Engine combustion isometric degree calculation method and device and engine combustion analyzer

An engine and capacity technology, used in jet engine testing, gas turbine engine testing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

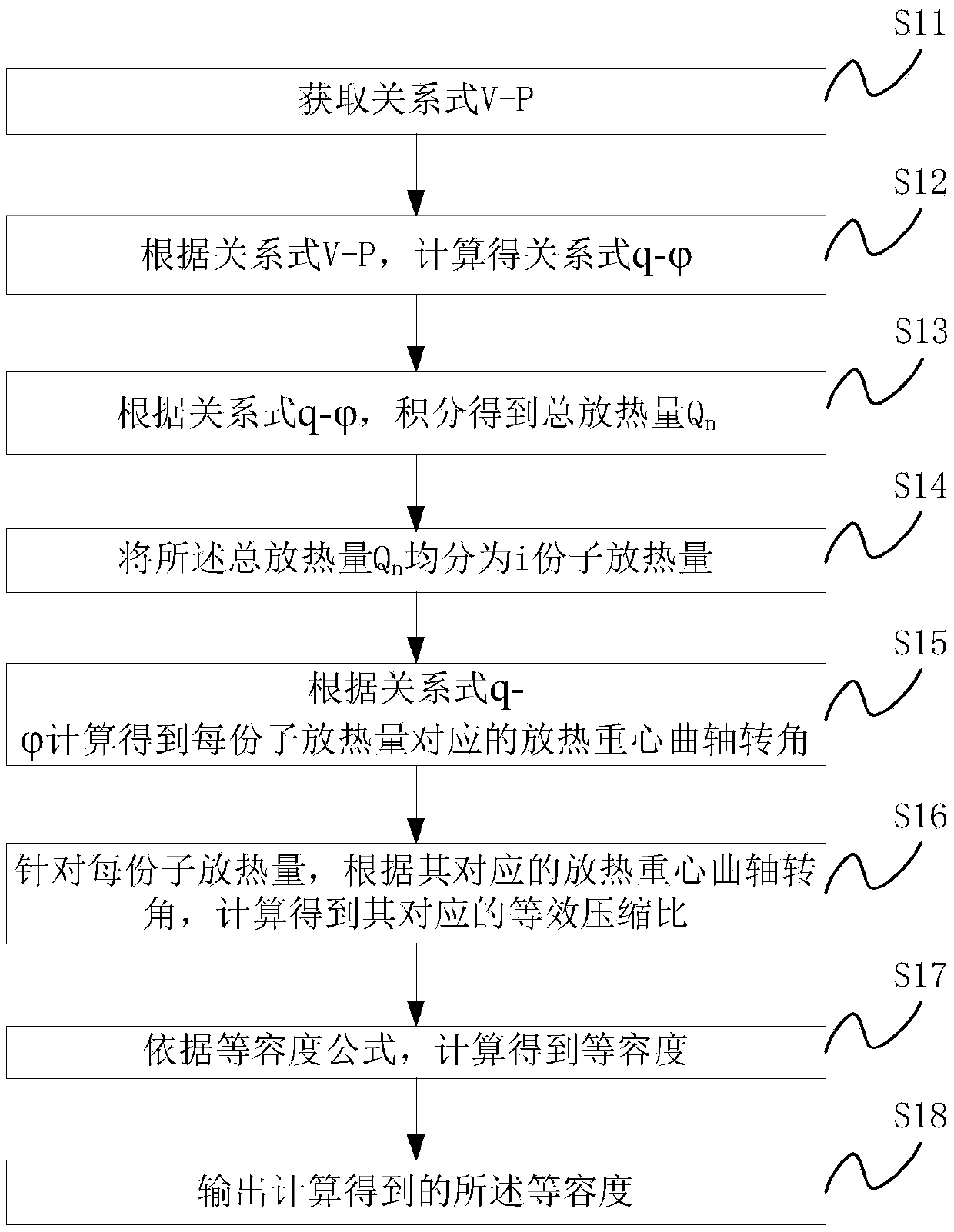

[0055]Existing engine combustion analyzers mainly detect cylinder pressure parameters, combustion phase parameters, knock index parameters, and corresponding cylinder pressure curves, heat release curves, etc., and lack a device for calculating combustion isovolume. The present invention provides a calculation method of combustion isovolumism and output display, the originality provides the quantification method of combustion isovolume, provides direct and objective reference data for combustion analysis and diagnosis in actual engineering, and at the same time provides The automatic calibration of the engine provides reference data.

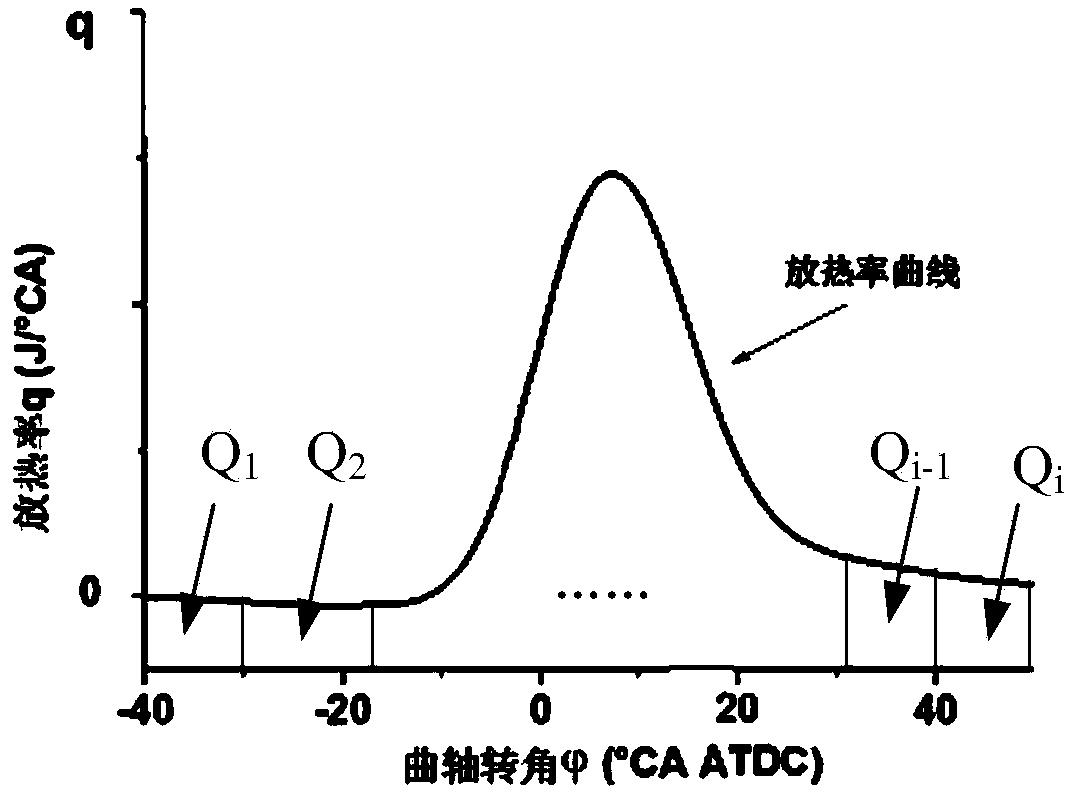

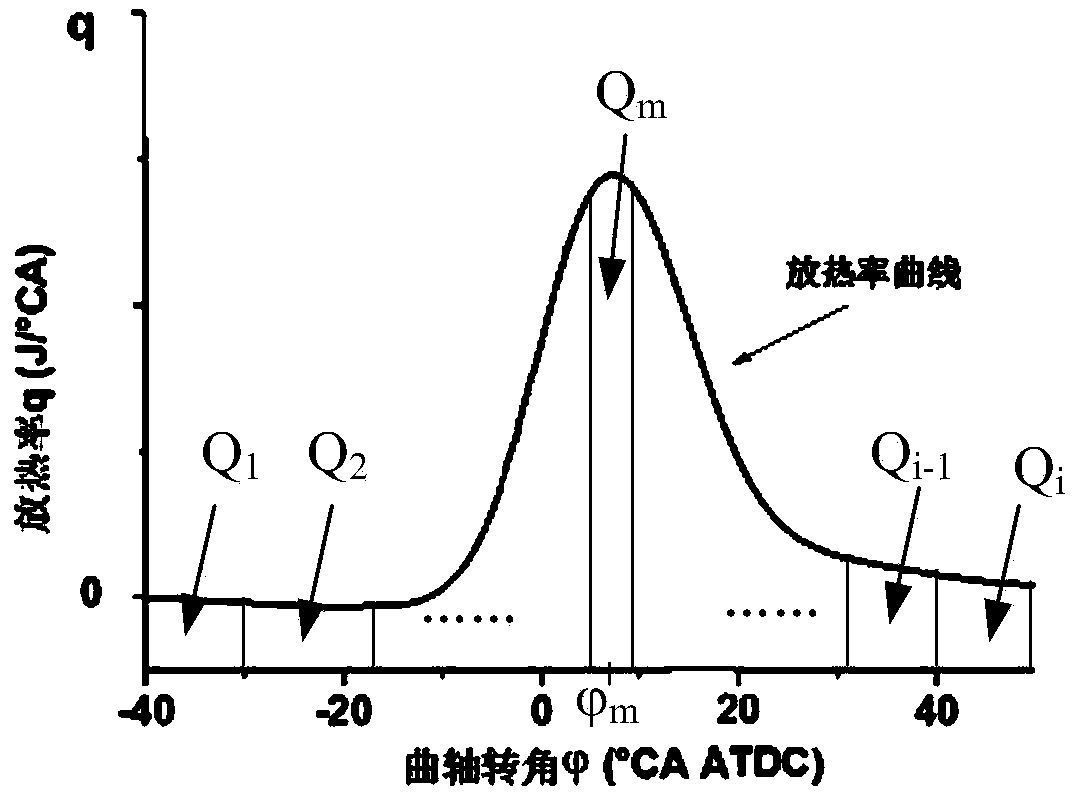

[0056] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention. Based on the embodiments of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com