume of gas of atmospheric pressure from the outside of the pressure chamber to the residual gas volume, and a pressure sensor for detecting a low pressure value and a high pressure value, respectively. The method further comprises the steps of supplying the volume of gas to the residual gas volume by using the pressurization system, determining the volume of gas supplied by the pressurization system from the outside of the pressure chamber to the residual gas volume, and establishing a measure of the volume of beverage included in the collapsible beverage container.

Owner:CARLSBERG BREWERIES AS

Spatial characterization of a structure located within an object by identifying 2D representations of the structure within section planes

InactiveCN101523438AAvoid or counteract local flow neckingClearly present the shapeImage enhancementImage analysisSonificationSection plane

It is described a virtual pullback as a visualization and quantification tool that allows an interventional cardiologist to easily assess stent expansion. The virtual pullback visualizes the stent and / or the vessel lumen similar to an Intravascular Ultrasound (IVUS) pullback. The virtual pullback is performed in volumetric data along a reference line. The volumetric data can be a reconstruction of rotational 2D X-ray attenuation data. Planes perpendicular to the reference line are visualized as the position along the reference line changes. This view is for interventional cardiologists a very familiar view as they resemble IVUS data and may show a section plane through a vessel lumen or a stent. In these perpendicular section planes automatic measurements, such as minimum and maximum diameter, and cross sectional area of the stent can be calculated and displayed. Combining these 2D measurements allows also volumetric measurements to be calculated and displayed.

Owner:KONINK PHILIPS ELECTRONICS NV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com