System and method for measuring true volume of gathered-state substances with gaps

A measurement system, a technology of true volume, applied in measurement devices, fluid devices, instruments, etc., can solve the problems of difficult measurement of volume and density, reduced accuracy of measurement results, and difficulty in reaching a sealed state, achieving strong practicability, Avoid low or even unreliable measurement accuracy, simple and practical device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

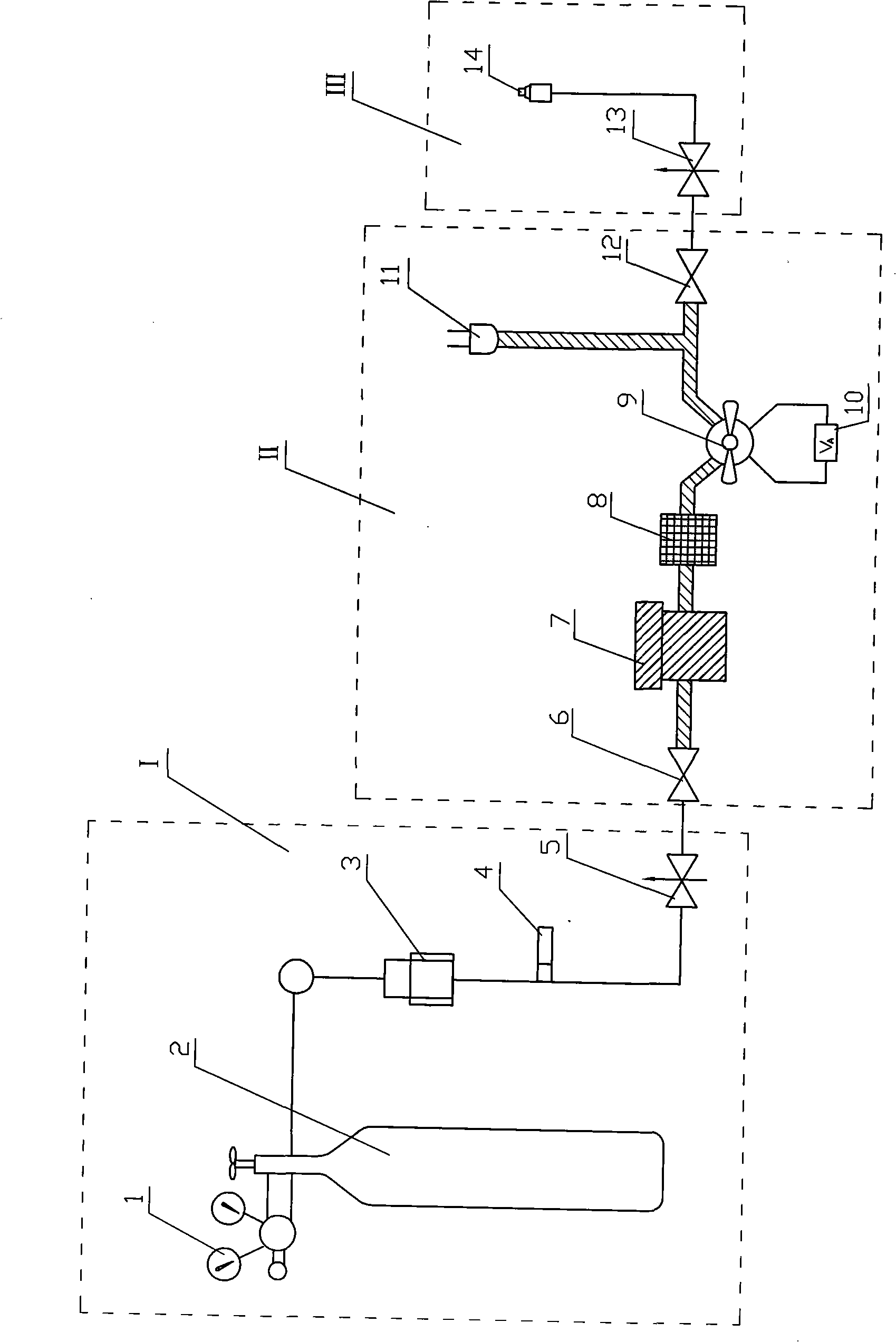

[0050] A true volume measurement system for interstitial substances in a collective state, including a gas input part I composed of a gas cylinder 2 connected in sequence, a gas input port 3, an overpressure protection valve 4, and an input air flow control valve 5, connected in sequence The closed measurement part II with the intake and exhaust switch valves composed of the input air flow switch valve 6, the sample pool to be tested 7, the filter screen 8, the standard volume access valve 9, the standard volume chamber 10 and the exhaust switch valve 12 is composed of The exhaust part III composed of the exhaust gas flow control valve 13 and the exhaust interface 14 is also equipped with a pressure sensor 11 between the standard volume access valve 9 and the exhaust switch valve 12;

[0051] The input air flow control valve 5 of the gas input part I communicates with the input air flow switching valve 6 of the closed measurement system II, and is used to control the gas input ...

Embodiment 2

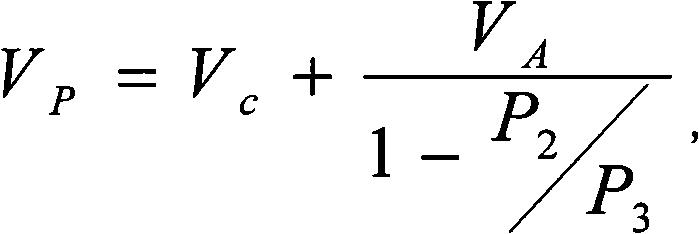

[0058] A method for measuring the true volume of interstitial substances in an aggregated state. The method is to use the measurement system described in Embodiment 1 of the present invention, using helium or nitrogen as the measurement medium, and place a sample of interstitial substances in an aggregated state. Into the sample cell of the measurement system, first fill the entire measurement system with the gas measurement medium, then close the exhaust switch valve and the standard volume access valve of the closed measurement part of the belt inlet and exhaust switch valves, and supply the inlet and exhaust switch valves The closed measuring part of the valve is filled with gas measuring medium until the pressure value of the closed measuring part of the intake and exhaust switching valve is higher than the ambient pressure of 1.195kg / cm 2 When, measure its pressurized pressure value P 2 , after that, connect the standard additional volume and measure the pressure P of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com