Method for obtaining J resistance curve of ductile material by I type crack elastoplasticity theoretical equation

A technology of resistance curve and ductile material, which is applied in the direction of analyzing materials, testing material strength by applying stable bending force, testing material strength by applying stable tension/compression, etc. The process is cumbersome and other problems, to achieve the effect of easy popularization and application, solid theoretical foundation, and clear physical meaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0032] The invention includes two parts: round bar uniaxial tension test and I-type crack sample test, J integral calculation principle-finite element model.

[0033] 1. Round bar uniaxial tensile test and type I crack test

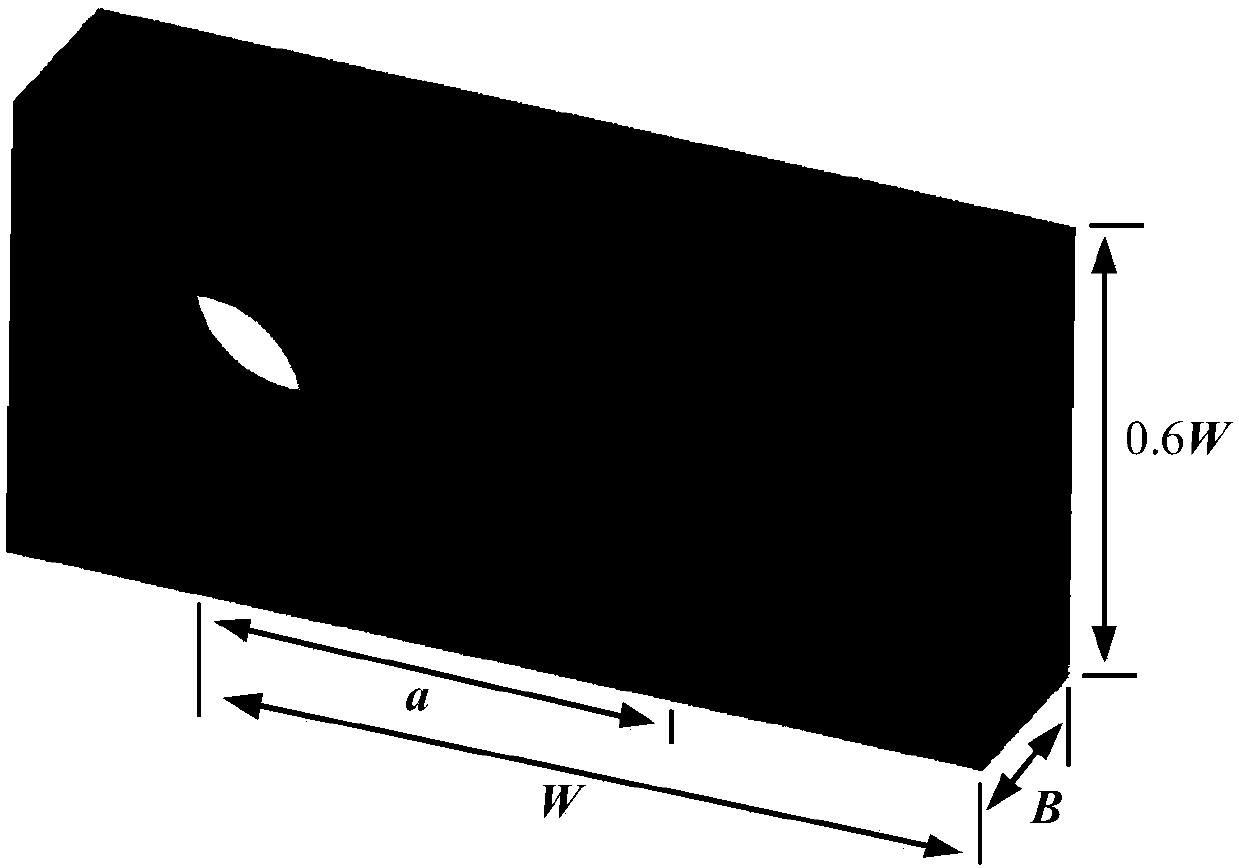

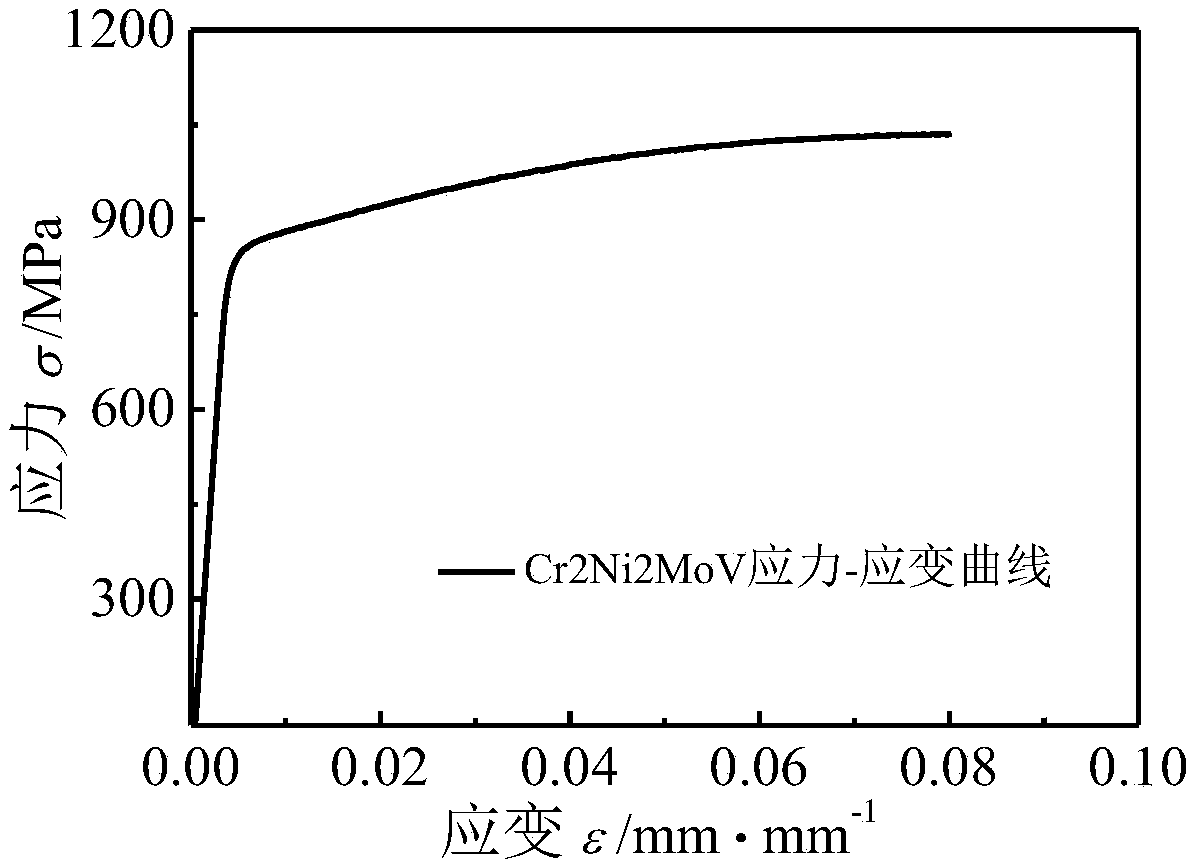

[0034] Carry out round bar uniaxial tensile test on ductile materials to obtain their true stress-strain curves, and then use the fracture toughness test method recommended by the national standard GB / T21143-2014 to carry out the fracture toughness test of CT specimens. The specimen width W=50mm, thickness B =25mm, the crack length a / W is between 0.5 and 0.8, and the P-h test curve of the sample is obtained by stretching.

[0035] 2. Calculation principle of J integral - finite element model

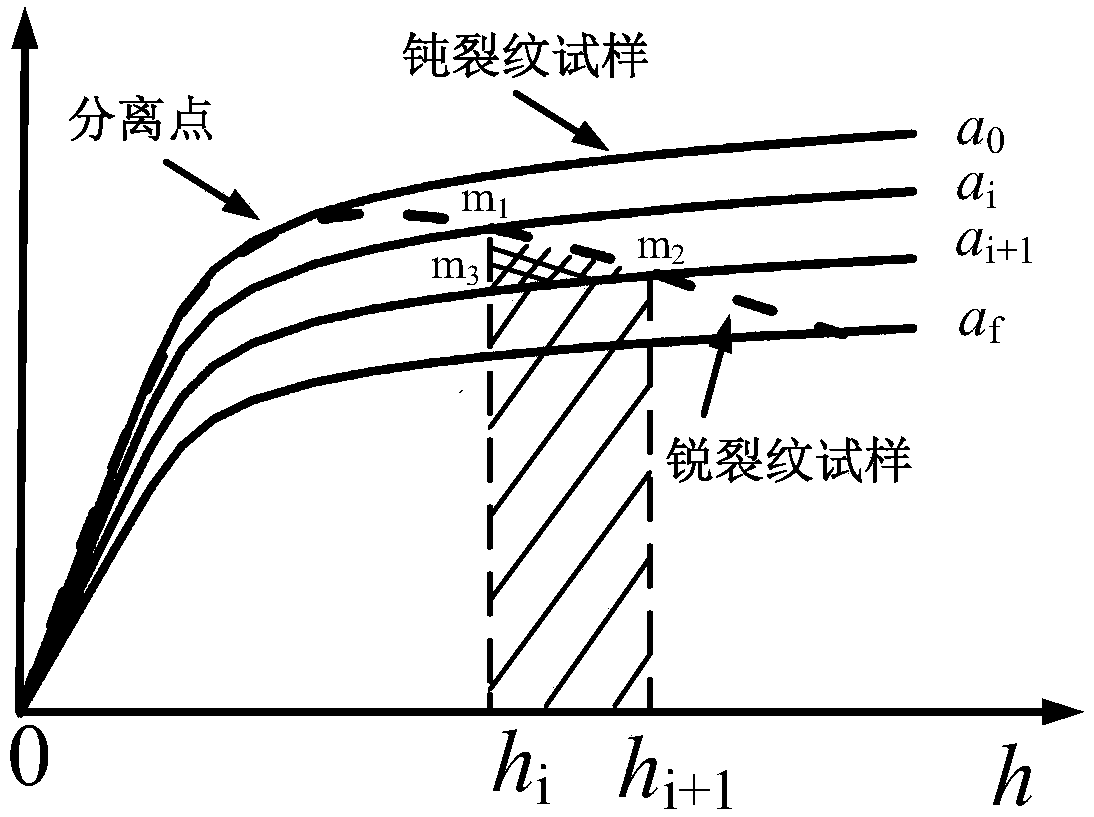

[0036] figure 2 The three-dimensional finite element simulation model of the CT sample is given. Through theoretical ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com