Continuously operated adiabatic method for producing nitrobenzene by nitration of benzene

A technology of nitrobenzene and nitration, which is applied in the direction of nitro compound preparation, chemical instruments and methods, sulfur compounds, etc., can solve the accumulation and clogging of phase separators and crude nitrobenzene heat exchangers, and cannot completely eliminate black substances, and cannot It has the feasibility of industrial application and other issues, so as to avoid the formation of black matter, improve the stable operation cycle and reduce the maintenance cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Embodiment 1 (comparative embodiment)

[0037] The preparation of nitrobenzene was carried out as described in General conditions for the preparation of nitrobenzene. In the phase separation device, the suspended black oil droplets generated by the reaction accumulate in the nitrobenzene layer in the phase separator, and precipitate to form black solid particles at the flanges, gaskets and other equipment parts where the nitrobenzene layer is located in the phase separation device. The black solid particles flow through the crude nitrobenzene cooler along with the crude nitrobenzene, blocking the nitrobenzene cooler and causing the shutdown of the device. It is necessary to open the phase separator and the crude nitrobenzene cooler for cleaning 6-8 times a year.

Embodiment 2

[0038] Embodiment 2 (according to the present invention)

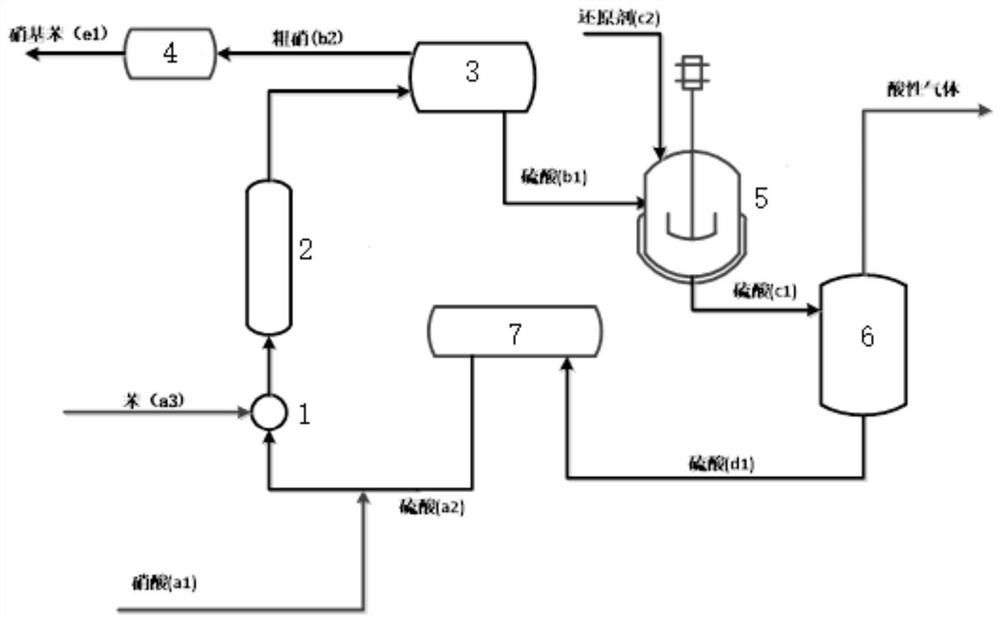

[0039] The preparation of nitrobenzene is carried out as described in the general conditions for the preparation of nitrobenzene, with the difference that the following additional measures are taken: the aqueous phase containing sulfuric acid (b1) obtained in the phase separator enters the sulfuric acid regenerator, the sulfuric acid regenerator Add reducing agent (C2) in, wherein reducing agent (C2) is sulfurous acid, reducing agent concentration is controlled at 1000ppm, obtains the aqueous phase (b1) containing sulfuric acid based on the mass meter of phase separator. Through long-term operation, no black matter was found in the phase separator and crude nitrobenzene cooler.

Embodiment 3

[0040] Embodiment 3 (according to the present invention)

[0041] The preparation of nitrobenzene is carried out as described in the general conditions for the preparation of nitrobenzene, with the difference that the following additional measures are taken: the aqueous phase containing sulfuric acid (b1) obtained in the phase separator enters the sulfuric acid regenerator, the sulfuric acid regenerator Add a reducing agent (C2) to the mixture, wherein the reducing agent (C2) is a mixture of sulfurous acid, thiosulfuric acid, and dithionous acid (the mass ratio of sulfurous acid, thiosulfuric acid, and dithionous acid is 1:1:1 ), the reducing agent concentration is controlled at 1000ppm, and the mass meter of the aqueous phase (b1) containing sulfuric acid is obtained based on the phase separator. Through long-term operation, no black matter was found in the phase separator and crude nitrobenzene cooler.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com