Mercury injection capillary pressure curve roughening method

A capillary pressure curve, coarsening technology, applied in suspension and porous material analysis, instrumentation, permeability/surface area analysis, etc., can solve problems such as large influence, poor curve representation, porosity is not considered, etc., to achieve a solid theoretical foundation , the effect of increasing representativeness and increasing flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

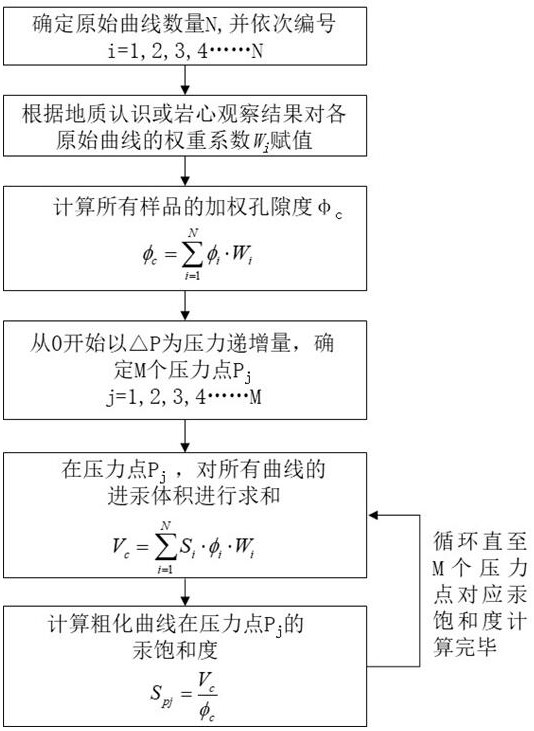

[0042] A method for roughening a mercury injection capillary pressure curve, comprising the steps of:

[0043] a. Determine the number N of original sample curves;

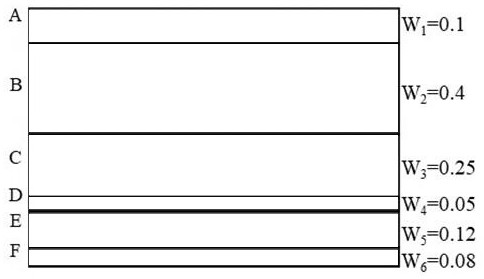

[0044] b. Weight coefficient W for each original curve i Assign values to obtain synthetic samples;

[0045] c. Calculate the weighted porosity φ of the synthetic sample c ;

[0046] d. Starting from the 0 pressure point, take △P as the pressure increment to determine M pressure points P j ;

[0047] e. Cycle through pressure points one by one, at each pressure point P j , sum the mercury injection volumes of the synthesized samples, and calculate the roughened curve at P j The mercury saturation corresponding to the pressure point.

[0048] In the step a, the number N of core samples whose original capillary pressure curve needs to be roughened is determined and numbered in sequence.

[0049] In the step b, the ratio W of the reservoir thickness represented by each sample to the total reservoir thicknes...

Embodiment 2

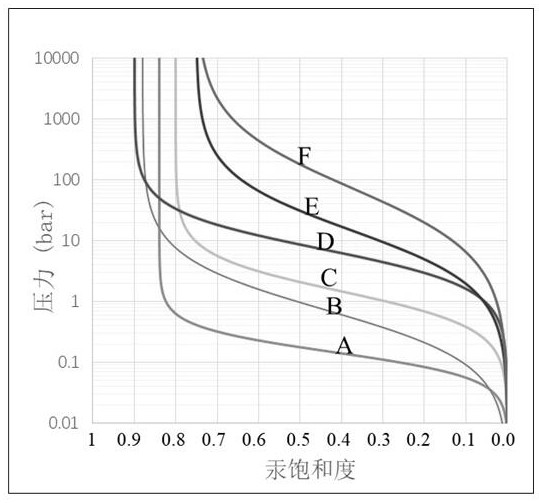

[0067] A mercury injection capillary pressure curve roughening method can synthesize N capillary pressure curves obtained from N samples into one capillary pressure curve, aiming to solve the representative problem of capillary pressure curves in oil and gas reservoir evaluation. The method flow is as follows figure 1 As shown, all samples in the figure are synthetic samples. This method first determines the weight of a single sample curve (W i ) and the total number of samples (N), and then according to the porosity of a single sample (φ i ), to calculate the porosity of the synthetic sample (φ c ) and the mercury injection volume at any pressure point (V c ). Finally, the porosity of the synthesized sample was divided by the mercury injection volume at any pressure point to obtain the mercury saturation at any pressure point. This method is based on the basic principle and experimental process of mercury intrusion experiment, and fully considers that the change of mercu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com