Patents

Literature

32 results about "Adiabatic process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

An adiabatic process occurs without transfer of heat or mass of substances between a thermodynamic system and its surroundings. In an adiabatic process, energy is transferred to the surroundings only as work. The adiabatic process provides a rigorous conceptual basis for the theory used to expound the first law of thermodynamics, and as such it is a key concept in thermodynamics.

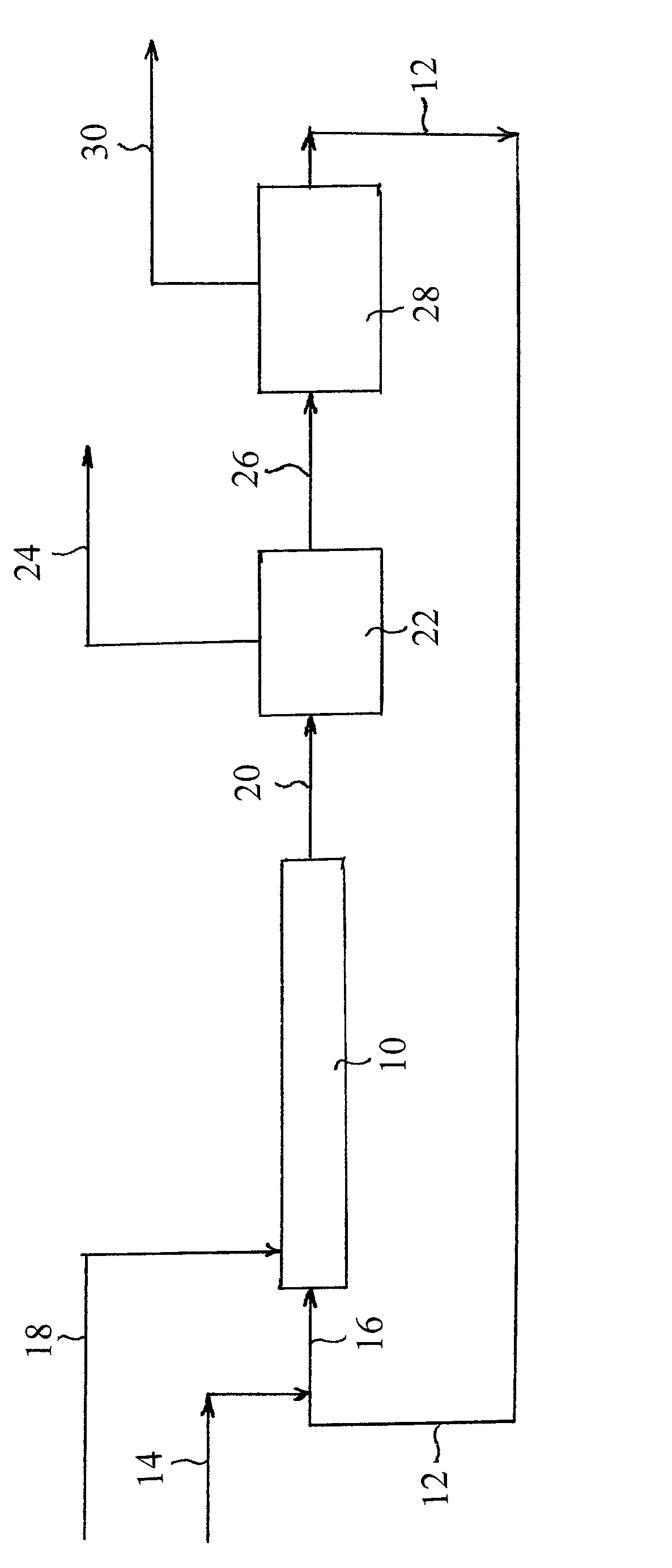

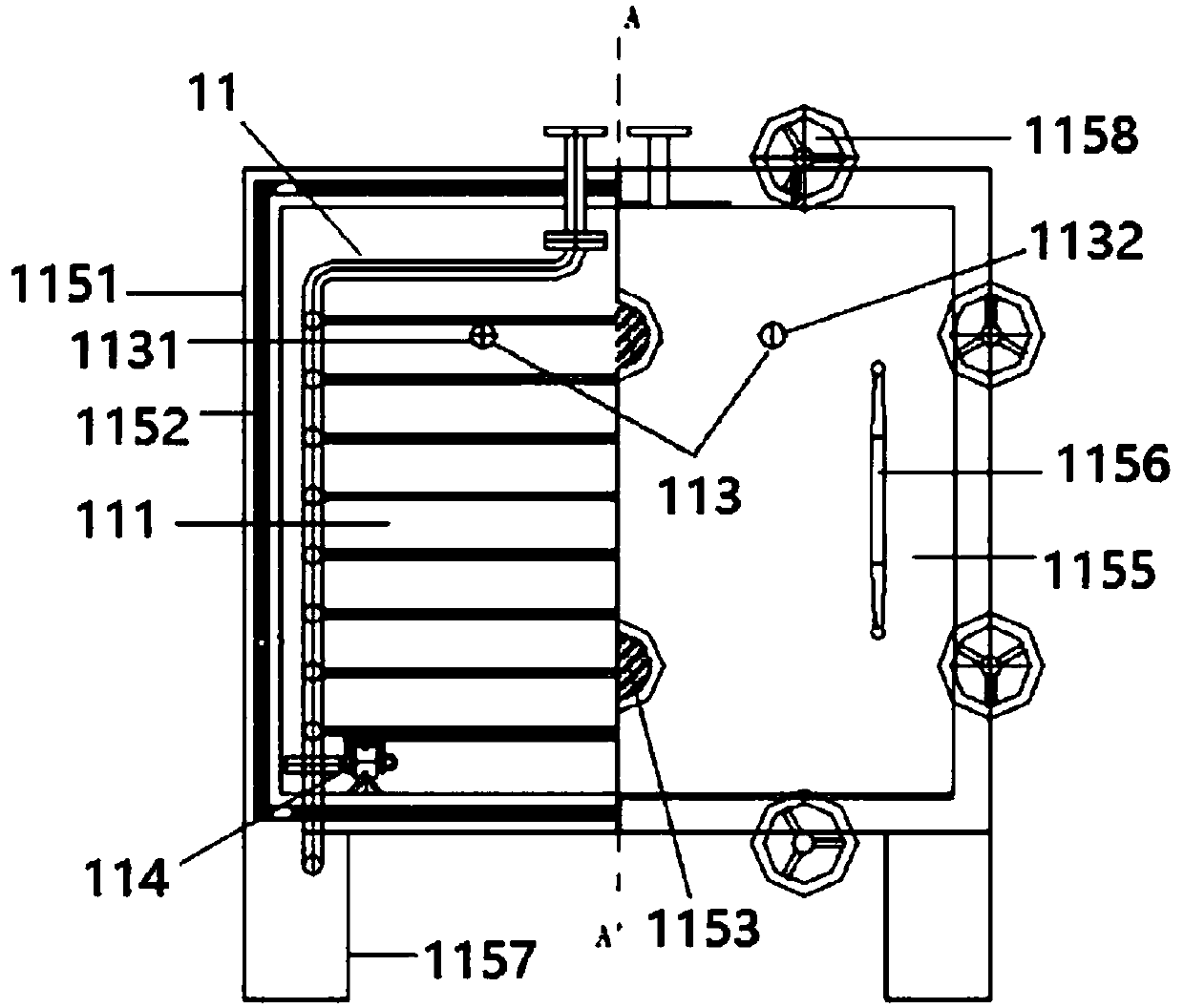

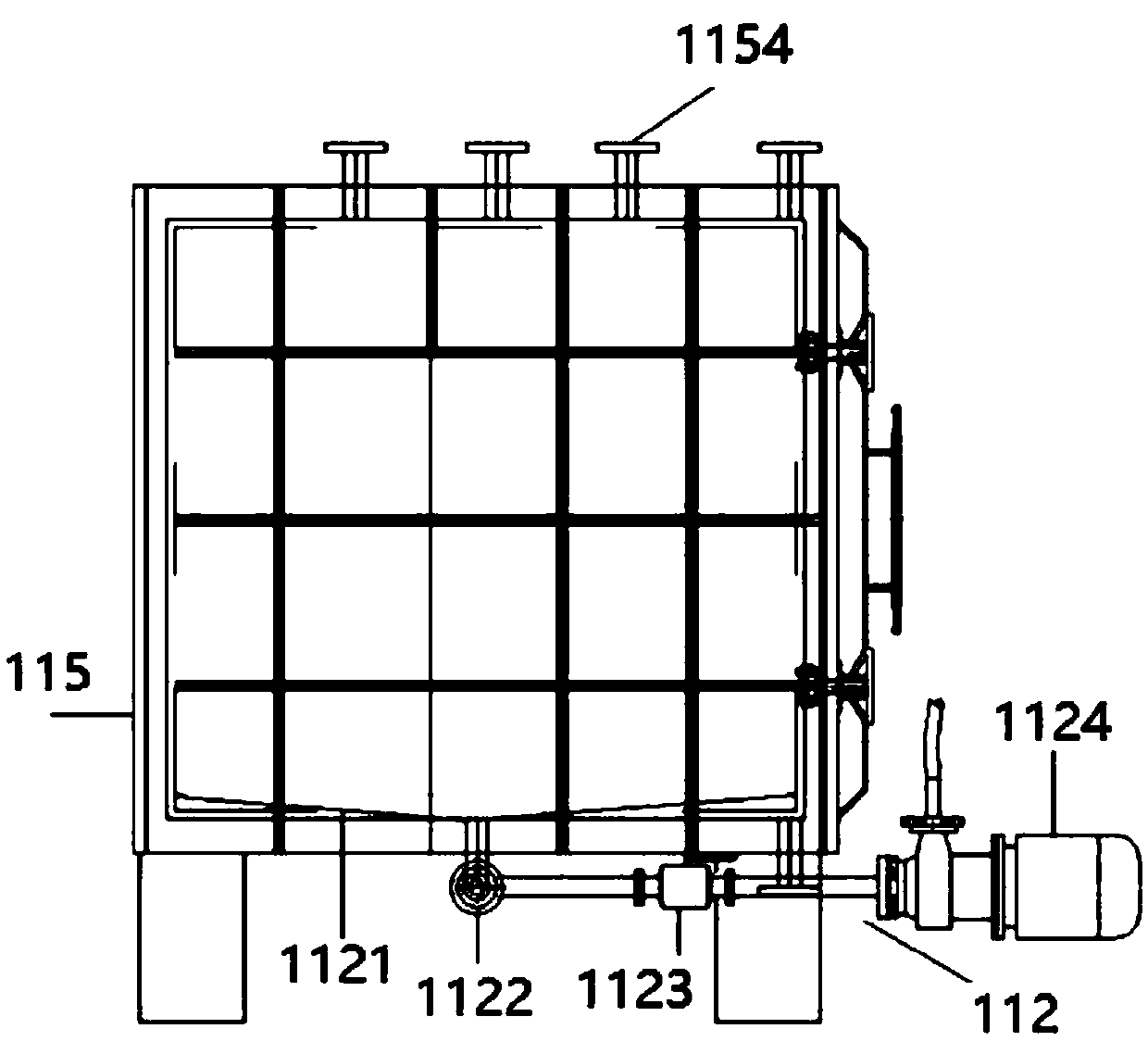

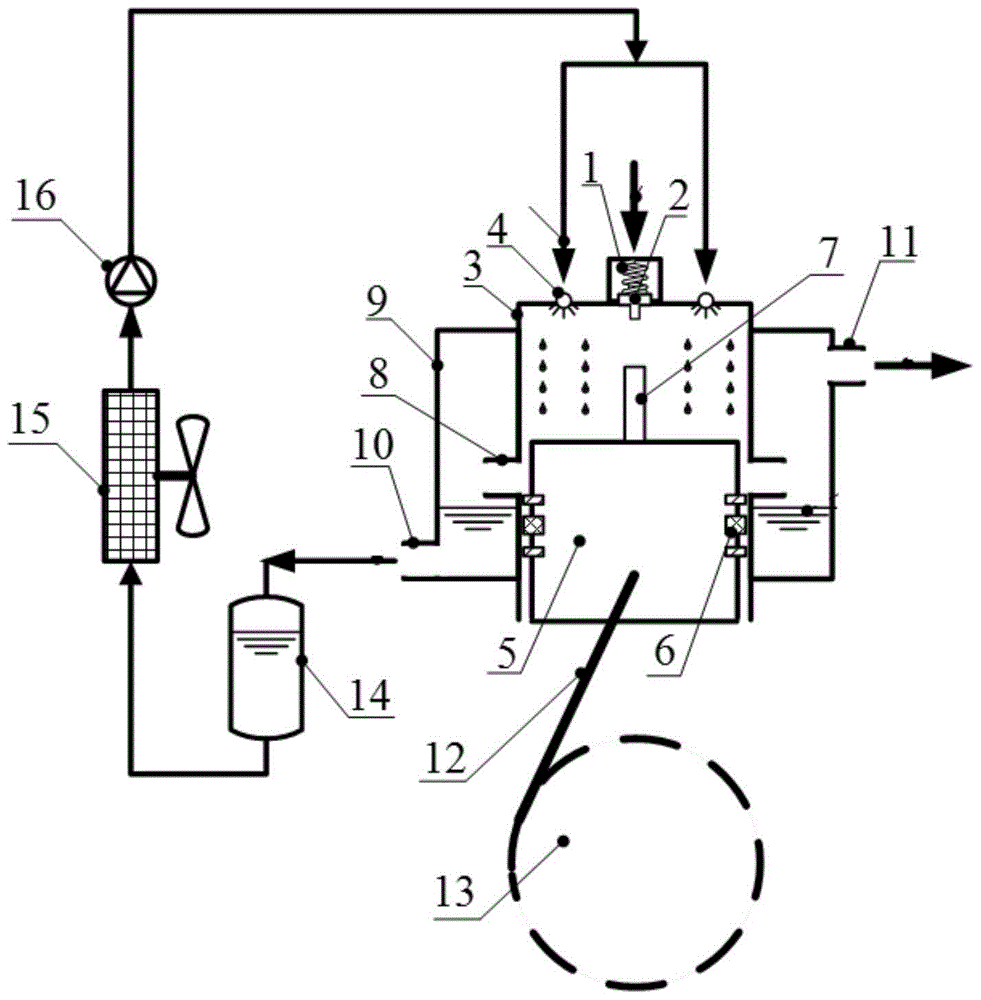

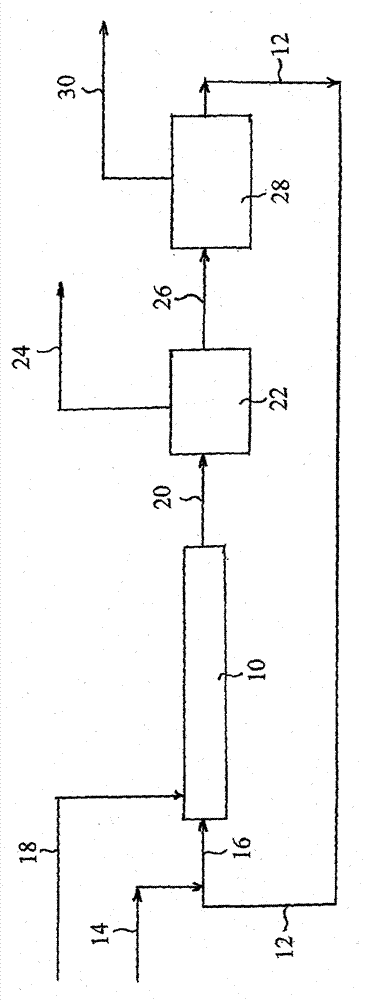

Constant temperature compressed air energy storage system and method

ActiveCN104806313AReduce the temperatureGood technical effectPositive displacement pump componentsPiston pumpsVapor–liquid separatorAdiabatic process

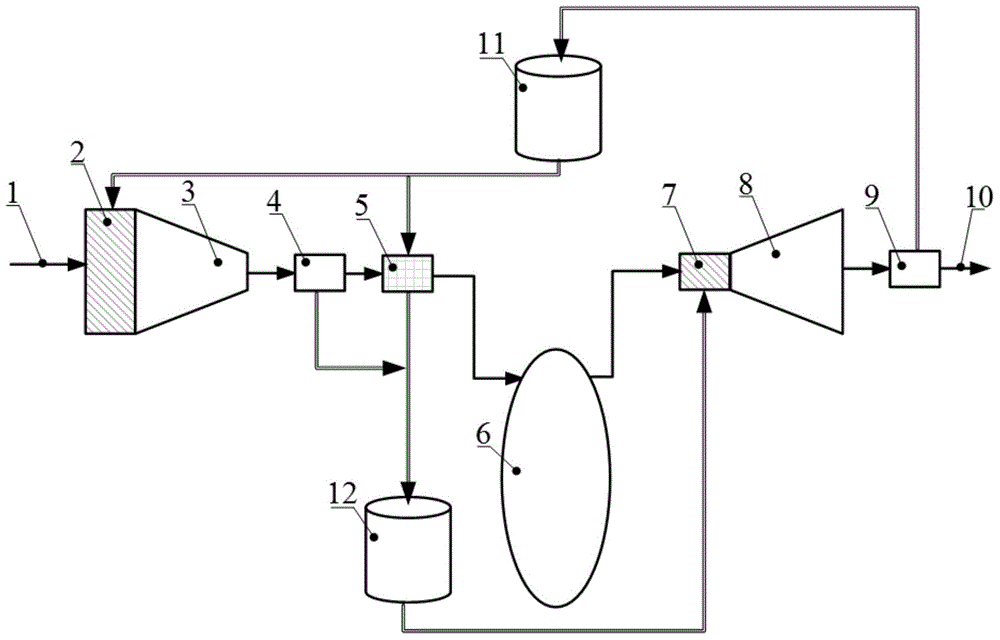

The invention relates to a constant temperature compressed air energy storage system and method. Ejectors are respectively arranged at air inlets of a compressor unit and an expander unit; during an energy storage compressing process, a quasi isothermal compression process is realized by spraying a mist or spumescent liquid heat transfer medium into the compressed air, so that the compression work of unit working medium is reduced; an air-liquid separator is assembled behind the compressor unit and is used for separating and storing the cooling medium in the compressed air; during an energy-releasing expansion process, a quasi isothermal expansion process is realized by spraying the mist or spumescent liquid heat transfer medium into the gas during the expansion process, so that the output work of unit working medium is increased and the whole efficiency of the system is increased. Compared with the traditional compressed air energy storage system, the constant temperature compressed air energy storage system has the advantages that the compressing and expanding processes can be obviously deviated from the adiabatic process, the almost constant-temperature quasi isothermal compression and quasi isothermal expansion processes are acquired, and the working efficiency of the system is increased.

Owner:中储国能(北京)技术有限公司

Method and device for on-line acoustic monitoring of foam and aerated fluid properties

InactiveUS20090006005A1Testing/calibration apparatusVibration measurement in fluidAdiabatic processElectronic form

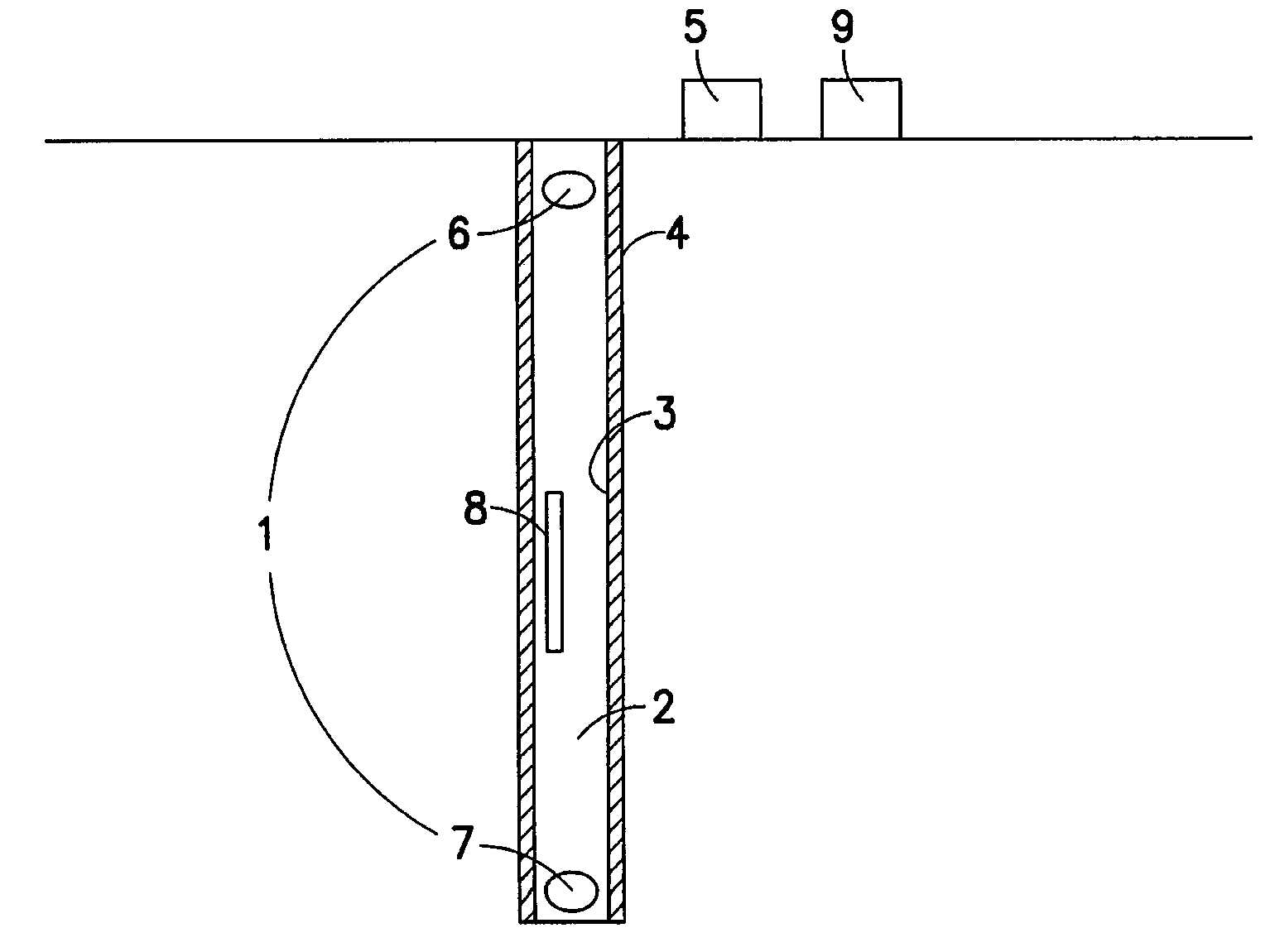

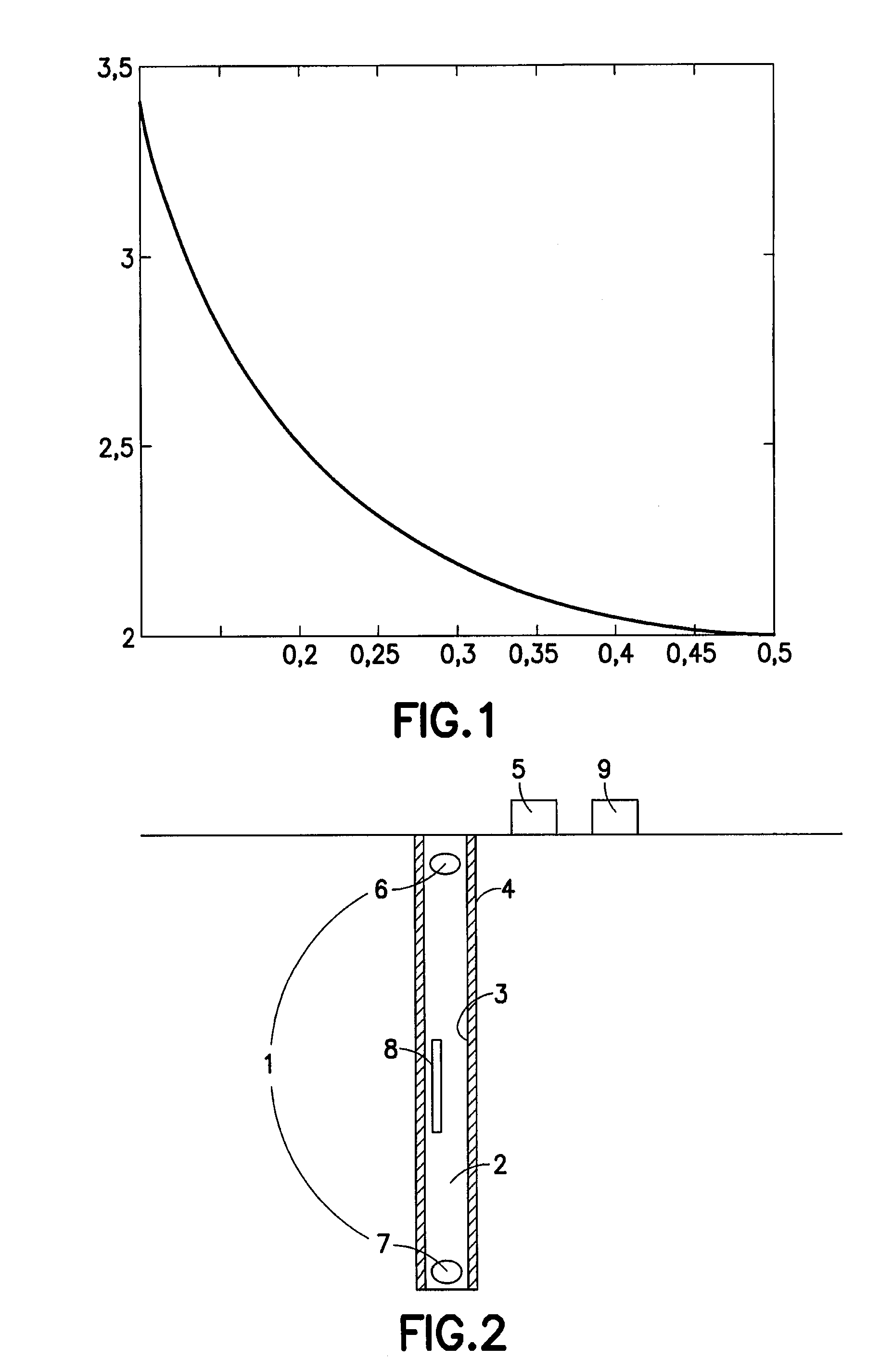

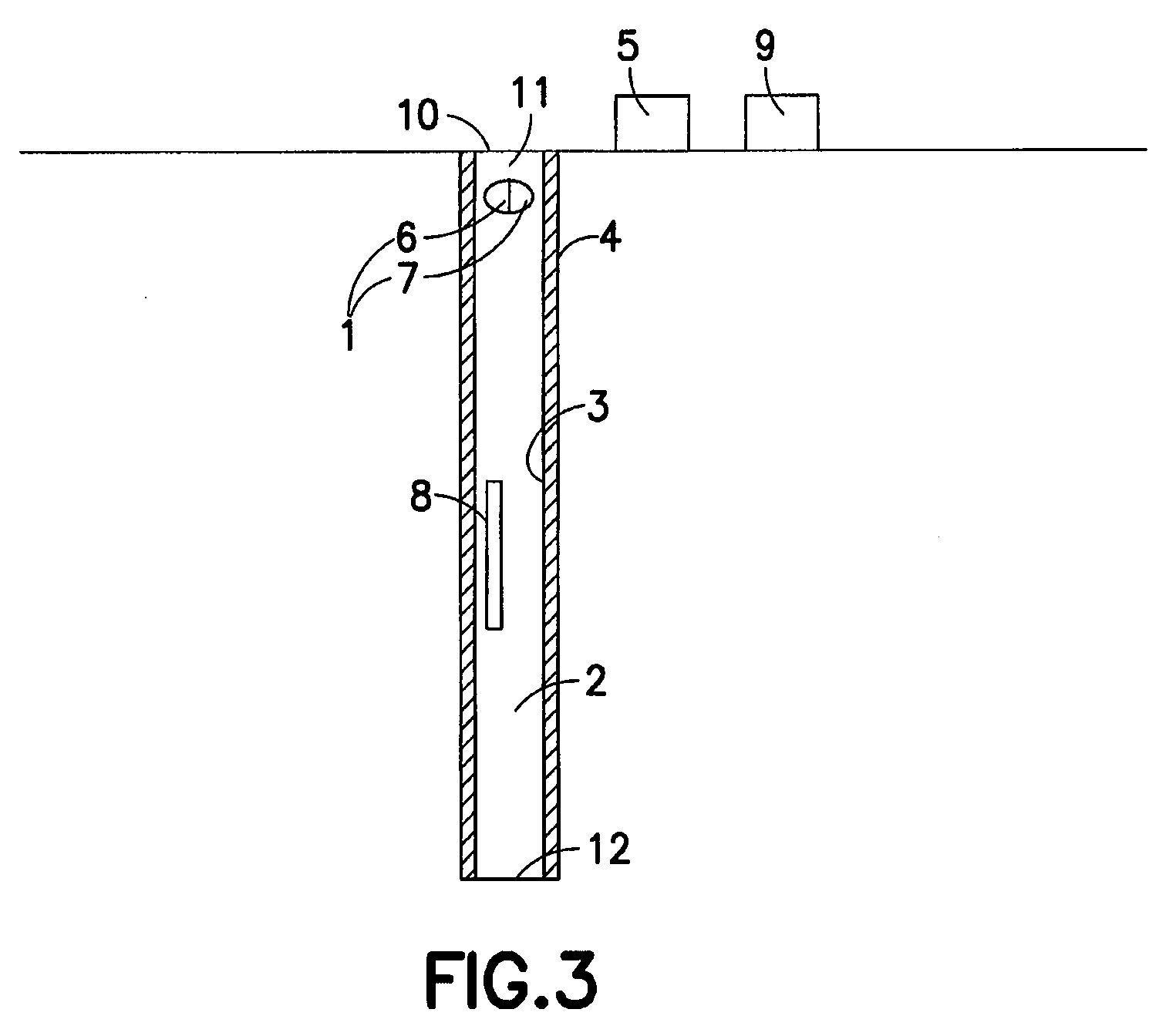

A method and device for on-line foam quality acoustic monitoring are suggested. As per the invention, the method provides for the following: at least one emitter / receiver pair is placed in a close vicinity to the foam flow; at least one acoustic pulse is emitted; time, within which the acoustic pulse overcomes the way from the emitter to the receiver, is recorded; acoustic pulse speed (sound speed) is determined by analyzing an acoustic response of the receiver. After that, pressure in the foam in the area between the emitter and receiver is defined and the foam quality Γ is calculated as per the equation:Γ=12±14-NρflpCfm2,where: Cfm—speed of sound in the foam, p—pressure, ρfl—fluid density, Γ—foam quality, N—polytrophic expansion coefficient (N=1 for isothermal process; N=1.4 for adiabatic process), in case of a foam composed of a perfect gas and a perfect fluid for cases, when the foam quality is supposedly much lower than ½ or much bigger than ½, the sign to be selected in the said formula is <<−>> and <<+>>, respectively; in cases when both values of Γ are near ½, the both quality values should be considered as a possible option, or in more complicated cases, it can be found from the Value Spreadsheet

Owner:SCHLUMBERGER TECH CORP

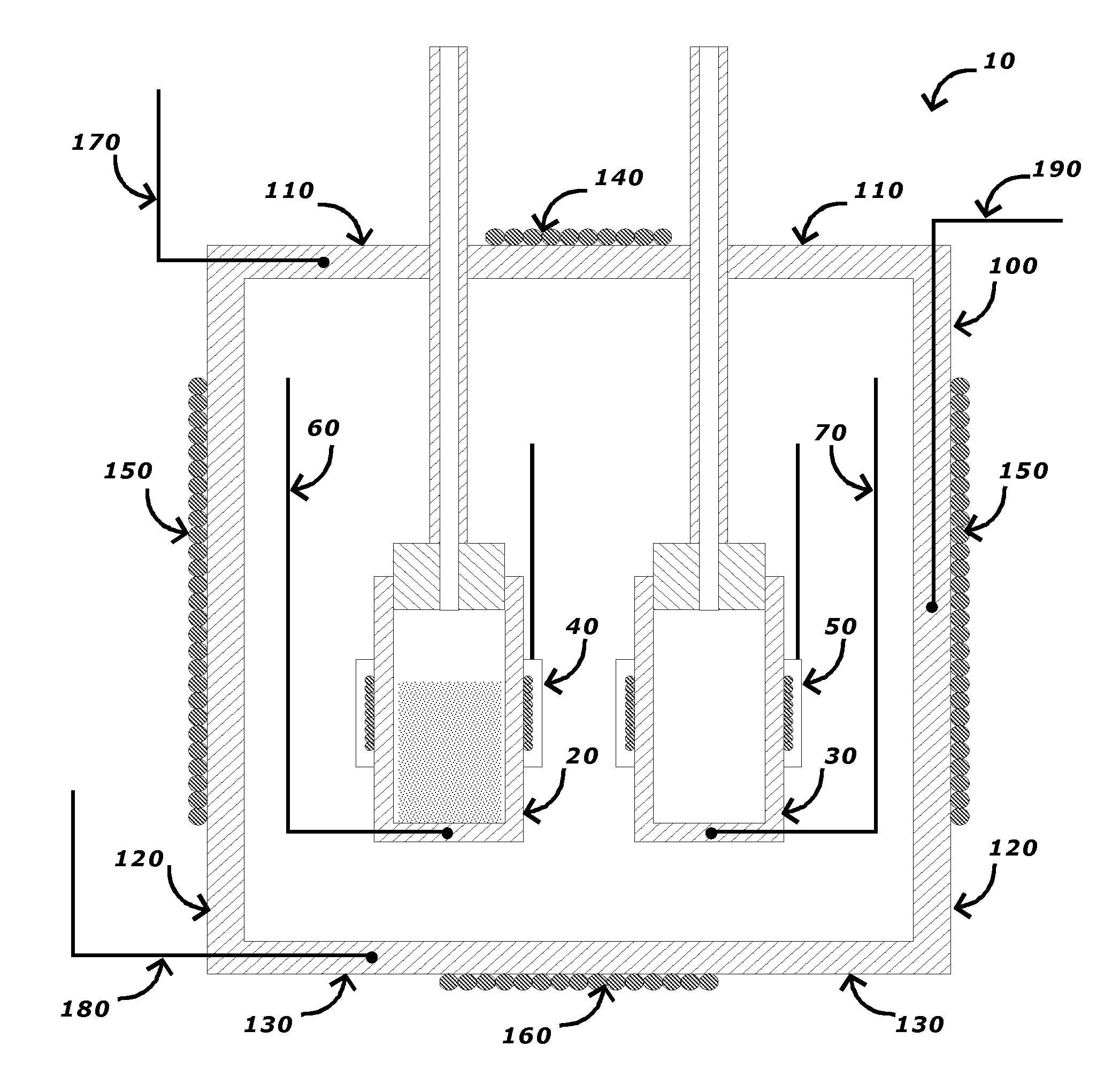

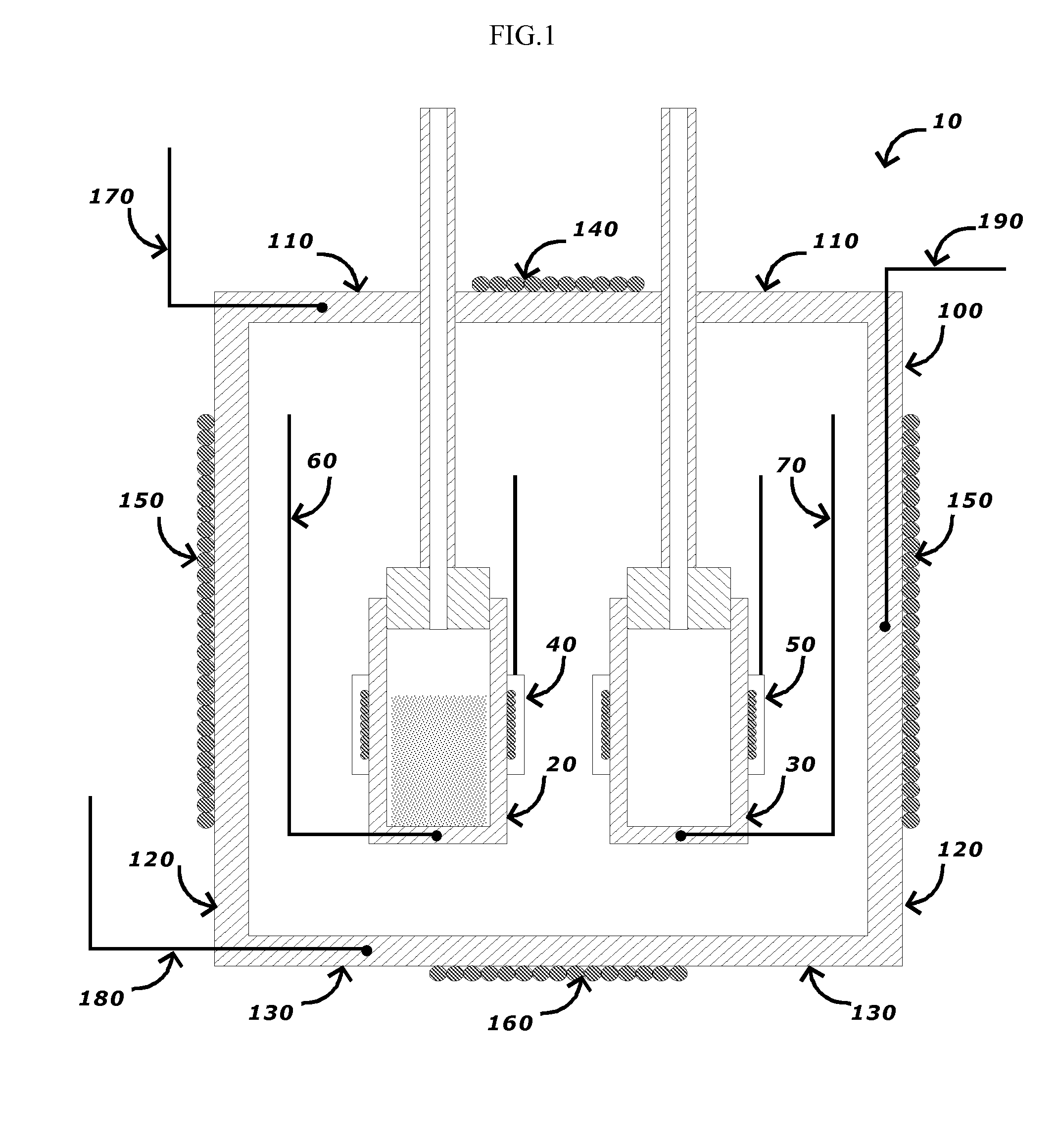

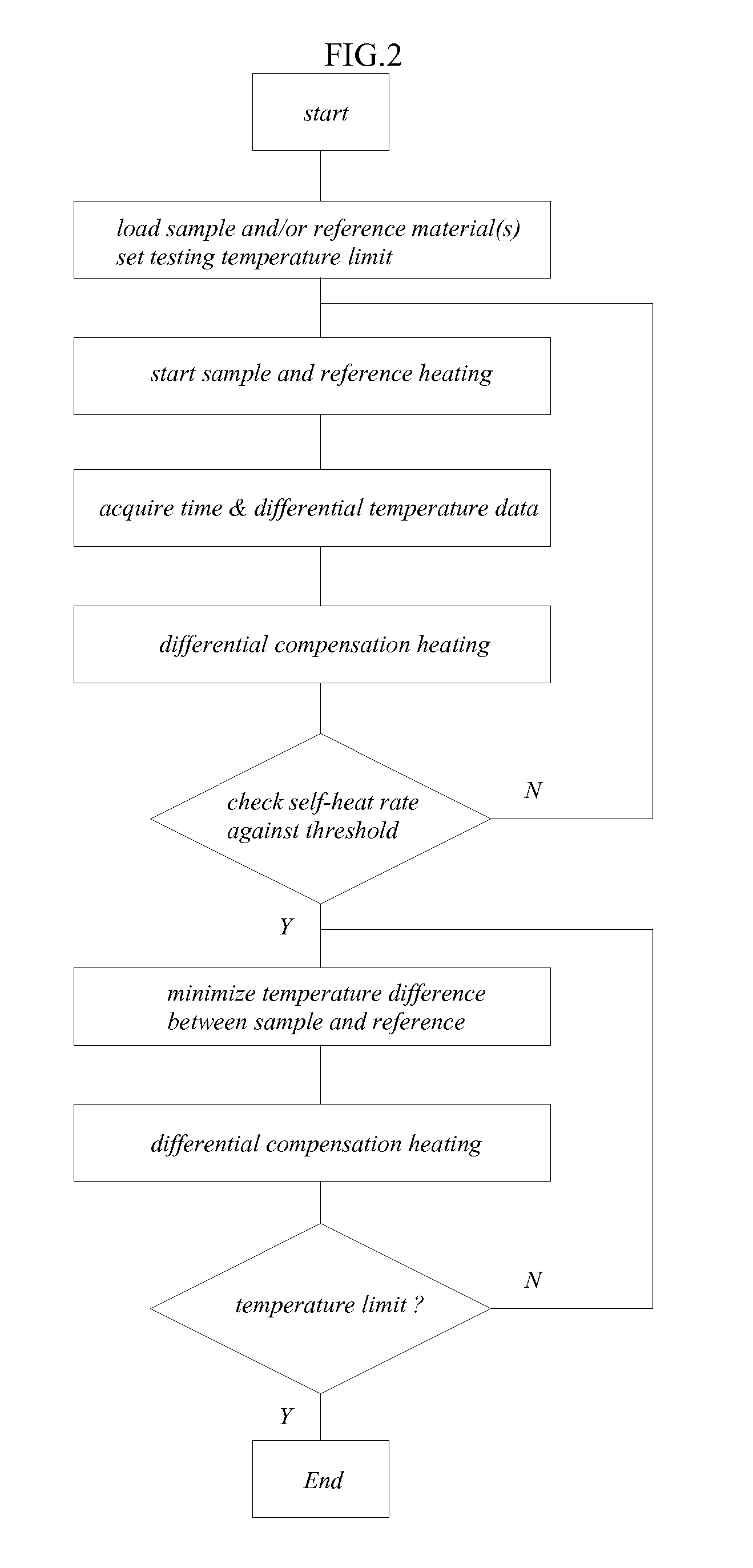

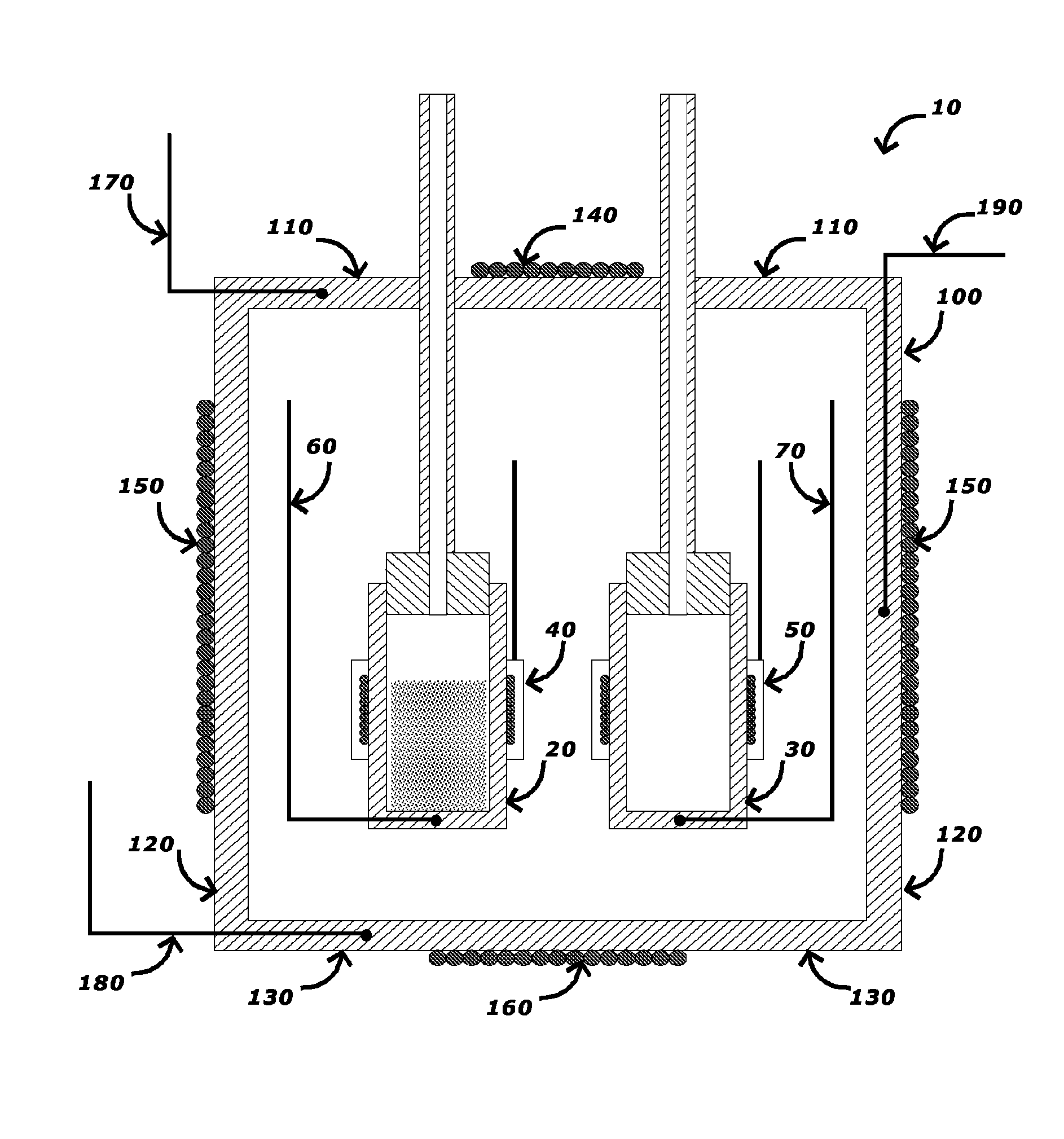

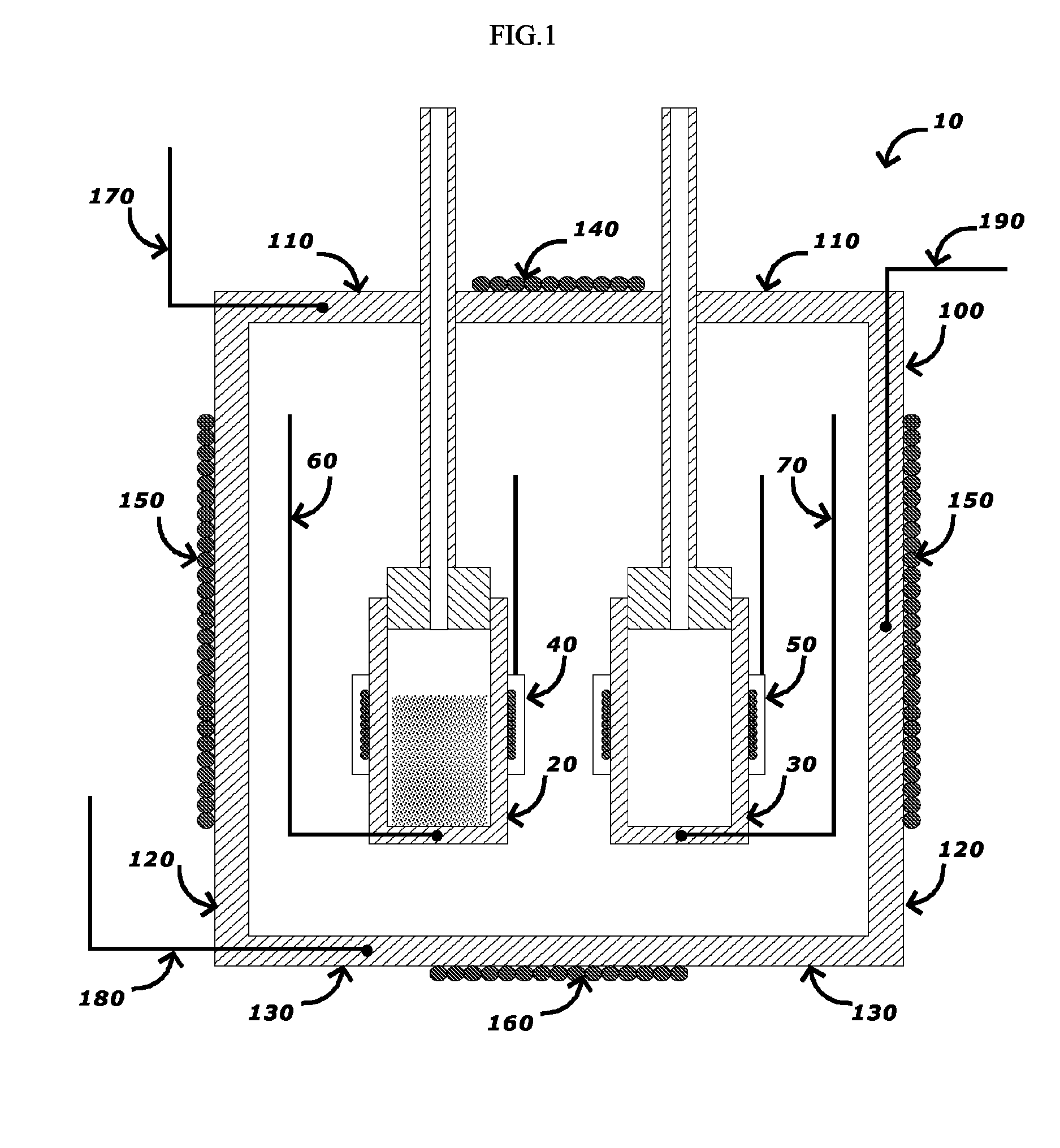

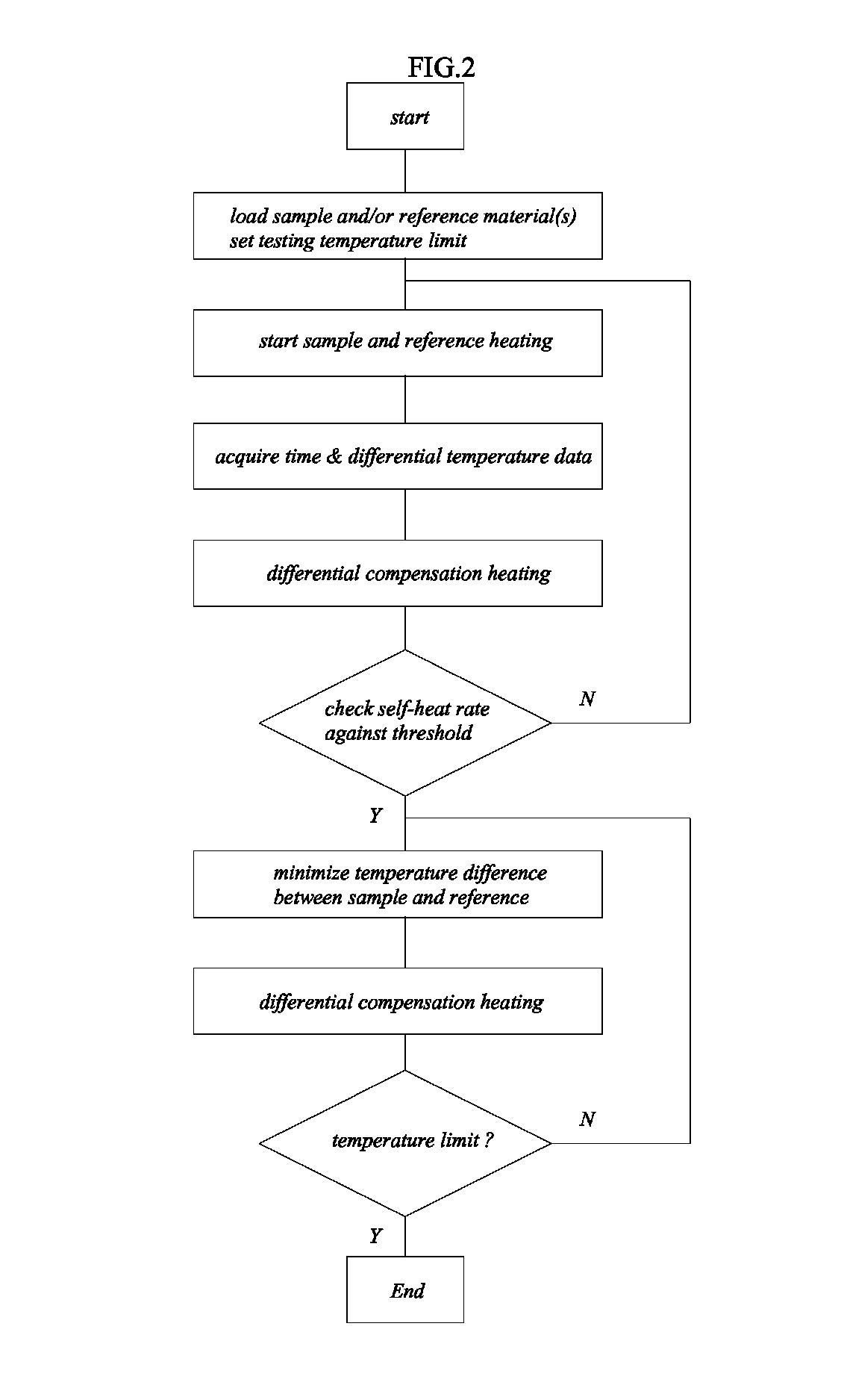

Differential Adiabatic Compensation Calorimeter and Methods of Operation

ActiveUS20110007775A1Simplify the test procedureEliminate Control ErrorsMaterial thermal analysisCalorimeterTemperature controlReaction calorimeter

The differential adiabatic compensation calorimeter comprises sample and reference containers, sample and reference temperature sensors connected back-to-back, in series, sample and reference compensating heaters coupled to the sample and reference containers, and a temperature-controlled chamber. In this differential adiabatic mixing and reaction calorimeter, the sample heat-sink heat loss to the sample container is compensated so that the exothermic reaction is conducted in an adiabatic state, resulting in an undistorted adiabatic process gaining the highest adiabatic temperature rise that corresponds to the theoretical value and an experimentally measured time to maximum rate value. The calorimeter is designed for measuring the time-resolved adiabatic temperature rise, the rate of temperature rise, the time to maximum temperature peak and time to maximum rate of an exothermic chemical reaction.

Owner:WU FR LEU

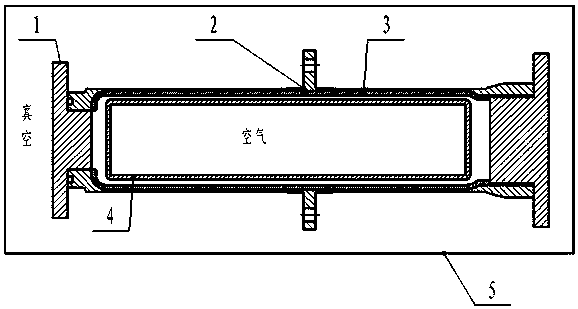

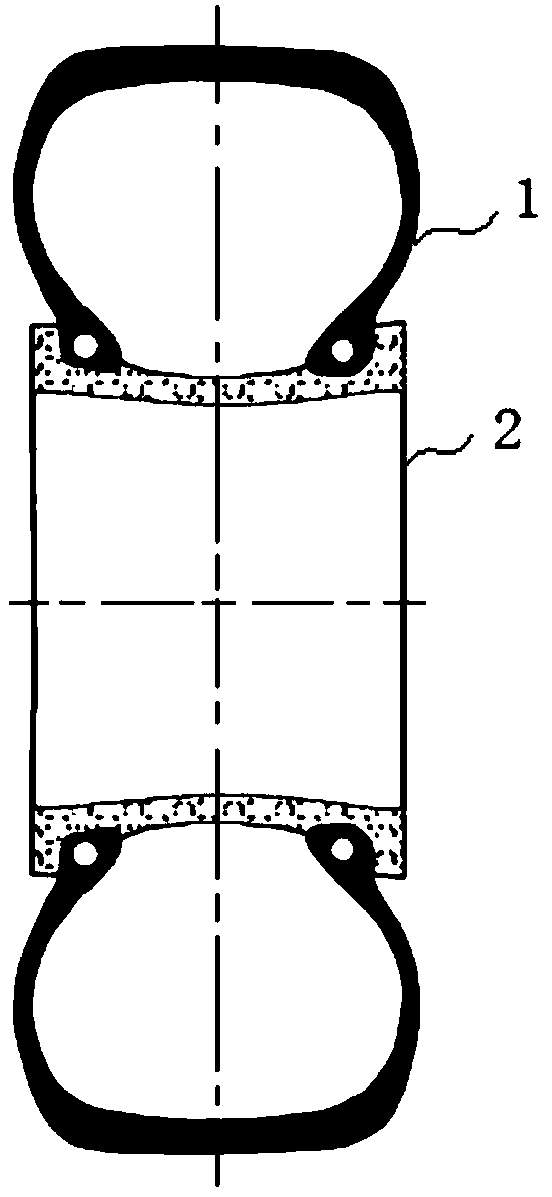

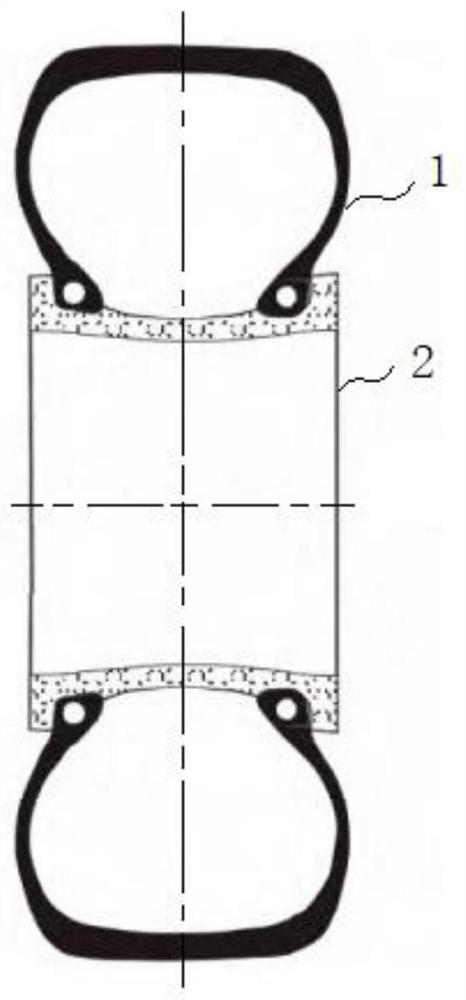

Solid rocket engine inner insulation layer forming method

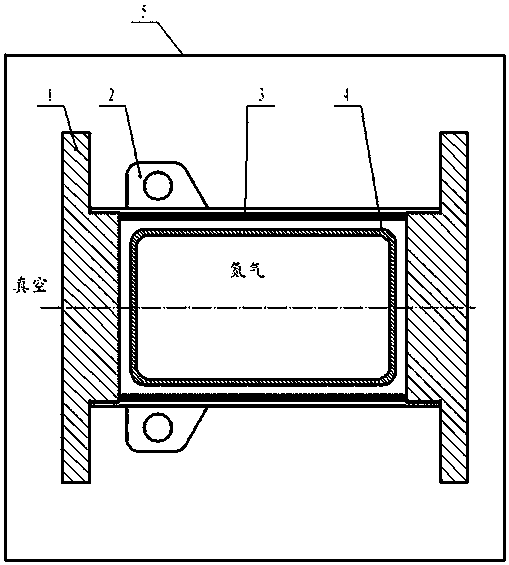

A solid rocket engine inner insulation layer forming method comprises the following steps: 1, evenly coating the inner wall of a solid rocket engine casing with an adhesive, drying in air, pasting aninsulation layer rubber sleeve onto a corresponding bonding position on the inner wall of the solid rocket engine casing; 2, putting a gas bag fully filled with a gas into the solid rocket engine casing with the insulation layer rubber sleeve, mounting positioning fixtures on both ends of the solid rocket engine casing, and putting the solid rocket engine casing into a vacuum container; 3, vacuumizing the vacuum container for expansion of air in the gas bag under vacuum conditions so as to apply 0.1MPa pressure to the insulation layer rubber sleeve pasted on the inner wall of the solid rocketengine casing to complete solidification of the adhesive so as to complete pasting forming of the insulation layer rubber sleeve and the solid rocket engine casing; and 4, taking the solid rocket engine casing out of the vacuum container, removing the positioning fixtures on the both ends of the solid rocket engine casing, and taking the gas bag out. According to the method, a gas bag pressurizingmedium is changed from a high-pressure compressed gas to an ordinary pressure gas, production energy consumption is reduced, the sealing treatment process on the casing in the adiabatic process is omitted, and production operation difficulty is effectively reduced.

Owner:HUBEI INST OF AEROSPACE CHEMOTECHNOLOGY

Differential adiabatic compensation calorimeter and methods of operation

ActiveUS8926172B2Improve scalabilitySimplify the test procedureMaterial heat developmentCalorimeterTemperature controlReaction calorimeter

Owner:WU FR LEU

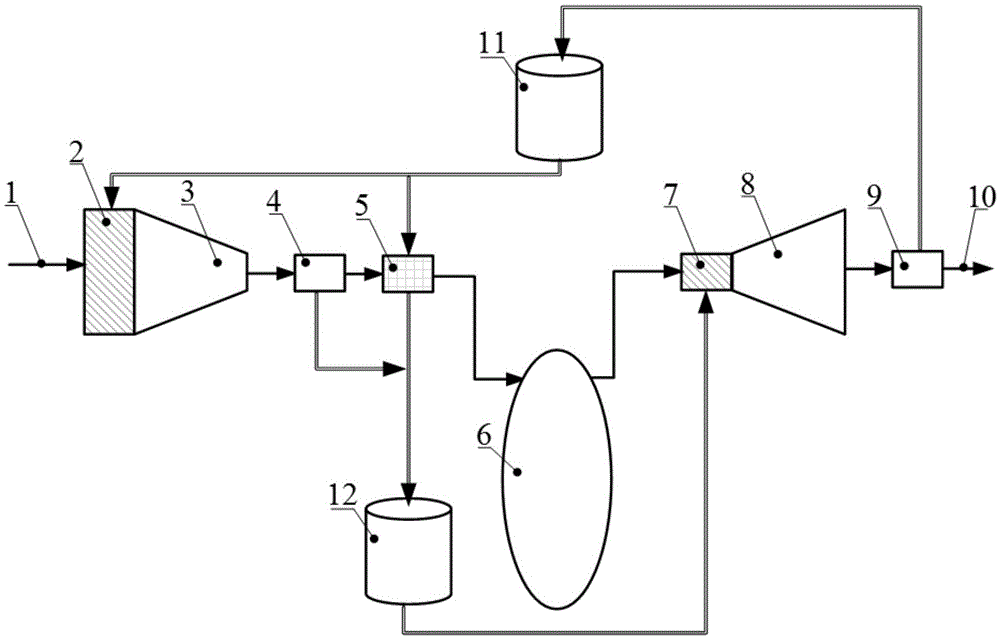

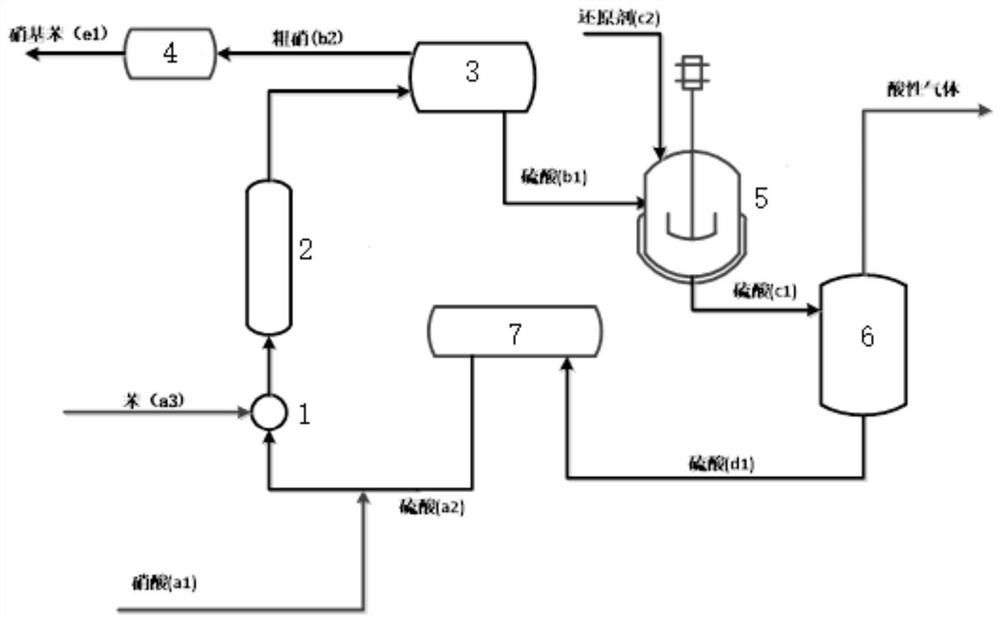

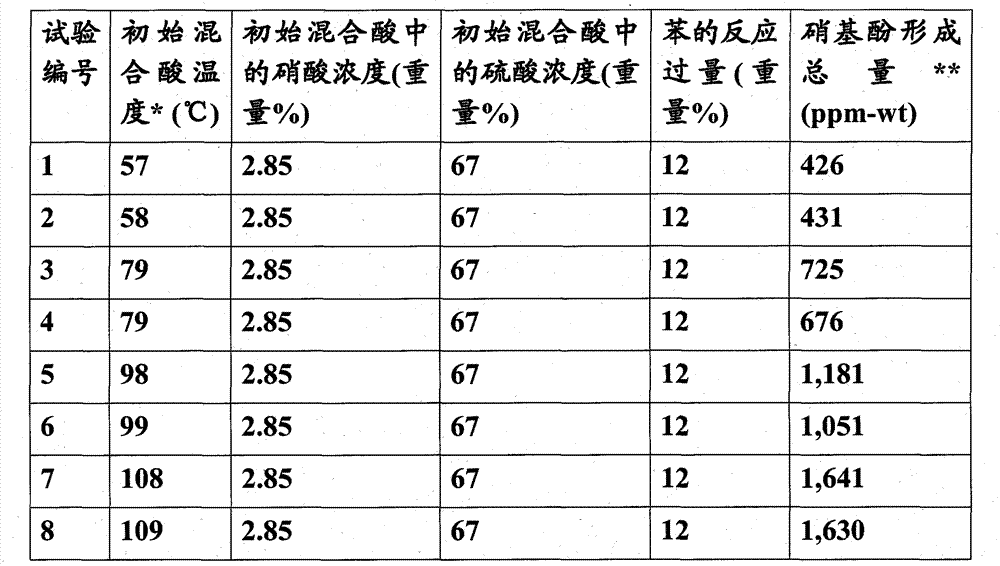

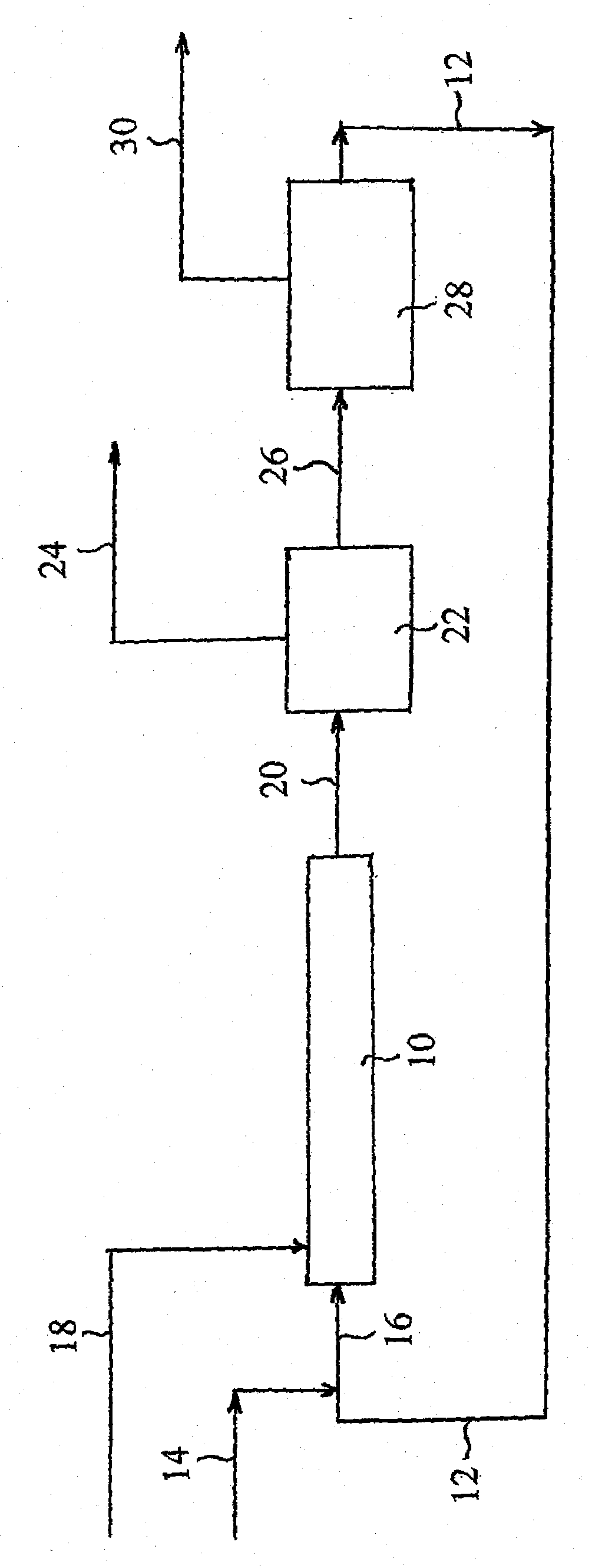

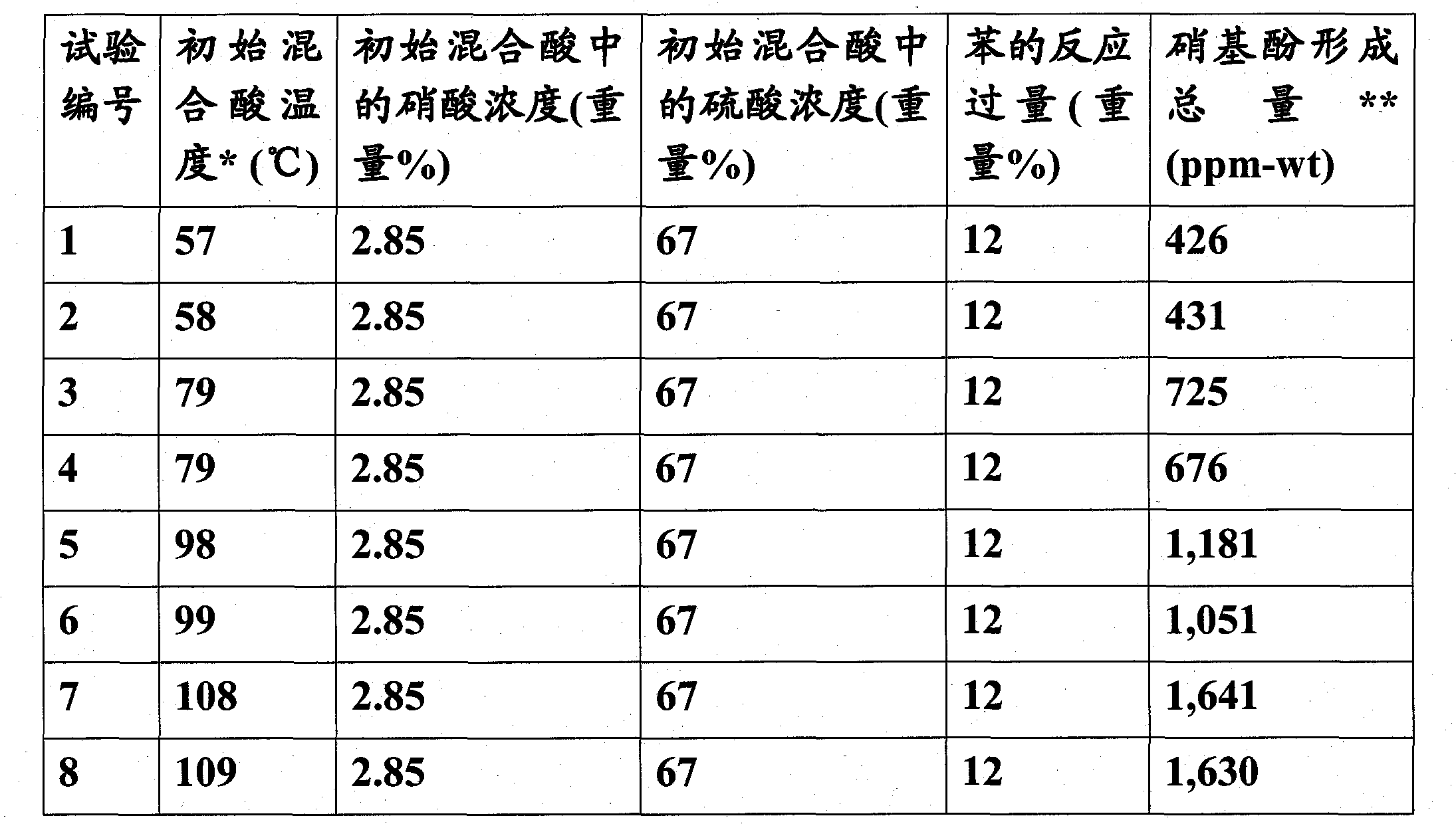

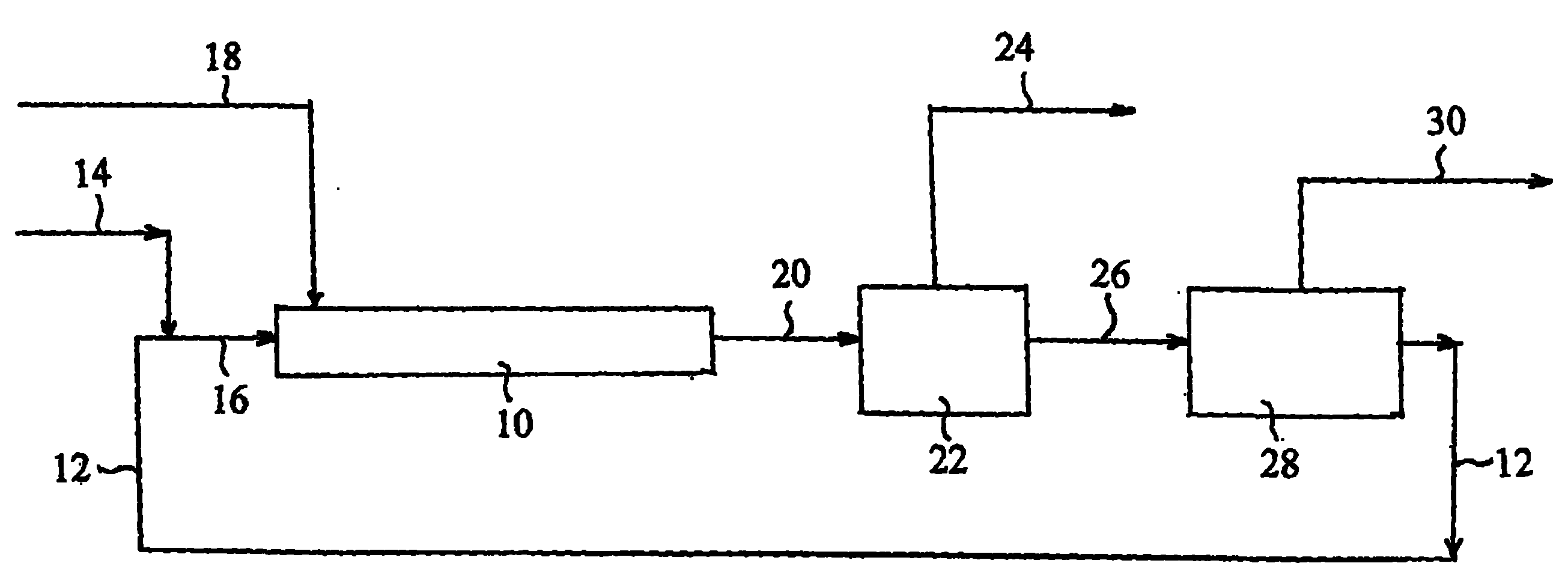

Adiabatic process for making mononitrobenzene

ActiveUS8692035B2Increase response rateReduce formationChemical/physical/physico-chemical stationary reactorsNitro compound preparationBenzeneAdiabatic process

An adiabatic process for making mononitrobenzene by the nitration of benzene which minimizes the formation of nitrophenols and dinitrobenzene by-products. The process uses a mixed acid having less than 3 wt % nitric acid, 55 to 80 wt % sulfuric acid, and water. The initial temperature of the mixed acid is in the range of 60 to 96° C. The nitration reaction is complete in about 300 seconds and produces less than 1,200 ppm nitrophenols and less than about 80 ppm dinitrobenzene. The reaction can be carried out in a plug-flow or a stirred pot reactor, or a combination of such reactors.

Owner:NORAM INT

Improved air generator and corresponding circulation thereof

The invention provides a non-conventional generator which utilizes gases, such as, air, hydrogen gas or helium gas as a working medium. The improved air generator and corresponding circulation thereof are mainly the improvement of the air generator and corresponding circulation thereof (the Chinese patent application number is 200910192135.1) invented by the inventor. In the invention, the flow of gas in a spray pipe II is an adiabatic process or a polytropic process and applies work for a turbomachine II installed at the outlet of the spray pipe II, and then the gas absorbs external heat in an air cylinder II with favorable heat transfer performance as isobaric and heat absorption expansion, applies work for a turbomachine III installed at the outlet of the air cylinder II or a piston and is finally emitted to a closed space.

Owner:龚炳新

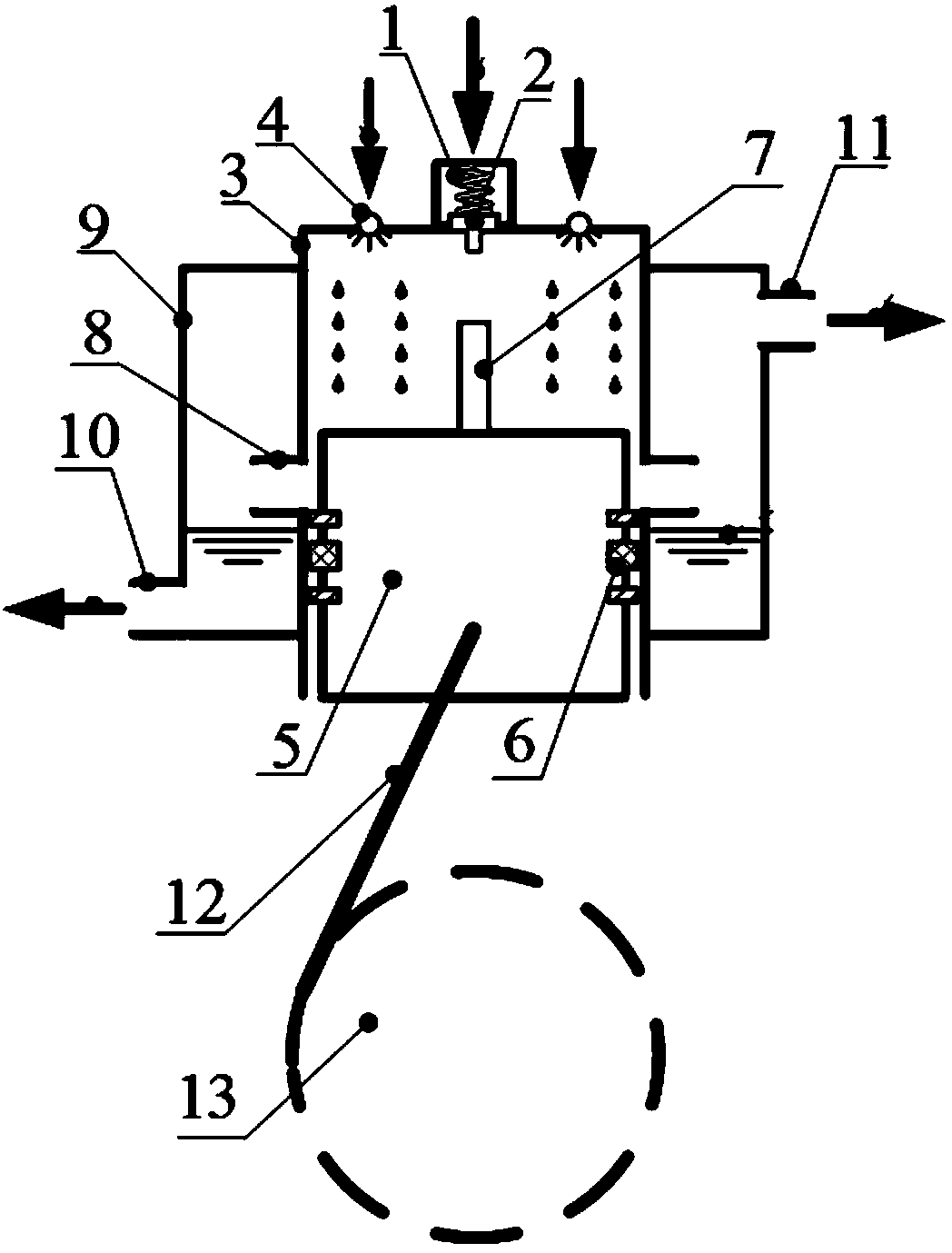

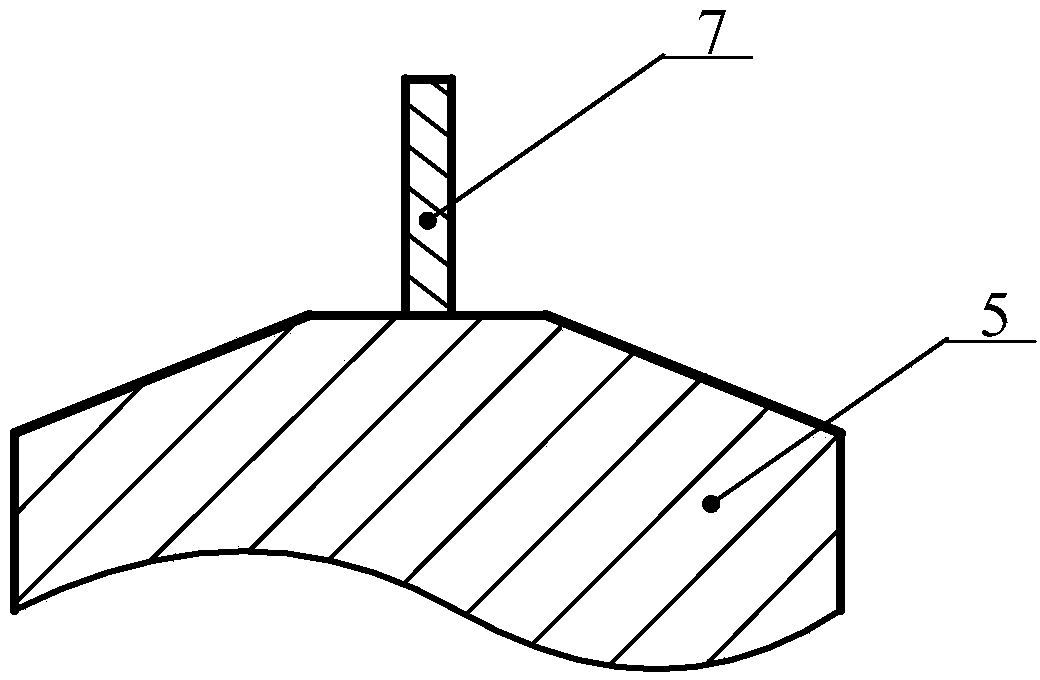

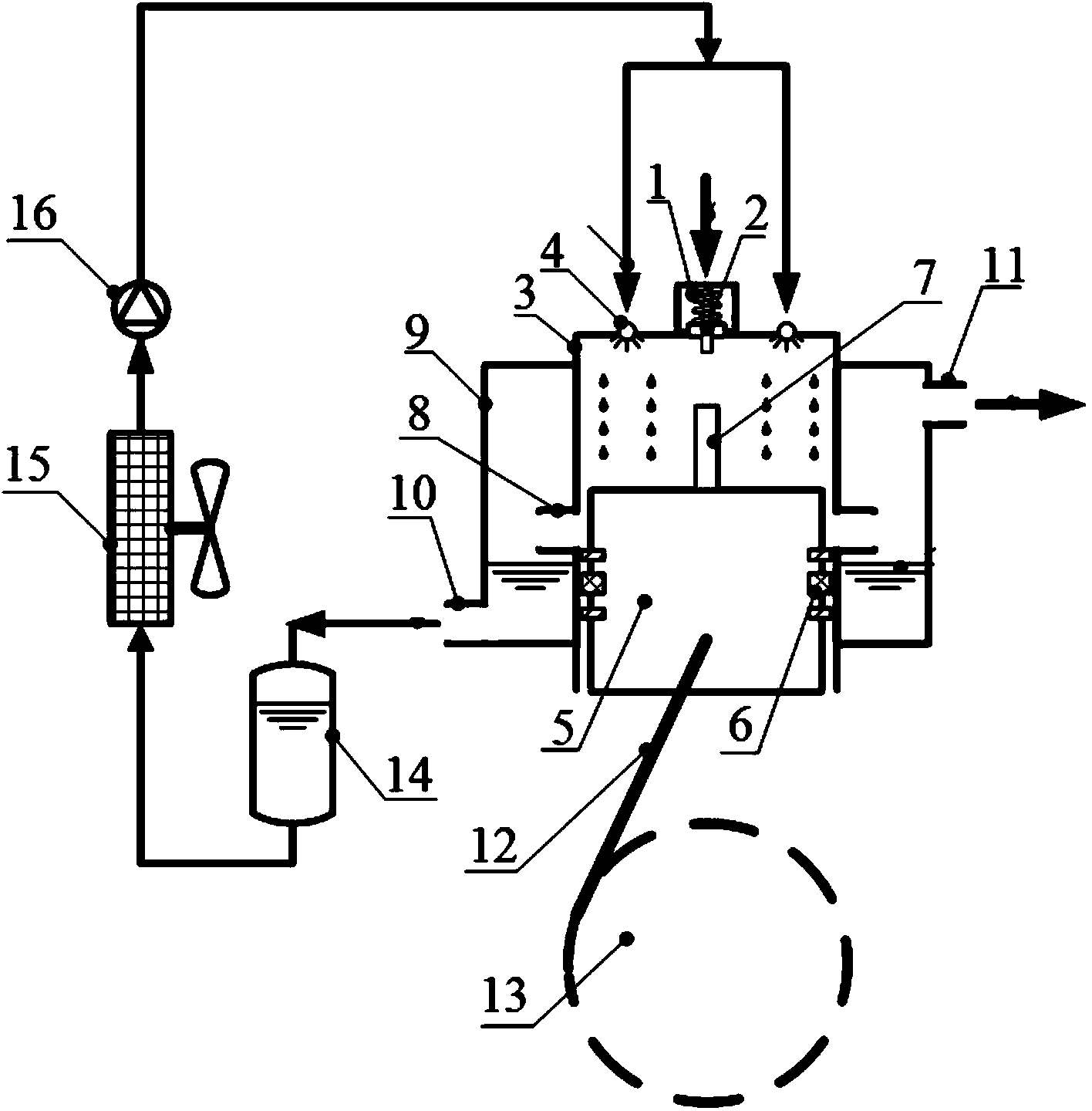

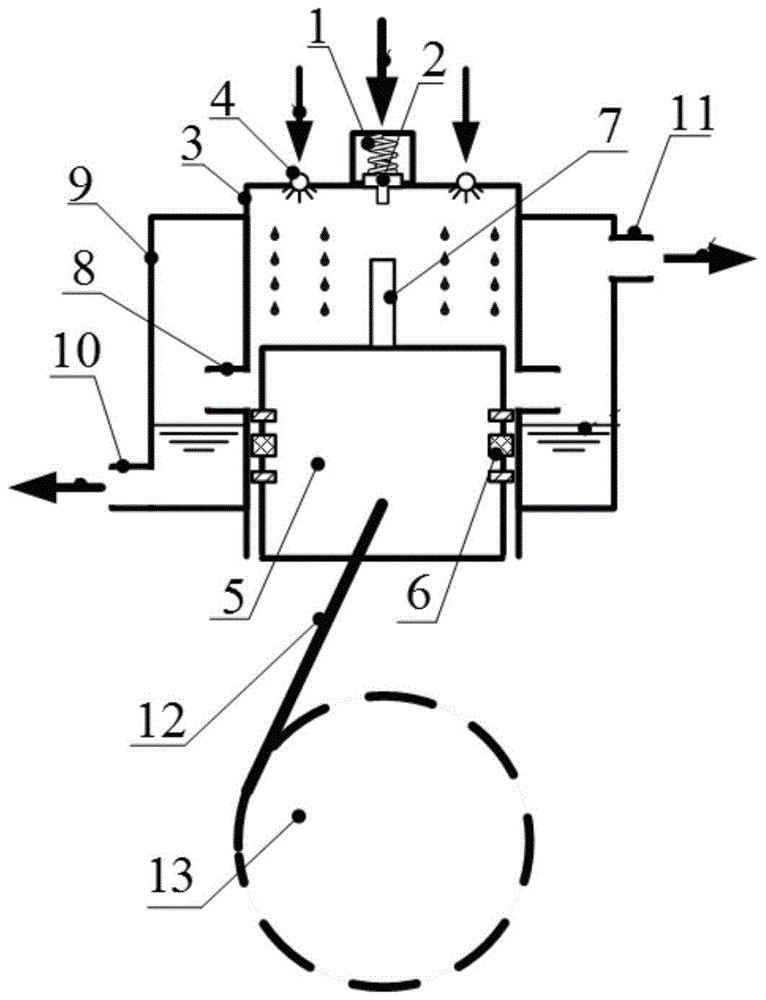

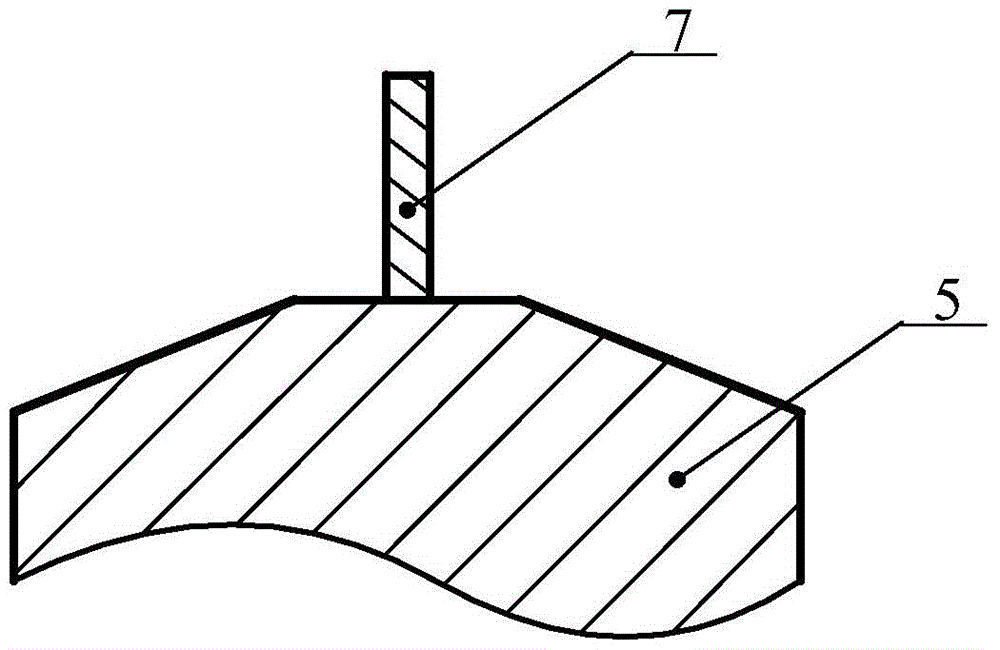

Single valve expander system capable of realizing isothermal expansion and method

ActiveCN104358593AExpansion progression reductionSingle-stage expansion ratio increaseMachines/enginesEngine componentsAdiabatic processInlet valve

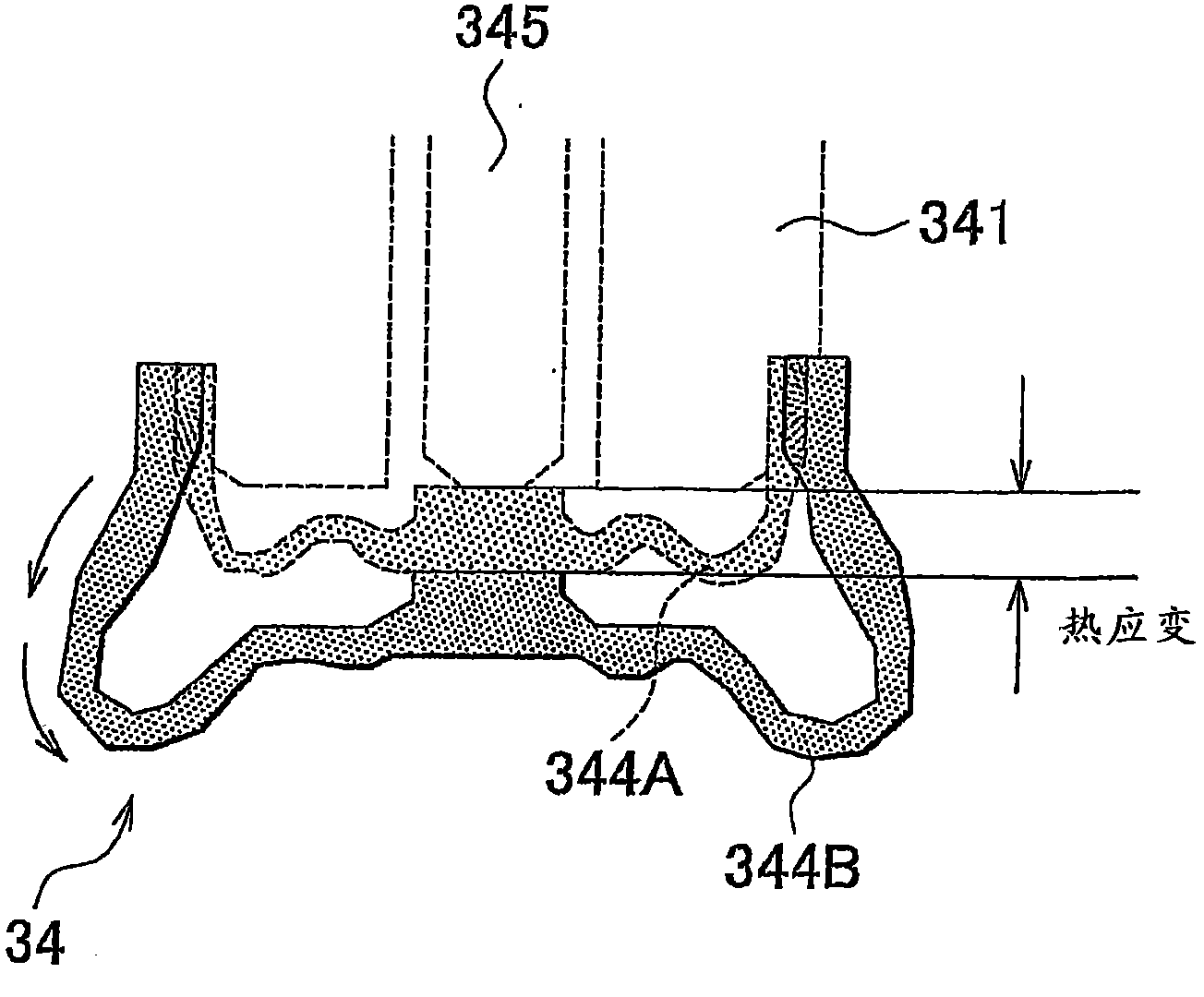

The invention relates to a single valve expander system capable of realizing isothermal expansion and a method. The single valve expander system can be applied to a small-sized / micro compressed air energy storage system or other power systems; a quasi isothermal expansion process is realized by ejecting vaporous or foamy mediums into gas in the expansion process, so that the output work of unit working mediums is improved, and the overall efficiency of the system is improved. Specifically, the single valve expander system is characterized in that an air inlet valve and an annular ejector are mounted at the top of an air cylinder, the air inlet valve is communicated with an external high-pressure gas working medium source, and the annular ejector is communicated with an external heating medium source system; in the working process of an expander, heated heating mediums are atomized or form foam and are fed into the air cylinder at a certain mass flow rate. Compared with a traditional single valve expander, the single valve expander system has the benefits that the expansion process can obviously deviate from an adiabatic process, the quasi isothermal expansion process close to the isothermal temperature is obtained, and the output work of the unit working mediums and the working efficiency of the expander are improved.

Owner:中储国能(北京)技术有限公司

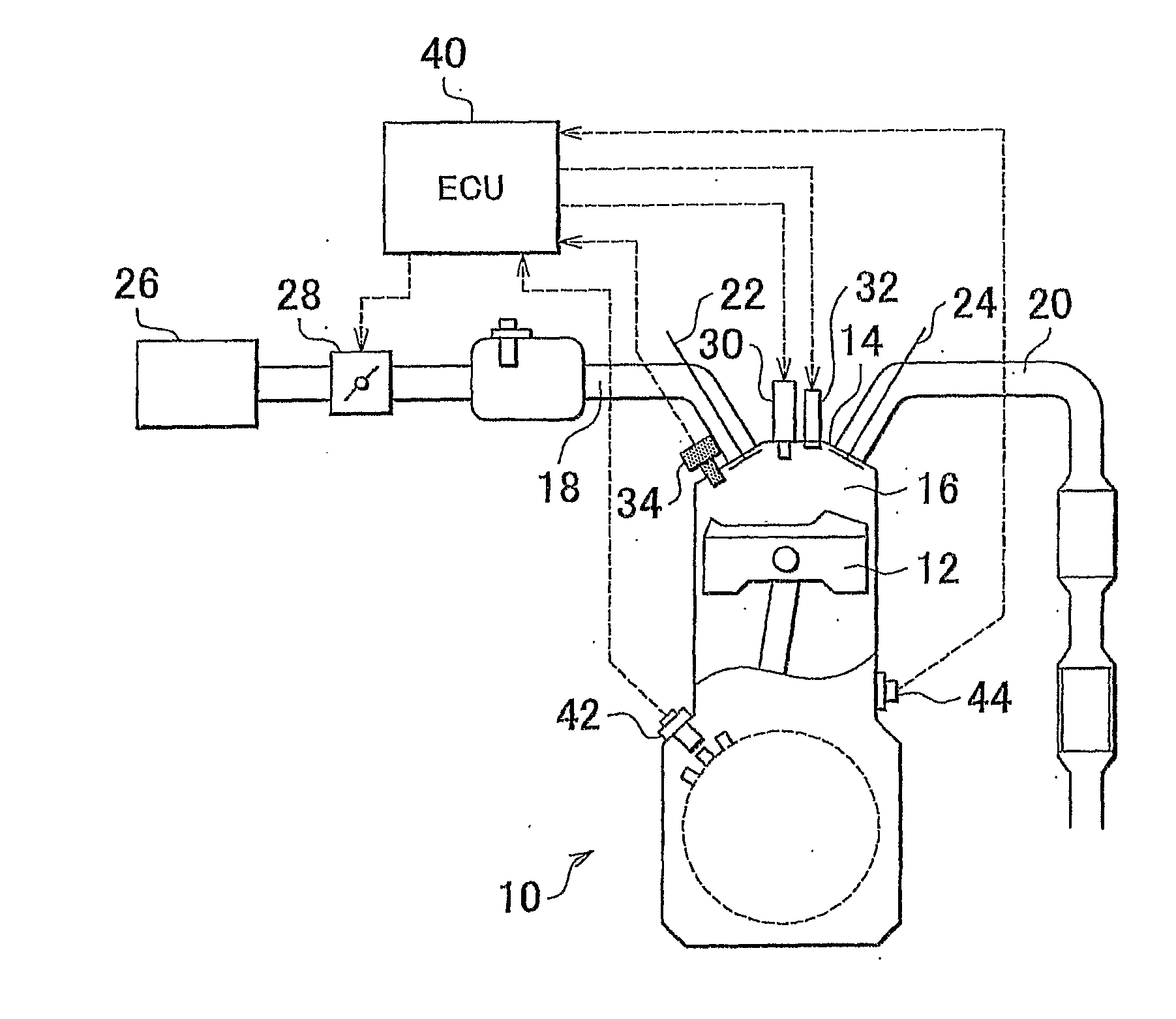

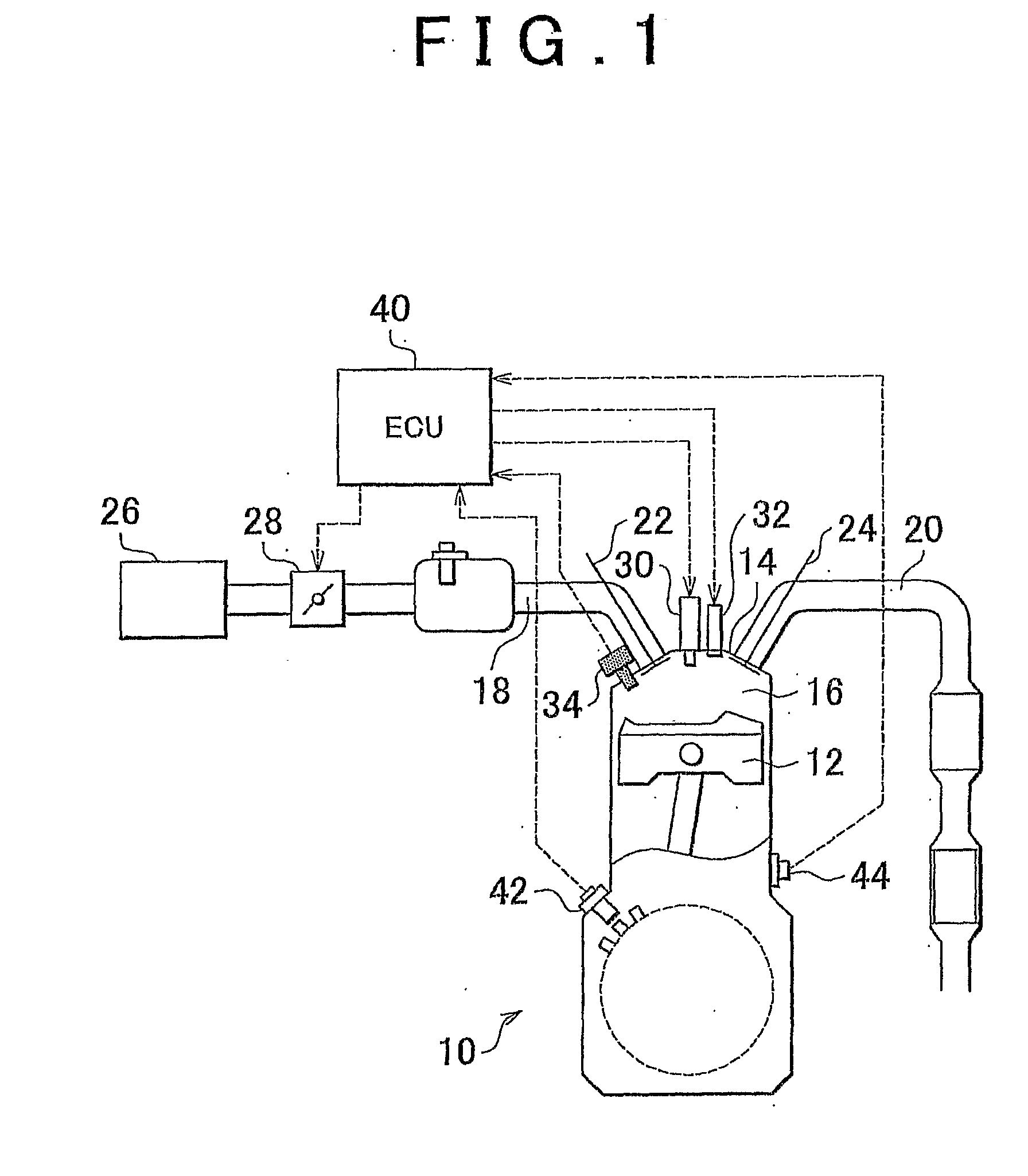

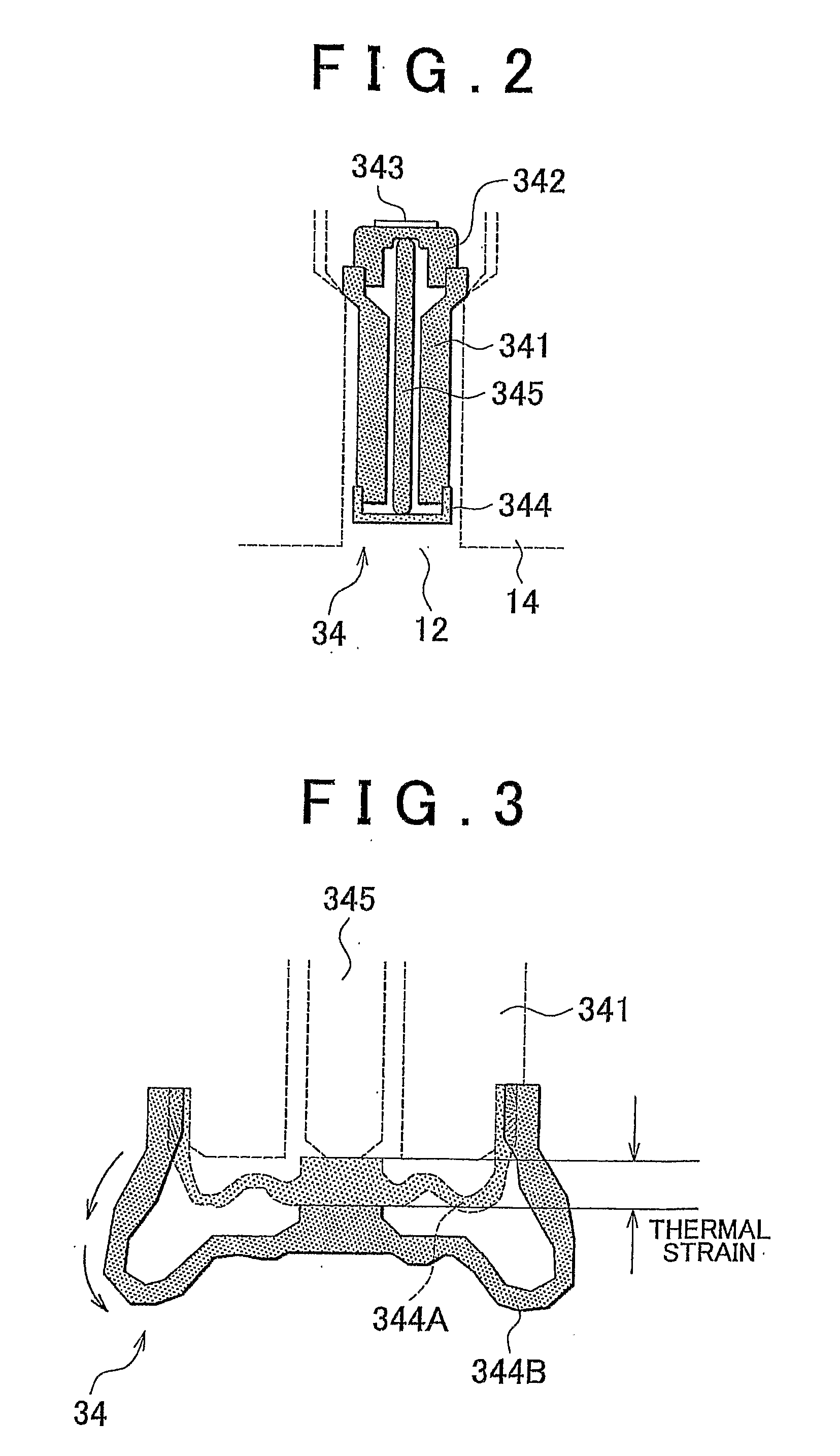

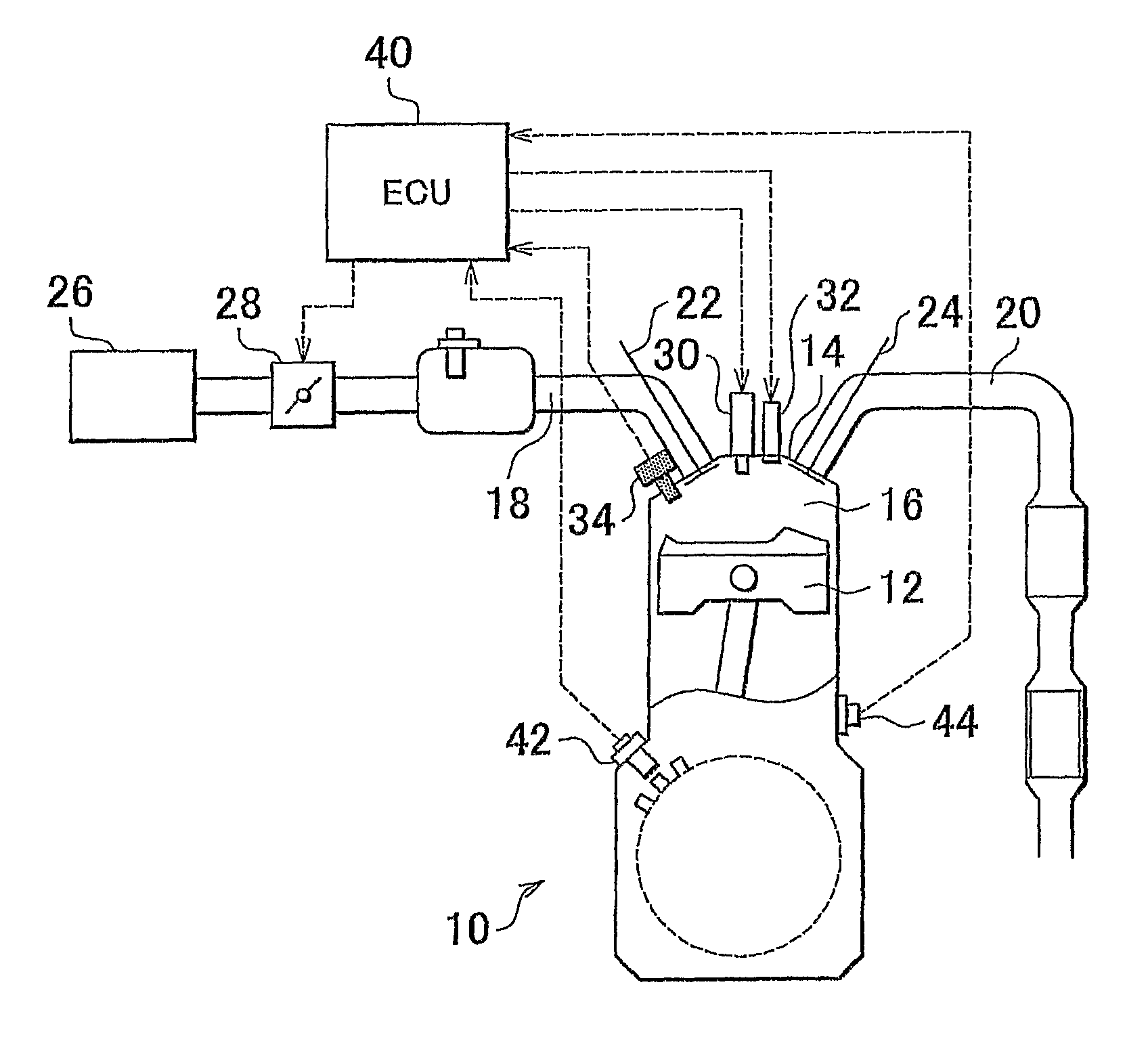

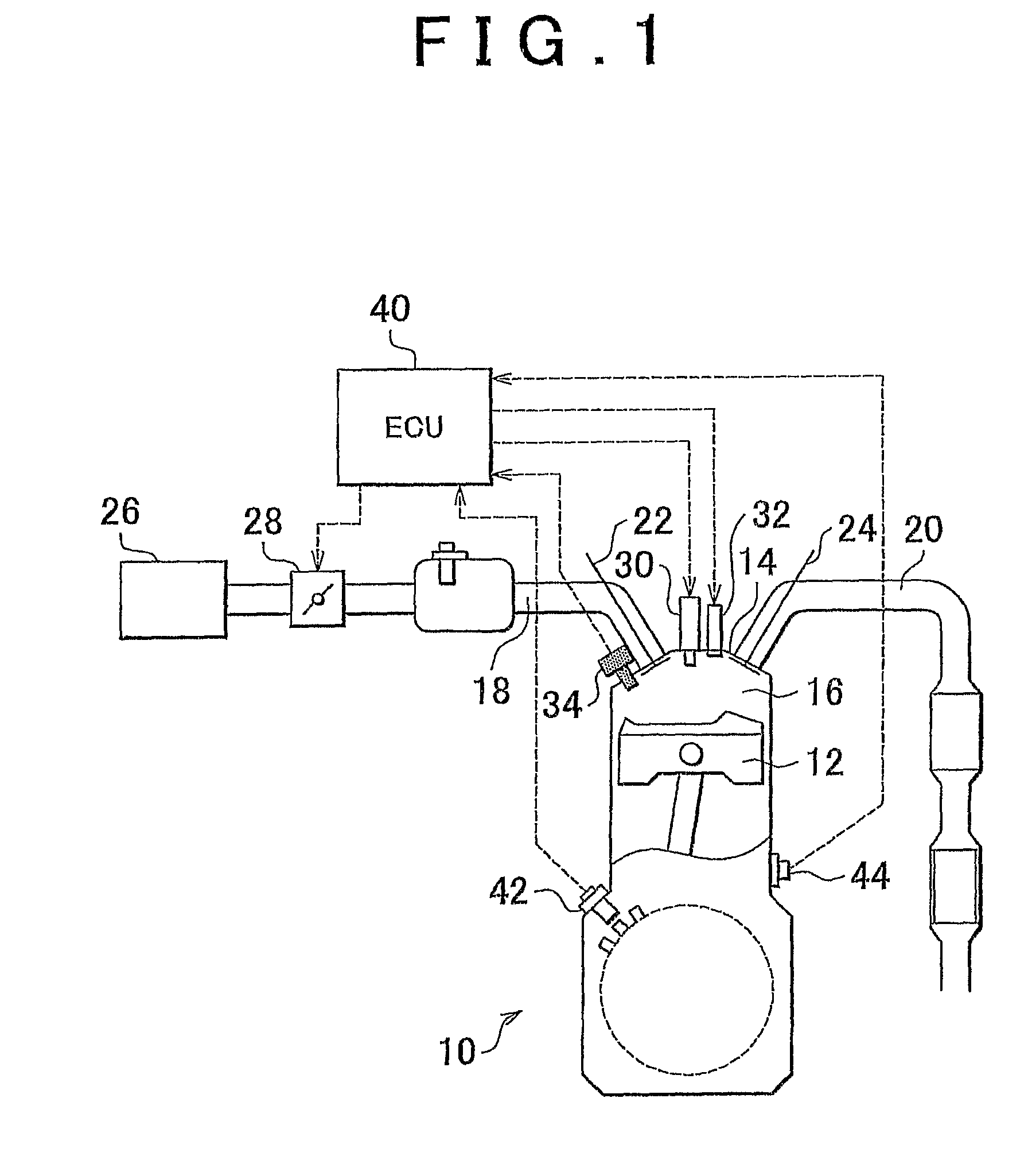

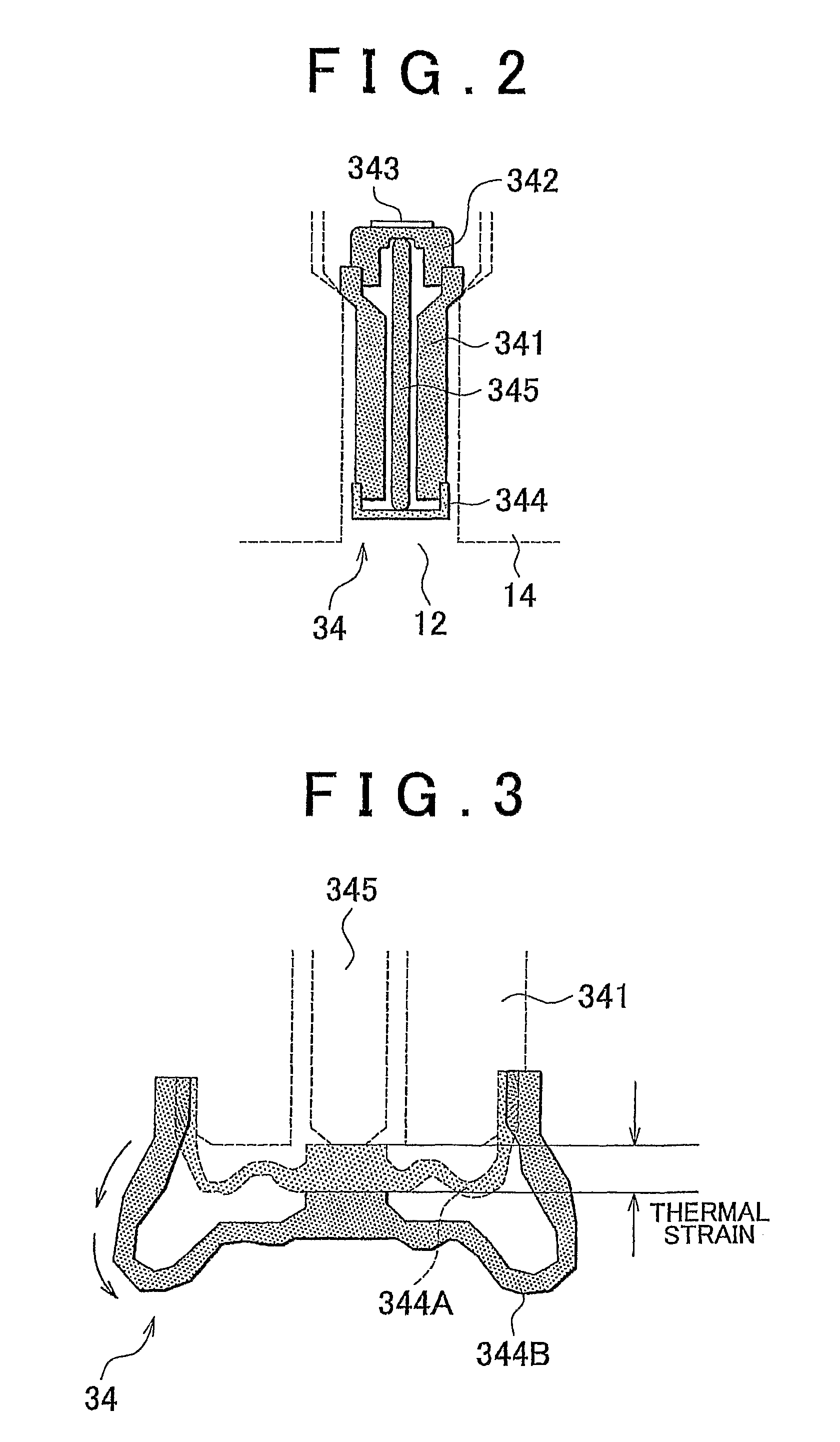

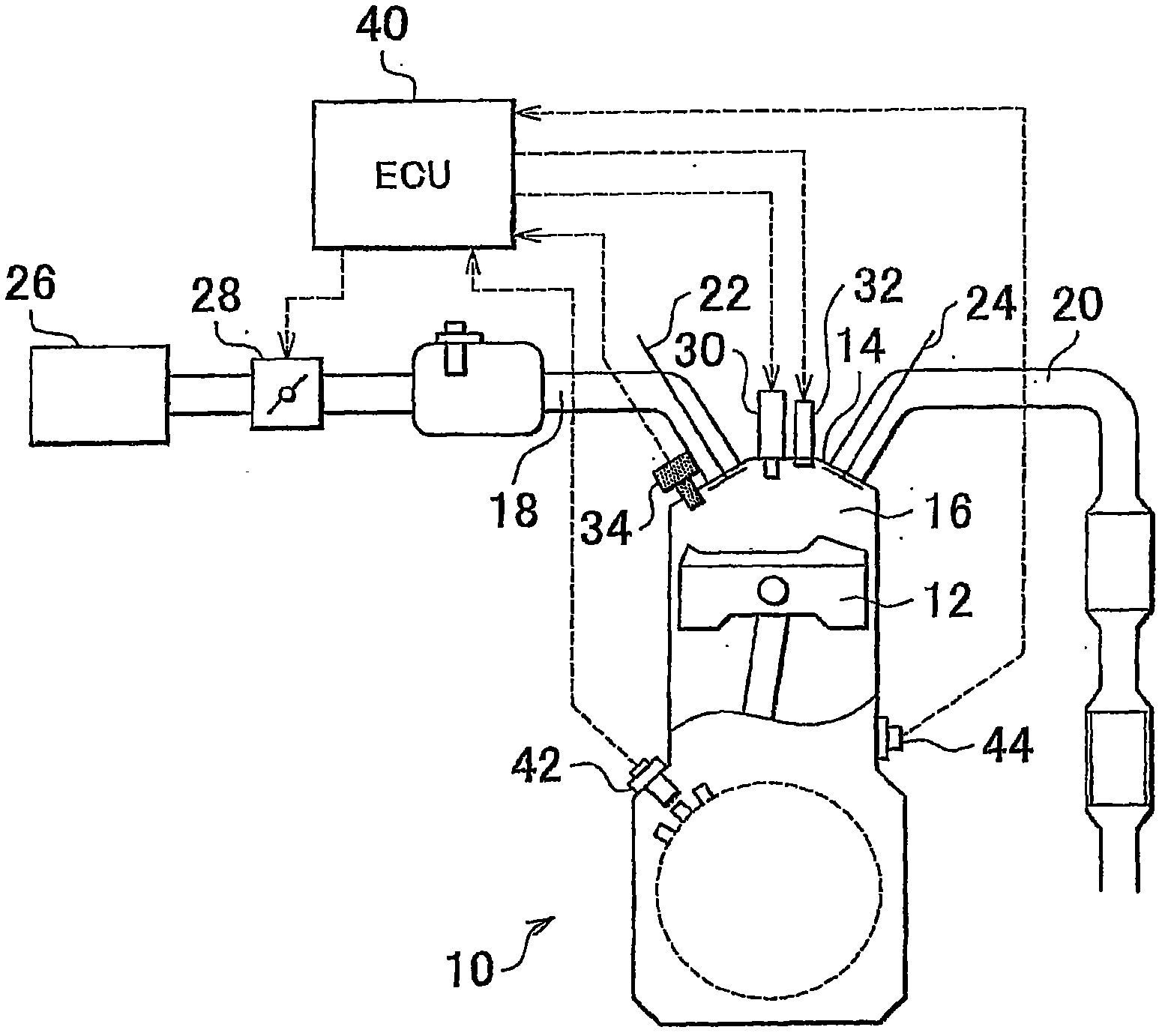

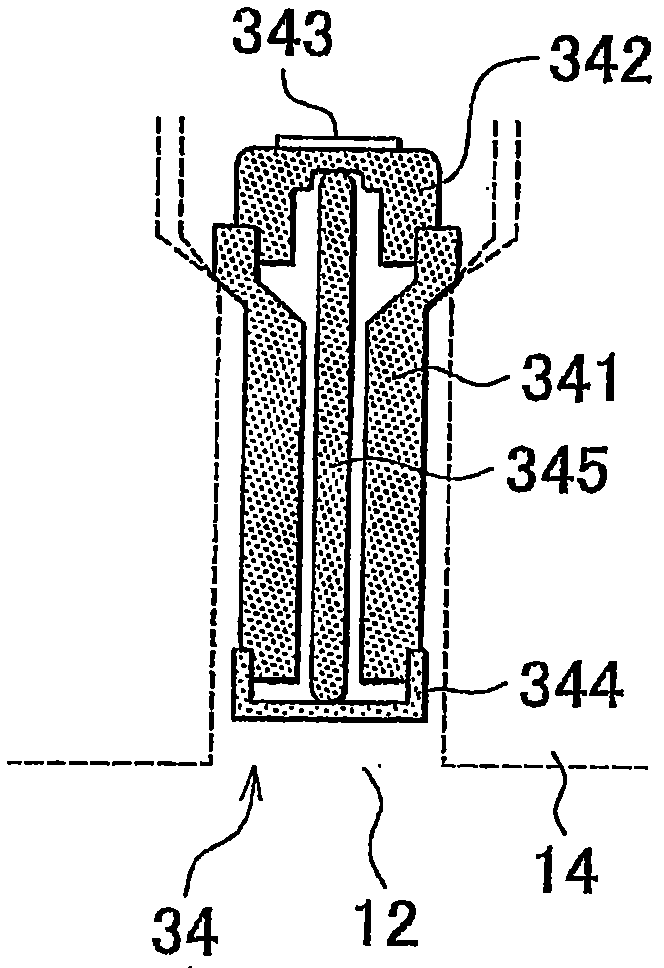

Controller for and method of controlling internal combustion engine

InactiveUS20120053819A1Simple calculationCorrection errorAnalogue computers for vehiclesElectrical controlAdiabatic processInternal combustion engine

Heat generation amount PVκ(θ) is calculated with the use of cylinder pressure P(θ), detected by a cylinder pressure sensor, cylinder, volume V(θ), and specific heat ratio κ (steps 100 to 102). A crank angle θfix, at which the value of PVκ(θ) peaks, is determined as a start crank angle, at which an adiabatic process after combustion starts (step 104). A correction coefficient Kfix is calculated based on the variation of the value of PVκ(θ) after θfix (step 106). An actual heat generation amount PVκ(θ) is calculated with the use of the correction coefficient Kfix (step 110). A cooling loss coefficient Kcool that determines a correlation between the cooling loss and crank angles may be calculated based on a water temperature and an engine speed and the actual heat generation amount PVκfix(θ) may be made to reflect the cooling loss coefficient Kcool.

Owner:TOYOTA JIDOSHA KK

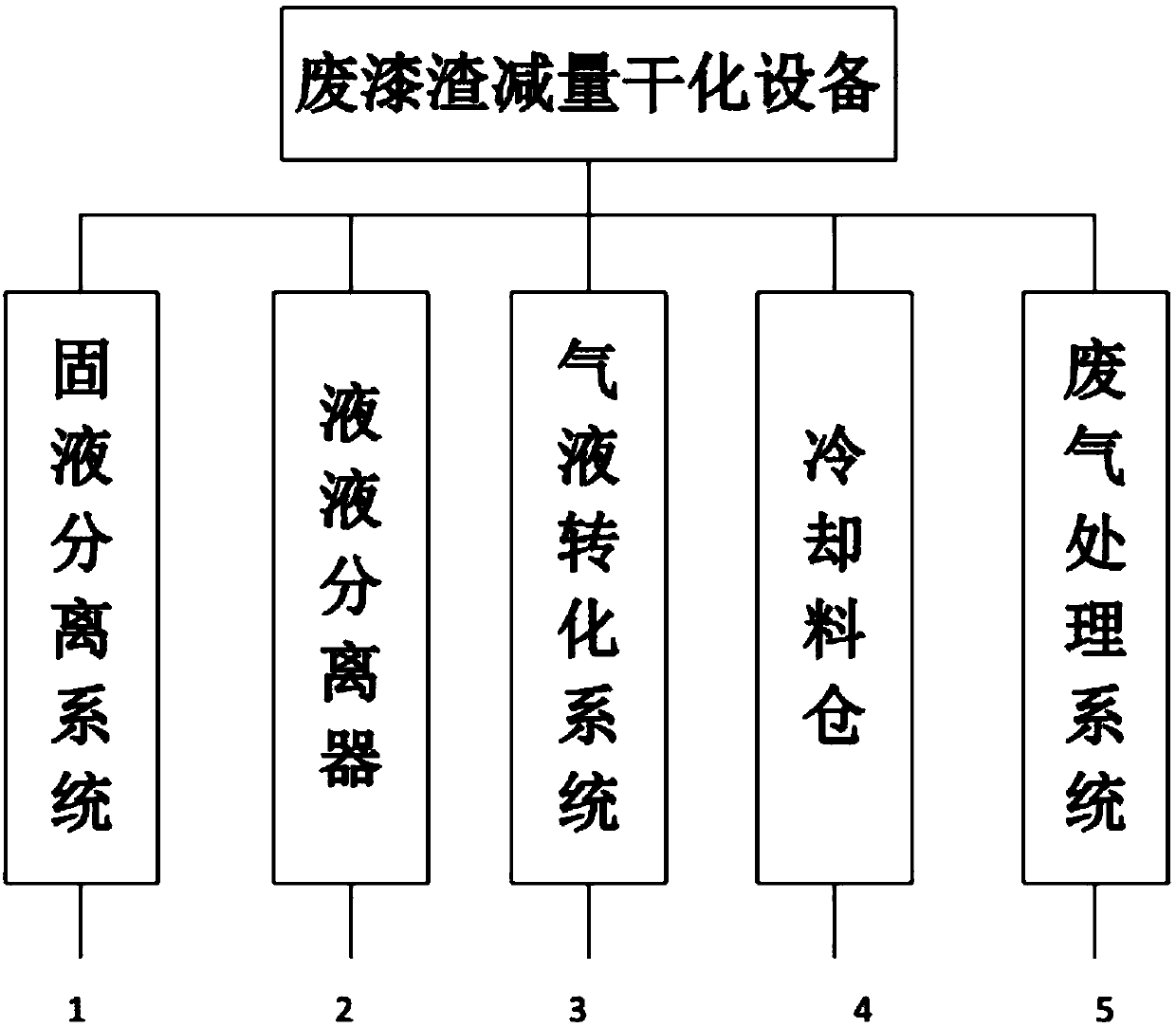

Solid-liquid separation system and device provided with system

PendingCN107588596AAchieve reductionAppropriate treatmentDrying solid materials without heatDispersed particle separationOrganic solventAdiabatic process

The invention discloses a solid-liquid separation system and a device provided with the system. The solid-liquid separation system comprises a drying box and a heat conducting oil tank, wherein a drying rack tube is arranged in the drying box and processes a material in a heat insulating process, the heat conducting oil tank comprises a plurality of electric heating tubes for heating heat conducting oil and provide a heat source for the drying box. After the heat conducting oil is heated by the heat conducting oil tank, the oil flows into the drying rack tube of the drying box and used for heating the material, water and an organic solvent evaporate in the heating process, separation with the material is achieved, finally the heat conducting oil flows back to the heat conducting oil tank again for reheating. The inside of the drying box is a negative pressure environment. On one hand, boiling points of the water the organic solvent are reduced, and the water the organic solvent are evaporated out at lower temperature; on the other hand, formation of sticky film wrapped air bubbles in the drying process of waste paint residues is destroyed, so that the dried waste paint residues arein honeycomb block shapes, the core wrapping problem is solved, thorough dryness is achieved, the working efficiency of the solid-liquid separation system is effectively improved, and the solid-liquid separation system has higher drying efficiency and is environmentally friendly and economic.

Owner:江苏瑞德斯环保科技有限公司

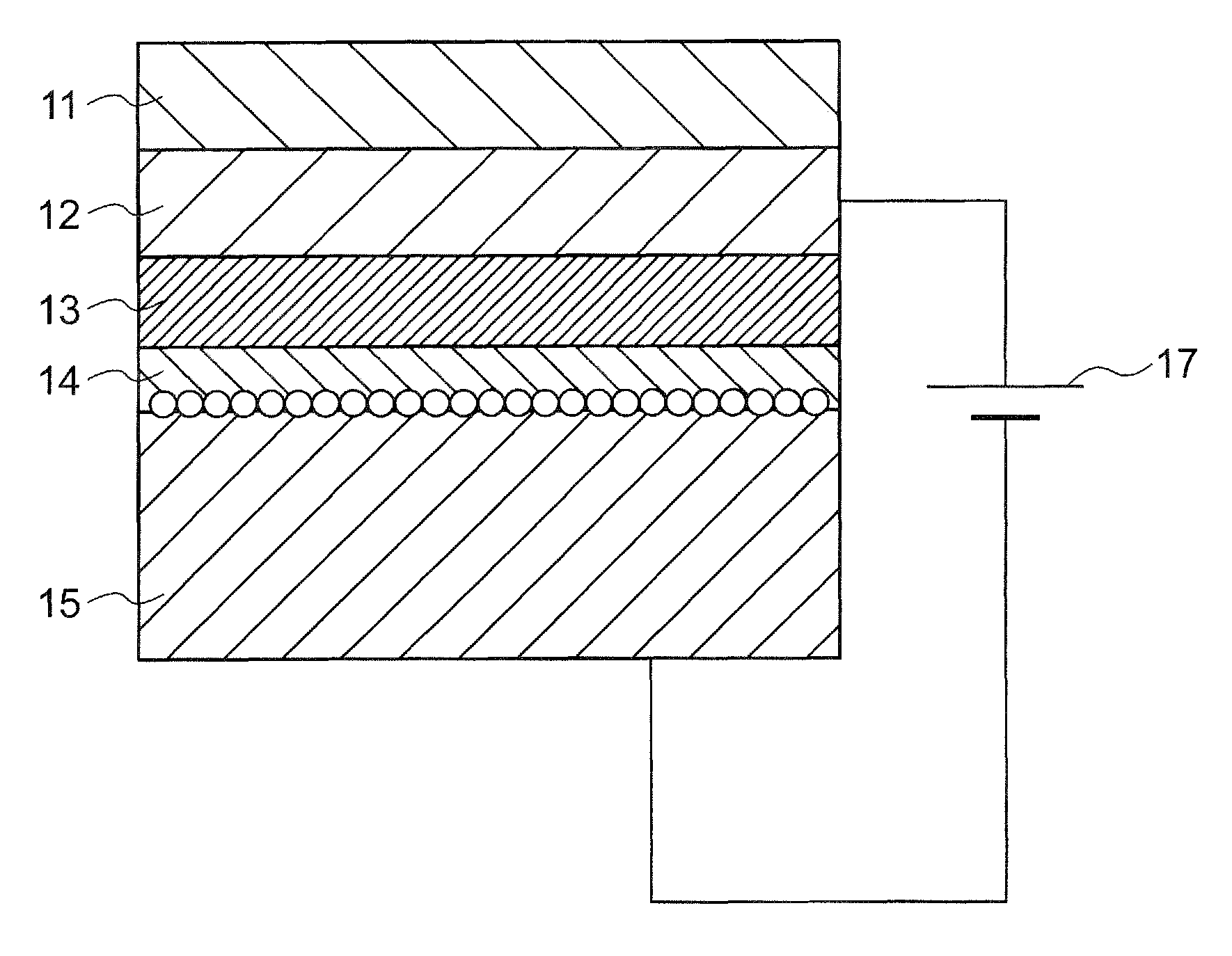

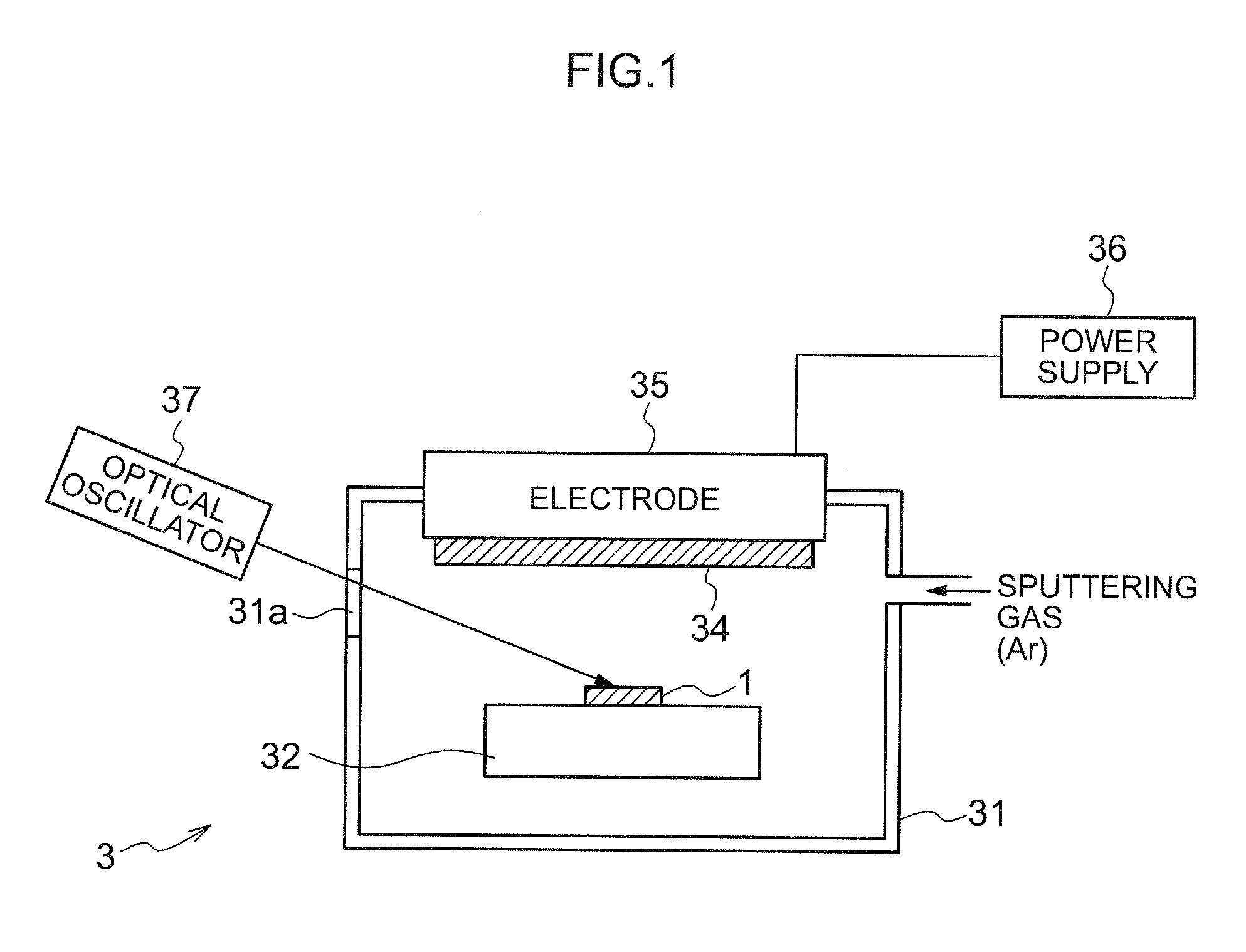

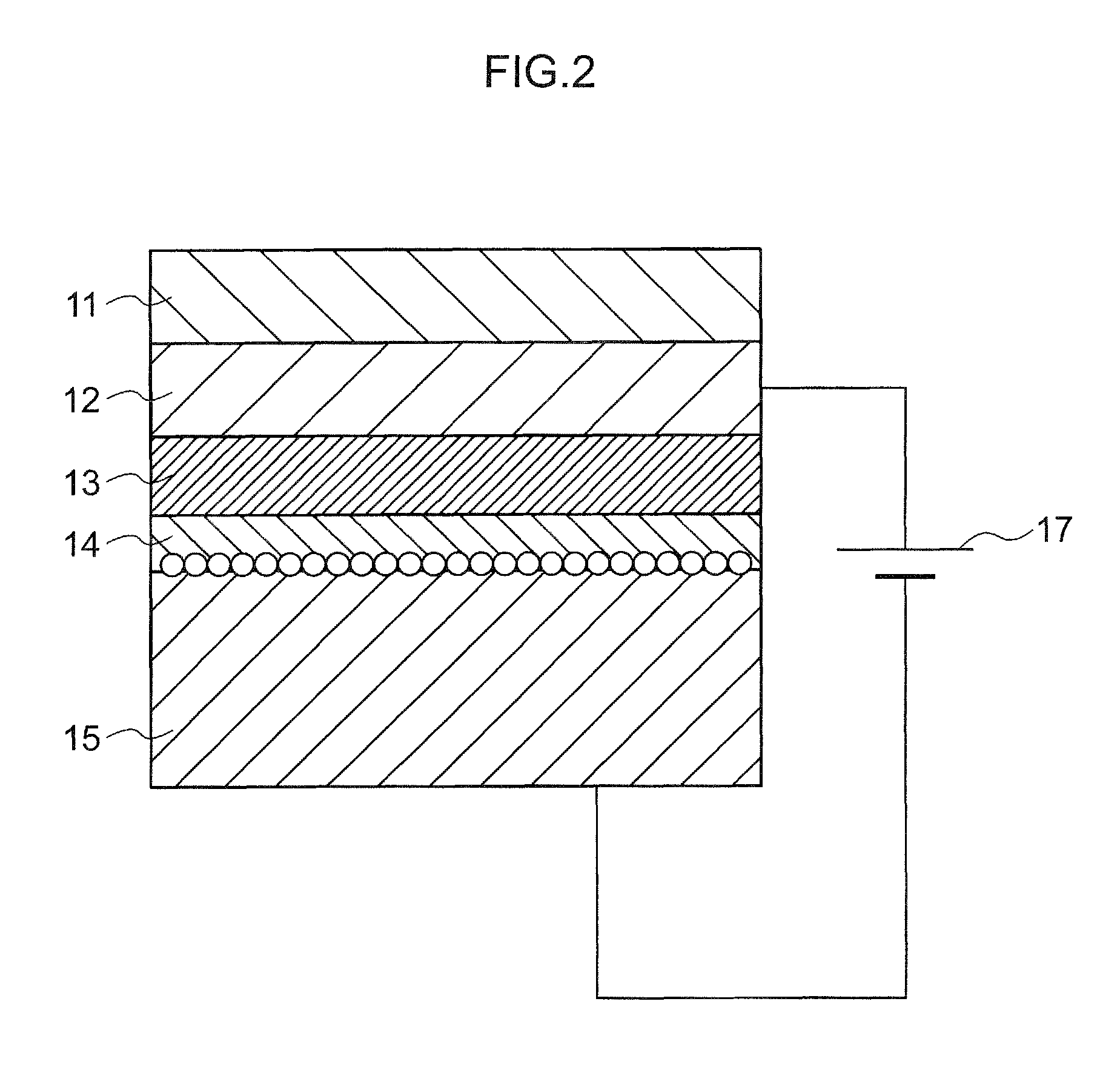

Method of fabricating light receiving element and apparatus for fabricating light receiving element

A method of fabricating a light receiving element includes depositing a material for one of a P-type semiconductor, an N--type semiconductor, and electrodes, while applying a reverse bias voltage and irradiating light of a desired wavelength longer than an absorption wavelength of the material. The deposition has a non-adiabatic flow of, at a portion where a local shape to enable generation of near field light is formed on a surface of the deposited material with the irradiation light, absorbing the irradiation light through a non-adiabatic process with the near field light, thereby generating electrons, and canceling generation of a local electric field based on the voltage, and a particle adsorbing flow of, at a portion where the shape is not formed, causing the portion where the local electric field is generated to sequentially adsorb particles forming the material, and shifting to the non-adiabatic flow when the shape is formed.

Owner:JAPAN SCI & TECH CORP

Controller for and method of controlling internal combustion engine

InactiveUS8862366B2Simple calculationCorrection errorAnalogue computers for vehiclesElectrical controlAdiabatic processEngineering

Owner:TOYOTA JIDOSHA KK

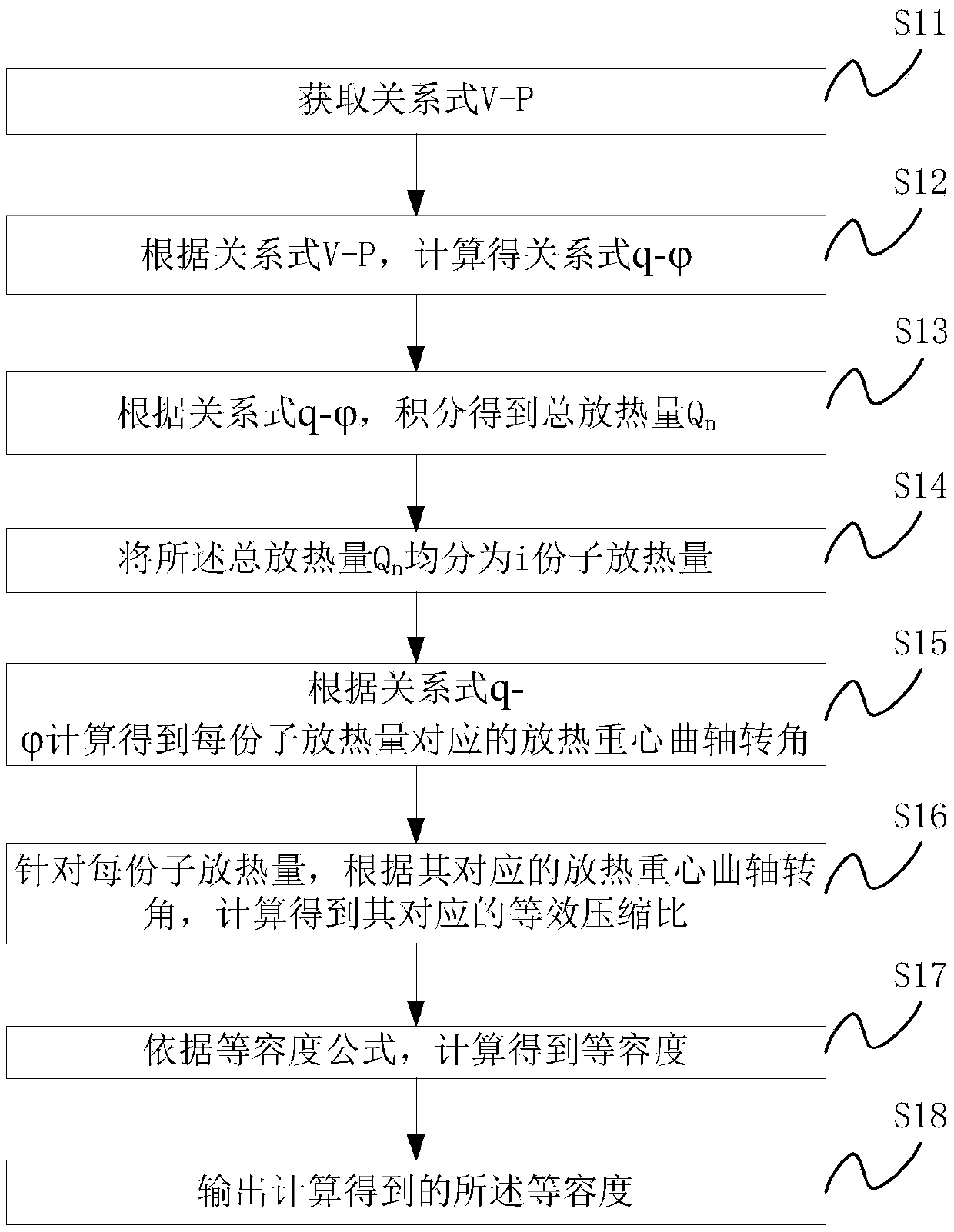

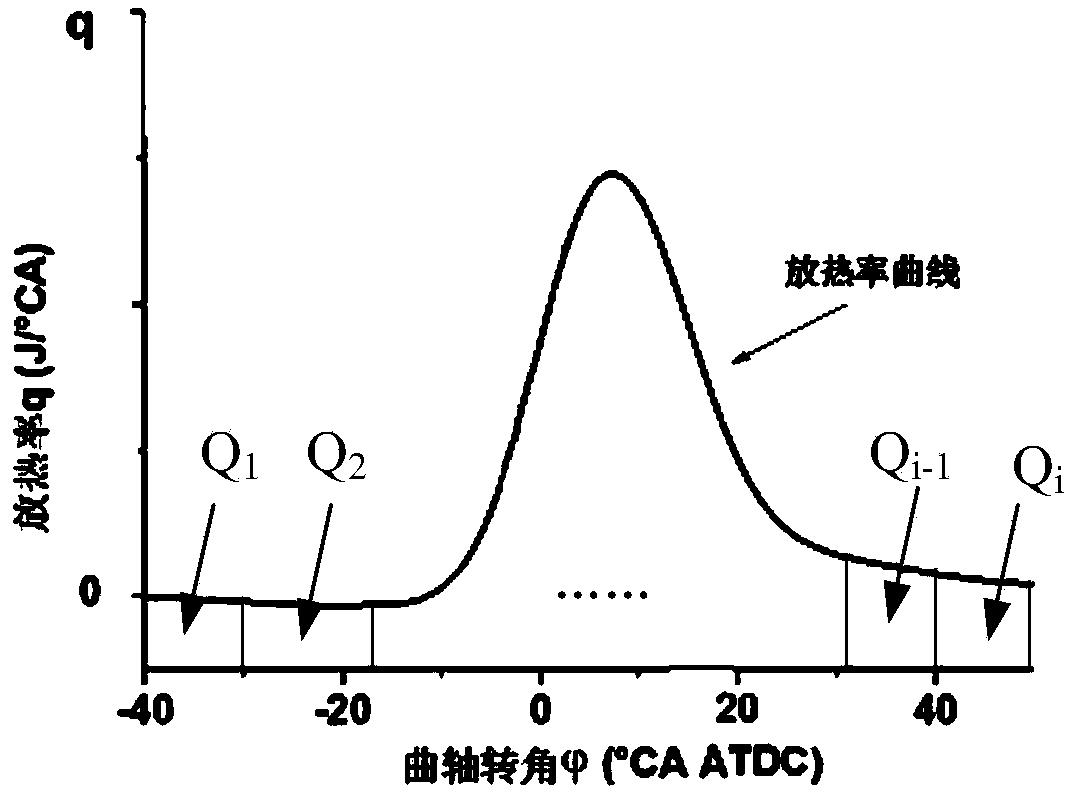

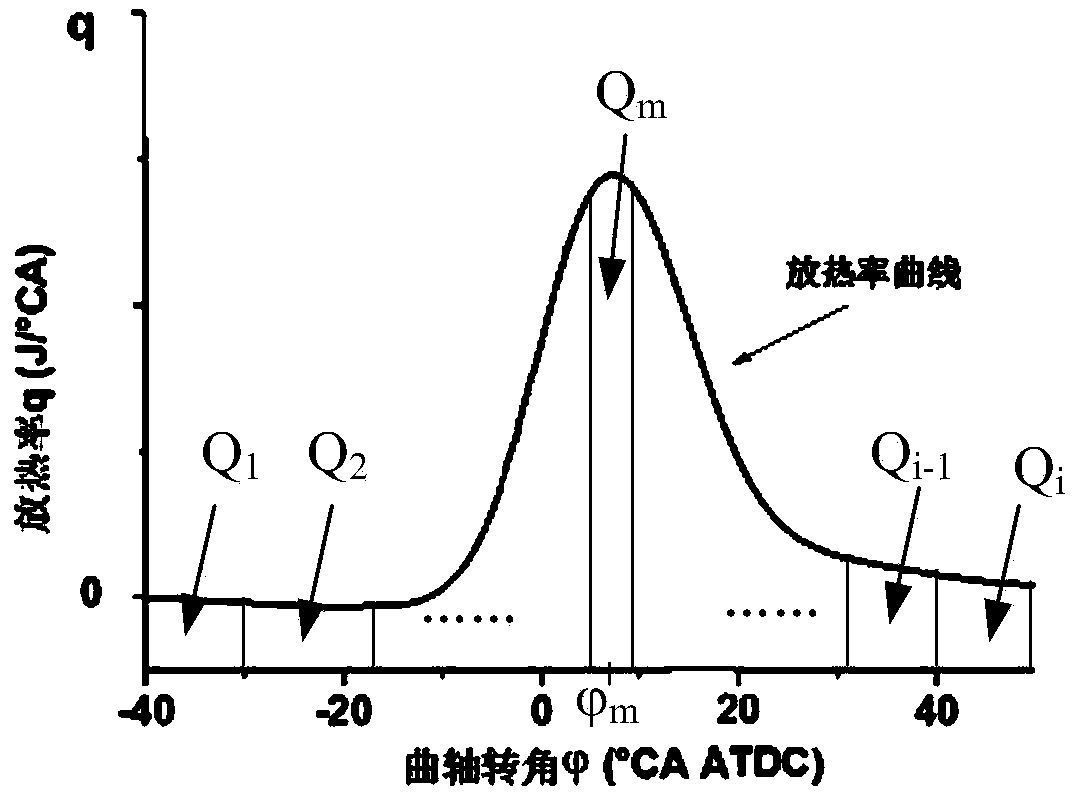

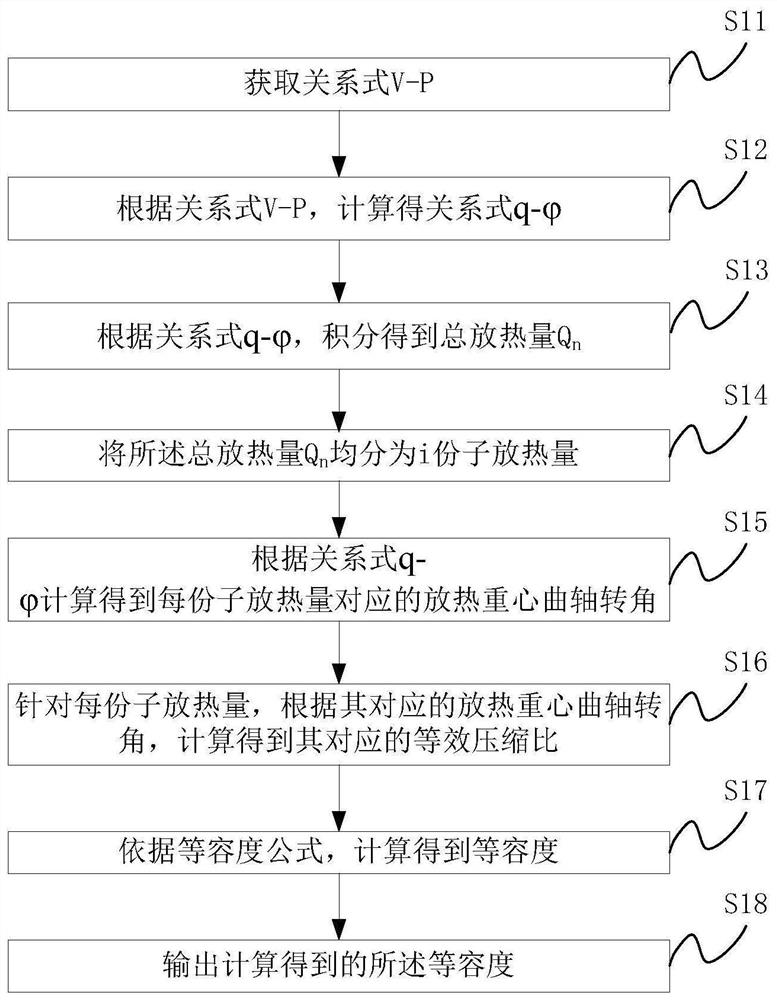

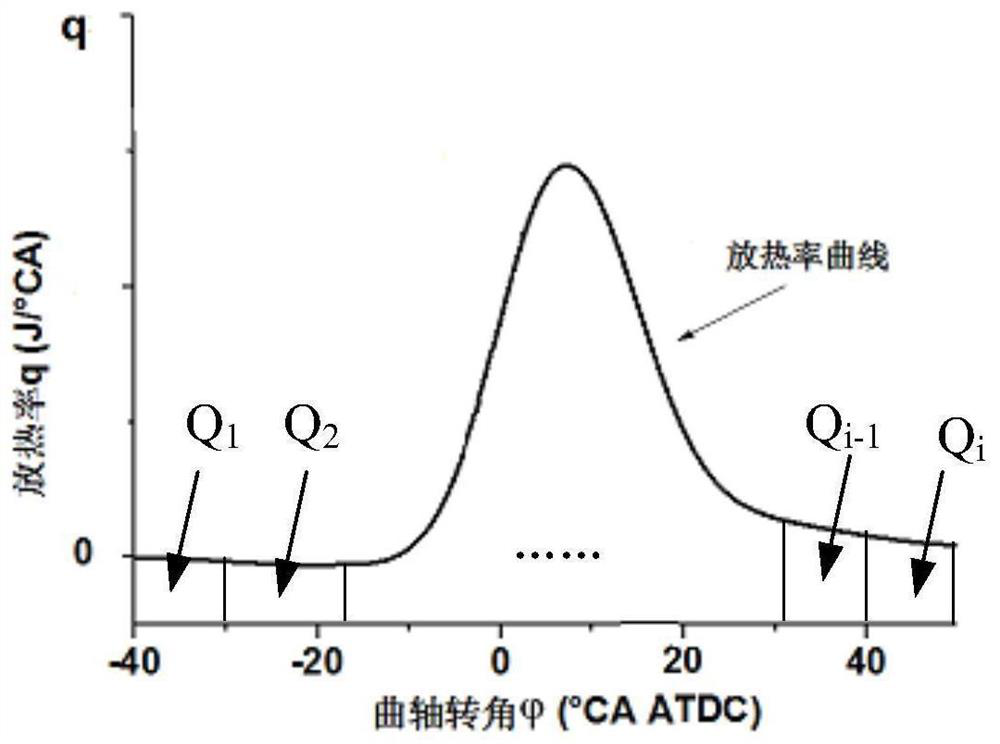

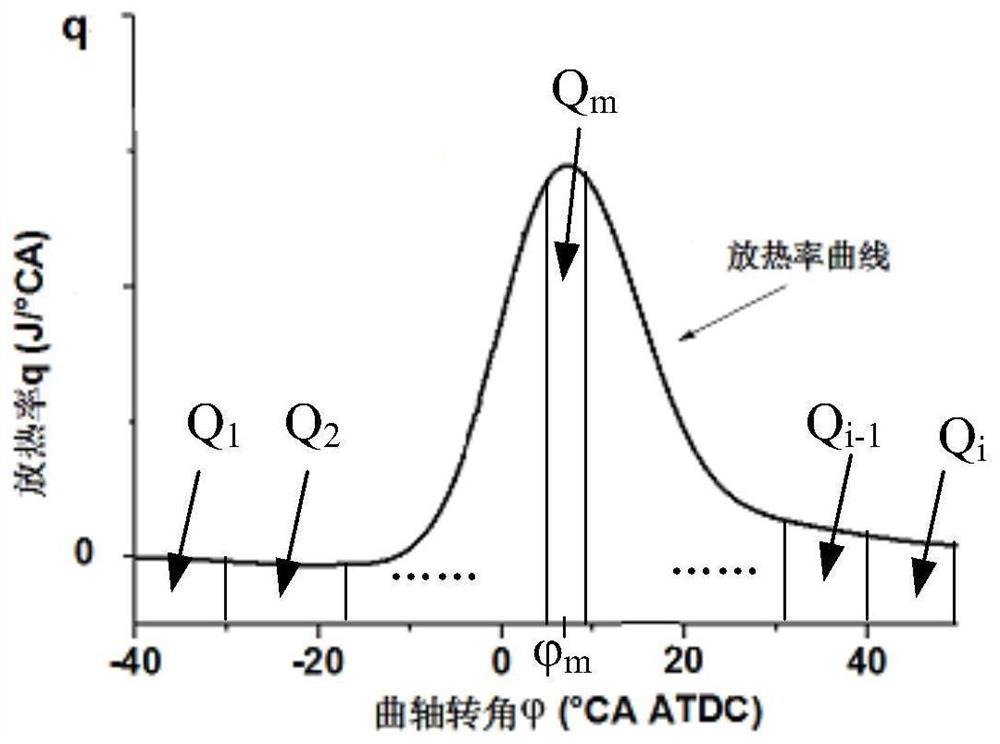

Engine combustion isometric degree calculation method and device and engine combustion analyzer

ActiveCN111006872AGas-turbine engine testingJet-propulsion engine testingCombustion analysisAdiabatic process

The invention discloses an engine combustion isometric degree calculation method and device and an engine combustion analyzer, and belongs to the technical field of engines. The method comprises the steps that the total heat release amount Qn of an actual combustion cycle is equally divided into multiple sections of constant-volume heat release at different crankshaft corners, and the heat releasesections are considered to be adiabatic processes; and the actual combustion cycle is divided into multiple sections of Otto cycles, the average heat efficiency of the divided multiple sections of Otto cycles is compared with the theoretical heat efficiency of the combustion cycle of the engine, and the isometric degree of the actual combustion cycle is obtained and output. According to the invention, the isometric degree of the combustion cycle of the engine can be displayed in real time, direct and objective reference data is provided for combustion analysis and diagnosis in actual engineering, and reference data is provided for automatic calibration work of the engine.

Owner:SAIC MOTOR

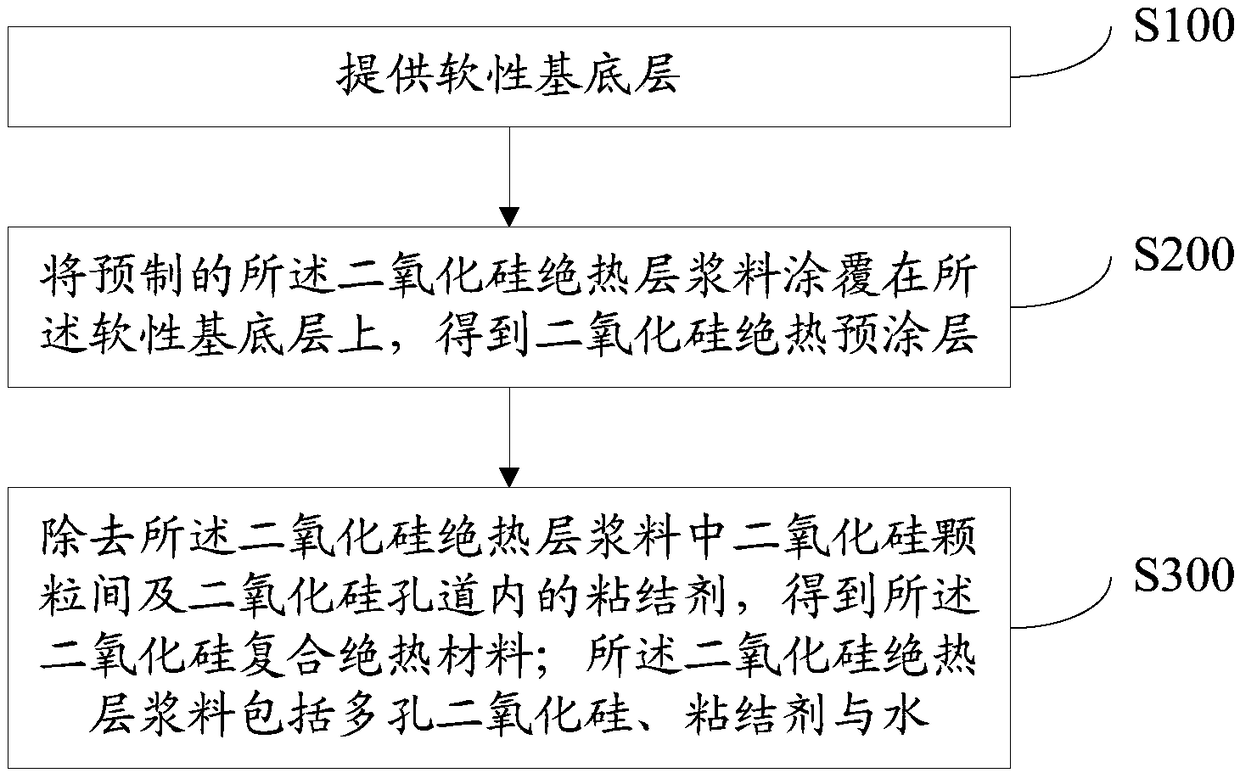

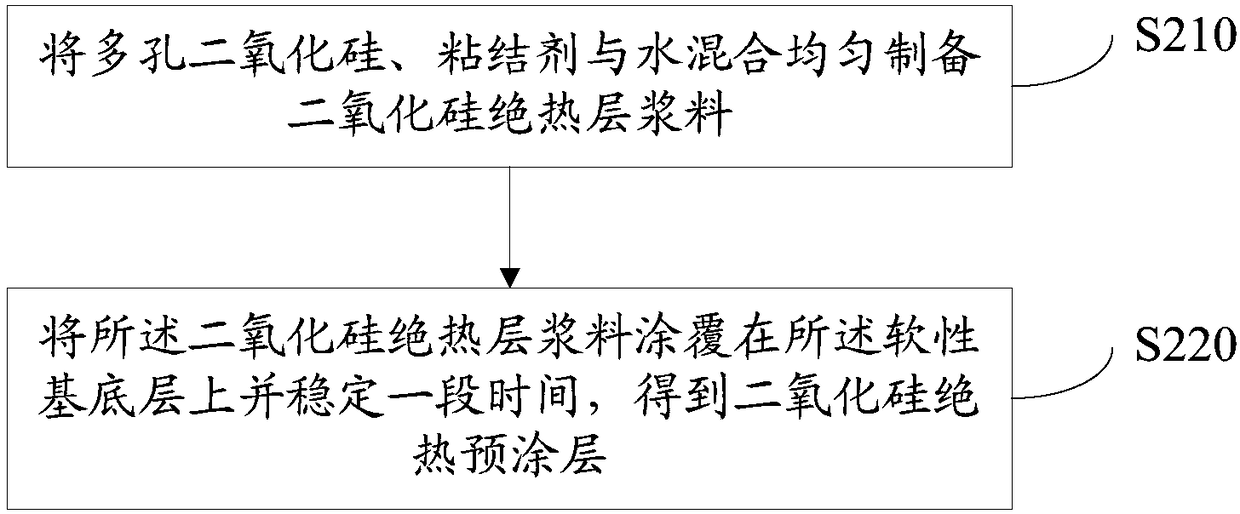

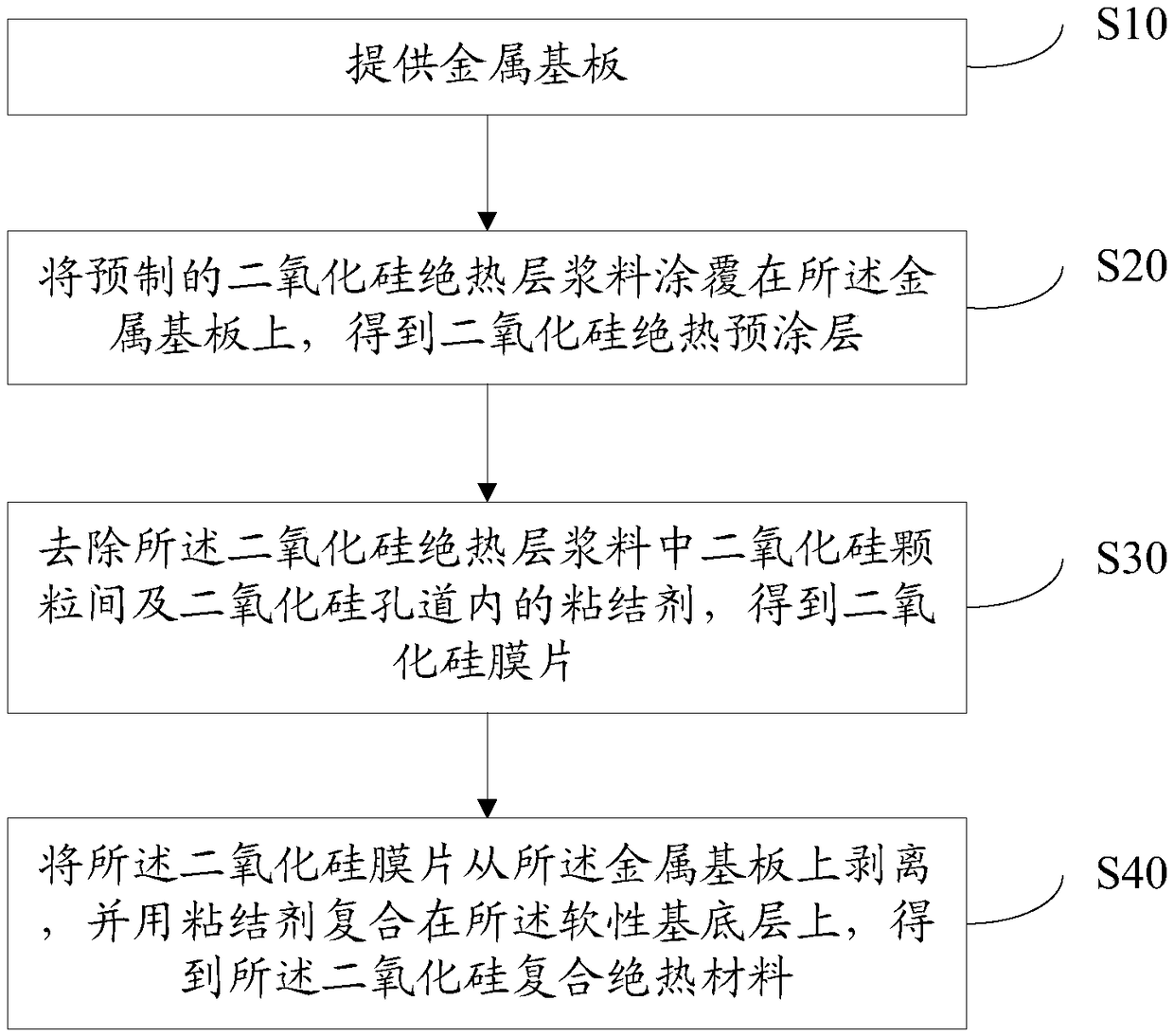

Coating machine oven, silicon dioxide composite thermal insulation material and preparation method thereof

InactiveCN108422722AGood insulation performanceReduced risk of breakageLamination ancillary operationsSynthetic resin layered productsAdiabatic processThermal insulation

The invention provides a coating machine oven, a silicon dioxide composite thermal insulation material and a preparation method thereof. The method comprises: providing a soft base layer; coating thesoft base layer with a prefabricated silicon dioxide thermal insulation layer slurry to obtain a silicon dioxide thermal insulation precoated layer; and removing a binder among porous silicon dioxideparticles and in the pore channels of porous silicon dioxide in the silicon dioxide thermal insulation layer slurry to obtain the silicon dioxide composite thermal insulation material. Specifically, the silicon dioxide thermal insulation layer slurry comprises porous silicon dioxide, the binder and water. By the way, the thermal insulation process can be more reliable, also the operation is convenient, and the application range is wide.

Owner:SHENZHEN QIANHAI YOURONG TECH LTD

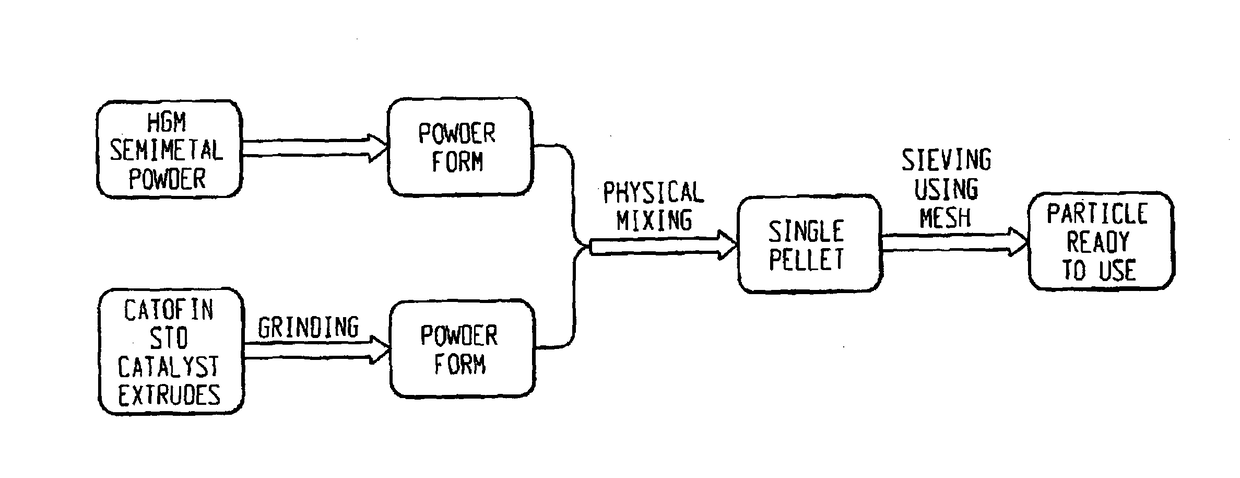

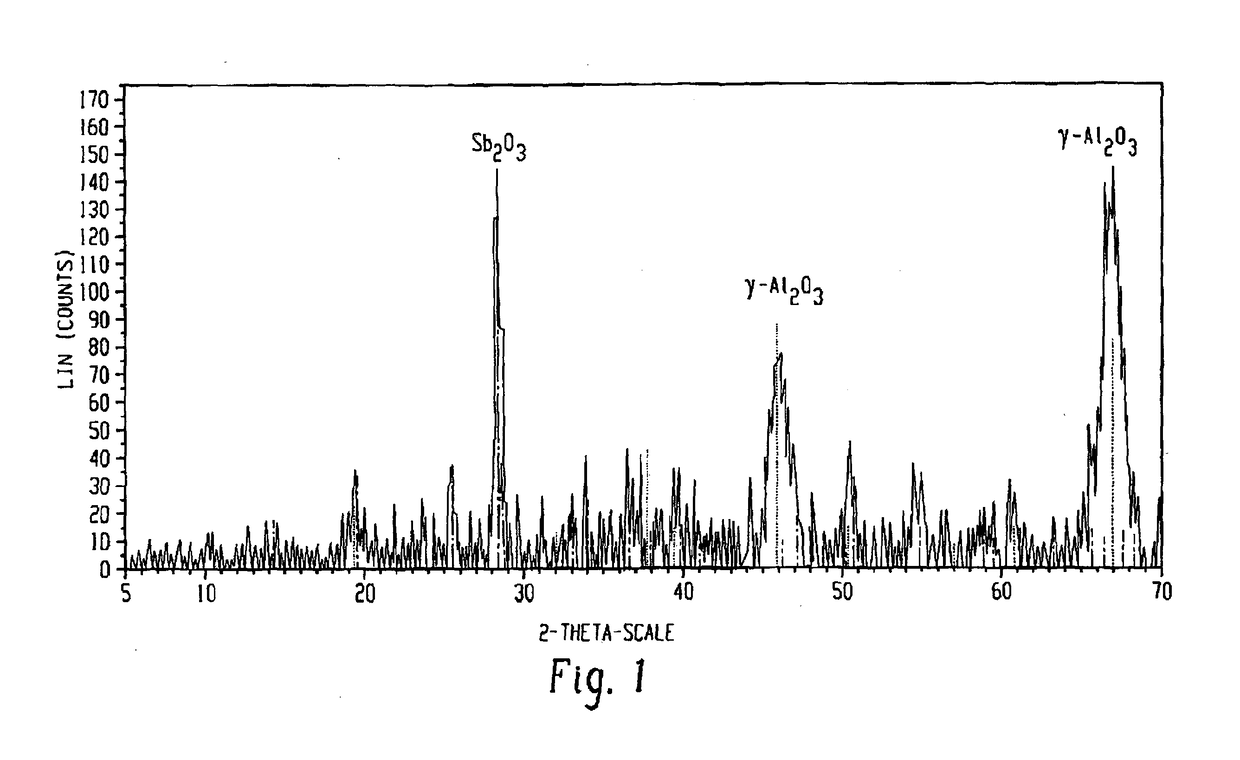

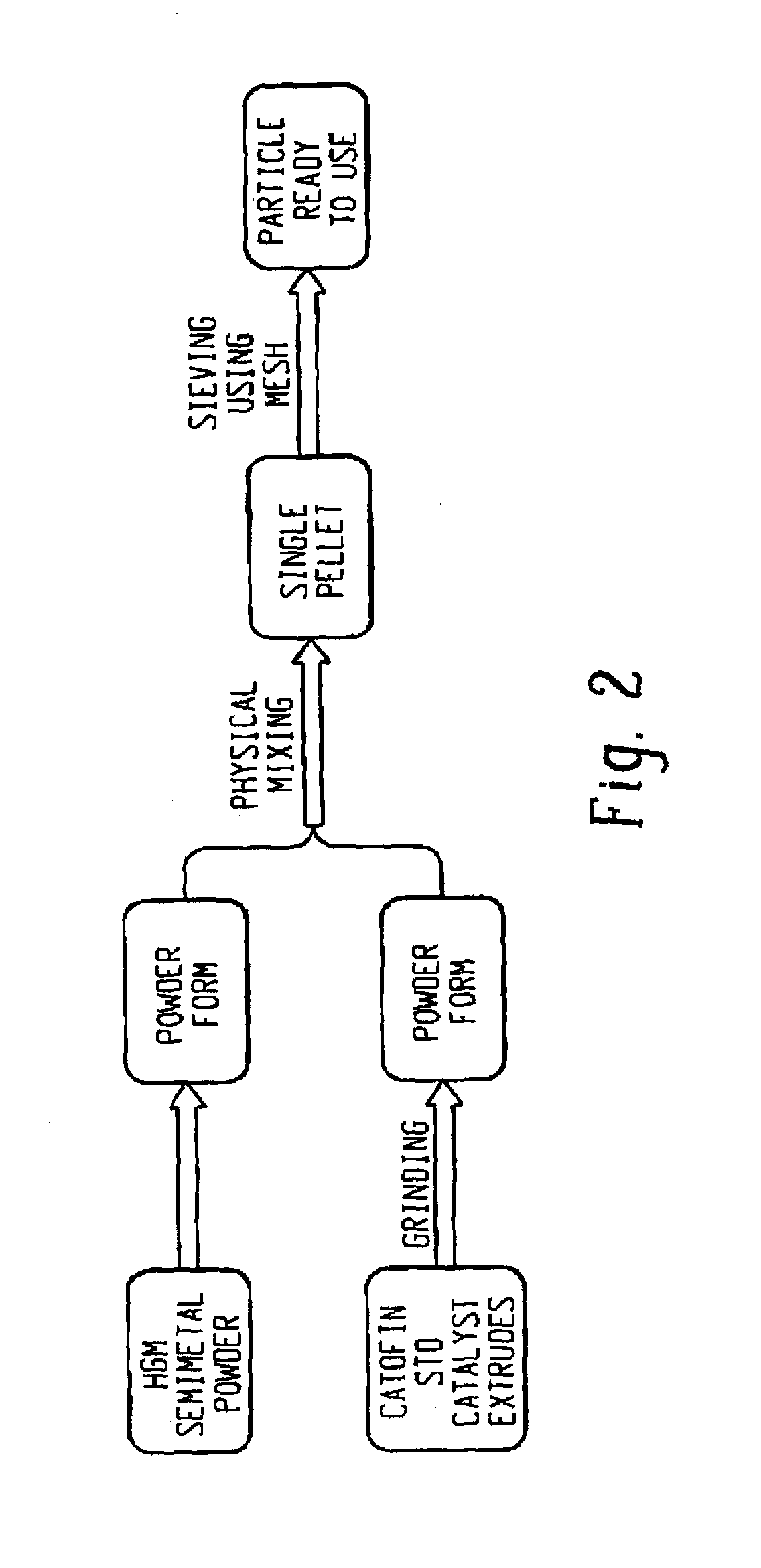

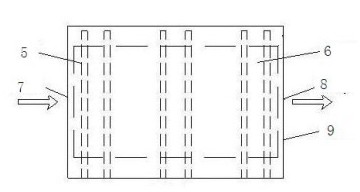

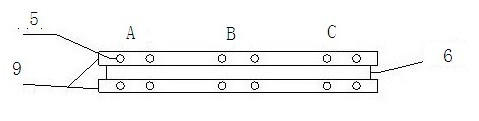

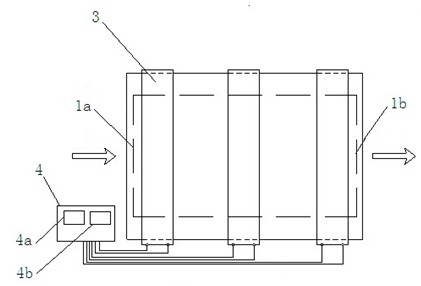

Catalytic composite and improved process for dehydrogenation of hydrocarbons

InactiveUS20180029015A1Hydrocarbon by dehydrogenationCatalyst regeneration/reactivationCyclic processAlkane

A catalytic composite for a cyclic process of adiabatic, non-oxidative dehydrogenation of an alkane into an olefin, comprising a dehydrogenation catalyst, a semimetal and a carrier supporting the catalyst and the semimetal. During the reduction and / or regeneration stages of the adiabatic process, the semimetal releases heat which can be used to initiate the dehydrogenation reactions, which are endothermic in nature, thereby reducing the need for hot air flow and combustion of coke as heat input. The semi-metal is inert towards the dehydrogenation reaction itself, alkane feed and olefin product as well as other side reactions of the cyclic process such as cracking and decoking.

Owner:SABIC GLOBAL TECH BV

An electromagnetic heating FRP profile pultrusion machine

The invention relates to an electromagnetic heating type pultrusion machine for FRP profiles, which includes a forming die, a die clamp, an electromagnetic coil and a controller. In the middle, the electromagnetic coil is sleeved on the forming mold and the mold fixture and connected to the controller, and the two sides of the forming mold are respectively provided with a material inlet and a material outlet. The present invention uses electromagnetic heating to heat only the mold, which has high thermal efficiency and remarkable energy-saving effect; the electromagnetic coil used in the present invention is subjected to heat insulation treatment, which will not age, and the maintenance cost is greatly reduced; the present invention uses electromagnetic heating, only the mold itself is heated, so It will not affect the equipment itself and the surrounding environment, can effectively reduce the room temperature, and improve the working environment; the heating method adopted in the present invention has a fast heating speed, and can easily control the temperature of the mold by controlling the number of coils or the power supply voltage. The control is simple, flexible and high precision.

Owner:NANJING JIHUA 3521 SPECIAL EQUIP

A single-valve expander system and method for isothermal expansion

ActiveCN104358593BExpansion progression reductionSingle-stage expansion ratio increaseMachines/enginesEngine componentsWorking fluidAdiabatic process

The invention relates to a single-valve expander system and method for isothermal expansion, which can be applied to small / miniature compressed air energy storage systems or other power systems, and realize quasi-isothermal expansion by spraying mist or foam medium into the gas in the expansion process process, thereby increasing the output power per unit of working fluid and improving the overall efficiency of the system. The specific method is that the top of the cylinder is equipped with an intake valve and an annular injector, the intake valve communicates with an external high-pressure gas working medium source, and the annular injector communicates with an external heating medium source system, during the working process of the expander , the heated heating medium is atomized or foamed and injected into the cylinder at a certain mass flow rate. Compared with the traditional single-valve expander, the present invention can make the expansion process obviously deviate from the adiabatic process, obtain a "quasi-isothermal expansion" process close to isothermal, and improve the output power per unit of working fluid and the working efficiency of the expander.

Owner:华科超能(北京)能源科技有限公司

Continuous thermo-insulation method for production of nitro-chlorobenzene

The present invention relates to a continuous adiabatic process for preparing nitrochlorobenzene, in which the waste sulfuric acid produced during the practice of the process is reconcentrated and recycled into the nitration reaction.

Owner:LANXESS DEUTDCHLAND GMBH

An isothermal compressed air energy storage system and method

ActiveCN104806313BLarge specific heat capacityIncrease the heat exchange areaPositive displacement pump componentsPiston pumpsAdiabatic processVapor–liquid separator

The invention relates to a constant temperature compressed air energy storage system and method. Ejectors are respectively arranged at air inlets of a compressor unit and an expander unit; during an energy storage compressing process, a quasi isothermal compression process is realized by spraying a mist or spumescent liquid heat transfer medium into the compressed air, so that the compression work of unit working medium is reduced; an air-liquid separator is assembled behind the compressor unit and is used for separating and storing the cooling medium in the compressed air; during an energy-releasing expansion process, a quasi isothermal expansion process is realized by spraying the mist or spumescent liquid heat transfer medium into the gas during the expansion process, so that the output work of unit working medium is increased and the whole efficiency of the system is increased. Compared with the traditional compressed air energy storage system, the constant temperature compressed air energy storage system has the advantages that the compressing and expanding processes can be obviously deviated from the adiabatic process, the almost constant-temperature quasi isothermal compression and quasi isothermal expansion processes are acquired, and the working efficiency of the system is increased.

Owner:华科超能(北京)能源科技有限公司

Engine combustion isovolume calculation method, device and engine combustion analyzer

ActiveCN111006872BGas-turbine engine testingJet-propulsion engine testingCombustion analysisAdiabatic process

The invention discloses a method, device and engine combustion analyzer for calculating the equal volume of combustion of an engine, belonging to the technical field of engines. The method includes calculating the total heat release Q of an actual combustion cycle n Evenly divided into multi-stage equal-volume heat release at different crank angles, and each heat release stage is considered as an adiabatic process. In this way, an actual combustion cycle is divided into multi-stage Otto cycles, and the average thermal efficiency ratio of the divided multi-stage Otto cycles is The theoretical thermal efficiency of the combustion cycle of the engine is obtained and outputted from the isovolumic value of the actual combustion cycle. The invention can display the isovolume of the engine combustion cycle in real time, provides direct and objective reference data for combustion analysis and diagnosis in actual engineering, and provides reference data for the automatic calibration of the engine at the same time.

Owner:SAIC MOTOR

Continuously operated adiabatic method for producing nitrobenzene by nitration of benzene

ActiveCN112939781AAvoid formingImprove stable operation cycleChemical industrySulfur compoundsBenzeneAdiabatic process

Owner:WANHUA CHEMICAL (NINGBO) CO LTD +1

Adiabatic process for making mononitrobenzene

ActiveCN102209703BChemical/physical/physico-chemical stationary reactorsNitro compound preparationBenzeneAdiabatic process

Owner:NORAM INT LTD

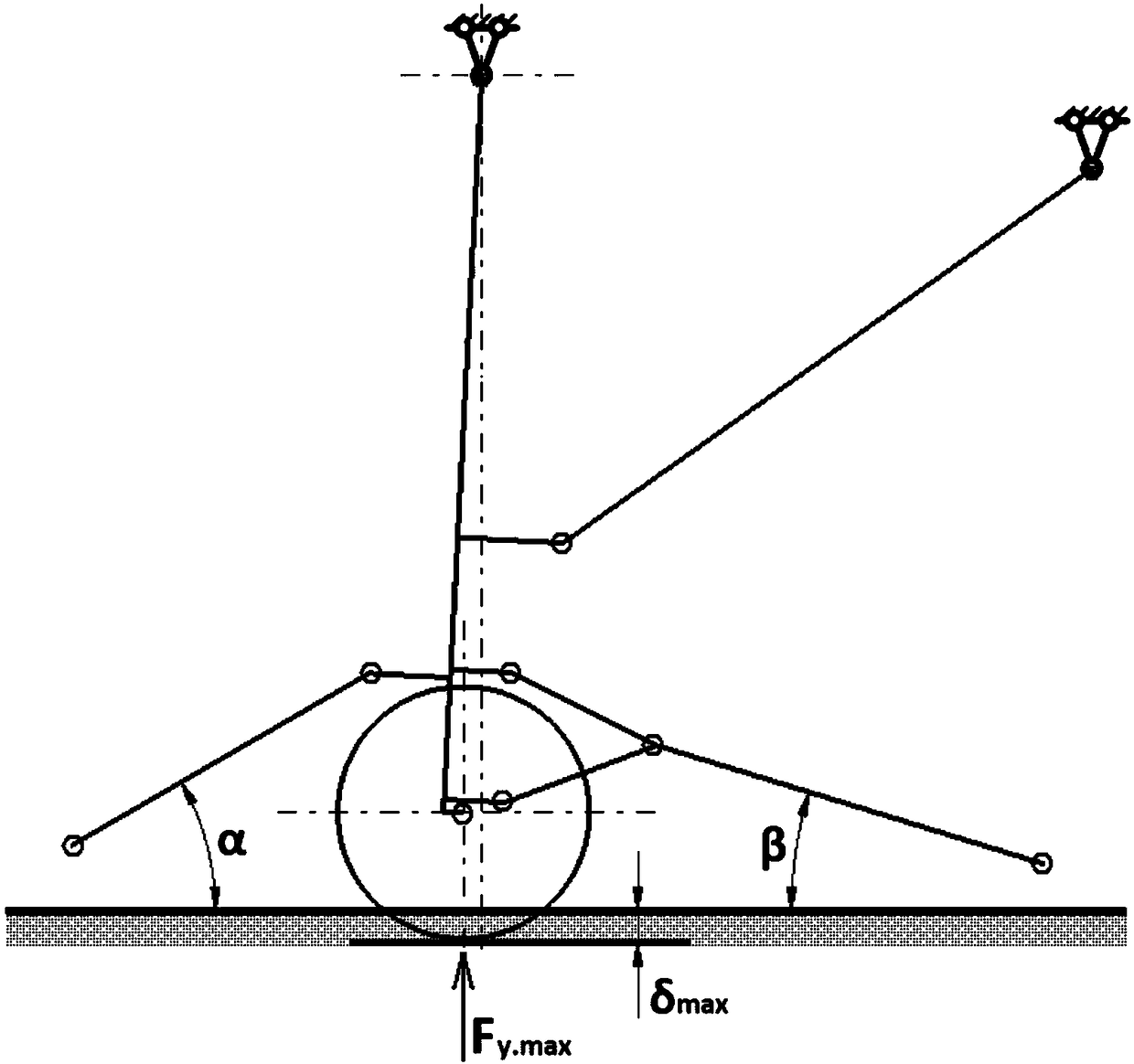

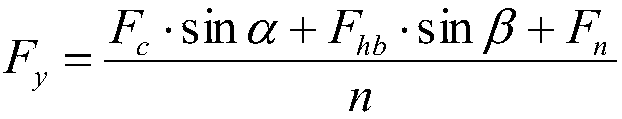

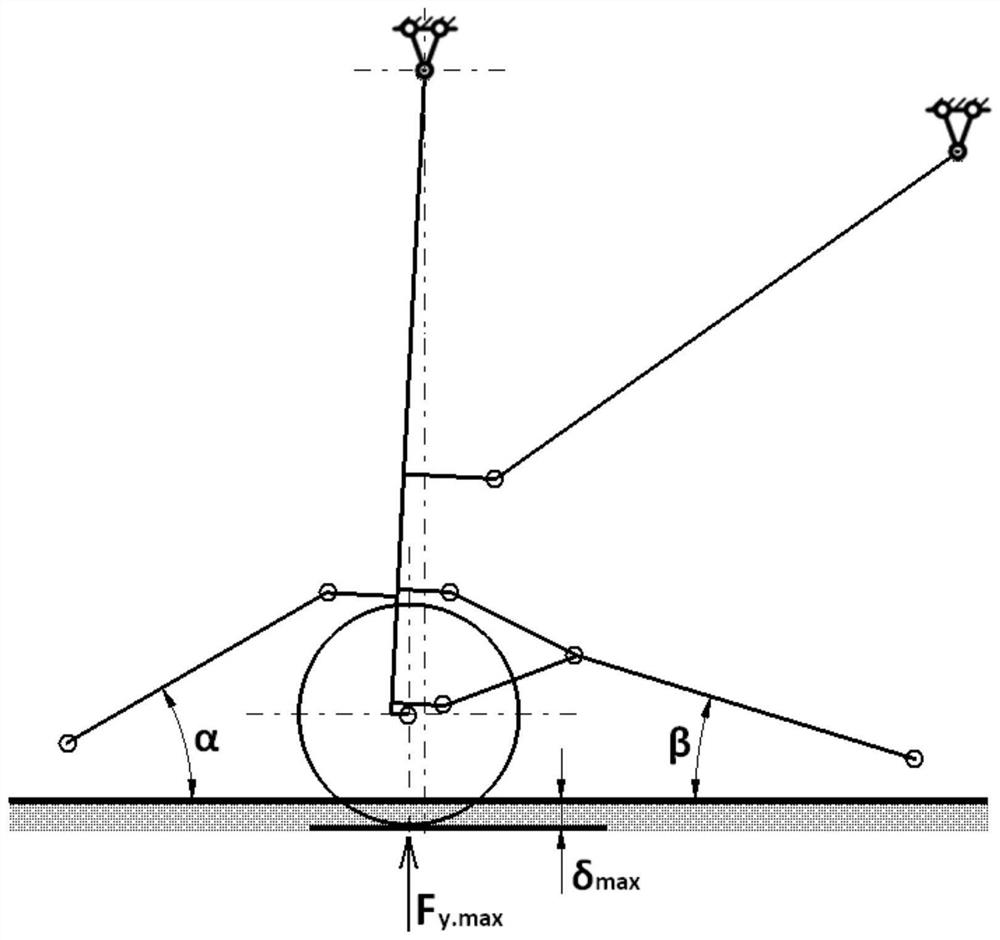

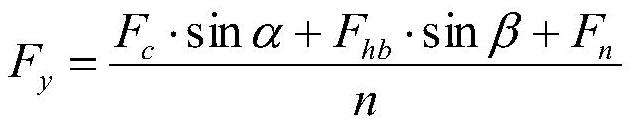

Method for calculating maximum deflection of tires of aircraft taking off in stress state

ActiveCN108304638AAccurate calculation of maximum sinkageGeometric CADDesign optimisation/simulationAdiabatic processThermal insulation

The invention relates to a method for calculating the maximum deflection of tires of an aircraft taking off in a stress state, and belongs to the field of aircraft design. The method includes the steps of firstly, calculating the tire vertical force Fy in the stress state; secondly, determining the tire deflection delta of the tires according to the tire vertical force Fy. Compared with the method, the method has the advantages that the problem that the calculation of the maximum deflection of the undercarriage tires of the land-based aircraft is precise in the prior art, but large errors exist in the calculation of the maximum deflection of the undercarriage tires of the aircraft taking off in the stress state in the prior art is solved, the method is suitable for calculating the maximumdeflection of the undercarriage tires of the aircraft taking off in the stress state, and errors are within 5% compared with measured data; the loads of catapult bars and holdback bars are consideredin the method but not considered in the prior art; the constant-temperature process is adopted for gas inside tires when the compression amount of the tires is calculated in the prior art, but rapid compression characteristics are considered and the thermal insulation process is adopted in the method.

Owner:SHENYANG AIRCRAFT DESIGN INST AVIATION IND CORP OF CHINA

Adiabatic process for making mononitrobenzene

ActiveCN102209703AChemical/physical/physico-chemical stationary reactorsNitro compound preparationBenzeneAdiabatic process

An adiabatic process for making mononitrobenzene by the nitration of benzene which minimizes the formation of nitrophenols and dinitrobenzene by-products. The process uses a mixed acid having less than 3 wt% nitric acid, 55 to 80 wt% sulfuric acid, and water. The initial temperature of the mixed acid is in the range of 60 to 96 DEG C. The nitration reaction is complete in about 300 seconds and produces less than 1,200 ppm nitrophenols and less than about 80 ppm dinitrobenzene. The reaction can be carried out in a plug-flow or a stirred pot reactor, or a combination of such reactors.

Owner:NORAM INT LTD

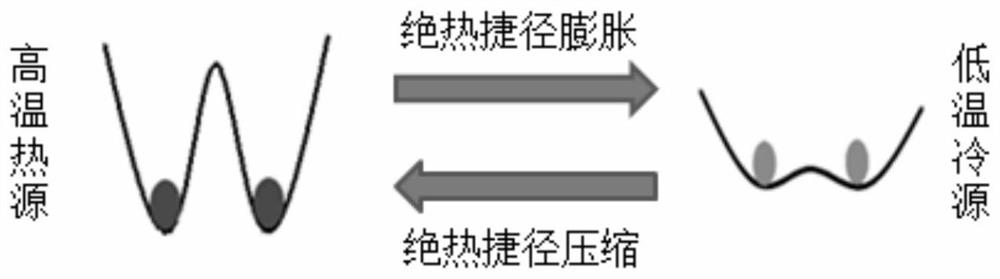

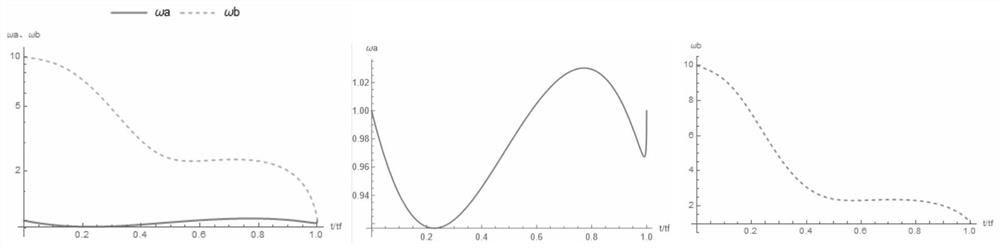

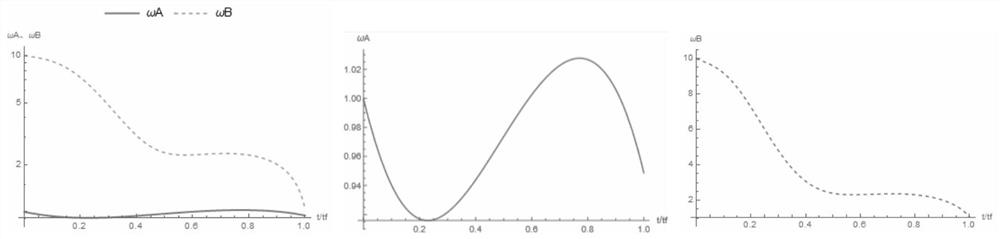

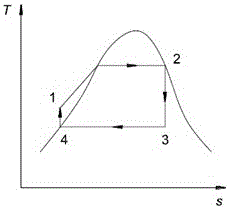

Quantum adiabatic shortcut heat engine with coupled harmonic oscillator as working medium and design method of its adiabatic shortcut process

ActiveCN111120236BIncrease powerLow powerMachines/enginesUsing photonsAdiabatic processWorking fluid

The invention discloses a quantum adiabatic shortcut heat engine using a coupled harmonic oscillator as a working medium and a design method of the adiabatic shortcut process. The heat engine uses the coupled harmonic oscillator as the working medium, and realizes the thermodynamic cycle of the heat engine through four processes of equal-volume heat absorption, adiabatic shortcut expansion, constant-volume heat release, and adiabatic shortcut compression. The adiabatic shortcut expansion process and the adiabatic shortcut compression process are adiabatic shortcut processes, which are used to replace the adiabatic process in the traditional heat engine. With the help of the anti-control method based on Lewis-Riesenfeld quantum invariants, an adiabatic shortcut is designed for the eigenfrequency of the coupled harmonic oscillator, and then the adiabatic shortcut process of the frequency change of the coupled harmonic oscillator is obtained by using the transformation relationship between the eigenfrequency and the bare frequency. Using the invention to drive the heat engine to complete the adiabatic stroke of the thermodynamic cycle increases the power more than 5 times. Compared with traditional heat engines, this heat engine does not reduce efficiency while increasing power, thus overcoming the problem of power-efficiency antagonism.

Owner:SHANGHAI UNIV

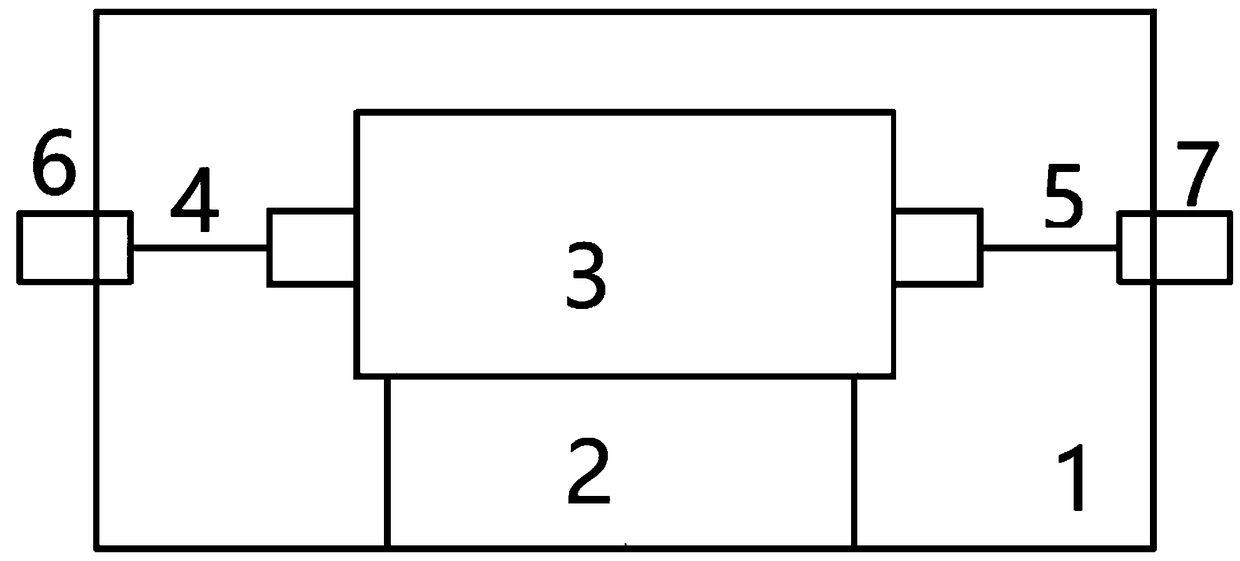

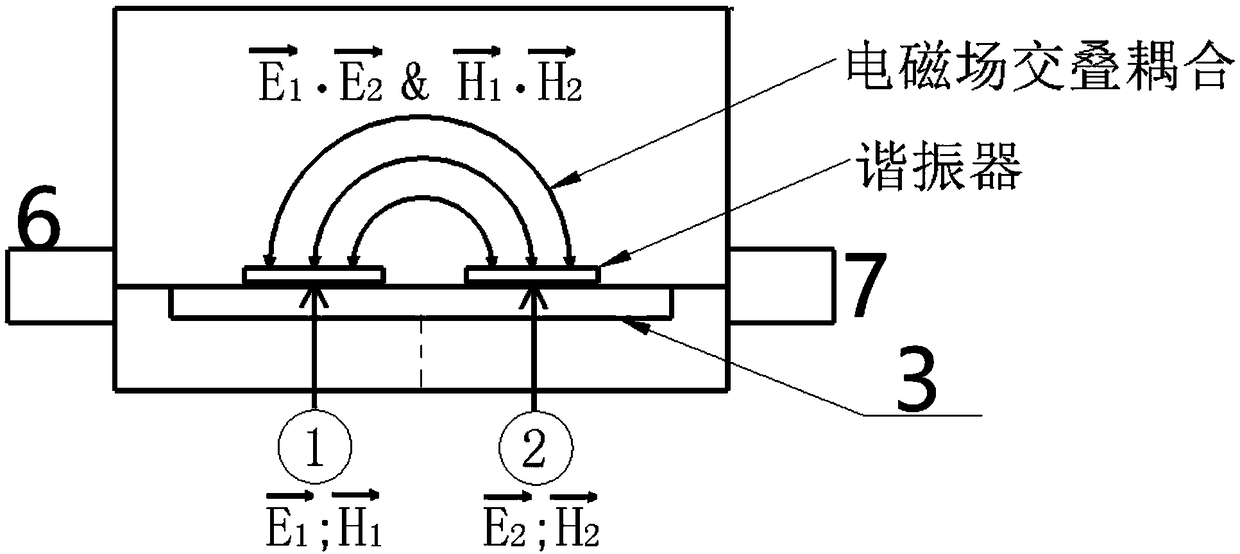

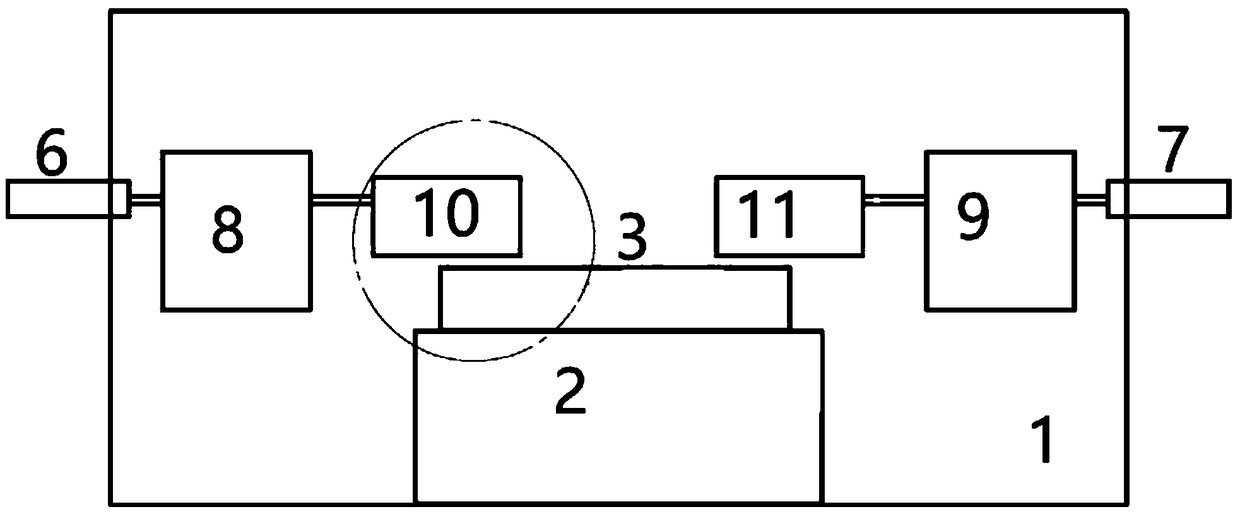

A low temperature microwave filtering system based on electromagnetic coupling in adiabatic space

ActiveCN109167127ASolve the problem of large conduction heat leakageReduce conduction heat leakageWaveguide type devicesAdiabatic processEngineering

The invention discloses a low-temperature microwave filtering system based on electromagnetic coupling of adiabatic space, The invention can effectively solve the problem that the conductive heat leakage of the low-temperature microwave filter module is large due to the direct connection of the input and output cables, and the conductive heat leakage of the low-temperature microwave filter moduleis reduced by the way of electromagnetic coupling in the adiabatic space, so that the whole temperature of the low-temperature microwave filter module is uniform and stable, and the performance of thelow-temperature microwave filter module is more stable and excellent; (cable with more excellent performance, i. E., coarser and short than previously available, enable that overall volume of the microwave electronic system to be reduced, the performance to be better, the power to be great, and the miniaturization of the microwave electronic system to be facilitated; On the premise of installingthe same number of cryogenic filter modules, the power consumption of the refrigeration platform is greatly reduced, and the volume and manufacturing cost of the superconducting electronic system aregreatly reduced. It makes possible the realization of some multi-channel superconducting electronic systems which can not be manufactured due to the limitation of cryogenic platforms.

Owner:TSINGHUA UNIV

Controller for and method of controlling internal combustion engine

InactiveCN102348883BAccurately determineCooling Loss AccurateElectrical controlInternal combustion piston enginesAdiabatic processPeak value

Heat generation amount PVκ(θ) is calculated with the use of cylinder pressure P(θ), detected by a cylinder pressure sensor, cylinder, volume V(θ), and specific heat ratio κ (steps 100 to 102). A crank angle θfix, at which the value of PVκ(θ) peaks, is determined as a start crank angle, at which an adiabatic process after combustion starts (step 104). A correction coefficient Kfix is calculated based on the variation of the value of PVκ(θ) after θfix (step 106). An actual heat generation amount PVκ(θ) is calculated with the use of the correction coefficient Kfix (step 110). A cooling loss coefficient Kcool that determines a correlation between the cooling loss and crank angles may be calculated based on a water temperature and an engine speed and the actual heat generation amount PVκfix(θ) may be made to reflect the cooling loss coefficient Kcool.

Owner:TOYOTA JIDOSHA KK

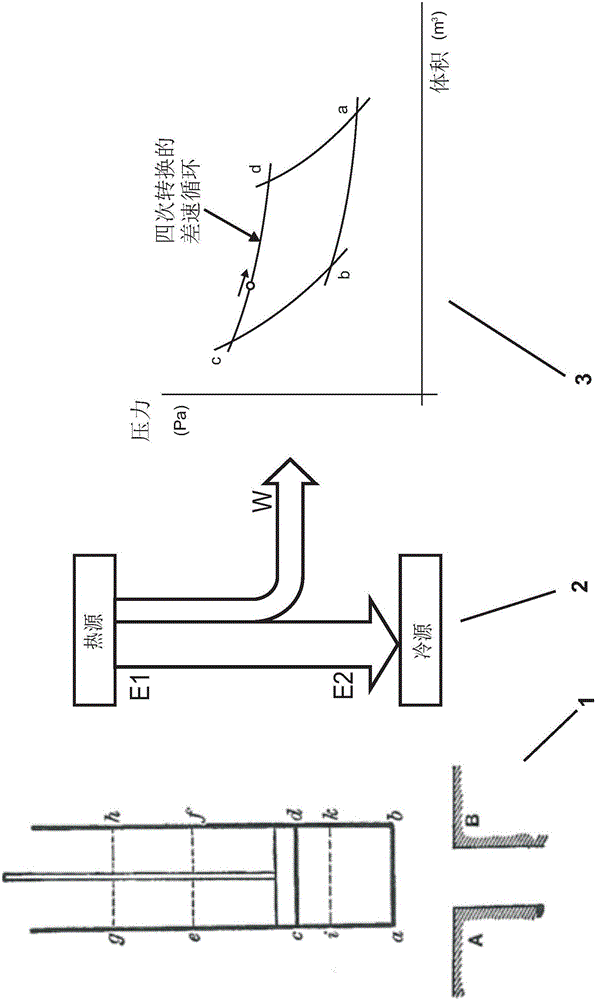

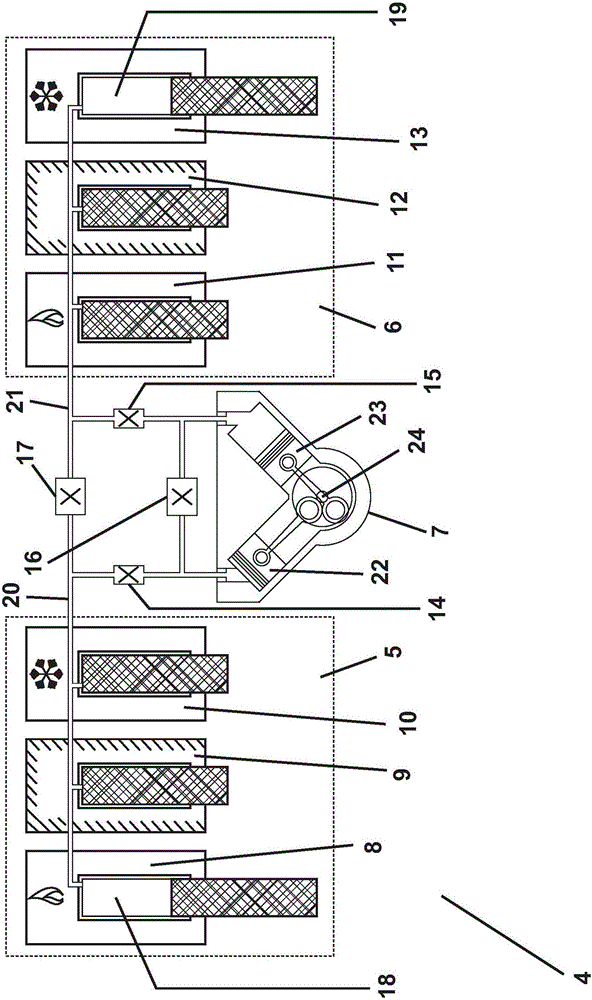

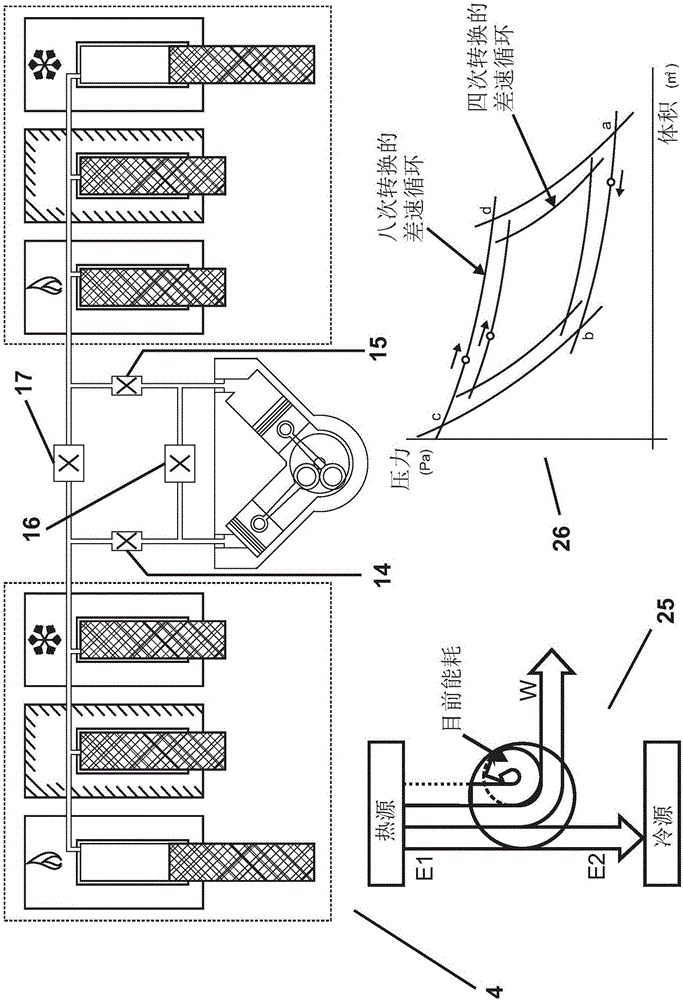

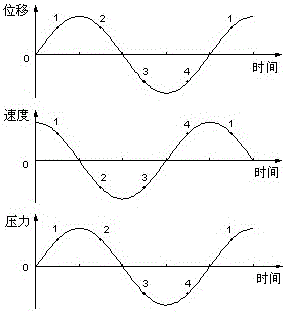

Differential thermodynamic machine with a cycle of eight thermodynamic transformations, and control method

The present invention refers to the technical field of thermodynamic engines, and more specifically to a heat engine that operates with gas in closed loop in differential configuration which is characterized by performing a thermodynamic cycle eight transformations or otherwise explain, it performs two thermodynamic cycles simultaneously, each with four interdependent, additional transformations, two of these transformations "isothermal" and two "adiabatic" in mass transfer in phases of adiabatic processing to provide a new performance curve no longer dependent solely on temperature but the mass transfer rate which allows the construction of machines with high yields and low thermal differentials.

Owner:ASSOCIAOS PARANAENSE DE CULTURA APC

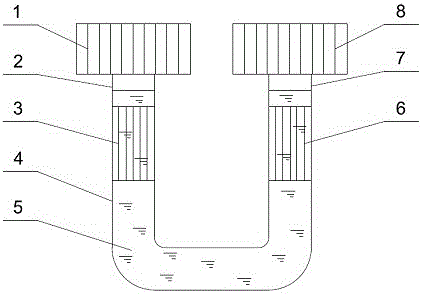

Standing wave gas-liquid phase change thermoacoustic engine driven by low-grade heat source

ActiveCN102734099BTake advantage of the realizationRealize comprehensive utilizationMachines/enginesMechanical power devicesLiquid mediumAdiabatic process

The invention discloses a low-grade heat source driven standing wave type gas and liquid phase change thermoacoustic engine. The thermoacoustic engine comprises a first heater, a first thermal buffering pipe, a first cooler, a U-shaped pipe, a second cooler, a second thermal buffering pipe and a second heater which are connected sequentially, wherein a liquid piston is arranged in the U-shaped pipe. The thermoacoustic exchange is realized based on a gas and liquid phase change thermoacoustic effect, and the ideal thermodynamic cycle can be approximately two isobaric processes and two adiabatic processes. Compared with the conventional gas medium thermoacoustic engine system, the thermoacoustic engine has the characteristics that the temperature difference of cold and heat sources is low, the thermoacoustic engine can run in small temperature difference and at a large pressure ratio, and the low-grade heat source can be utilized; the energy density of unit volume is high, so that the system can be miniaturized; and the gas and liquid coupled oscillation can be realized, and the acoustic impedance of the thermoacoustic engine system can be optimized by comprehensively utilizing the compressibility of gaseous medium, and the high-density mass inertia of the liquid medium.

Owner:ZHEJIANG UNIV

A Calculation Method for the Maximum Subsidence of Aircraft Tire Taking Off Under Compression

ActiveCN108304638BAccurate calculation of maximum sinkageGeometric CADDesign optimisation/simulationAdiabatic processClassical mechanics

The invention relates to a method for calculating the maximum sinkage of an aircraft tire taking off under pressure, belonging to the field of aircraft design, which includes step 1: calculating the tire vertical force F under pressure y ;Step 2: According to the tire vertical force F y Determine the tire sinkage δ. Compared with the prior art, the calculation method of the present invention has the following advantages: a, the prior art is more accurate for the calculation of the maximum sinkage of land-based aircraft landing gear tires, and for the maximum sinkage of the landing gear tires of the aircraft taking off under pressure. Calculation of the sinkage, the error of the prior art is relatively large; the present invention is applicable to the calculation of the maximum sinkage of the landing gear tire of the aircraft taking off under pressure, compared with the measured data, the error is within 5%; b, the prior art does not consider ejection Rod, check bar load, the present invention has considered ejection bar, check bar load; c, prior art calculates the tire compression amount, tire interior gas is according to isothermal process; The present invention considers rapid compression characteristic, adopts adiabatic process.

Owner:SHENYANG AIRCRAFT DESIGN INST AVIATION IND CORP OF CHINA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com